System and method for efficiently removing sulfur oxide in ship waste gas

A technology of sulfur oxides and waste gas, which is applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of low desulfurization efficiency, achieve the effects of improving desulfurization efficiency, reducing occupied space, and reducing system energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

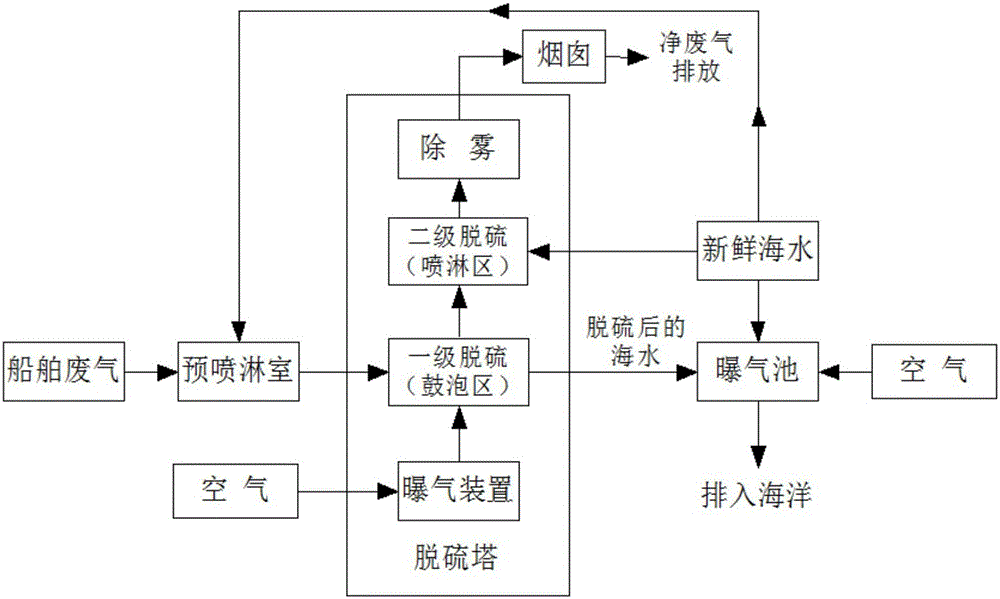

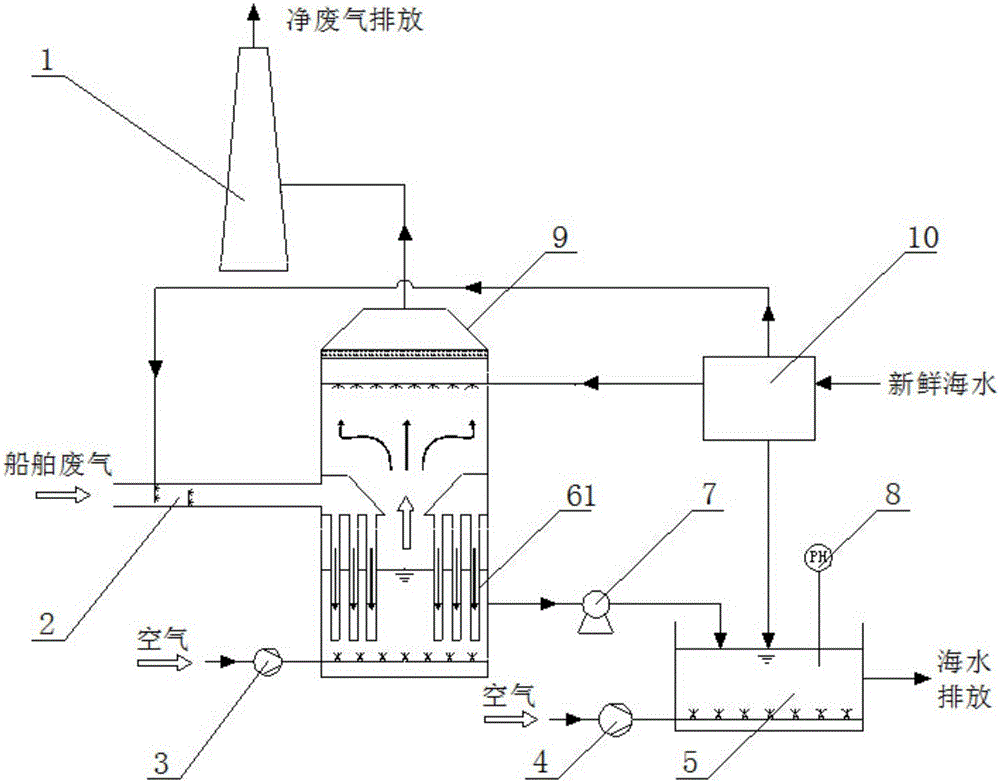

[0048] Such as figure 2 Shown is a system schematic diagram of an embodiment of the method for efficiently removing sulfur oxides from ships of the present invention. The system of this embodiment includes a fresh seawater pool 10, an aeration tank 5, a pre-spray chamber 2, a desulfurization tower 9, and a fresh seawater pool 10 The aeration tank 5, the pre-spray chamber 2 and the desulfurization tower 9 are respectively connected, and the fresh seawater pool 10 is connected with the upper part of the desulfurization tower 9; the pre-spray chamber 2 is connected with the exhaust gas outlet of the ship, and is connected with the desulfurization tower 9 through a pipeline, and the desulfurization The lower part of the tower 9 is a seawater bubbling area, in which a gas distribution pipe is arranged, and the bottom of the gas distribution pipe is connected to the first aeration fan 3, and the bottom of the desulfurization tower 9 is also connected to the aeration tank 5 through t...

Embodiment 2

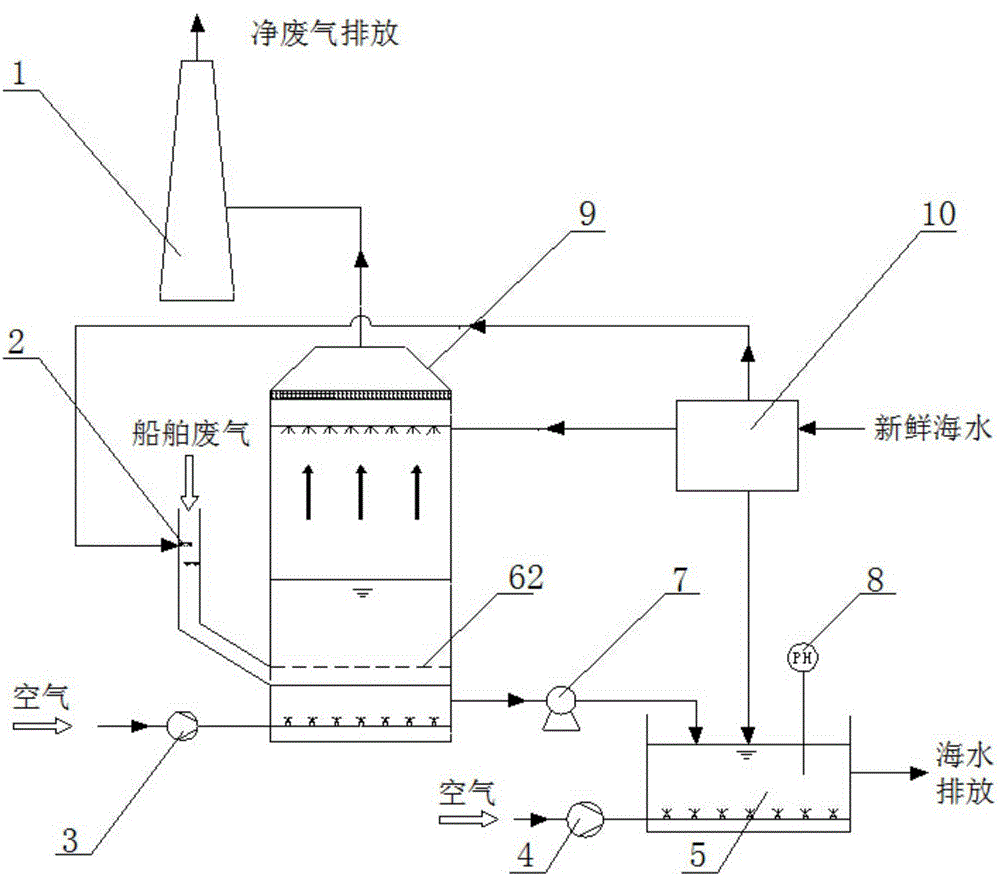

[0063] Such as image 3 Shown is a schematic diagram of another embodiment of the method for efficiently removing sulfur oxides in ships according to the present invention. The difference from Embodiment 1 is that the bubbling method of this embodiment adopts coil bubbling, and the coil 62 is completely immersed in the seawater liquid surface Below, the exhaust gas inlet pipeline is arranged vertically, and the rest of the system and desulfurization steps are consistent with those in Example 1. The desulfurization efficiency of this embodiment can reach more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com