Arc type self-adaptive stud welding gun

An adaptive, stud welding technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problem that the moving iron core is stuck in the fixed sleeve, increase the main shaft body and linear bearing, and the moving iron core and the fixed sleeve. The problems of wear amount and low welding efficiency can achieve the effect of basically the same height of the welding feet, flexible and reliable axial sliding, and high welding qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

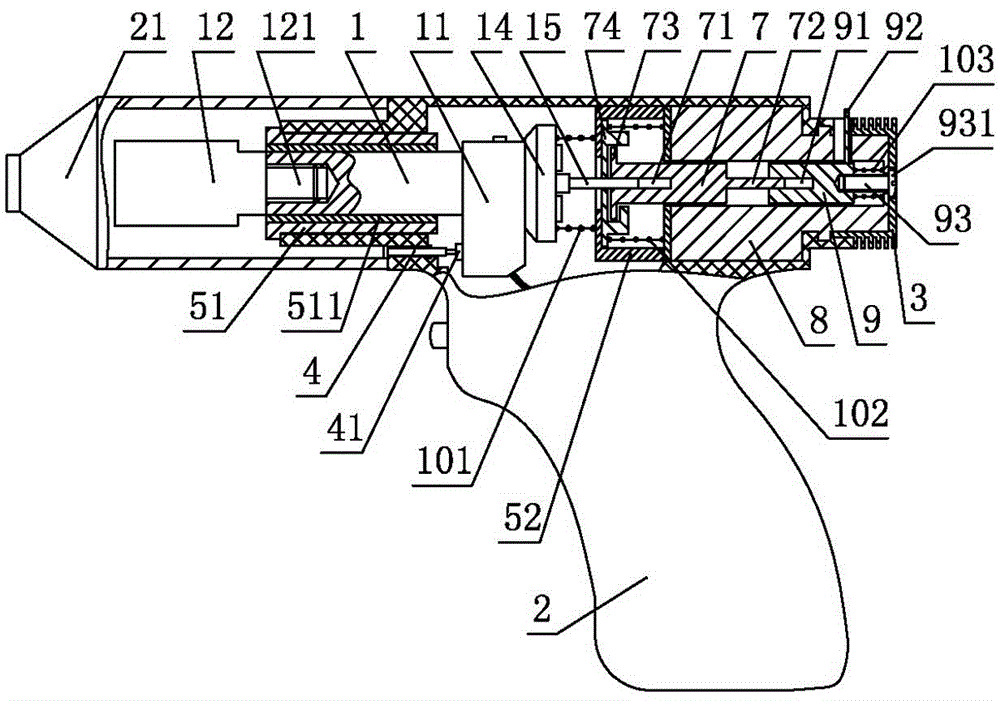

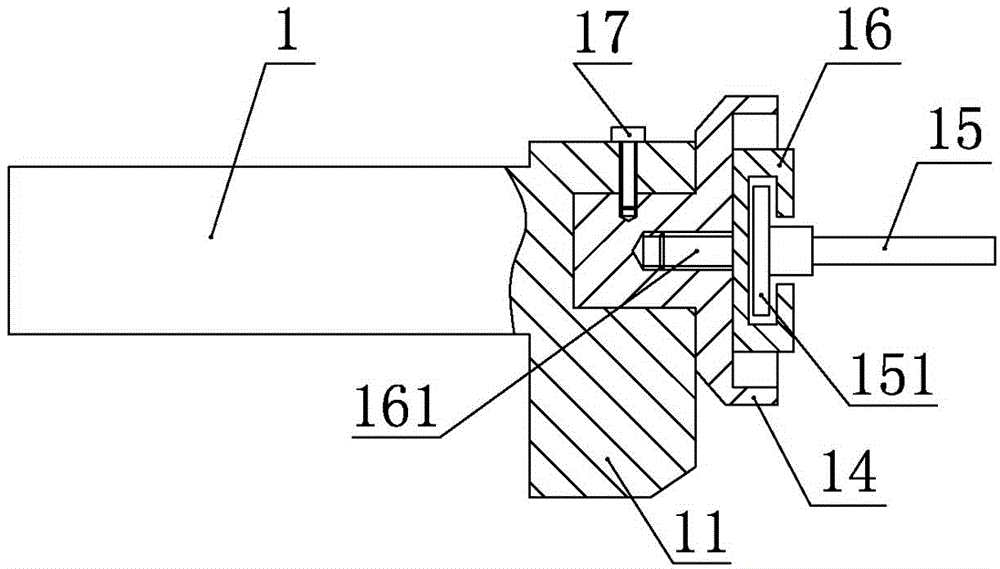

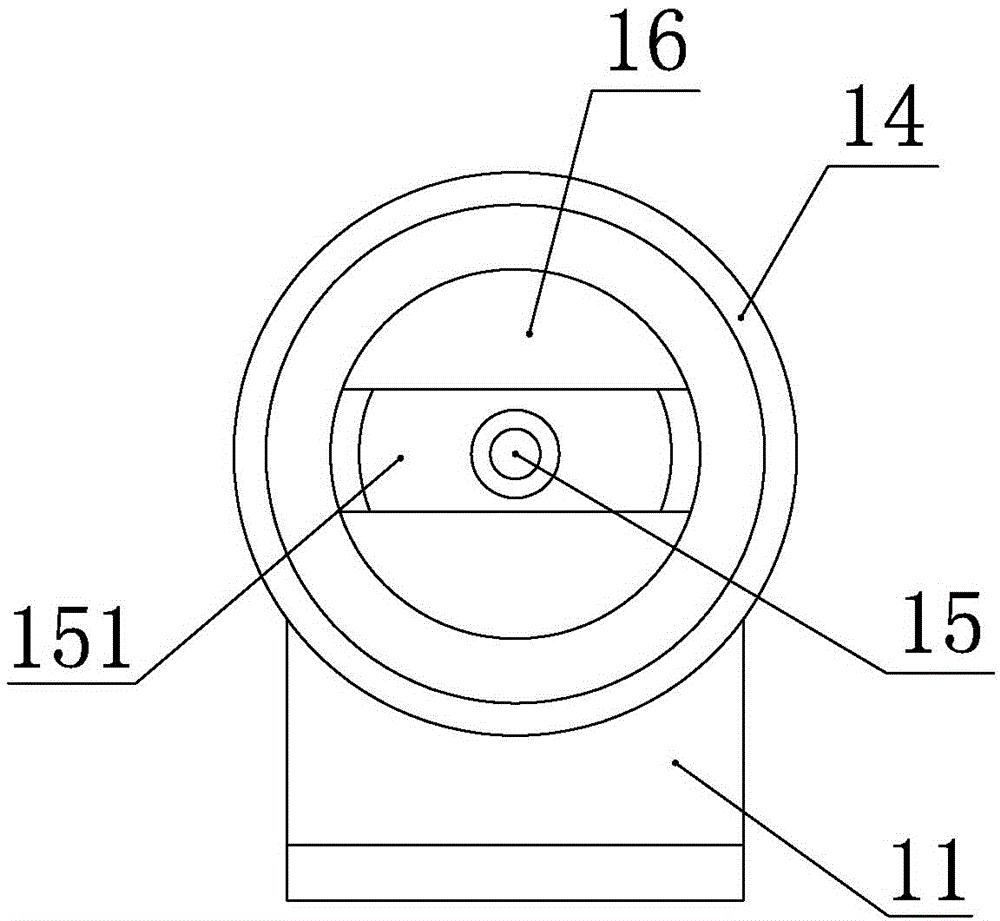

[0027] Such as figure 1As shown, the drawn-arc self-adaptive stud welding torch of the present invention includes: a welding torch housing 2 with a cavity, in which a main shaft body 1 and a moving iron are arranged in sequence from front to end in the cavity Core 7, a fixed sleeve 8 and a static iron core 9 with a coil inside, and a control circuit device that provides operating current to the main shaft body 1 and the coil is also provided in the welding torch housing 2; it is fixed in the cavity of the welding torch housing 2 A shaft sleeve 51 is provided, and the main shaft body 1 is penetrated in the shaft sleeve 51 and can slide axially in the shaft sleeve 51. The grinding bush 511, the wear-resistant bush 511 and the main shaft body 1 are electrically insulated from each other, the main shaft body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com