Aluminum-tantalum-molybdenum intermediate alloy and preparing method thereof

A master alloy and molybdenum alloy technology, which is applied in the field of aluminum tantalum molybdenum master alloy and its preparation, can solve the problems of difficulty in the intermediate process of producing titanium alloy, unstable product performance, complicated production process, etc., and achieve shortened production process, convenient preparation, low cost effect

Inactive Publication Date: 2015-09-23

CHENGDE TIANDA VANADIUM IND

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most titanium alloy master alloys use binary alloys and ternary alloys. The master alloys produced with simple metals as raw materials have complex production processes and high costs. In order to meet the performance requirements during use, several binary alloys or ternary alloys need to be added. Therefore, it is easy to cause the instability of product performance and bring difficulties to the intermediate process of producing titanium alloy.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2~5

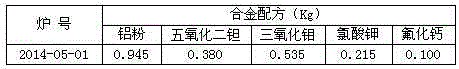

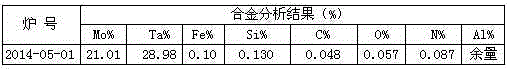

[0025] Embodiment 2~5, operate according to the method of embodiment 1, see the table below for the difference with embodiment 1.

[0026] Table 3 Example of aluminum tantalum molybdenum alloy

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an aluminum-tantalum-molybdenum intermediate alloy and a preparing method thereof, in particular to an intermediate alloy for titanium alloy production and a preparing method thereof. The intermediate alloy is characterized by comprising, by weight, 27.0% to 32.0% of Ta, 18.0% to 23.0% of Mo, and the balance of Al; metallothermic reduction is adopted in preparation. The intermediate alloy is a metallic compound comprising mainly tantalum, molybdenum and aluminum and features crispiness and breakage proneness; the production process of the titanium alloys is shortened; the production of the titanium alloys is easier to operate. By the use of oxides as raw material, the cost is low, the smelting process is stable, and the alloy is in good formation state; alloying is uniform; by adding the intermediate alloy into titanium sponge and aluminum shots, segregation degree of the titanium alloys is lowered.

Description

technical field [0001] An aluminum-tantalum-molybdenum master alloy and a preparation method thereof relate to a master alloy used for preparing titanium alloys and a preparation method thereof. Background technique [0002] Titanium alloys are widely used in military industry, aerospace industry and civilian industry, and master alloys are important raw materials for the production of titanium alloys. At present, most titanium alloy master alloys use binary alloys and ternary alloys. The master alloys produced with simple metals as raw materials have complex production processes and high costs. In order to meet the performance requirements during use, several binary alloys or ternary alloys need to be added. Therefore, it is easy to cause the instability of product performance and bring difficulties to the intermediate process of producing titanium alloy. Contents of the invention [0003] The purpose of the present invention is to provide an aluminum-tantalum-molybdenum...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C1/03C22C21/00C22C30/00C22B5/04

Inventor 王志军刘建丰刘强朱艳彬胡利志

Owner CHENGDE TIANDA VANADIUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com