Flaky ceramic/aluminum alloy composite material and preparation method thereof

A composite material and aluminum alloy technology, which is applied in the field of sheet ceramic/aluminum alloy composite material and its preparation, can solve the problems of poor interface bonding performance and complicated process, and achieves improved bending strength and deformation resistance, and simple preparation process. , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

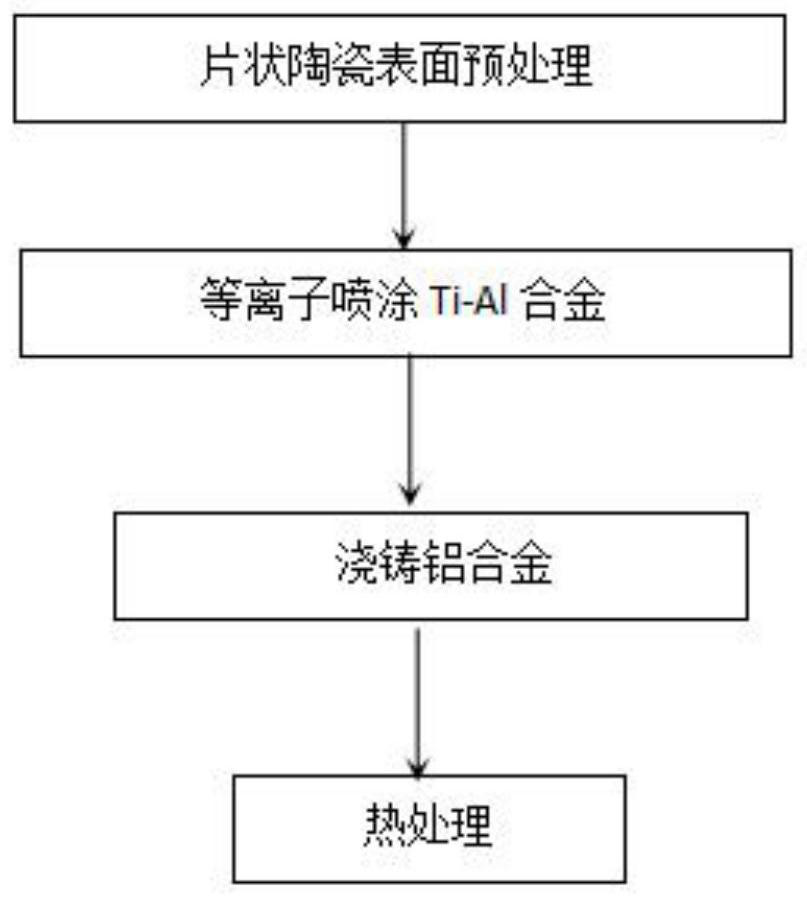

[0036] The preparation of sheet ceramic / aluminum alloy composite material comprises the following steps:

[0037] (1) Choose a SiC ceramic sheet with a pressureless sintering purity greater than 99%, use acetone solution for ultrasonic cleaning to remove the oily surface of the ceramic, and then use hydrofluoric acid to clean it, and then use 10-20 mesh white corundum to clean the ceramic sheet at 0.8MPa The surface is sandblasted to roughen the surface of the ceramic sheet, and then the corundum grit is removed;

[0038] (2) Plasma spraying Ti-Al alloy on the ceramic sheet after the surface roughening in step (1): use plasma spraying equipment to spray Ti-Al alloy on the surface of the ceramic sheet to form a thin film with a film thickness of 50 μm; the spraying parameters are: current 620A, voltage 60V, spray distance 10cm, powder feeding voltage 5V, powder feeding carrier gas 200L / h, gun speed 100mm / s;

[0039] In the Ti-Al alloy, the Al content is 25wt%;

[0040](3) Use...

Embodiment 2

[0049] The preparation of sheet ceramic / aluminum alloy composite material, the steps are as follows:

[0050] (1) Choose a SiC ceramic sheet with a pressureless sintering purity greater than 99%, use acetone solution for ultrasonic cleaning to remove the oily surface of the ceramic, and then use hydrofluoric acid to clean it, and then use 10-20 mesh white corundum to clean the ceramic sheet at 0.8MPa The surface is sandblasted to roughen the surface of the ceramic sheet, and then the corundum grit is removed;

[0051] (2) Plasma spray Ti-Al alloy on the ceramic sheet after the surface roughening in step (1): use plasma spraying equipment to spray Ti-Al alloy on the surface of the ceramic sheet to form a thin film with a film thickness of 30 μm; the spraying parameters are: current 600A, voltage 65V, spraying distance 8cm, powder feeding voltage 6V, powder feeding carrier gas 180L / h, gun speed 90mm / s;

[0052] In the Ti-Al alloy, the Al content is 20wt%;

[0053] (3) Use a mo...

Embodiment 3

[0064] The preparation of sheet ceramic / aluminum alloy composite material comprises the following steps:

[0065] (1) Select B with pressureless sintering purity greater than 99% 4 C ceramic sheet, use acetone solution for ultrasonic cleaning to remove the oiliness of the ceramic surface, then use hydrofluoric acid to clean, and then use 10-20 mesh white corundum to sandblast the surface of the ceramic sheet at 0.8MPa to roughen the surface of the ceramic sheet , after removing the corundum grit;

[0066] (2) Plasma spray Ti-Al alloy on the ceramic sheet after the surface roughening in step (1): use plasma spraying equipment to spray Ti-Al alloy on the surface of the ceramic sheet to form a thin film with a film thickness of 100 μm; the spraying parameters are: current 650A, voltage 55V, spraying distance 12cm, powder feeding voltage 3V, powder feeding carrier gas 220L / h, gun speed 110mm / s;

[0067] In the Ti-Al alloy, the Al content is 30wt%;

[0068] (3) Use the mold to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com