Process, method, and system for removing heavy metals from fluids

A technology for heavy metals and trace heavy metals, which is applied in the fields of refining with metal salts, petroleum industry, and treating hydrocarbon oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

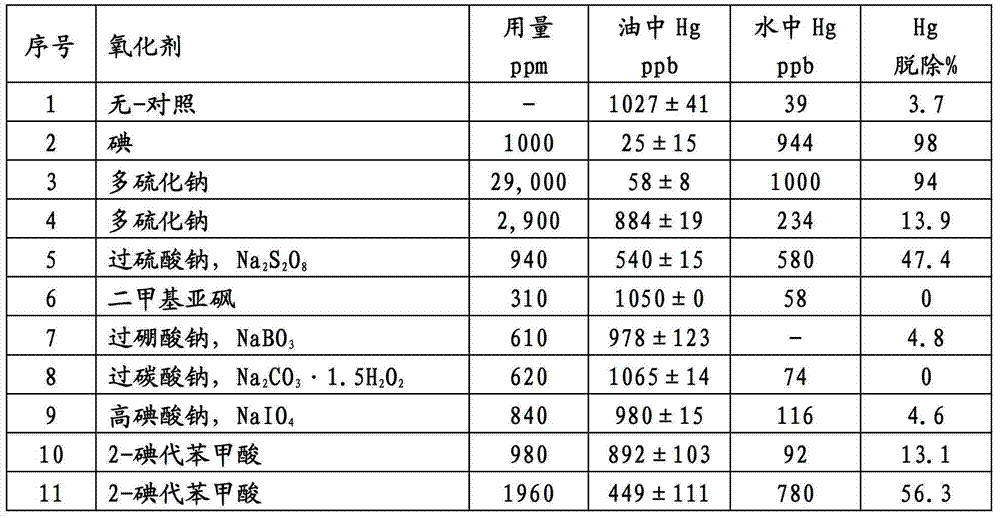

[0086] Examples 1-11 : A series of experiments were performed, each using a different oxidant. Example 1 is a control experiment without using any oxidizing agent (only using the complexing agent TETREN at a final concentration of 30 μM). For each of experiments 2-11, 5 mL of the mercury vapor feed was placed in a 10 mL Teflon capped centrifuge tube. Oxidant was added to achieve the final concentrations shown in Table 1. Shake the tube vigorously for about 2 minutes. Add 5 mL of distilled water to the tube. A predetermined volume of TETREN was added to achieve a final concentration of 30 μM. Again, shake the tube vigorously by hand for about 2 minutes, then centrifuge for 1 minute to separate the oil and water. Hg was determined on oil and water aliquots using a Lumex Hg analyzer equipped with a Pyro-915+. The experimental results are shown in Table 1.

[0087] Table 1

[0088]

Embodiment 12-14

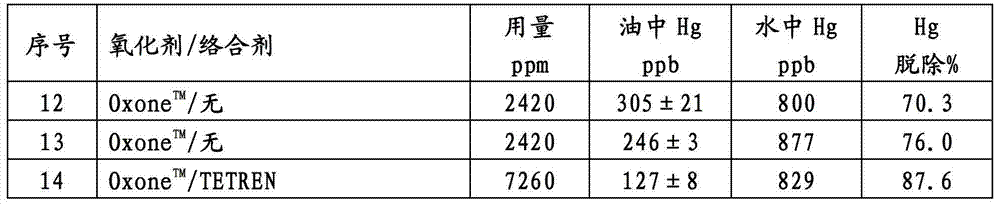

[0089] Examples 12-14: Repeat the same procedure of Examples 1-11, but use different dosage levels of Oxone TM (2KHSO 5 ·KHSO 4 ·K 2 SO 4 ) as the oxidizing agent, and using the different complexing agents shown in Table 2 (or not). The results are listed in Table 2.

[0090] Table 2

[0091]

Embodiment 15-25

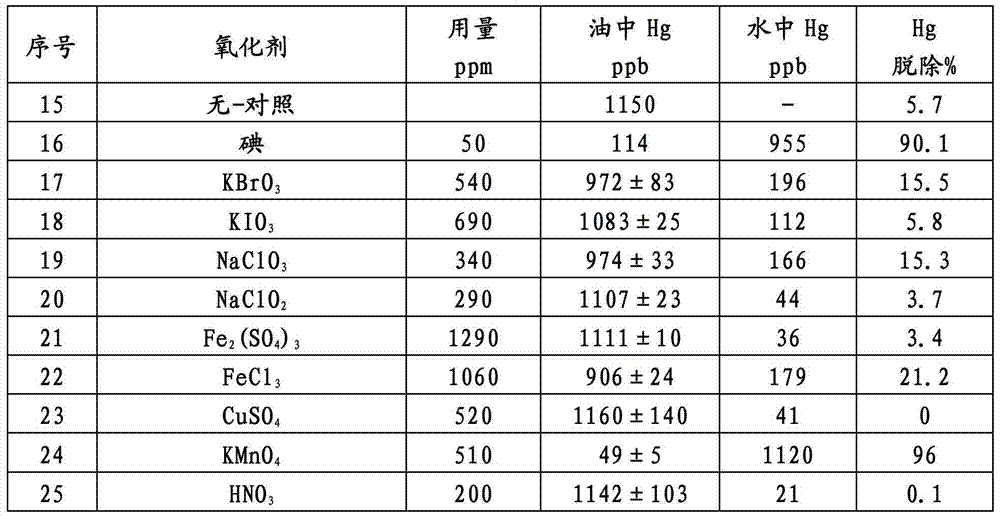

[0092] Examples 15-25 : The same procedure was repeated, but using different oxidizing agents at different concentrations as indicated in the table, and using TETREN as the complexing agent at a final added concentration of 1,500 ppm. The results are shown in Table 3.

[0093] table 3

[0094]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com