Ceramic coated metal material and production method thereof

A technology of metal materials and manufacturing methods, applied in the direction of electrolytic coating, anodic oxidation, surface reaction electrolytic coating, etc., can solve the problems of limitation and no consideration, achieve stable formation, improve uniformity, improve uniformity and quality stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

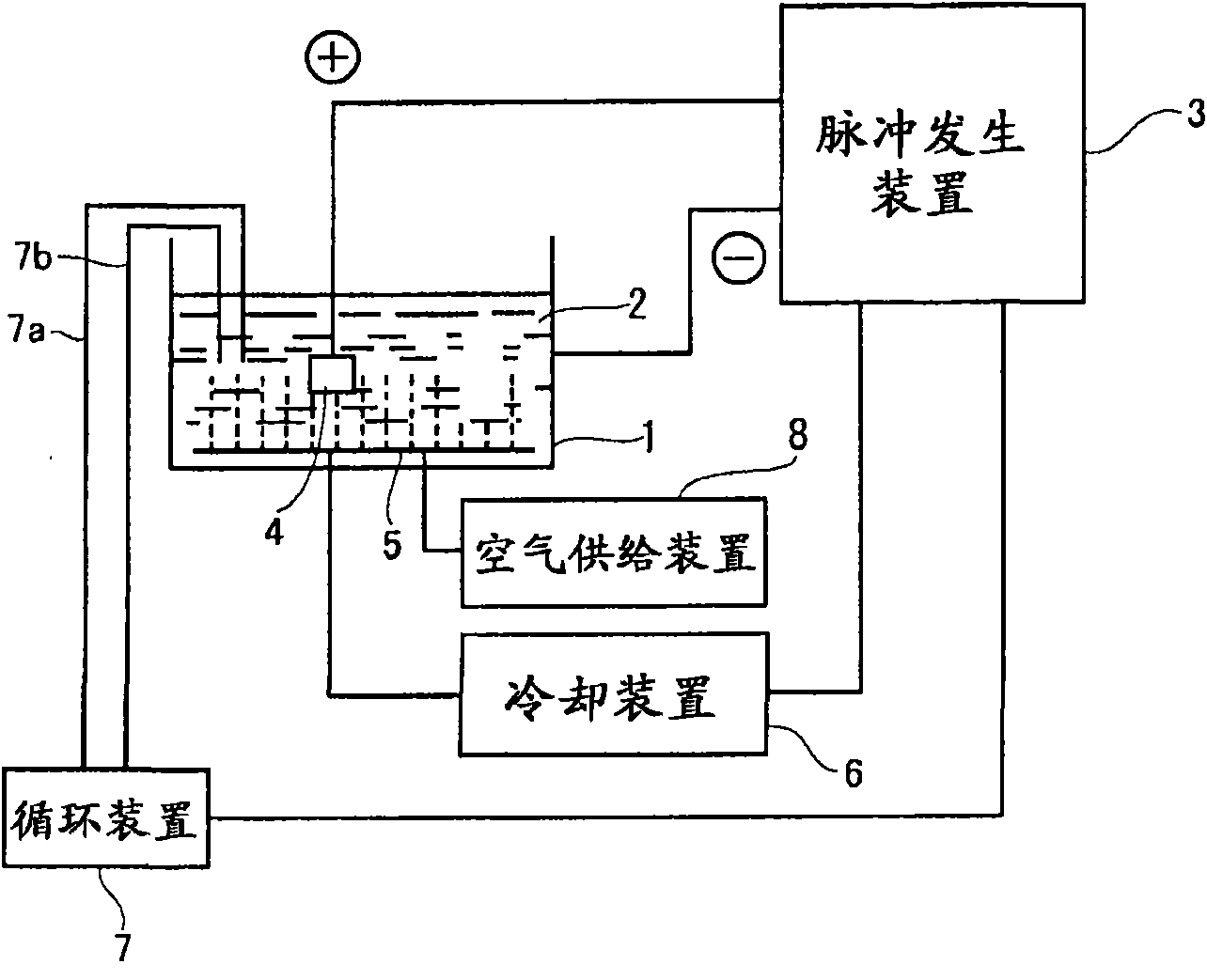

[0042] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings, but before that, an apparatus configuration for carrying out the method for manufacturing a ceramic-coated metal material of the present invention will be described.

[0043] Such as figure 1 As shown, an electrolytic solution 2 obtained by stirring and mixing at least an alkali metal hydroxide, an alkali metal silicate, and an alkali metal polyphosphate is stored in a bathtub-shaped electrolytic tank 1 . Examples of the alkali metal hydroxide used in the electrolytic solution 2 include NaOH and the like in addition to KOH which is particularly suitably used. In addition, water glass (Na 2 SiO 2 ). On the other hand, as the alkali metal polyphosphate, for example, Na 4 P 2 o 7 、Na 2 PO 4 、Na 6 P 6 o 18 One or both of these.

[0044] Such an electrolytic solution 2 is prepared by dissolving the above-mentioned components in distilled or deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com