Patents

Literature

32results about "Refining with halogen compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

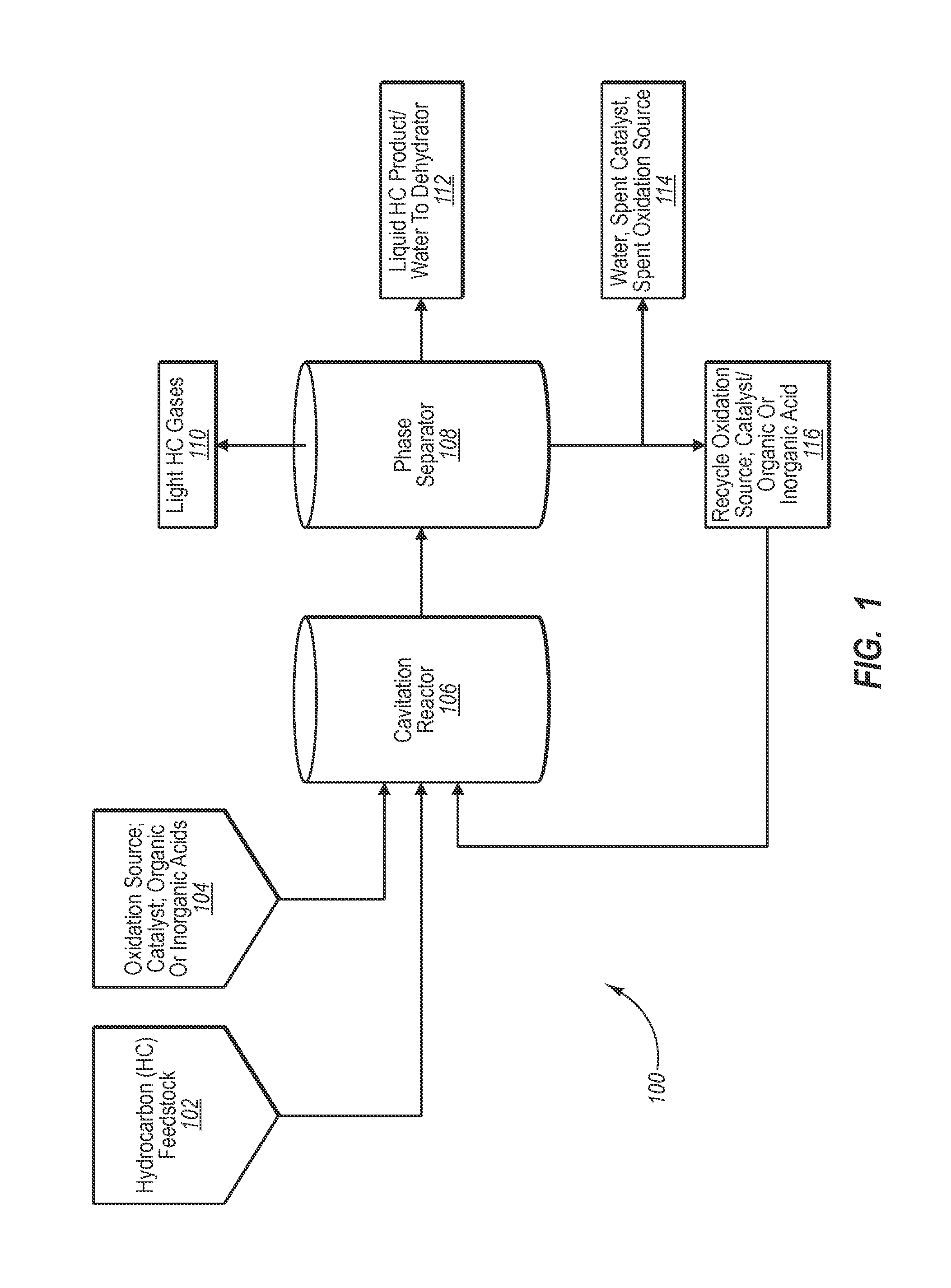

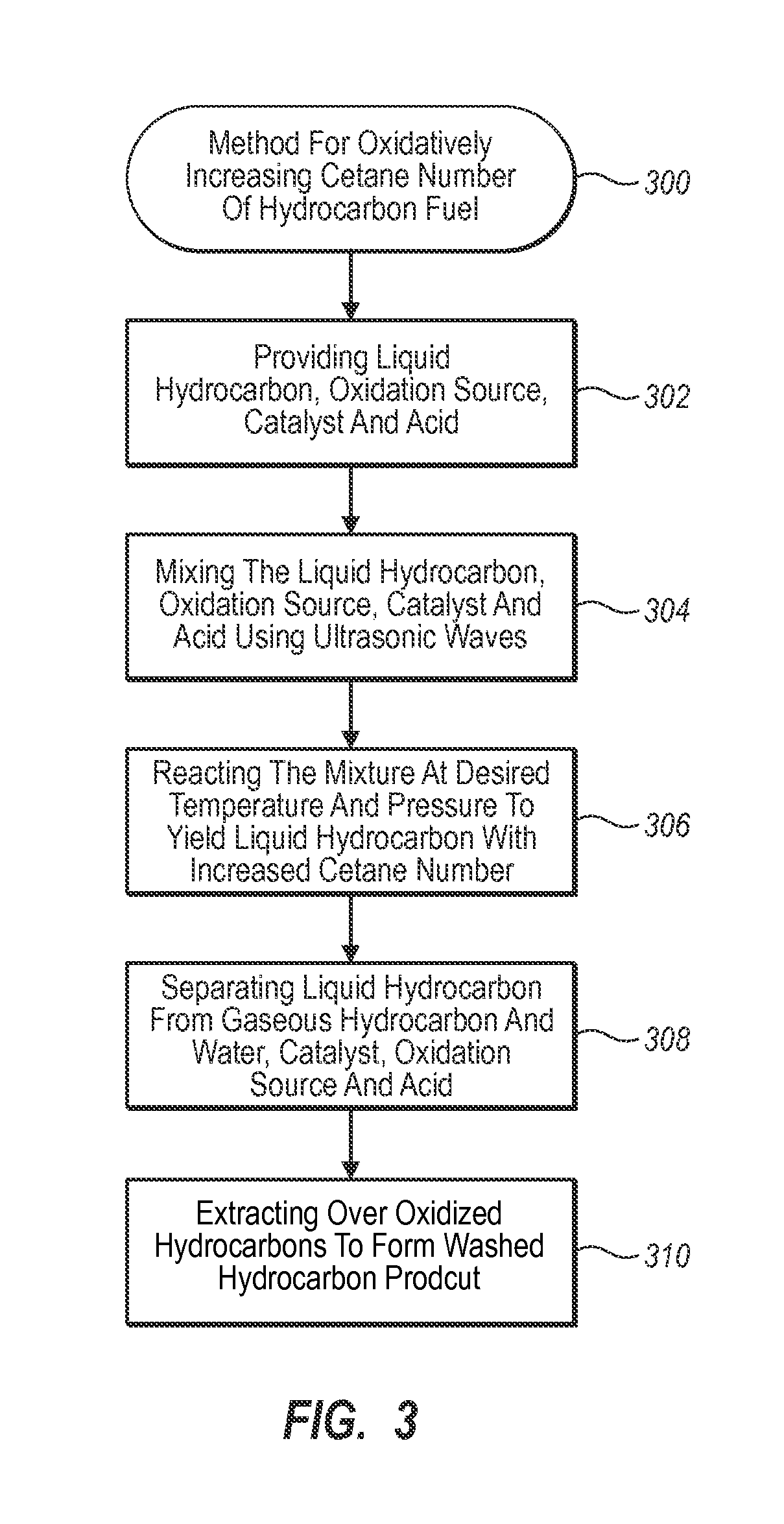

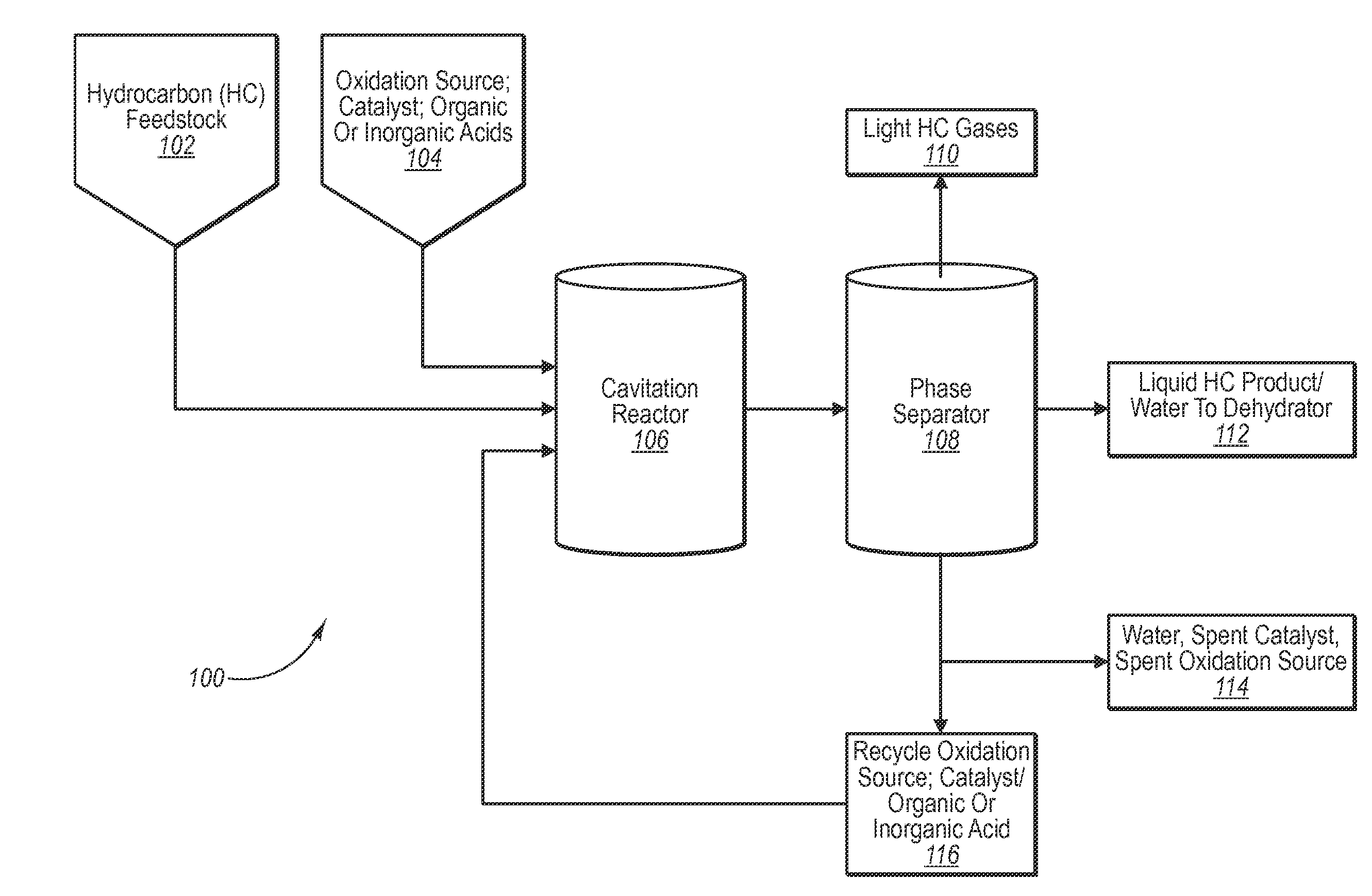

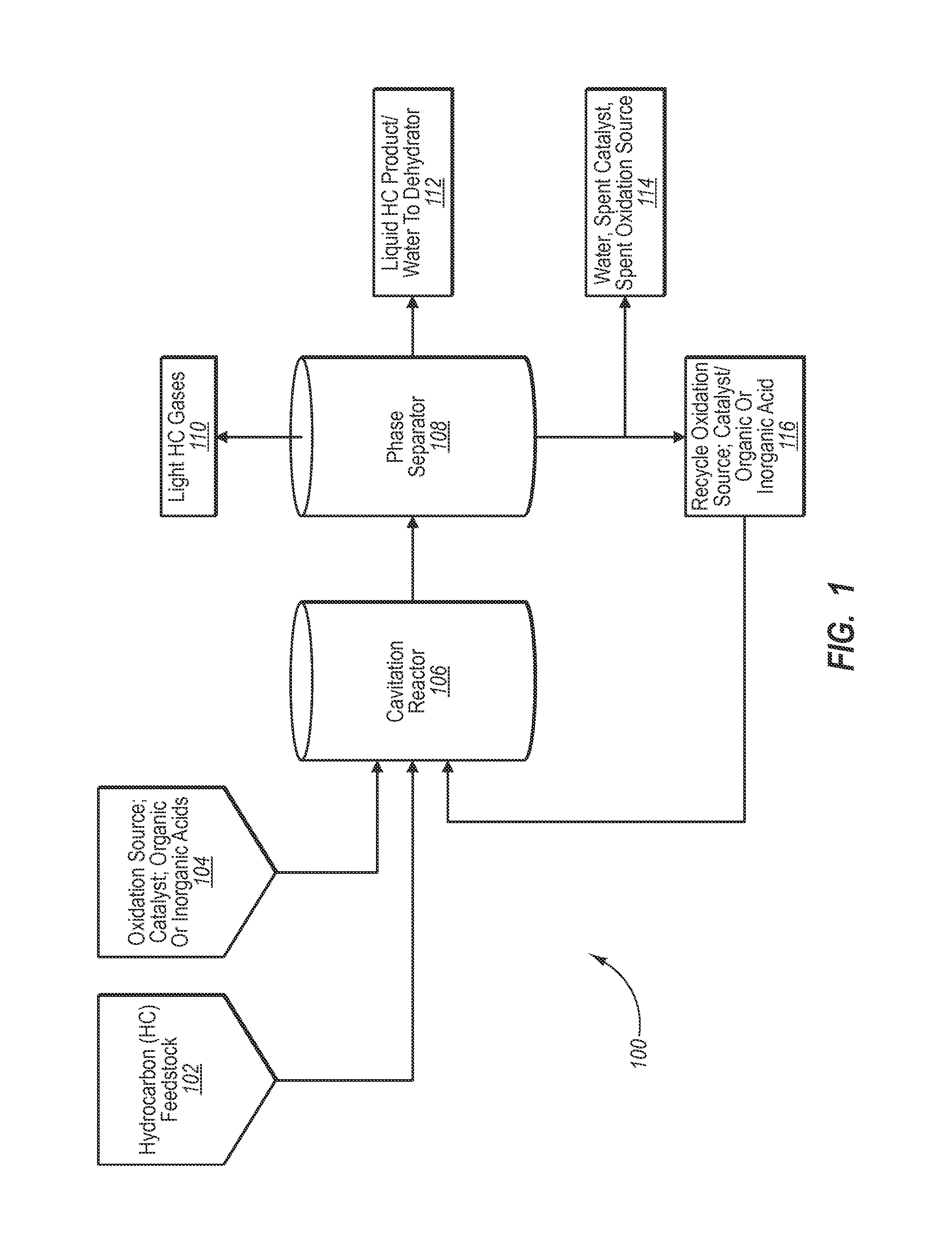

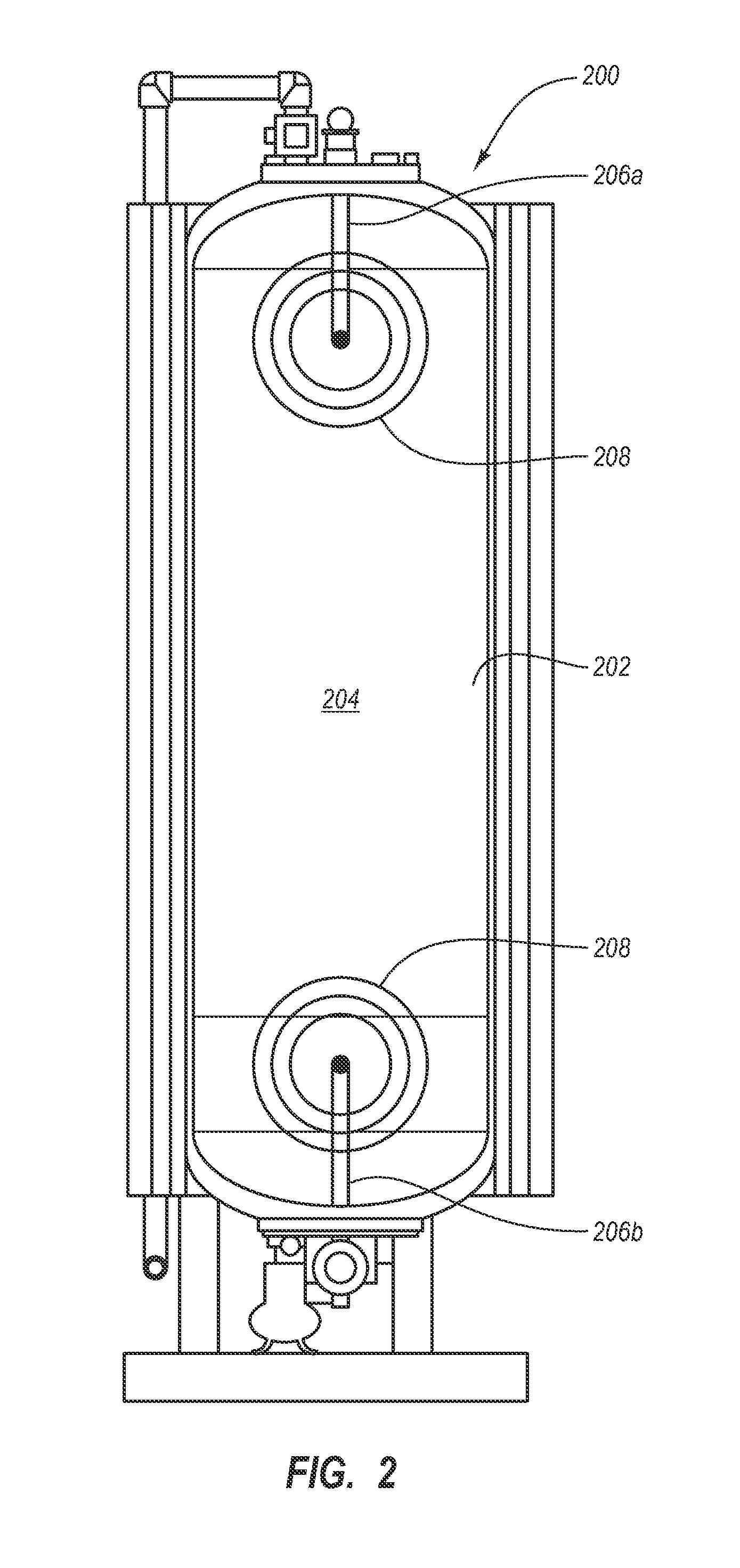

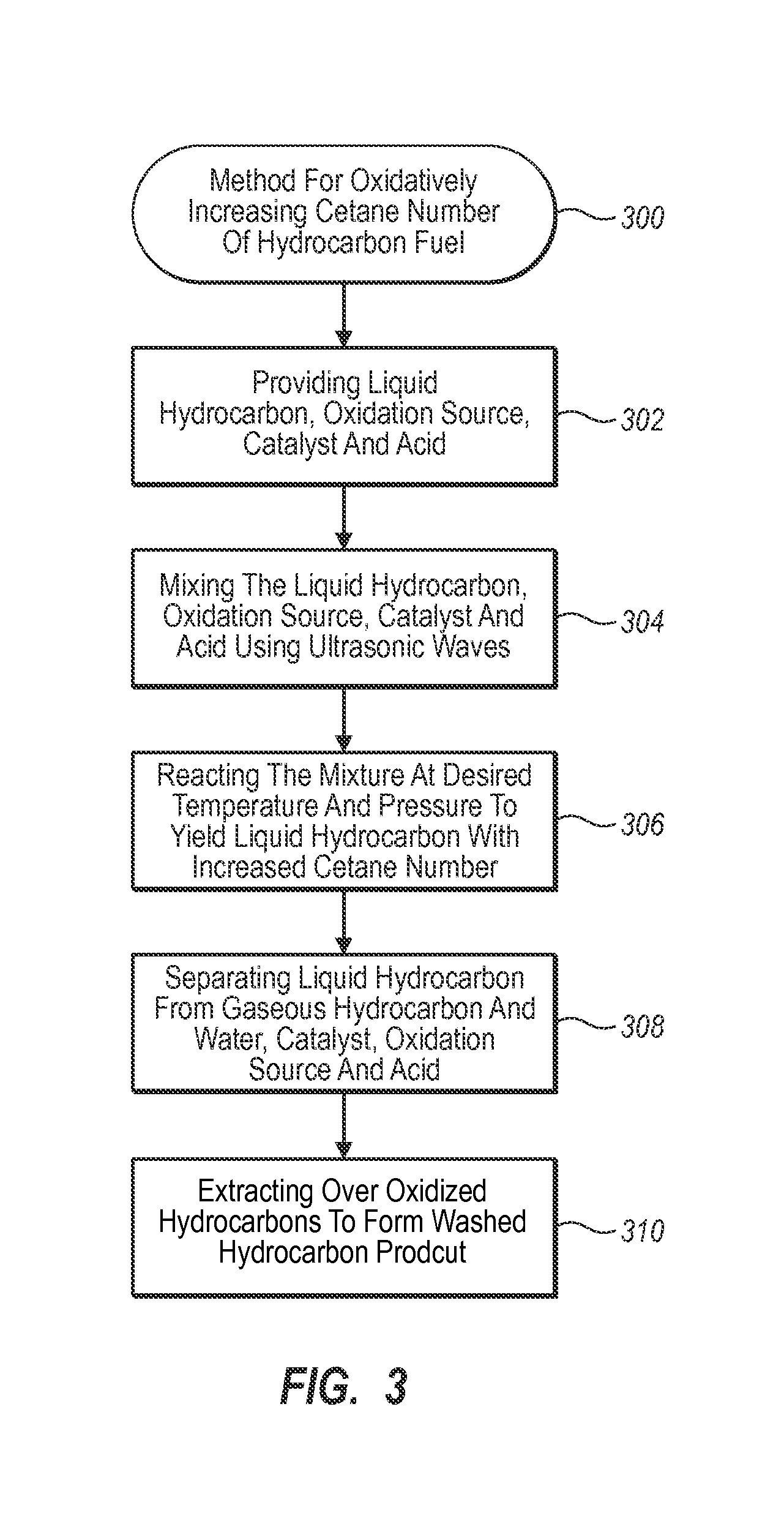

Method and system for oxidatively increasing cetane number of hydrocarbon fuel

InactiveUS20110065969A1Increase heightIntense release of energyRefining with halogen compoundsRefining with oxygen compoundsUltrasonic cavitationHigh energy

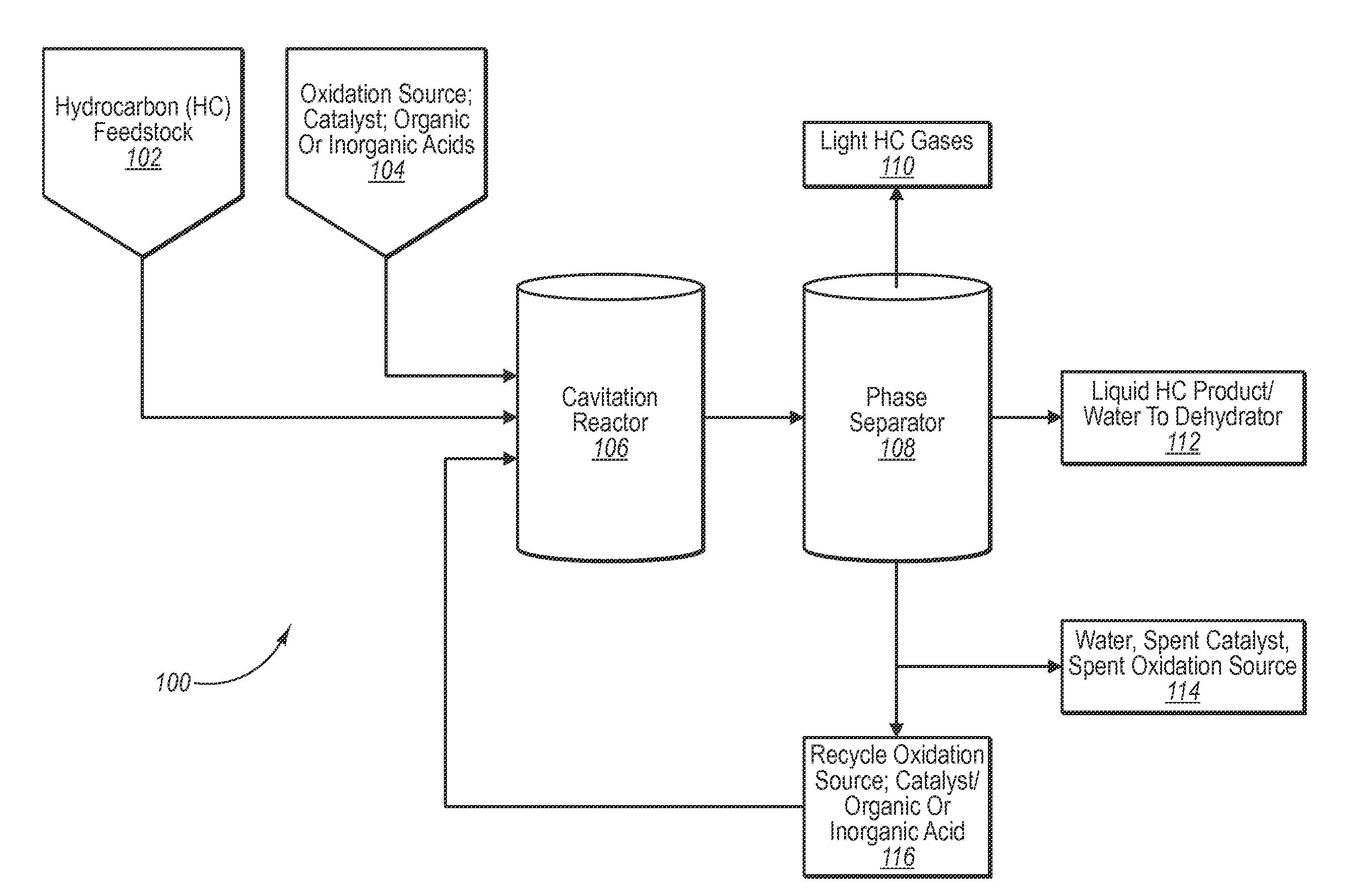

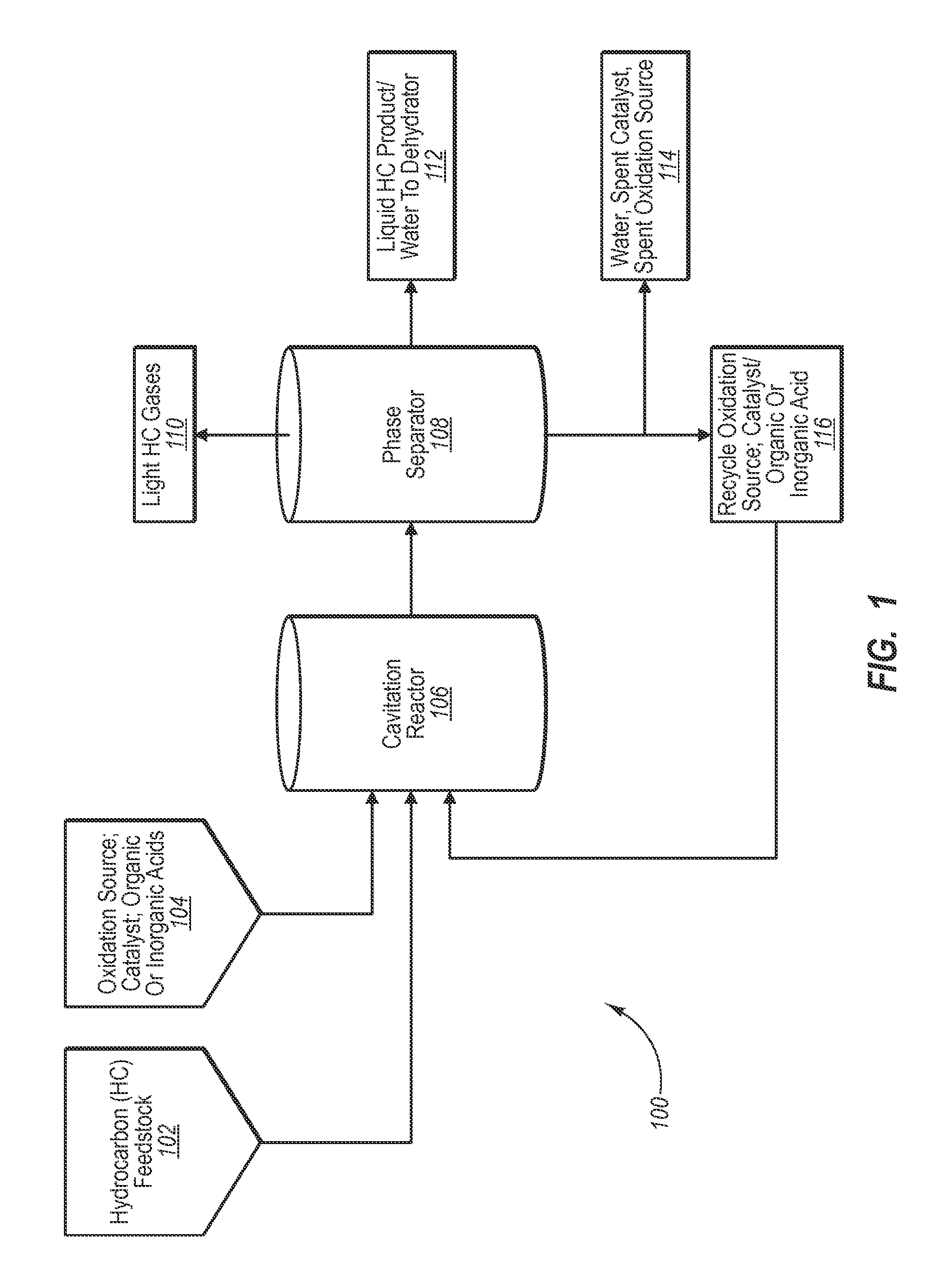

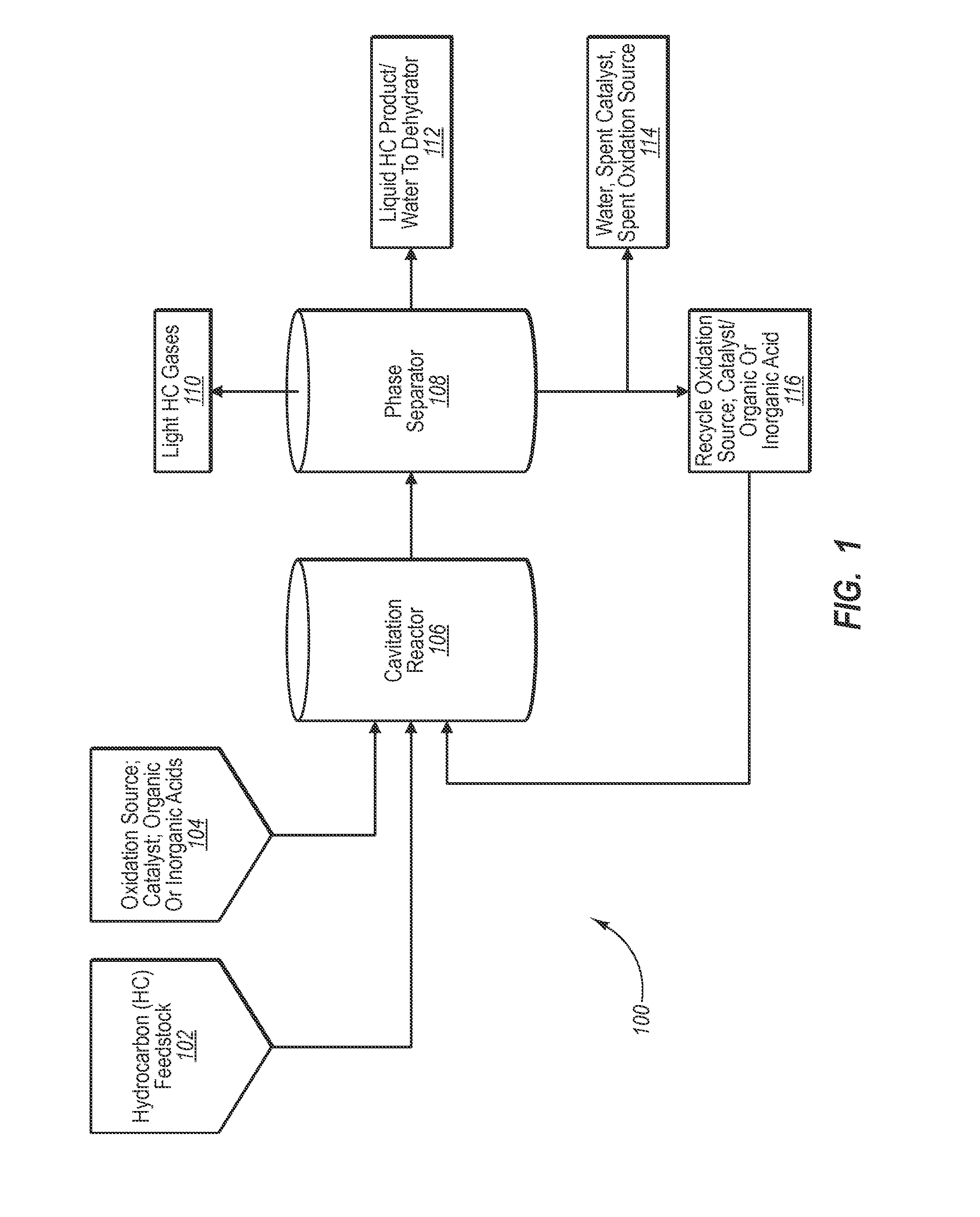

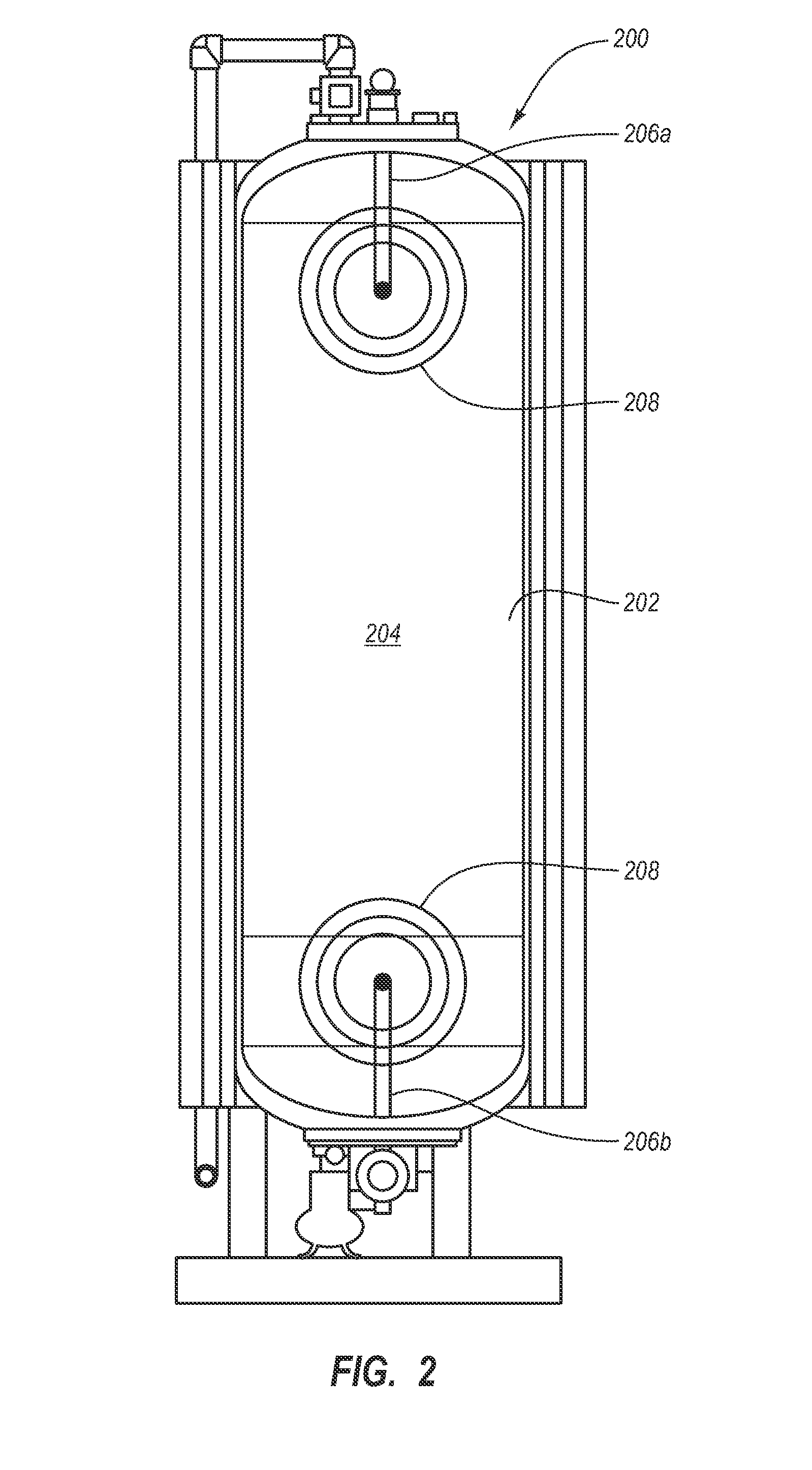

High energy (e.g., ultrasonic) mixing of a liquid hydrocarbon feedstock and reactants comprised of an oxidation source, catalyst and acid yields a diesel fuel product or additive having substantially increased cetane number. Ultrasonic mixing creates cavitation, which involves the formation and violent collapse of micron-sized bubbles, which greatly increases the reactivity of the reactants. This, in turn, substantially increases the cetane number compared to reactions carried out using conventional mixing processes, such as simple mechanical stirring. Alternatively, an aqueous mixture comprising water and acid can be pretreated with an oxidation source such as ozone and subjected to ultrasonic cavitation prior to reacting the pretreated mixture with a liquid hydrocarbon feedstock.

Owner:CETAMAX VENTURES

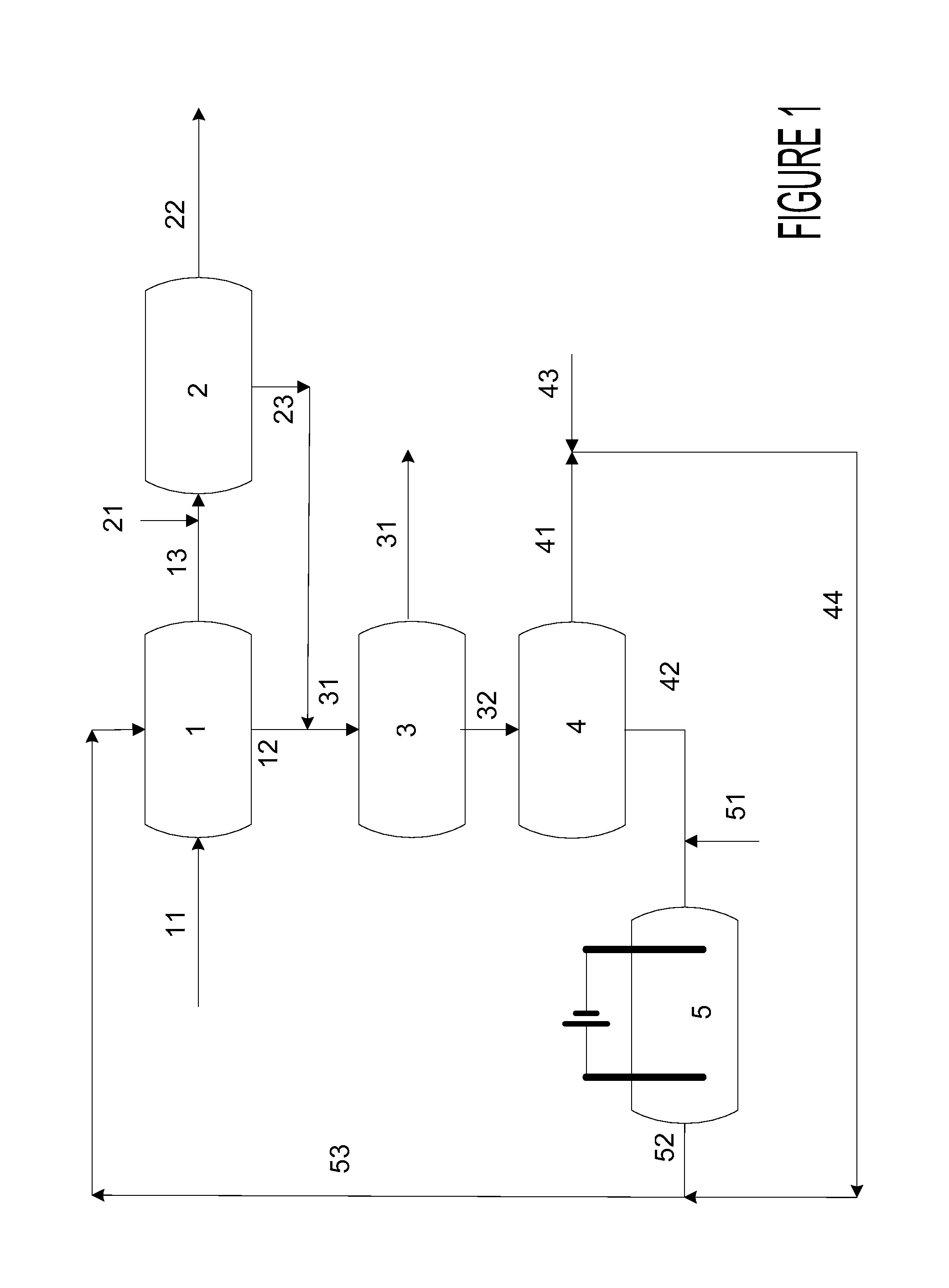

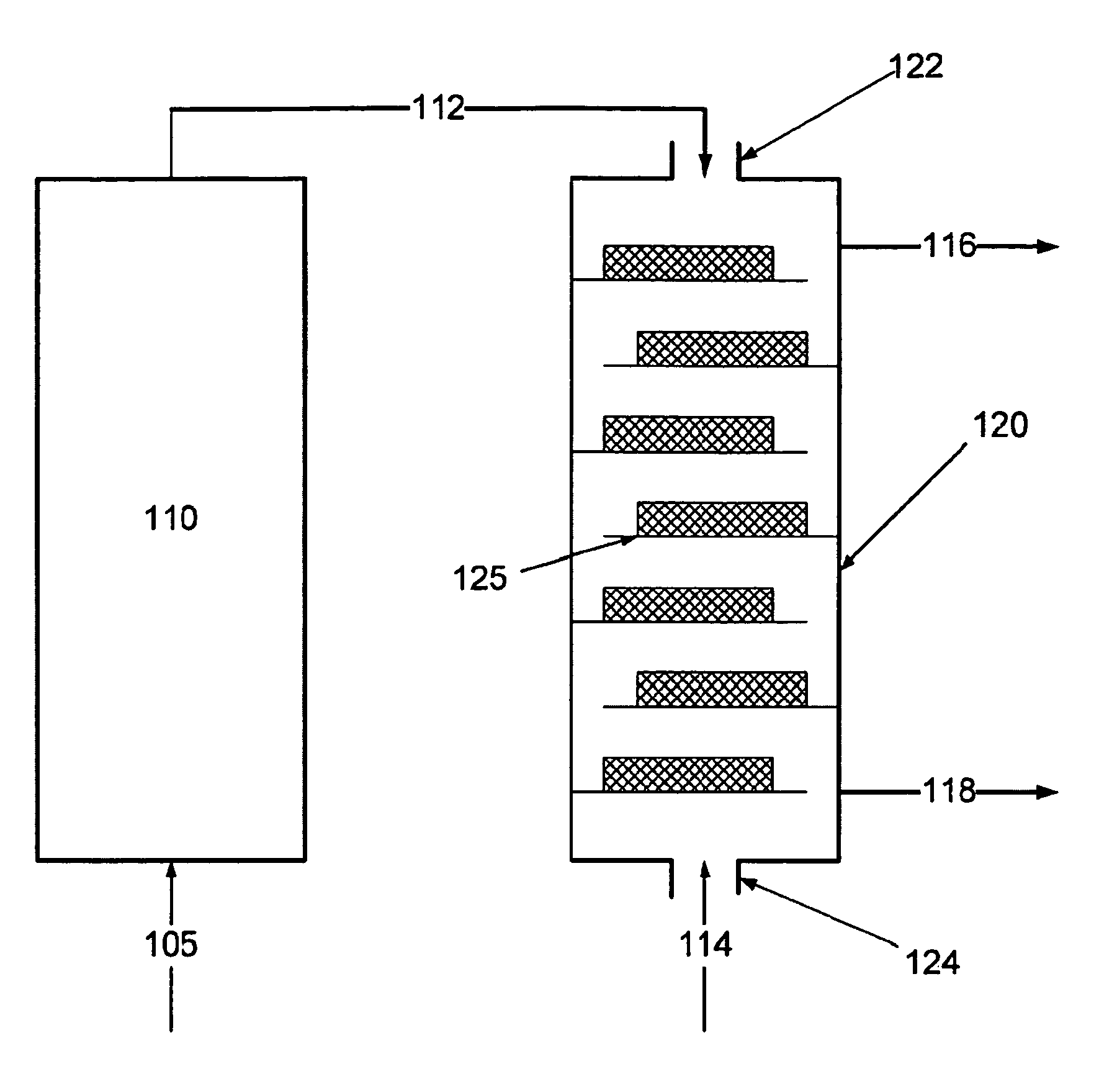

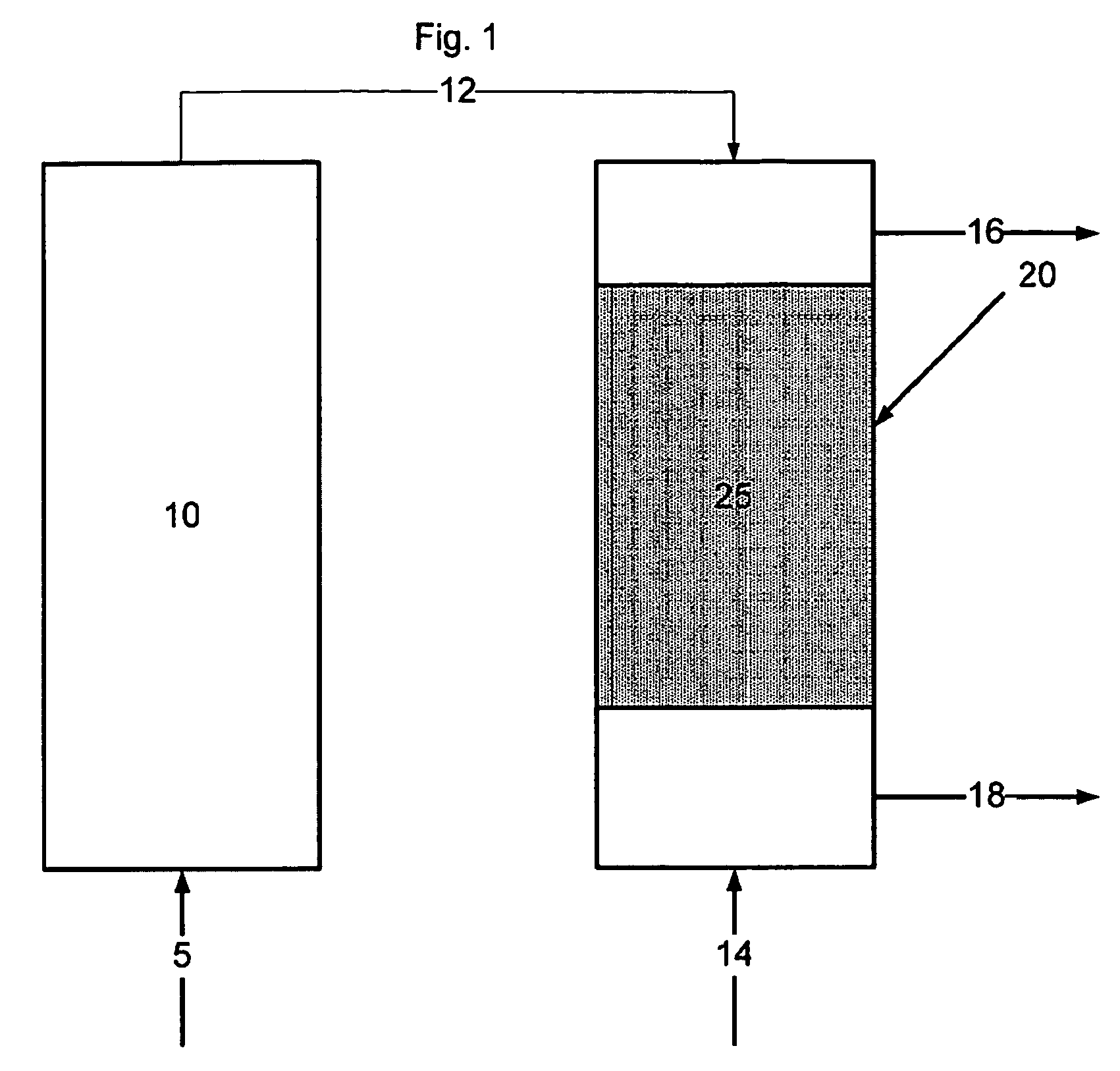

Sulfoxidation catalysts and methods and systems of using same

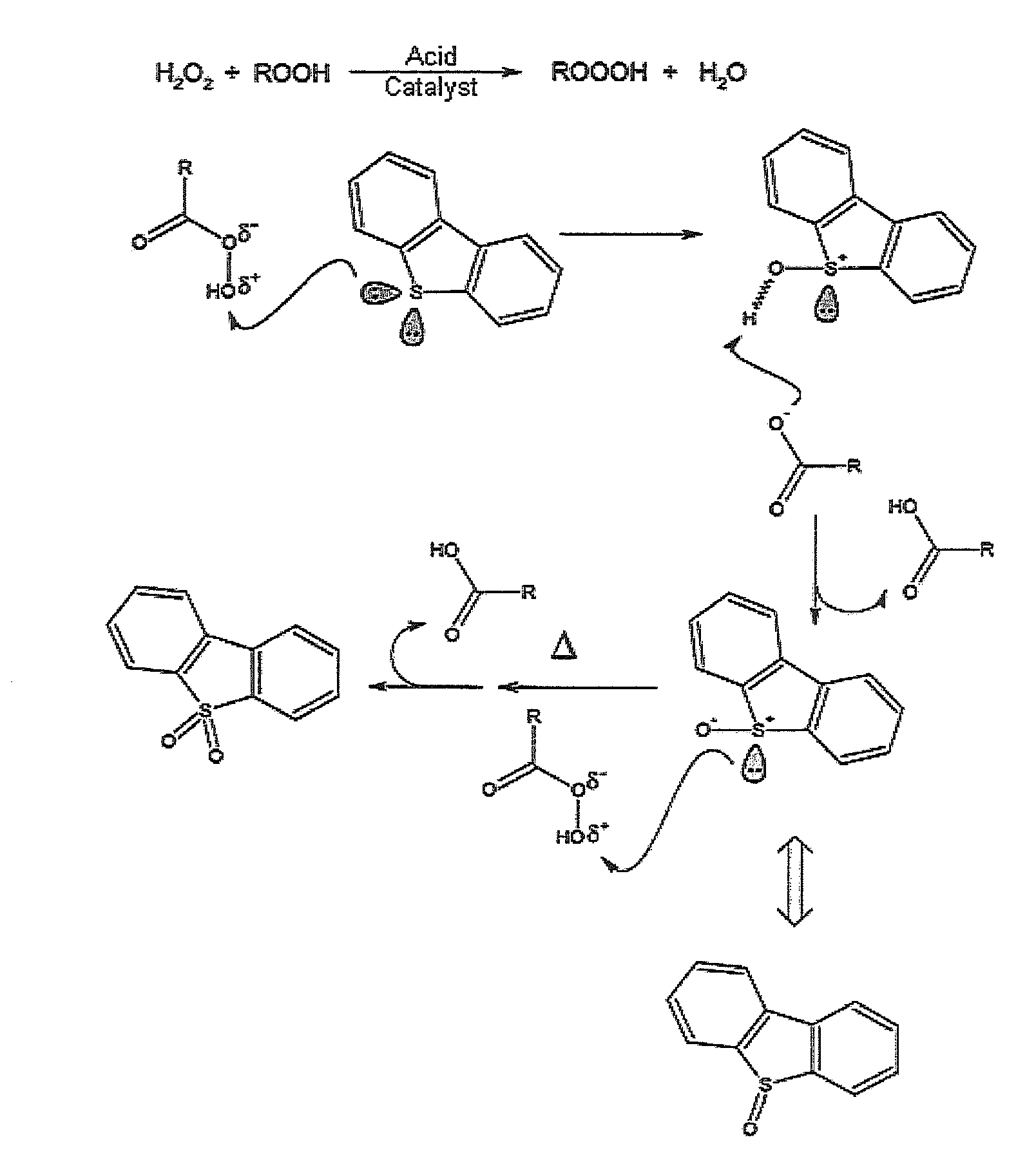

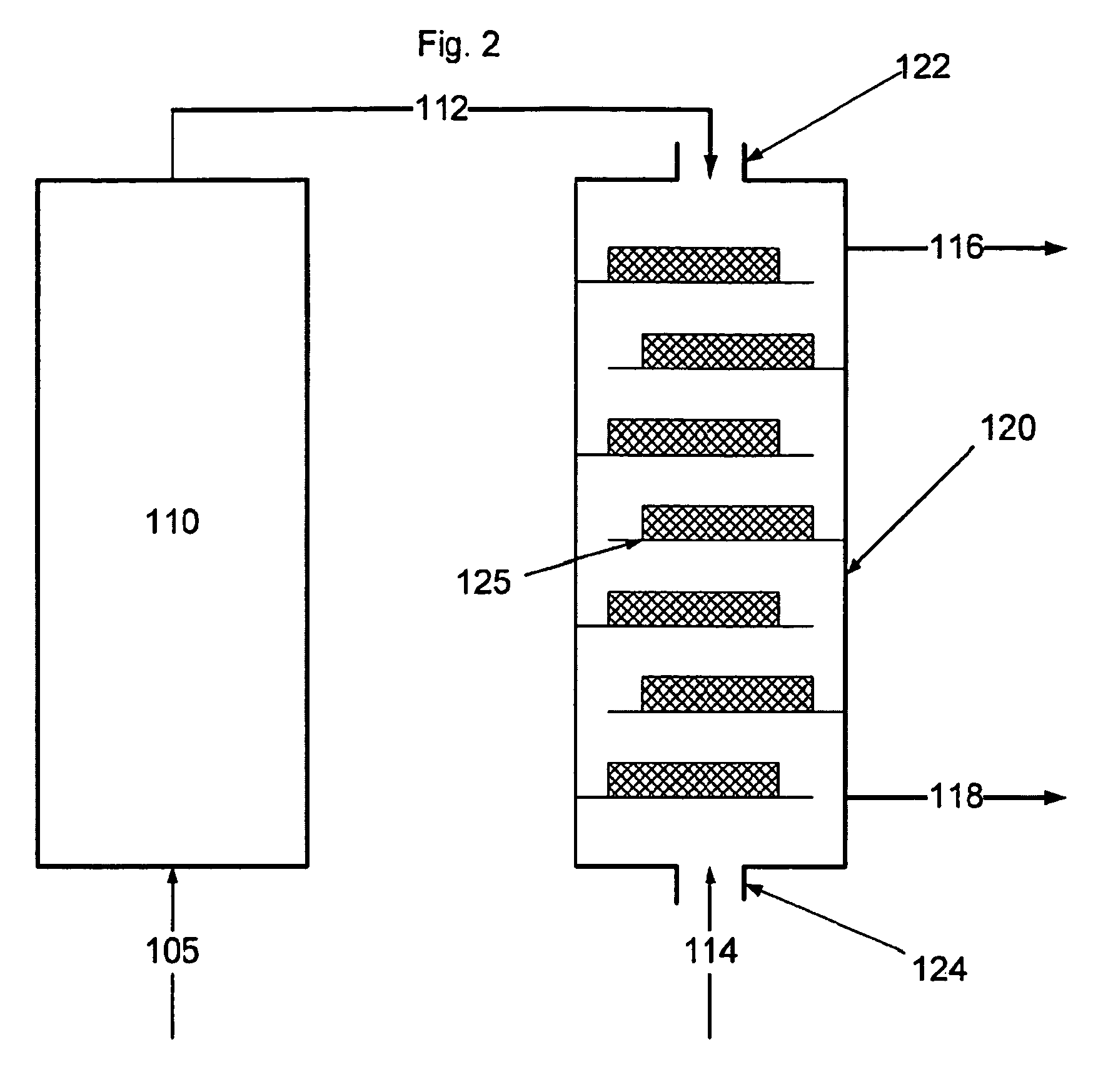

ActiveUS20110011771A1Refining with halogen compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymeric surfaceSulfur

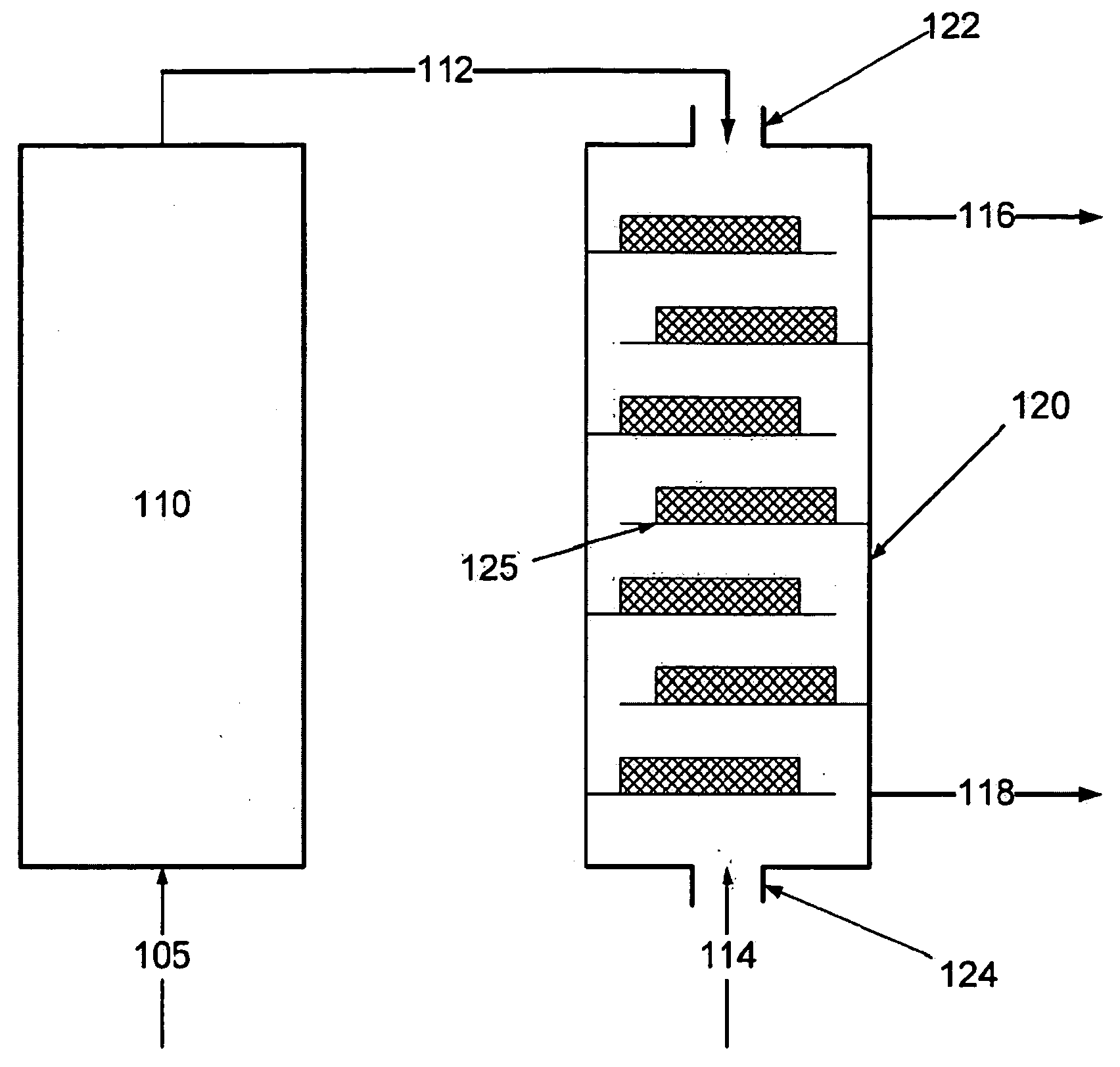

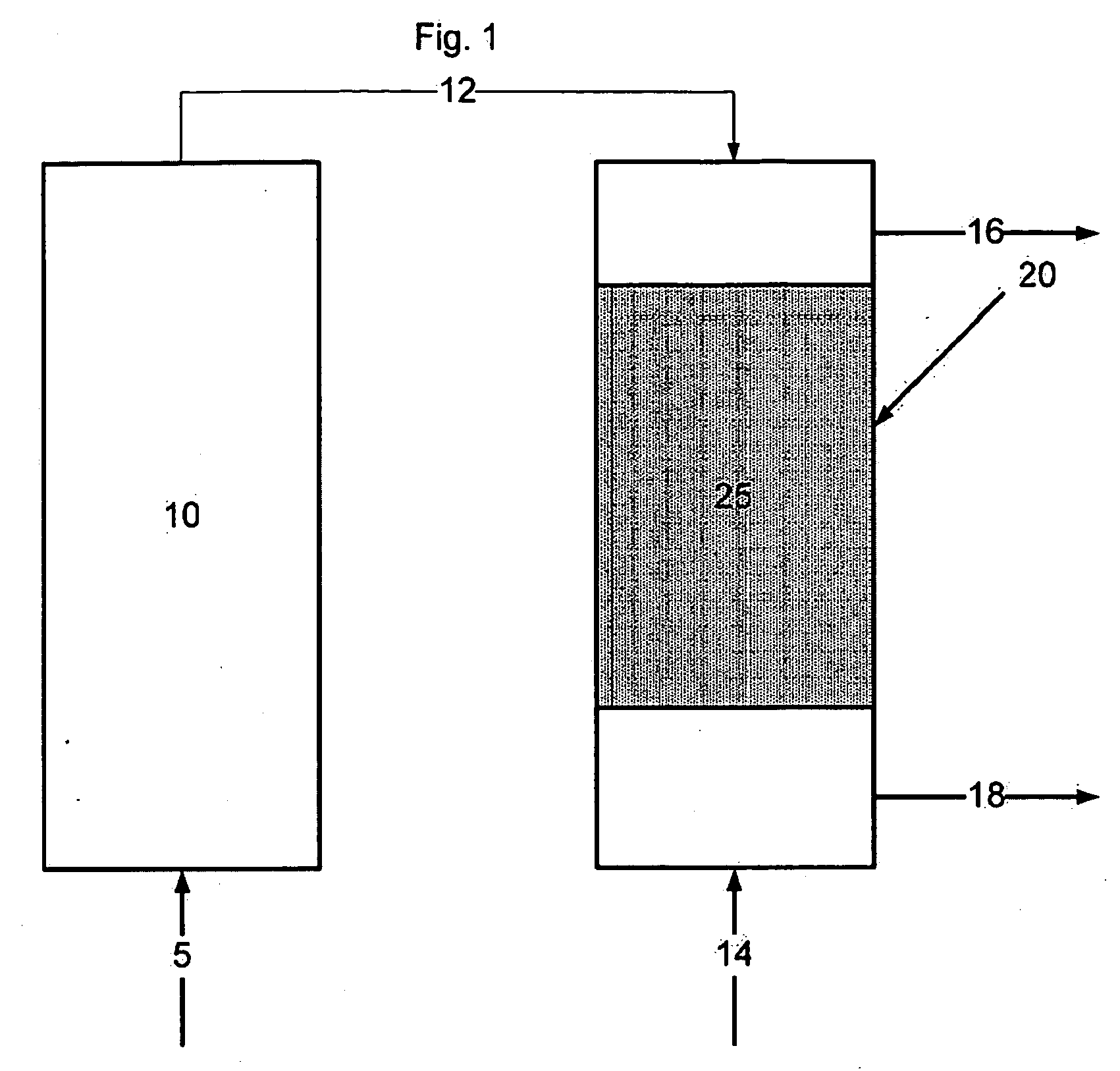

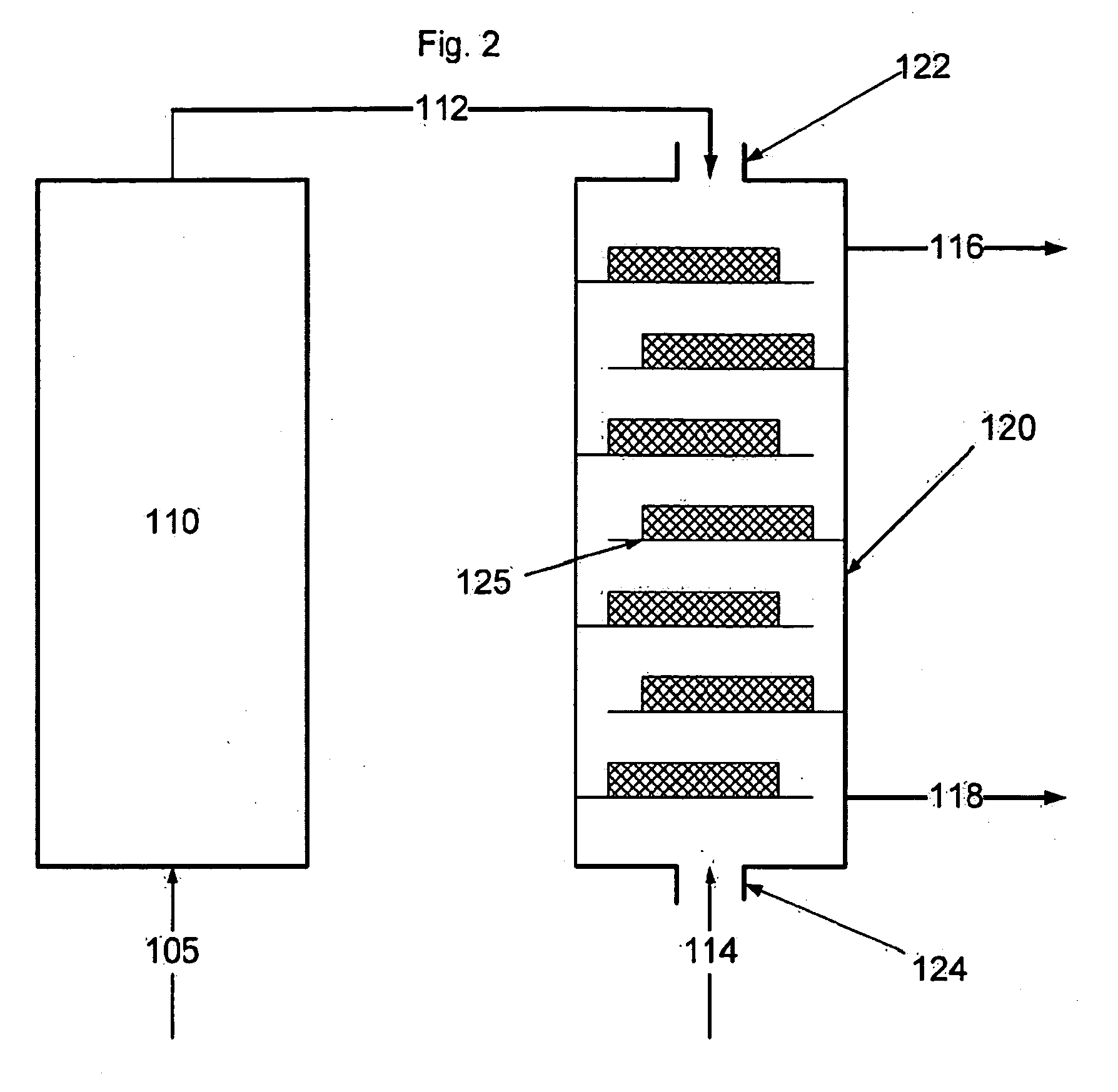

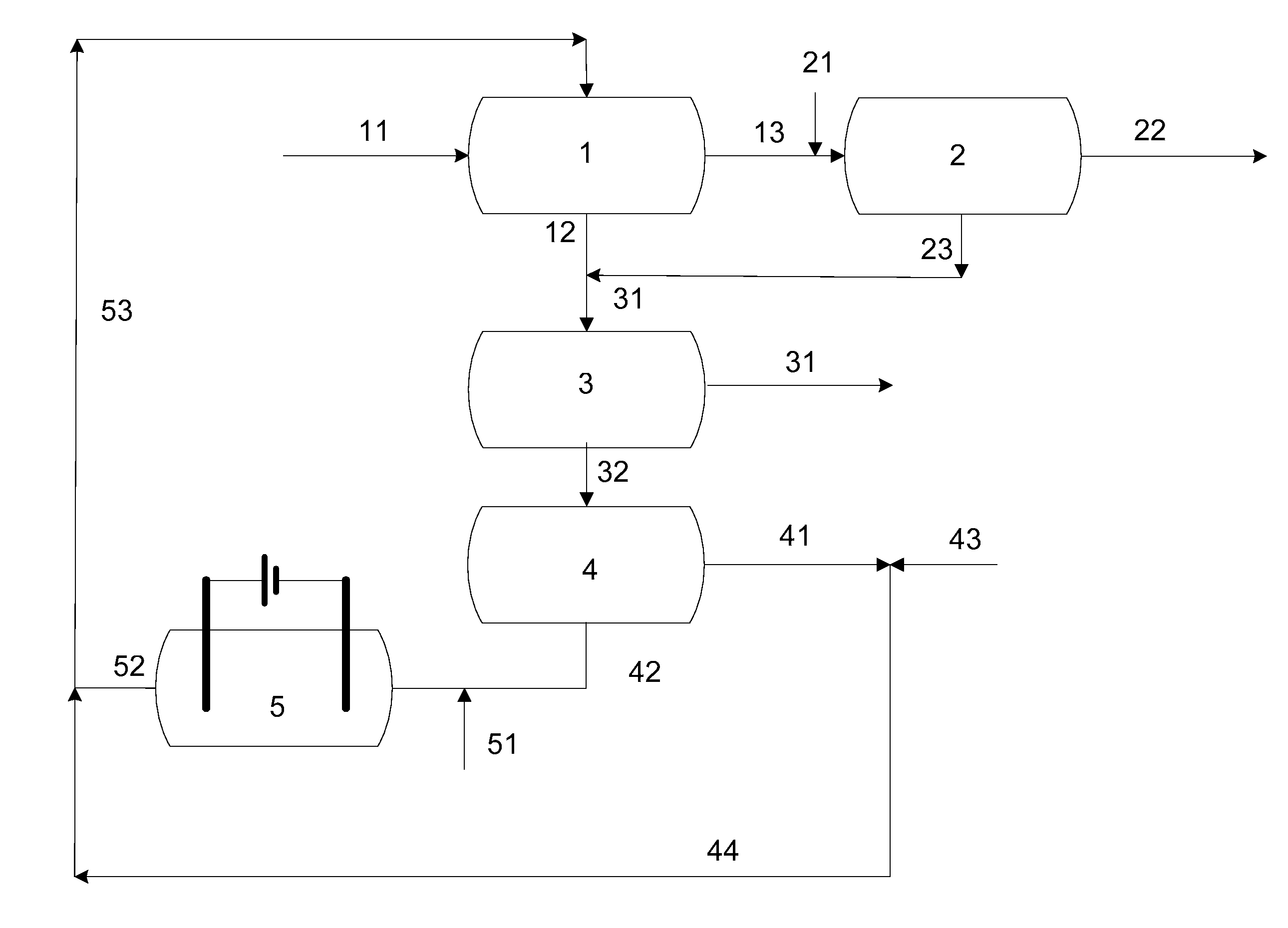

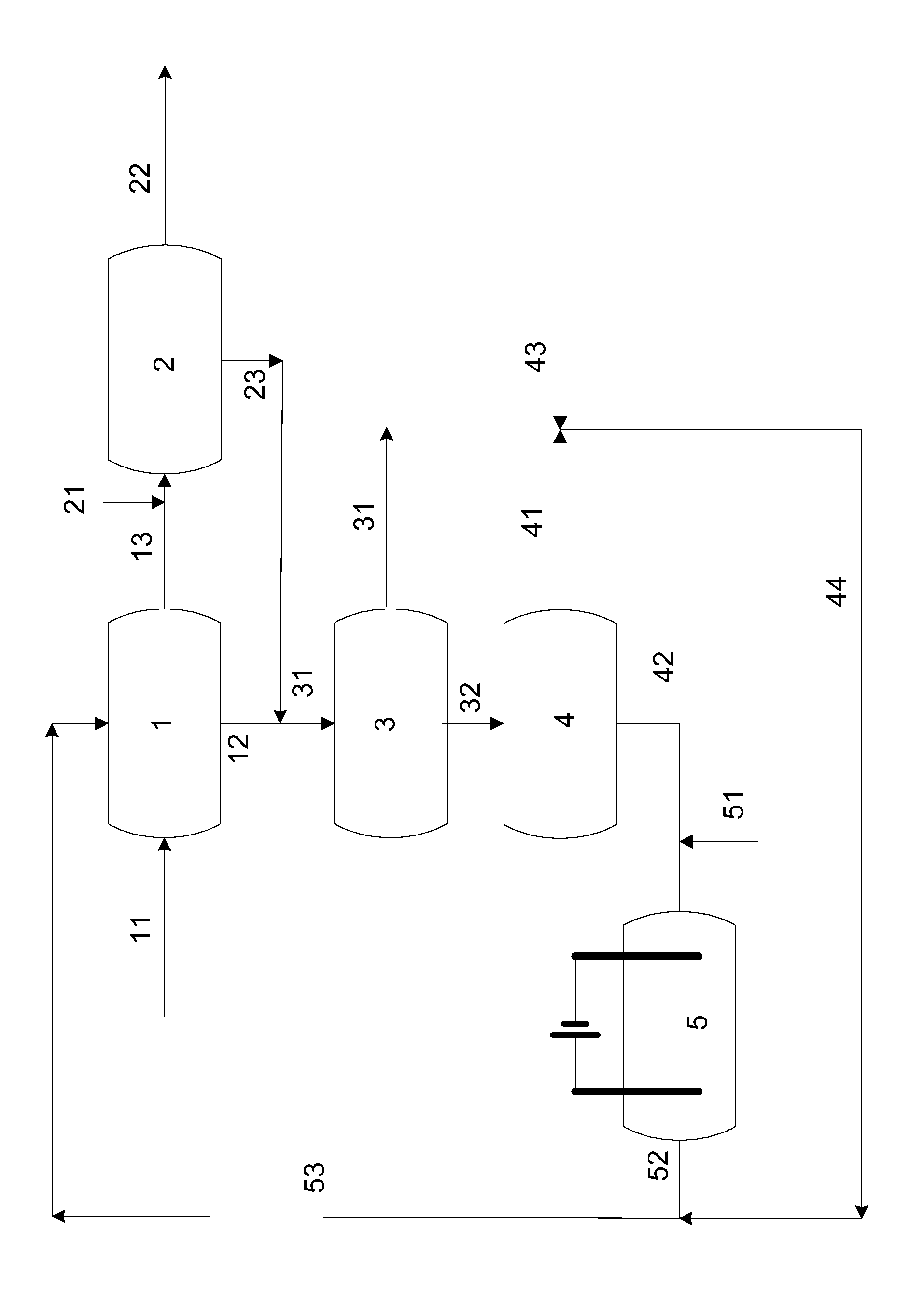

Catalysts amenable to oxidizing sulfur compounds and systems and methods of using these catalysts to effect the removal of sulfur from crude oil and crude oil distillates are disclosed. The catalyst is disposed with a titanyl moiety which serves to selectively coordinate sulfur compounds and affect their oxidation. The titanyl may be bound within a polymer or on the surface of a polymer or on the surface or in the pores of an inorganic support. The resulting oxidized sulfur compounds are readily separated from the initial crude oil or crude oil distillate streams by traditional separation techniques arrayed as described in the systems and methods disclosed.

Owner:AUTERRA INC

Sulfoxidation catalysts and methods and systems of using same

ActiveUS8394261B2Refining with halogen compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymeric surfaceSulfur

Catalysts amenable to oxidizing sulfur compounds and systems and methods of using these catalysts to effect the removal of sulfur from crude oil and crude oil distillates are disclosed. The catalyst is disposed with a titanyl moiety which serves to selectively coordinate sulfur compounds and affect their oxidation. The titanyl may be bound within a polymer or on the surface of a polymer or on the surface or in the pores of an inorganic support. The resulting oxidized sulfur compounds are readily separated from the initial crude oil or crude oil distillate streams by traditional separation techniques arrayed as described in the systems and methods disclosed.

Owner:AUTERRA INC

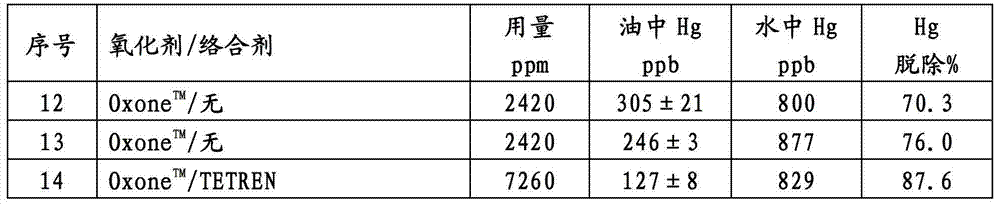

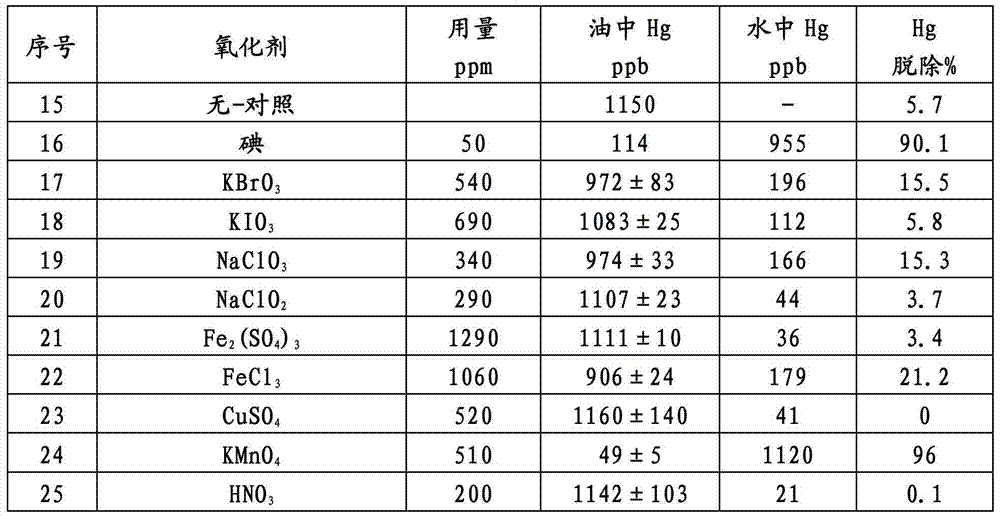

Process, method, and system for removing heavy metals from fluids

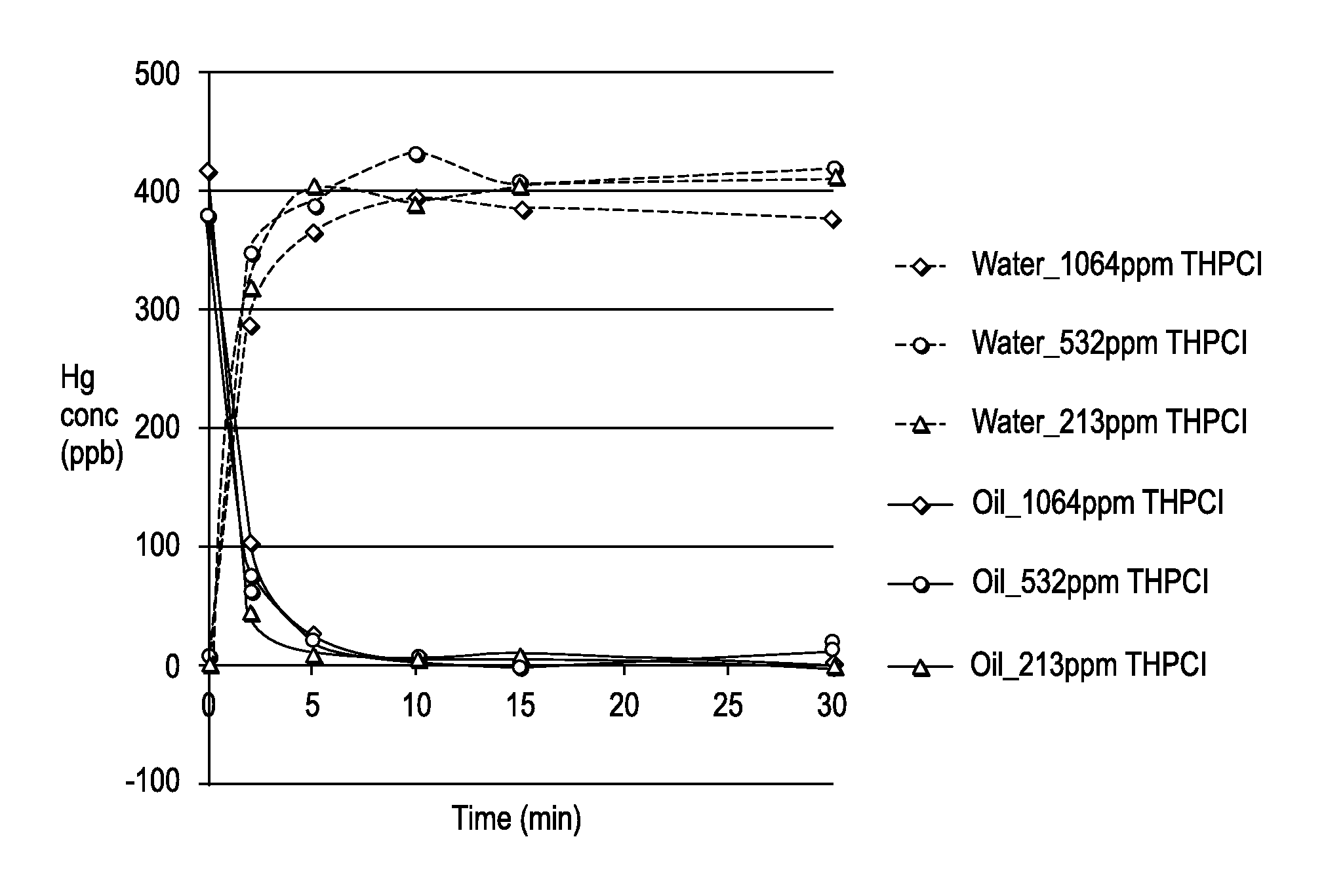

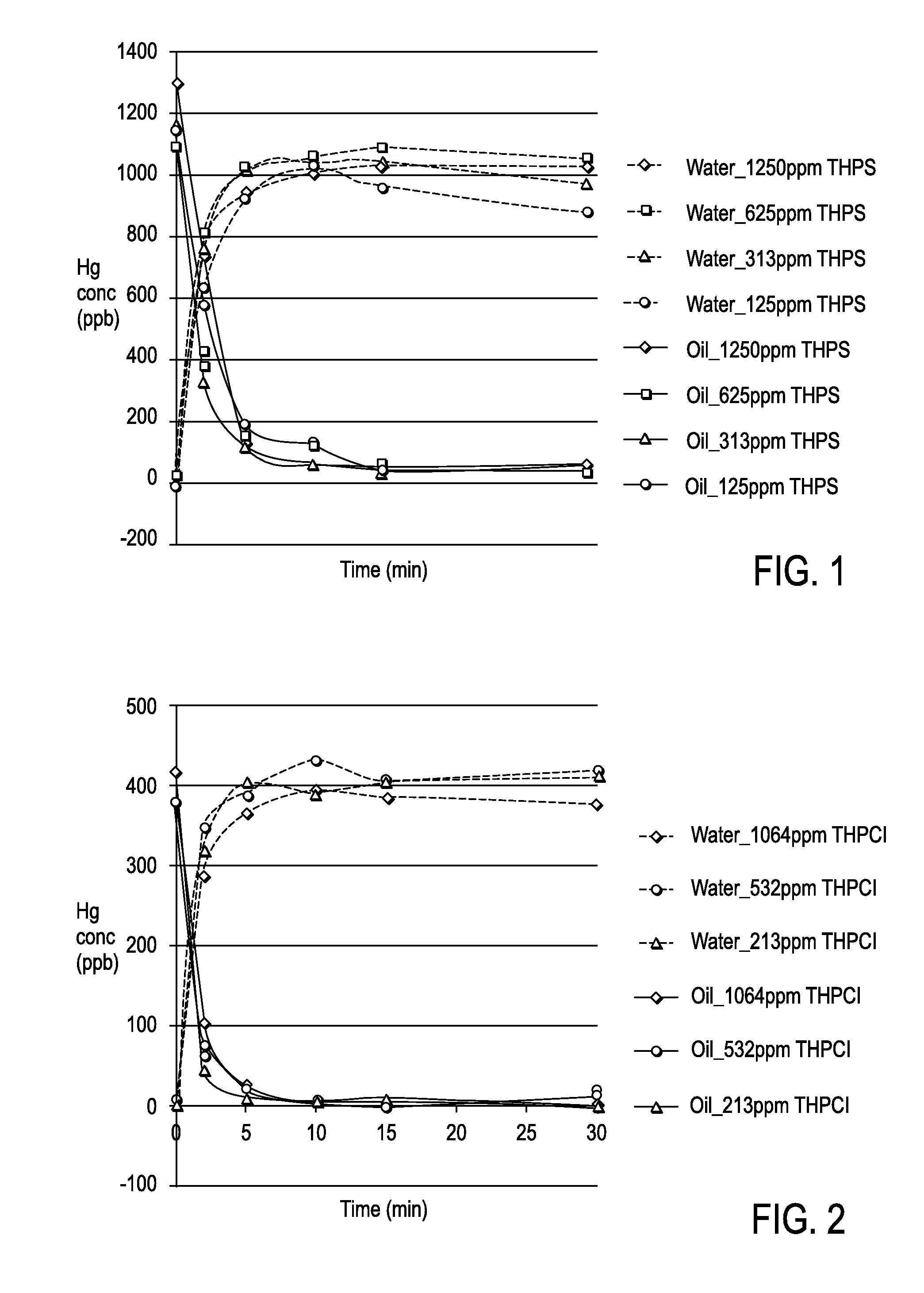

InactiveUS20120067786A1Mercury is reducedReduce its mercury concentrationRefining with non-metalsRefining with halogen compoundsRedoxWater soluble

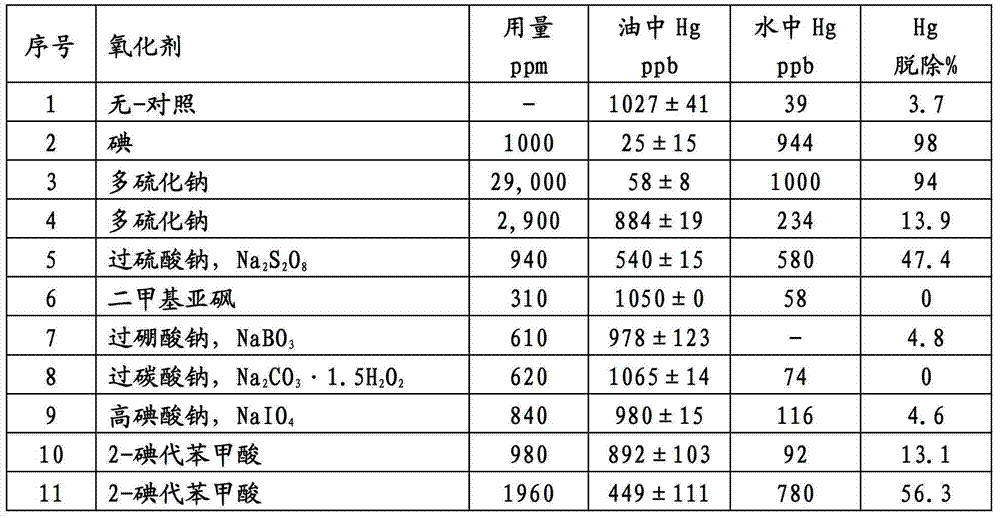

Trace element levels of heavy metals such as mercury in crude oil are reduced by contacting the crude oil with an iodine source, generating a water soluble heavy metal complex for subsequent removal from the crude oil. In one embodiment, the iodine source is generated in-situ in an oxidation-reduction reaction, by adding the crude oil to an iodine species having a charge and a reductant or an oxidant depending on the charge of the iodine species. In one embodiment with an iodine species having a positive charge and a reducing reagent, a complexing agent is also added to the crude oil to extract the heavy metal complex into the water phase to form water soluble heavy metal complexes which can be separated from the crude oil, for a treated crude oil having reduced levels of heavy metals.

Owner:CHEVROU USA INC

Process, method, and system for removing heavy metals from fluids

InactiveUS20130168293A1Reduce its mercury concentrationReduce concentrationRefining with metalsPhysical/chemical process catalystsBromineIodine

Trace amount levels of heavy metals such as mercury in crude oil are reduced by contacting the crude oil with an oxidizing agent and then with a reducing agent. In one embodiment, the oxidizing agent is selected from the group of hydroperoxides, organic peroxides, inorganic peracids and salts thereof, organic peracids and salts thereof, halogens such as iodine (I2), bromine (Br2), and ozone. The treatment converts non-volatile mercury in the crude oil into a volatile form for subsequent mercury removal by any of stripping, scrubbing, adsorption, and combinations thereof. In one embodiment, at least 50% of the mercury is removed. In another embodiment, the removal rate is at least 99%.

Owner:CHEVROU USA INC

Process, method, and system for removing heavy metals from fluids

Trace element levels of heavy metals such as mercury in crude oil are reduced by contacting the crude oil with an iodine source, generating a water soluble heavy metal complex for subsequent removal from the crude oil. In one embodiment, the iodine source is generated in-situ in an oxidation-reduction reaction, by adding the crude oil to an iodine species having a charge and a reductant or an oxidant depending on the charge of the iodine species. In one embodiment with an iodine species having a positive charge and a reducing reagent, a complexing agent is also added to the crude oil to extract the heavy metal complex into the water phase to form water soluble heavy metal complexes which can be separated from the crude oil, for a treated crude oil having reduced levels of heavy metals.

Owner:CHEVROU USA INC

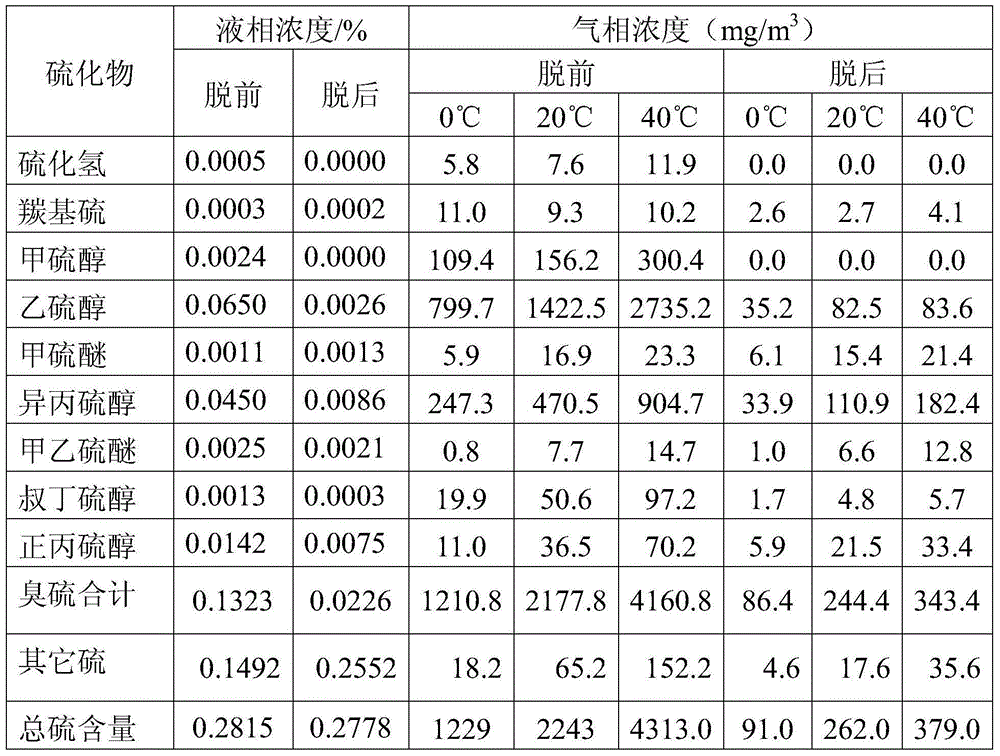

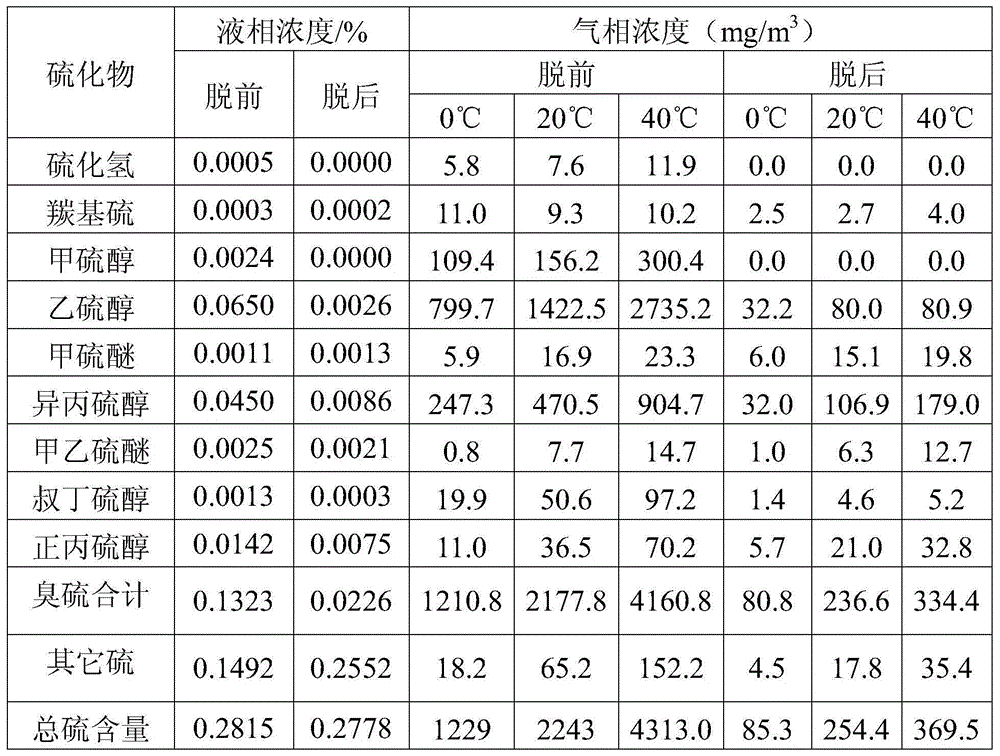

Removing unstable sulfur compounds from crude oil.

ActiveUS20100140142A1Reduce sulfur contentRefining with metalsMolecular sieve catalystsSulfurReaction zone

A crude oil which contains at least 0.1 wt % unstable sulfur compounds is treated in a reaction zone at low temperature to convert at least 50 wt % of the unstable sulfur compounds contained therein. The reaction and removal of sulfur from the crude may be facilitated by contacting the crude oil with a catalytic material in the presence of a stripping fluid.

Owner:CHEVROU USA INC

Process, method, and system for removing heavy metals from fluids

InactiveCN103249814ATrace arsenic reductionReduce the concentration of arsenicRefining with halogen compoundsRefining with oxygen compoundsSulfurBromine

Trace amount levels of heavy metals such as mercury, arsenic, etc., in crude oil are reduced by contacting the crude oil with an oxidizing agent, extracting heavy metals into a water phase for subsequent separation from the crude oil. In one embodiment, the oxidizing agent is selected from the group of hydroperoxides, organic peroxides, inorganic peracids and salts thereof, organic peracids and salts thereof, halogens such as iodine (I2), bromine (Br2), and ozone. In another embodiment, at least a complexing agent selected from the group of metal halides and / or sulfur compounds can be added to facilitate the removal of heavy metals from crude oil by forming soluble heavy metal complexes in the water phase.

Owner:CHEVROU USA INC

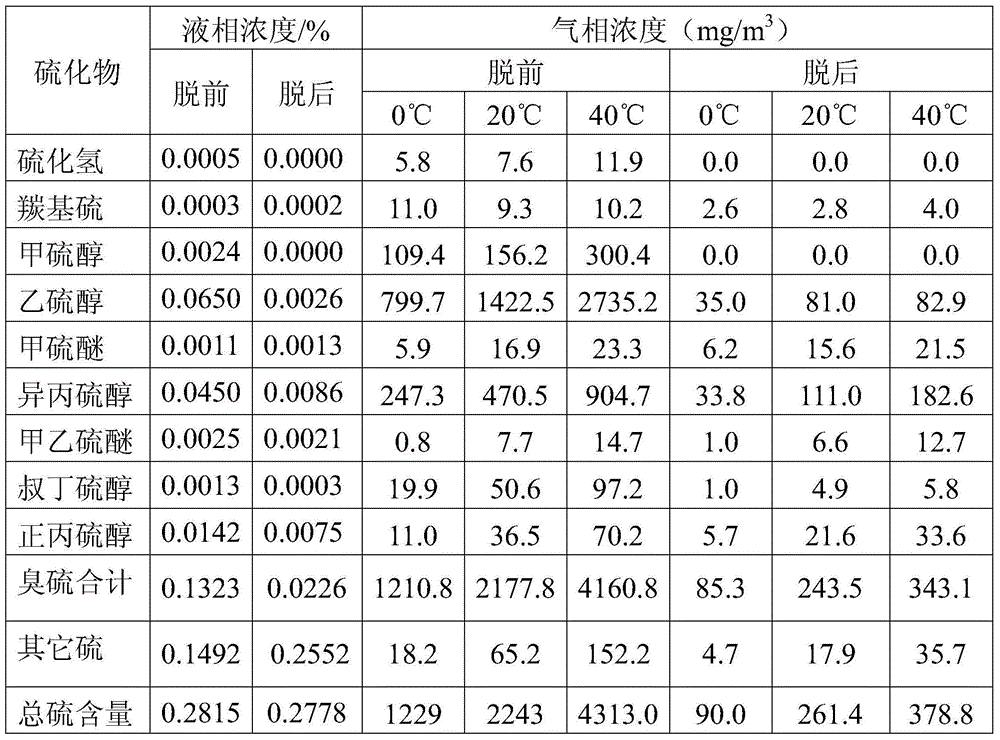

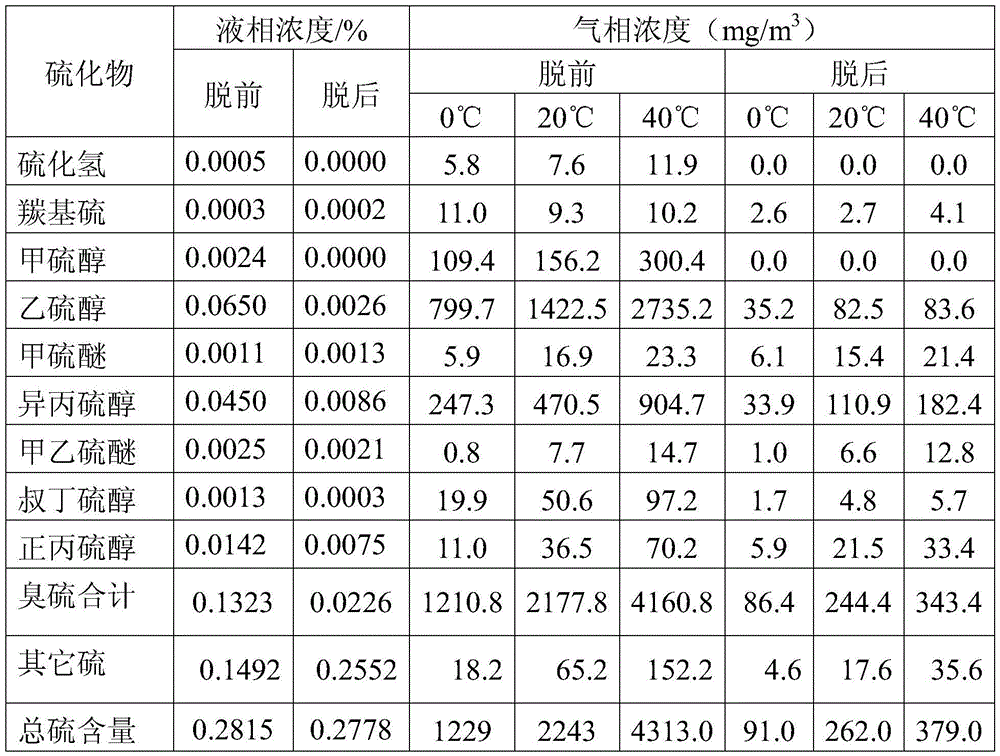

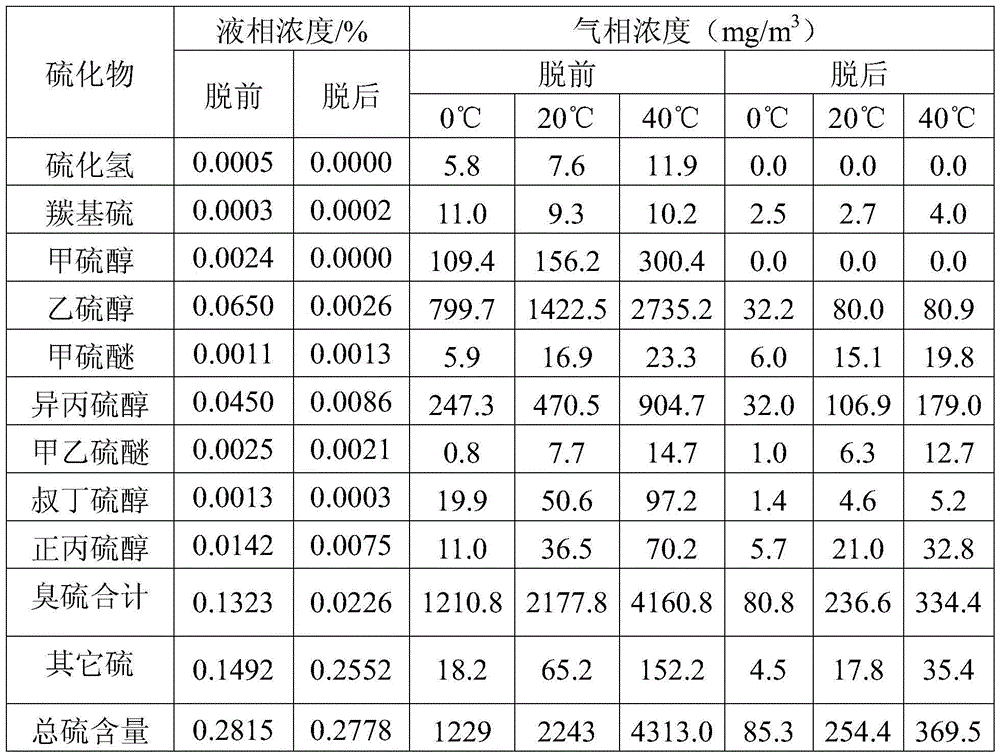

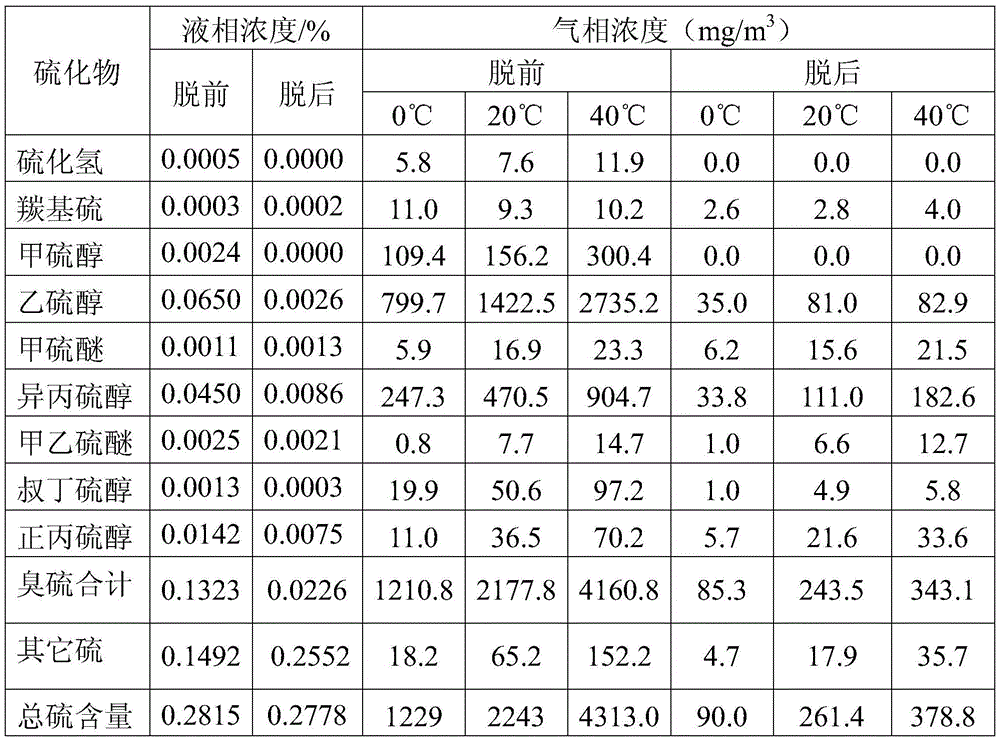

Gas condensate deodorization method

ActiveCN104593043AFacilitate subsequent processingNo emissionsRefining with halogen compoundsRefining with oxygen compoundsSolventChemistry

The invention provides a gas condensate deodorization method. The method comprises the following steps of mixing or contacting gas condensate, an activator, an oxidizing agent and a deodorization catalyst, and collecting the mixed or contacted gas condensate, wherein the activator comprises a mixture of a water-soluble ether compound, inorganic base and / or organic base, and a water-soluble polar solvent, the water-soluble ether compound has a structure of R1(OR2)nOR3, R1, R2 and R3 respectively represent C1-C8 alkyl and n is an integer of 1-5. The gas condensate deodorization method transforms low-boiling point sulfide in the gas condensate into high-boiling point sulfide thereby realizing deodorization, can be operated simply and safely, does not discharge waste, is suitable for oil field, harbor, oil depot and oil refinery and is conducive to follow-up processing of gas condensate. The gas condensate deodorization method has lasting deodorization effects, can substantially improve smell, directly improves gas condensate corrosivity to a distillation column, reduces sulfur content of a follow-up product and desulphurization load in processing and reduces desulphurization sewage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process, method, and system for removing heavy metals from fluids

Trace amount levels of heavy metals such as mercury in crude oil are reduced by contacting the crude oil with an oxidizing agent and then with a reducing agent. In one embodiment, the oxidizing agent is selected from the group of hydroperoxides, organic peroxides, inorganic peracids and salts thereof, organic peracids and salts thereof, halogens such as iodine (I2), bromine (Br2), and ozone. The treatment converts non-volatile mercury in the crude oil into a volatile form for subsequent mercury removal by any of stripping, scrubbing, adsorption, and combinations thereof. In one embodiment, at least 50% of the mercury is removed. In another embodiment, the removal rate is at least 99%.

Owner:CHEVROU USA INC

Method for reducing mercaptans in hydrocarbons

ActiveUS20120103872A1Reducing mercaptan concentrationReduced concentration of chlorideRefining with halogen compoundsTreatment with plural serial refining stagesHypochloriteOrganic chloride compound

A method for reducing mercaptan concentration in a crude oil is disclosed. The method comprises contacting the crude with a treating solution comprising a hypochlorite solution, whereby the mercaptan sulfur is oxidized and converted to at least one sulfur oxoacid or salt thereof, yielding a treated crude oil having less than 50 ppm mercaptan sulfur and residual organic chloride. The treated crude oil containing residual organic chloride is brought in contact with a caustic solution at a molar ratio of caustic to chloride of 0.1:1 to 50:1, generating an upgraded crude oil with less than 10 ppm organic chloride. In one embodiment, the spent treating solution is recycled to form a regenerated hypochlorite stream for use in the treatment solution.

Owner:CHEVROU USA INC

Method for desulfurizing oil through oxidation-extraction coupling

InactiveCN103602346ANo pollution in the processImprove solubilityRefining with halogen compoundsRefining with oxygen compoundsSolubilitySteam pressure

The invention discloses a method for desulfurizing oil through oxidation-extraction coupling. The method comprises the following steps: taking one or a mixture of a plurality of sulfonyl alkyl imidazole, sulfonyl alkyl pyridine, sulfonyl alkyl quaternary ammonium and sulfonyl alkyl quaternary phosphorus ionic liquid as a reaction medium, a catalyst and an extraction agent, taking H2O2 and NaClO as oxidants, oxidizing sulfur-containing compounds in oil into corresponding sulfone and sulfoxide compounds, extracting the compounds to enter ionic liquid with high polarity so as to remove sulfur. According to the process, the ionic liquid serves as a solvent and an extraction agent, and the method has the advantages of high solubility, mild operating conditions, low steam pressure, high structure designability and the like. Moreover, the method is pollution-free to the environment and is a high-efficiency and green desulphurization method.

Owner:大连杰信生物科技有限公司

Method and system for oxidatively increasing cetane number of hydrocarbon fuel

InactiveUS8920633B2Increase heightIntense release of energyCatalytic naphtha reformingBiofuelsUltrasonic cavitationHigh energy

High energy (e.g., ultrasonic) mixing of a liquid hydrocarbon feedstock and reactants comprised of an oxidation source, catalyst and acid yields a diesel fuel product or additive having substantially increased cetane number. Ultrasonic mixing creates cavitation, which involves the formation and violent collapse of micron-sized bubbles, which greatly increases the reactivity of the reactants. This, in turn, substantially increases the cetane number compared to reactions carried out using conventional mixing processes, such as simple mechanical stirring. Alternatively, an aqueous mixture comprising water and acid can be pretreated with an oxidation source such as ozone and subjected to ultrasonic cavitation prior to reacting the pretreated mixture with a liquid hydrocarbon feedstock.

Owner:CETAMAX VENTURES

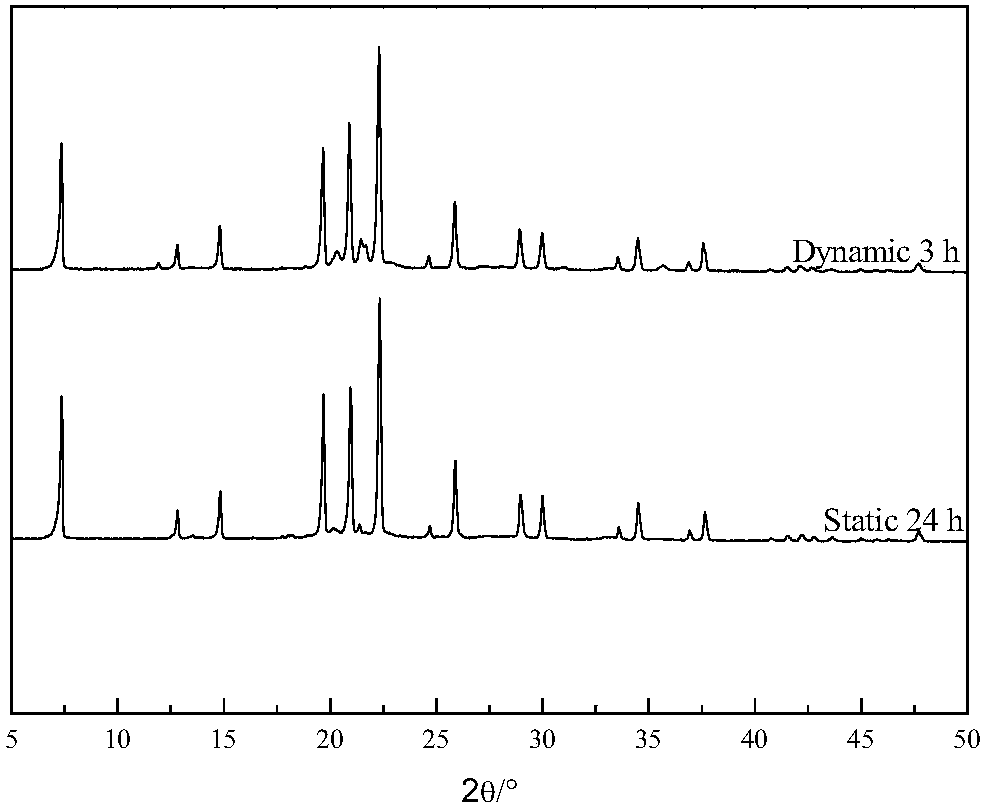

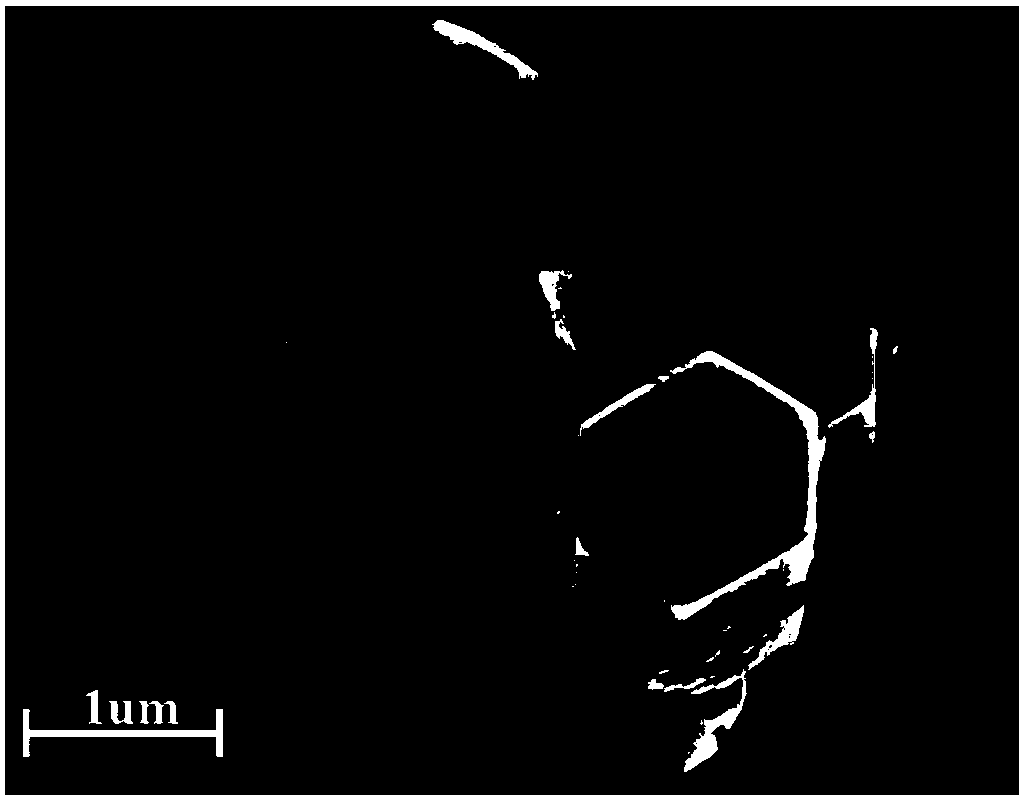

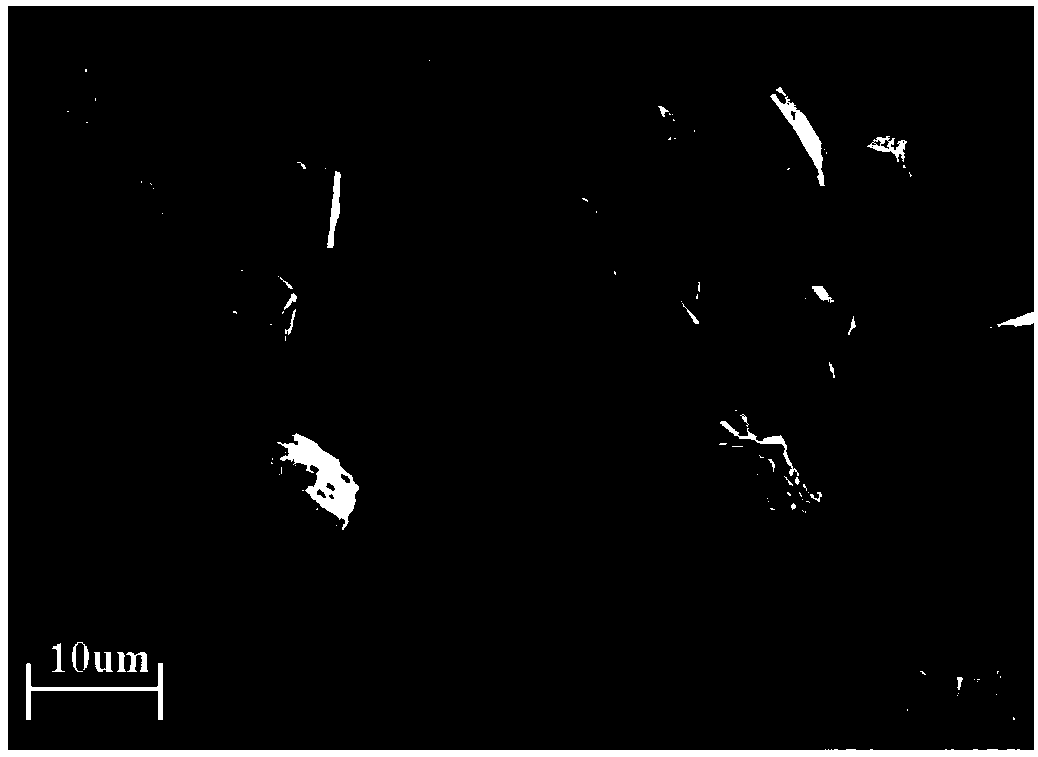

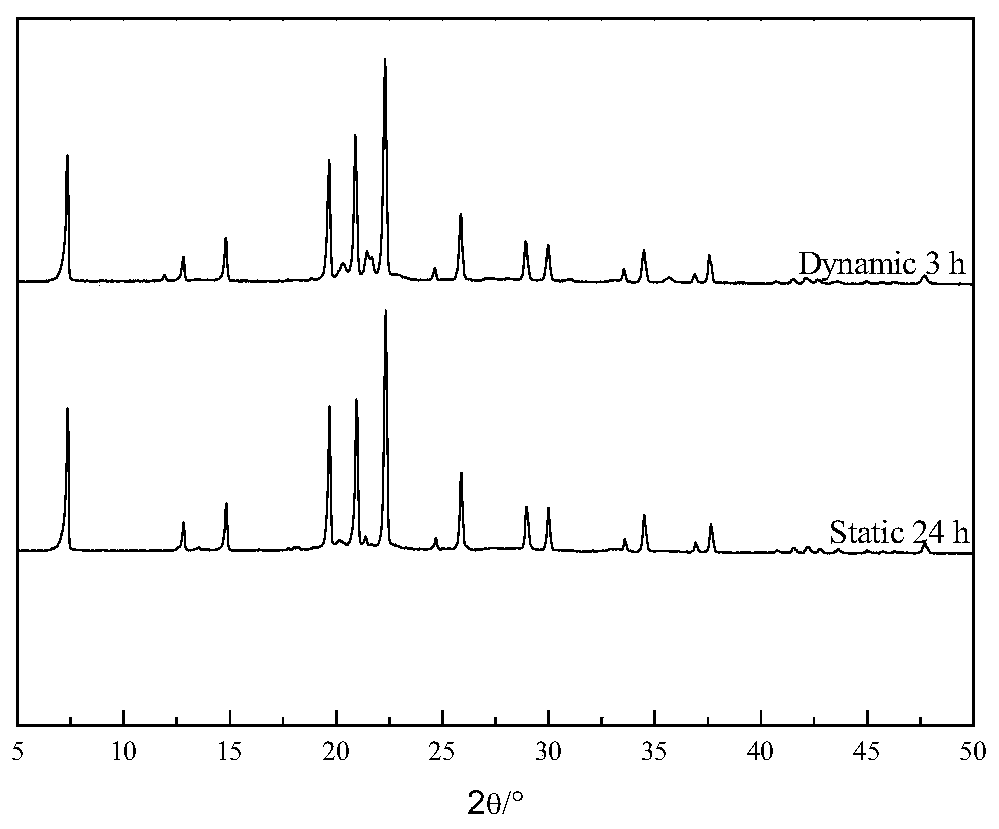

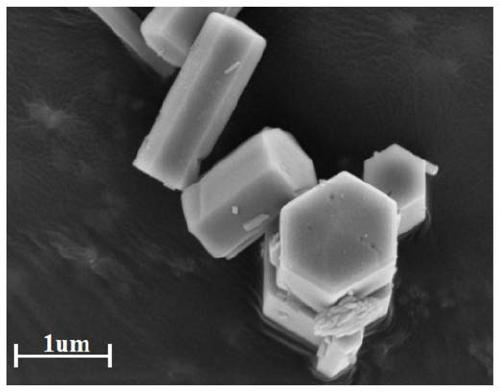

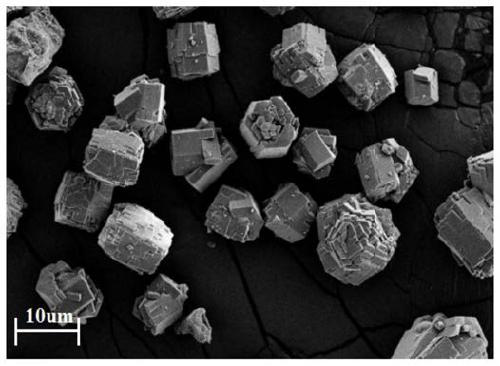

Preparation method of hierarchical pore heteroatom aluminum phosphate molecular sieve for oxidative desulfurization

ActiveCN107777702AHigh crystallinityAvoid reunionRefining with halogen compoundsMolecular-sieve aluminophosphatesMolecular sieveHeteroatom

The invention belongs to the technical field of chemical catalysts, and specifically relates to a preparation method of a hierarchical pore heteroatom aluminum phosphate molecular sieve for oxidativedesulfurization. The method comprises the following steps: synthesizing a microporous aluminum phosphate molecular sieve through a dynamic hydrothermal crystallization manner; and preparing the hierarchical pore heteroatom aluminum phosphate molecular sieve in a mesoporous template agent and metal source synthesizing system by taking the prepared microporous aluminum phosphate molecular sieve as aseed crystal. According to the method, the synthesizing time is reduced; the prepared molecular sieve is controllable and uniform in crystal particles; and the desulfurization effect is high in catalytic oxidative desulfurization reaction.

Owner:CHANGZHOU UNIV

Hydrogen peroxide-chlorine combined fuel oil oxidation treatment method

InactiveCN104694152AReduce oxidation treatment costsEasy to getRefining with halogen compoundsHydrocarbon oils treatmentFuel oilEngineering

The invention provides a fuel oil oxidation treatment method applicable to fuel oil desulfurization. Hydrogen peroxide and chlorine together react with fuel oil at the same time, and the fuel oil at the end of reaction is oxidation treated fuel oil. The fuel oil treated by the method is more easily desulfurized by a liquid-liquid extraction process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

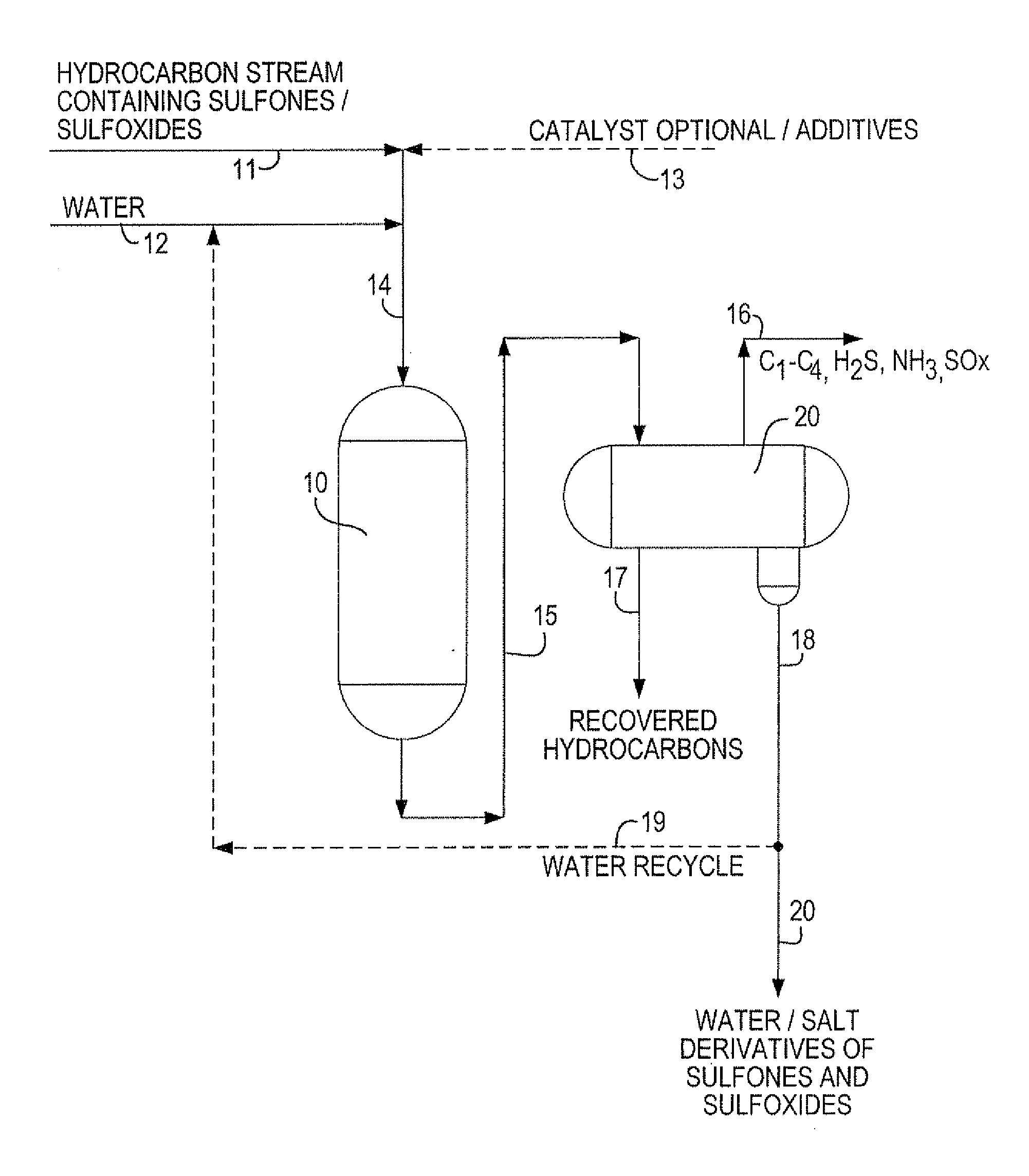

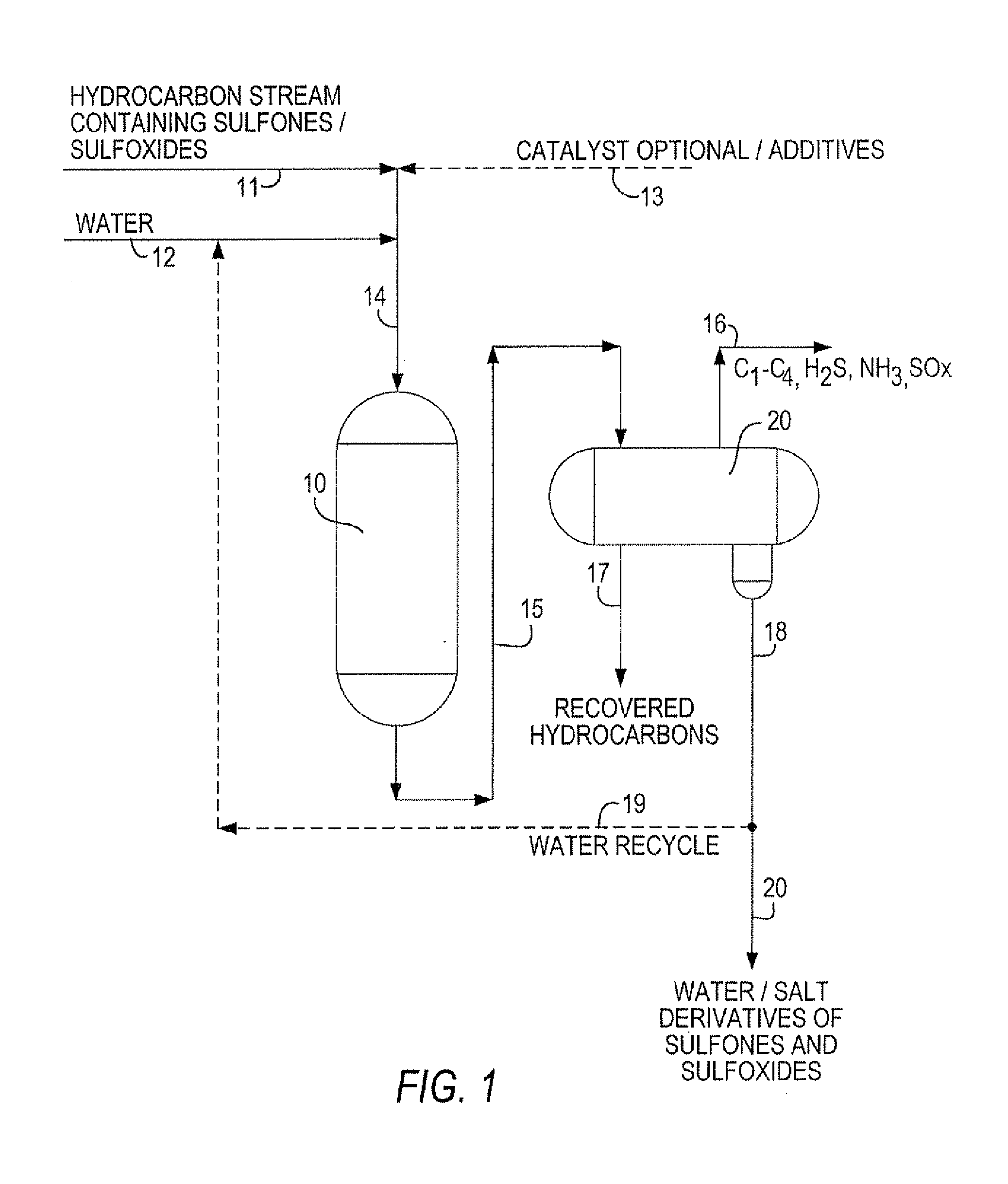

Sulfone cracking using supercritical water

ActiveUS20150284642A1Excessively large volumeRefining with non-metalsRefining with metalsSulfoneChemistry

Owner:SAUDI ARABIAN OIL CO

Preparation method of liquefied petroleum gas oxidation desulfurization agent

ActiveCN109233895AHigh affinityImprove adsorption capacityRefining with halogen compoundsOther chemical processesAbsorption capacityPetrochemical

The invention discloses a preparation method of a liquefied petroleum gas oxidation desulfurization agent, and relates to the technical field of petrochemical industry. The preparation method of the desulfurization agent comprises the steps of activating silica gel, modifying the silica gel and loading the silica gel; alpha-hydroxy acid and a silane coupling agent can enhance the affinity of silica gel for liquefied petroleum gas and the absorption capacity for polar substances; under the catalysis of additives, an oxidizing agent supported on the silica gel can quickly and efficiently oxidizesulfur-containing substances in the liquefied petroleum gas into polar oxides which can be absorbed by the silica gel. The modified silica gel is used as a desulfurizing agent, and an organic solventis not involved; the method is simple to operate, environmentally-friendly and remarkable in sulfur removal effect; furthermore, after absorption, the silica gel can be recycled, so that the method is low in cost and suitable for industrial production.

Owner:ANHUI HAIDE PETROCHEM

Method for removing sulfide in sulfur-containing raw oil by using ionic liquid

InactiveCN112300831AEfficient removalEasy to operateRefining with halogen compoundsRefining with oxygen compoundsPtru catalystSulfide

The invention provides a method for removing sulfide in sulfur-containing raw oil by utilizing ionic liquid. The method comprises the following steps: sulfur-containing raw oil is contacted with ionicliquid, an oxidizing agent and a catalyst and then stands still so that an obtained mixed system is layered, the lower layer is a sulfur-rich ionic liquid phase, and the upper layer is a sulfur-pooroil phase; and the mixed system is separated, and the sulfur-poor oil phase at the upper layer is collected. According to the method for removing the sulfide in the sulfur-containing raw oil by utilizing the ionic liquid, the sulfide in the sulfur-containing raw oil can be effectively removed, and the operation cost is relatively low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

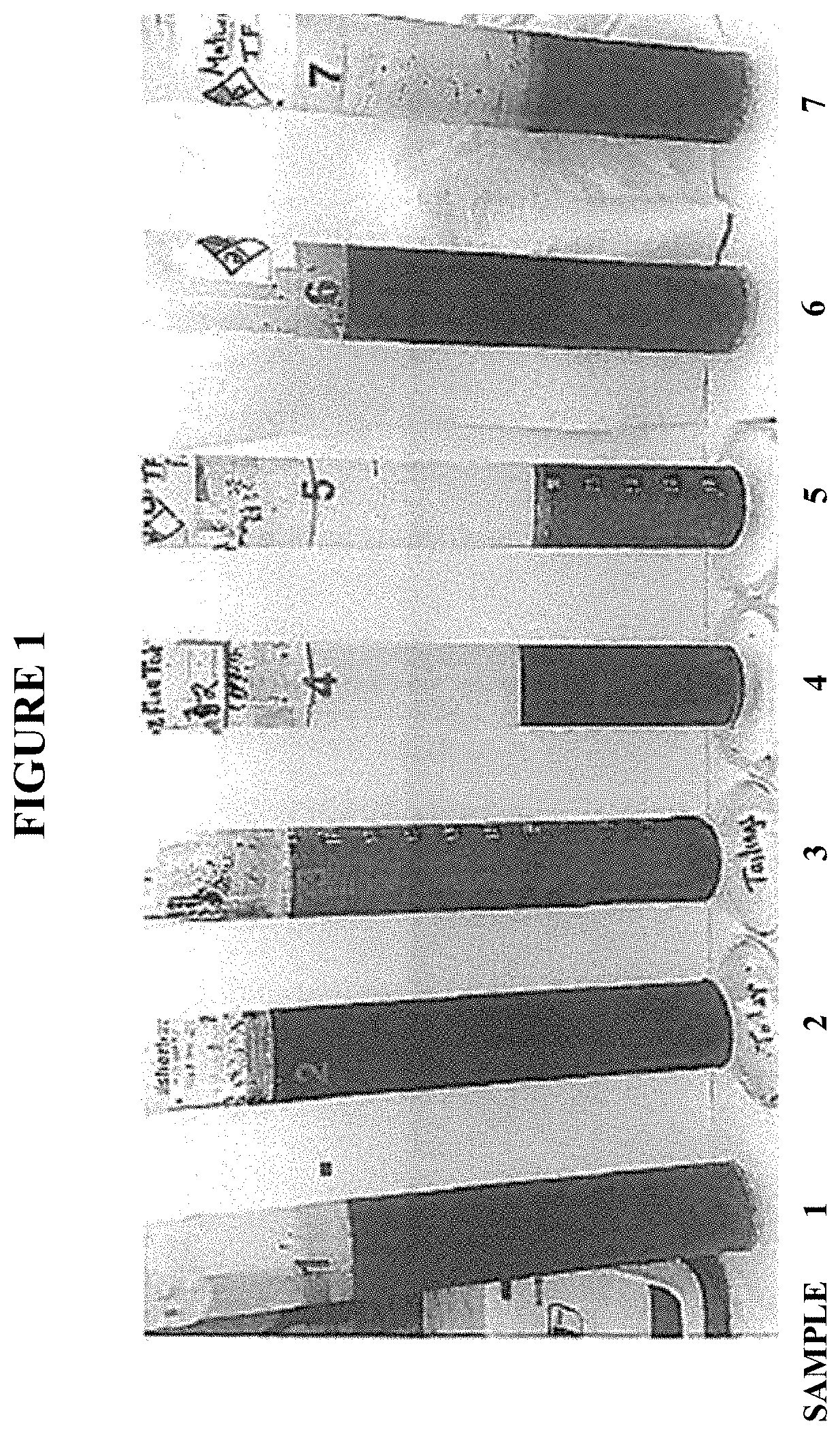

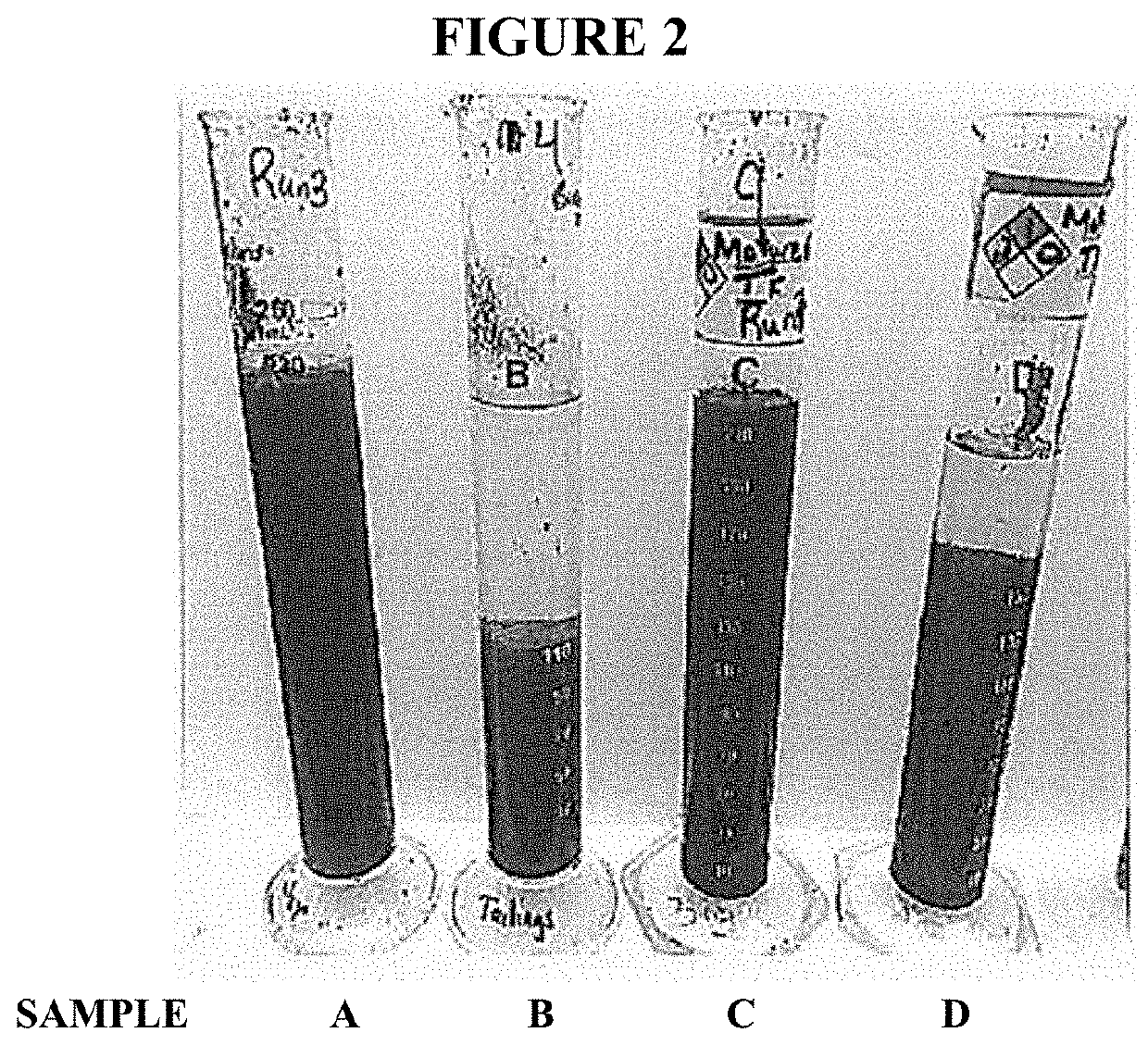

Methods of treating tailings

ActiveUS20190375994A1Promote flocculationImprove faultDewatering/demulsification with mechanical meansRefining with halogen compoundsMining engineeringOxidizing agent

The present embodiments generally relate to methods for the treatment of tailings, e.g., oil sands tailings, including methods comprising the use of one or more flocculants, one or more coagulants and one or more oxidants to treat said tailings and / or to improve the performance of said one or more flocculants.

Owner:KEMIRA OY

A kind of preparation method of hierarchical porous heteroatom aluminum phosphate molecular sieve for oxidative desulfurization

ActiveCN107777702BHigh crystallinityAvoid reunionRefining with halogen compoundsMolecular-sieve aluminophosphatesMolecular sievePtru catalyst

Owner:CHANGZHOU UNIV

Method of removing sulfides including hydrogen sulfide and mercaptan

InactiveUS7704380B2Adverse influenceLow costWaste water treatment from quariesGas treatmentAcetic acidThiol

In accordance with the present invention, a method of removing sulfide(s), which is safe, is effective over long periods at low cost, and exerts no adverse influences on the environment. The present invention relates to a method of removing sulfide(s), characterized in that a medium containing sulfide(s), including hydrogen sulfide and mercaptan(s), is allowed to come into contact with 2-bromo-2-nitropropane-1,3-diyl diacetate. Also, the present invention relates to the method, wherein the medium is a solid, liquid, or gas. In accordance with the present invention, sulfide(s), including hydrogen sulfide and mercaptan(s), can efficiently be treated so that they may be removed at low cost without the need for large-capacity equipment. In addition, the present invention can be safely practiced because there is no generation of byproducts that irritate the skin.

Owner:K I CHEM IND CO LTD

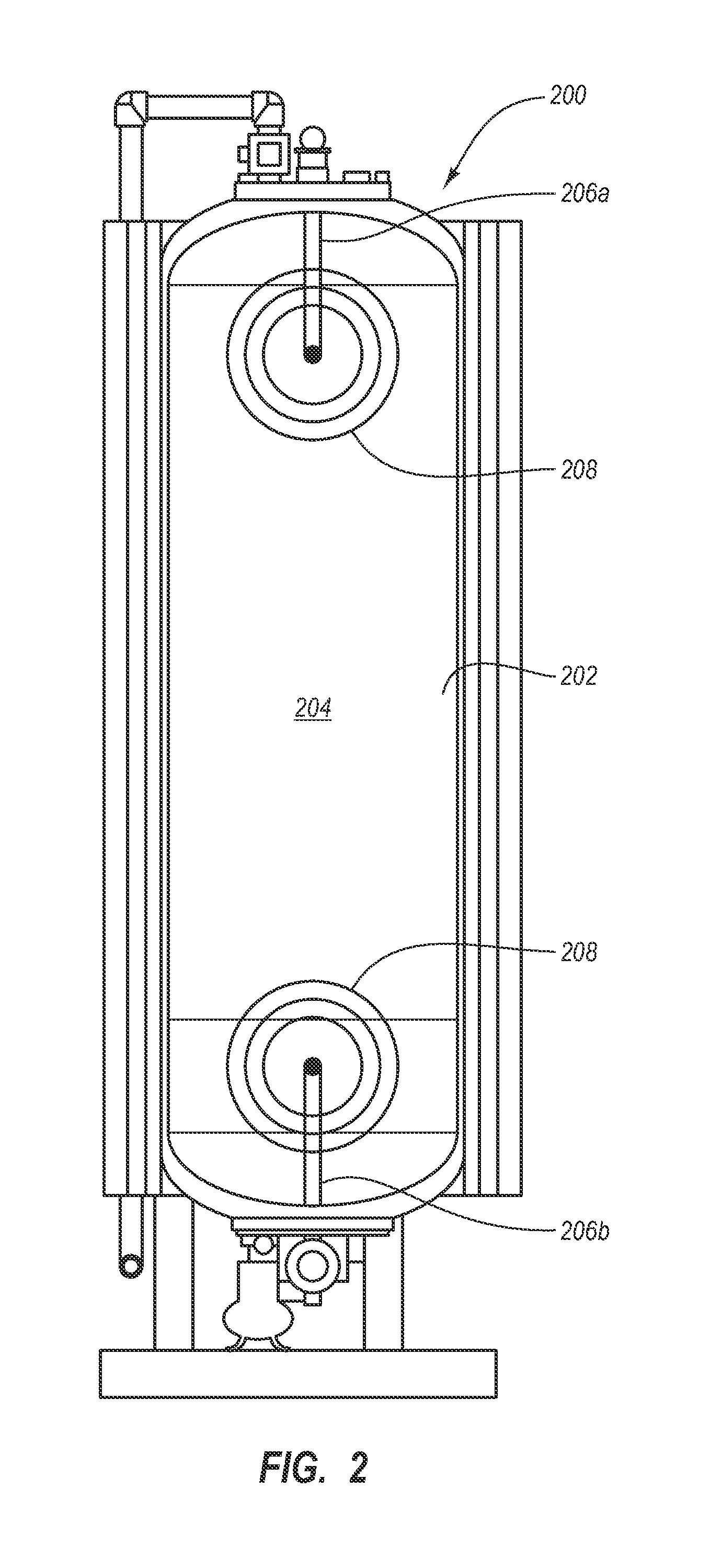

Method and system for oxidatively increasing cetane number of hydrocarbon fuel

ActiveUS20150075063A1Increase heightMinimize formationRefining with halogen compoundsRefining with oxygen compoundsUltrasonic cavitationHigh energy

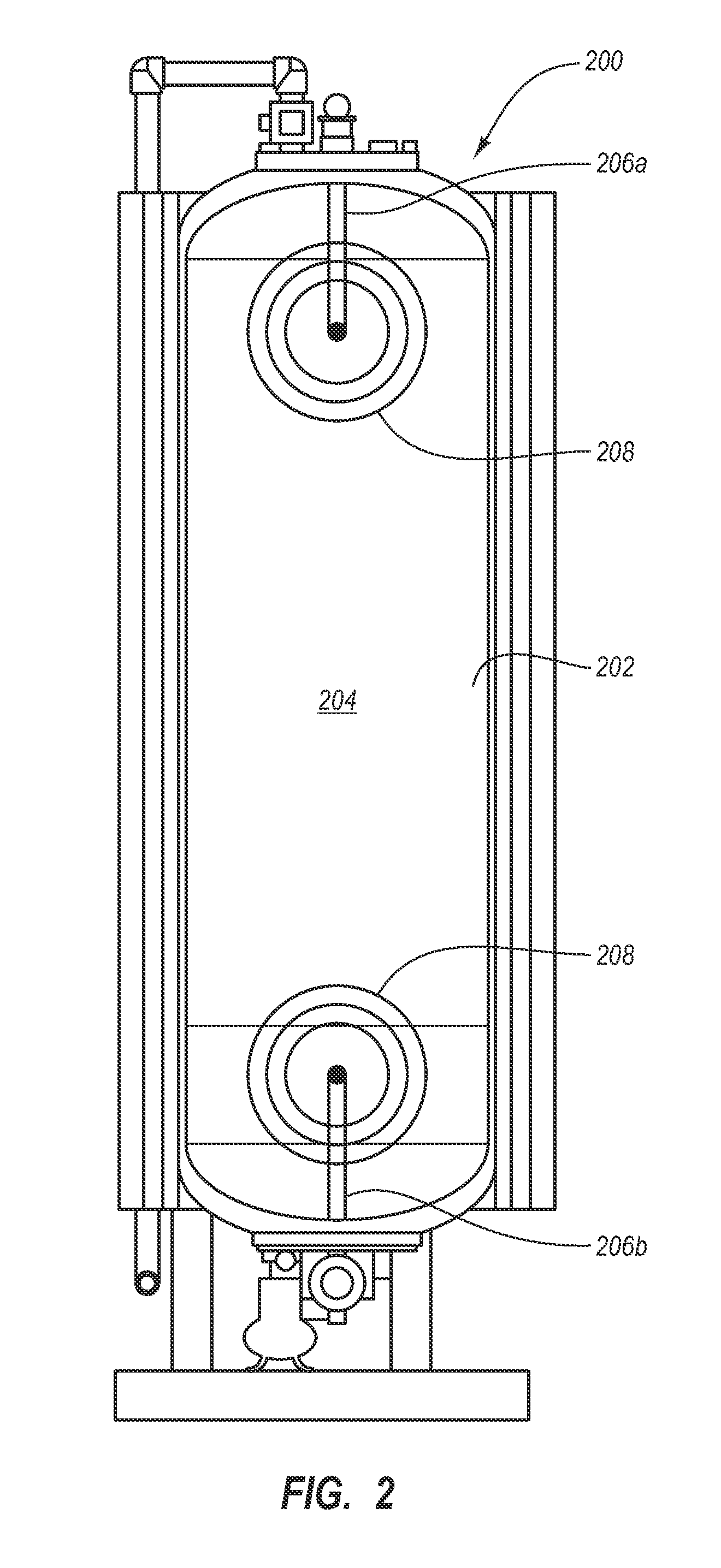

High energy (e.g., ultrasonic) mixing of a hydrocarbon feedstock and reactants comprised of an oxidation source, acid, and optional catalyst yields a liquid hydrocarbon product having increased cetane number. Ultrasonic mixing creates cavitation, which involves formation and violent collapse of micron-sized bubbles, which greatly increases reactivity of the reactants. Cavitation substantially increases cetane number compared to reactions carried out using conventional mixing processes, such as simple mechanical stifling. An aqueous mixture comprising water and acid can be pretreated with ozone or other oxidizer using ultrasonic cavitation prior to reacting the pretreated mixture with a hydrocarbon feedstock to promote cetane-increasing reactions. Controlling temperature inside the reactor promotes beneficial cetane-increasing reactions while minimizing formation of water-soluble sulfones.

Owner:CETAMAX VENTURES

Method for reducing mercaptans in hydrocarbons

ActiveUS9296956B2Refining with halogen compoundsTreatment with plural serial refining stagesHypochloriteOrganic chloride compound

A method for reducing mercaptan concentration in a crude oil is disclosed. The method comprises contacting the crude with a treating solution comprising a hypochlorite solution, whereby the mercaptan sulfur is oxidized and converted to at least one sulfur oxoacid or salt thereof, yielding a treated crude oil having less than 50 ppm mercaptan sulfur and residual organic chloride. The treated crude oil containing residual organic chloride is brought in contact with a caustic solution at a molar ratio of caustic to chloride of 0.1:1 to 50:1, generating an upgraded crude oil with less than 10 ppm organic chloride. In one embodiment, the spent treating solution is recycled to form a regenerated hypochlorite stream for use in the treatment solution.

Owner:CHEVROU USA INC

Hydrogen peroxide-chlorine combined fuel oil oxidation treatment method

InactiveCN104694152BReduce oxidation treatment costsEasy to getRefining with halogen compoundsHydrocarbon oils treatmentFuel oilOxidative treatment

The invention provides a fuel oil oxidation treatment method applicable to fuel oil desulfurization. Hydrogen peroxide and chlorine together react with fuel oil at the same time, and the fuel oil at the end of reaction is oxidation treated fuel oil. The fuel oil treated by the method is more easily desulfurized by a liquid-liquid extraction process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of preparation method of liquefied petroleum gas oxidation desulfurizer

ActiveCN109233895BHigh affinityImprove adsorption capacityRefining with halogen compoundsOther chemical processesOrganosolvPetrochemical

The invention discloses a preparation method of a liquefied petroleum gas oxidation desulfurization agent, and relates to the technical field of petrochemical industry. The preparation method of the desulfurization agent comprises the steps of activating silica gel, modifying the silica gel and loading the silica gel; alpha-hydroxy acid and a silane coupling agent can enhance the affinity of silica gel for liquefied petroleum gas and the absorption capacity for polar substances; under the catalysis of additives, an oxidizing agent supported on the silica gel can quickly and efficiently oxidizesulfur-containing substances in the liquefied petroleum gas into polar oxides which can be absorbed by the silica gel. The modified silica gel is used as a desulfurizing agent, and an organic solventis not involved; the method is simple to operate, environmentally-friendly and remarkable in sulfur removal effect; furthermore, after absorption, the silica gel can be recycled, so that the method is low in cost and suitable for industrial production.

Owner:ANHUI HAIDE PETROCHEM

Methods of treating tailings

ActiveUS11242492B2Reduce molecular weightReduce turbidityDewatering/demulsification with mechanical meansRefining with halogen compoundsMining engineeringOxidizing agent

The present embodiments generally relate to methods for the treatment of tailings, e.g., oil sands tailings, including methods comprising the use of one or more flocculants, one or more coagulants and one or more oxidants to treat said tailings and / or to improve the performance of said one or more flocculants.

Owner:KEMIRA OY

Treatment method of ageing oil

InactiveCN107474874AChange physical propertiesImprove liquidityDewatering/demulsification with chemical meansRefining with halogen compoundsMedicineAdditive ingredient

The invention relates to a treatment method of ageing oil, and mainly solves the problem that the existing process cannot fundamentally change the condition of serious influence caused by the ageing oil form on the subsequent production. The treatment method is characterized by comprising the following steps of (1) determining the ingredients of the ageing oil: performing qualitative analysis on the ageing oil; (2) selecting an oxidizing agent for treating the ageing oil, and performing oxidation treatment on the ageing oil; (3) detecting the performance indexes of the ageing oil treated in the step (2): performing qualitative analysis on the treated ageing oil ingredients and performing qualitative analysis on the influence of the treated ageing oil on an electric dehydrator. The treatment method of the ageing oil has the advantages that the physical property of the ageing oil can be fundamentally changed; the oil and water separation effect of the ageing oil is enhanced.

Owner:PETROCHINA CO LTD +1

Condensate oil deodorization method

ActiveCN104593043BFacilitate subsequent processingNo emissionsRefining with halogen compoundsRefining with oxygen compoundsOrganic baseFractionating column

The invention provides a gas condensate deodorization method. The method comprises the following steps of mixing or contacting gas condensate, an activator, an oxidizing agent and a deodorization catalyst, and collecting the mixed or contacted gas condensate, wherein the activator comprises a mixture of a water-soluble ether compound, inorganic base and / or organic base, and a water-soluble polar solvent, the water-soluble ether compound has a structure of R1(OR2)nOR3, R1, R2 and R3 respectively represent C1-C8 alkyl and n is an integer of 1-5. The gas condensate deodorization method transforms low-boiling point sulfide in the gas condensate into high-boiling point sulfide thereby realizing deodorization, can be operated simply and safely, does not discharge waste, is suitable for oil field, harbor, oil depot and oil refinery and is conducive to follow-up processing of gas condensate. The gas condensate deodorization method has lasting deodorization effects, can substantially improve smell, directly improves gas condensate corrosivity to a distillation column, reduces sulfur content of a follow-up product and desulphurization load in processing and reduces desulphurization sewage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and system for oxidatively increasing cetane number of hydrocarbon fuel

ActiveUS9453177B2Increase heightMinimize formationRefining with halogen compoundsRefining with oxygen compoundsUltrasonic cavitationHigh energy

High energy (e.g., ultrasonic) mixing of a hydrocarbon feedstock and reactants comprised of an oxidation source, acid, and optional catalyst yields a liquid hydrocarbon product having increased cetane number. Ultrasonic mixing creates cavitation, which involves formation and violent collapse of micron-sized bubbles, which greatly increases reactivity of the reactants. Cavitation substantially increases cetane number compared to reactions carried out using conventional mixing processes, such as simple mechanical stirring. An aqueous mixture comprising water and acid can be pretreated with ozone or other oxidizer using ultrasonic cavitation prior to reacting the pretreated mixture with a hydrocarbon feedstock to promote cetane-increasing reactions. Controlling temperature inside the reactor promotes beneficial cetane-increasing reactions while minimizing formation of water-soluble sulfones.

Owner:CETAMAX VENTURES

Removing unstable sulfur compounds from crude oil

ActiveUS9062260B2Reduce sulfur contentRefining with metalsMolecular sieve catalystsSulfurReaction zone

A crude oil which contains at least 0.1 wt % unstable sulfur compounds is treated in a reaction zone at low temperature to convert at least 50 wt % of the unstable sulfur compounds contained therein. The reaction and removal of sulfur from the crude may be facilitated by contacting the crude oil with a catalytic material in the presence of a stripping fluid.

Owner:CHEVROU USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com