In-shower knife for coating a surface of a display glass

A surface coating and display technology, which is applied in the field of spraying knife, can solve the problems of inability to coat the coating liquid uniformly, splashing of coating liquid, clogging, etc., and achieve the goals of reducing quality defects, uniform coating, and preventing movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

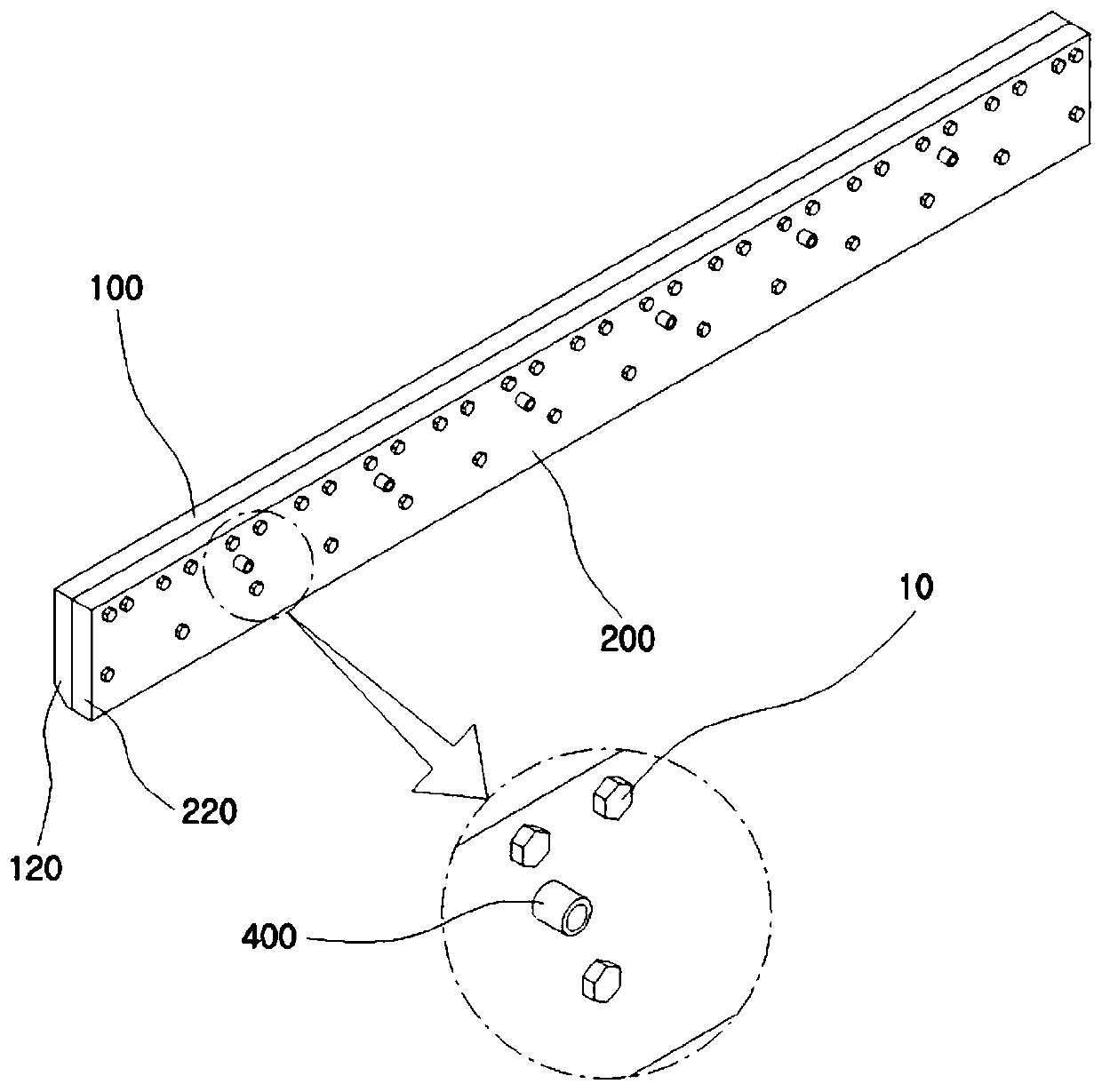

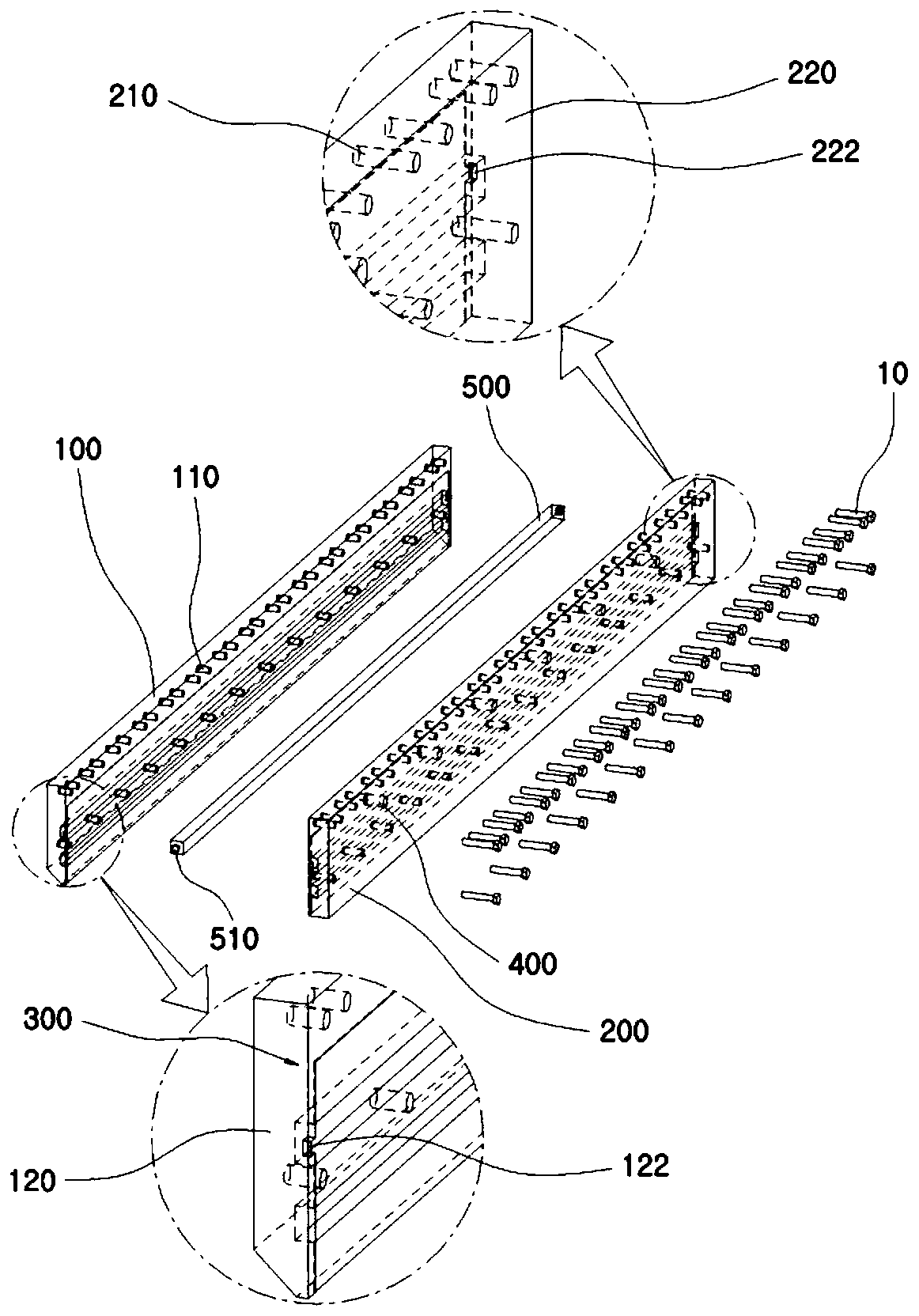

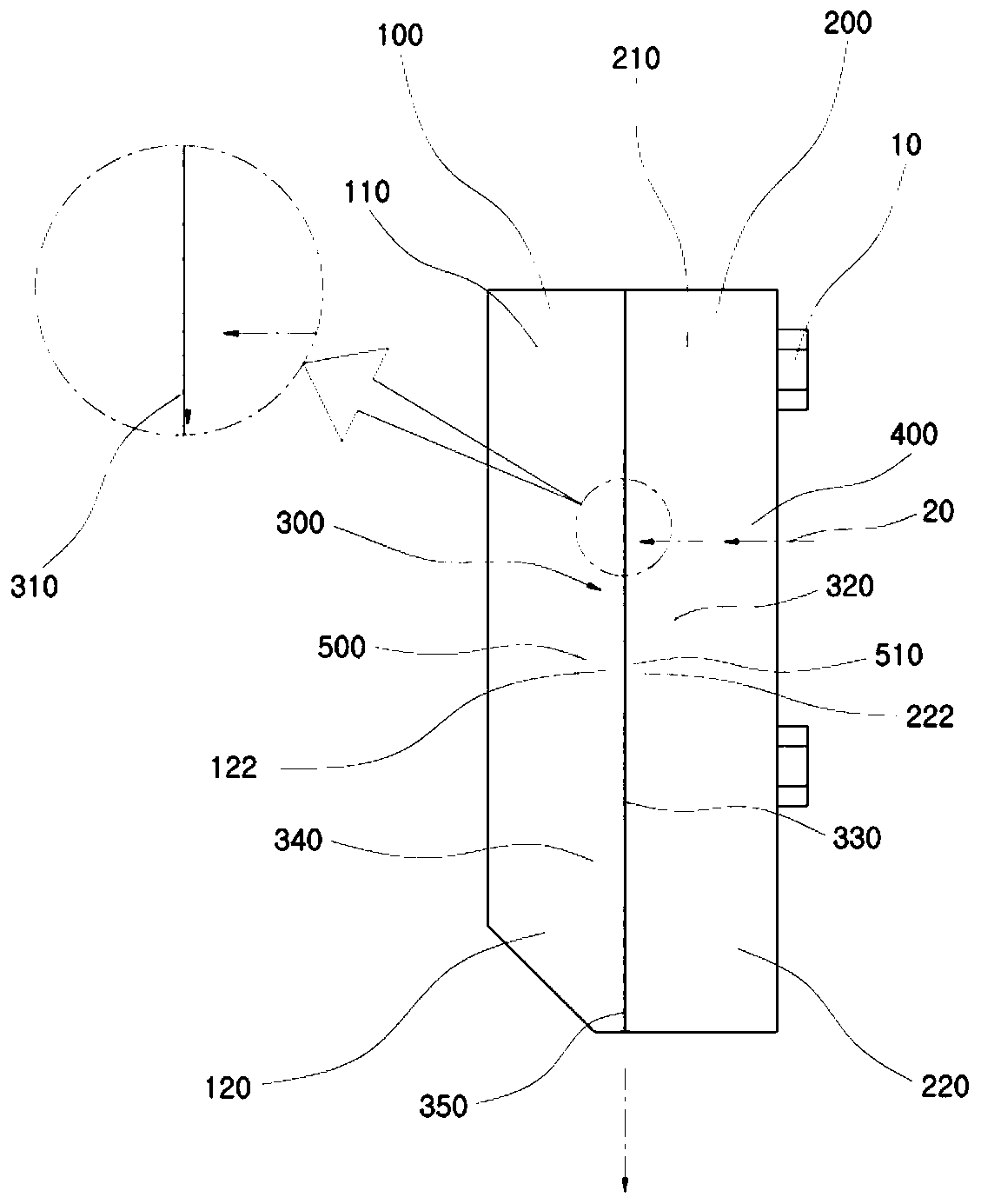

[0038] figure 1 is a perspective view of a spray knife for coating on the surface of a display screen according to an embodiment of the present invention, figure 2 is an isosceles triangle perspective view of a spray knife for coating on a display screen surface according to the present invention, image 3 is a front view of a spray knife for coating on the surface of a display screen according to an embodiment of the present invention. exist figure 2 and image 3 The illustration of the outwardly protruding portion of the injection port 400 is omitted in FIG.

[0039] The first connecting plate 100 is fixed on the object to be fixed, and is formed in a long and thin rectangular shape. The object to be fixed here refers to the bracket or fixture set in the manufacturing process. The first connection plate 100 needs to be provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com