A kind of arsenic-containing wastewater treatment method

A waste water treatment and waste water collection technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of large area of facilities and failure to meet discharge standards, etc., to achieve Save application costs, improve the efficiency of drug use, and avoid unstable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

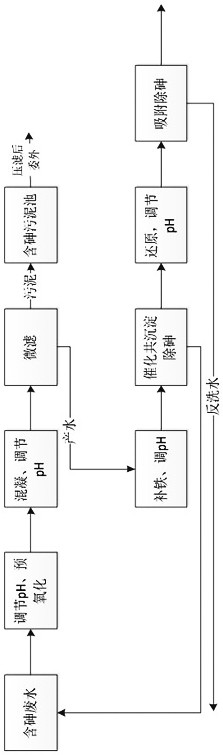

Image

Examples

Embodiment 1

[0037] Example 1: Water quality of arsenic-containing wastewater from a gallium arsenide semiconductor enterprise: There are two different concentrations of arsenic-containing wastewater in this enterprise: (1) arsenic-containing acid-alkaline wastewater: pH 3~9.5, arsenic content in wastewater TAs<100mg / L , Suspended solids content in wastewater SS<10mg / L, discharge rate 120m3 / d; (2) Arsenic-containing grinding wastewater: pH 3~9.5, TAs<100mg / L, SS<300mg / L, discharge rate 120m3 / d. Two kinds of waste water are jointly collected to the regulating tank for post-processing. This embodiment includes the following steps:

[0038] The first step: adjust the pH of the collected arsenic-containing wastewater to 6.5~7.5, and the reaction time is 30 minutes; then add 10% sodium hypochlorite to maintain ORP>400mV, and the reaction time is 30 minutes;

[0039] Step 2: Add 20% ferric chloride, the flow rate is 60L / h, adjust the pH to 7.5~9.5, and coagulate for 30 minutes. Then enter the c...

Embodiment 2

[0044] Example 2: An LED semiconductor production enterprise, the high-concentration arsenic-containing wastewater quality of the enterprise is: design discharge rate 20 m3 / h, COD 10-150 mg / L, SS 0-400 mg / L, TAs 50-250 mg / L , TP 10-20 mg / L, pH 3-7. The process steps before transformation are as follows:

[0045] The first step: adjust the pH of the collected arsenic-containing wastewater to 6.5~7.5, and the reaction time is 30 minutes; then enter the oxidation tank, add 10% sodium hypochlorite to maintain ORP>400mV, the reaction time is 30 minutes, and the effluent enters the reaction tank;

[0046] The second step: add 20% ferric chloride to the reaction tank, the flow rate is 288L / h, the pH is adjusted to 7.5~9.5, the coagulation reaction is 60min, then PAM is added, the reaction is 30min, and enter the sedimentation tank. The hydraulic retention time of the sedimentation tank is 4.5h, the supernatant enters the relay tank, and the hydraulic retention time of the relay tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com