Patents

Literature

137results about How to "No splashing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

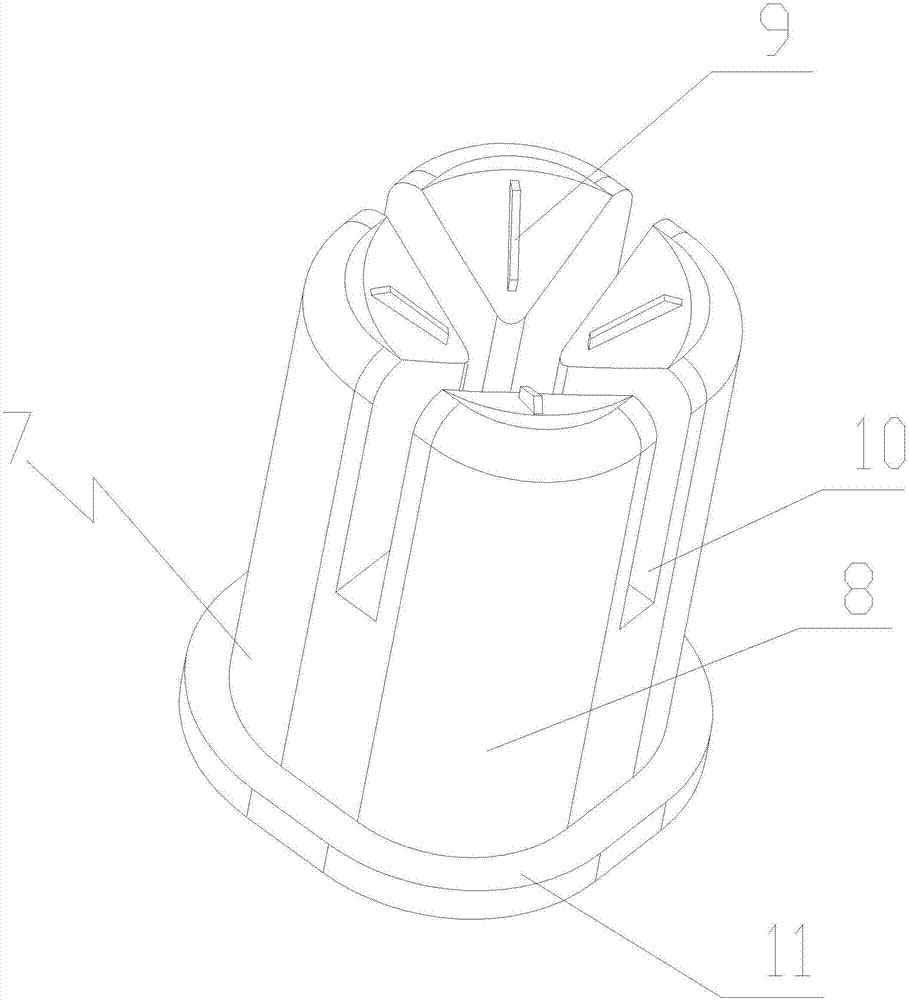

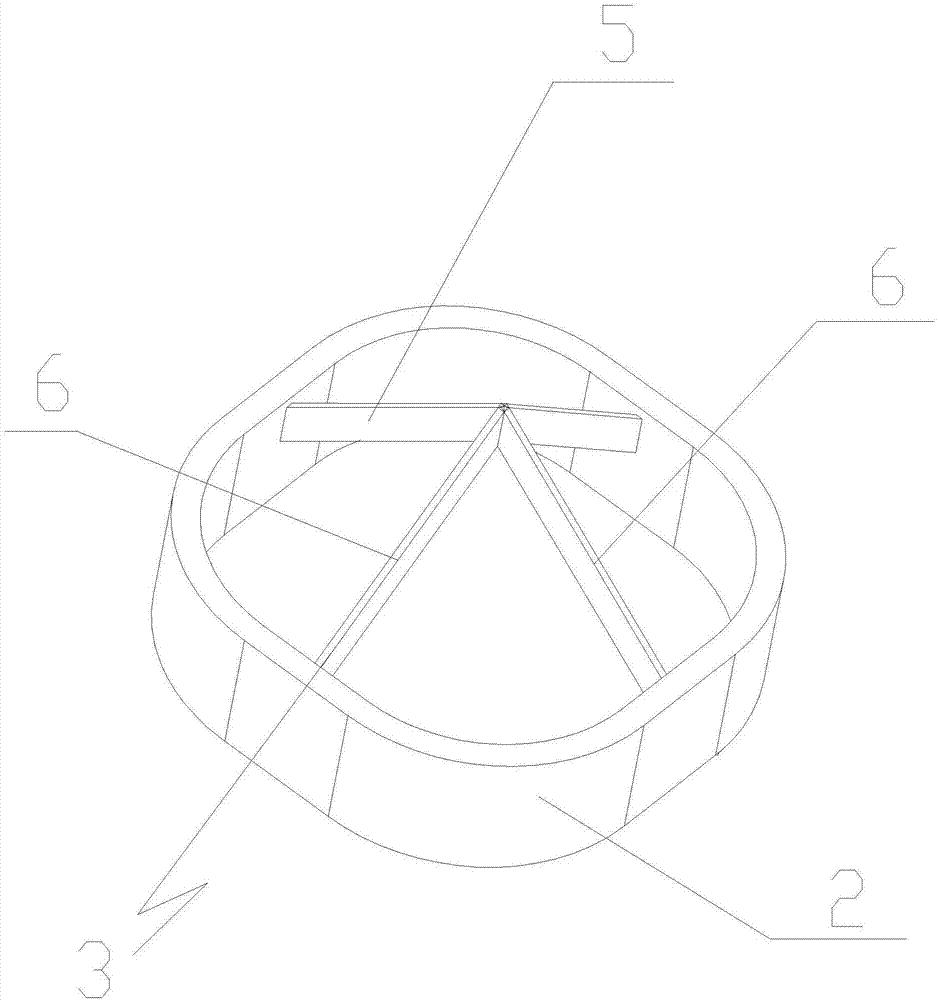

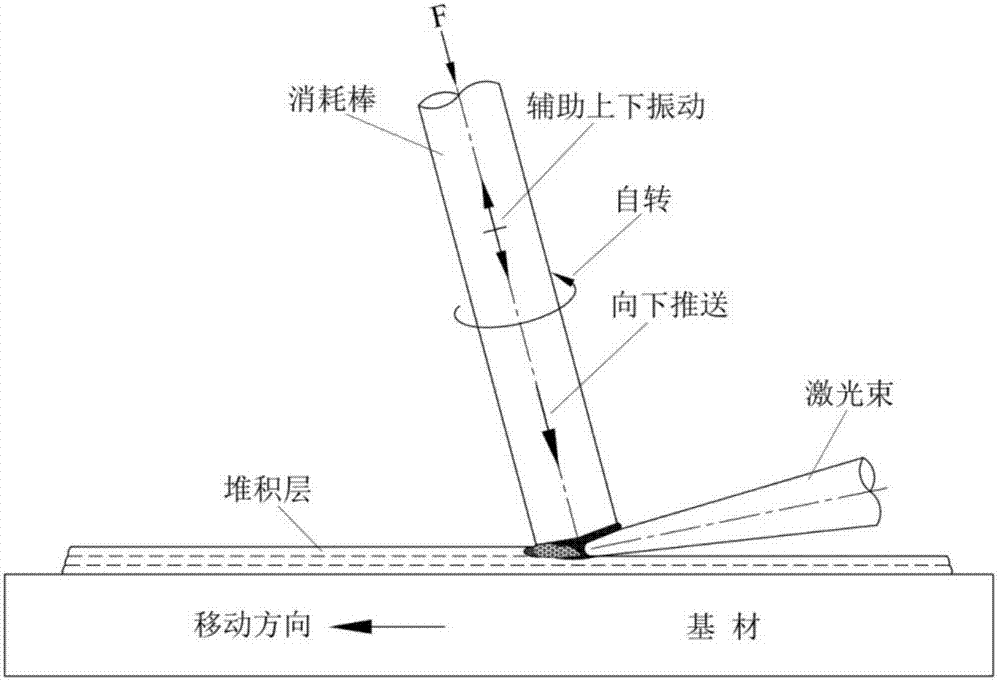

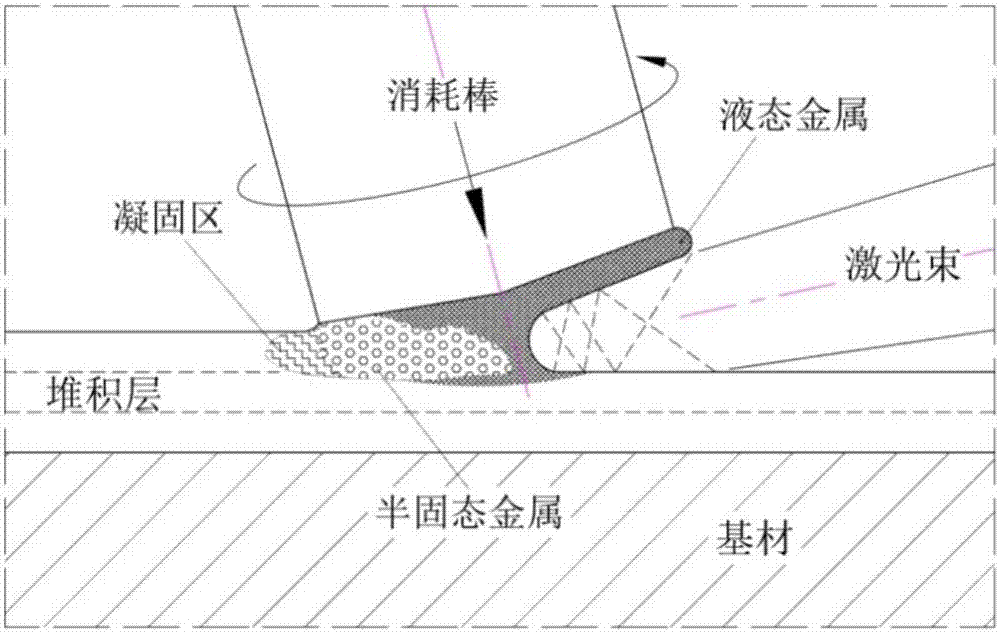

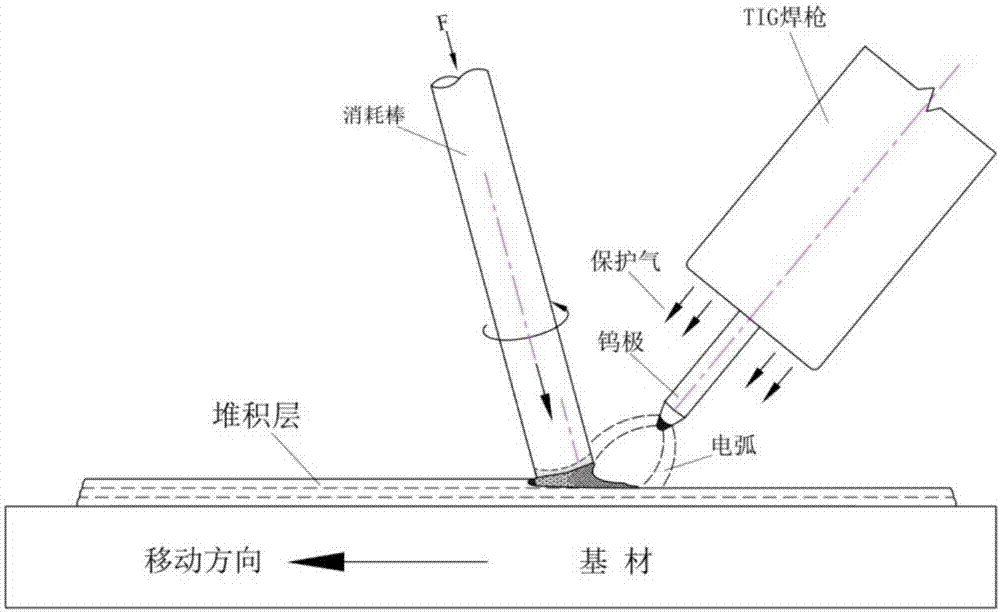

Micro-domain semi-solid state additive manufacturing method

ActiveCN107414325AReduce distortionReduced tendency to crackAdditive manufacturing apparatusArc welding apparatusMaterials preparationHigh energy

The invention provides a micro-domain semi-solid state additive manufacturing method. The problems about structure homogeneity, performance reliability, stress and deformation, air holes and cracks and the like of a molding piece are mainly solved. A stick-shaped material serves as a consumable item, and heating manners such as high energy beams, electric arcs and resistance heat are adopted for acting on the front end of the consumable item to enable the front end to be in a solid-liquid two-phase coexistence semi-solid state; and meanwhile, rotating twisting force and axial thrust are applied to the consumable item to conduct powerful effects such as shearing, stirring and extruding on semi-solid state metal, and in other words, mold-free semi-solid state flowing deformation molding is carried out. The consumable item is transited to bottom layer metal continuously in the manner to form metallurgical bonding, the stacking process is repeated according to a planned route obtained after discretization slicing treatment, and then a solid piece or a stacking layer in a special shape can be formed. The micro-domain semi-solid state additive manufacturing method is simple in operation process, the part performance is excellent, many defects in traditional additive manufacturing are overcome, and the prospects in the aspects of large structure shaping, damaged part repairing and composite material preparation are wide.

Owner:BEIJING UNIV OF TECH

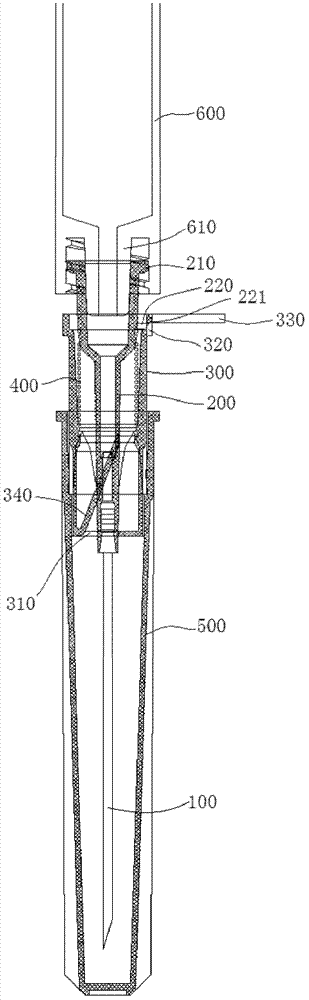

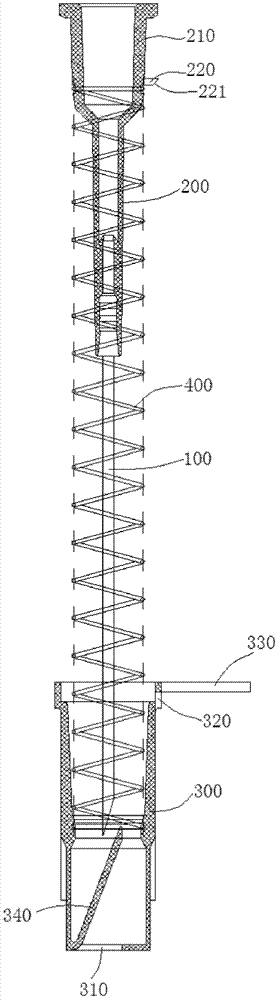

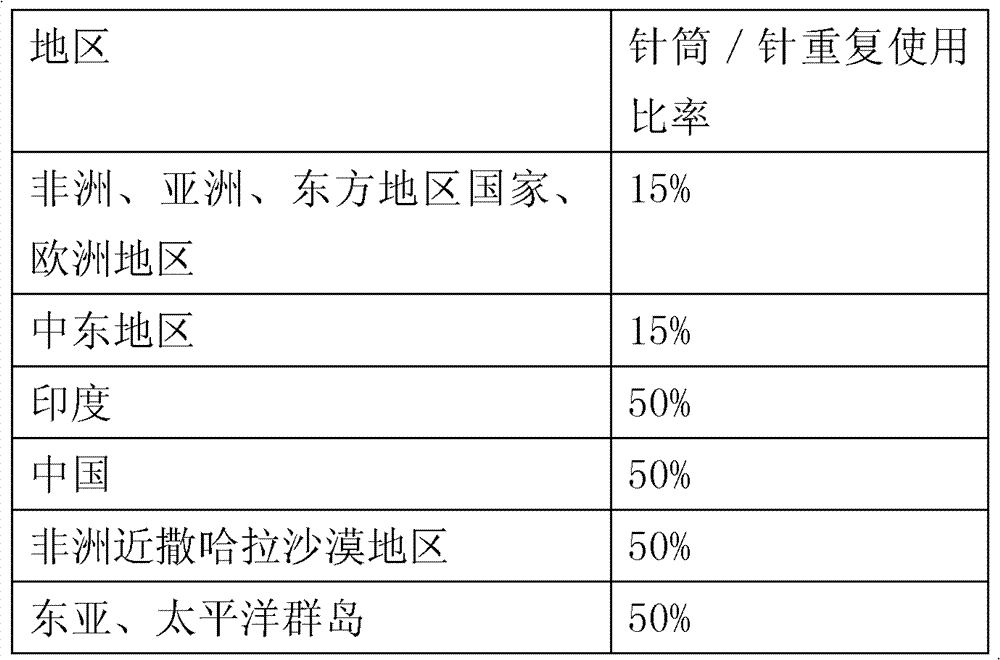

Safety syringe needle

A safety syringe needle comprises a needle, a needle holder, a needle protective cover, a spring, and a locking-releasing structure, wherein the needle protective cover, which is sleeved on the needle holder before and during injection, is moved to the needle after injection and protects the needle, the spring disposed between the needle holder and the needle protective cover is used for driving the needle protective cover to move from the needle holder to the needle after injection, and the locking-releasing structure disposed between the needle holder and the needle protective cover is used for locking the needle protective cover at the needle holder before and during injection and releasing the needle protective cover after injection. When located at the needle holder, the needle protective cover compresses the spring on the needle holder; and when the needle protective cover is located at the needle, the spring is released. The safety syringe needle prevents medical staff from being accidentally punched by the needle during use, prevents reusing of a syringe / needle, and has the advantages of disposability, safety, sanitation, convenience in use, and easiness in recycling.

Owner:上海双鸽实业有限公司

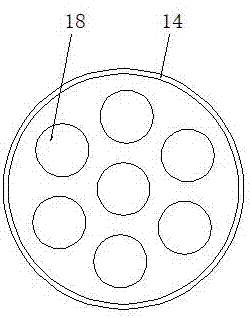

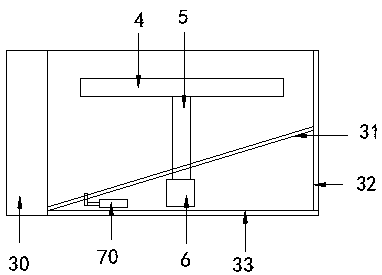

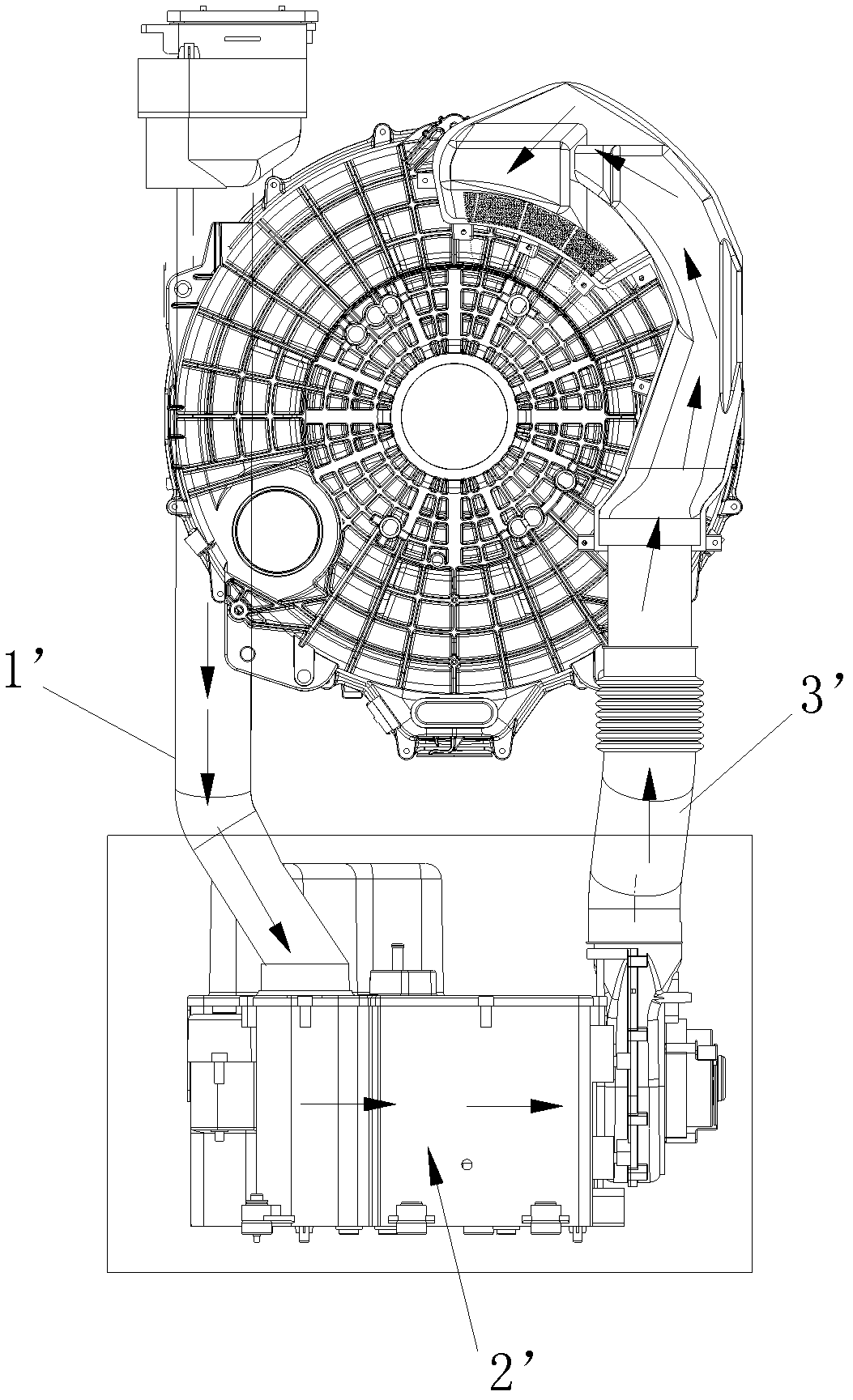

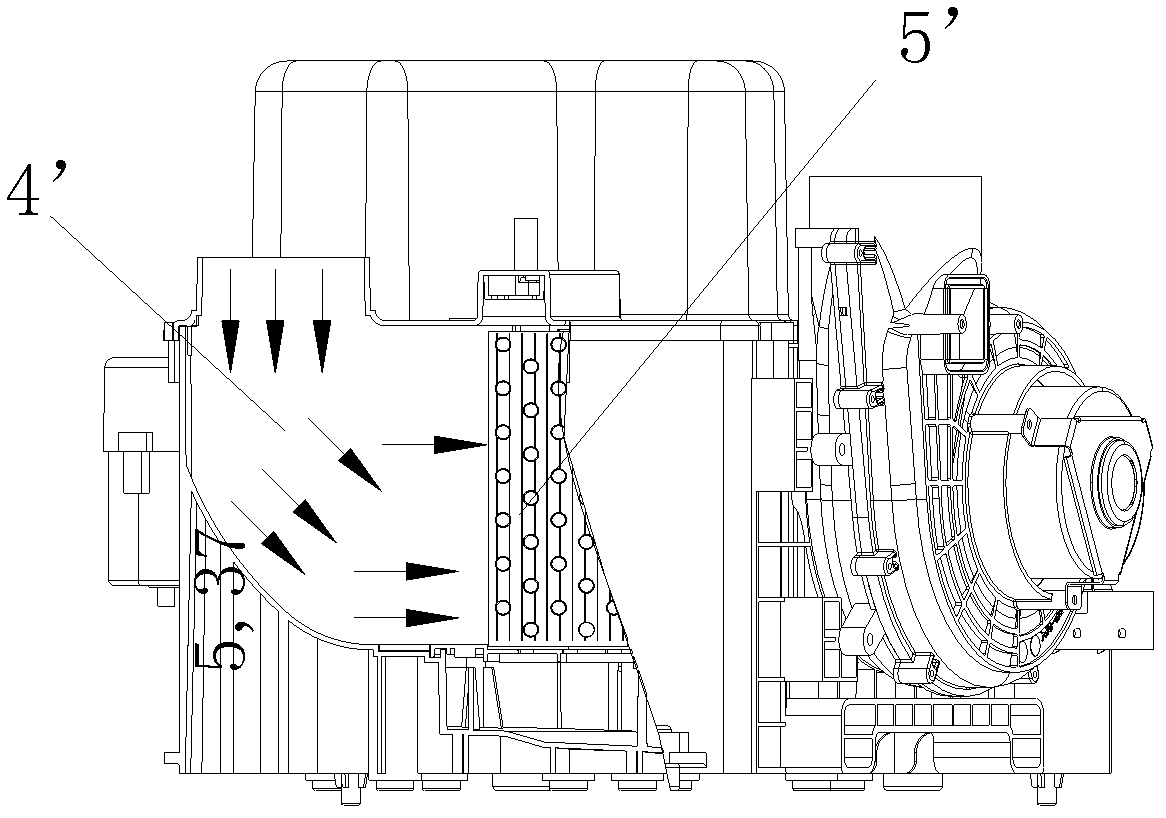

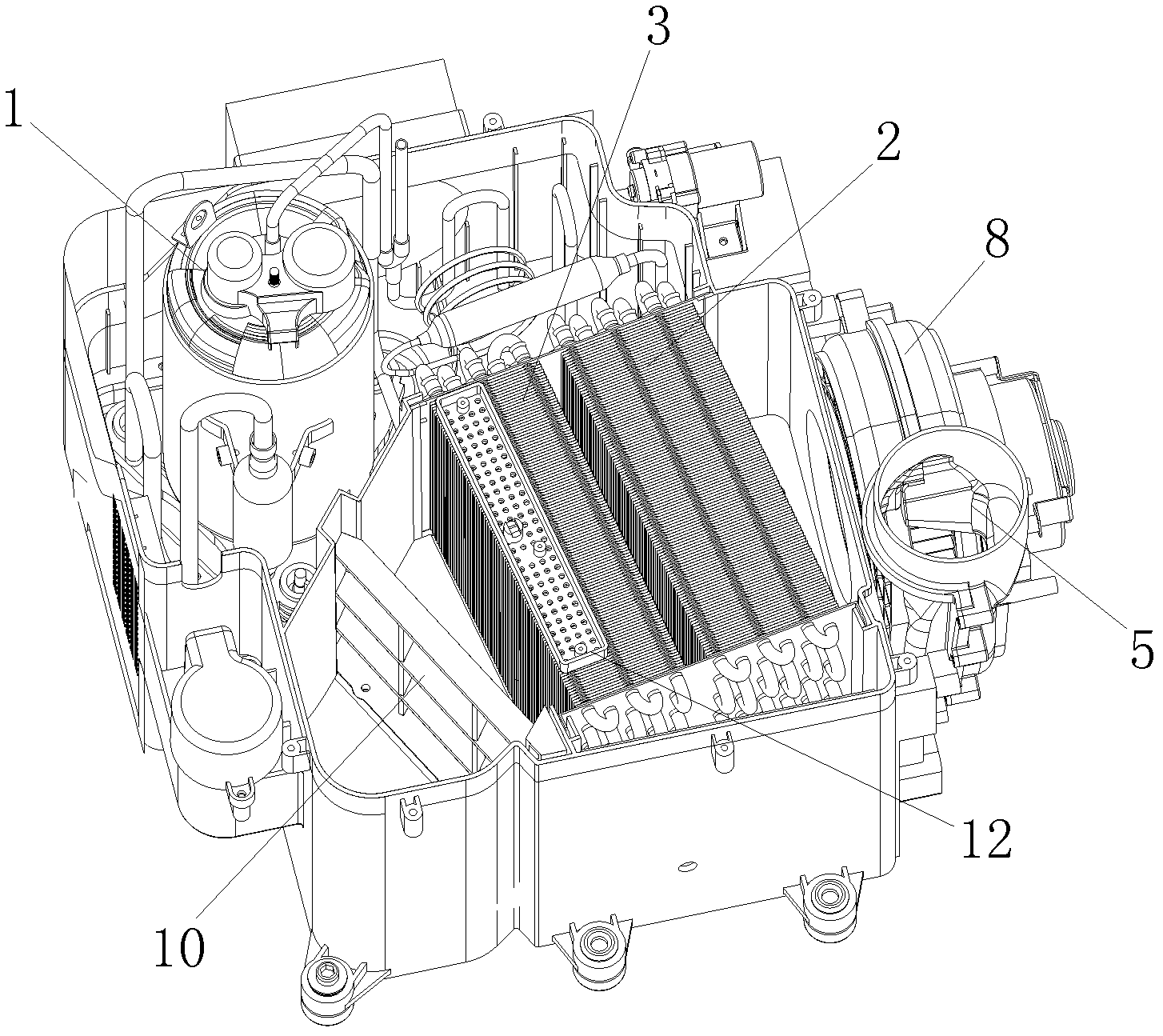

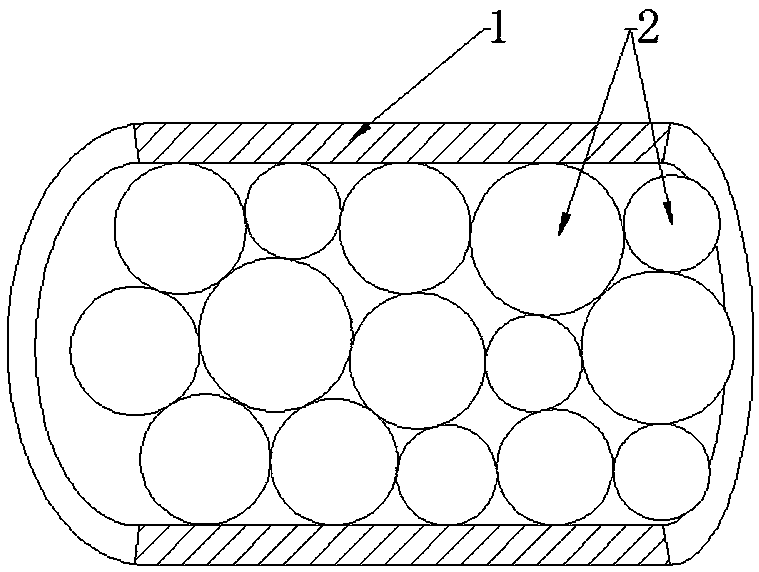

Air equalizing structure for heat pump module of heat pump type washing-drying integrated machine

ActiveCN102425066AImprove heat exchange efficiencyImprove drying effectTextiles and paperLaundry driersInlet channelLongest Diameter

The invention discloses an air equalizing structure for a heat pump module of a heat pump type washing-drying integrated machine. The air equalizing structure is arranged between the air inlet of the heat pump module and an evaporator and comprises an inlet air channel and a flow equalizing structure in sequence, wherein the air inlet channel is arranged between the air inlet of the heat pump module and the evaporator, the air inlet direction of the air inlet channel gradually changes to a horizontal direction from a vertical direction from the air inlet of the heat pump module at the top to the bottom in an circular arc manner, the flow equalizing structure comprises a plurality of guide plates corresponding to the evaporator, arranged vertically in the horizontal direction of the air inlet channel and used for changing the flowing direction of air, the guide plates incline upwards along the flowing direction of air. The air inlet channel gradually changes into an oval-section air channel from a round-section air channel at the air inlet of the heat pump module, the sectional area is increased gradually, the flowing direction of air gradually changes into a horizontal direction opposite to clearances of fins of the evaporator, and the oval section level is long diameter. By the adoption of the air equalizing structure provided by the invention, the effect of equalizing air passing through the evaporator is improved, splashing of condensate water caused by high-speed air can be avoided, and condensation effect of the evaporator is improved greatly.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Environment-friendly alloying method of metal bismuth for free-cutting steel

The invention relates to an environment-friendly alloying method of metal bismuth for free-cutting steel, belongs to the technical field of metallurgy and aims to prevent violent reaction produced bydirection addition of metal bismuth, reduce smoke pollution, increase yield of bismuth and further normalize a bismuth alloying method. According to the method, metal bismuth is fed into molten steelin an alloy cored wire manner by a wire feeder, diameter of a bismuth cored wire is 8-14 mm, thickness of steel skin is 0.5-1.5 mm, and diameter of bismuth particles is 0-3 mm; bottom blowing stirringis performed on a steel ladle, feeding temperature is in a range of 1600-1780 DEG C, feeding rate is 80-110 m / min, and stirring is continued for 3-8 min after feeding. With adoption of the method, the problems of high volatilization, sedimentation and oxidation loss caused by low melting and boiling points and active nature of metal bismuth are solved, yield reaches 50% or higher, and splashing danger and a large amount of smoke pollution due to the violent reaction produced by direction addition of metal bismuth are effectively reduced.

Owner:TAIYUAN IRON & STEEL GROUP

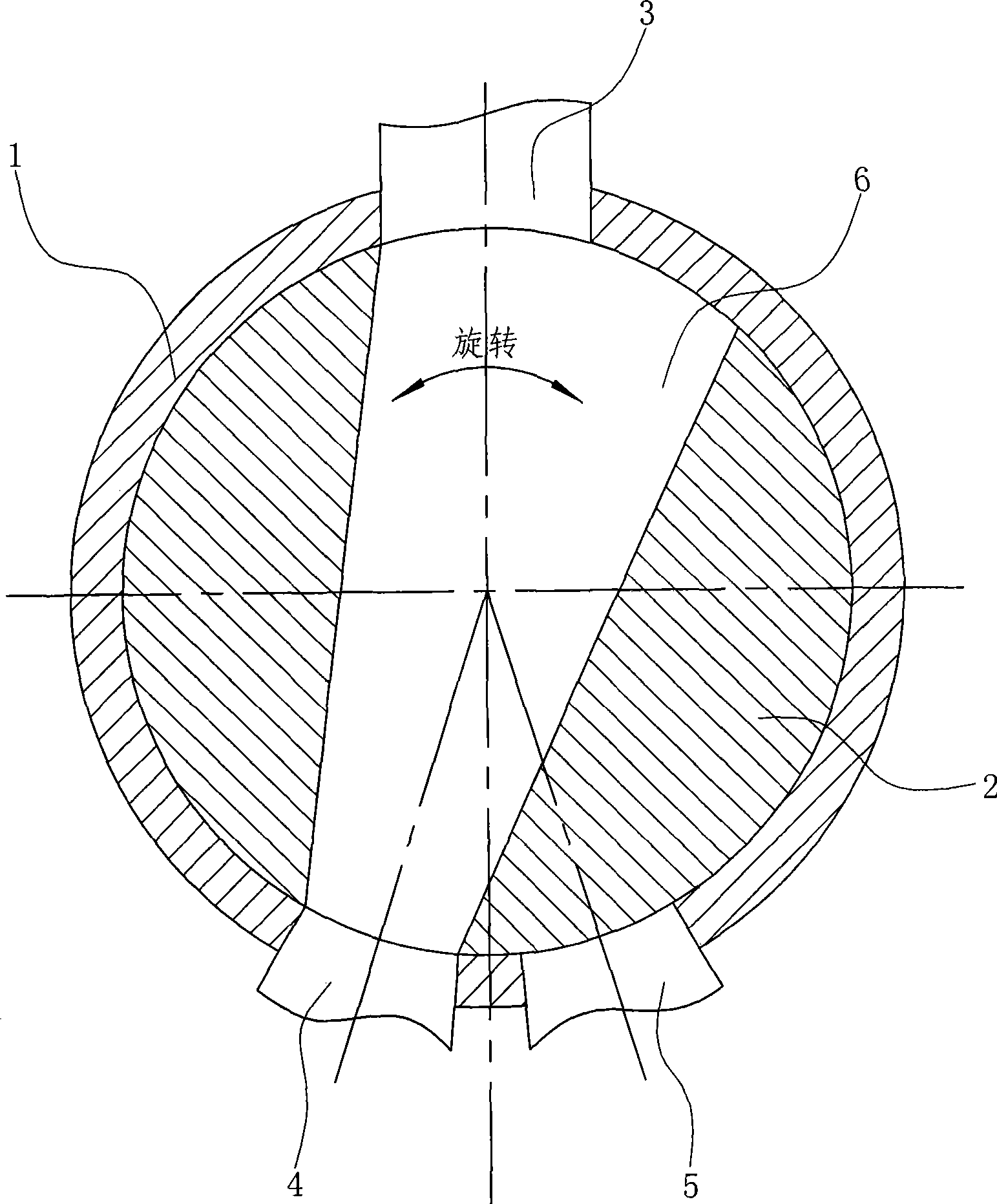

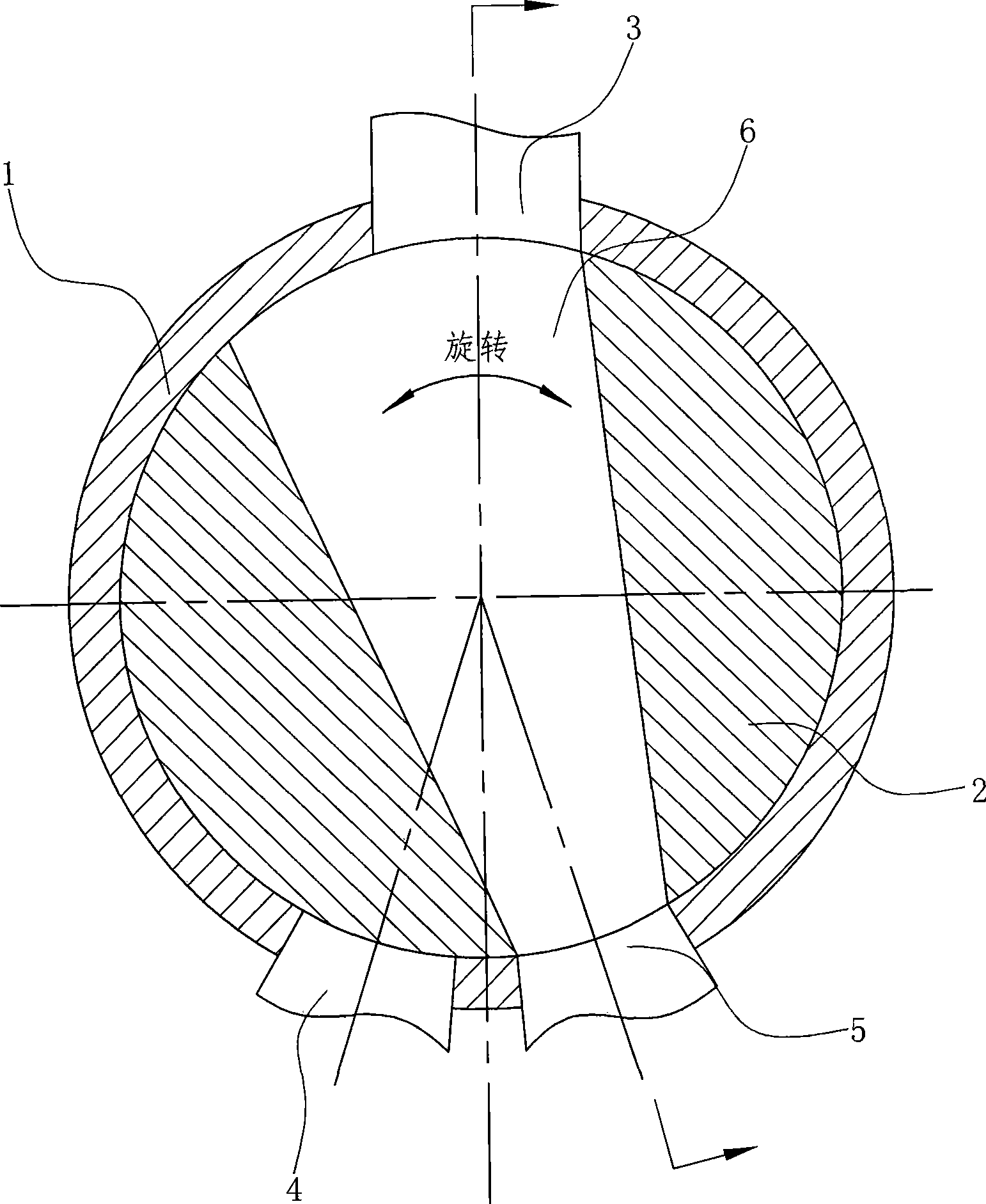

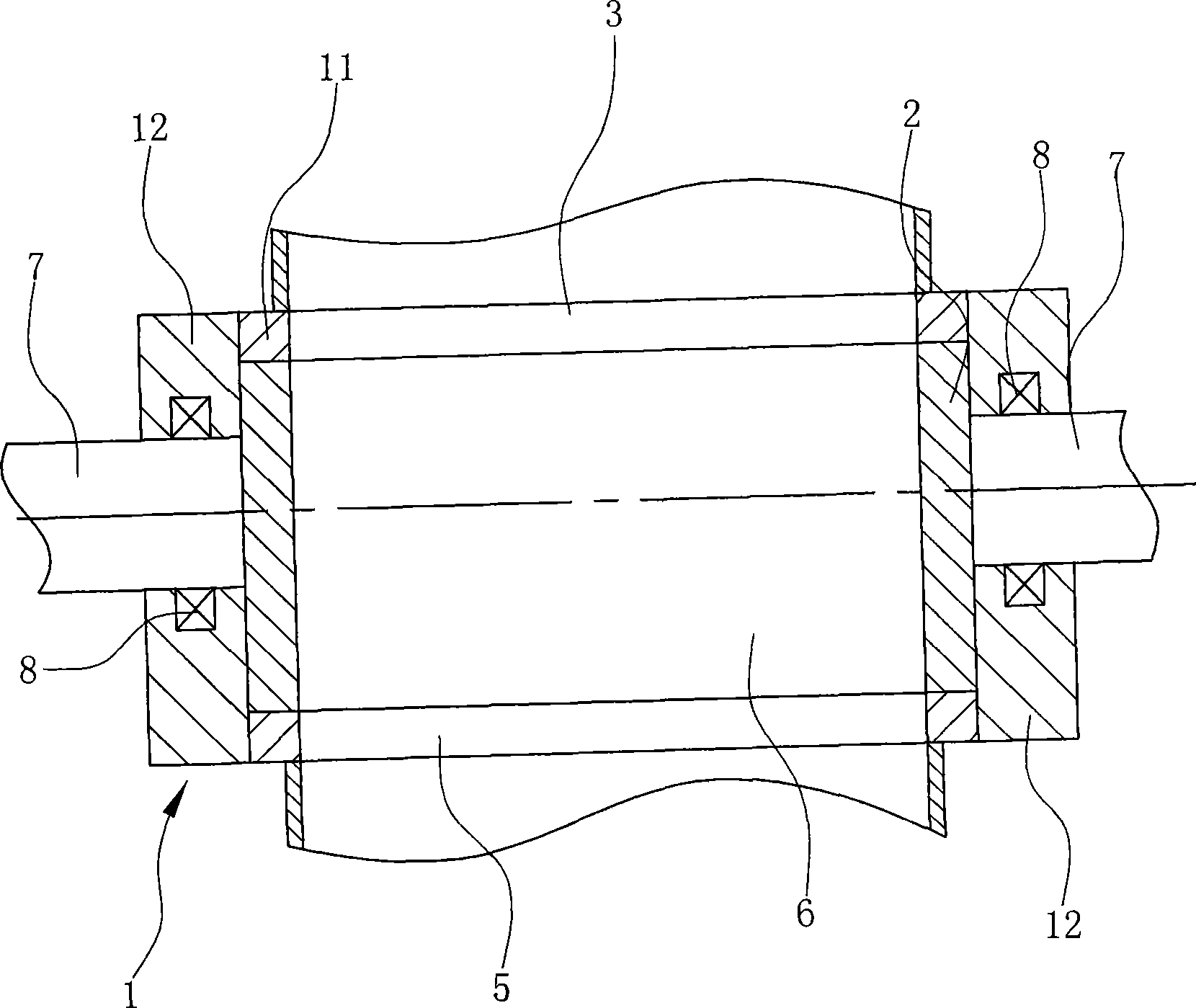

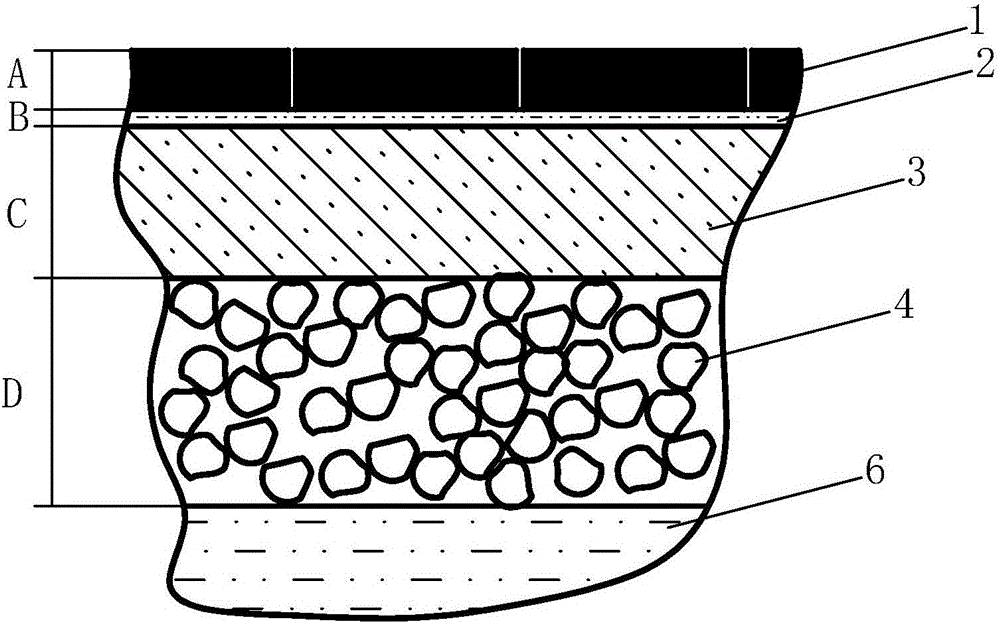

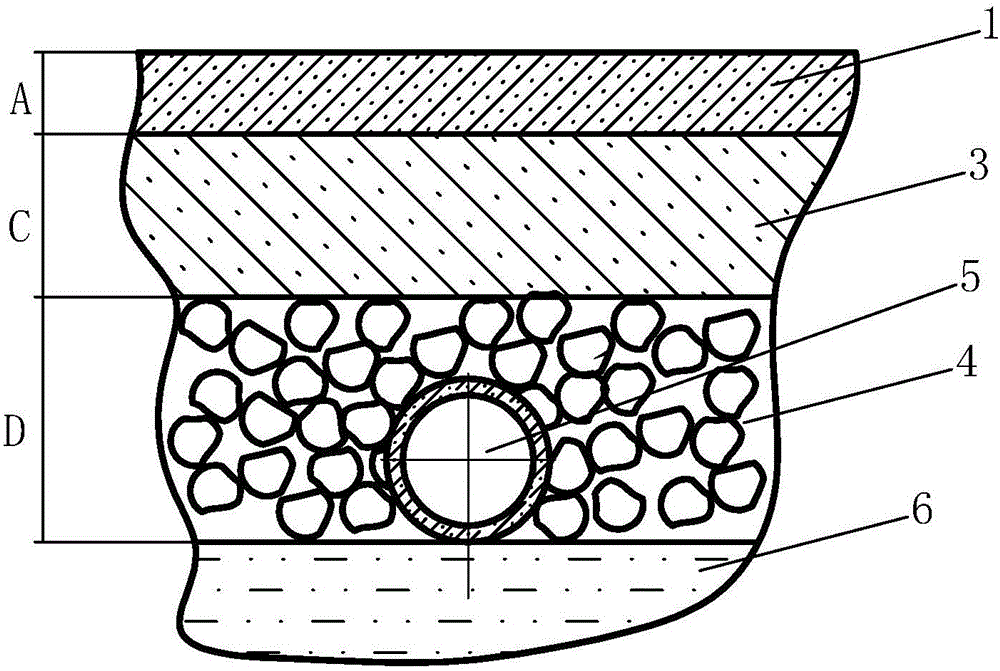

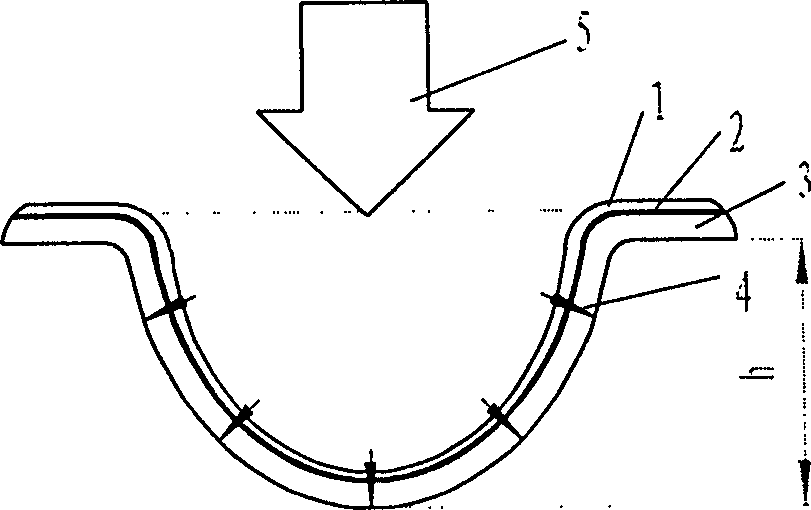

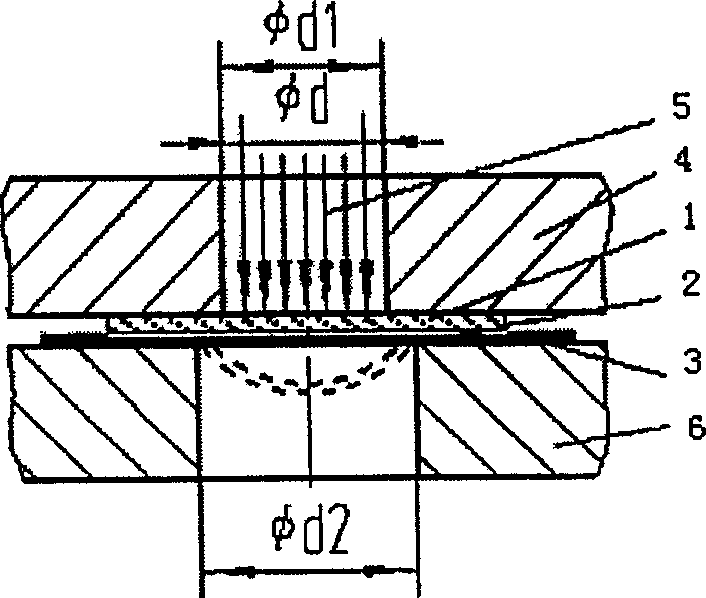

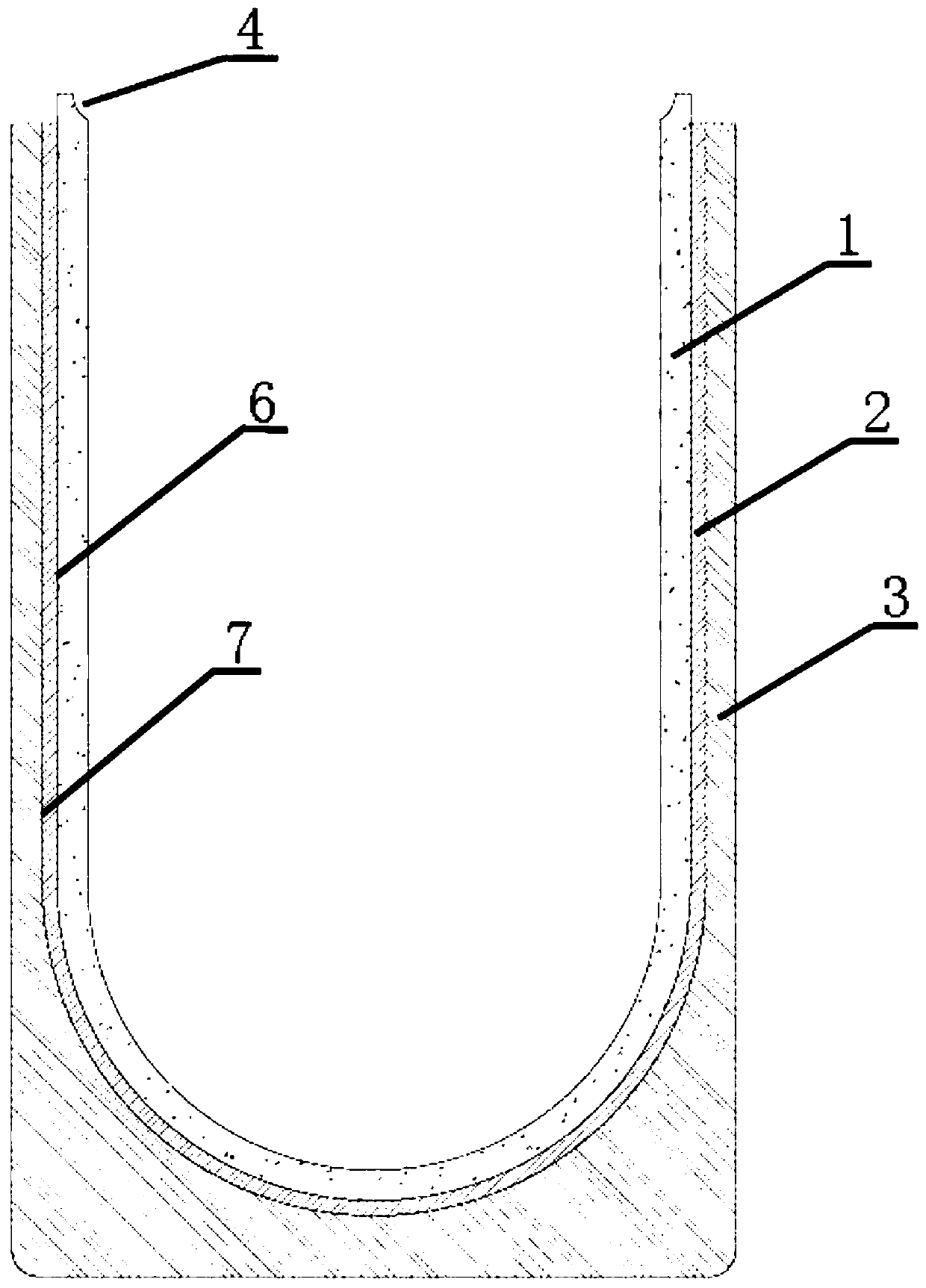

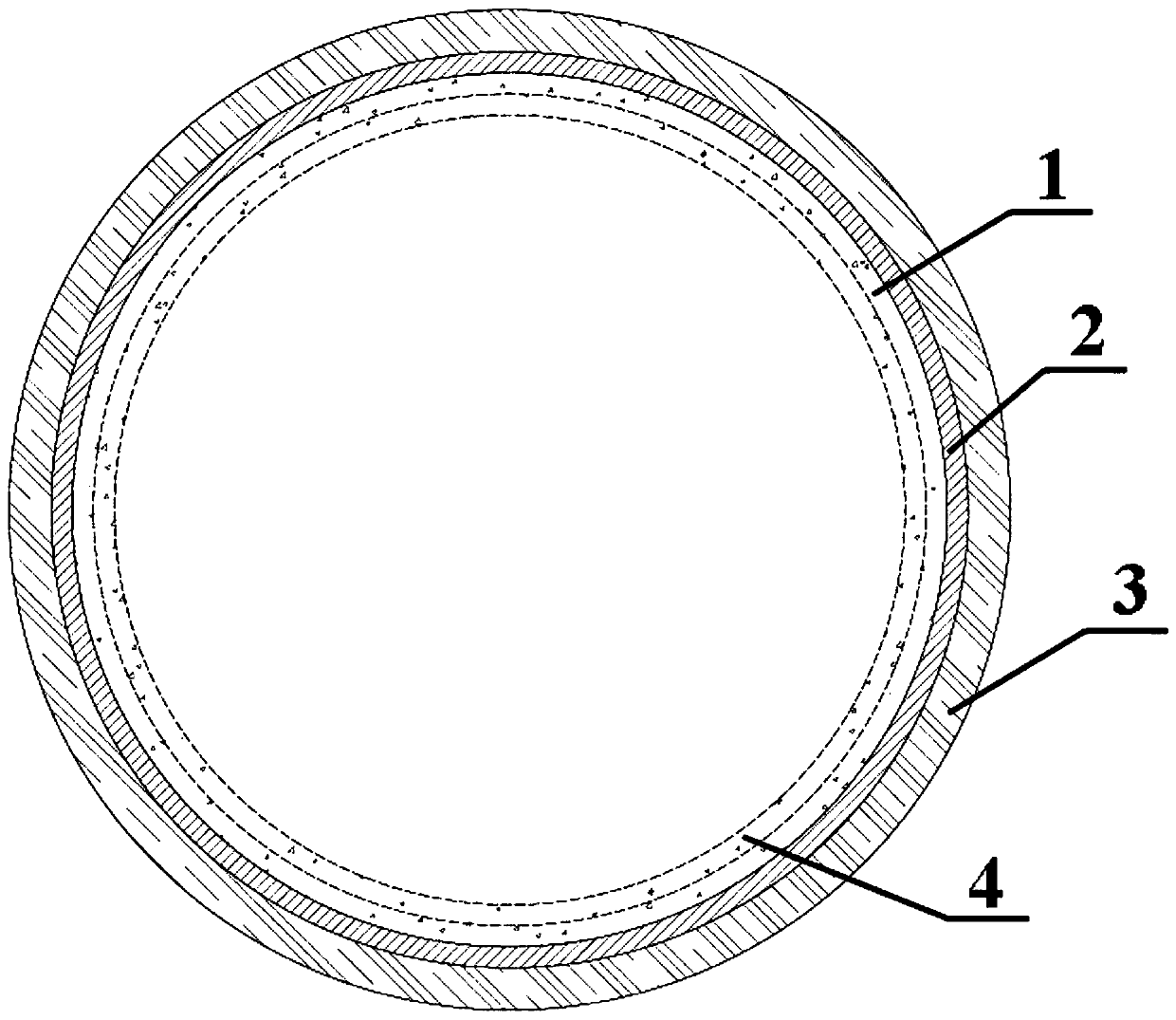

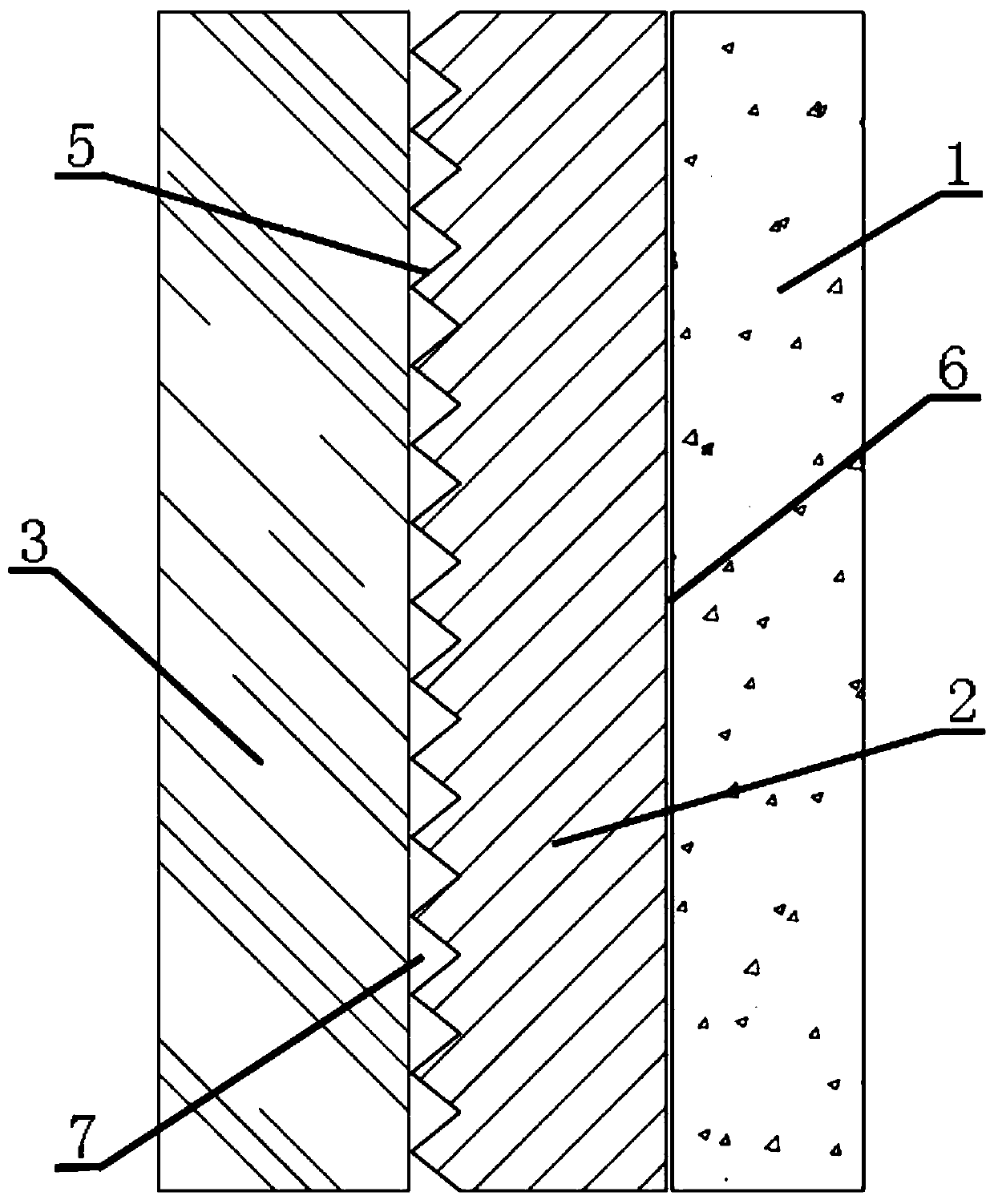

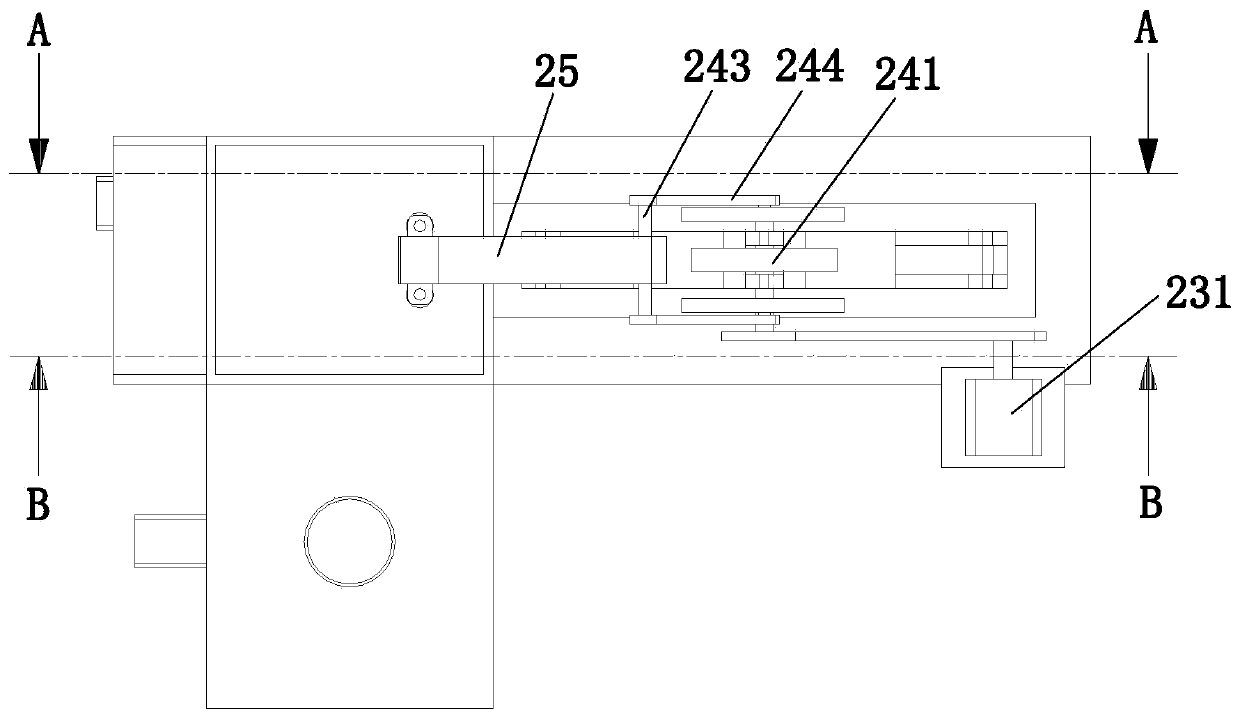

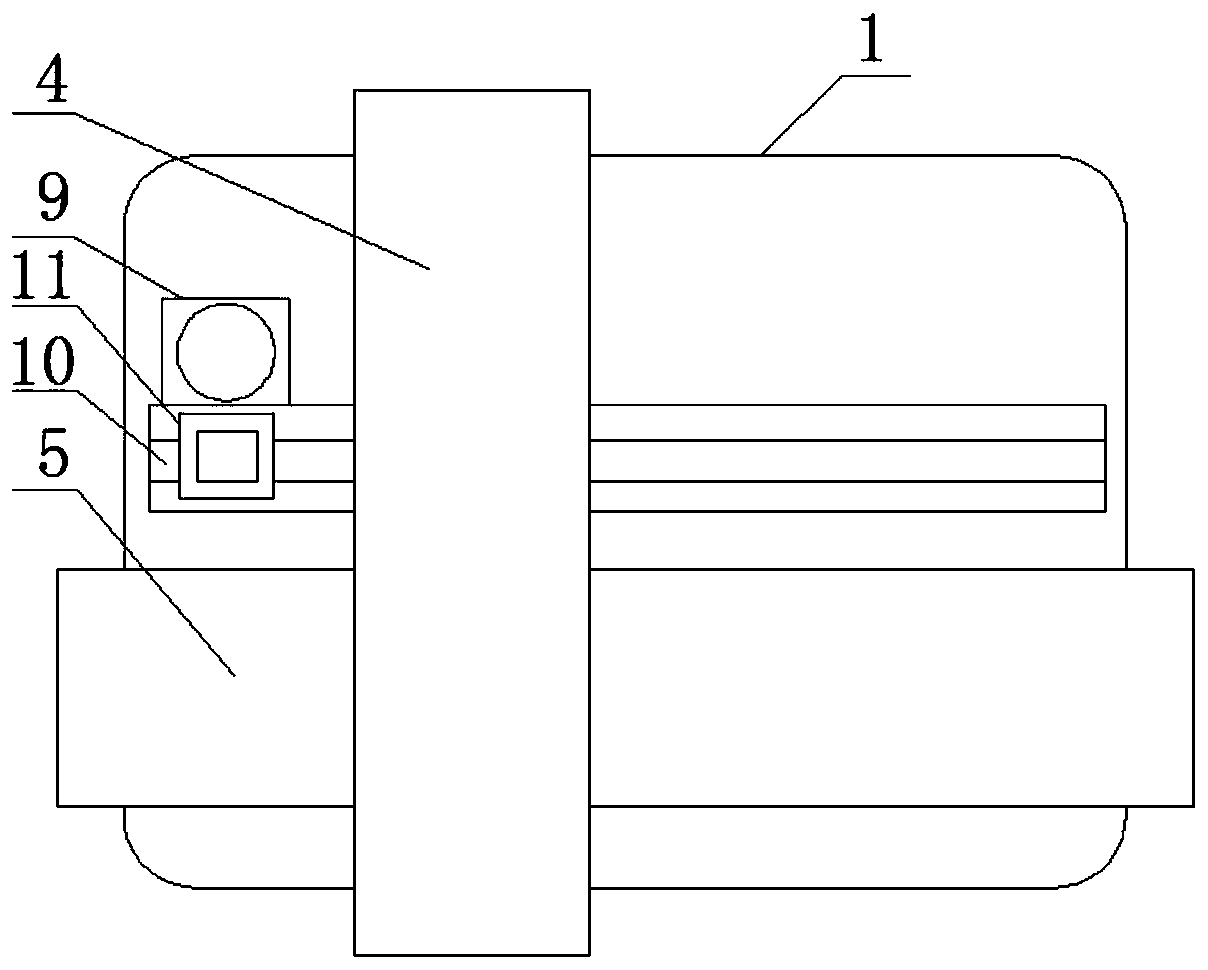

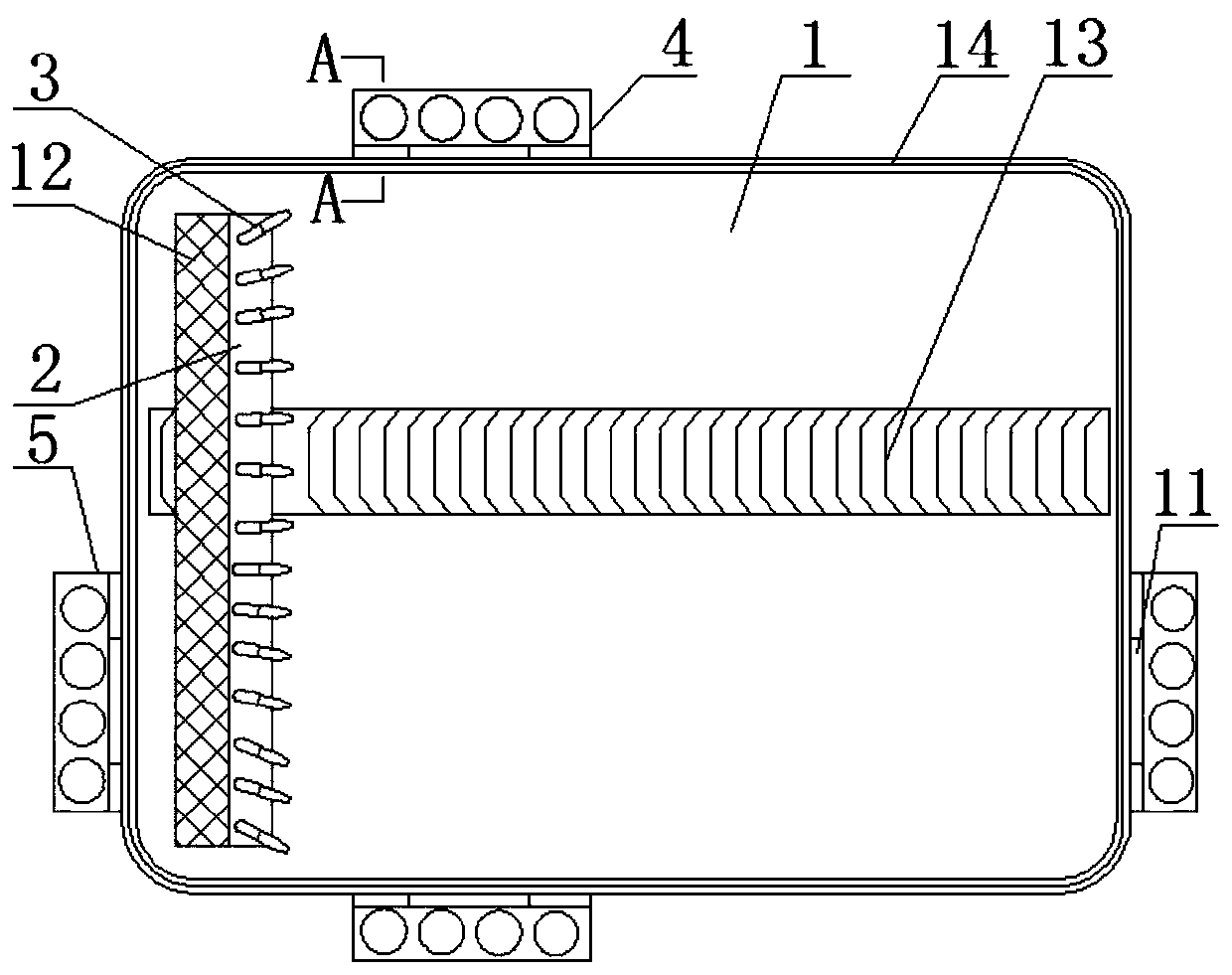

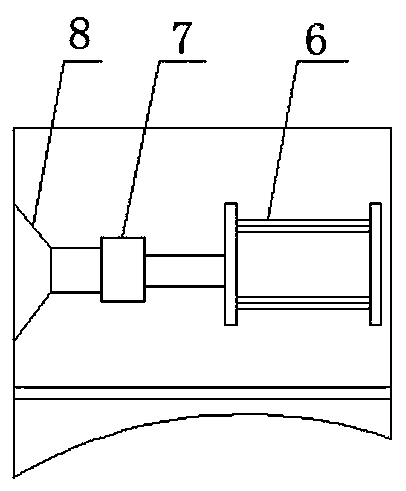

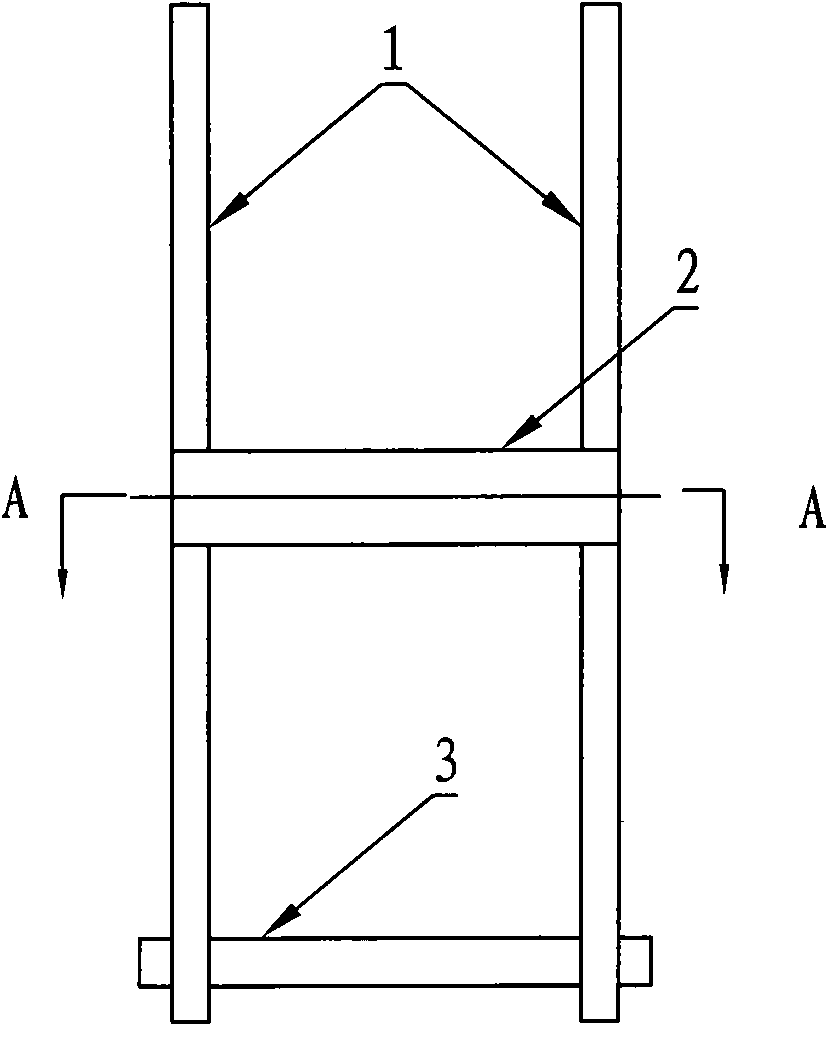

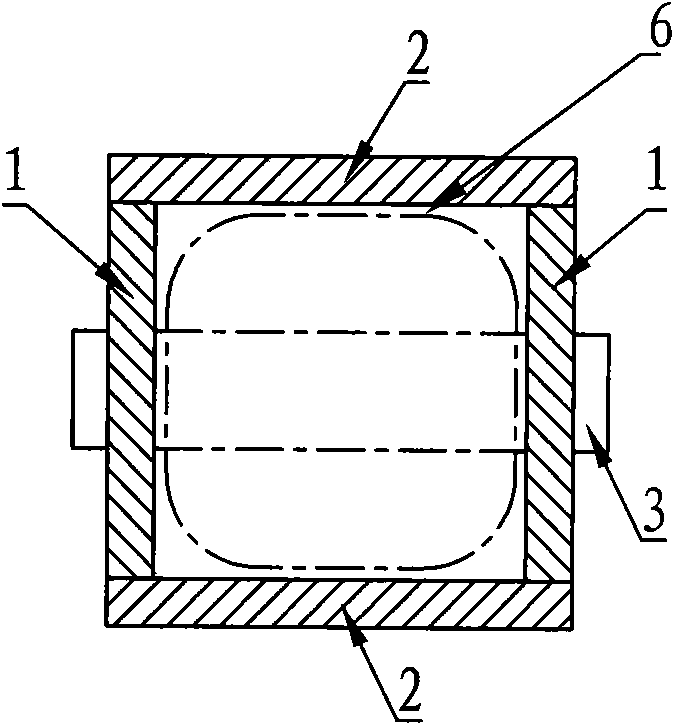

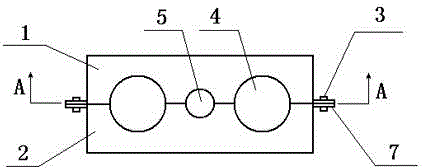

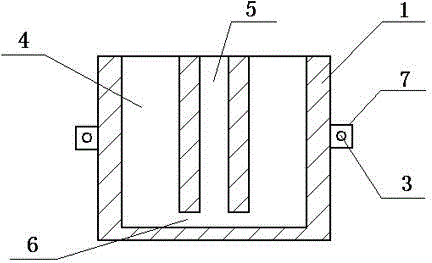

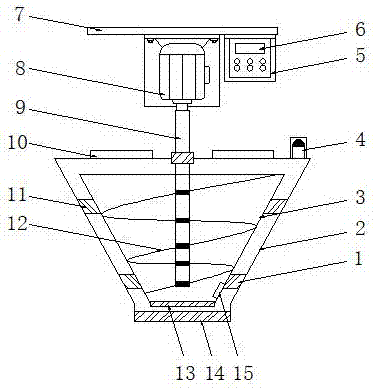

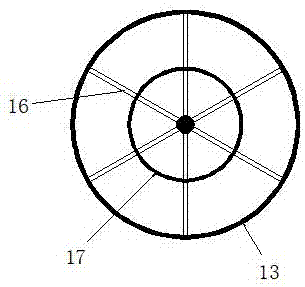

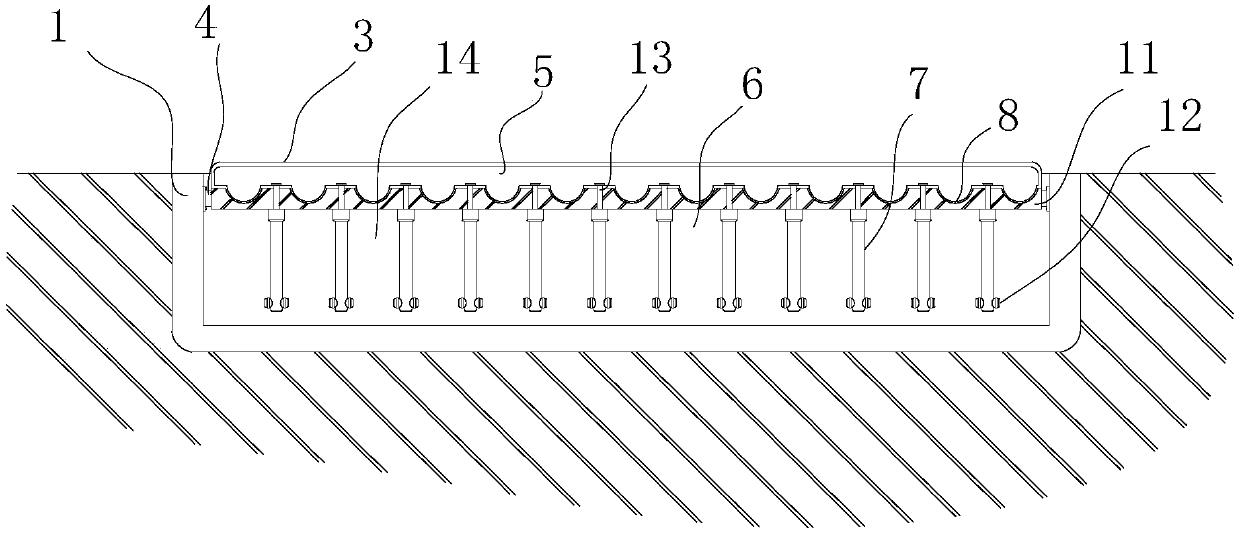

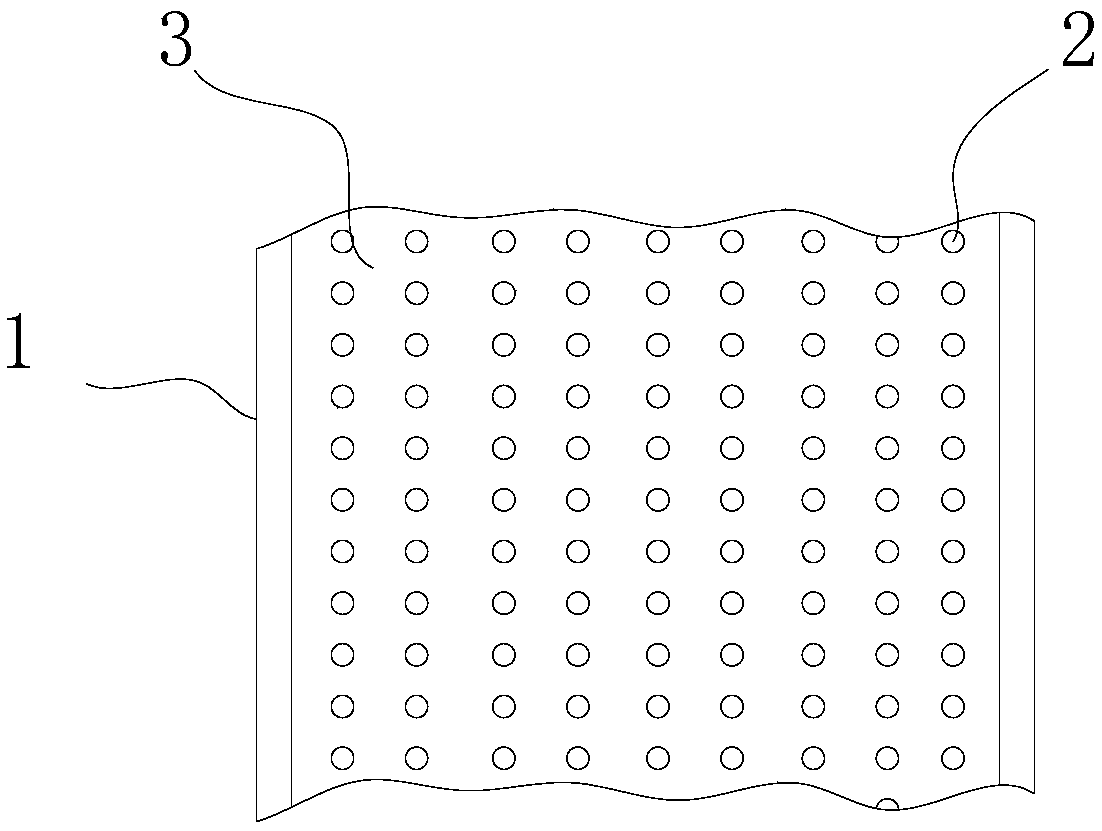

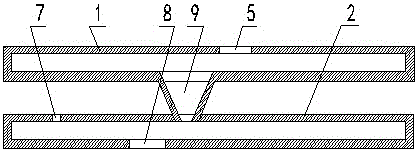

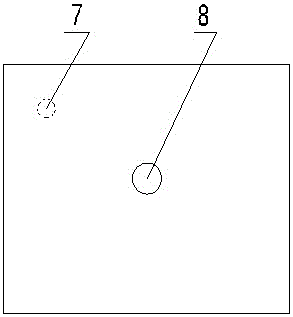

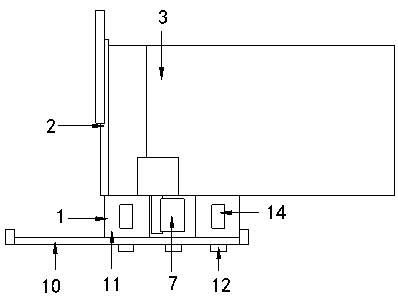

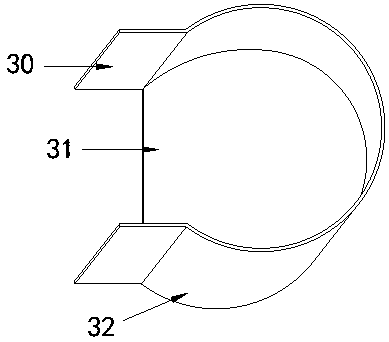

Converter steelmaking method for molten iron [Si] (0.50%)

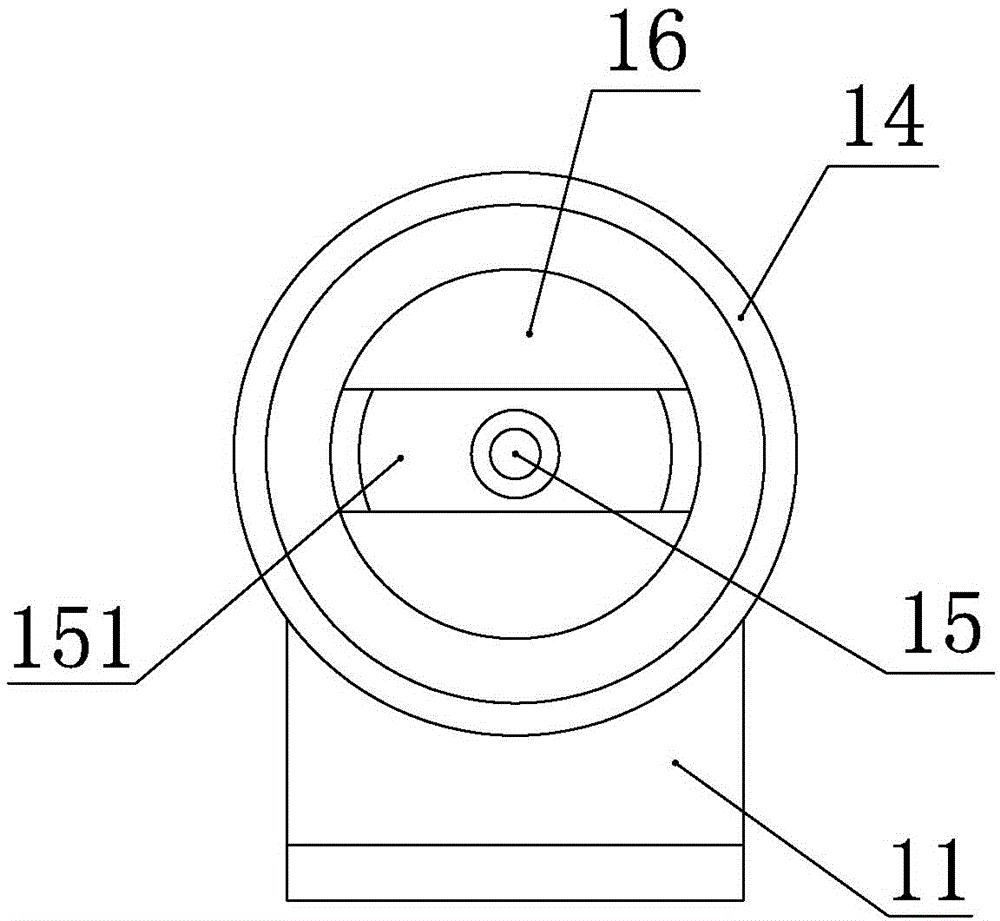

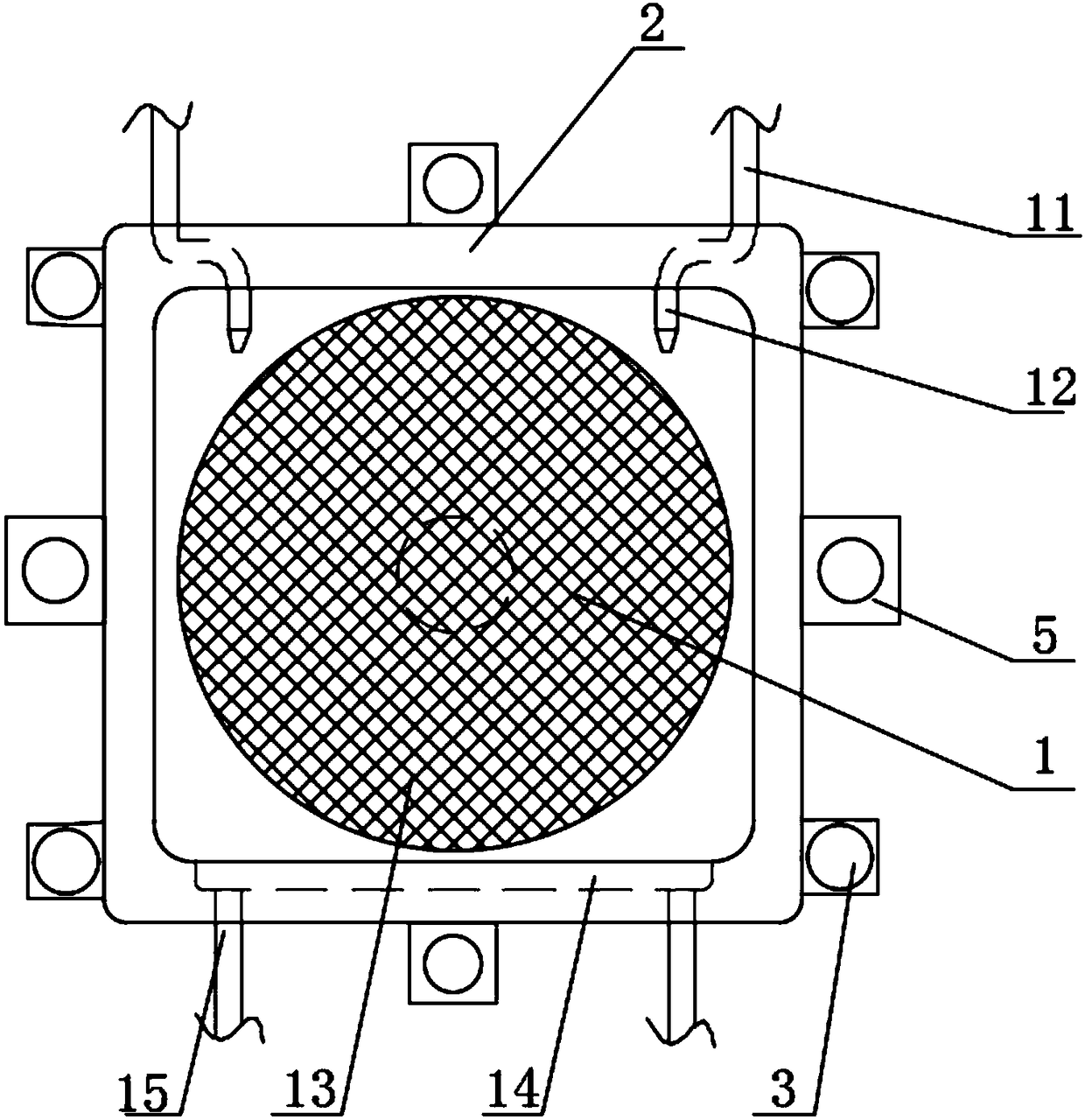

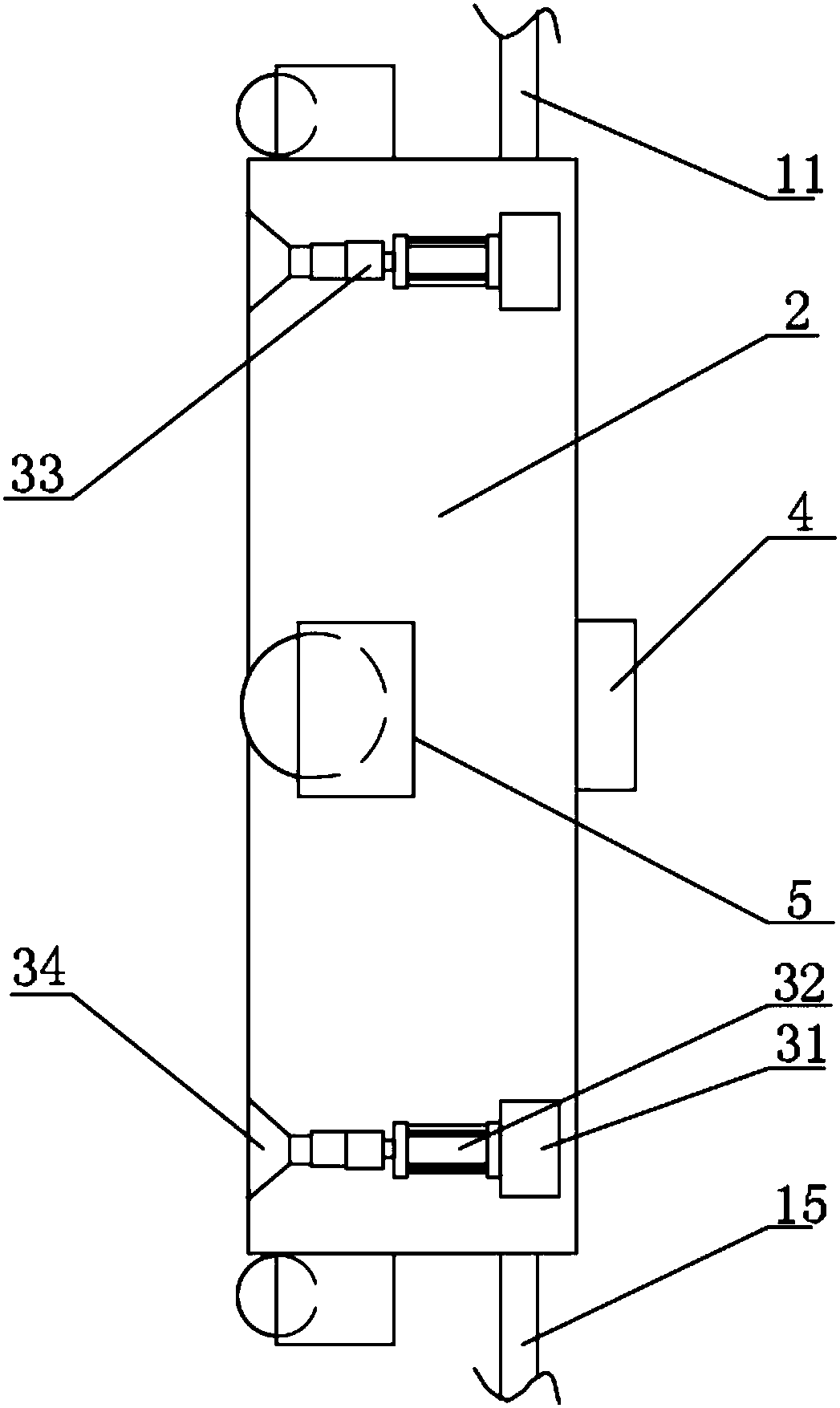

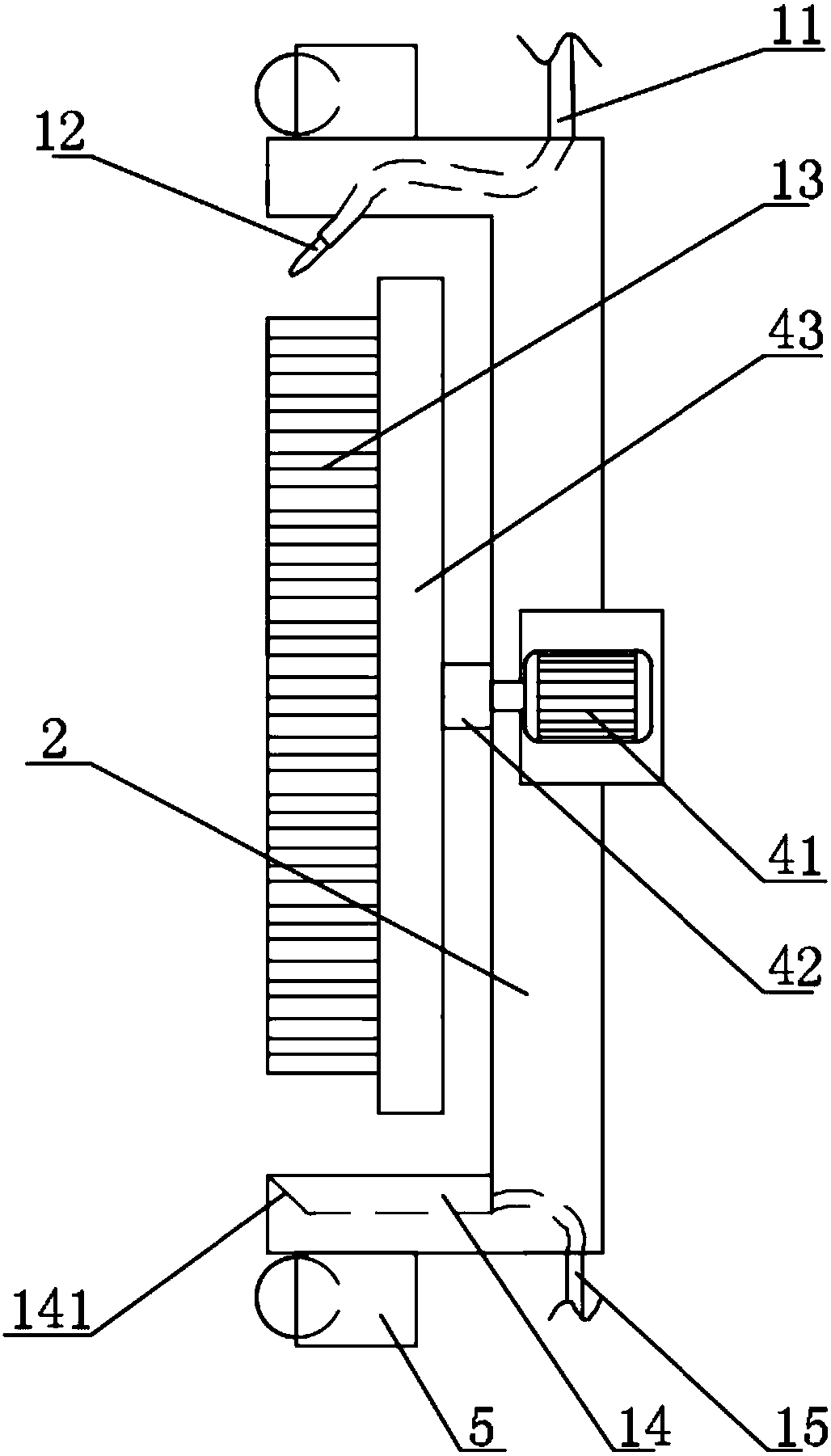

InactiveCN108893574ANo splashingThe smelting process is stableManufacturing convertersLime productionSteelmakingPhosphor

The invention discloses a converter steelmaking method for molten iron [Si] (0.50%). The converter steelmaking method comprises the following steps: confirming objective temperature, objective carbon,final phosphor, dephosphorizing rate and alkalinity of final residue according to different types of steel; calculating lime addition amount, dolomite addition amount, sinter addition amount and oxygen addition amount during a blowing process according to oxygen balance and heat balance; performing circular smelting in the smelting sequence of leaving residue in the converter, protecting the converter by splashing residue, adding waste steel and mixing with iron, blowing and then tapping. According to the invention, the slag amount and the process splashing phenomenon can be reduced and the consumption of lime and dolomite can be reduced without influence on the dephosphorizing rate.

Owner:SHANDONG IRON & STEEL CO LTD

Totally-enclosed open type commutator

ActiveCN101476922ANo splashingSmall structureTesting/calibration apparatusCalorimeterStatorHeat meter

The invention relates to a full-close type open type commutator. The commutator is characterized in that the commutator comprises a stator and a rotor which has relative rotation with the stator in the stator, wherein the inner surface of the stator and the outer surface of the rotor are in sealing fit by liquid; the stator is provided with a liquid inflow port and at least two liquid outflow ports; the rotor is provided with a connecting passage; when the rotor rotates, the liquid inflow port of the stator can be selectively communicated with one of the liquid outflow ports of the stator by the connecting passage; and when the rotor is in the process of rotating and switching a flow passage, the liquid inflow port of the stator is always positioned in the caliber range of an inlet of the connecting passage. When the commutator is reversed, no phenomenon of sputtering is produced; and simultaneously, flow fields of the commutator before and after reversing are still symmetrical to ensure that two liquid outflow ports have consistent flow. As the inner surface of the stator and the outer surface of the rotor are in sealing fit by liquid, the commutator solves the problem of the overflow of steam when the flow of hot water is measured; and therefore, the commutator is suitable for a standard device of a heat meter.

Owner:YUYAO YINHUAN FLOWMETER

Efficient wallpaper base film

The invention discloses an efficient wallpaper base film, prepared by mixing the following components by weight percent: 15-20 parts of water, 5-8 parts of ethylene glycol, 65-75 parts of emulsion, 1-2 parts of a dispersing agent and 1-2 parts of a modifying agent. The efficient wallpaper base film is made from environmental protection materials, thus not producing formaldehyde. The silicone acrylic emulsion used in a formula of the efficient wallpaper base film is capable of effectively permeating into a putty layer so as to solidity a wall. In addition, hydroxyethyl methyl cellulose ether is added into the efficient wallpaper base film, so that the constructability of the base film is effectively improved, a phenomenon of splashing is avoided, and the base film is enabled to be evenly painted. Furthermore, the drying time of the base film can be controlled to be 2-3 hours (surface dry), so that the emulsion is enabled to have enough time to permeate into the wall for solidifying the wall.

Owner:FOSHAN HENGXUE SCI & TECH SERVICES CO LTD

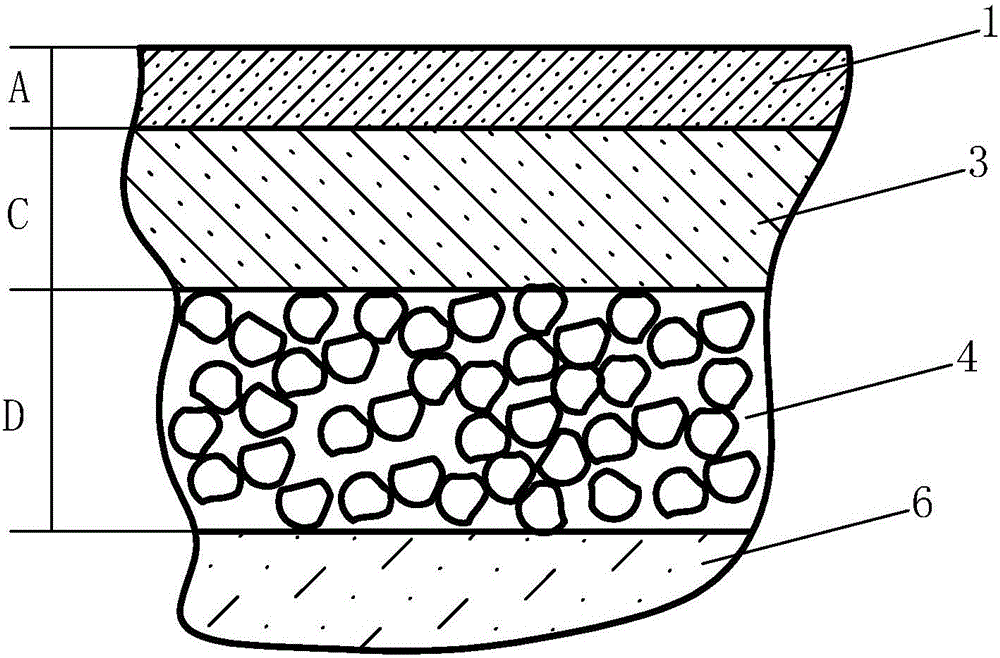

Water-retention water-water-permeable concrete utilizing construction waste and preparation method of water-retention water-permeable concrete

ActiveCN106431124AEfficient use ofReduce wasteSolid waste managementExpanded clay aggregateConstruction aggregate

The invention discloses water-retention water-permeable concrete utilizing construction waste and a preparation method of the water-retention water-permeable concrete. The water-retention water-permeable concrete is prepared from, by weight, 1-30 parts of cement, 1-3 parts of a mineral additive, 50-90 parts of aggregates, 0-3 parts of a coloring agent, 0.1-3 parts of a special additive SZ-BS-02 and 4-9 parts of water, wherein the mineral additive is ultrafine powder which is generated in the construction waste treatment process and has the specific surface area larger than or equal to 550 m<2> / kg, and the aggregates are prepared from, by weight, 25-35 parts of waste concrete particles with the particle size ranging from 2 mm to 30 mm, 45-55 parts of waste clay brick particles with the particle size ranging from 2 mm to 30 mm and 15-25 parts of light ceramisite with the particle size not larger than 15 mm. The water-retention water-permeable concrete prepared through the method has the good water retention, water permeability and gas permeability and is suitable for being used by a sponge city.

Owner:厦门宏鹭升建筑新材料有限责任公司

Flexible lamina for laser impact treatment

InactiveCN1151908CConvenient laser shock treatmentIncrease peak pressureLaser beam welding apparatusSilicone GelsLacquer

The present invention is applicable to utilization of laser impact wave technique to modify material surface or make cold-plasticity forming of metal plate material. Said invention adopts two groups of GN-521 organic silicone gel solutions with different components and additive, and mixes them according to a certain formula, after said mixture is solidified, a transparent constraining layer for laser is formed, and an energy-absorbing layer of 86-1 type black paint can be sprayed on the constraining layer to form the sticking film integrating energy-absorbing layer and constraining layer into one body and possessing a certain flexibility.

Owner:JIANGSU UNIV

Composite multi-layer crucible for induction melting of bismuth aluminum alloy and preparation method thereof

ActiveCN109824370AImprove structural strengthChemically stableLayered productsCrucibleSmelting process

The invention discloses a composite multi-layer crucible for induction melting of a bismuth aluminum alloy and a preparation method thereof.The problem in the prior art thata crucible suitable for theinduction melting of the bismuth aluminum alloy does not exist is solved. The composite multi-layer crucible comprises an inner layer crucible, a middle layer crucible and an outer layer crucible which are fixedly connected from the inside to the outside; the inner layer crucible is prepared from 92.5-97.5 parts of cerium oxide, 1.0-2 parts of calcium oxide, 0.5-2.0 parts of bismuth oxide and 1.0-3.5 parts of silicon carbide; the middle layer crucible is made of graphite; the outer layer crucible is prepared from 90-95 parts of calcium oxide, 1-3 parts of magnesium oxide, 2-4 parts of ceriumoxide, 1-1.5 parts of zirconiaand 0.5-1.5 parts of clay. The composite multi-layer crucible has a high strength structure, can shield a considerable portion of an induced magnetic field, has stable chemical properties, and has no splashing phenomenon in the smelting process, the degree of oxygenation is low, some single-layer structures can be replaced and can be reused, and the service life is long.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

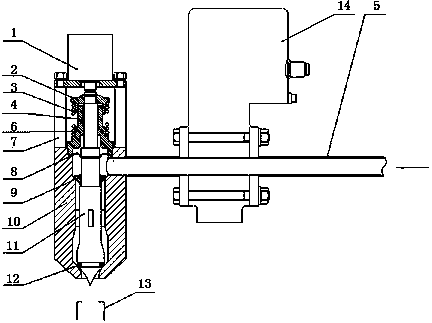

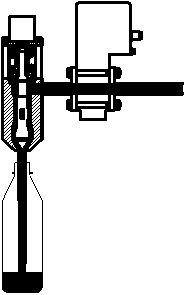

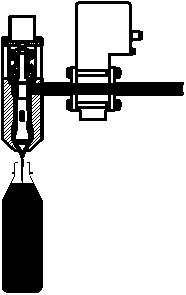

Liquid filling valve and operating method thereof

The invention provides a liquid filling valve and an operating method thereof. The liquid filling valve comprises a valve body, wherein a valve core is arranged in the valve body, the top of the valve body is sealed by a sealing diaphragm of the valve core, a discharge opening which is aligned with a container is formed in the bottom of the valve body, a filling channel is formed between the inner wall of the valve body and the valve core, the filling channel is connected to a feed pipe by virtue of a flowmeter, and a push device which is used for pushing the sealing diaphragm of the valve core to move is arranged on the top of the valve body. The liquid filling valve is characterized in that a pre-closed valve clack sleeves the upper part of the valve core, a clearance is left between the valve core and the pre-closed valve clack, the pre-closed valve clack can freely move up and down along the valve core, and a valve port sealing ring is arranged between the bottom of the valve core and the discharge opening in the lower end of the valve body. The liquid filling valve has the advantages of sanitation, no cleaning dead angle and low cost, and the splashing phenomenon is fully eliminated when the filling valve is closed.

Owner:南京保立隆包装机械有限公司

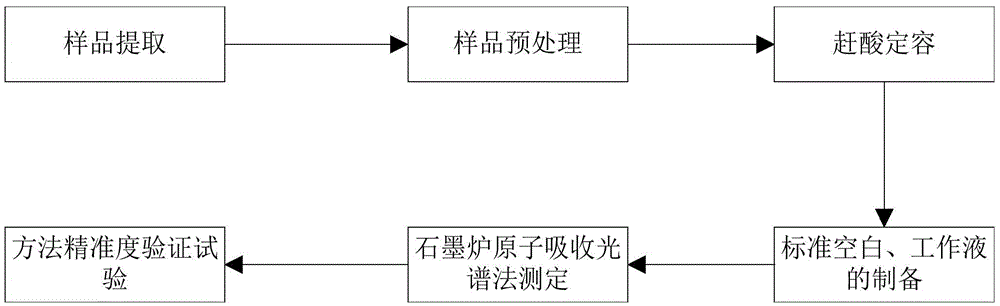

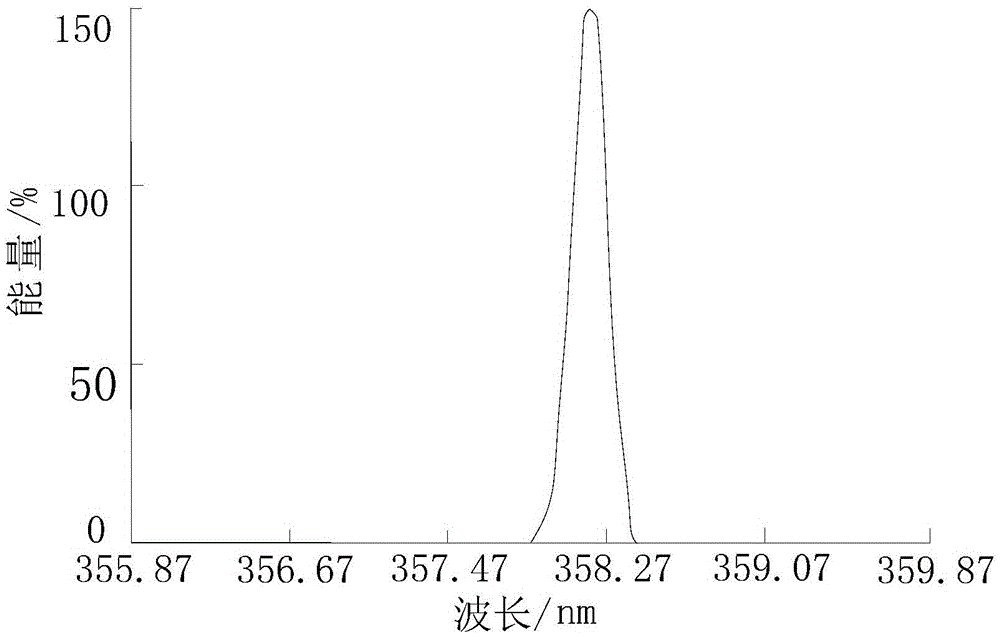

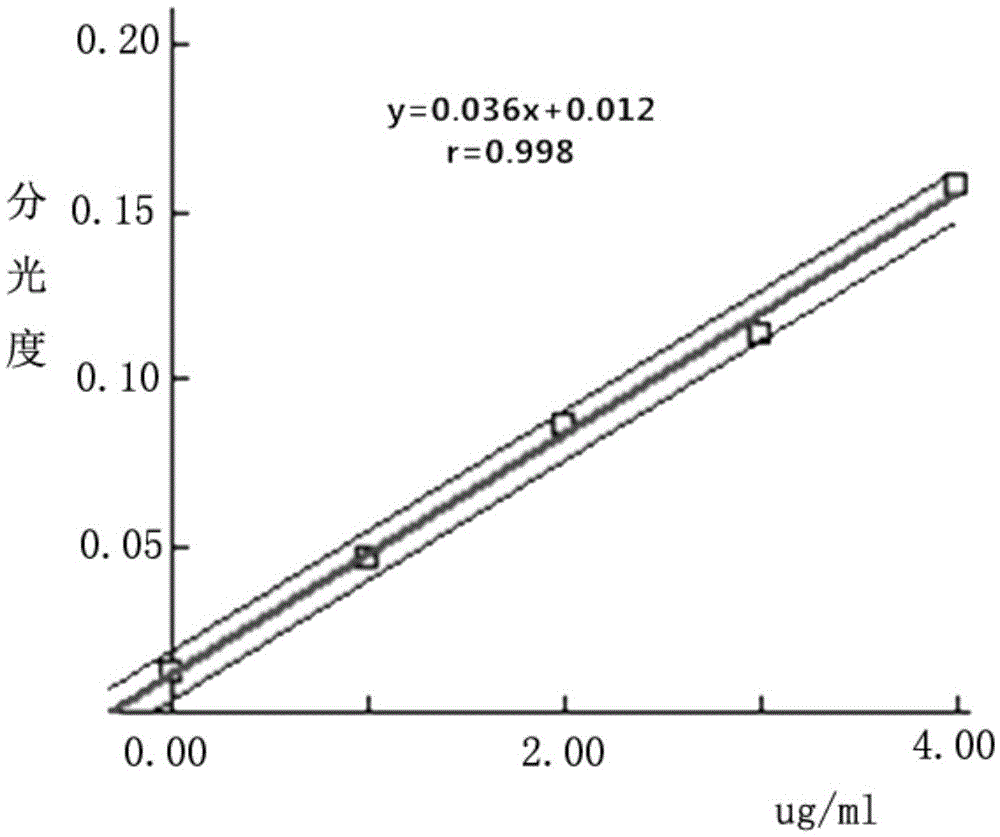

Determination method for chromium content of inhalable particles in soil dust and detection method

InactiveCN105651543AEasy to operateShort sampling periodWithdrawing sample devicesColor/spectral properties measurementsInhalable particlesNational standard

The invention discloses a determination method for the chromium content of inhalable particles in soil dust. The determination method includes the following steps of sample extraction, sample pretreatment, acid removal and volume metering, preparation of a standard blank solution and a standard working solution, and graphite furnace atomic absorption spectrometry determination. The invention further discloses a detection method for the accuracy of the determination method for the chromium content of inhalable particles in soil dust. The detection method includes the following steps that a national standard substance with the known chromium content is prepared into five parts of sample solutions to be detected, wherein the concentrations of the sample solutions to be detected are different; the chromium content in each sample solution to be detected is detected with the determination method for the chromium content of inhalable particles in soil dust so that the precision of the determination method for the chromium content of inhalable particles in soil dust can be verified. The determination method and the detection method have the advantage that sampling time is short, digestion is fast, little interference exists in determination, and the result is accurate and reliable.

Owner:SHANDONG UNIV OF SCI & TECH

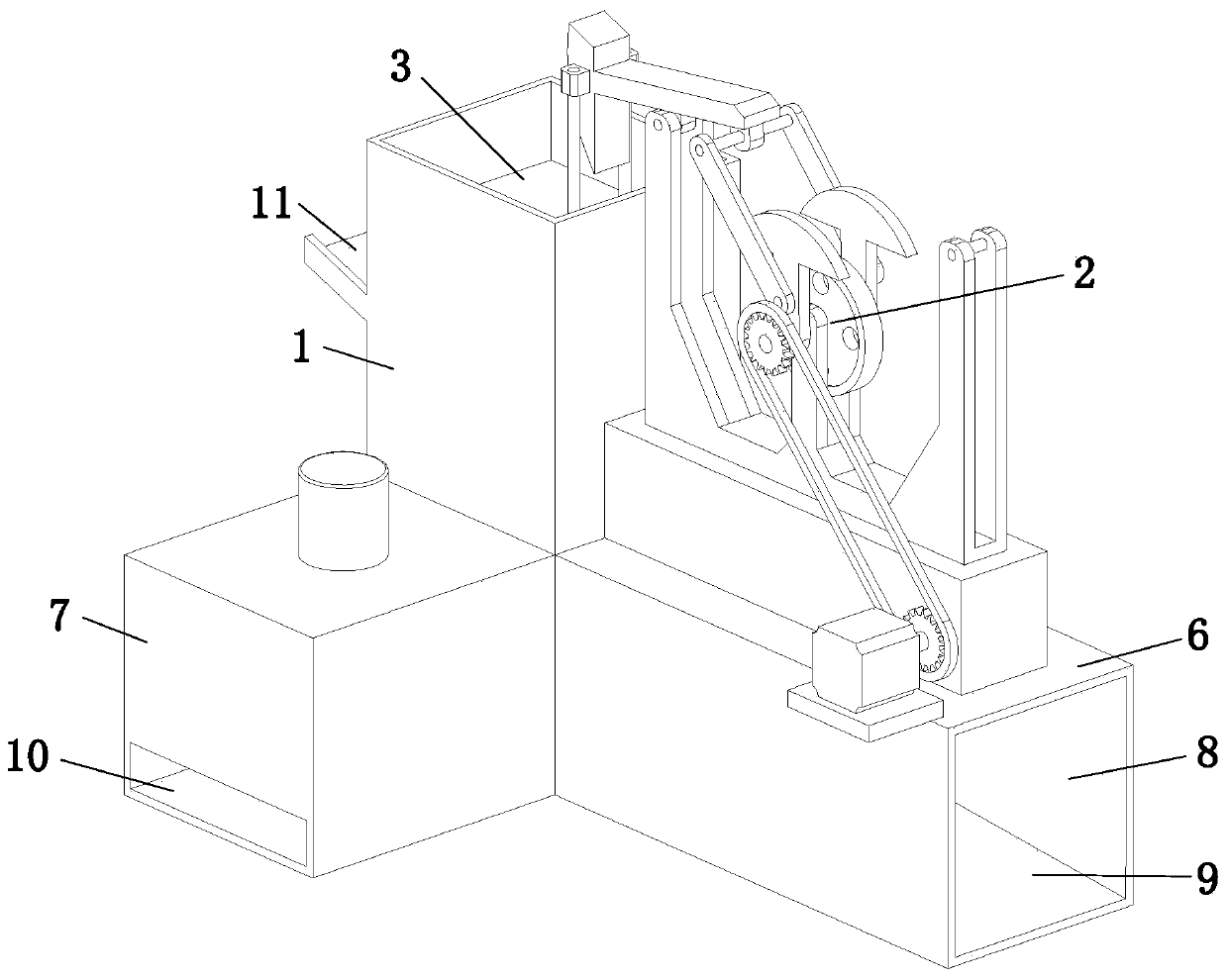

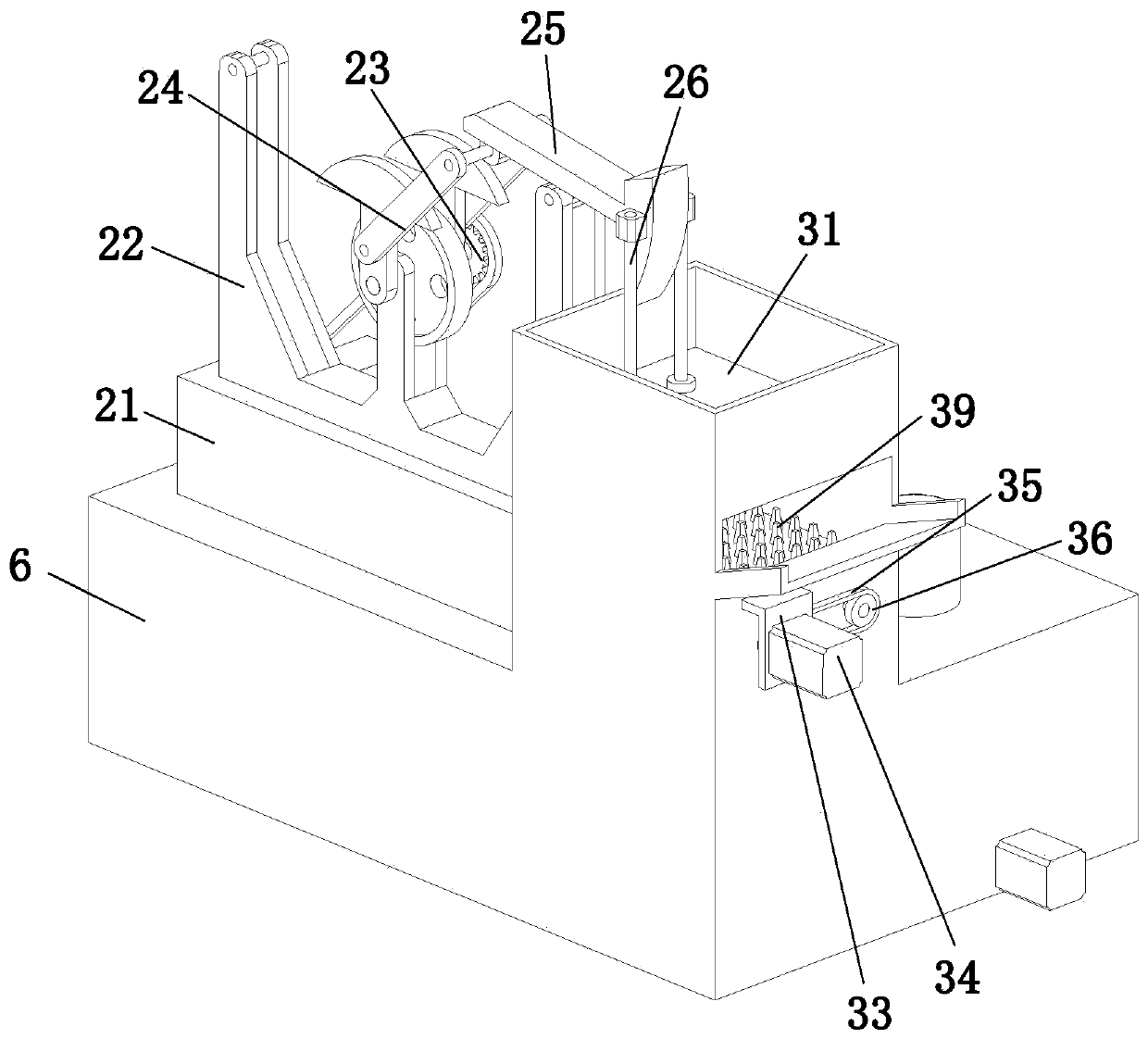

Recycling equipment for waste glass of new energy automobile

The invention relates to the field of glass recycling equipment, and discloses recycling equipment for waste glass of a new energy automobile. The recycling equipment comprises a treatment box vertically arranged, a downward pressing mechanism, a crushing mechanism, a screening mechanism and a grinding mechanism, wherein a first side box and a second side box are arranged on the two sides of the treatment box correspondingly, the downward pressing mechanism is installed at the top of the first side box, the front end of the downward pressing mechanism is fixedly connected with the top of the crushing mechanism, a first discharging opening is formed in one side of the first side box, a guide table is arranged in the first side box, the top face of the guide table is an inclined face, the rear end of the guide table extends to the position below the screening mechanism, a second discharging opening is formed in one side of the second side box, a feeding opening is formed in one outer side wall of the treatment box, and a guide plate is arranged at the feeding opening. According to the recycling equipment, the situation that the glass splashes is avoided while the steps of automatically crushing and grinding glass can be achieved, the safety of personnel is greatly improved, sorting of the glass can be completed, and the subsequent diversified production requirements of the glassare met.

Owner:高跃

Automatic washing device for glass curtain wall

InactiveCN109700369AIncrease displacementIncrease working areaCarpet cleanersFloor cleanersSpray nozzleEngineering

The invention provides an automatic washing device for a glass curtain wall, and belongs to the field of washing for glass curtain walls. The device comprises a machine body and a washing mechanism, wherein the machine body is of a rectangular-groove-shaped structure, the washing mechanism performs the reciprocal rectilinear motion along the length direction of the machine body through a sliding mechanism, a plurality of spray nozzles are arranged on the washing mechanism along the width direction of the machine body, horizontal moving assemblies for realizing the horizontal movement of the machine body and vertical moving assemblies for realizing the vertical movement of the machine body are further arranged on the machine body, each of the horizontal moving assembly and the vertical moving assembly comprises a door-shaped framework and at least one absorbing assembly arranged on two sides of the framework, each framework is arranged on the machine body in a sliding manner through another sliding mechanism, each absorbing assembly comprises an air cylinder, an electromagnetic valve and a vacuum chuck, one end of the air cylinder is fixedly connected to the framework, and the otherend of the air cylinder is sequentially fixedly provided with the electromagnetic valve and the vacuum chuck. With the device provided by the invention, the problems that in the prior art, washing liquid drips, the washing work efficiency is not high, etc., are solved.

Owner:CHONGQING JIAOTONG UNIVERSITY

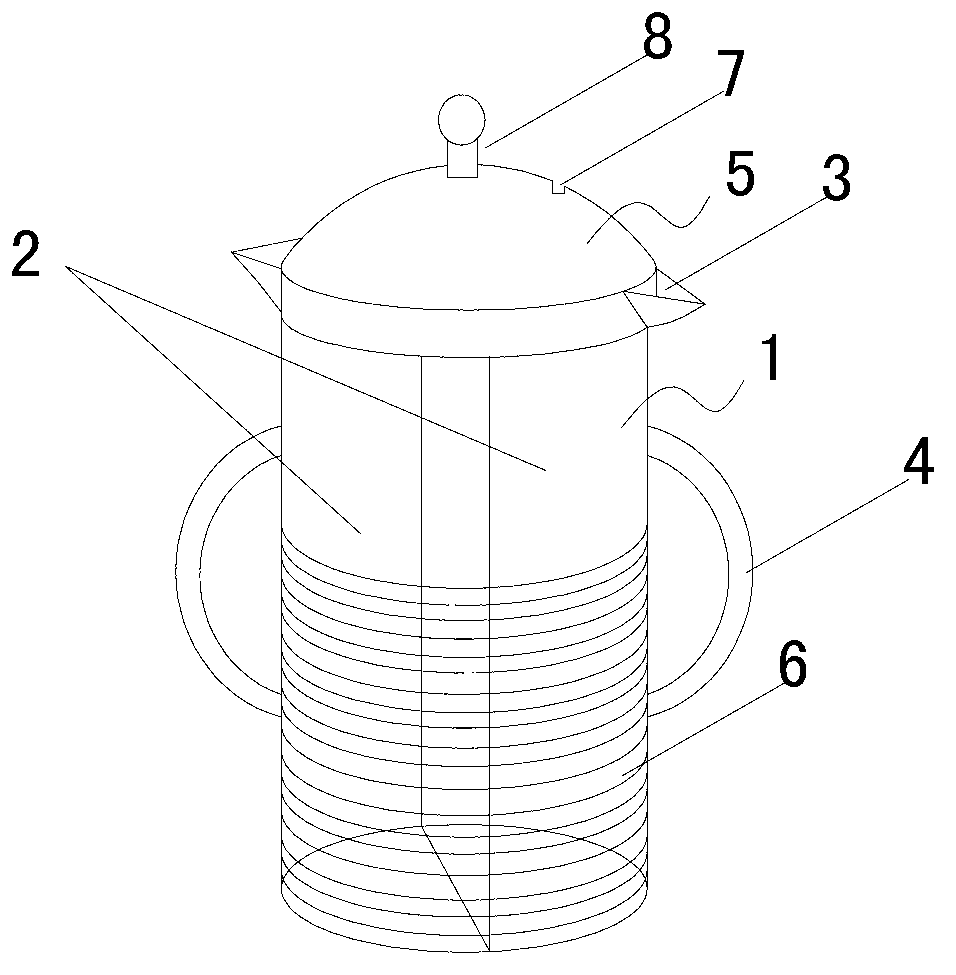

Medical inspection beaker

InactiveCN103341373AMeet the needs of simultaneous heatingNo splashingLaboratory glasswaresFiberMechanical engineering

The invention discloses a medical inspection beaker which comprises a beaker body, wherein the beaker body is internally divided into a plurality of liquid containing chambers evenly in the vertical direction; liquid outlets in one-to-one correspondence to the liquid containing chambers are evenly distributed in the edge at the top end of the beaker body along the circumferential direction; at least one handle is arranged on the outer side wall of the beaker body; a lid is arranged at an opening of the beaker body; the lid is provided with drainage holes which have the quantity same as that of the liquid outlets and correspond to the liquid outlets in position; and the beaker body is wound with a heatproof fiber layer. By designing the plurality of liquid containing chambers, simultaneous heating for various liquids can be achieved, flexibility of use is improved and the medical inspection beaker is very safe to use.

Owner:贵州森威商贸有限公司

Passivating metal magnesium particles and passivating method thereof

ActiveCN103695884AEvenly wrappedPrecise active magnesium contentLiquid surface applicatorsMetallic material coating processesGraphiteOrganosilicon

The invention discloses passivating metal magnesium particles and a passivating method thereof. The passivating metal magnesium particles comprise the following components in percentage by weight: less than or equal to 99% and greater than or equal to 92% of Mg, less than or equal to 0.002% of S, less than or equal to 0.01% of Cu, less than or equal to 0.001% of P and less than or equal to 1.2% and greater than or equal to 0.1% of H2O. The passivating method comprises the following steps: (I), preparing a metal magnesium particle passivator, placing metal magnesium particles in the passivator, and then naturally cooling to room temperature; (II), coating a coating on the surface of the magnesium particles: firstly, coating an organic silicon compound on the surface of the metal magnesium particles, coating magnesium oxide on the surface of the metal magnesium particles, then, coating compound rare earth on the on the surface of the metal magnesium particles, and finally coating graphite powder on the surface of the metal magnesium particles; and (III), sieving the metal magnesium particles cooled to room temperature. The metal magnesium particle passivating layer is uniform in coating, and the storage and use safety is ensured.

Owner:JIANGSU ZHENGDA FURNACE CHARGE

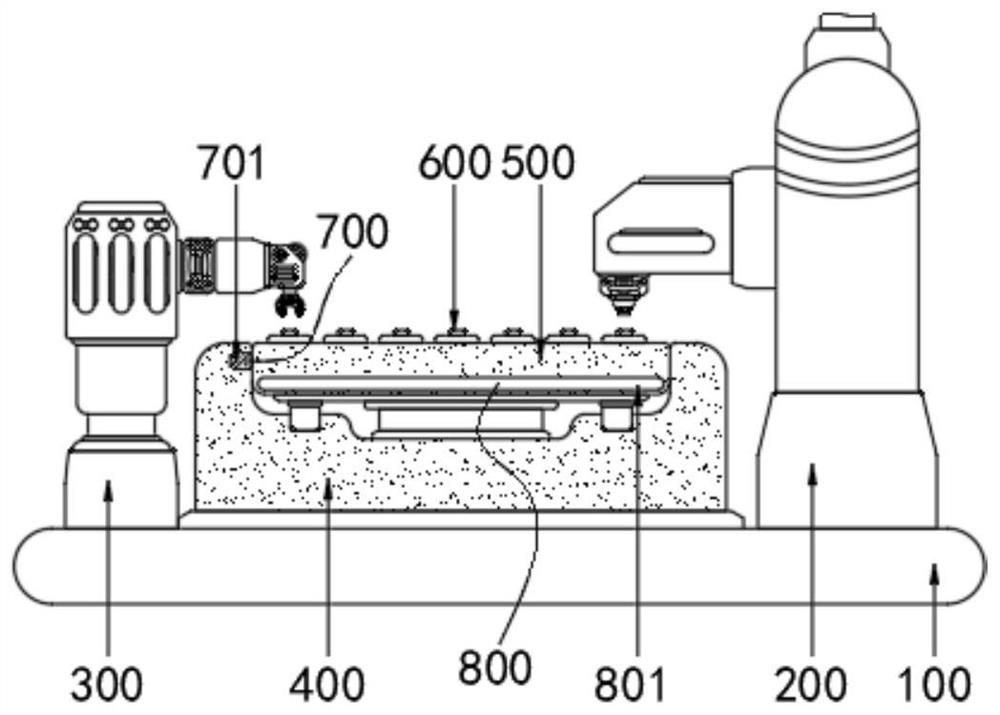

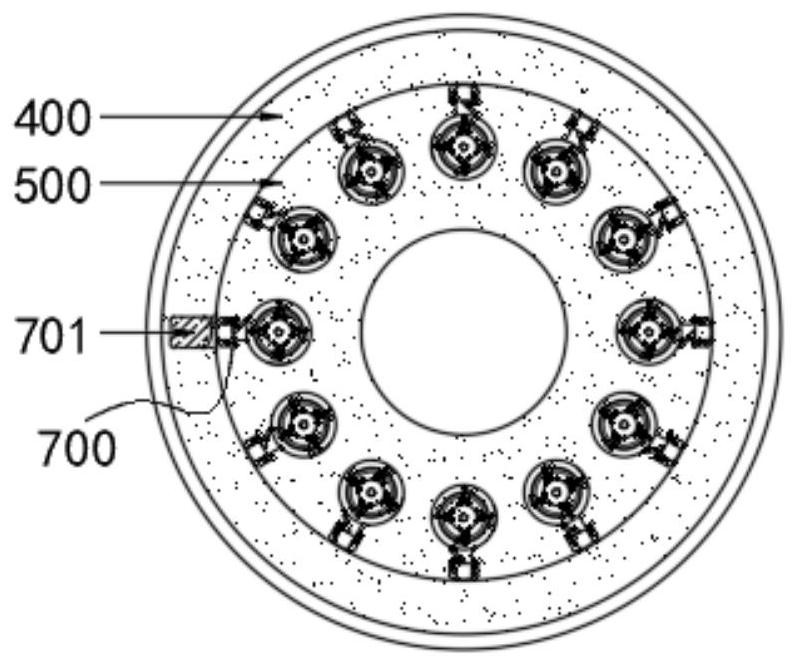

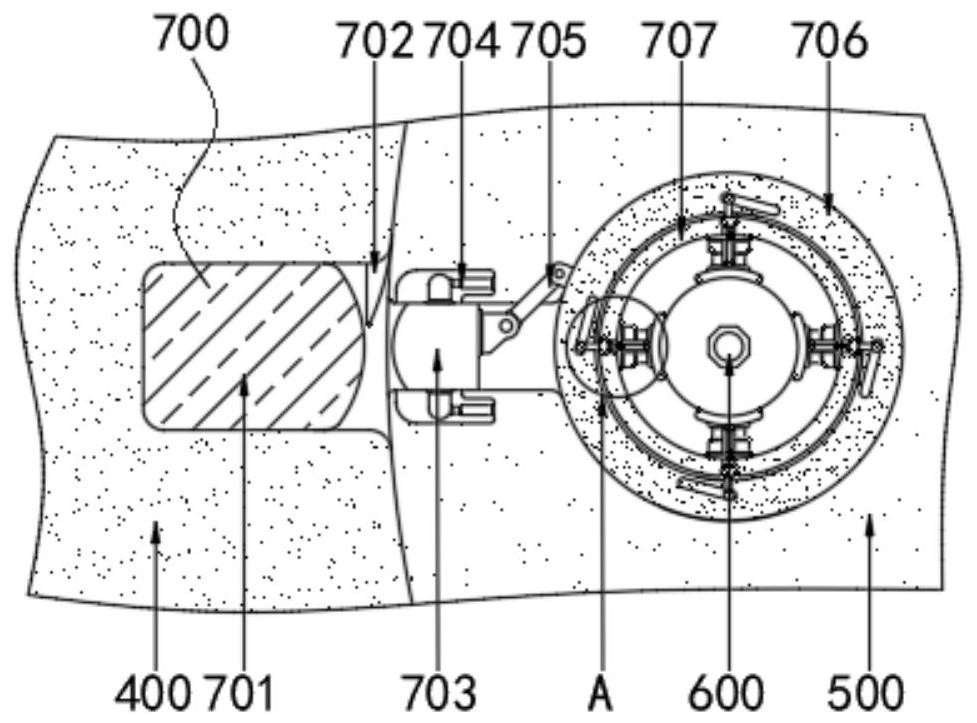

Rotary pouring machine for casting machining

ActiveCN112775419AStable clampingEasy to holdMould handling equipmentsMolten metal conveying equipmentsCircular discElectric machinery

The invention relates to the technical field of casting machining, and discloses a rotary casting machine for casting machining. The rotary casting machine for casting machining comprises a base, a liquid injection column, a mechanical arm, a box body, a rotary disc, a mold, a clamping assembly and a buffer assembly, wherein the top end of the base is fixedly connected with the liquid injection column; the box body is located on the left side of the liquid injection column and fixedly connected with the top end of the base; the top end of the inner wall of the box body is movably connected with the rotary disc; the top end of the inner wall of the rotary disc is movably connected with the mold; the inner wall of the rotary disc is movably connected with the buffer assembly; the left side of the rotary disc is movably connected with the clamping assembly; and a driving motor is arranged in the rotary disc and drives the rotary disc to rotate when running; Compared with traditional manual pouring, the rotary casting machine for casting machining is accurate during casting, the phenomenon that molten metal splashes is not prone to being generated, and the mold does not shake greatly in the initial rising stage, so that the phenomenon that the molten metal in the mold splashes is avoided.

Owner:临沂凯士彼机械有限公司

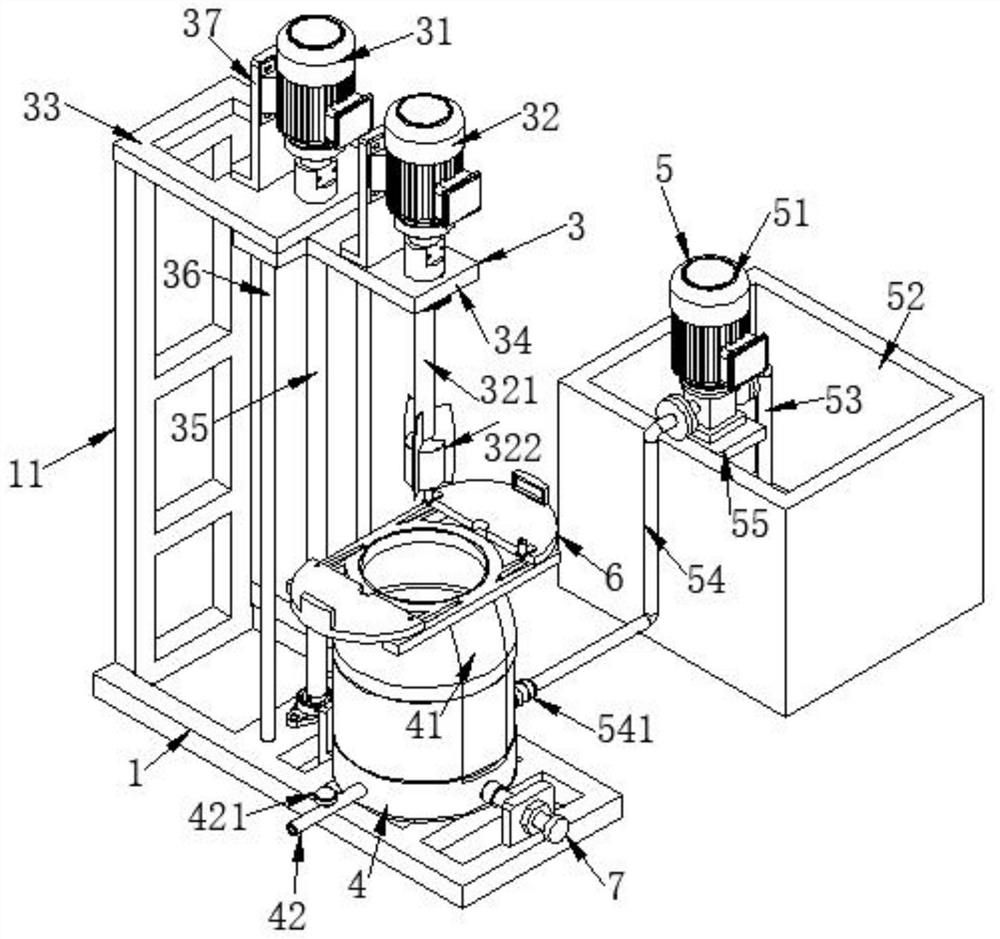

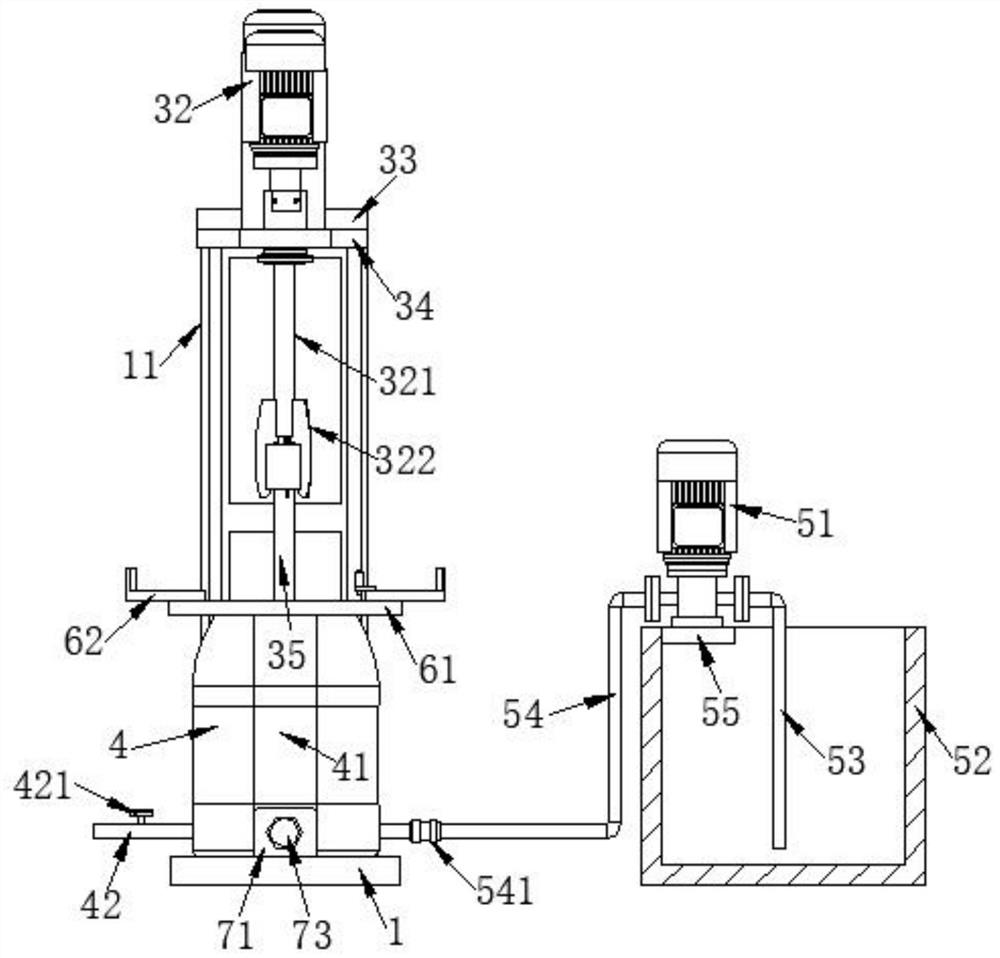

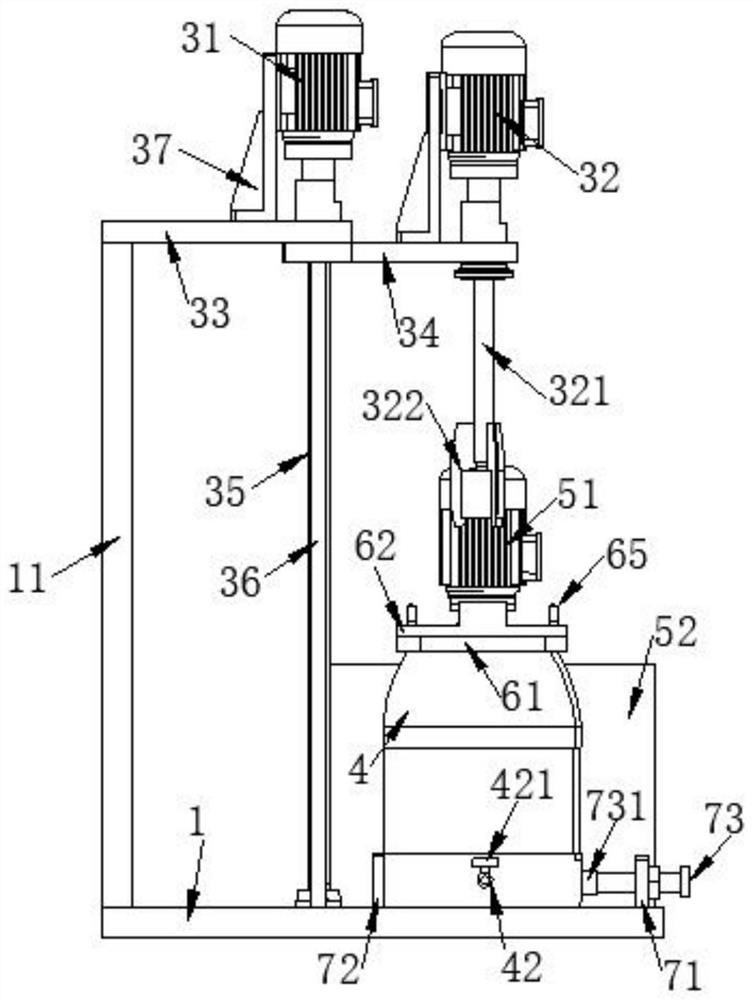

Stirring equipment and stirring method for daily chemical production

InactiveCN112675730AIncrease productivityStir wellRotary stirring mixersMixer accessoriesElectric machineProcess engineering

The invention discloses stirring equipment and a stirring method for daily chemical production. The stirring equipment comprises a base, wherein a supporting frame is fixedly connected to the top of the base; a stirring mechanism is arranged at the top of the supporting frame; the stirring mechanism comprises a first motor, a second motor, a mounting frame and a movable plate; the first motor and the second motor are both electrically connected with an external power source; the mounting frame is fixed to the top of the supporting frame; and the output end of the first motor is fixedly connected with a lead screw used for driving the movable plate to move. By starting a water pump to pump chemical solvents in storage tanks, discharging the chemical solvents into a stirring barrel through liquid conveying pipes, directly discharging the mixed chemical solvent through a liquid discharging pipe after stirring is completed and repeating the above operation, chemicals can be stirred and chemical production efficiency is improved; and meanwhile, the solvents in the stirring barrel can be fully stirred through an innovatively-arranged sealing mechanism, so the phenomenon that the chemical solvents are splashed out during stirring is avoided, and the equipment is safe and reliable in stirring.

Owner:涡阳县华腾日用化学品有限公司

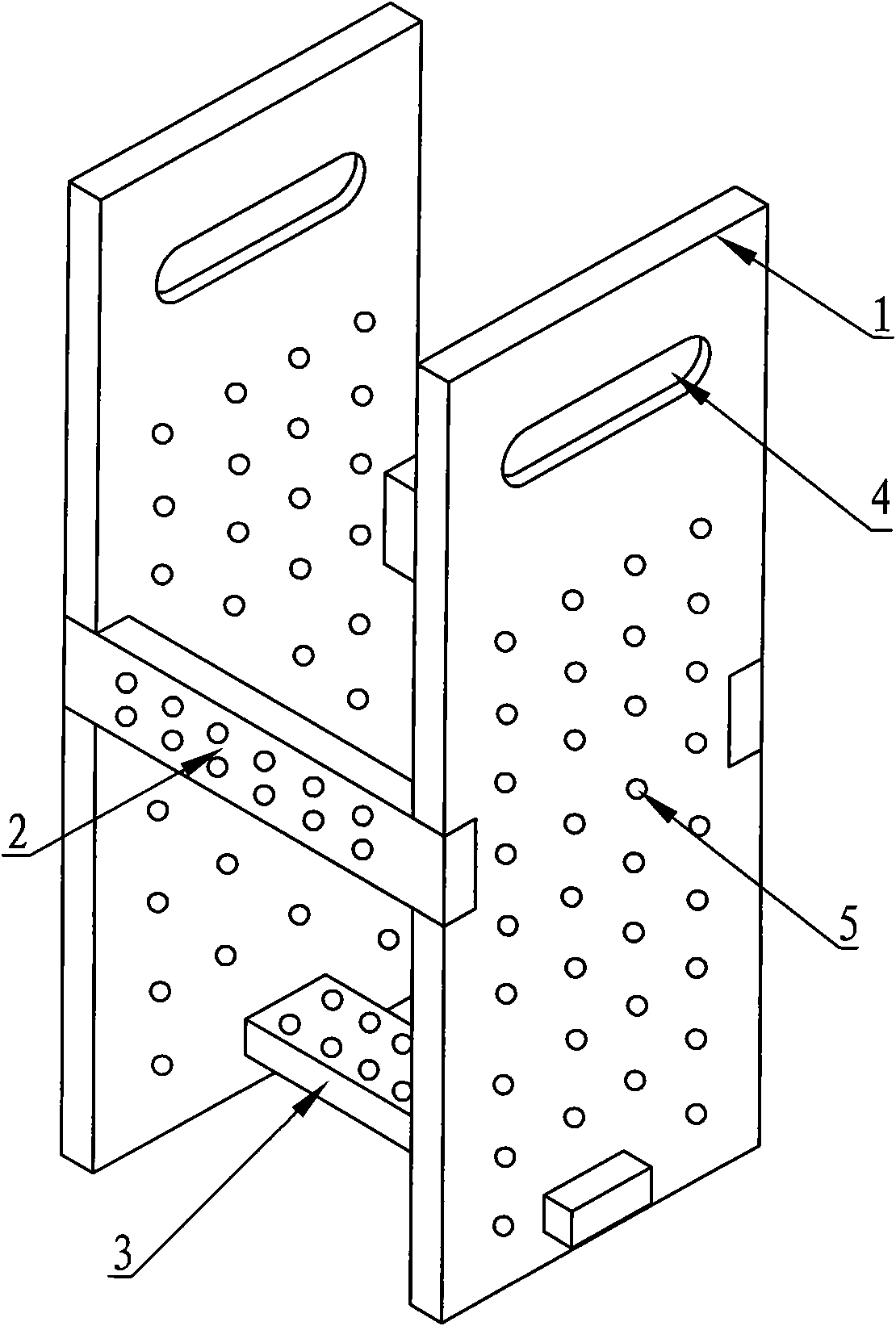

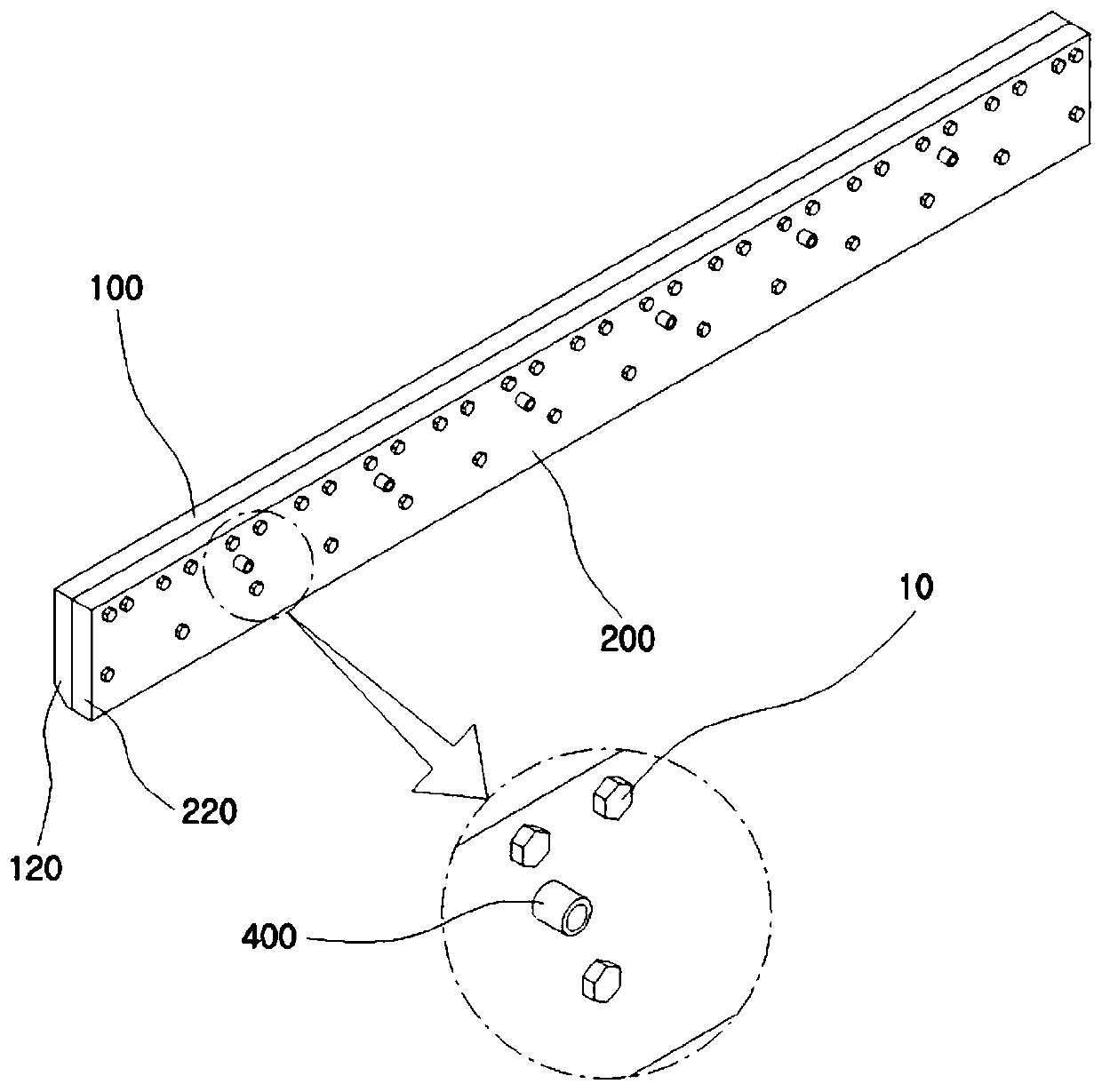

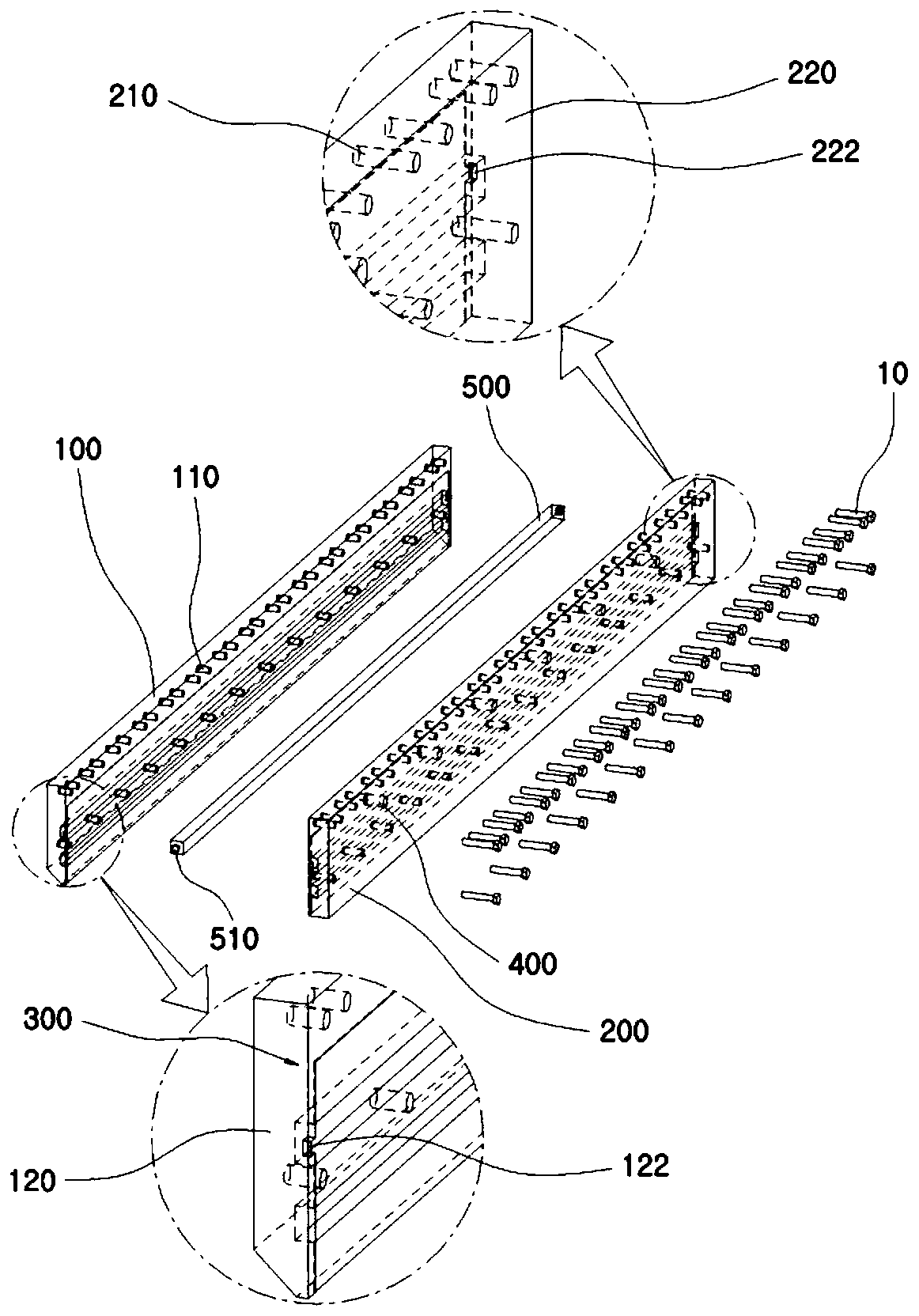

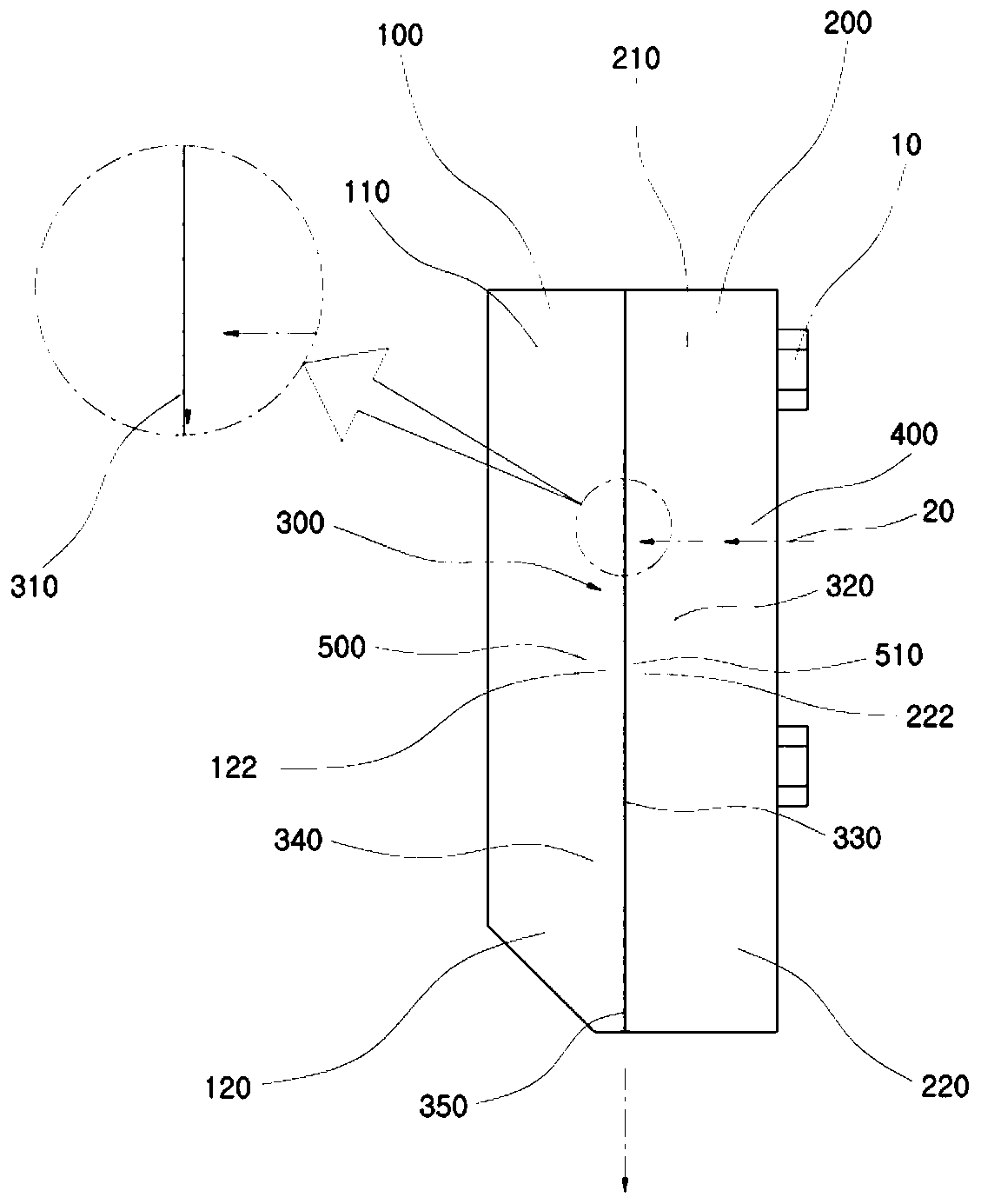

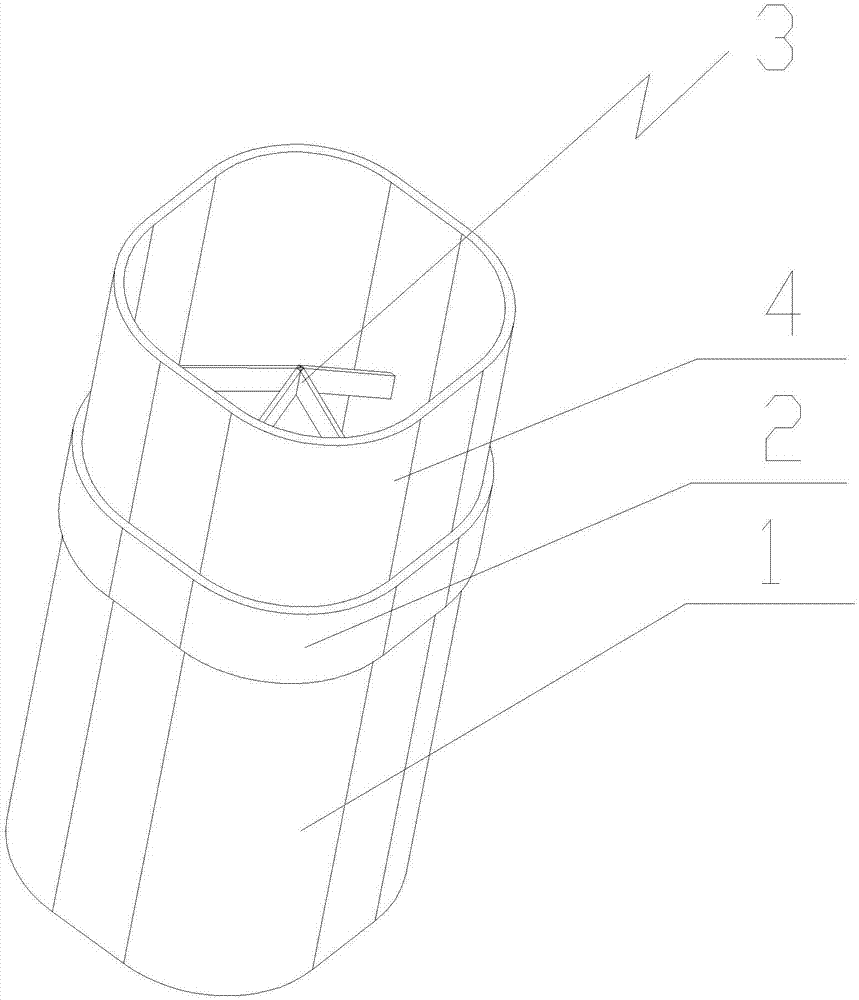

Loading device specially for silicon material square section pickling

InactiveCN102172584AGuaranteed cleaning qualityEliminate damageCleaning using liquidsEngineeringSilicon

The invention relates to a loading device specially for silicon material square section pickling, comprising two main backing plates, a side connecting plate and a bottom connecting plate, wherein the main backing plates, the side connecting plate and the bottom connecting plate are connected into a hollow barrel structure, the silicon material square section is placed in the hollow barrel structure, and hand holes are respectively arranged at the upper end parts of the two main backing plates. The hollow barrel structure is adopted, the silicon material square section is placed in the hollow barrel structure, the bottom is limited by the bottom connecting plate, the periphery is limited by the main backing plates and the side connecting plate, the hand holes are arranged at the upper ends of the main backing plates, hands of an operator hold the hand holes at the upper ends of the two main backing plates when the loading device is slowly placed into a pickling tank, thus soft landing is realized; and when the loading device is placed into the pickling tank, no splashing of a cleaning solution is produced in a cleaning tank, and the cleaning solution can be ensured to be fully contacted with the periphery of the silicon material square section, thus both the cleaning quality of the silicon material square section and the production safety of the operator in the pickling process can be guaranteed.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

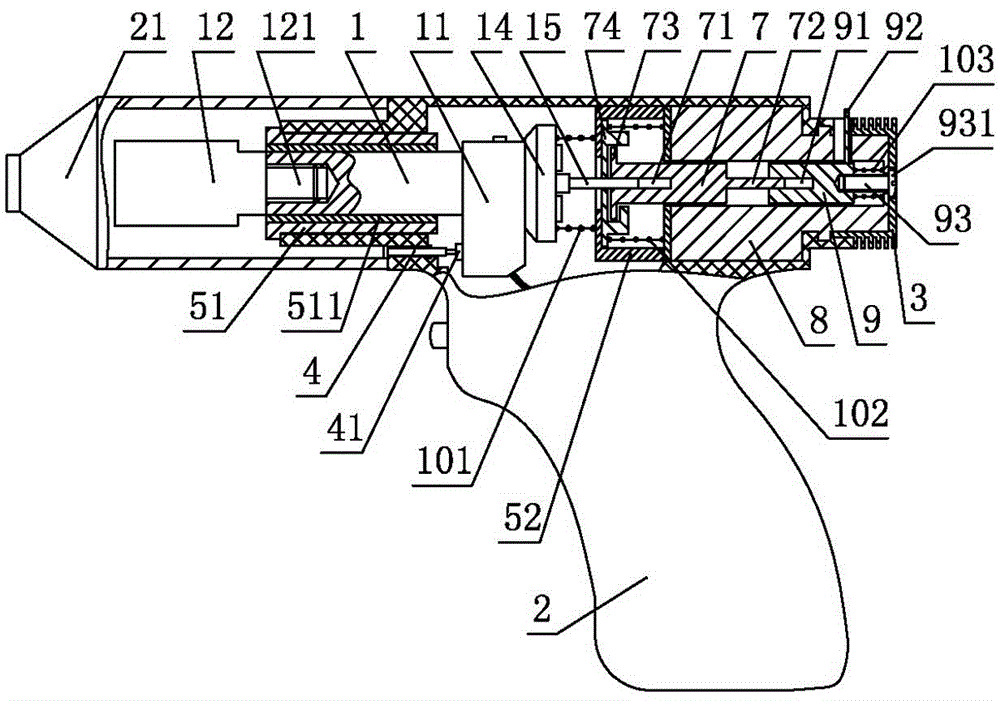

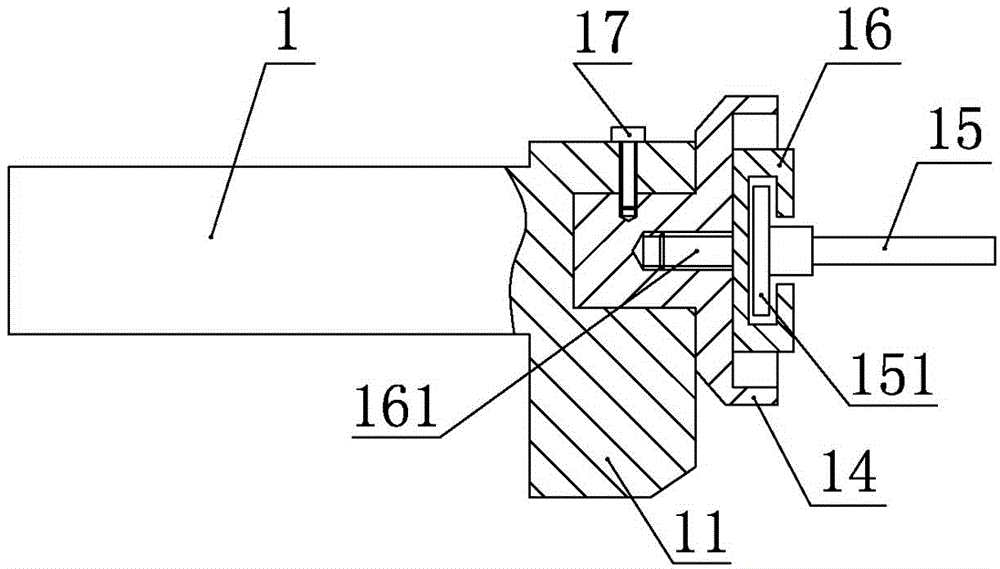

Arc type self-adaptive stud welding gun

ActiveCN104308328ANo splashingFlexible and reliable slidingArc welding apparatusSelf adaptiveControl circuit

The invention discloses an arc type self-adaptive stud welding gun. The interior of a cavity of a welding gun casing is provided with a main shaft body, a movable iron core, a fixing sleeve, a stationary iron core and a control circuit device, the front end of the main shaft body is provided with an integral clamping head seat, the interior of the fixing sleeve is provided with a coil, the main shaft body is movably arranged in a shaft sleeve in a penetrating way, the shaft sleeve is fixedly arranged in the cavity, the front end of the fixing sleeve is movably inserted into the movable iron core, the tail end of the fixing sleeve is inserted into the stationary iron core, a lifting clearance is formed between the movable iron core and the stationary iron core, a reset structure is arranged in the welding gun casing and is used for resetting the main shaft body after arc striking, a damper is fixedly arranged in the welding gun casing and is used for the main shaft body to stably reset, a self-adaptive structure is arranged between the main shaft body and a driving shaft and is used for the driving shaft to adjust the self position, the driving shaft is arranged at the tail end of the main shaft body in an electric insulation way, and a locking structure with an engagement and disengagement function is arranged between the driving shaft and the movable iron core. The arc type self-adaptive stud welding gun has the advantages that the main shaft body can be stably reset after arc striking, the smooth sliding of the main shaft body along the axial direction is guaranteed, and the set lifting clearance is not changed.

Owner:SUZHOU MENGZHIJIE WELDING TECH

Cleaning device for glass curtain wall

PendingCN108412219ANo splashingWill not polluteBuilding repairsWindow cleanersDrive shaftMagnetic valve

The invention discloses a cleaning device for a glass curtain wall. The cleaning device comprises a cleaning mechanism, a rack, an adsorption mechanism and a rotary mechanism, the rack is of a cube hollow structure, and universal wheels are fixedly arranged in the middles of the periphery of the outer wall of the rack; water inlet pipes are formed in two sides of the top of the rack, water outletpipes are arranged on two sides of the bottom of the rack, and adsorption mechanisms are fixedly arranged on four ends of two sides of the rack; each adsorption mechanism comprises a fixed seat, an air cylinder, a magnetic valve and a vacuum chuck, the cleaning mechanism is fixedly arranged in a cavity inside the rack, and the cleaning mechanism comprises a spraying head, duster cloth and a watercollecting groove; the top of the spraying head is communicated with the water inlet pipe, the bottom of the water collecting groove is communicated with the water outlet pipe, the bottom of the duster cloth is fixedly connected with a rotary mechanism, and the rotary mechanism comprises a motor, a transmission shaft and a turntable. The cleaning mechanism is simple in structure and high in stability of adsorption, the whole wiping process is performed in enclosure space, the phenomenon of sewage splashing does not occur, and the environment cannot be polluted.

Owner:南京康翱峰自动化科技有限公司

Downward-pouring combined double-mold assembly for vacuum induction furnace

The invention discloses a downward-pouring combined double-mold assembly for a vacuum induction furnace. The downward-pouring combined double-mold assembly comprises a combination mold I and a combination mold II, wherein when the combination mold I and the combination mold II are combined, two connection bases correspondingly arranged on outer sides of the combination mold I and the combination mold II are fixedly connected through bolts respectively, after the combination mold I and the combination mold II are combined, ingot mold holes in two sides and a middle column hole in the middle are formed, and the bottoms of the ingot mold holes are communicated with the middle column hole through a flow guide hole. The downward-pouring combined double-mold assembly has the advantages that the structure is simple, operation is convenient, the quality of steel ingots is good, the yield of the steel ingots is high, and the economic efficiency is good.

Owner:JIANGSU XIHU SPECIAL STEEL

Discharging device for zinc oxide particle production

InactiveCN108002011AUniform feedingSmooth feedingConveyorsControl devices for conveyorsEngineeringSingle chip

The invention discloses a discharging device for zinc oxide particle production. The discharging device comprises an outer shell and a rotating roller; an inner shell is arranged on the inner side ofthe outer shell through a lower bearing and an upper bearing; a spiral plate is fixed inside the inner shell; the interior of the spiral plate is fixedly connected to the rotating roller; a feed portis formed in the upper end of the outer shell; an alarm lamp arranged at the upper end of the outer shell is arranged on one side of the feed port; a mounting plate is arranged right above the outer shell; a motor is fixed to the right lower end of the mounting plate; and the output end of the motor is in meshing connection with the upper end of the rotating roller. The discharging device has theadvantages that the outer shell, the inner shell, the alarm lamp, a single-chip microcomputer, a display screen, the motor, the rotating roller, the spiral plate, a first discharge port, a second discharge port and a gravity sensor are arranged, and therefore the problems that the discharging speed of an existing discharging device is not uniform and stable enough, an intelligent detection mechanism is lacked, and the amount of zinc oxide particles in the discharging device cannot be checked and known in time can be solved.

Owner:XINGHUA SANYUAN ZINC

Method for preventing molten steel of high nitrogen steel from spraying

InactiveCN103225010ANo splashingHigh nitrogen contentProcess efficiency improvementAlloyMolten steel

The invention relates to a method for preventing molten steel of high nitrogen steel from spraying, and comprises the following steps in order: I pouring molten steel smelted in a converter into a vacuum refining furnace, pumping vacuum, blowing argon at the bottom, and the stirring intensity is that the molten steel in per ton of steel is more than 2L / min; the requirements of the mass percents of C, Si, Mn, P, S, Cr and N in molten steel are as follows: C: 0.25-0.40%; Si: 0.02-0.2%; Mn: 0.06-2.0%; P<=0.018%; S<=0.02%; Cr: 16-22%; N: 0.12-0.8%; II setting vacuum degree 150 mbar-200 mbar, vacuum-pumping time>5 minutes; III setting oxygen lance position>1700 mm, flow <1200 m<3> / h; IV after oxygen blowing, setting vacuum degree valve<2 mbar for more than 10 minutes; V adding lime, fluorite and alloy; VI breaking vacuum and closing bottom argon blowing. The method for preventing molten steel of high nitrogen steel from spraying can prevent molten steel from spraying.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Water absorption trestle road in garden

ActiveCN109610269AEffective water absorptionNo splashingPaving gutters/kerbsSidewalk pavingsSoft layerEngineering

The invention discloses a water absorption trestle road in a garden. A pre-buried trough is formed in a trestle road surface; a water collection box is embedded into the pre-buried trough; a water collection cavity with an upper opening is formed inside the water collection box; a sealing net is mounted at an upper opening end of the water collection cavity; more than one first through holes are formed in the sealing net; an arc-shaped assembling cavity is formed in the upper end of the sealing net; the sealing net is covered by a water absorption soft layer; a corresponding arc-shaped convexpart is arranged right against the arc-shaped assembling cavity at the bottom of the water absorption soft layer; the arc-shaped convex part is embedded into the arc-shaped assembling cavity. By adopting the water absorption trestle road disclosed by the invention, rainwater can be effectively absorbed in rainy days, the rainwater can be also discharged because of gravities of walking people, thesituation of water splashing can be avoided, and people can walk on the trestle road comfortably.

Owner:长沙市望城区竞秀园林绿化有限公司

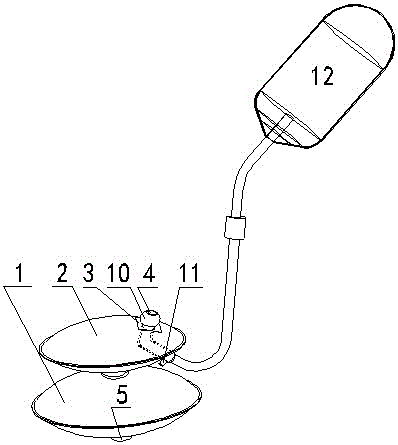

Enema Kit Device

ActiveCN104083811BEffective controlEfficient collectionEnemata/irrigatorsBodily discharge devicesStomaHuman body

The invention relates to an enema member device and an enema method. A fecal storing bag is communicated with a buffer bag, an infusion tube guiding hole is formed in the back of the buffer bag, and a fistulation hole is formed in the front of the buffer bag; one end of an infusion tube penetrates through the infusion tube guiding hole in the back of the buffer bag to extend out from the fistulation hole, and an air sac sleeve is arranged on the outer wall of the infusion tube extending out of the fistulation hole; a double-side adhesion ring is sleeved with the heel of the air sac sleeve, one side of the double-side adhesion ring is stuck to the fistulation hole in the buffer bag or skin all around an anus, and the other end of the infusion tube is a liquid inlet. The enema member device has the advantages that firstly, the fistulation hole in the buffer bag is in seal combination with the stoma of the skin of a human body or the anus, so that excrement and urine in returned liquid with pressure after enema can be effectively controlled and collected, and the phenomena that the excrement and urine and soiling solutions thereof are leaked and are splashed from the side surface are avoided; secondly, the device has a simple structure, low cost and lighter weight; thirdly, the device is convenient to carry for a patient; fourthly, the device has the function of enema, and has the functions of receiving and storing enema excrement and the effect of drug treatment.

Owner:杭州倍麦科技有限公司

Wafer cleaning liquid recovery equipment

InactiveCN110931394AAutomatically adjust the positionNo splashingSemiconductor/solid-state device manufacturingElectric machineryStructural engineering

Owner:王挺

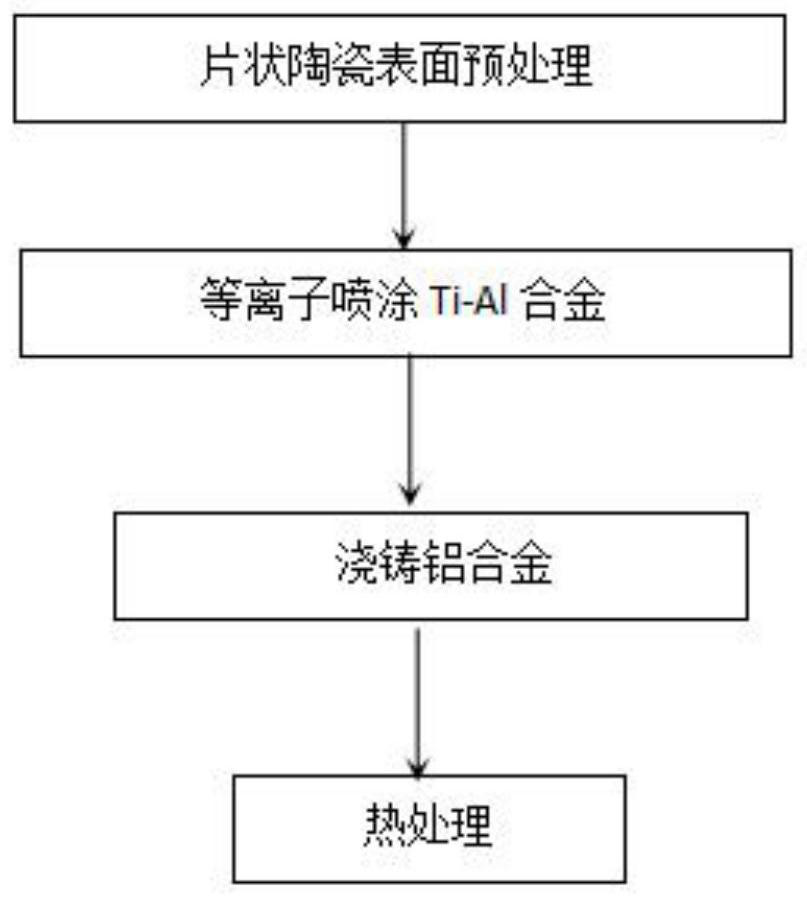

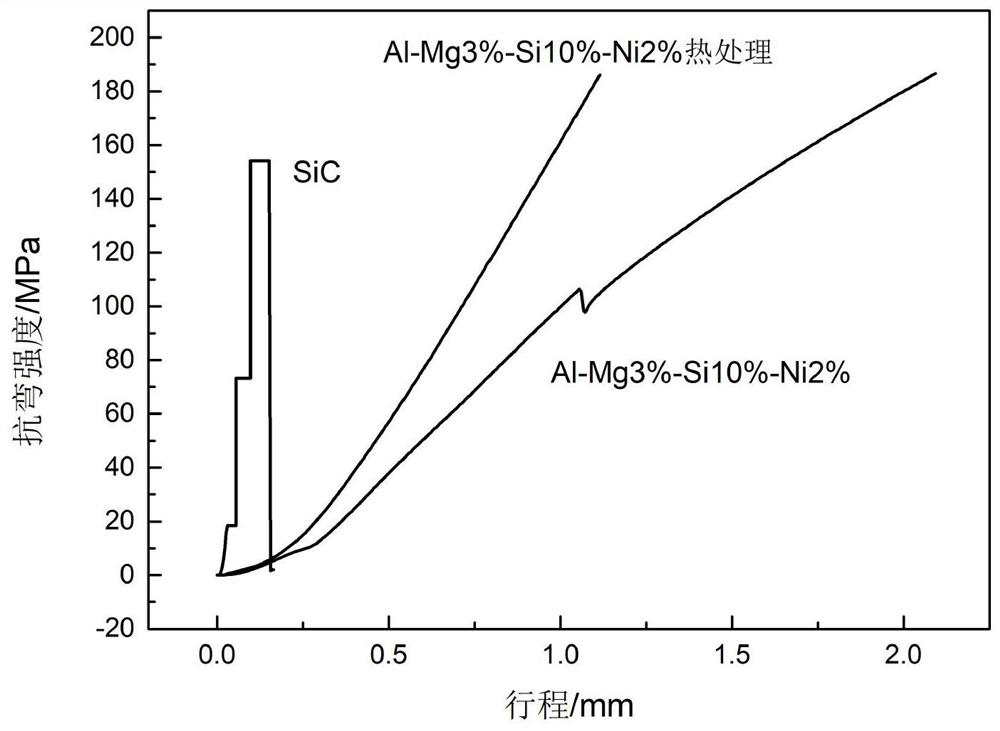

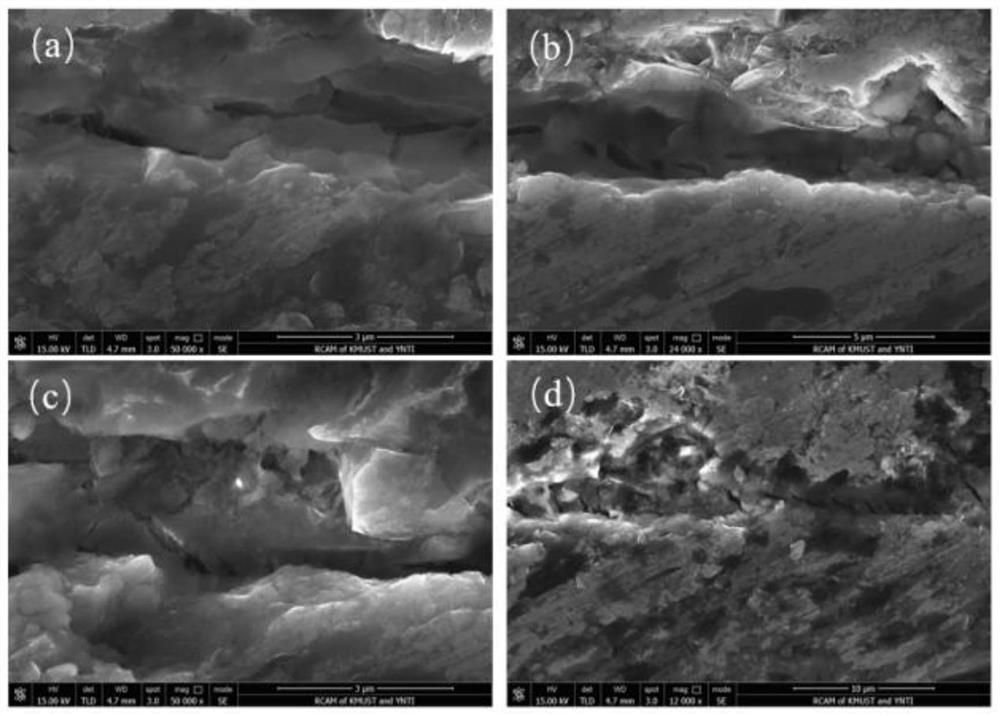

Flaky ceramic/aluminum alloy composite material and preparation method thereof

PendingCN113046677ATightly boundImprove binding propertiesMolten spray coatingFurnace typesCeramicAlloy composite

The invention discloses a flaky ceramic / aluminum alloy composite material and a preparation method thereof, and belongs to the technical field of ceramic-metal connection. The composite material comprises flaky ceramic and an aluminum alloy layer, wherein the flaky ceramic is coated in the aluminum alloy layer; and a Ti-Al alloy transition layer is further arranged between the flaky ceramic and the aluminum alloy layer. The preparation method comprises the steps of plasma-spraying Ti-Al alloy on the surface of the flaky ceramic to form the transition layer, then casting an aluminum alloy, and carrying out heat treatment to obtain the composite material. According to the flaky ceramic / aluminum alloy composite material and the preparation method thereof provided by the invention, the Ti-Al alloy is used as the transition layer for connecting a ceramic chip and the metal aluminum, so that the bending strength and the deformation resistance of the composite material are obviously improved; and meanwhile, the flaky ceramic is packaged in the alloy, the ceramic is tightly fixed in situ due to the existence of the packaging metal, and the broken ceramic cannot be splashed in the using process, so that the ceramic is effectively packaged.

Owner:KUNMING UNIV OF SCI & TECH

In-shower knife for coating a surface of a display glass

ActiveCN111434388AAvoid quality defectsNo splashingLiquid surface applicatorsLiquid spraying apparatusForeign matterDisplay device

The present invention relates to an in-shower knife for coating a surface of a display glass which can prevent a coating liquid from being cracked and discharged due to foreign matters trapped in a pipeline, thereby minimizing quality defects of a display caused by uneven application of the coating liquid to the glass. Even if partial clogging occurs in a secondary pipe due to the foreign matters,the coating liquid passing through a tertiary pipe is temporarily collected in a buffer part and is discharged without being cracked through a discharge port. Accordingly, the coating liquid is evenly and uniformly applied to the surface of the glass, thereby minimizing the occurrence of display quality defects.

Owner:李荣植 +1

Vegetable and fruit knife

PendingCN107511857AReduce resistanceFast cutting speedMetal working apparatusBiochemical engineeringFeeding tube

The invention discloses a vegetable and fruit knife. The vegetable and fruit knife comprises a feeding tube, a knife rest, a cutter and a pressing head, wherein the knife rest is arranged at the upper end of the feeding tube; the cutter is arranged inside the knife rest; the vegetable and fruit knife further comprises a protection tube arranged at the upper end of the knife rest; the cutter comprises a first blade and at least two second blades; one end of the first blade is fixed in the knife rest; the other end of the first blade is located on the axis of the knife rest; the first blade is inclined; the other end of the first blade is away from the pressing head; one end of each second blade is fixed in the knife rest; the other end of each second blade is fixedly connected with the other end of the first blade; and the first blade and the second blades are evenly distributed in the circumferential direction. The vegetable and fruit knife is good in cutting effect and convenient to use.

Owner:NINGBO ZHONGHAI ELECTRICAL APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Converter steelmaking method for molten iron [Si] (0.50%) Converter steelmaking method for molten iron [Si] (0.50%)](https://images-eureka.patsnap.com/patent_img/b91bb63e-6f3d-4dcb-be2c-2c0d3c4466dc/BDA0001701172290000041.png)

![Converter steelmaking method for molten iron [Si] (0.50%) Converter steelmaking method for molten iron [Si] (0.50%)](https://images-eureka.patsnap.com/patent_img/b91bb63e-6f3d-4dcb-be2c-2c0d3c4466dc/BDA0001701172290000042.png)

![Converter steelmaking method for molten iron [Si] (0.50%) Converter steelmaking method for molten iron [Si] (0.50%)](https://images-eureka.patsnap.com/patent_img/b91bb63e-6f3d-4dcb-be2c-2c0d3c4466dc/BDA0001701172290000051.png)