Preparation method of multi-layer metal nanometer structure based on two-dimensional material

A two-dimensional material and multi-layer metal technology, which is applied in the direction of metal material coating technology, nanotechnology, coating, etc., can solve the problems of inability to process sub-nanometer gaps and small structure density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

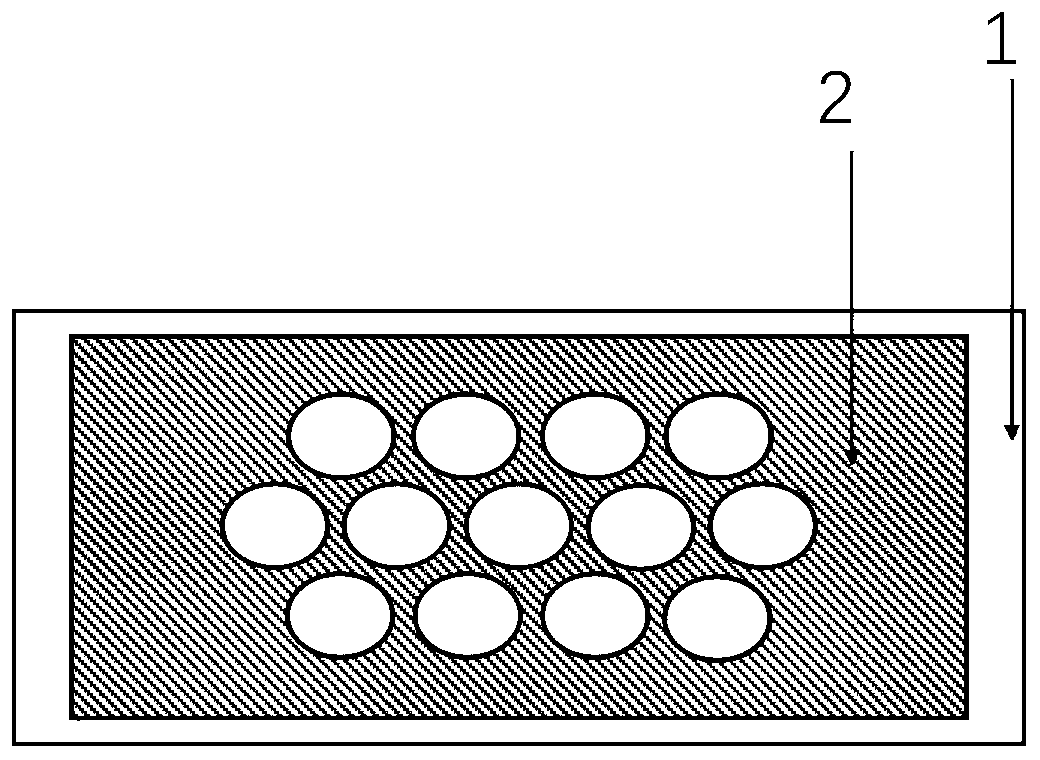

[0016] Using the method proposed by the present invention to prepare a multi-layer sub-nanometer gap metal nanostructure using an AAO template, the specific implementation is as follows:

[0017] S1. Soak the ultra-thin AAO template in acetone solution for 15 minutes to remove the PMMA support layer.

[0018] S2. Put the Si sheet into the sulfuric acid hydrogen peroxide solution and heat it for 2 minutes for hydrophilic treatment to prevent the AAO template from sticking to the Si sheet.

[0019] S3. Transfer the AAO film to clean water with a transfer Si sheet to clean away the residual acetone, and the surface tension of the water will make the AAO film float on the water surface for easy transfer to the substrate.

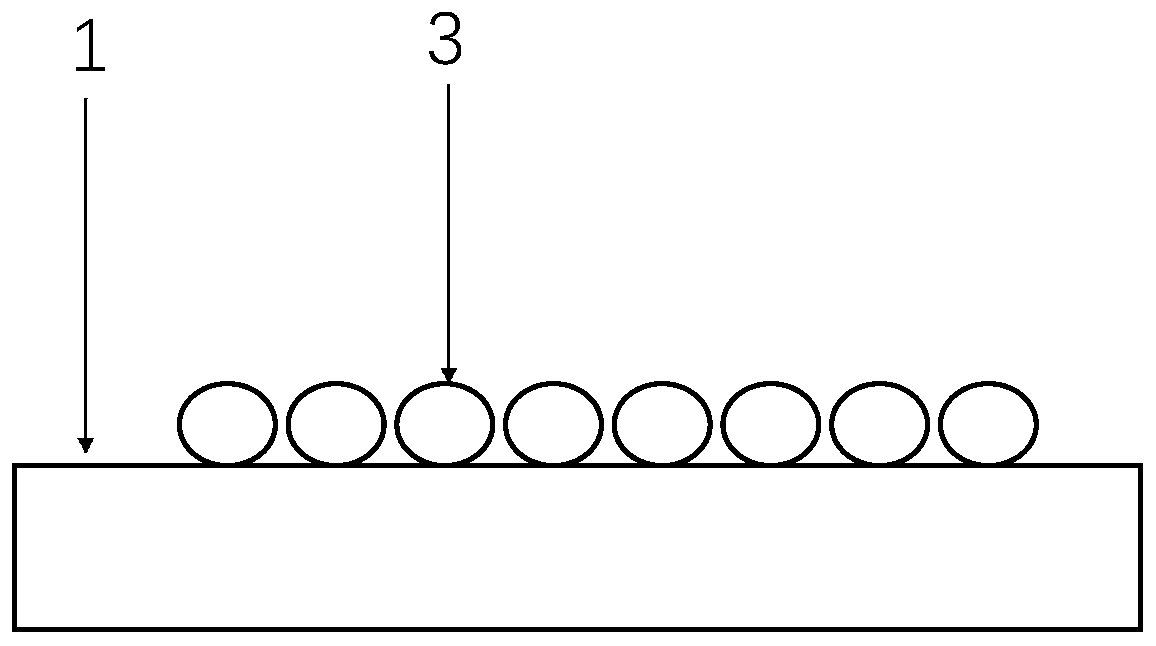

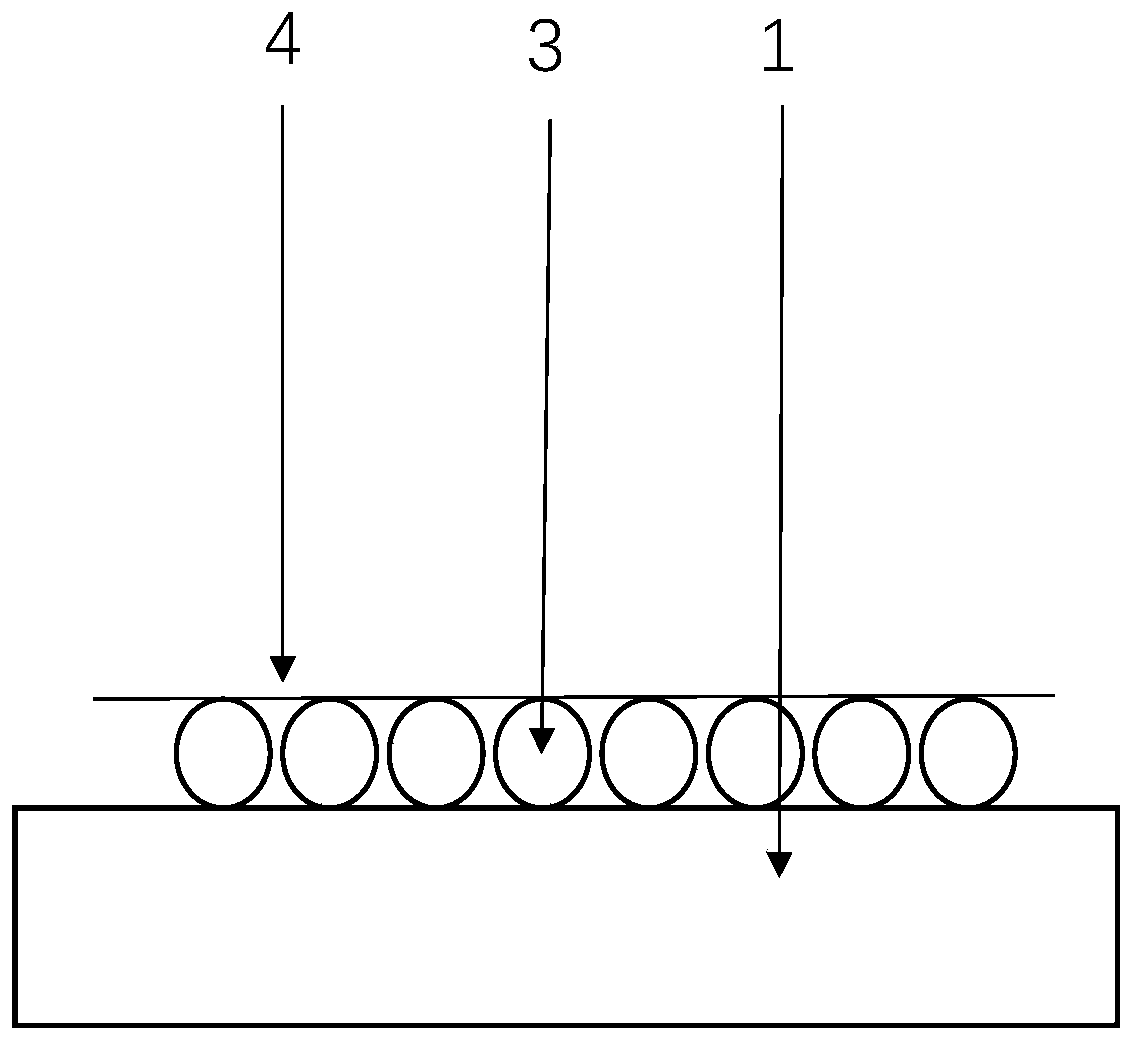

[0020] S4. Use the substrate to pick up the AAO film from the water, dry it, and put it into a metal sputtering device to sputter the metal film.

[0021] S5. Stick the AAO film with tape and tear it off. Since the thickness of the metal is much smaller than th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com