Biphase rectification flue gas desulfurization technique

A desulfurization process and two-phase rectification technology, applied in the field of desulfurization, can solve problems such as uneven distribution of flue gas, excessive pressure drop in the absorption tower, uneven flow field in the tower, etc., and achieve energy saving and consumption reduction device costs and maintenance costs, Reduced device cost and maintenance cost, quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

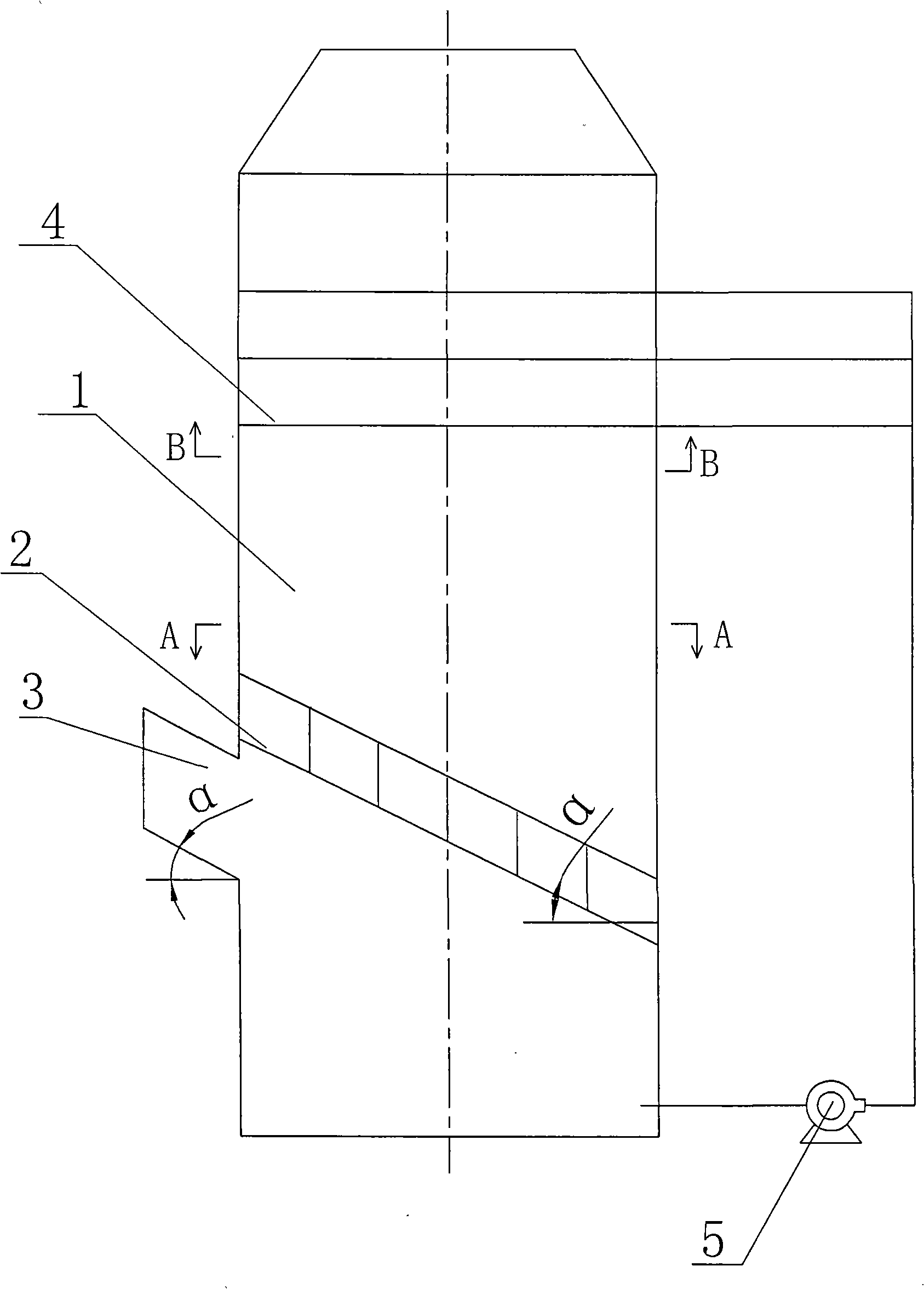

[0020] Such as figure 1 , figure 2 , image 3 As shown, a two-phase rectification flue gas desulfurization process is carried out as follows:

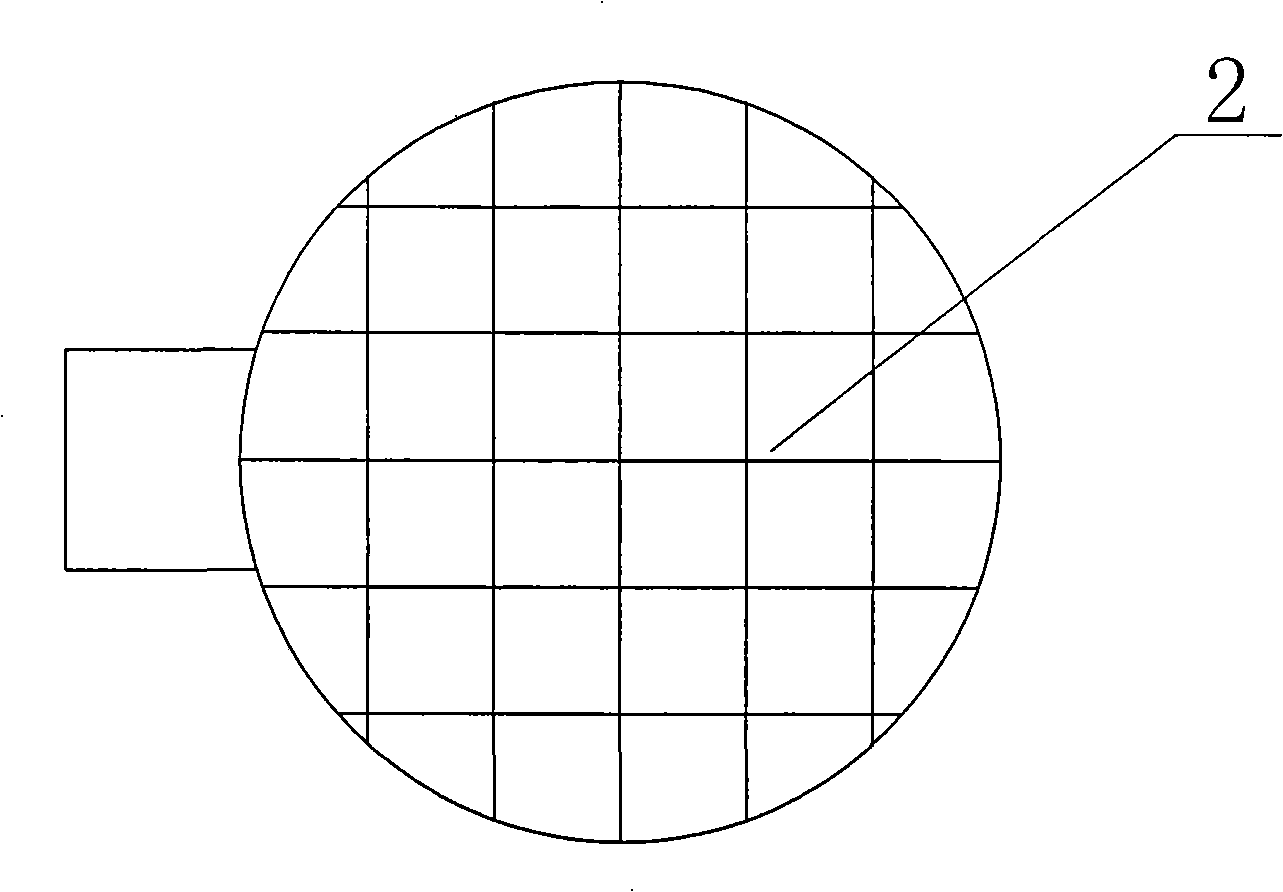

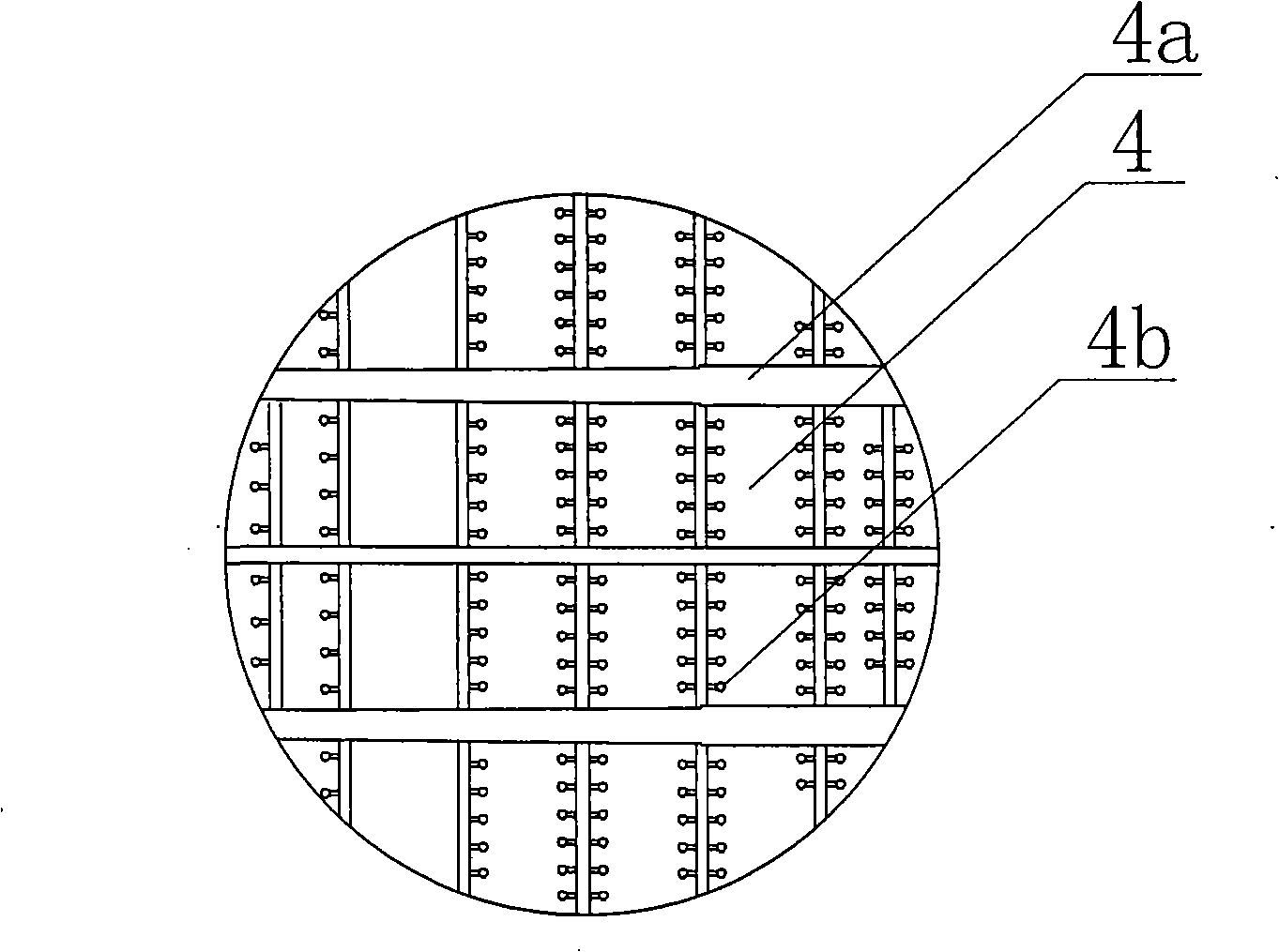

[0021] Step 1, install an absorption tower, and a flue 3 is arranged on the lower side wall of the absorption tower 1. The flue 3 is inclined downward, and the axis line of the flue 3 is at an angle α with the horizontal plane. In the absorption tower 1 A grid-shaped rectifying plate 2 is arranged obliquely, the highest point end of the grid-shaped rectifying plate 2 is close to the air inlet of the flue 3, and is located above the air inlet of the flue 3, and the lowest point is located at the air inlet of the flue 3 On the inner wall of the absorption tower 1 at the opposite end of the air inlet, the axis line of the rectifying plate 2 is parallel to the axis line of the flue 3, and the grid line in the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com