Hydrogen peroxide-chlorine combined fuel oil oxidation treatment method

A hydrogen peroxide, oxidation treatment technology, applied in the treatment of hydrocarbon oil, petroleum industry, refining with halogen compounds, etc., to achieve the effect of reducing the cost of oxidation treatment and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

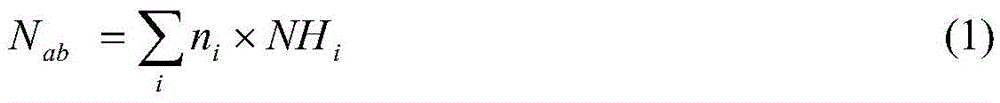

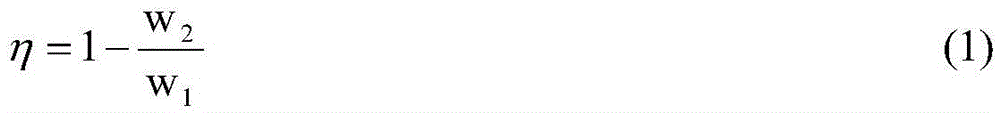

[0044] Simulated gasoline formulated from n-octane and 4,6-dimethyldibenzothiophene (composition: 3.3112g 4,6-dimethyldibenzothiophene + 996.7g n-octane) and decahydronaphthalene and 4 , The simulated diesel oil formulated with 6-dimethyldibenzothiophene (the composition is 3.3112g 4,6-dimethyldibenzothiophene + 996.7g decahydronaphthalene) has a sulfur content of 500mg / kg. Take 50ml of any simulated fuel (simulated gasoline or simulated diesel) and keep the simulated fuel at -20°C. Add 2g of KOH solid and 2ml of aqueous hydrogen peroxide solution with a mass fraction of 51.47% to the simulated fuel successively, stir to mix the oil phase and the water phase, and inject chlorine gas into the simulated fuel at a chlorine gas flow rate of 0.026mmol / min for 5 hours Afterwards, the feeding of chlorine gas was stopped to terminate the reaction, and the reaction mixture was left to stand and then separated into layers. After the water layer and the oil layer are separated, use 50ml...

Embodiment 2

[0046] Simulated gasoline formulated from n-octane and 4,6-dimethyldibenzothiophene (composition: 3.3112g 4,6-dimethyldibenzothiophene + 996.7g n-octane) and decahydronaphthalene and 4 , The simulated diesel oil formulated with 6-dimethyldibenzothiophene (the composition is 3.3112g 4,6-dimethyldibenzothiophene + 996.7g decahydronaphthalene) has a sulfur content of 500mg / kg. Take 50ml of any simulated fuel (simulated gasoline or simulated diesel) and keep the simulated fuel at -16°C. Dissolve 50g of KOH solid into 50g of water to form an aqueous potassium hydroxide solution, then slowly add the entire aqueous potassium hydroxide solution to 84g of an aqueous hydrogen peroxide solution with a mass fraction of 51.47% at -16°C to form hydrogen peroxide-water-potassium hydroxide solution. Take 5.0g of hydrogen peroxide-water-potassium hydroxide solution and add it to the simulated fuel oil, stir to mix the oil phase and the water phase, and inject chlorine gas into the simulated f...

Embodiment 3

[0048] Simulated gasoline formulated from n-octane and 4,6-dimethyldibenzothiophene (composition: 3.3112g 4,6-dimethyldibenzothiophene + 996.7g n-octane) and decahydronaphthalene and 4 , The simulated diesel oil formulated with 6-dimethyldibenzothiophene (the composition is 3.3112g 4,6-dimethyldibenzothiophene + 996.7g decahydronaphthalene) has a sulfur content of 500mg / kg. Take 50ml of any simulated fuel (simulated gasoline or simulated diesel) and keep the simulated fuel at -20°C. Add 5gCH to the simulated fuel successively 3 COONH 4 Solid and 2ml hydrogen peroxide aqueous solution with a mass fraction of 51.47%, stirring to mix the oil phase and the water phase, and injecting chlorine gas into the simulated fuel oil at a chlorine gas flow rate of 0.026mmol / min, and stopping the chlorine gas injection after 5 hours to complete the reaction , the reaction mixture was separated after standing. After the water layer and the oil layer are separated, use 50ml of water to extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com