Patents

Literature

83results about How to "Strong reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Music intelligence universe server

ActiveUS20080021851A1Fast yet highly individualized music discoveryStrong reactionInput/output for user-computer interactionElectrophonic musical instrumentsSpeech recognitionRecommender system

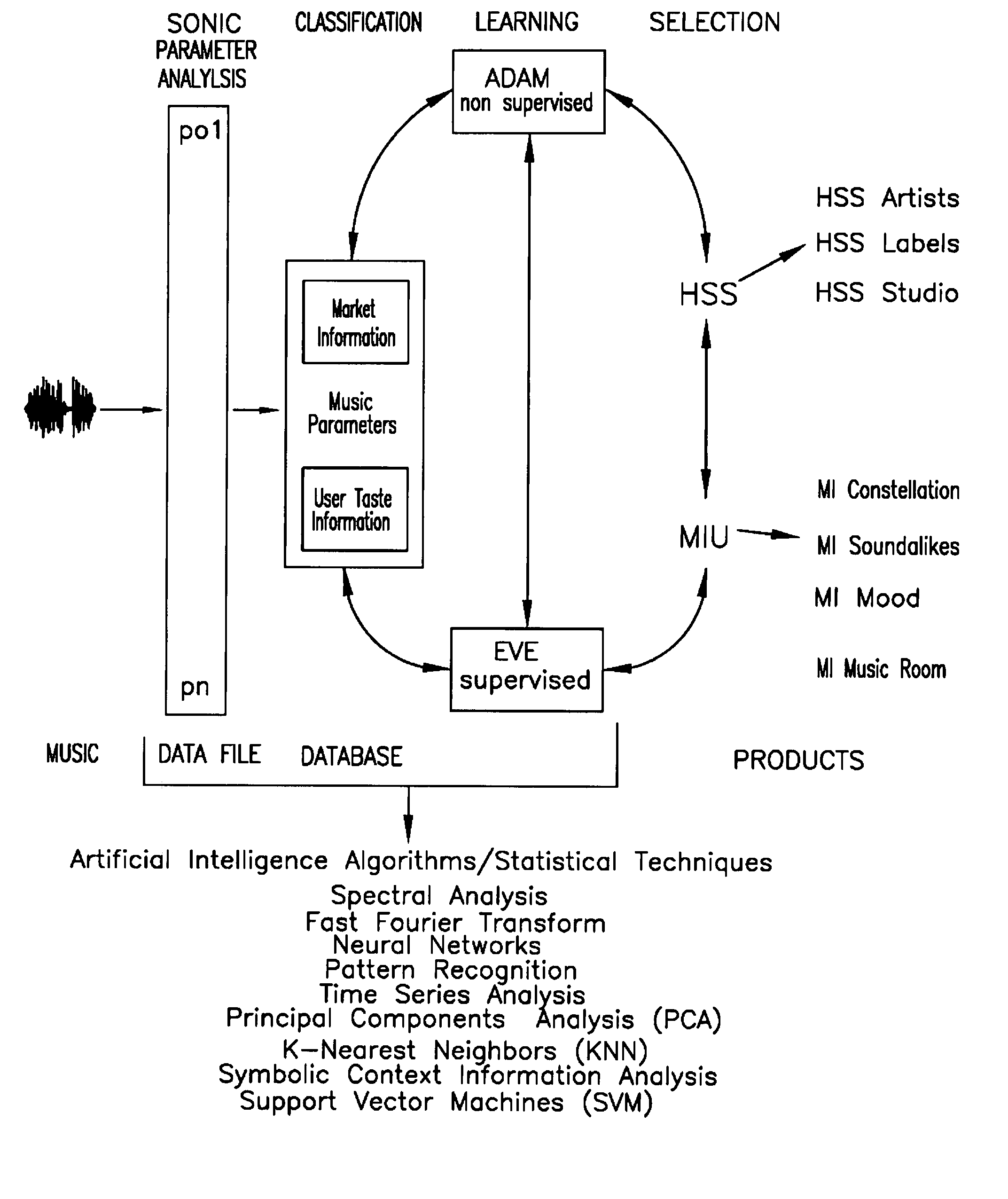

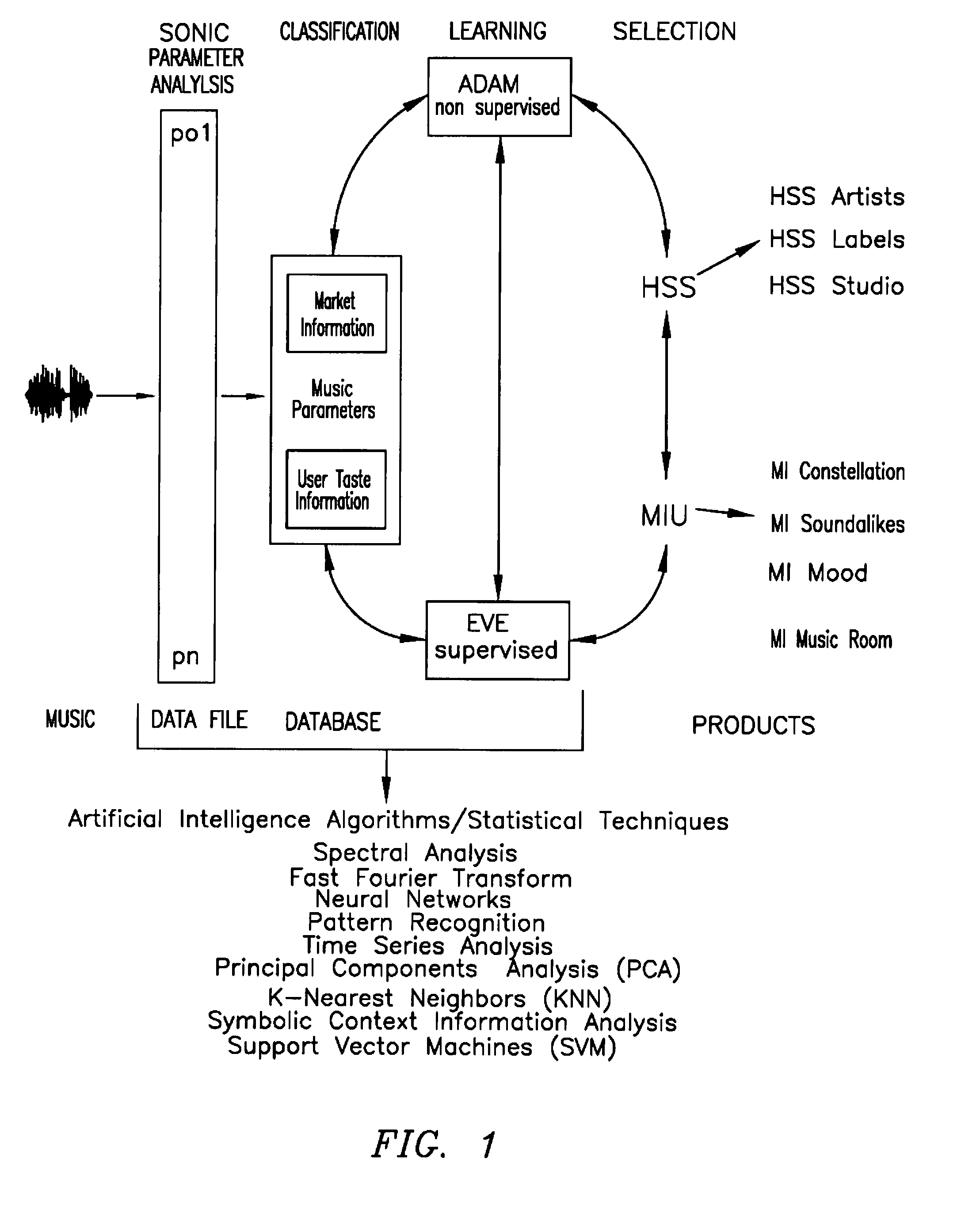

An artificial intelligence song / music recommendation system and method is provided that allows music shoppers to discover new music. The system and method accomplish these tasks by analyzing a database of music in order to identify key similarities between different pieces of music, and then recommends pieces of music to a user depending upon their music preferences.

Owner:MUSIC INTELLIGENCE SOLUTIONS INC

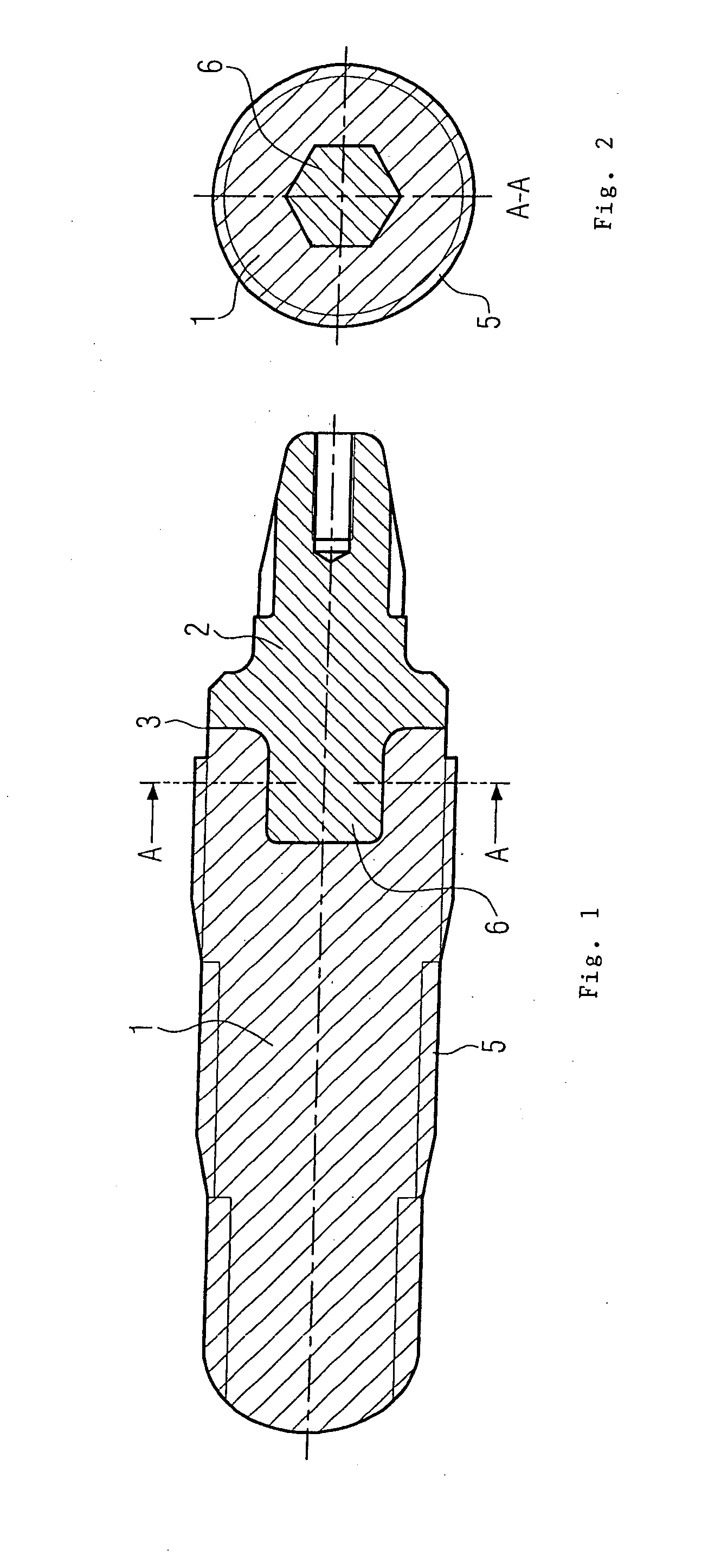

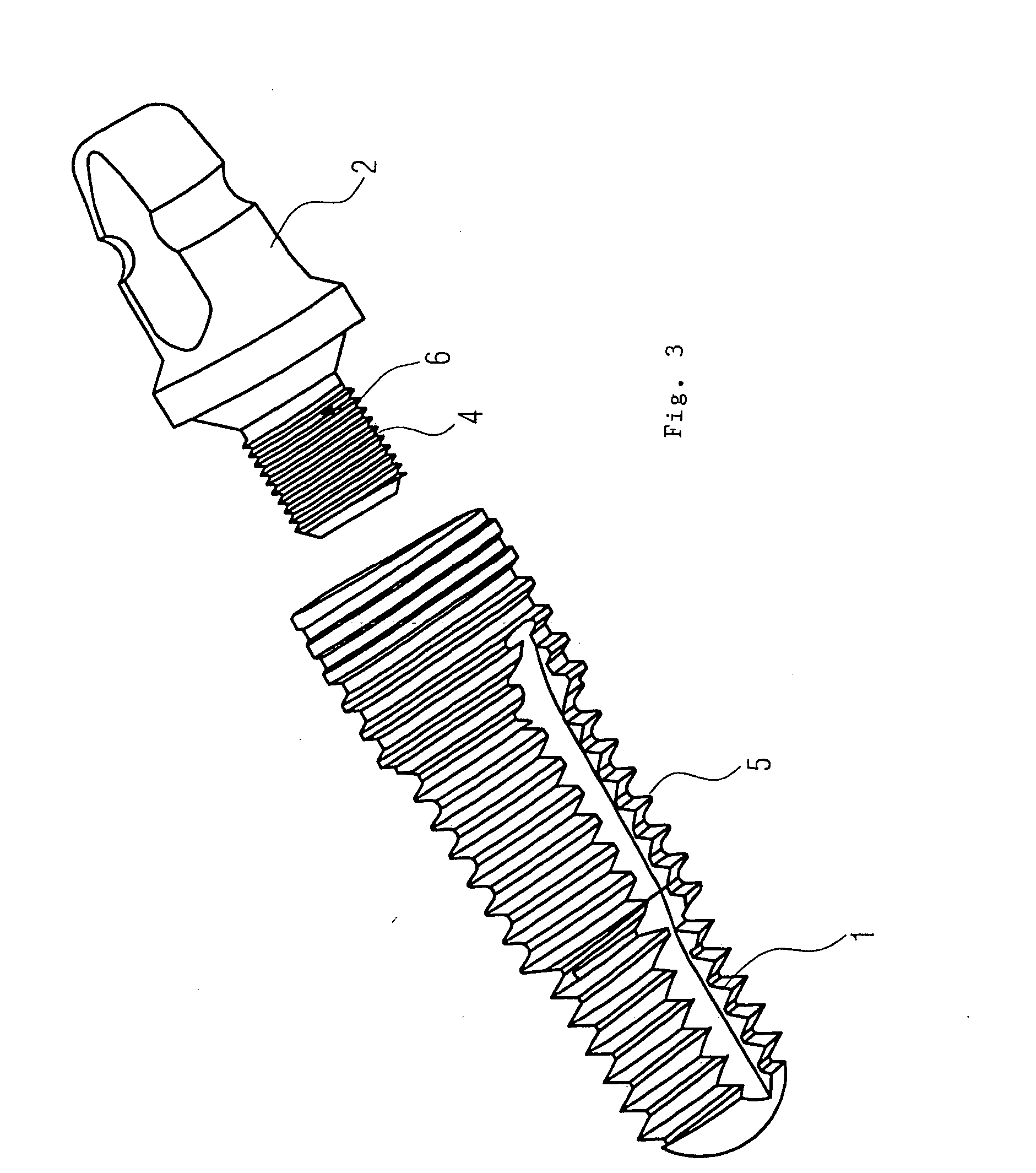

Dental implant

InactiveUS20080160483A1Avoids drawbackSimple structureDental implantsMetallic materialsDental implant

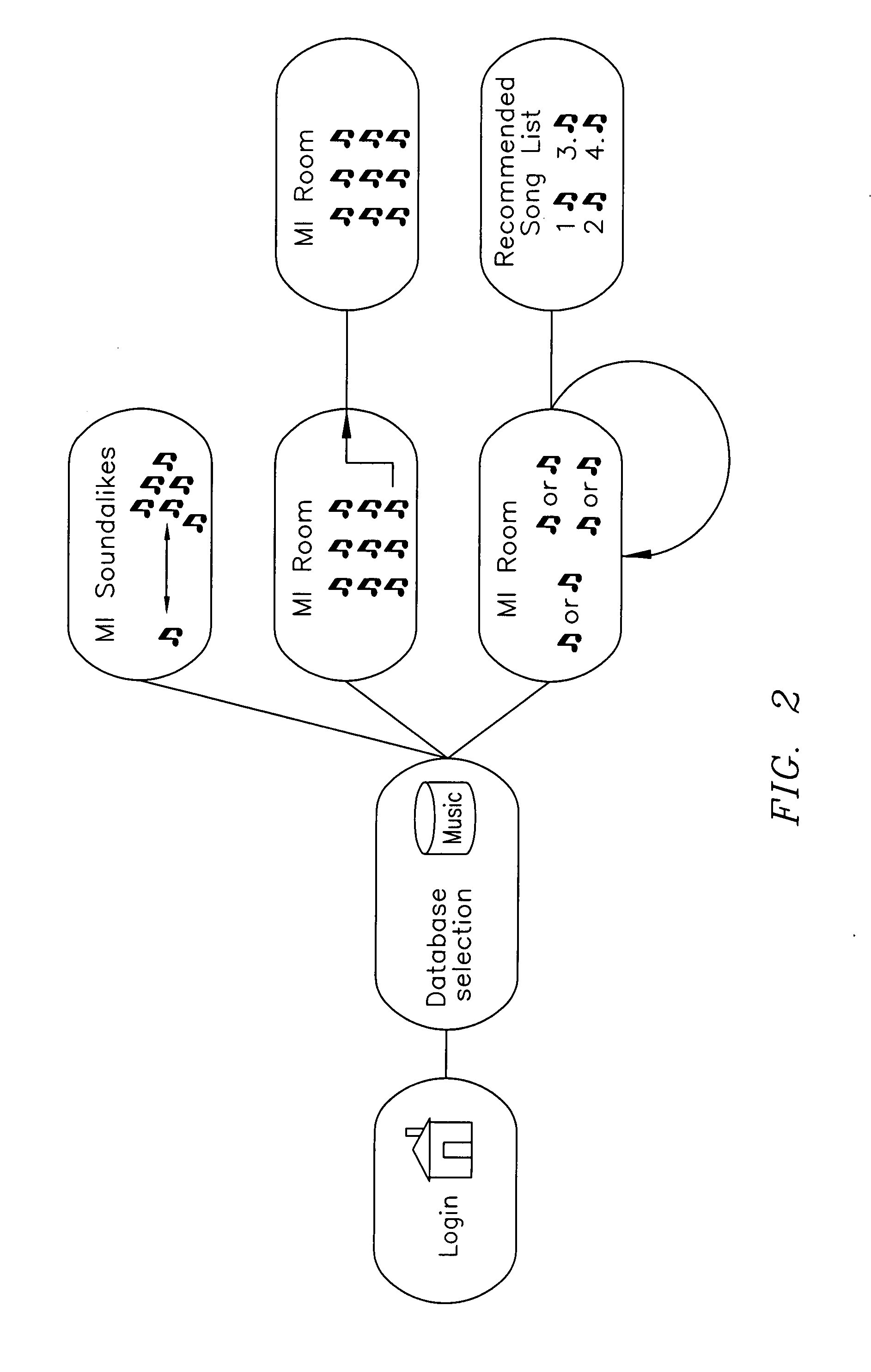

A one-part dental implant has an enossal portion made of a metallic material and a coronal portion made of a ceramic material. The enossal portion is integrally connected to the coronal portion, wherein a connection portion between the coronal portion and the enossal portion is formed gap-free. The coronal portion and the enossal portion is in a form-fit engagement and a connection between the coronal portion and the enossal portion is formed as a force-fit joining connection.

Owner:GEBR BRASSELER

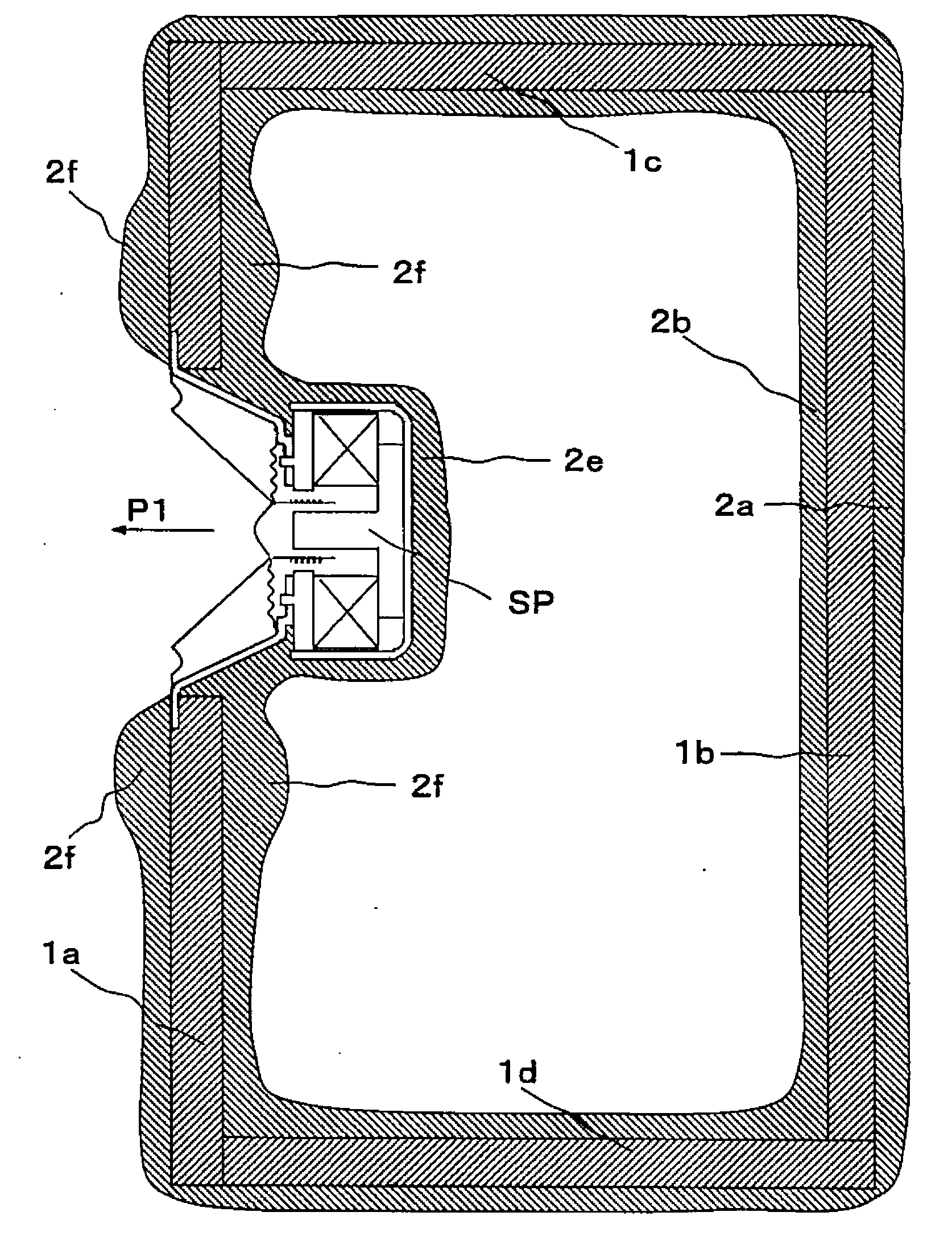

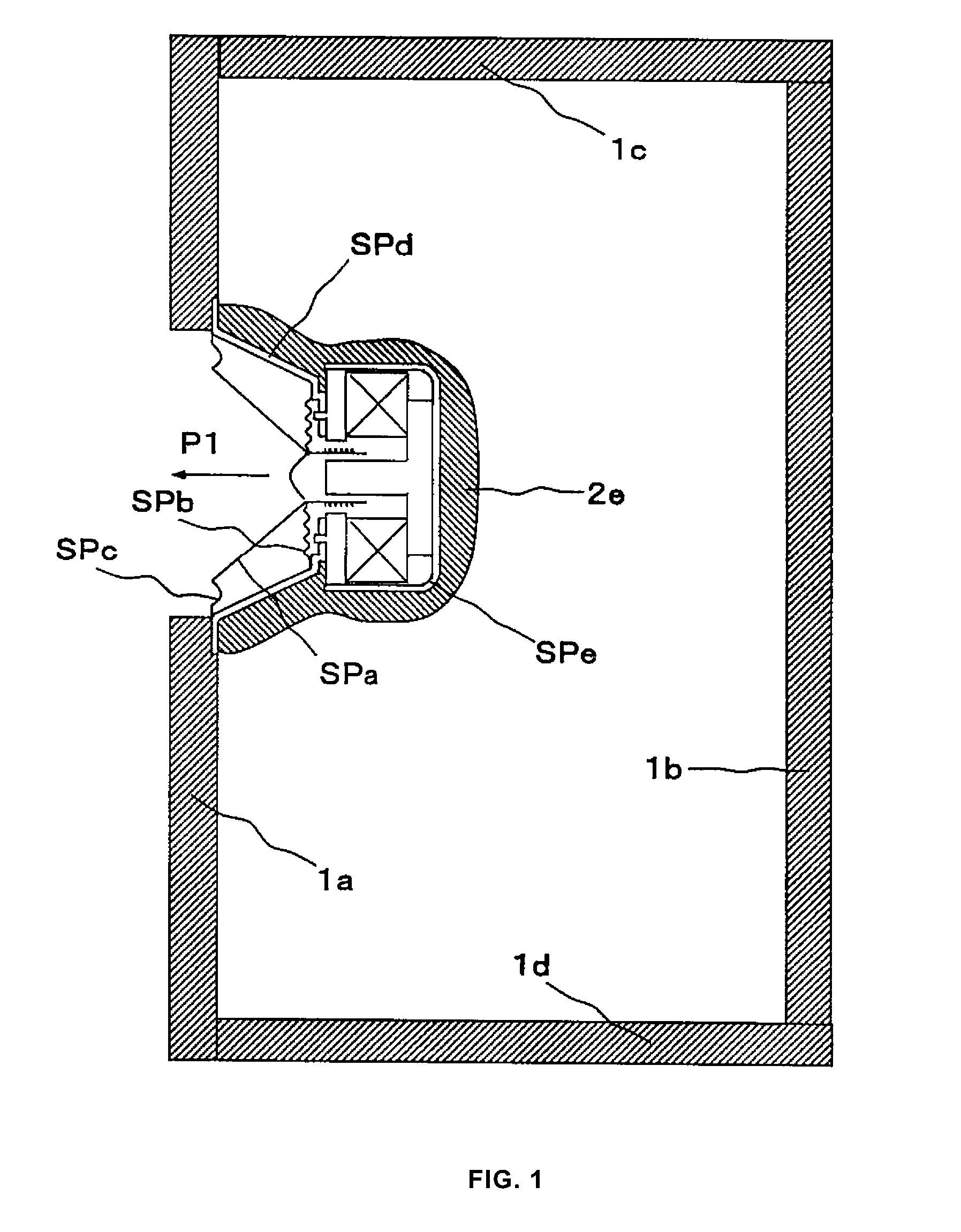

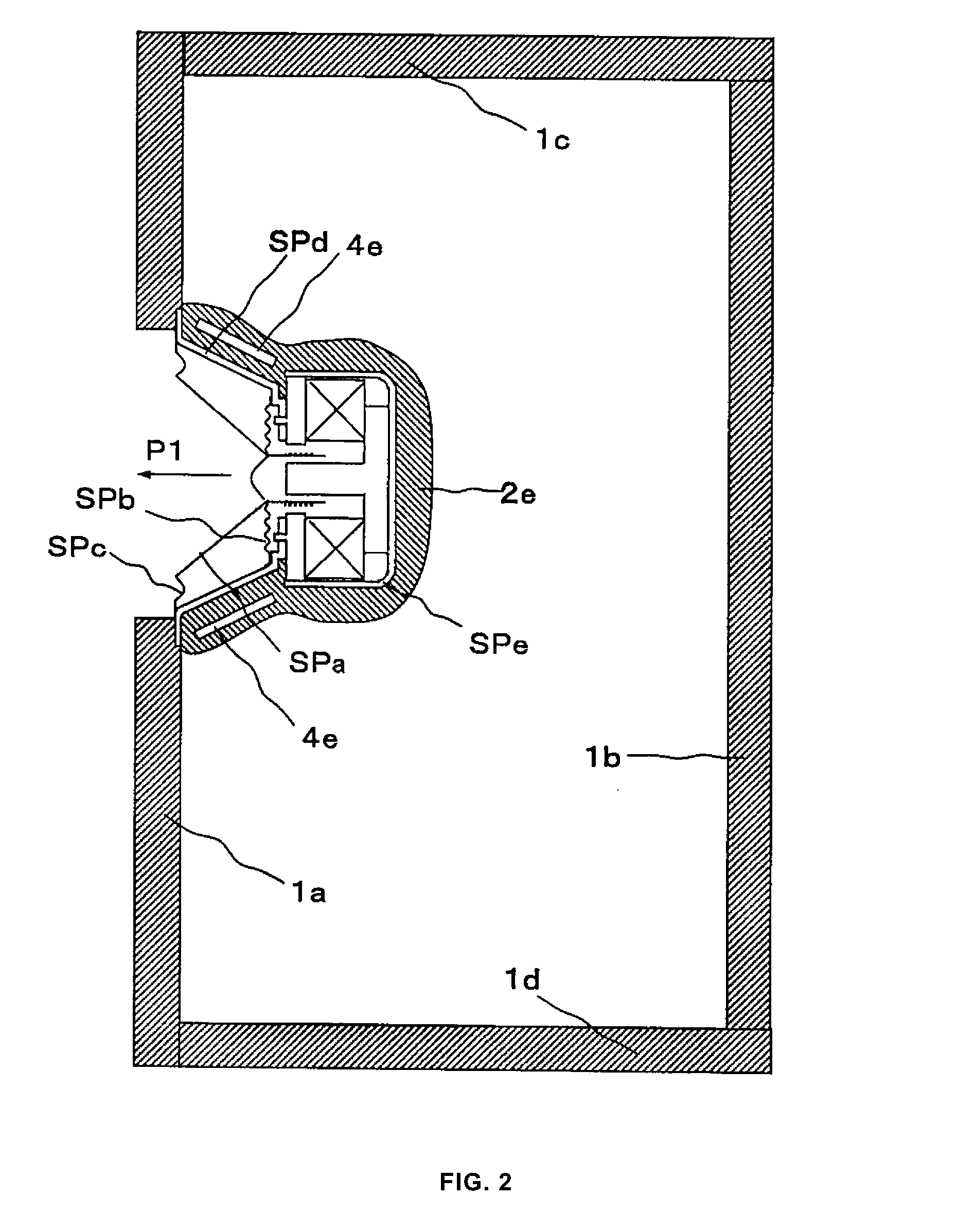

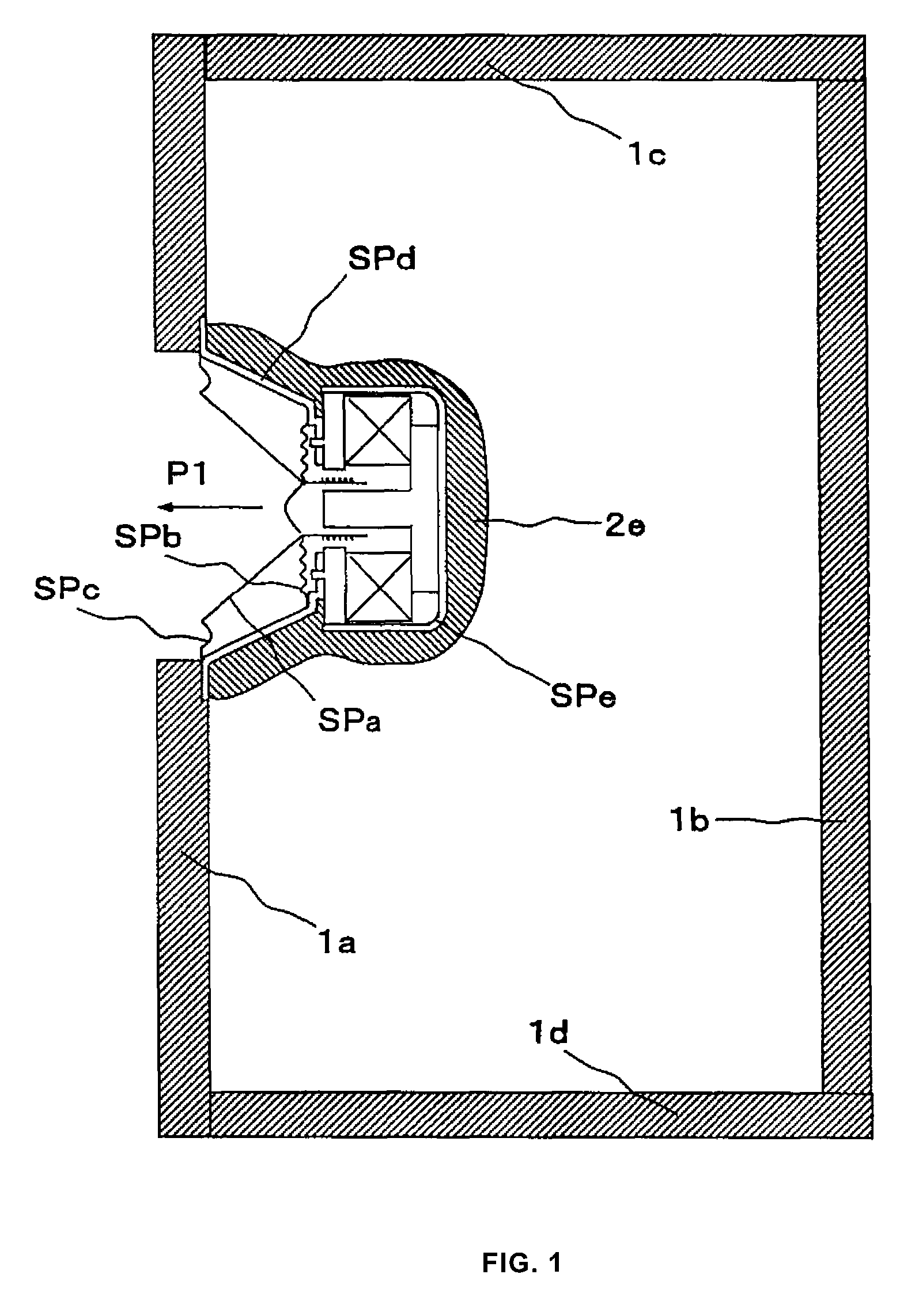

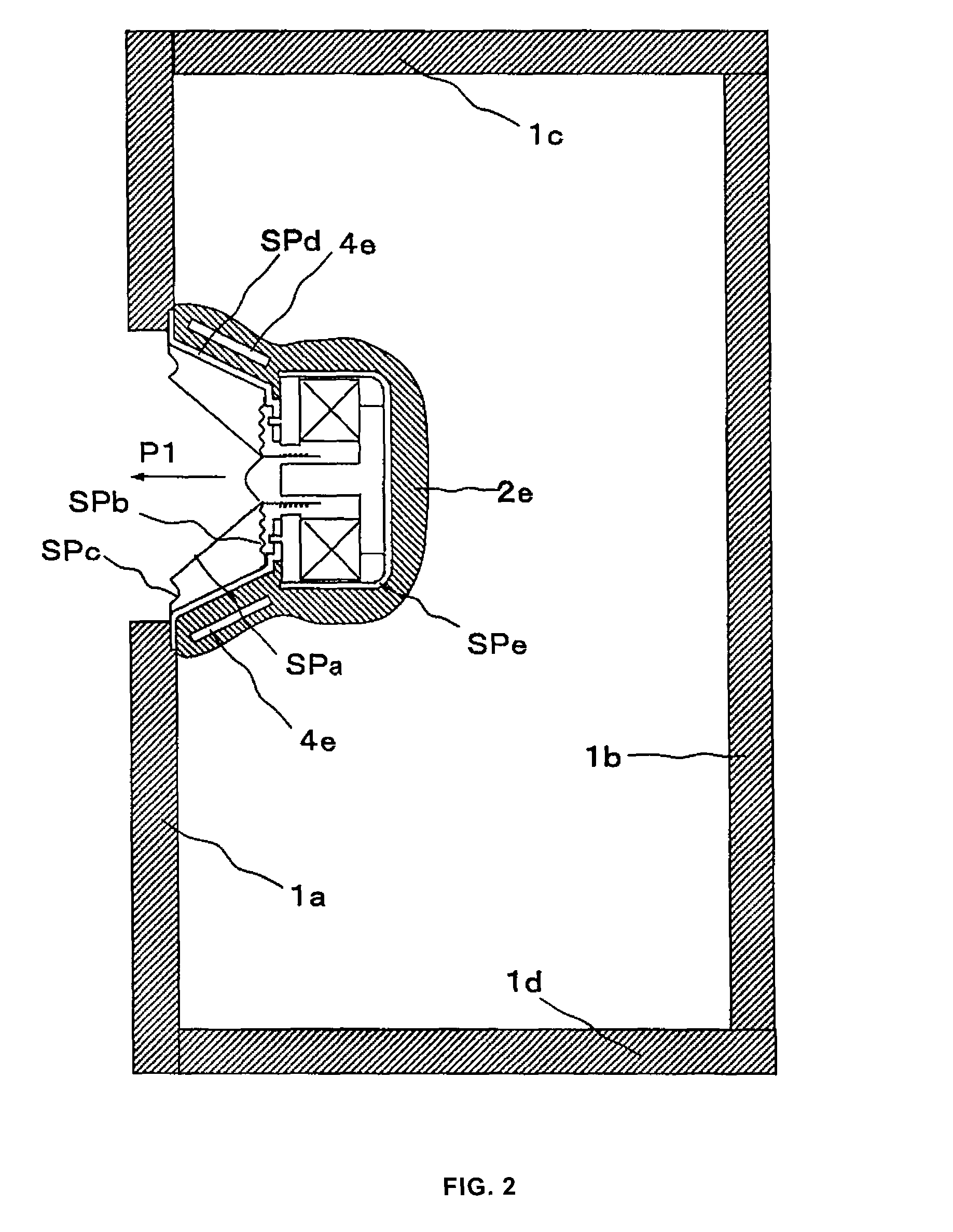

Speaker device

ActiveUS20140348349A1Reduce decreaseGood effectAdhesivesTransducer casings/cabinets/supportsEngineeringAcoustic wave

The object of the present invention is that the surplus vibration involved therewith simultaneously generating a sound wave by the vibration of the vibrating cone of the loudspeaker unit is generated in the loudspeaker system, which has impaired the sound quality of the loudspeaker system. The purpose of the present invention is to provide a technique for improving the sound quality by reducing the this surplus vibration which are the loudspeaker frame vibration and the cabinet vibration like a front baffle vibration. The present invention is characterized in being configured with a viscoelastic material layer upon rear portions such as the frame surface of the loudspeaker unit and inside and outside surfaces of each surface configuring the loudspeaker cabinet, and additionally suppresses vibration by addition of a heavy member or pressurization caused by constraint of a binding member.

Owner:NAGAOKA MITSUO

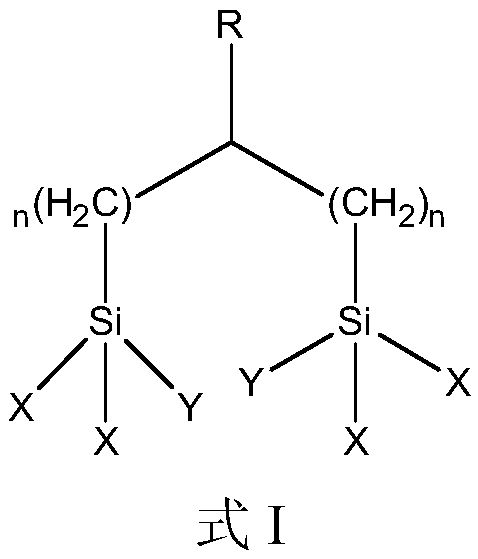

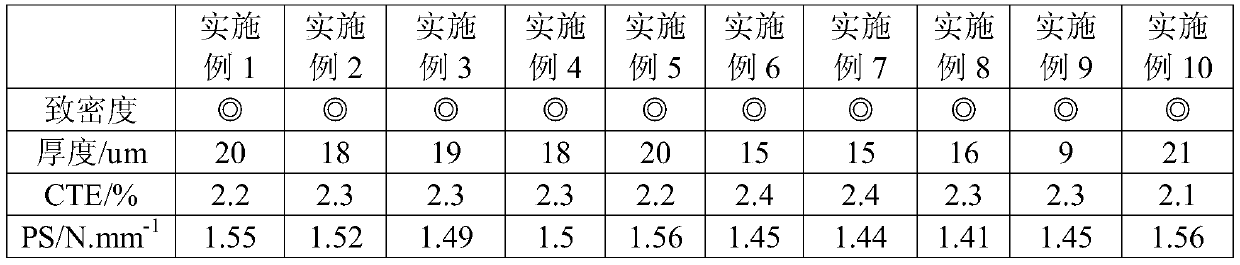

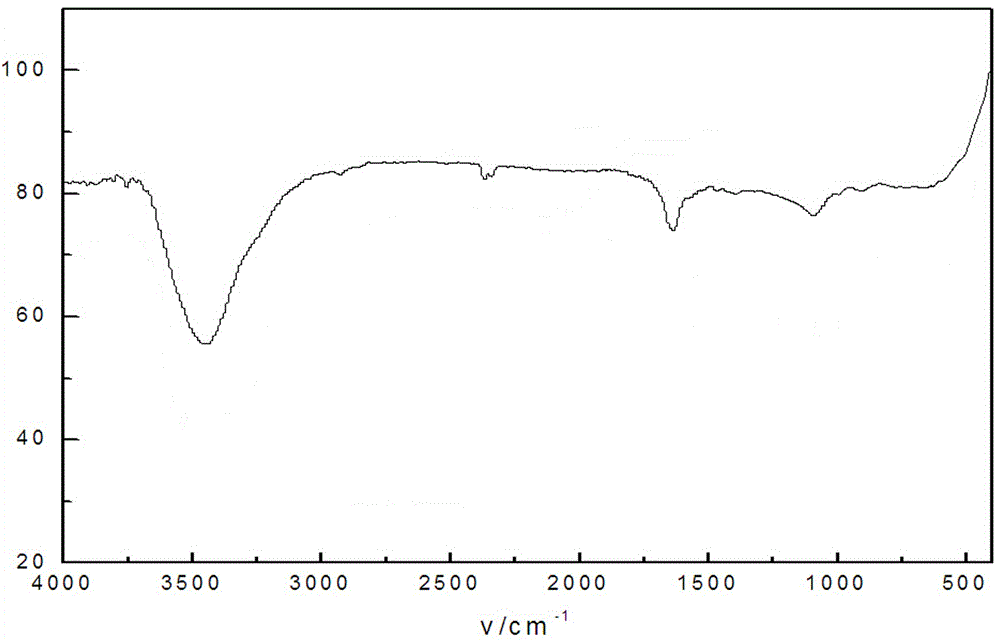

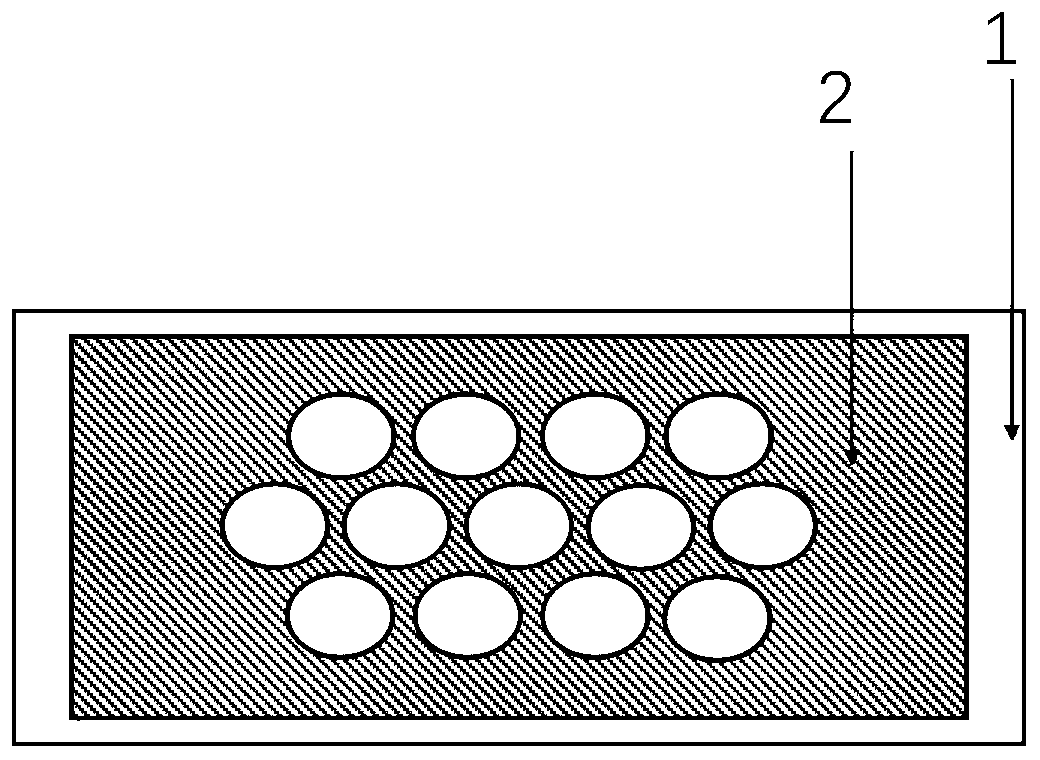

Thermosetting resin composition as well as prepreg, laminated board and circuit carrier containing same

ActiveCN105504686ASmall expansion coefficientPromote absorptionSynthetic resin layered productsGlass/slag layered productsThermal expansionCopper

The invention provides a thermosetting resin composition as well as a prepreg, a laminated board and a circuit carrier containing the same. The thermosetting resin composition comprises thermosetting resin, a laser direct forming additive, an inorganic filler, and a silane coupling agent with 2-3 groups capable of being hydrolyzed at each of two ends of a molecular chain. The laser direct forming additive is added in the thermosetting resin composition provided by the present invention to ensure that a circuit can be formed on thermosetting resin after laser irradiation and metallization, the CTE of the composition can be reduced and the absorption of laser energy by a matrix can be enhanced by adding the inorganic filler and the silane coupling agent with 2-3 groups capable of being hydrolyzed at each of the two ends of the molecular chain, the activation rate of an LDS auxiliary agent is effectively improved, the attachment and the sedimentary thickness of the matrix to copper are obviously enhanced at the same time, and three types of components mutually cooperate with the thermosetting resin to ensure that the thermosetting resin composition has a low coefficient of thermal expansion, thereby making the prepared circuit carrier have relatively good quality of signal transmission.

Owner:江苏生益特种材料有限公司

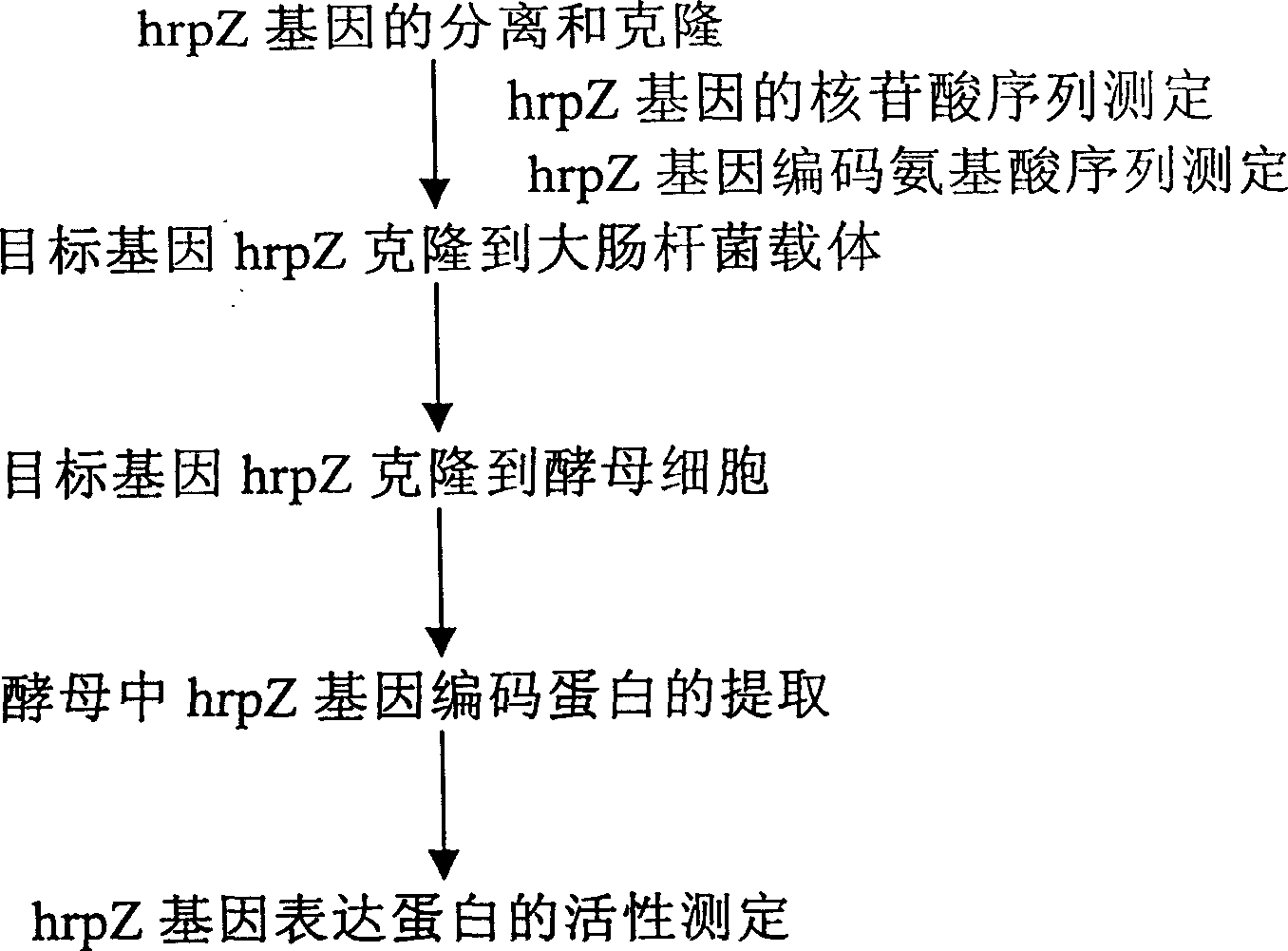

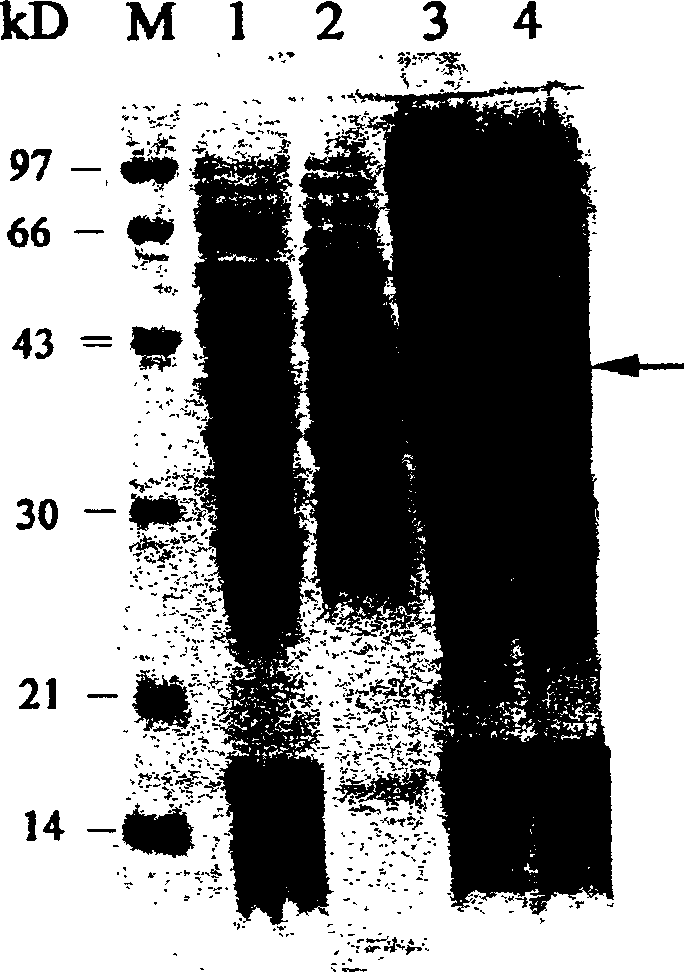

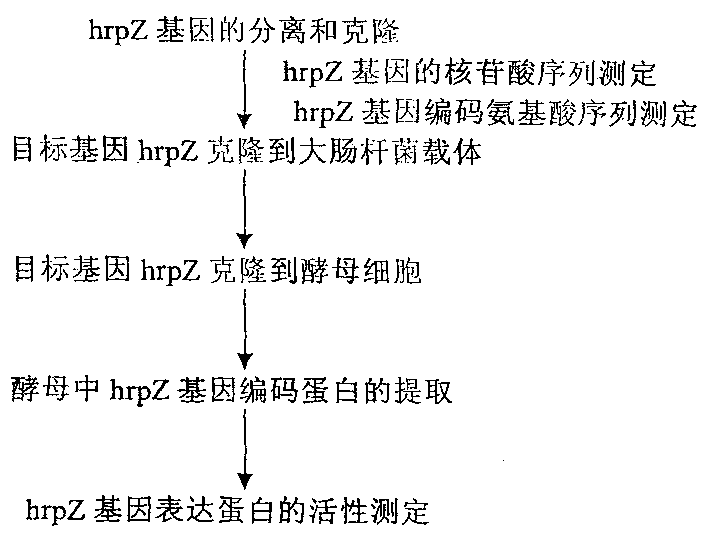

Yeast genetically engineered strain expressing hrp gene and constructing method thereof

InactiveCN1454989AStrong reactionImprove biological activityFungiBacteriaBiotechnologyBio engineering

The present invention relates to a yeast gene engineering strain capable of expressing hrp gene and its construction method. The name of said strain is Saccharomyces cerevisiae hrp Z, its number is CCTCC No:M203004. Its construction method includes: extraction of pseudomonas syringae genome DNA; using genome DNA as template PCR primer to make construction of hrp Z recombinant yeast gene engineering strain; hrpZ gene contained yeast conversion and induction. The gene engineering harpin protein produced by said strain can induce plant hypersensitive reaction, activate internal self-defense function of plant and promote plant growth. so that it can raise yield and quality of crops.

Owner:WUCAI FINE CHEM JIANGSU

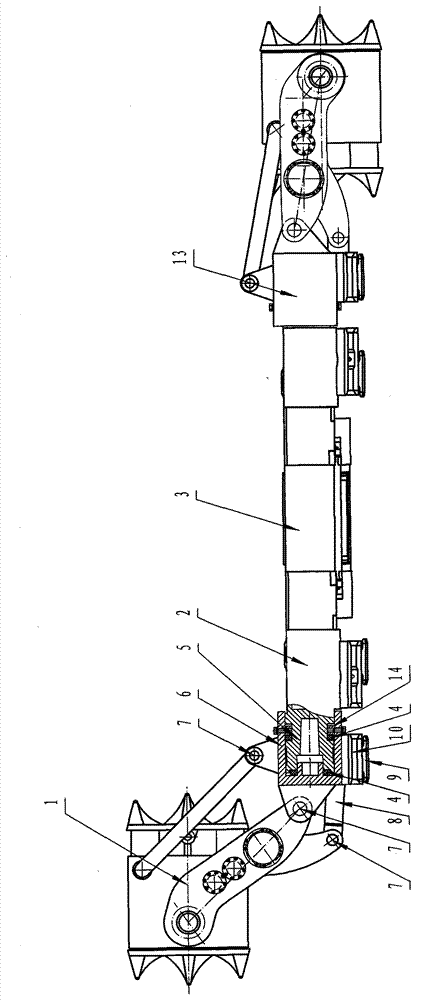

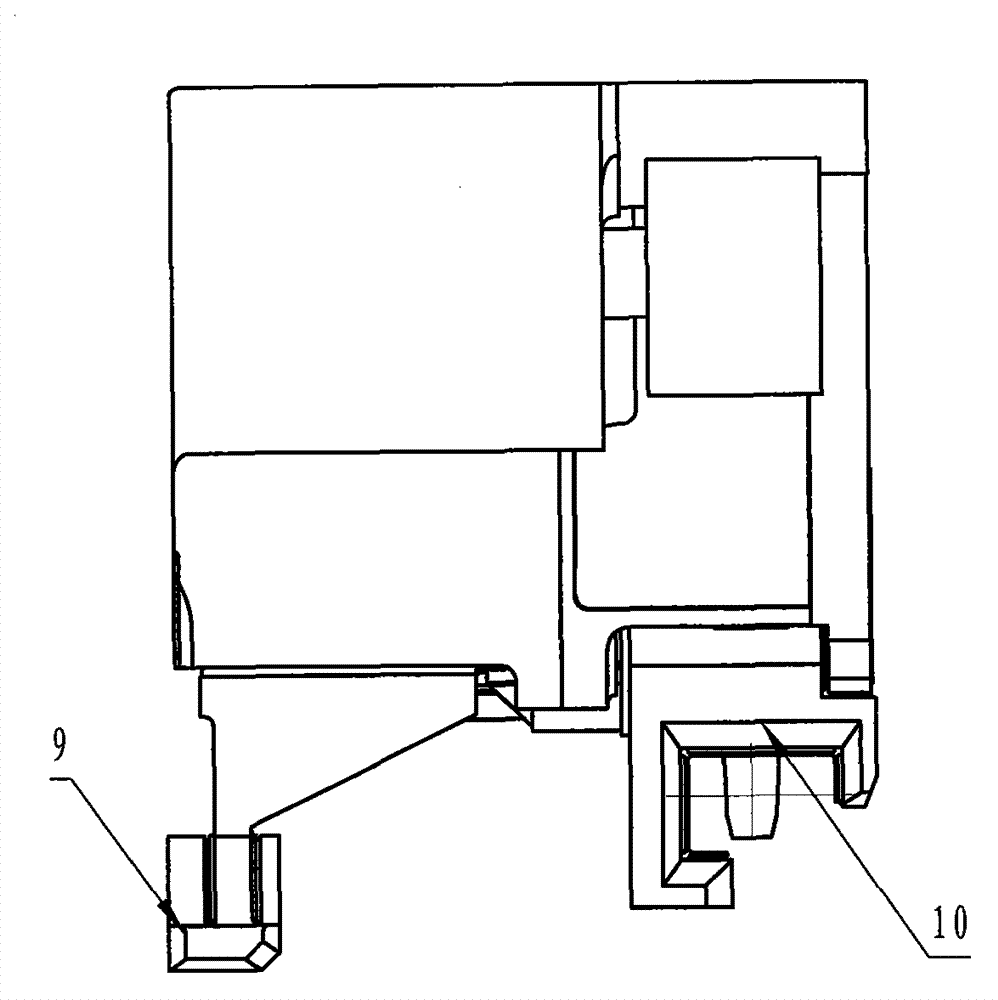

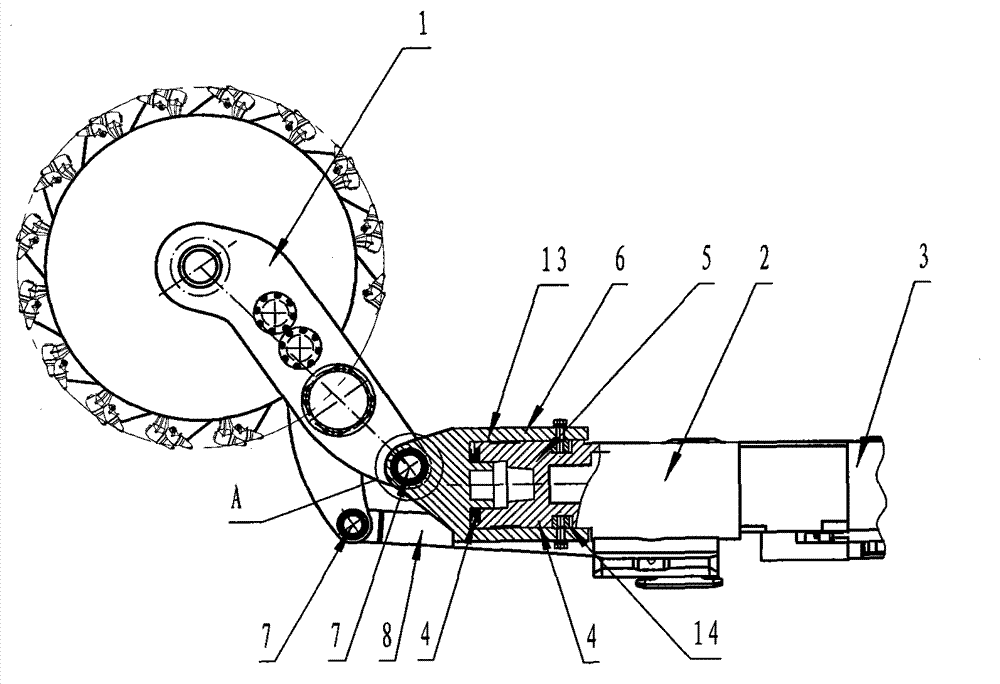

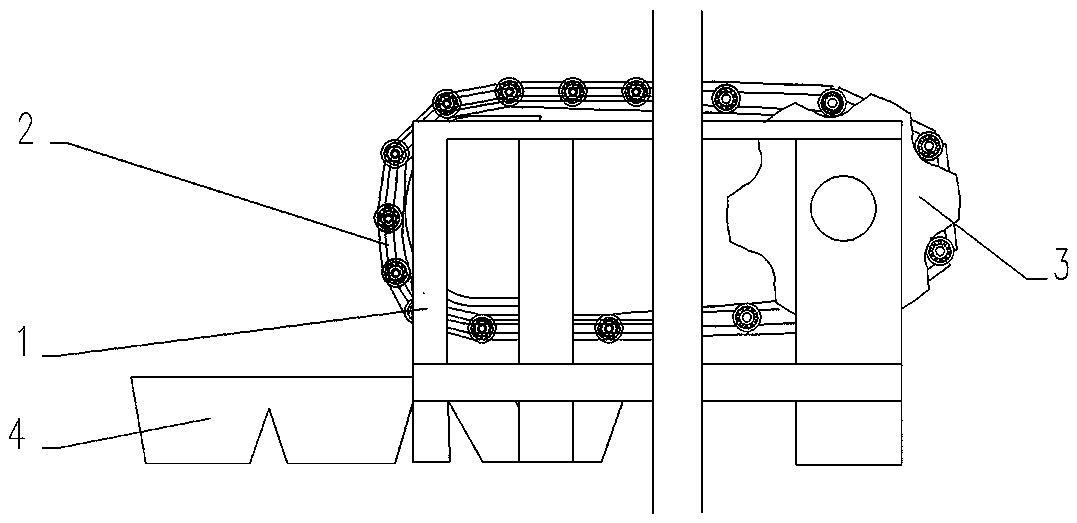

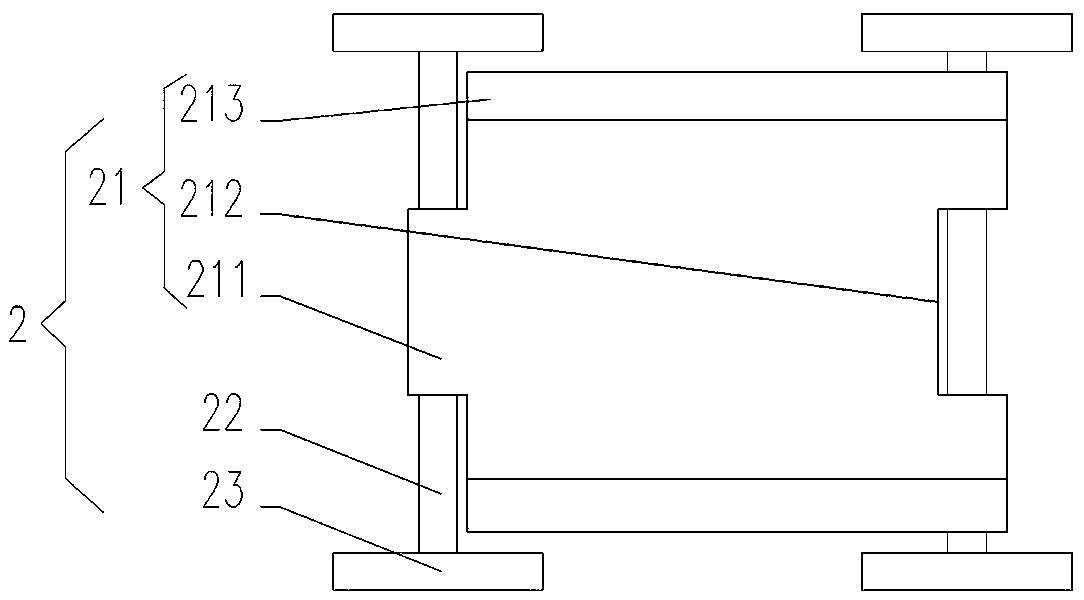

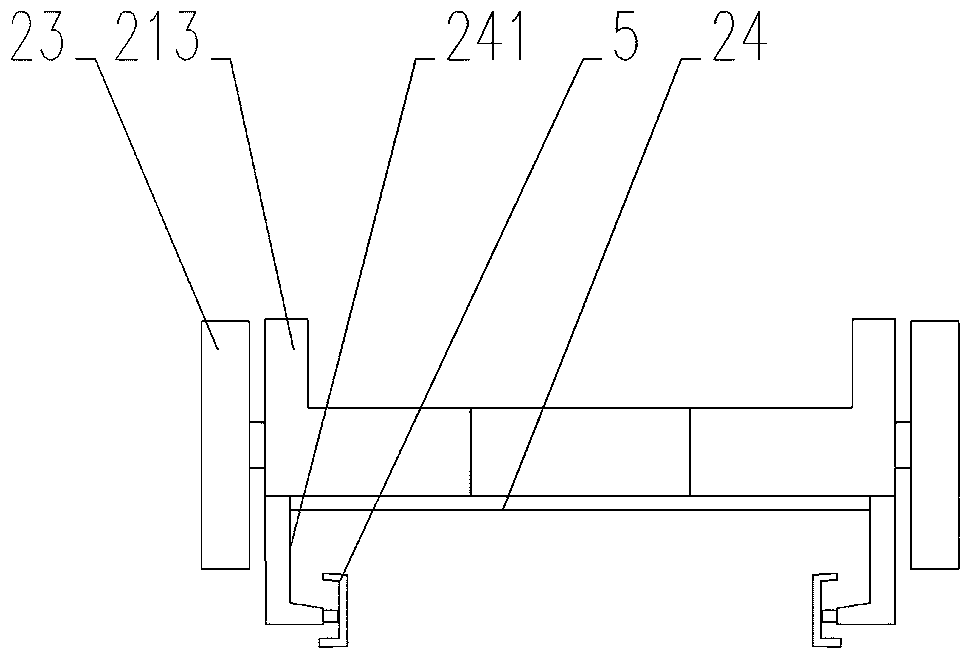

Vibration isolation coal cutter

ActiveCN103016003AWon't twist and cutTwist shearNon-rotating vibration suppressionSlitting machinesFatigue damageFailure rate

The invention relates to a vibration isolation coal cutter, which comprises a cutting mechanism and a body, wherein a buffer mechanism is arranged between the cutting mechanism and the body; the body comprises a traction box; the traction box is provided with a guide piece; the buffer mechanism is provided with a guide sleeve matched with the guide piece; and a buffer is arranged between the guide piece and the guide sleeve. According to the vibration isolation coal cutter, the impact vibration generated by a cutting part can be isolated, the impact on a traction part and the body is reduced, each connecting and fixing piece is prevented from loosening, the fatigue damage of each connecting piece is avoided, the failure rate of the coal cutter is reduced, and the working efficiency of the coal cutter is improved.

Owner:刘素华

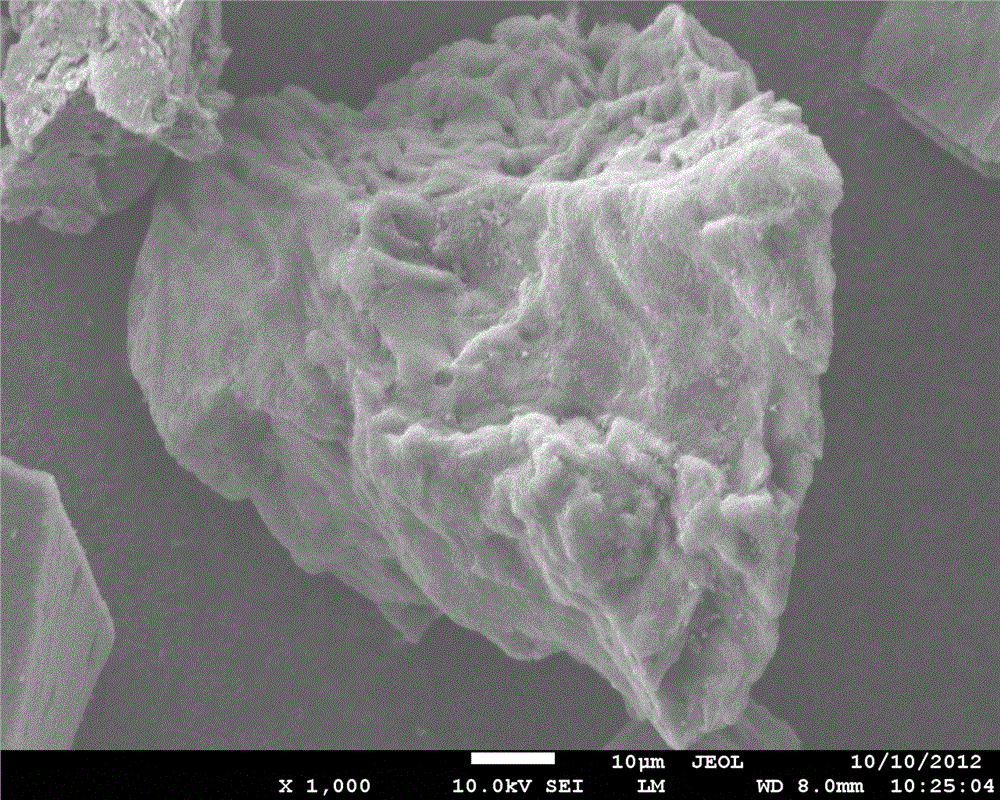

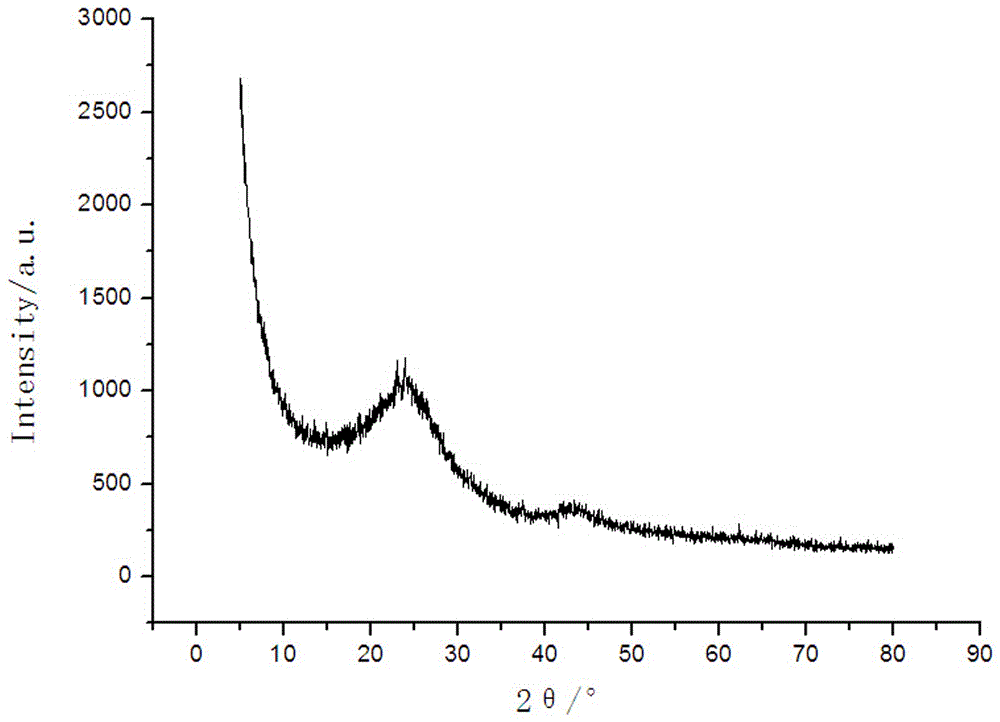

Preparation method of deciduous leaf activated carbon

ActiveCN106348294AEasy to prepareLarge specific surface areaCarbon compoundsActivated carbonEnvironmental chemistry

The invention discloses deciduous leaf activated carbon which is obtained by pulverizing deciduous leaves, impregnating in phosphoric acid, carbonizing in a carbonization furnace, activating, washing with acid, washing with water, and drying. The deciduous leaf activated carbon has a well-developed gap structure, a large internal specific surface area, stable properties, and high adsorption capacity. The deciduous leaf activated carbon has an iodine absorption value of 1853-1873 mg / g, a methylene blue adsorption value of 606-621 mg / g and a specific surface area of 1628.5-1645.3 m2 / g; and the deciduous leaf activated carbon can be used for decolorization, military gas masks, cigarette filters, air purifiers, water plant water treatment, drinking water purification, detoxification, control of radioactive element pollution, reduction of soil pesticide residues, conditioning of soil properties, control of indoor formaldehyde, preservation of vegetables and the like, thereby having very strong practicality.

Owner:NANYANG NORMAL UNIV

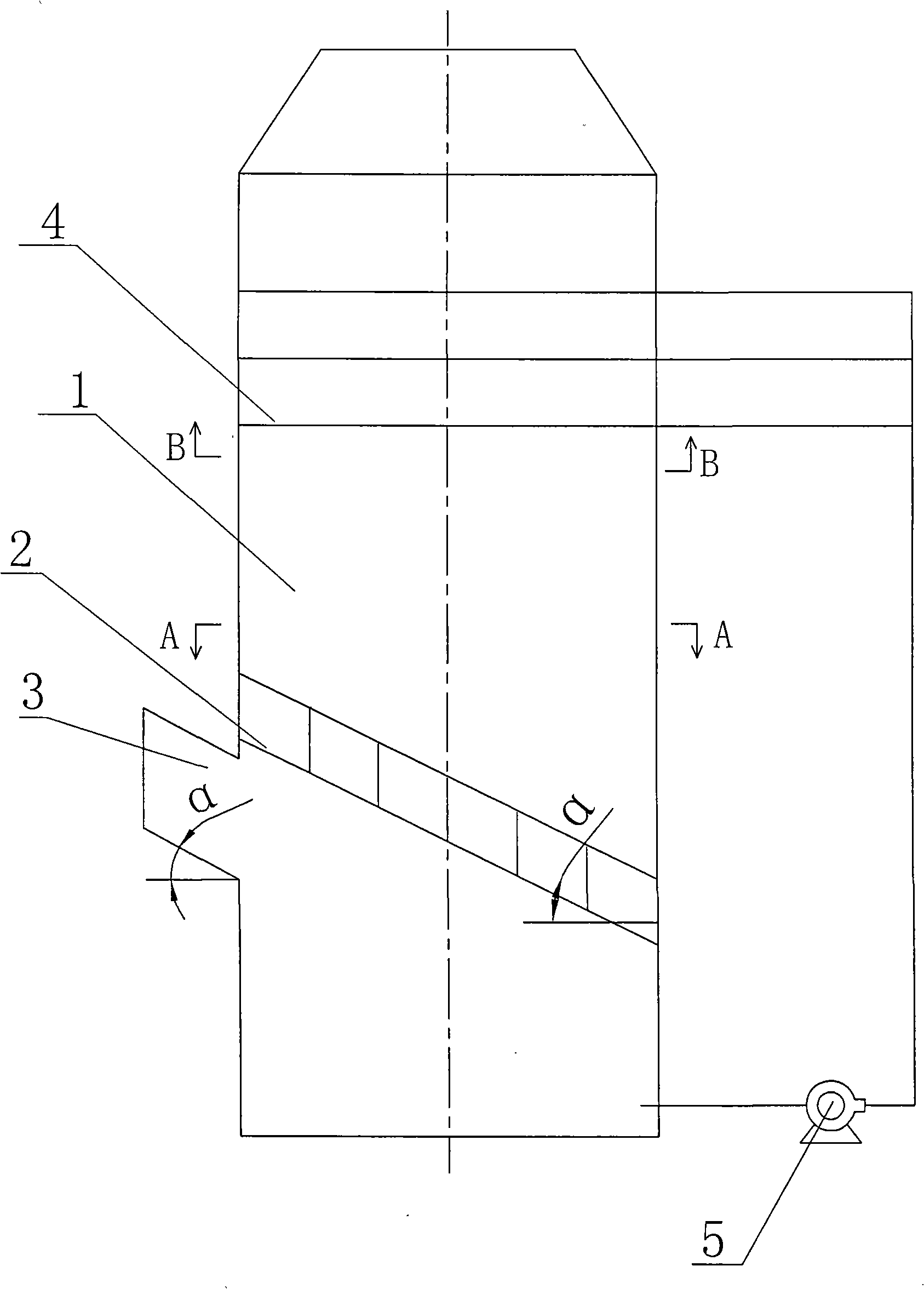

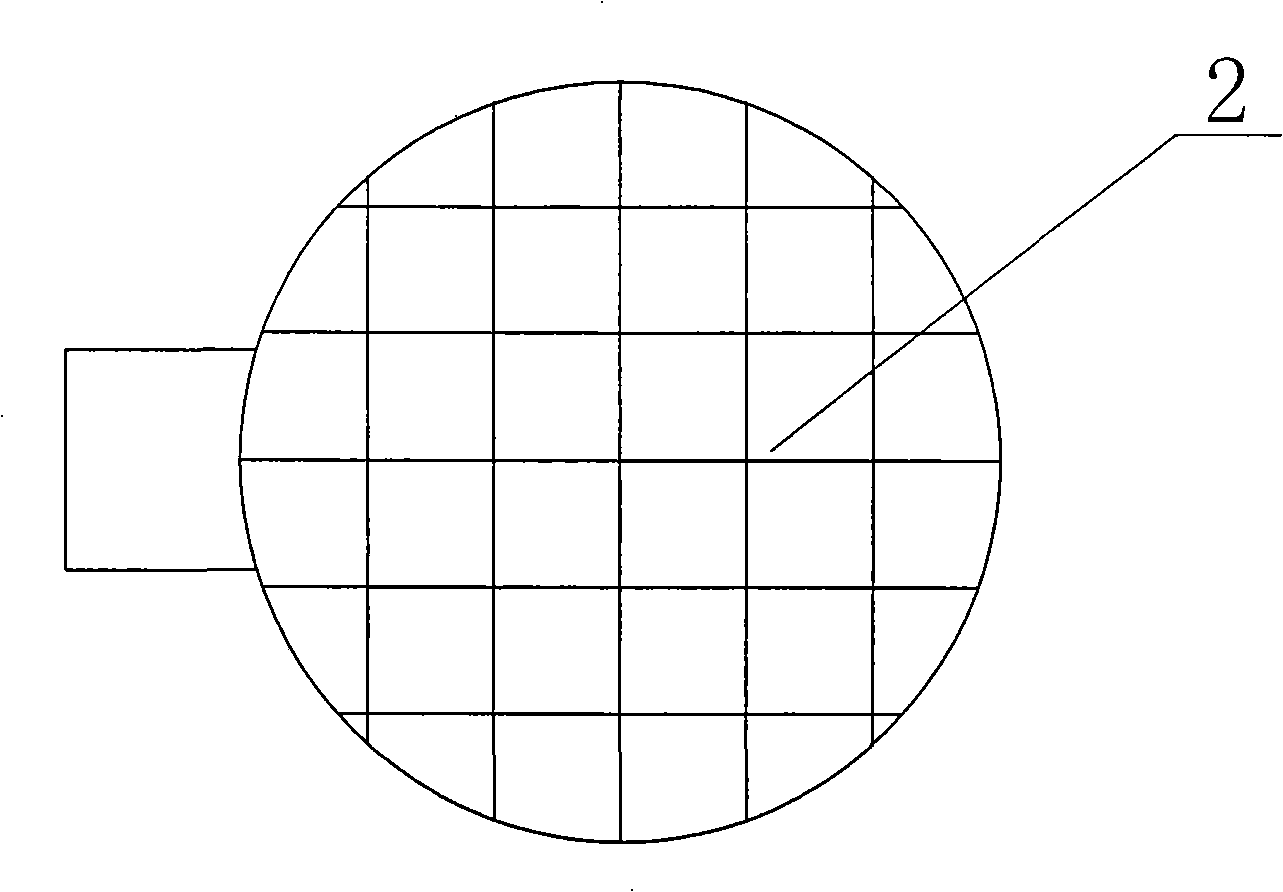

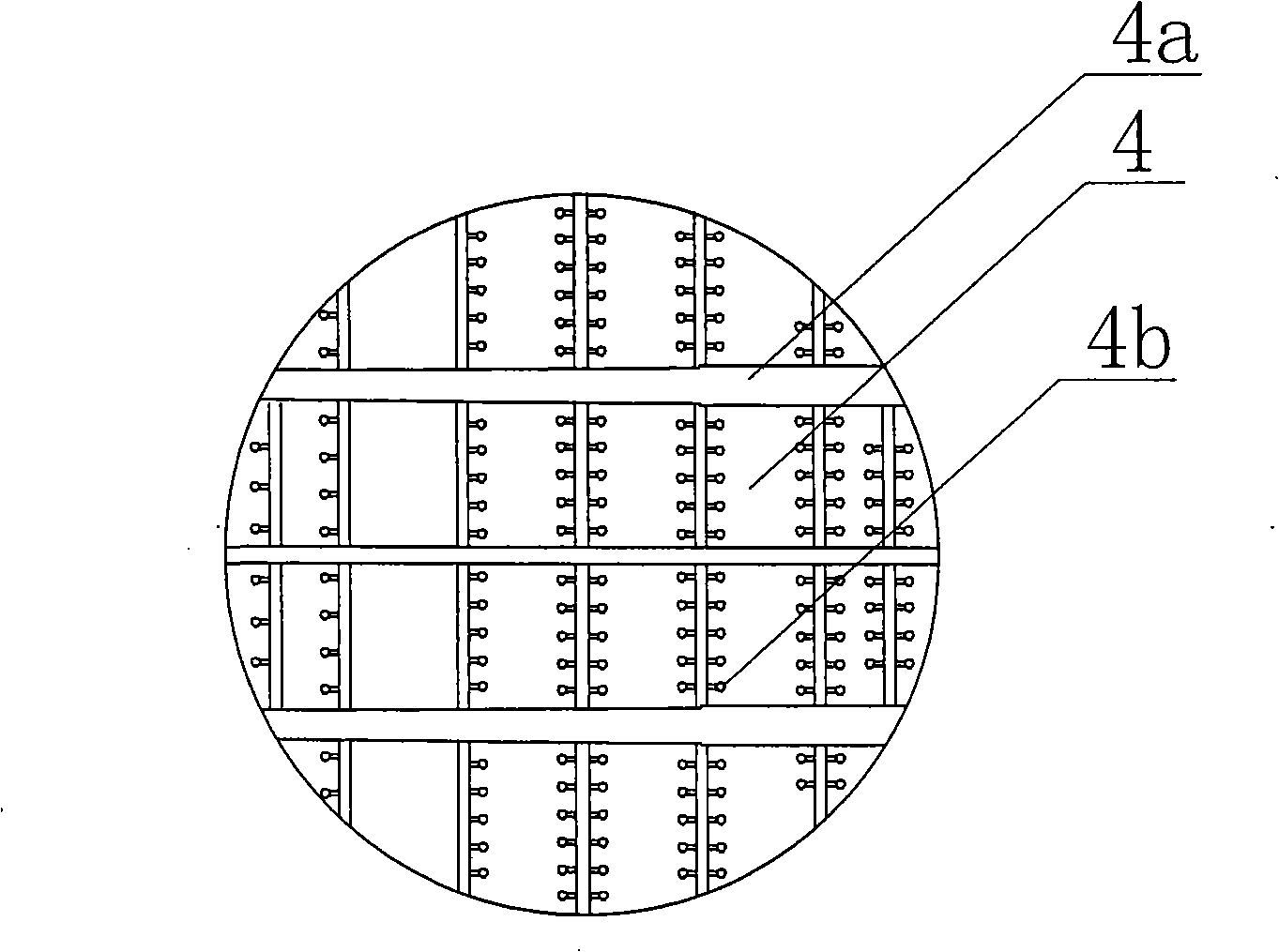

Biphase rectification flue gas desulfurization technique

ActiveCN101244363AReduce resistanceDoes not cause reduced reflux reactionsDispersed particle separationReaction rateGas phase

The invention discloses a dual-phase rectification flue gas desulfurization technology, which comprises a plurality of steps that (1) an absorption tower is arranged, (2) the flue gas is injected, (3) the limestone slurry is pumped in, and (4) the reaction product is collected. The dual-phase rectification flue gas desulfurization technology is characterized in that (1) the nonuniformity of flow field inside the spray tower is utilized, (2) the even rectification of liquidoid and gas phase is not processed on account of the design of rectifying plate and spray layer intentionally, (3) the resistance of flue gas is decreased and the velocity of flow of flue gas is uninfluenced, and (4) the liquidoid and the gas phase are kept turbulent state consistently because of the nonuniformity of liquidoid and gas phase. The dual-phase rectification flue gas desulfurization technology has the advantages of fierce collision, intense reaction, enough absorption, good performance of desulfurization, high efficiency, fast reaction rate, good performance of counter-current reaction, optimization of flow field, low system pressure drop, energy-saving, low device cost and maintenance cost, and direct maintenance and shift of inner parts without building temporary maintenance platform in the process of maintenance of absorption tower inner parts.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

Method for closed-ring synthesizing anthraquinone from o-benzoylbenzoic acid

InactiveCN1683305AIncrease the feeding speedSave unloading timeOrganic compound preparationQuinone preparationChemistrySpent acid

The process of close-ring synthesizing anthraquinone from o-benzoylbenzoic acid includes the following steps: A. heating o-benzoylbenzoic acid in close-ring reactor to eliminating surface water; B. adding fuming sulfuric acid with SO3 content of 16-24 % in 1.3-1.8 times weight of o-benzoylbenzoic acid and close-ring reaction at 138-200 deg.c for 1 hr; C. separating the reaction product in separating reactor, filtering, water washing, drying, etc. to obtain dry anthraquinone product. The present invention has less sulfuric acid consumption, low production cost, less exhausted waste acid, low power consumption and short reaction time.

Owner:赵振国

Pesticide spraying device

ActiveCN106614479AAvoid mixingAchieve pressurizationInsect catchers and killersSlide plateElectrical and Electronics engineering

The invention relates to the field of planting, and particularly discloses a pesticide spraying device. A plurality of horizontal sliding plates and a plurality of fixed plates are arranged in a machine shell, the right sides of the sliding plates are in contact with the left sides of the fixed plates, first containing cavities for containing water are defined by the sliding plates, partition plates and the machine shell, first locking beads are arranged on the peripheries of the sliding plates, a plurality of first grooves are formed in the peripheries of the sliding plates, first springs are arranged in the first grooves, one ends of the first springs are fixedly connected with the first grooves, and the other ends of the first springs are fixedly connected with the first locking beads; second containing cavities for containing powder are defined by the fixed plates, the partition plates and the machine shell, and the fixed plates and the machine shell are fixedly connected; the pesticide spraying device also comprises the partition plates for partitioning the first containing cavities and the second containing cavities , the partition plates are vertically arranged between the adjacent fixed plates, the upper ends of the partition plates are hinged to the fixed plates, and the lower ends of the partition plates are in contact with second locking beads in second grooves in the fixed plates. By means of the pesticide spraying device in the technical scheme, the water and the powder can be automatically mixed, and manual operation is avoided.

Owner:重庆博创知识产权运营有限公司

Tundish magnesium calcium ladle cover casting materials and preparation method thereof

ActiveCN109095897AImprove medium temperature strengthImproved thermal shock stabilityThermal shockOxide

The invention relates to tundish magnesium calcium ladle cover casting materials. The tundish magnesium calcium ladle cover casting materials comprise the following components in percentage by weight:20-40wt% of magnesium sand granules, 20-40wt% of magnesium calcium sand granules, 5-15wt% of quick lime granules, 10-20wt% of a magnesium sand fine powder, 0.5-3wt% of an organic magnesium compound,1-6wt% of organic calcium, 2-6wt% of a thermoplastic micro powder, 2-8wt% of a magnesium oxide micro powder and 0.1-0.2wt% of a water reducing agent. The invention further relates to a method for preparing the tundish magnesium calcium ladle cover casting materials. According to the tundish magnesium calcium ladle cover casting materials and the preparation method thereof disclosed by the invention, the heat shock stability of fireproof materials is improved, besides, dissipation of heat quantity is effectively reduced, and favorable heat preservation properties and favorable thermal shock resistance of the materials are guaranteed; and when the tundish magnesium calcium ladle cover casting materials are applied to high-quality steel continuous casting tundishes, the temperature of a housing of a tundish ladle cover can be reduced by 10% or above averagely, and the average service life reaches 15 times or above.

Owner:阳泉市庚光高温材料有限公司

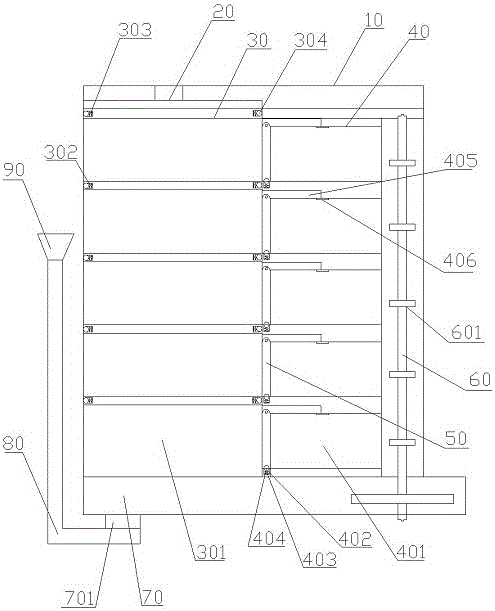

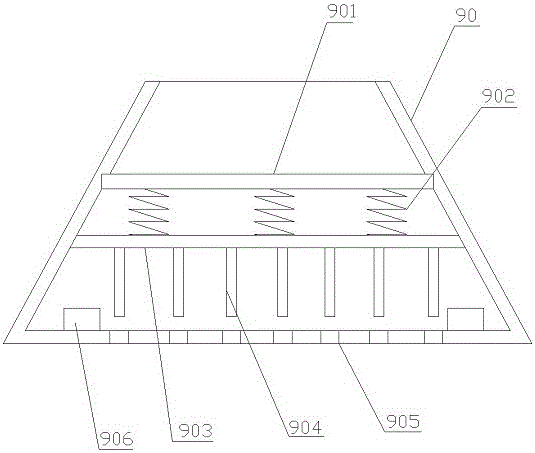

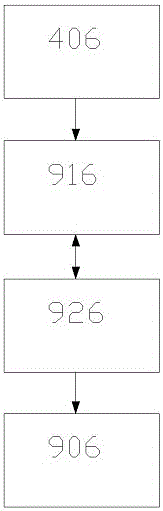

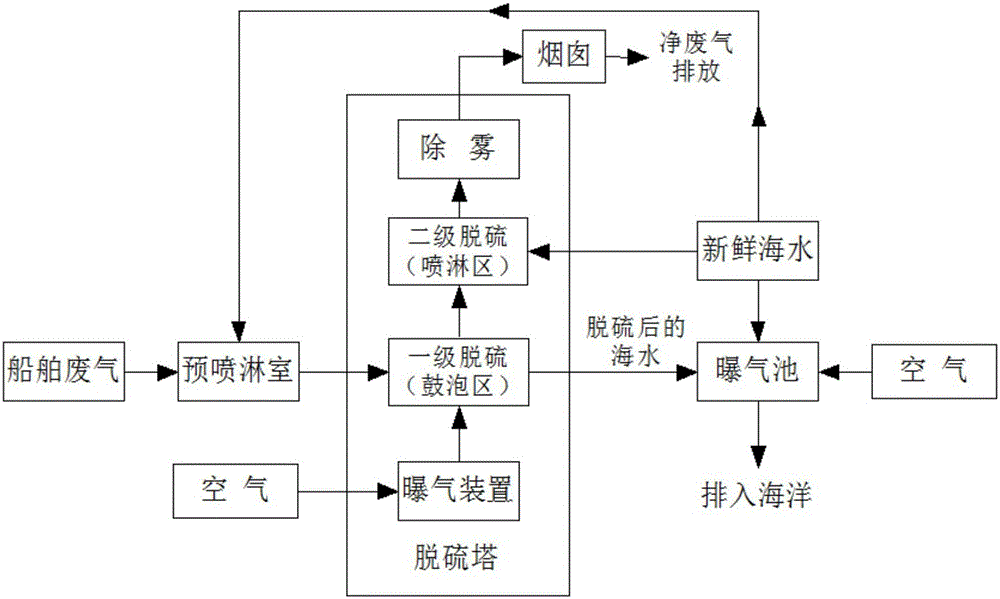

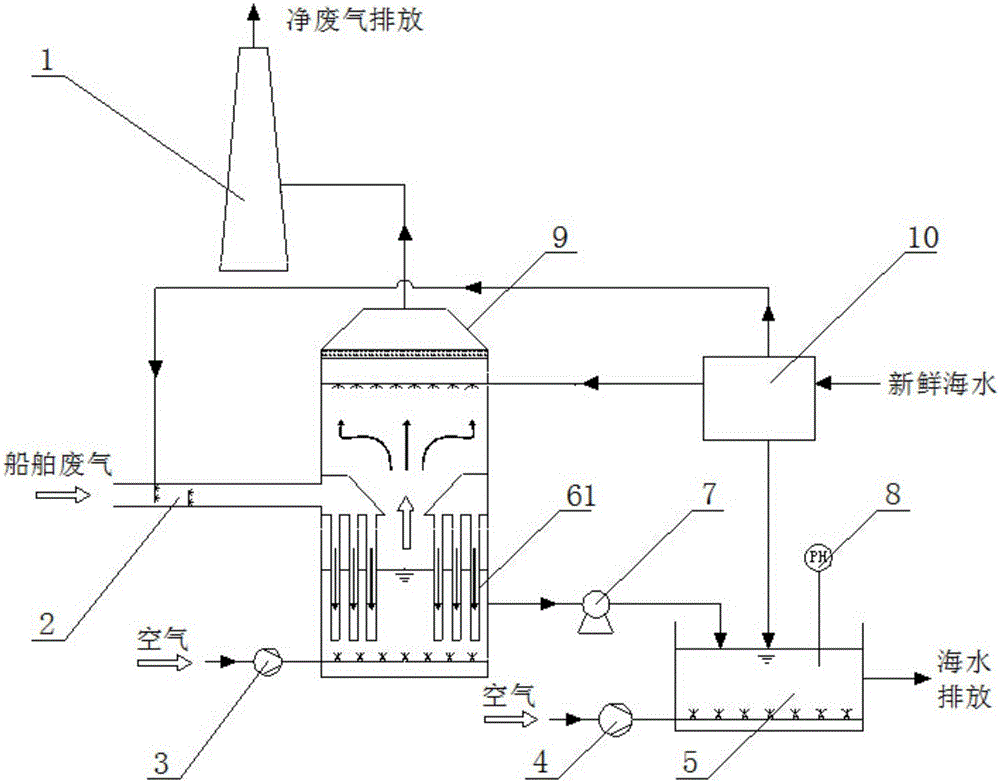

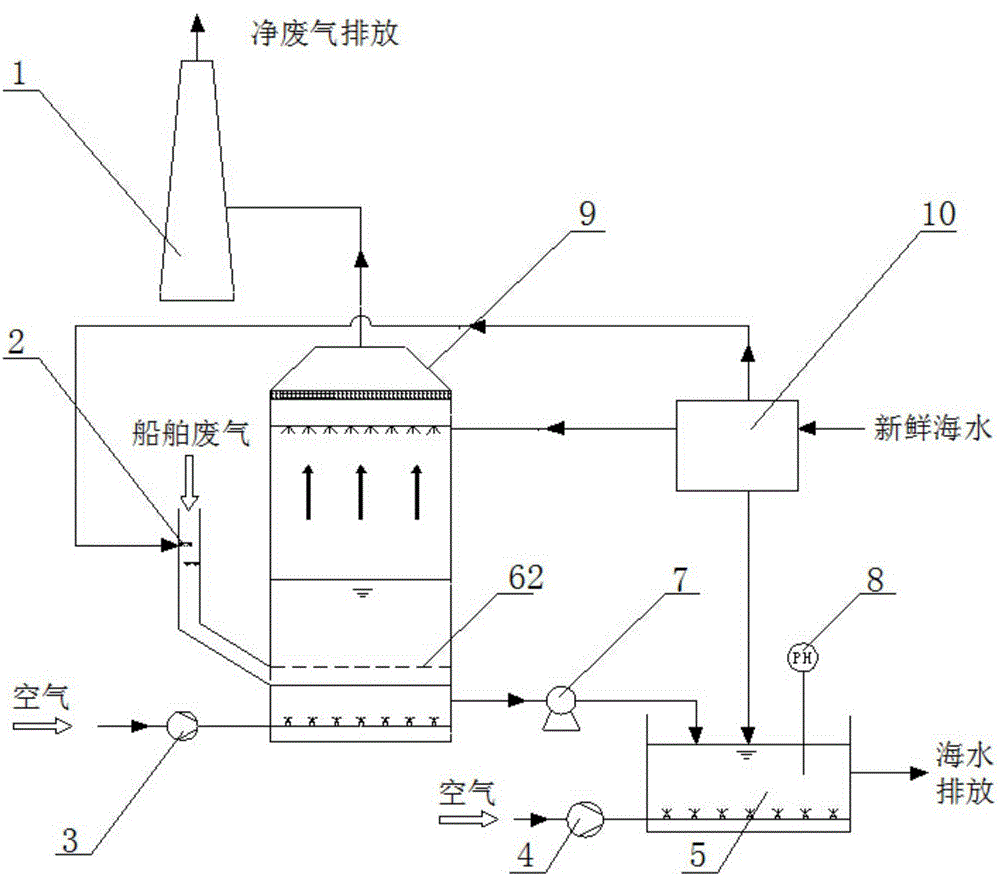

System and method for efficiently removing sulfur oxide in ship waste gas

InactiveCN105056714AReduce desulfurization loadSolve the contradiction of low temperature absorptionDispersed particle separationAtmospheric airWater quality

The present invention discloses a system and a method for efficiently removing sulfur oxide in ship waste gas. The removal process is divided into three stages: a pre-treatment stage, bubbling and primary desulfurization stage, and a spraying and secondary desulfurization stage. The method comprises the following steps of: respectively introducing fresh sea water into a pre-spraying chamber, a desulfurization tower and an aeration tank through pipelines; firstly cooling the high-temperature waste gas, and removing part of sulfur oxides in the pre-spraying chamber; introducing the cooled waste gas into the desulfurization tower and uniformly spraying the cooled waste gas into a sea water bubbling zone through a gas distribution tube; introducing the waste gas into a spraying zone through an ascending passage of the desulfurization tower so as to carry out further removal of sulfur oxides; demisting the waste gas by a demister, and discharging the demisted waste gas into the atmosphere through a chimney; and restoring the water quality of desulfurized seawater by virtue of primary aeration in the desulfurization tower and secondary aeration in an aeration tank. Compared with a traditional seawater desulfurization technology, on the premise of not increasing the space occupancy rate of the seawater desulfurization system, the method solves the problem that the desulfurization efficiency is generally low when seawater desulfurization technology is applied in ships.

Owner:SOUTHEAST UNIV

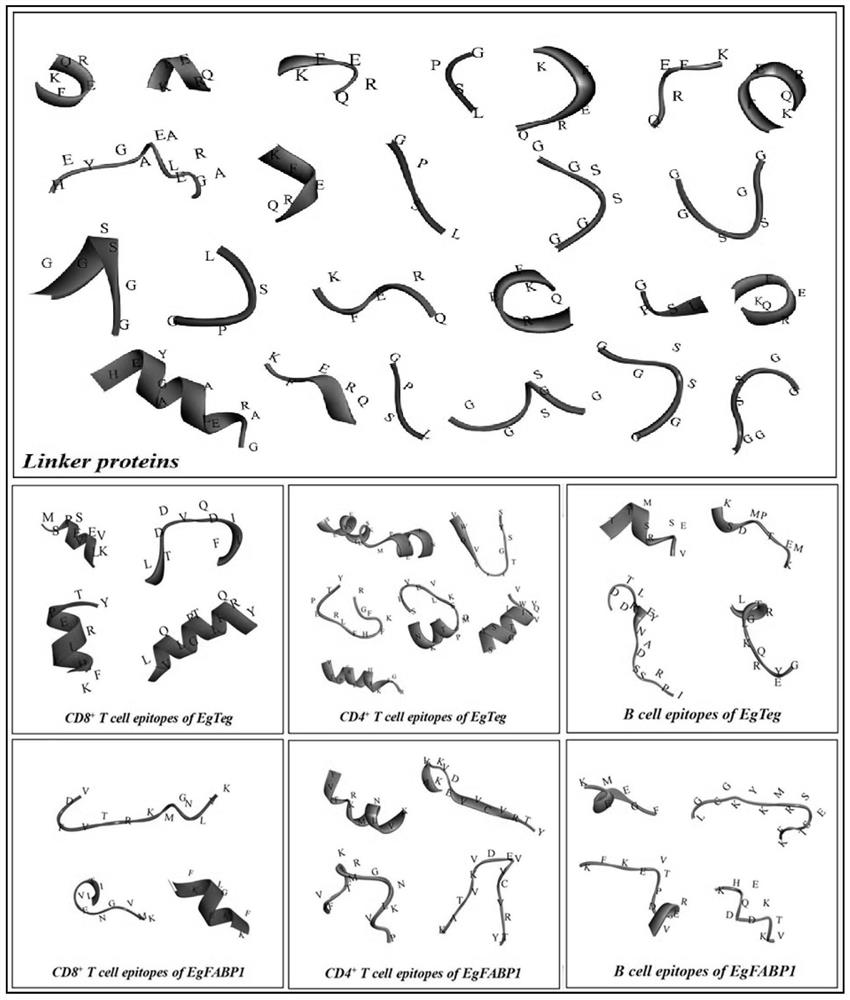

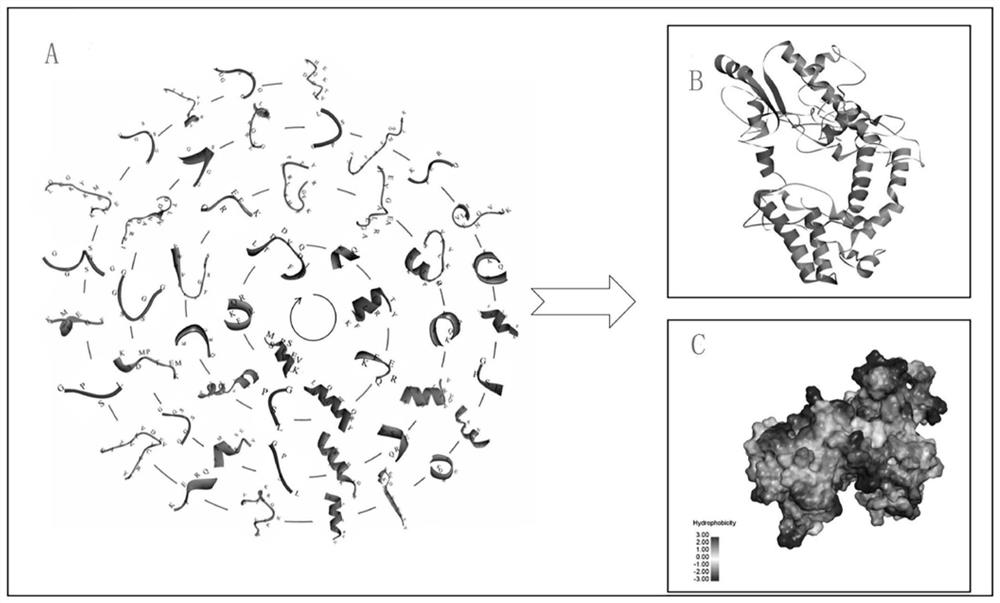

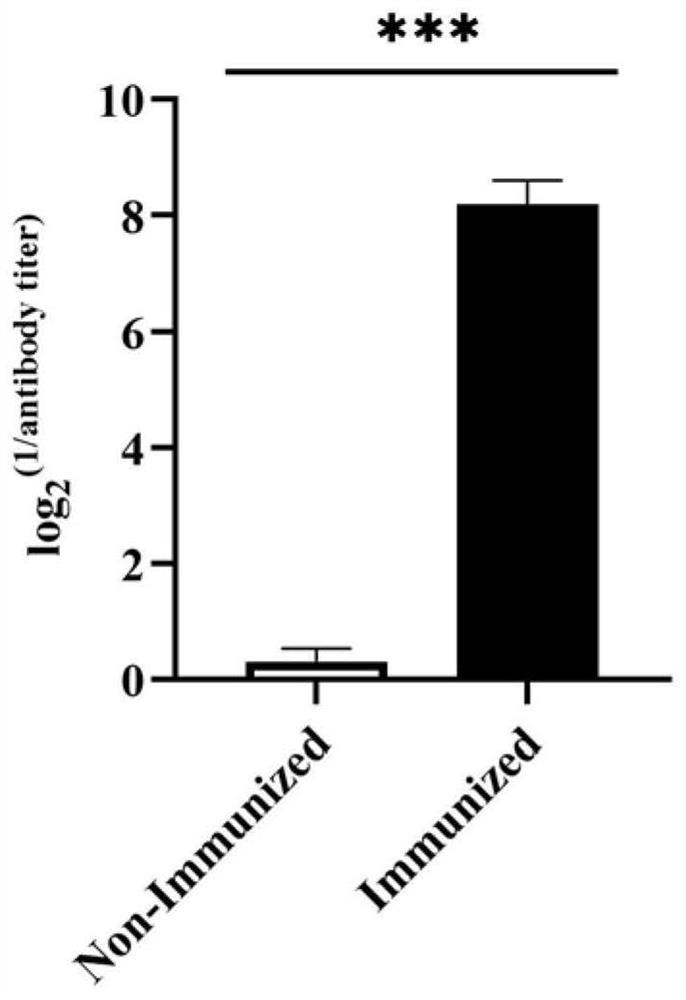

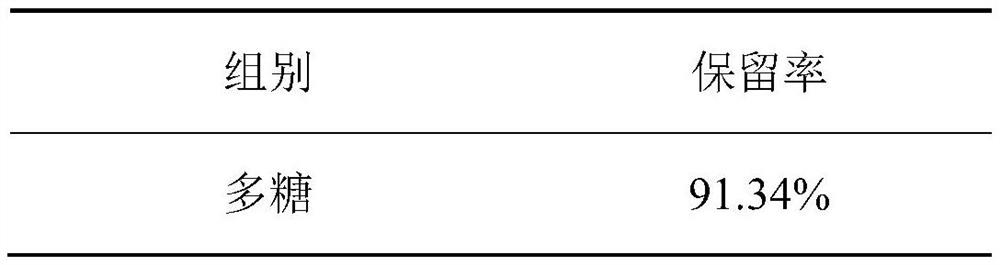

Echinococcus granulosus EgTeg and EgFABP1 multi-epitope vaccine and application

ActiveCN113577257AImproving immunogenicityGood allergenic propertiesAntiparasitic agentsBiological testingAntigen epitopeAntigen

The invention belongs to the technical field of biotechnology, and particularly discloses an echinococcus granulosus EgTeg and EgFABP1 multi-epitope vaccine and application. Theechinococcus granulosus EgTeg and EgFABP1 multi-epitope vaccine comprises a CD8 + T cell epitope, a CD4 + T cell epitope and a B cell epitope of an EgTeg protein and an EgFABP1 protein. The invention further discloses a screening method and application of the multi-epitope vaccine, and compared with a vaccine obtained by a traditional antigen epitope screening method, after the EgTeg and EgFABP1 multi-epitope vaccine provided by the invention is inoculated, the wet weight of the echinococcus granulosus cyst in a mouse body infected by echinococcus granulosus protoscolex can be effectively reduced; and the screening time and economic cost are low, the experimental process is simplified, and the echinococcus granulosus EgTeg and EgFABP1 multi-epitope vaccine is suitable for wide screening, popularization and application of the antigen epitopes.

Owner:THE FIRST TEACHING HOSPITAL OF XINJIANG MEDICAL UNIVERCITY

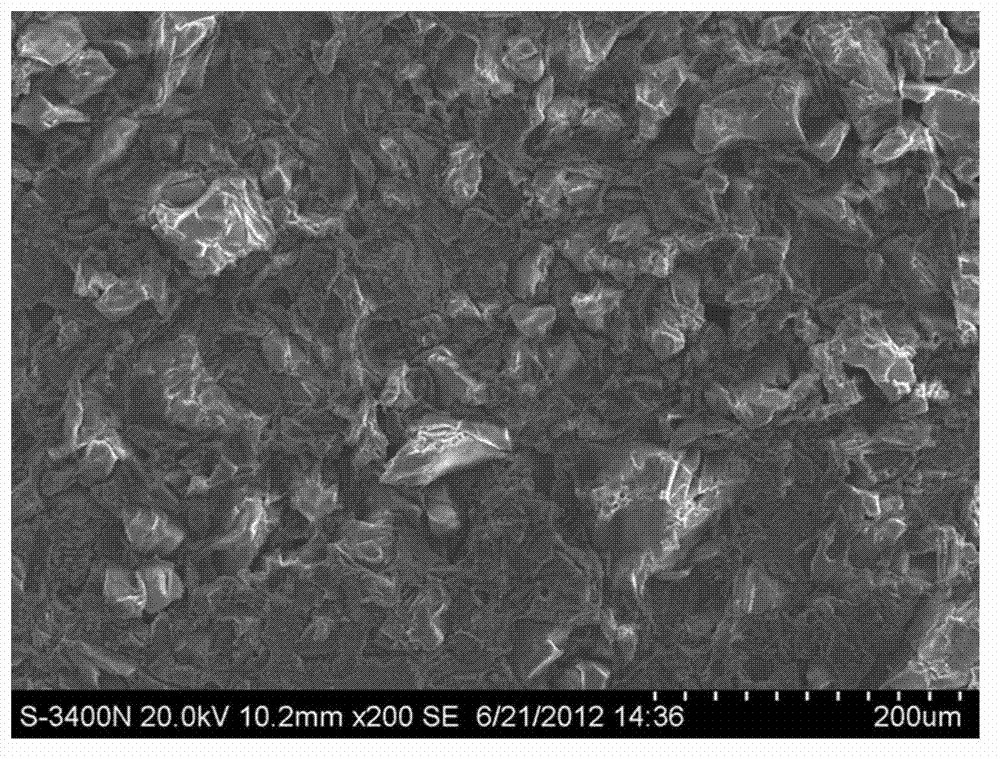

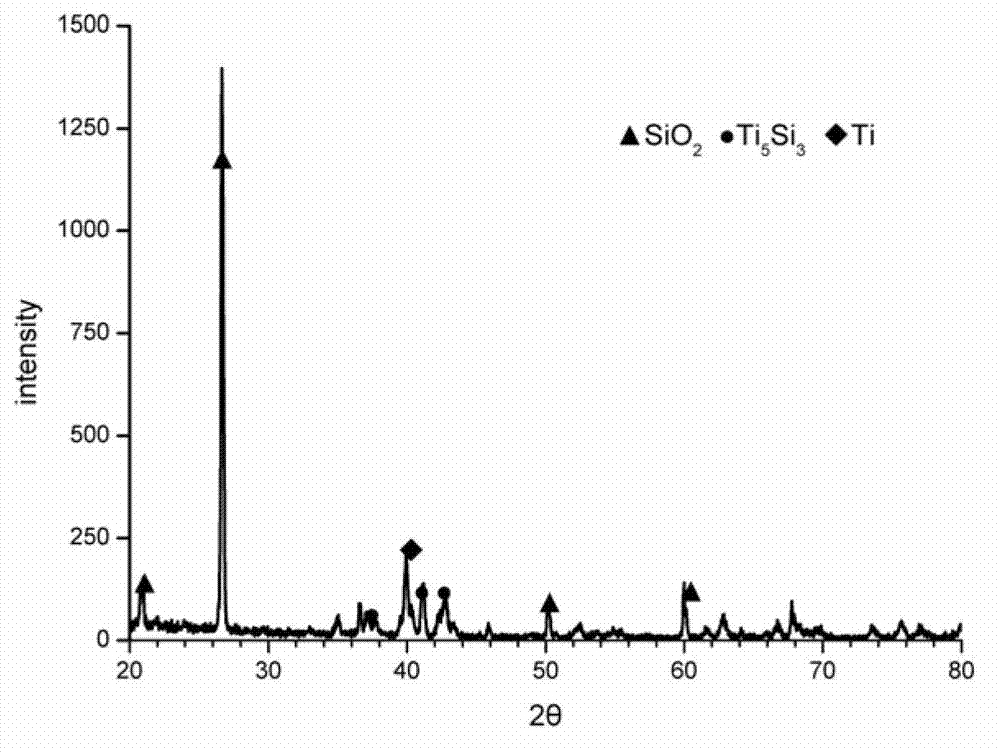

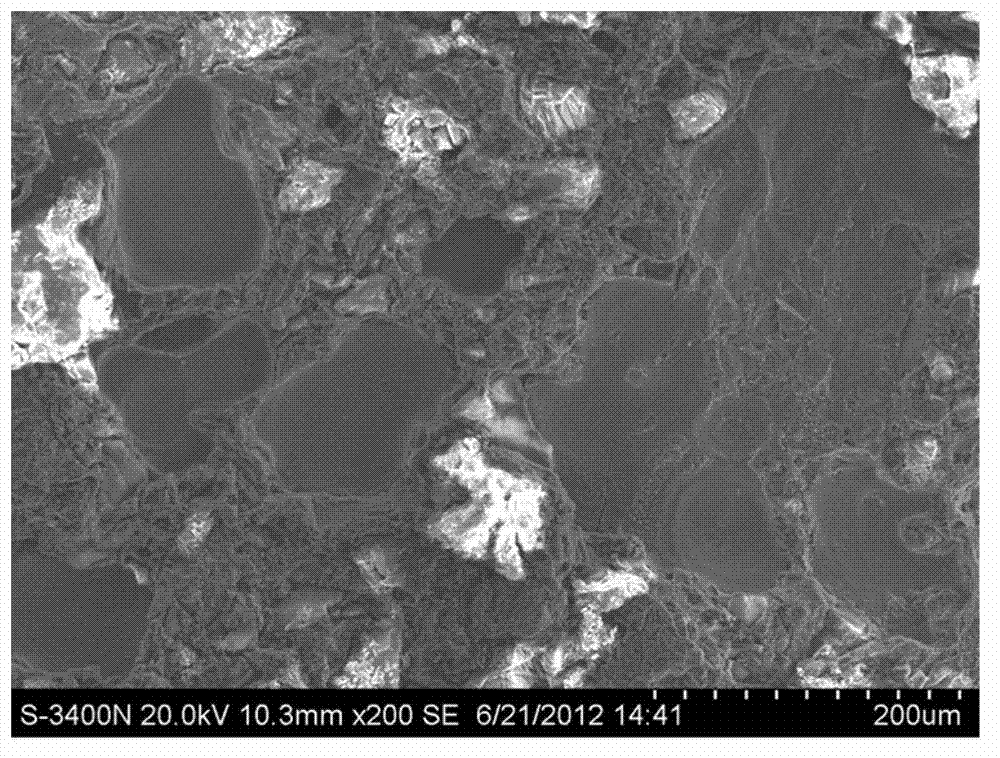

Titanium surface casting modification method for reinforcing titanium-porcelain combination strength

ActiveCN102756110AOvercoming problems such as poor bondingSolve problems such as the formation of brittle and loose oxide filmsImpression capsDentistry preparationsTitanium surfaceWax

The invention discloses a titanium surface casting modification method for reinforcing titanium-porcelain combination strength and belongs to the technical field of titanium-porcelain metal-porcelain. The method comprises the steps of: selecting one or a plurality of silicon dioxide, aluminum oxide, chromium oxide, low-smelting bonding porcelain powder, high-smelting bonding porcelain powder, screen color porcelain powder and dentin porcelain as basic ingredients of an internal embedding material; regulating the internal embedding material to gel substance through ethyl orthosilicate acidified by hydrochloric acid, or calcium aluminate cement and distilled water and water; wetting a casting wax pattern through amiable fog, coating the internal embedding material on the side to be fused with porcelain, and curing the internal embedding material at room temperature; embedding the internal embedding material through a titanium casting; and commonly casting the internal embedding material. The method disclosed by the invention forms an oxidization shield when the titanium porcelain is formed and the reaction gradient mixed layer and the glass phase in the porcelain powder form chemical combination to improve the titanium-porcelain combination strength.

Owner:BEIJING STOMATOLOGY HOSPITAL CAPITAL MEDICAL UNIV +1

Ceramic coated metal material and production method thereof

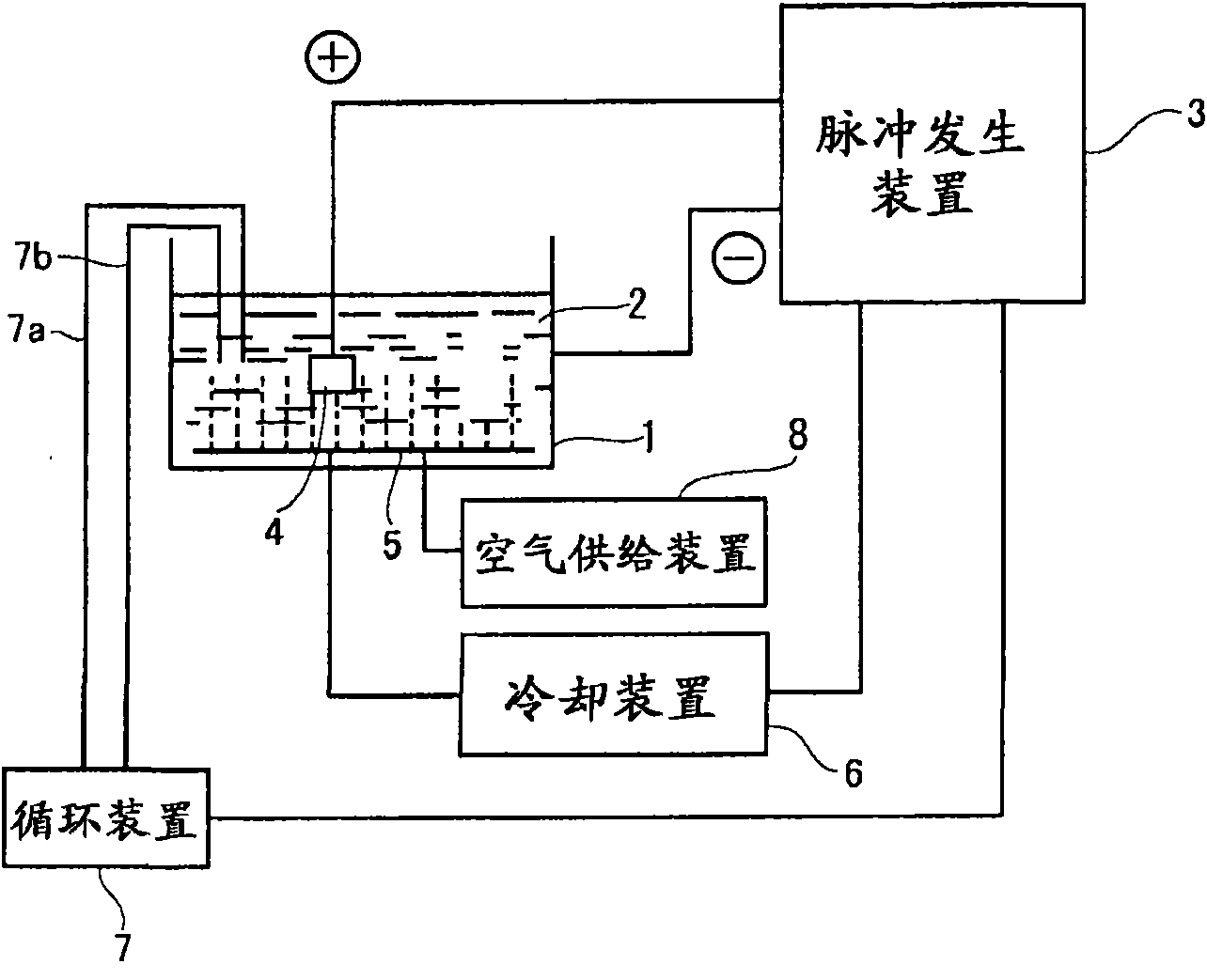

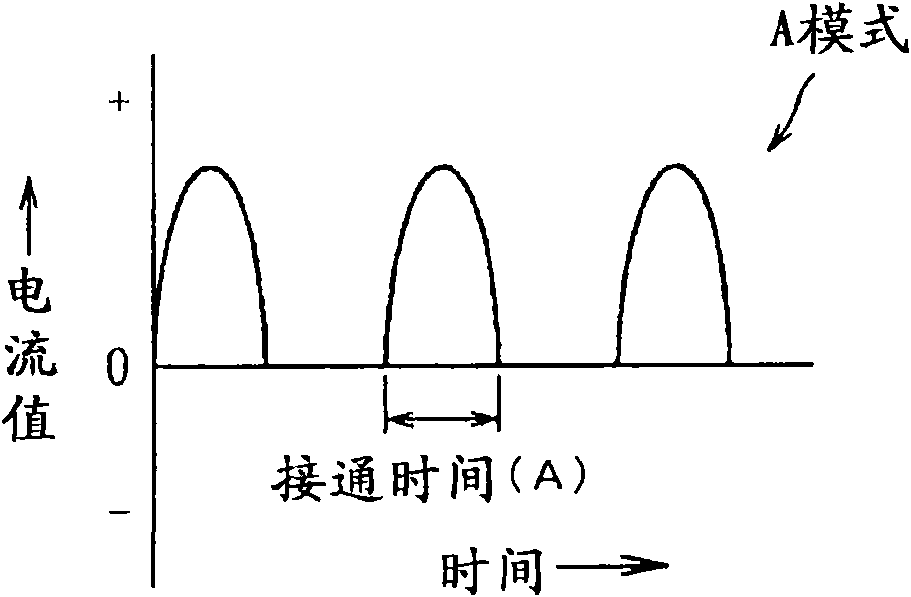

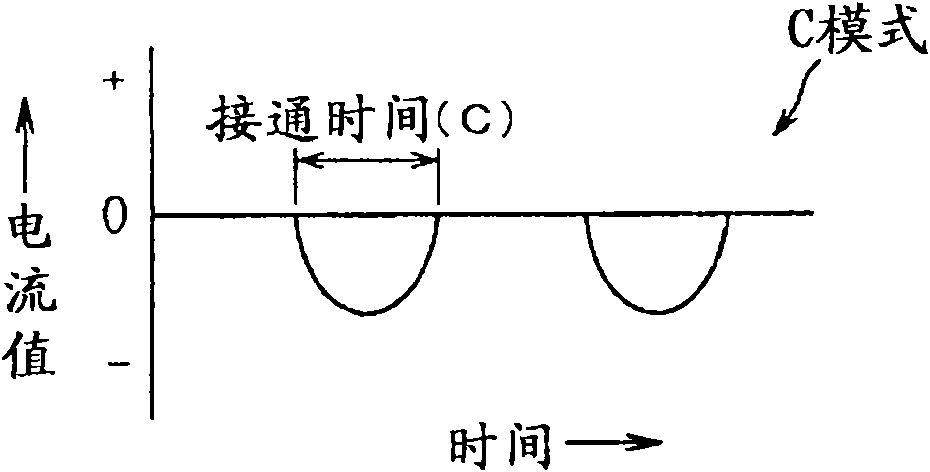

InactiveCN101605929AImprove uniformityUniform temperature distributionCellsAnodisationPlasma electrolytic oxidationElectrolysis

A plasma electrolytic oxidation film (ceramic film) which is very smooth and highly resistant to not only an Al-based metal substrate but Mg-based metal and Ti-based metal substrates can be formed. An energization pattern is used in which, as a pulse mode, a alternating pulse mode in which one anode type pulse mode or one cathode type pulse mode appears before or after at least one anode type pulse mode to be positively polarized or at least one cathode type pulse mode to be negatively polarized is arranged, and a deformed sine wave shape in which the peak position of its pulse mode current wave shape is deviated from the center position of the pulse is used.

Owner:丸八殖产株式会社 +1

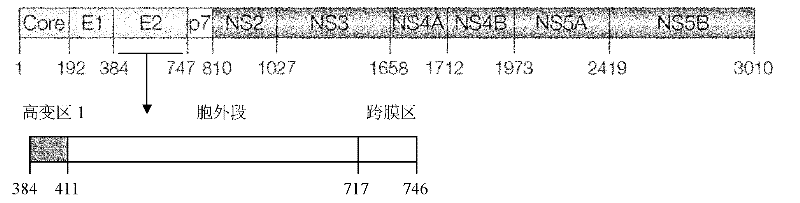

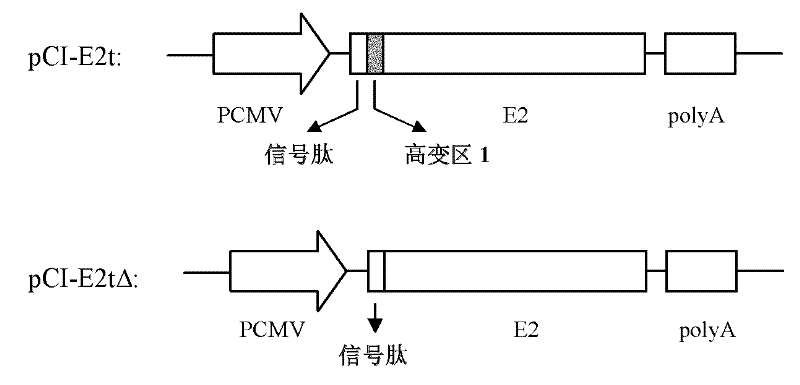

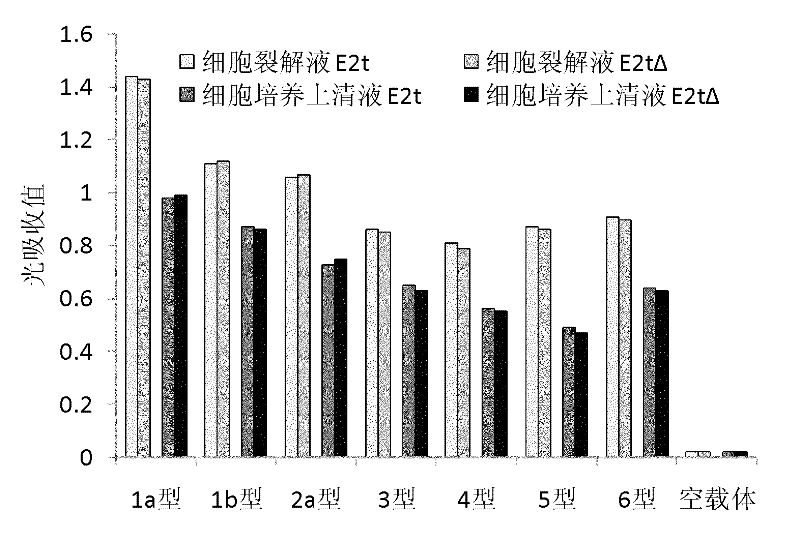

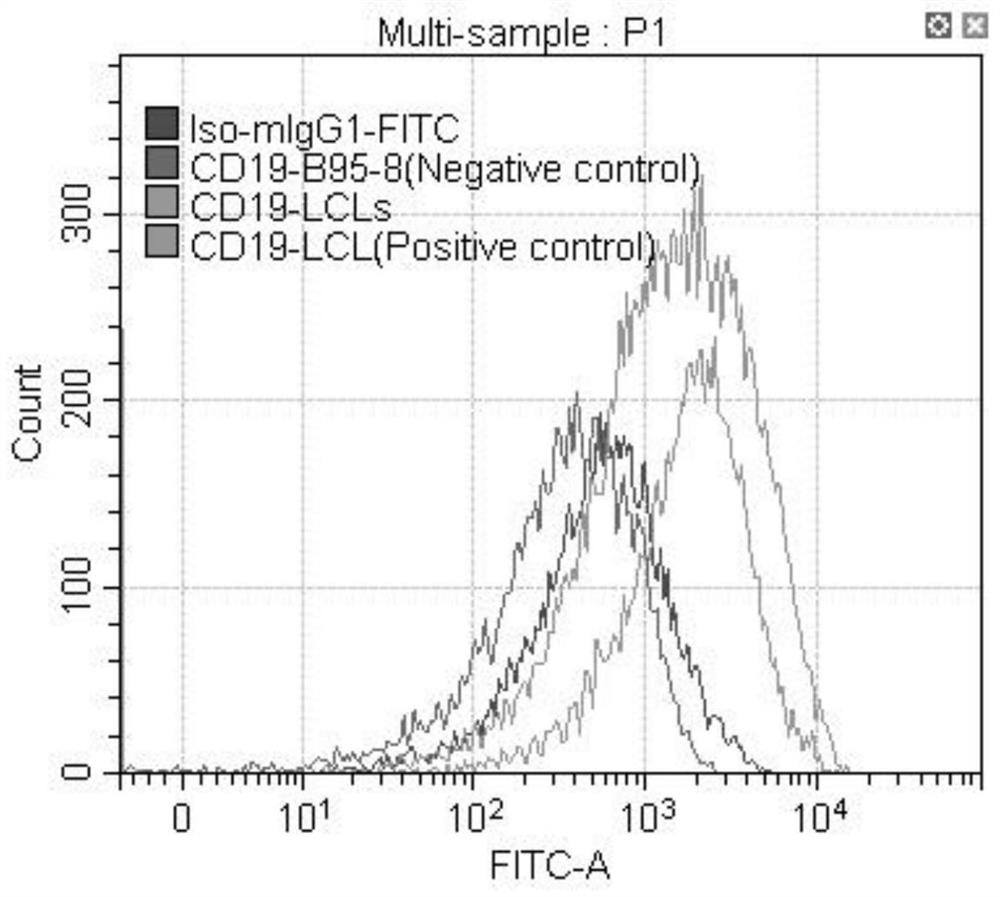

HCV envelope protein E2 with deleting hypervariable region 1 and use thereof

InactiveCN102206256AGood inhibitory effectImmunogenicity suppressionMicrobiological testing/measurementVirus peptidesGenotypeNeutralizing antibody

The invention relates to the technical field of biological engineering. At present, there is no effective vaccine for preventing hepatitis C virus (HCV) infection. The amino terminal of HCV envelope protein E2 has 27 amino acid residues with highest variability, known as hypervariable region 1(HVR1). The invention provides an HCV envelope protein E2 without HVR1, also provides an application of the HCV envelope protein E2 without HVR1 on HCV vaccines and HCV infection immunity diagnostic reagents. Animal immunization tests have discovered that HVR1 in 1-6 genotype HCV envelope protein E2 has substantial inhibition effect against immunogenicity of conservative neutralizing epitope in the envelope protein E2, the effectiveness of inducting broad spectrum neutralizing antibody by the E2 protein is significantly enhanced by deleting HVR1, the HCV envelope protein E2 with deleting HVR1 possibly can be used as an effective target antigen of HCV vaccines. The invention has proved that the HCV envelope protein E2 with deleting HVR1 has strong reaction with E2 antibody in serums of HCV infections and can be used as an immunity diagnostic antigen of HCV infections.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

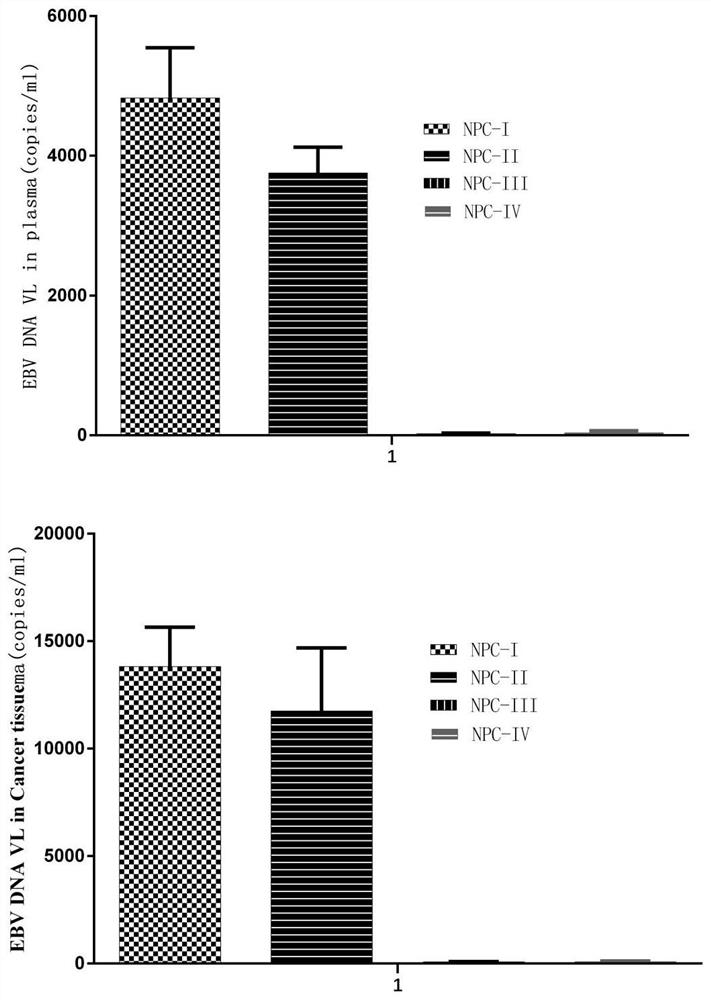

Tumor composite antigen, dendritic cell multivalent vaccine and application of dendritic cell multivalent vaccine

PendingCN114246942AFast evolutionLower immune resistanceAnimal cellsStomach cancer vaccineIn vitro stimulationCancer cell

The invention discloses a tumor composite antigen, a dendritic cell multivalent vaccine and application of the tumor composite antigen and the dendritic cell multivalent vaccine. Dendritic cells of a patient are stimulated in vitro, multiple tumor cell lysates with super immunogenicity aiming at different EBV related tumors are loaded, mature dendritic cells are formed under induction of multiple cell factors and specific agonists, a complete DC vaccine with corresponding cancer antigens is formed, the DC vaccine is transfused back to a human body to activate an immune system, and the EBV related tumors are subjected to tumor immunogenicity. Natural immunity (such as induction of NK cells) is stimulated, lymphocytes are stimulated to generate acquired immune response, cytotoxic T cells are generated to kill cancer cells, and the cancer cells are accurately killed together; compared with radiotherapy and chemotherapy, the composition is particularly safe and almost has no side effect; and the dendritic cell vaccine has a preparation cycle of about 1 week, and is short in time and low in cost.

Owner:刘慧宁 +1

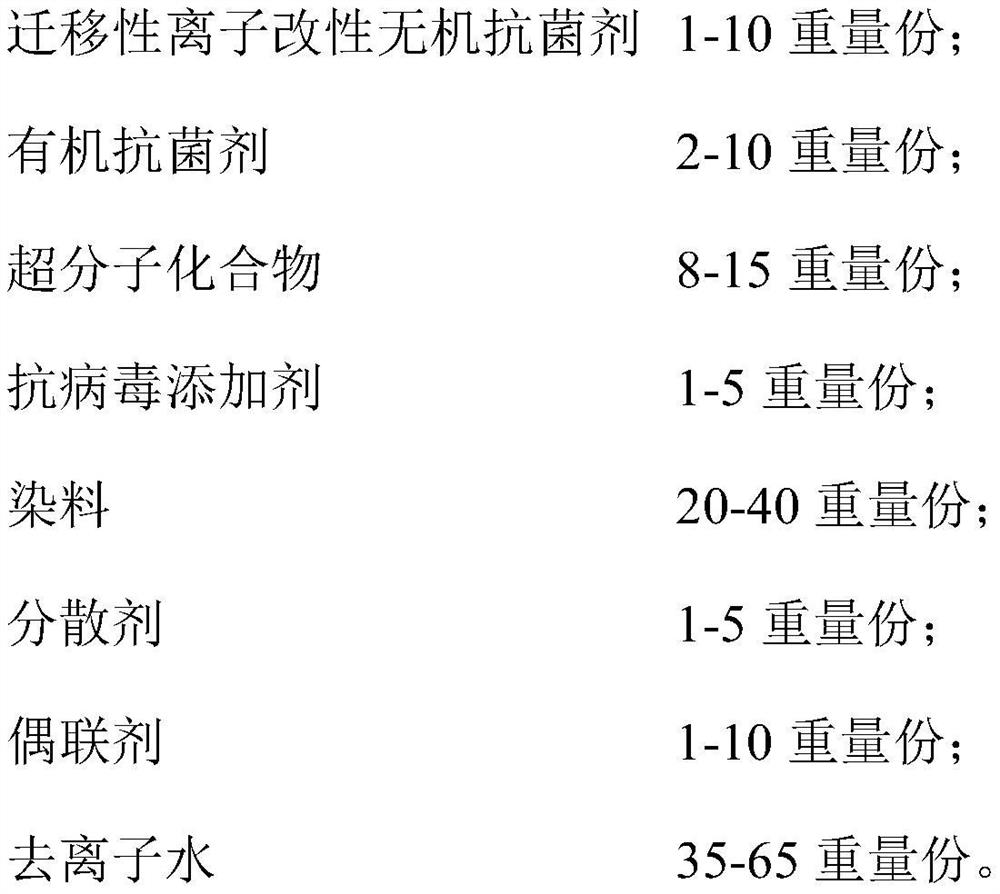

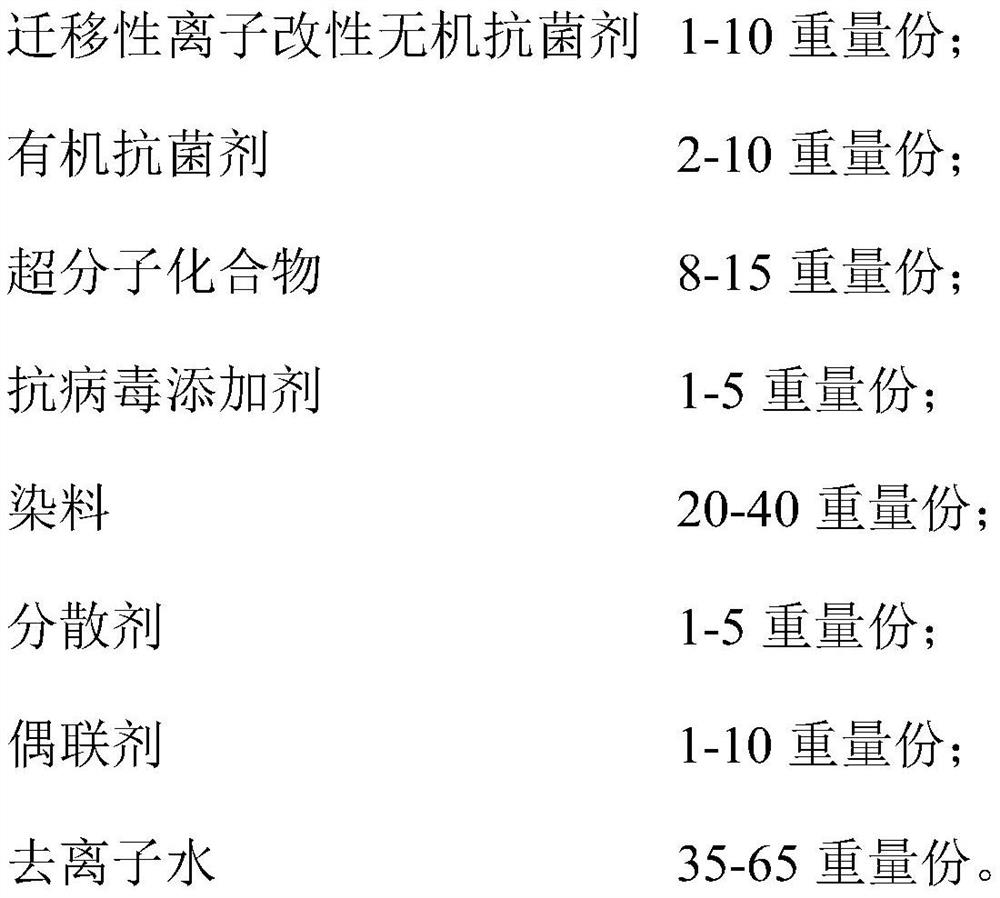

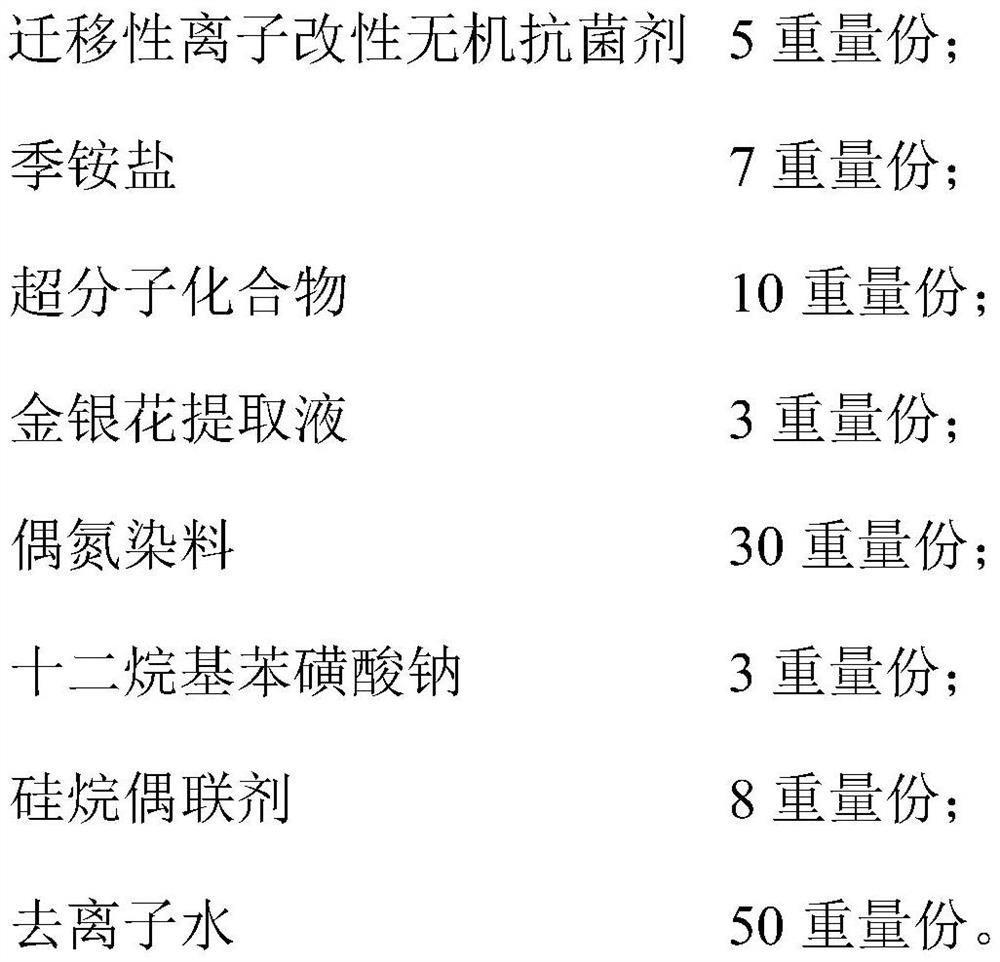

Antibacterial anti-virus dye slurry as well as preparation method thereof and application thereof

PendingCN111607984AImprove the bactericidal effectExcellent anti-virusDyeing processColour fastnessFiber

The invention provides antibacterial anti-virus dye slurry as well as a preparation method thereof and application thereof. The antibacterial anti-virus dye slurry comprises the following components in parts by weight: 1-10 parts of a modified inorganic antibacterial agent, 2-10 parts of an organic antibacterial agent, 8-15 parts of a super-molecular compound, 1-5 parts of an anti-virus additive,20-40 parts of dyes, 1-5 parts of a dispersing agent, 1-10 parts of a coupling agent, and 35-65 parts of deionized water. The dye slurry has better sterilizing, anti-virus and dyeing effects: the modified inorganic antibacterial agent, the organic antibacterial agent and the super-molecular compound are matched for use, so that the sterilizing effect of dye slurry is improved; and in a fiber product dyeing process, sterilizing and anti-virus additives further can be added into a fiber product, so that the fiber product has better color fastness, and better sterilizing and anti-virus ability.

Owner:同曦集团有限公司

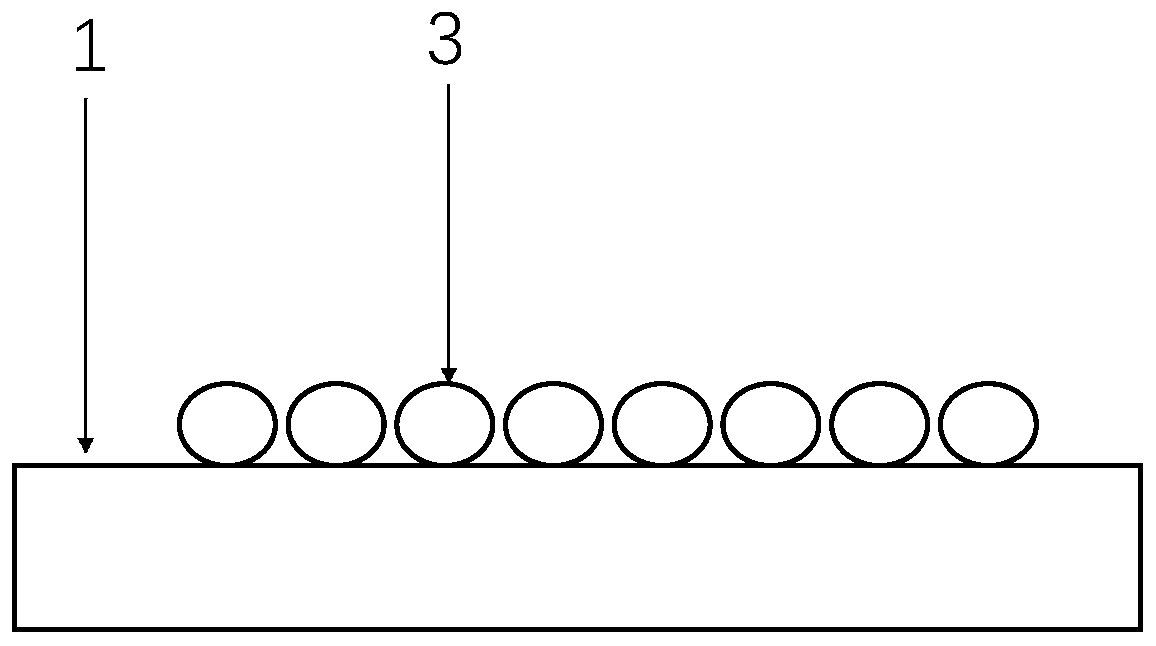

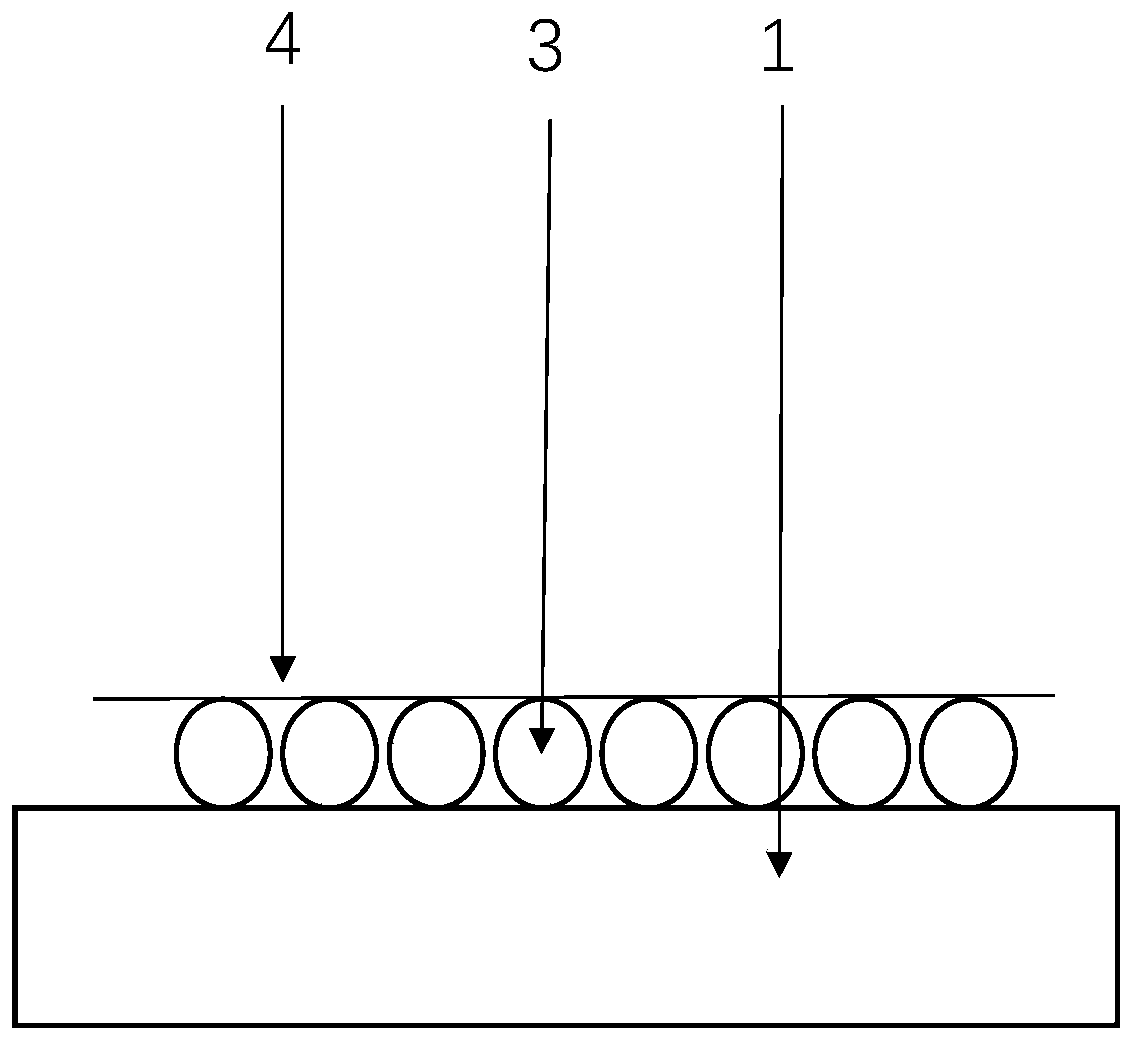

Preparation method of multi-layer metal nanometer structure based on two-dimensional material

ActiveCN110616408AHigh densityReduce gapVacuum evaporation coatingSputtering coatingRepeatabilityParameter control

The invention discloses a preparation method of a multi-layer metal nanometer structure based on a two-dimensional material, and belongs to the field of novel nanometer structure machining. The preparation process of the multi-layer metal nanometer structure mainly comprises the following four steps that (1) an ultra-thin AAO template is transferred to a substrate which is already subjected to hydrophilic treatment; (2) metal is uniformly deposited into a hole of the AAO template according to a sputtering method; (3) the AAO template on the substrate is removed by a tape in a sticking mode, one layer of h-BN is transferred onto the substrate, and then a layer of ultra-thin AAO template is transferred onto the h-BN; and (4) the substrate is placed in sputtering equipment to deposit a layerof metal again, the AAO template is removed, and the third step and the fourth step are repeated to carry out the next-layer nano-particle deposition. The preparation method is simple in process, lowin cost, strong in process repeatability and good in process parameter control. A multi-layer metal nanostructure array with periodicity can be prepared in a large area.

Owner:BEIJING UNIV OF TECH

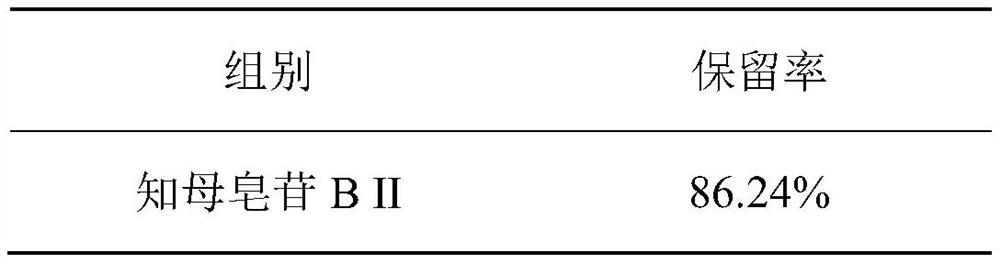

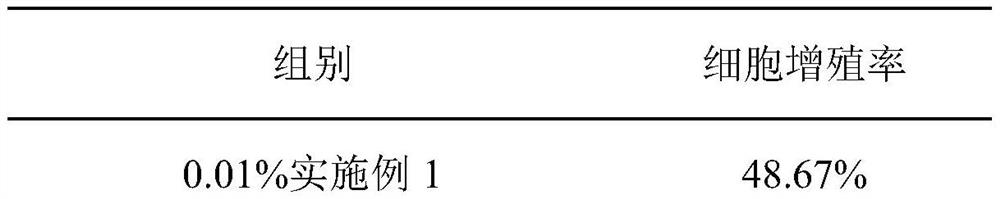

Composition for relieving and repairing skin and application of composition

PendingCN112263522AReduce high responseReduce inflammationCosmetic preparationsToilet preparationsAnemarrhenaPortulaca

The invention discloses a composition for relieving and repairing skin and application of the composition, and aims to provide a plant composition for sensitive skin problems. The composition is simple in formula, has the effects of relieving skin scorching hot stimulation, repairing skin barrier damage and inhibiting skin swelling in a targeted manner, and particularly can enhance the skin barrier repairing function. The composition comprises 40-60 parts of a component A and 10-40 parts of a component B, wherein the component A is prepared from raw material medicines including herba portulacae and radix astragali; and the component B is prepared from rhizoma anemarrhenae.

Owner:广州市中通生化制品有限公司

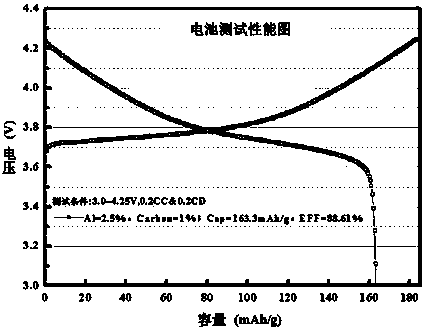

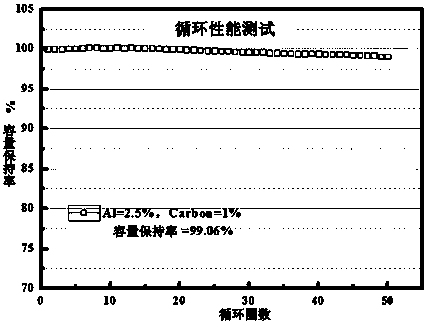

Modified Ni-Co-Mn ternary material and preparation method thereof

InactiveCN109888214AImprove conductivityHigh specific capacityCell electrodesSecondary cellsManganeseLayer thickness

The invention discloses a modified Ni-Co-Mn ternary material. The material is a core-shell structure, and an inner core is aluminum-doped Ni-Co-Mn ternary material, and the shell is a carbon claddinglayer; the mole ratio of the Ni: Co: Mn in the inner core is 8: 1: 1 to 5: 2: 3, the mole ratio of the Al / (Ni+Co+Mn) is 1%-5%, the shell is the carbon-cladding layer with uniform thickness, and the weight of the carbon cladding layer is 0.5%-2% of the total weight of the modified Ni-Co-Mn ternary material. By optimizing the doping amount of the Al and the carbon cladding layer thickness, the material capacity is further improved. The invention further discloses a preparation method of the material at the same time. The material can be used as positive active materials of the lithium primary battery, a lithium secondary battery, a lithium ion secondary battery and like lithium batteries; and the modified Ni-Co-Mn ternary material has excellent electrochemical performances of being high in specific capacity, high in conductivity and good in stability.

Owner:TIANJIN B&M SCI & TECH

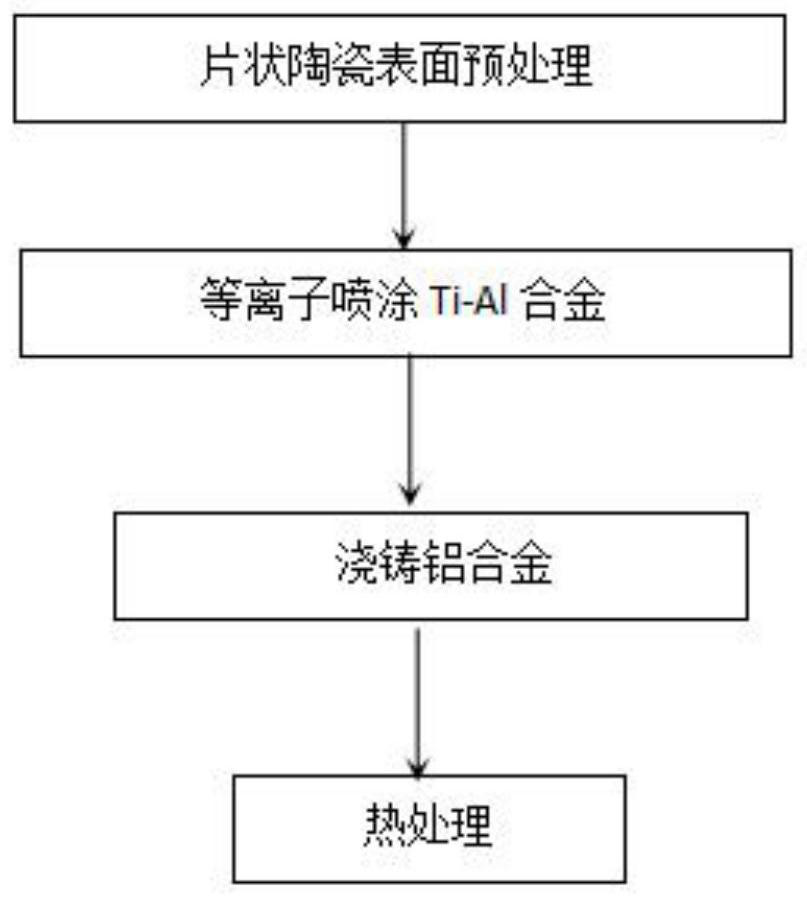

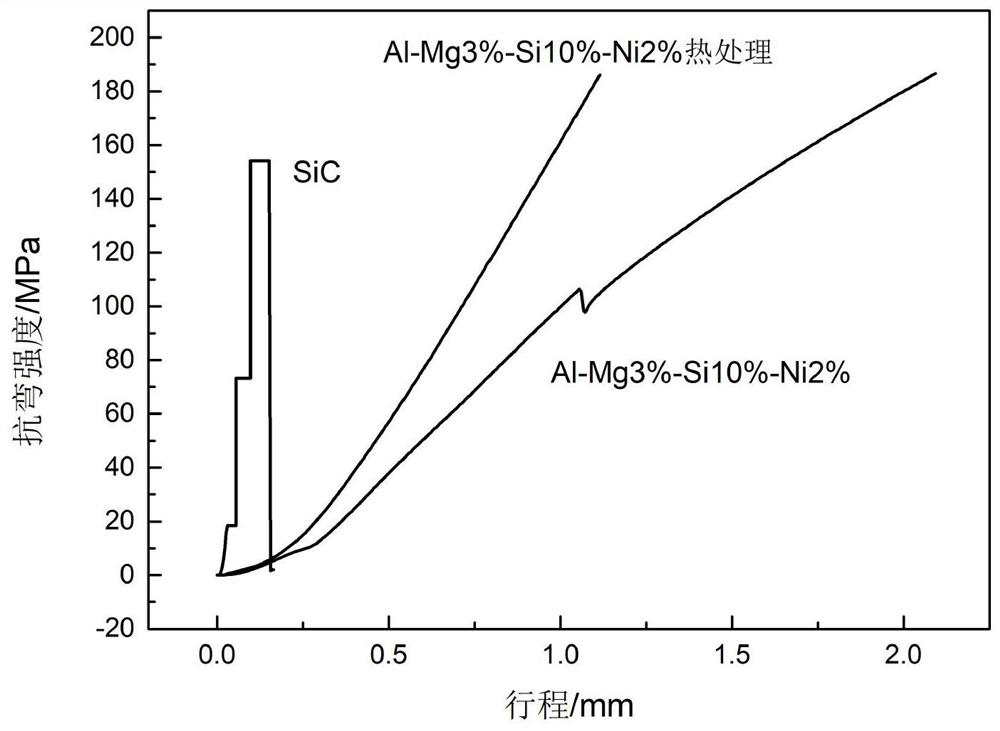

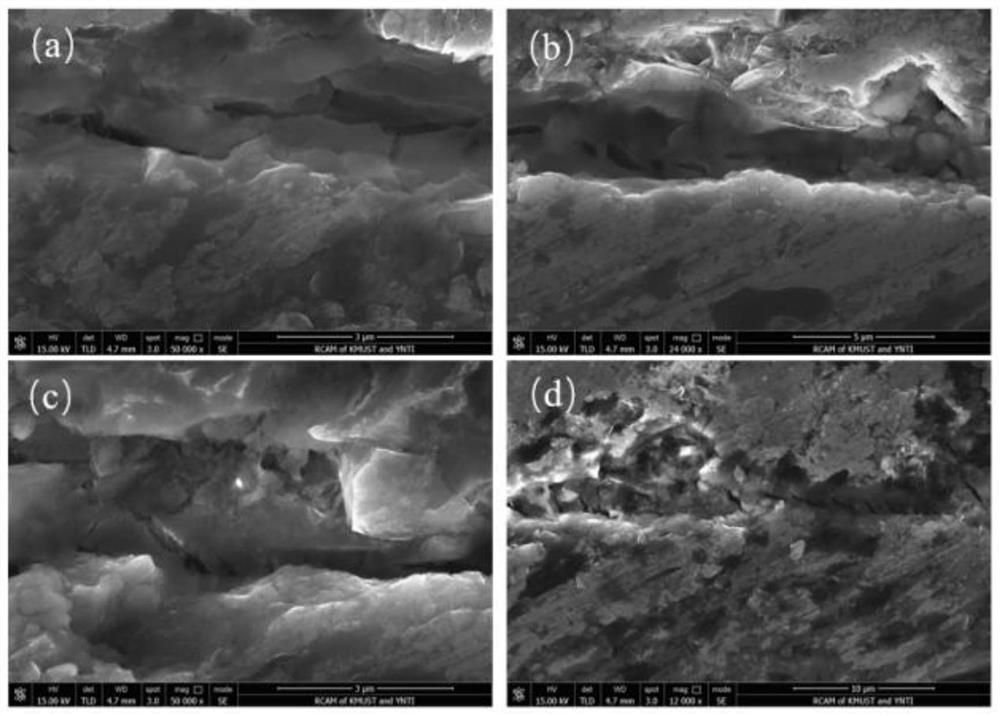

Flaky ceramic/aluminum alloy composite material and preparation method thereof

PendingCN113046677ATightly boundImprove binding propertiesMolten spray coatingFurnace typesCeramicAlloy composite

The invention discloses a flaky ceramic / aluminum alloy composite material and a preparation method thereof, and belongs to the technical field of ceramic-metal connection. The composite material comprises flaky ceramic and an aluminum alloy layer, wherein the flaky ceramic is coated in the aluminum alloy layer; and a Ti-Al alloy transition layer is further arranged between the flaky ceramic and the aluminum alloy layer. The preparation method comprises the steps of plasma-spraying Ti-Al alloy on the surface of the flaky ceramic to form the transition layer, then casting an aluminum alloy, and carrying out heat treatment to obtain the composite material. According to the flaky ceramic / aluminum alloy composite material and the preparation method thereof provided by the invention, the Ti-Al alloy is used as the transition layer for connecting a ceramic chip and the metal aluminum, so that the bending strength and the deformation resistance of the composite material are obviously improved; and meanwhile, the flaky ceramic is packaged in the alloy, the ceramic is tightly fixed in situ due to the existence of the packaging metal, and the broken ceramic cannot be splashed in the using process, so that the ceramic is effectively packaged.

Owner:KUNMING UNIV OF SCI & TECH

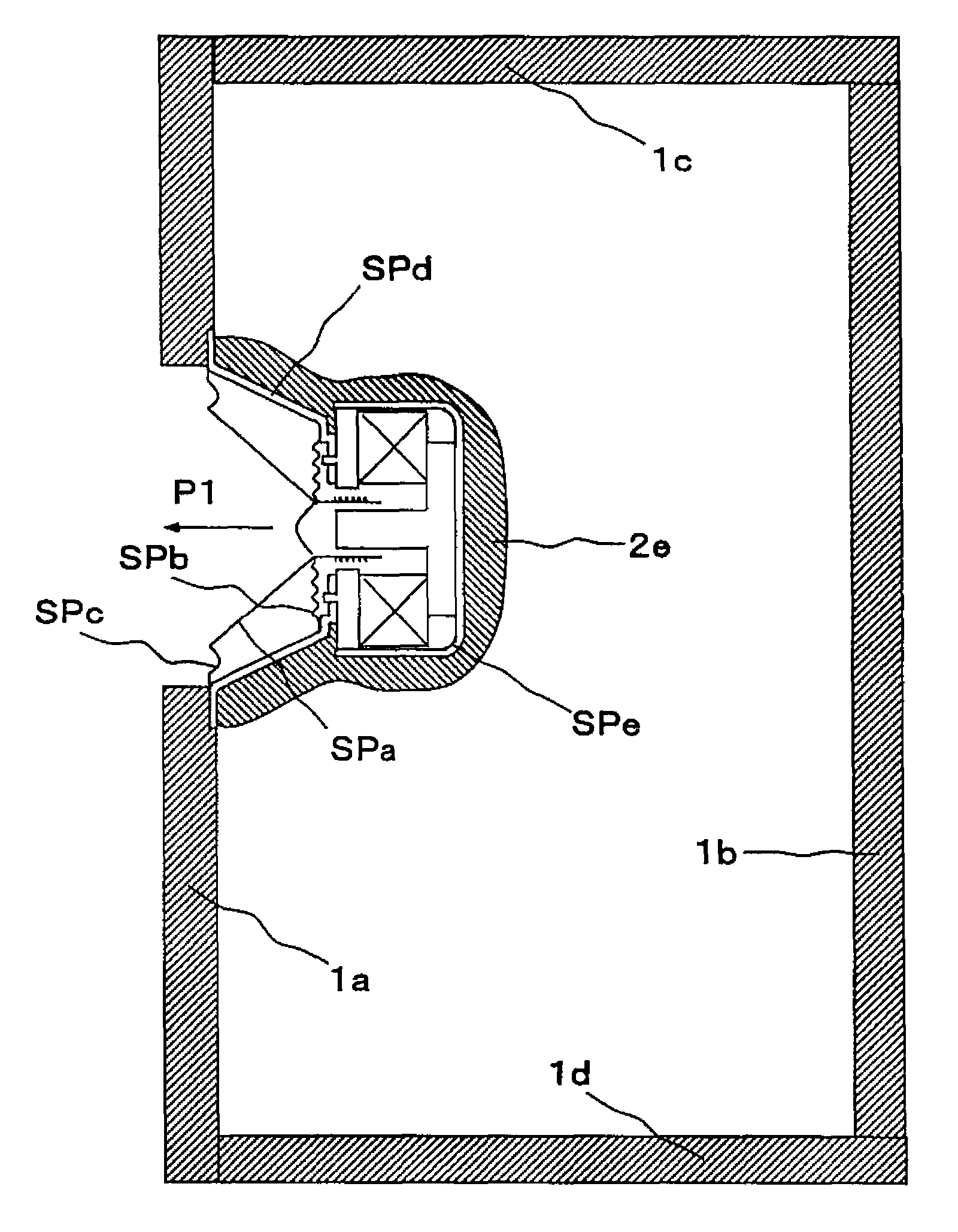

Speaker device

ActiveUS9538269B2Reducing frame vibrationDamping is increasedAdhesivesFrequency/directions obtaining arrangementsEngineeringAcoustic wave

The object of the present invention is that the surplus vibration involved therewith simultaneously generating a sound wave by the vibration of the vibrating cone of the loudspeaker unit is generated in the loudspeaker system, which has impaired the sound quality of the loudspeaker system. The purpose of the present invention is to provide a technique for improving the sound quality by reducing the this surplus vibration which are the loudspeaker frame vibration and the cabinet vibration like a front baffle vibration. The present invention is characterized in being configured with a viscoelastic material layer upon rear portions such as the frame surface of the loudspeaker unit and inside and outside surfaces of each surface configuring the loudspeaker cabinet, and additionally suppresses vibration by addition of a heavy member or pressurization caused by constraint of a binding member.

Owner:NAGAOKA MITSUO

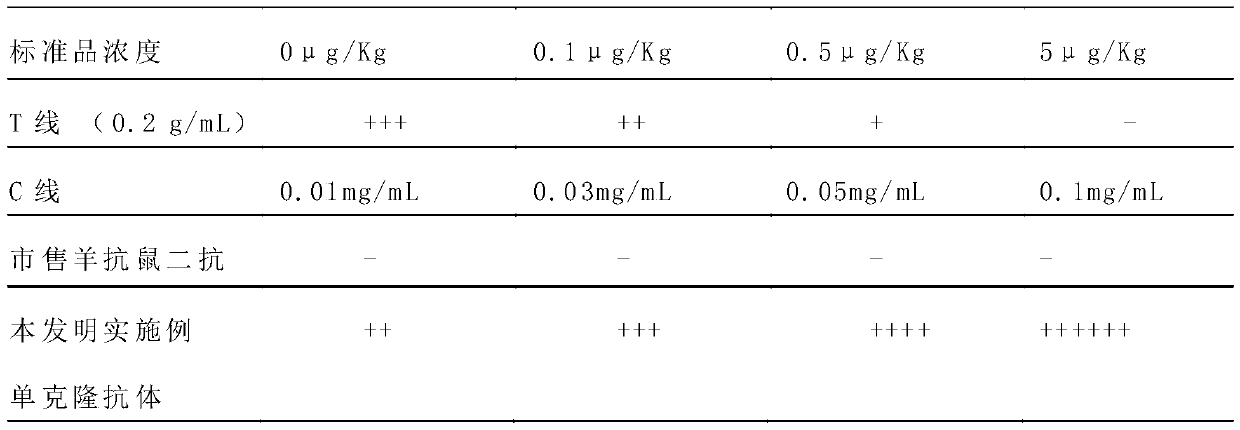

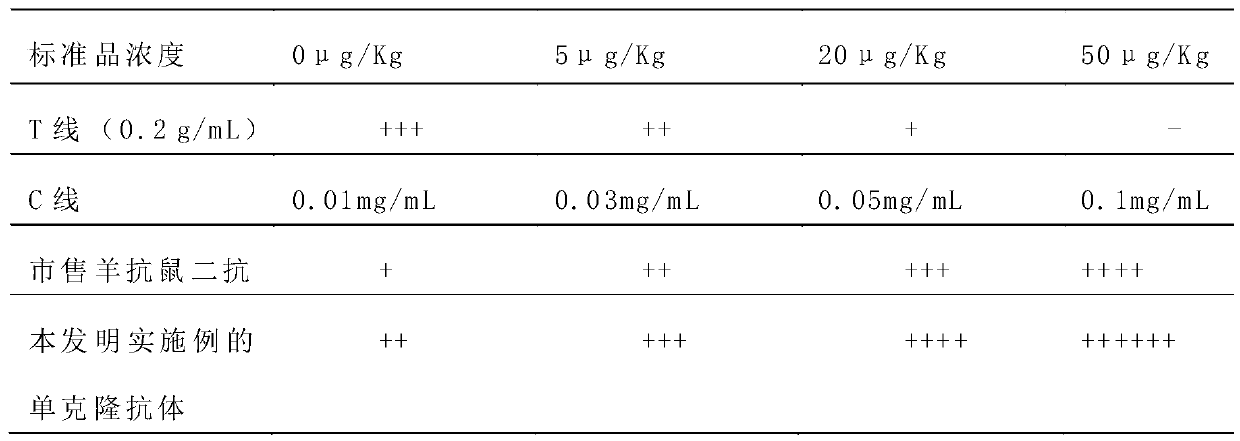

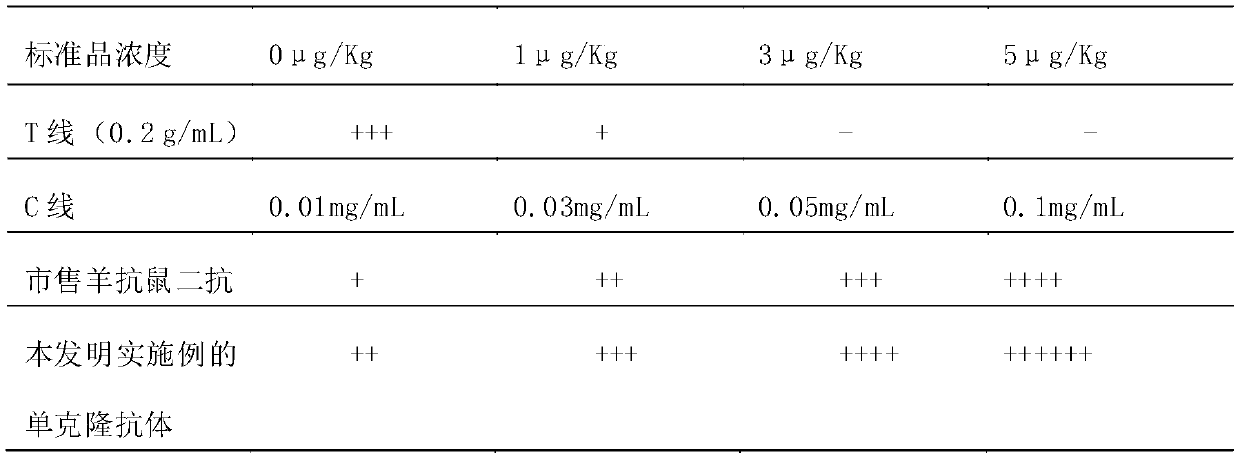

Preparation method of monoclonal antibody for replacing anti-mouse rabbit secondary antibody

ActiveCN110981963AEasy to prepareImprove stabilityImmunoglobulinsMaterial analysisAntiendomysial antibodiesMonoclonal

The embodiment of the invention discloses a preparation method of a monoclonal antibody for replacing an anti-mouse rabbit secondary antibody. The method comprises the steps of using purified rabbit serum as a holoantigen, and carrying out immunoreaction and cell fusion screening to obtain hybridoma cells. The embodiment of the invention provides the preparation method of a mouse non-specific monoclonal antibody, which uses the rabbit serum holoantigen as an immunogen, and obtains the anti-mouse rabbit secondary antibody used for replacing the prior art through immunogen purification, immune procedure, cell fusion, hybridoma screening and cloning, and antibody preparation and purification. The monoclonal antibody prepared by the embodiment of the invention is simple in preparation method,can be produced in batches, is good in stability, can be applied to immunochromatographic detection, is high in titer and strong in reaction, and is suitable for immunochromatographic reactions in various modes.

Owner:SHANDONG LVDU BIO SICIENCE & TECH

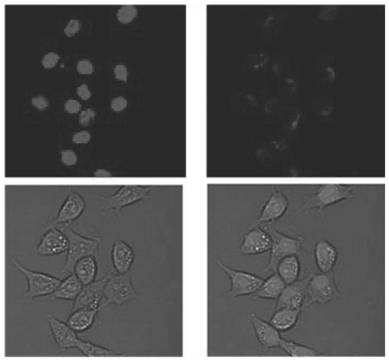

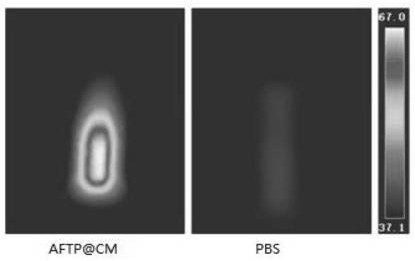

Targeting nanomaterial with cell membrane coated with Au-Fe3O4 as well as preparation method and application of targeting nanomaterial

ActiveCN112791062AGood curative effectGive full play to the therapeutic effectHeavy metal active ingredientsMaterial nanotechnologyCancer cellCell membrane

The invention provides a targeting nanomaterial with a cell membrane coated with Au-Fe3O4 as well as a preparation method and application of the targeting nanomaterial, belonging to the technical field of targeting nanomaterials. The targeting nanomaterial provided by the invention comprises a cancer cell membrane, Au-Fe3O4 nanoparticles, tannic acid and phorbol 12-myristate 13-acetate, wherein the Au-Fe3O4 nanoparticles, the tannic acid and the phorbol 12-myristate 13-acetate are wrapped in the cancer cell membrane. PMA can effectively stimulate cells to generate H2O2 and active oxygen O2 <->, can supplement insufficient H2O2 in cancer cells, and can supplement raw materials for Fenton reaction; the Fe3O4 can be partially decomposed in the presence of the tannic acid to form Fe<2+> and Fe<3+>, Fe<2+> can catalyze H2O2 in the cancer cells to be decomposed into hydroxyl radicals, and TA can promote rapid conversion of Fe<3+> generated by Fe3O4 into Fe<2+>; and meanwhile, Au and Fe3O4 have good photo-thermal conversion efficiency, and can give full play to the therapeutic effect of PTT.

Owner:山东济清科技服务有限公司

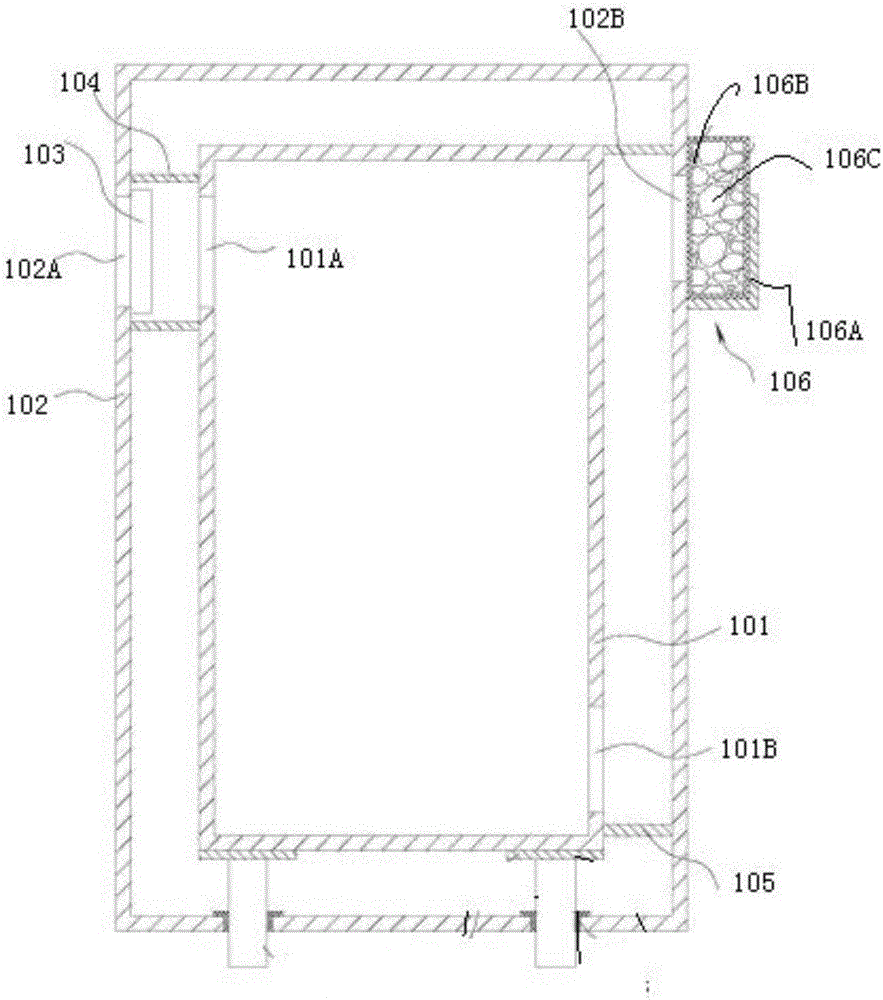

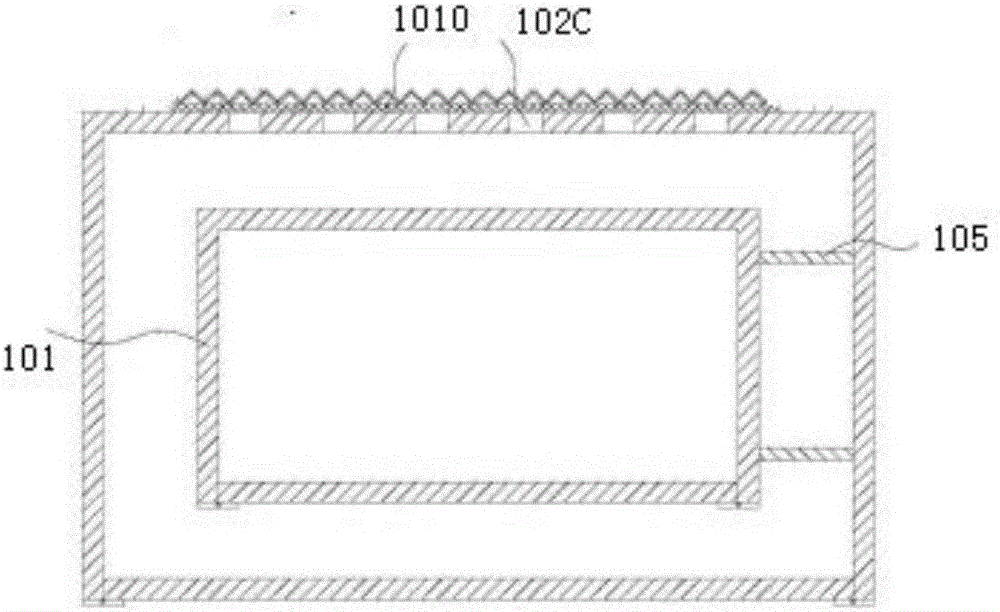

Reinforced cleaning robot

InactiveCN106304726AGood cooling functionEasy to disassembleCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsEngineeringControl circuit

The invention discloses a reinforced cleaning robot. The reinforced cleaning robot comprises a control box, wherein the control box is mounted inside a shell, and control circuits of the robot are all mounted in the control box; the reinforced cleaning robot further comprises a box body, a plastic layer is erected around the outer surface of the box body, a cooling cavity circuit is arranged between the plastic layer and the box body, and a penetrating groove used for exhausting is formed in the top on one side of the box body; an accommodating room for accommodating an air intake machine is erected inside the box body; the intake machine is erected in the accommodating room, and a cut-through air supply hole is formed in the lower end of the accommodating room, and communicated with an air guiding passage; the reinforced cleaning robot disclosed by the invention effectively avoids the defects of risks caused by low refrigerating efficiency and easy penetration of external liquids into the box body during invasion of the external liquids and harm on humidity increase and looseness because the box body is difficult to be connected firmly.

Owner:汤在英

Electromagnetic induction metal screening equipment

PendingCN110116049AStrong influenceStrong reactionCleaningMagnetic separationNonferrous metalMetallic materials

The invention relates to the field of nonferrous metal recovery, in particular to the recycling of metal after the disassembly and breakage of waste and old articles, and specifically relates to electromagnetic induction metal screening equipment. The electromagnetic induction metal screening equipment disclosed by the invention adopts a conveying classified screening mode, and achieves the targeted screening of non-ferrous metals easy to magnetize, non-ferrous metals not easy to magnetize and other non-metallic materials by adopting the eddy current electromagnetic induction technology. The equipment employs a special chain plate conveying device, completes the screening of materials in the conveying process, automatically classifies the materials into different material piles in the falling process, and completes the screening work of different kinds of materials, thereby greatly improving the screening efficiency. Moreover, the metals not prone to being magnetized are separated, theseparation kinds are increased, and the later sorting procedure is reduced.

Owner:ANYANG INST OF TECH +1

Preparation of highly sensitive 2,4-dinitrophenylhydrazine

The invention relates to a preparation method of 2,4-dinitrophenylhydrazine, and concretely relates to a preparation method of highly sensitive 2,4-dinitrophenylhydrazine. The purpose of the invention is to solve the problems of high impurity content, low sensitivity and unable meeting of detection needs of a tiny amount of aldehyde ketone of 2,4-dinitrophenylhydrazine prepared through present 2,4-dinitrophenylhydrazine preparation methods, and high preparation cost of the present preparation methods. The method concretely comprises the following steps: adding 2,4-dinitrochlorobenzene, 1.6-1.7 times ethanol with the concentration of 95% and active carbon into a flask with three necks and with the capacity of 20L; pouring the obtained filtrate into a flask with three necks and with the capacity of 20L, and adding a hydrazine hydrate solution having a same amount to 2,4-dinitrochlorobenzene; continuously refluxing for 1-2h, and stopping refluxing when red crystals precipitate; and washing the red crystals by hot ethanol 1-3 times, and drying the washed crystals at 60-80DEG C. The preparation method can be used in the field of chemical reagents.

Owner:TIANJIN GUANGFU TECH DEV

Method of water-based vulcanized adhesive for shoes

InactiveCN110358475AStrong cohesion and adhesionGood initial tackNatural rubber adhesivesPolyureas/polyurethane adhesivesRosinChemistry

The invention relates to the technical field of water-based vulcanized adhesive for shoes, in particular to a method of water-based vulcanized adhesive for shoes. The method comprises the following steps: S1, selecting raw materials of the water-based vulcanized adhesive for shoes: natural latex, an emulsifier, water-based rosin terpene resin, a thickening agent, a stabilizer, a novel ammonia-freepreservative and water-based polyurethane resin; and S2, after selecting the raw materials of the water-based vulcanized adhesive for shoes, weighing 100 parts of natural latex according to parts byweight. Through design, the water-based polyurethane resin has the characteristics of strong cohesion and adhesive power after being solidified by adding a solidifying agent and no pollution, the natural latex has the characteristics of high initial adhesion property and good film formation, the natural latex takes ammonia water as preservative, the ammonia water reacts with a water-based isocyanate solidifying agent added by the water-based polyurethane strongly, ammonia in the natural latex is removed, aids are added to physically blend the water-based polyurethane and the improved natural latex, and a stable water-based vulcanized adhesive product with high mechanical water property is obtained.

Owner:广州泽远实业股份有限公司

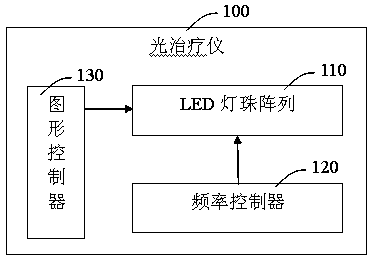

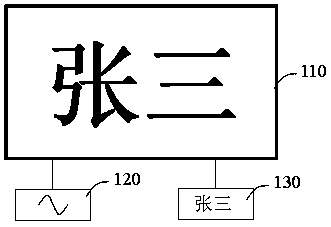

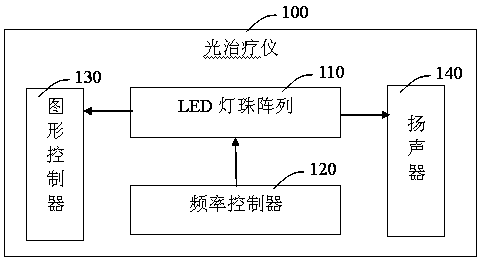

A light therapy device based on LED lamp bead array

Owner:GUIZHOU MINZU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com