A kind of method for separating gasoline fraction and gasoline desulfurization method

A gasoline fraction and fraction technology, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrocarbon oil treatment products, etc., can solve problems such as loss of octane number, difficulty in obtaining gasoline products, and incomplete separation of olefins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

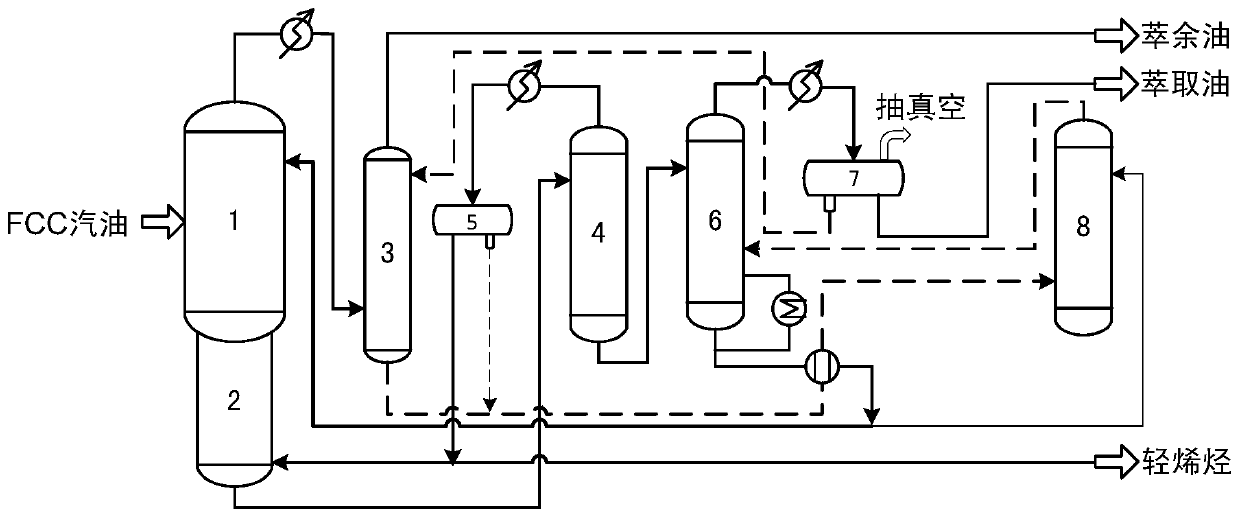

[0101] use image 3 The separation device shown and the above-mentioned process flow are used to separate the full-fraction FCC gasoline from Daqing. The composition and physical properties of this raw material are shown in Table 1.

[0102] The raw material enters from the lower part of the extraction section 1, and the extraction solvent (92v% sulfolane, 7v% tetraethylene glycol, 1v% water) enters from the upper part of the extraction section 1.

[0103] The solvent-poor raffinate obtained from the top of the extraction section 1 enters the solvent removal tower 3 for water washing, and the amount of washing water is about 4 times the mass flow rate of the poor-solvent raffinate oil, and the obtained raffinate is discharged from the top of the solvent removal tower 3 .

[0104] The solvent-rich extraction oil obtained at the bottom of the extraction section 1 enters the olefin recovery column 4 from the stripping section 2 . The olefin-rich fraction is obtained at the top...

Embodiment 2

[0117] use image 3 The separation device shown and the above process flow are used to separate the distillates from Jingbo FCC gasoline. The composition and physical properties of the raw material are shown in Table 4, the control of specific process conditions is shown in Table 5, and the composition of raffinate oil, extracted oil and light olefin fraction is shown in Table 6.

[0118] Table 4 Composition of Distillate Raw Materials in FCC Gasoline

[0119]

[0120] Table 5 Process condition parameters of each equipment

[0121]

[0122]

[0123] Table 6 The composition of the properties of the three streams

[0124]

[0125] It can be seen from Table 6 that by using the separation method in this example, the FCC gasoline fraction with an end boiling point not higher than 130°C can be separated into raffinate, extracted oil and light olefin fraction, which have significant hydrocarbon composition differences. part. After calculation, the sum of the olefin co...

Embodiment 3

[0128] With Prime-G + technology, the extracted oil obtained in Example 2 is subjected to selective hydrodesulfurization to obtain desulfurized oil, wherein the reaction pressure is 2.3MPa, the hydrogen-oil volume ratio is 9.6, and the space velocity is 4.9 / h -1 , the reaction temperature is 250°C;

[0129] The raffinate oil in Example 2 was mixed with the above-mentioned desulfurized oil to obtain a mixed oil.

[0130] Among them, the specific composition and physical properties of the gasoline fraction in Example 2 (from Chambord FCC gasoline), and the specific composition and physical properties of the mixed oil can be found in Table 7.

[0131] It can be seen from Table 7 that the olefin content in the mixed oil is significantly lower than that in the gasoline fraction, but the octane number is slightly increased.

[0132] By mixing the mixed oil with blended gasoline such as isomerized gasoline and aromatic gasoline, gasoline products with an olefin content of less than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com