Patents

Literature

31results about How to "Save unloading time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of 5-acetyl acetamino benzimidazolone

The invention relates to a technology for producing 5-acetyl amido benzimidazolone. The condensation process is as follows: o-phenylendiamine, carbamide, water and concentrated sulfuric acid are added into a condensation reaction kettle step by step, the pH value is controlled to between 6 and 7, and benzimidazolone is obtained by drying the mixture; the nitration process is as follows: the benzimidazolone, chlorinated benzene and concentrated sulfuric acid are added into a nitration reaction kettle, the chlorinated benzene is reclaimed and purified by reduced pressure distillation and water boiling, and 5-nitryl benzimidazolone is obtained by drying the mixture; the reduction process is as follows: the 5-nitryl benzimidazolone, iron powder, hydrochloric acid and water are added into a reduction reaction kettle, the mixture is subject to suction filtering, cooling, crystallization and drying after the reaction for producing the 5-amino benzimidazolone; and the acetylization process is as follows: the 5- amino benzimidazolone, Diketene, phosphoric acid, caustic soda liquid and water are added into an acetylization kettle, the pressure inside the kettle is discharged in the temperature rising process, and the mixture is subject to suction filtering and drying to produce the 5-acetyl amido benzimidazolone. The process has the total yield coefficient up to 75 percent, purity quotient more than 99 percent and the product quality which meets the international standards of the same products at home and abroad.

Owner:DONGYING TIANZHENG CHEM

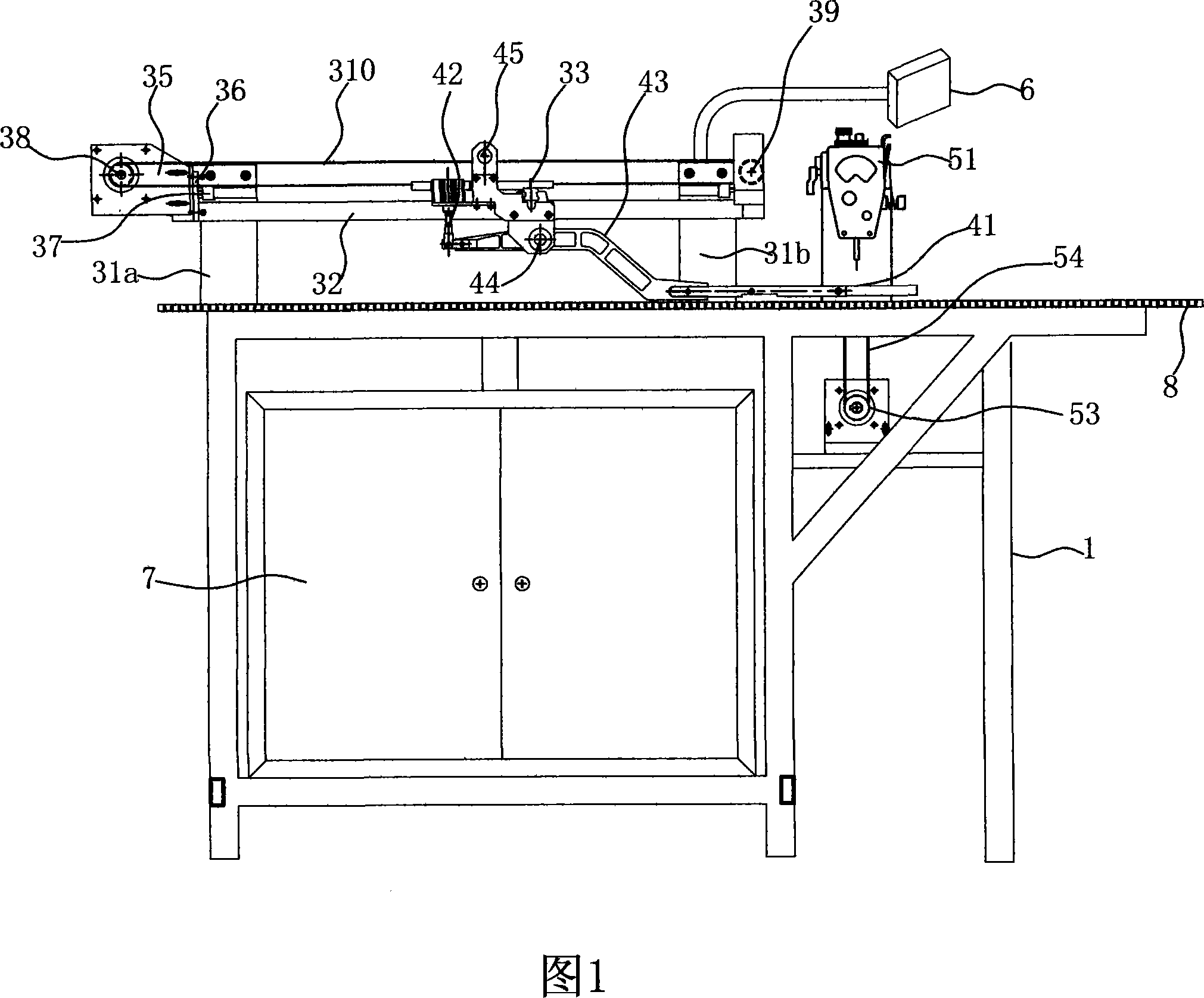

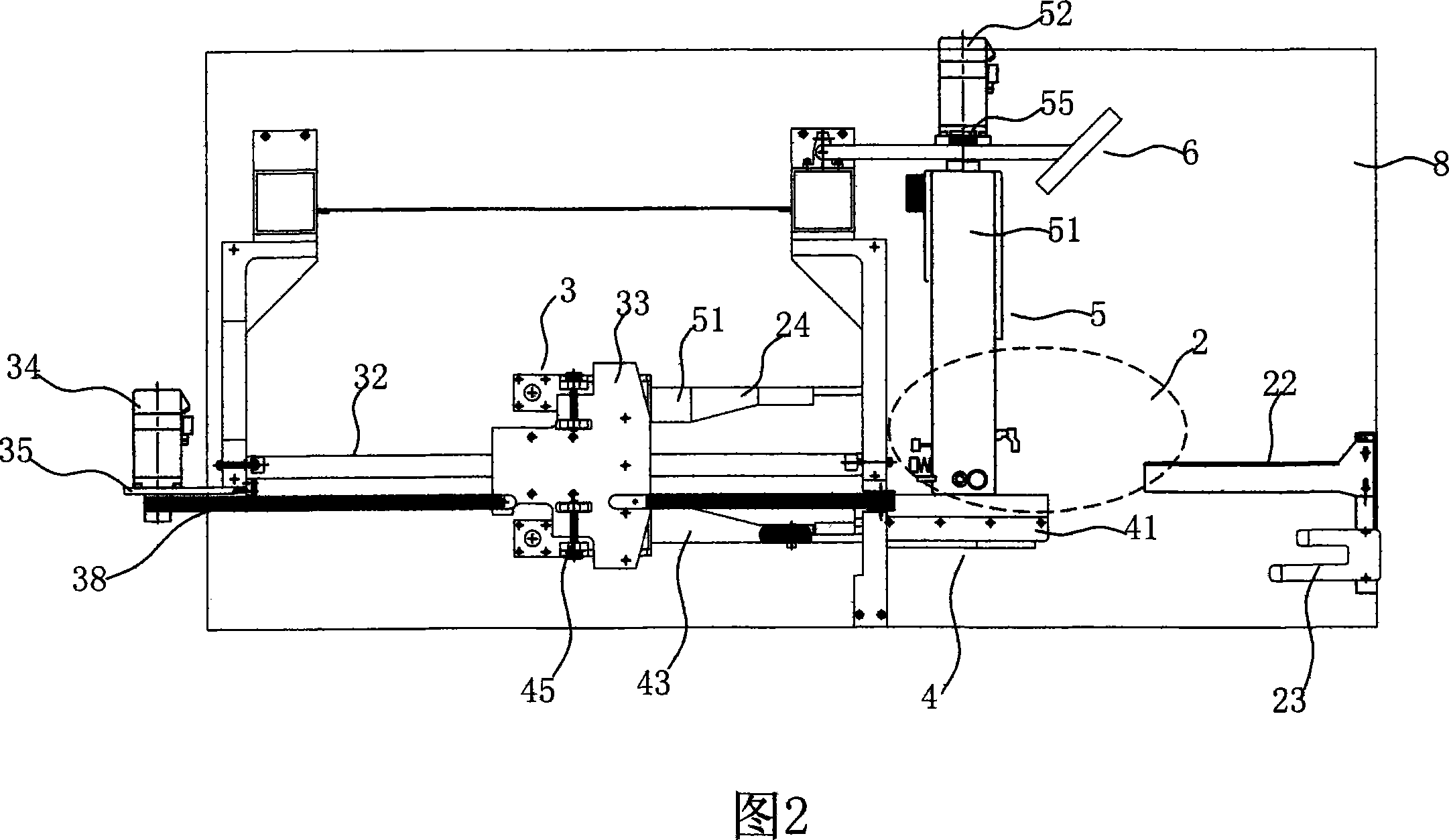

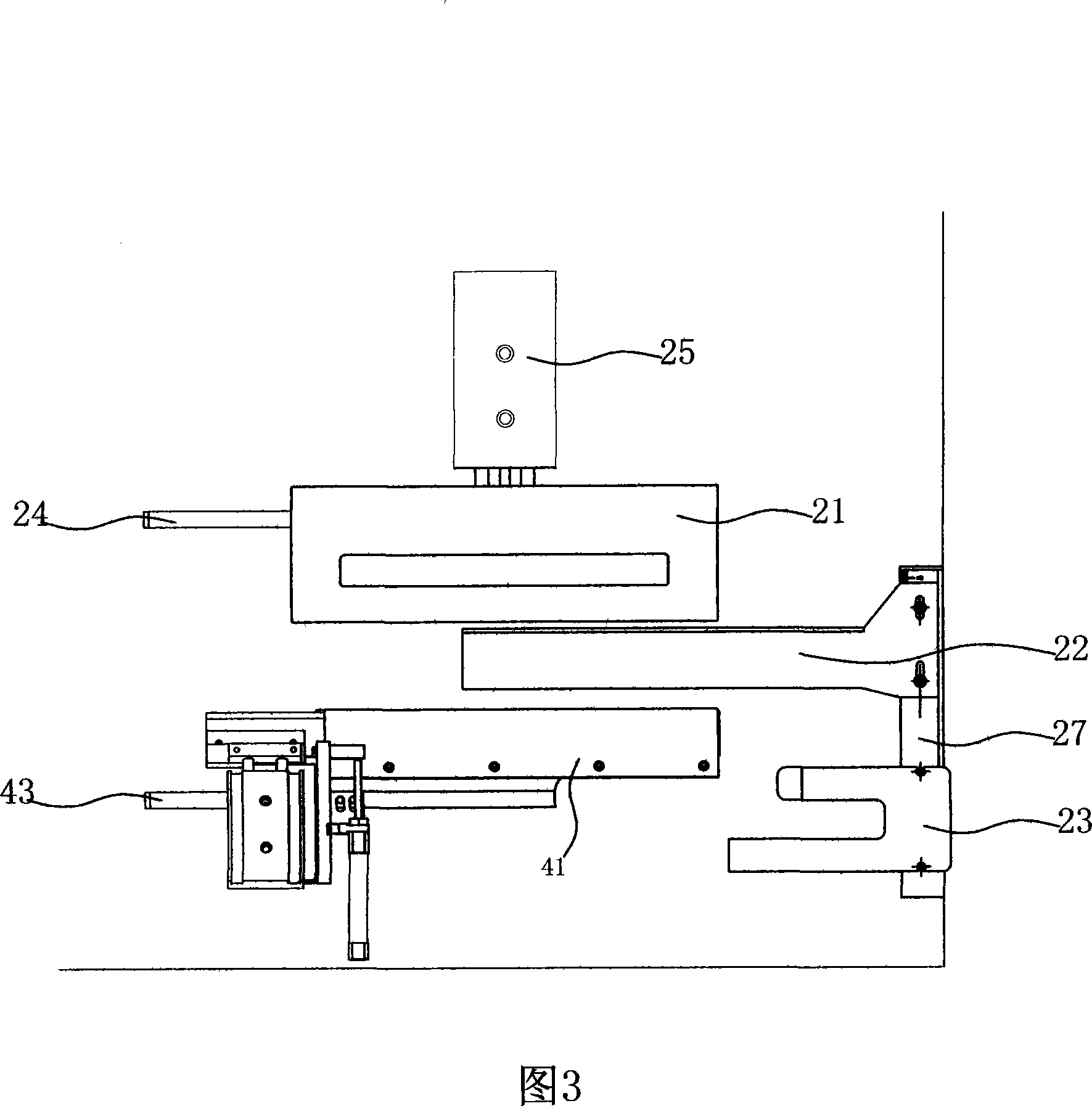

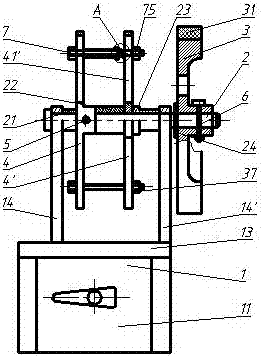

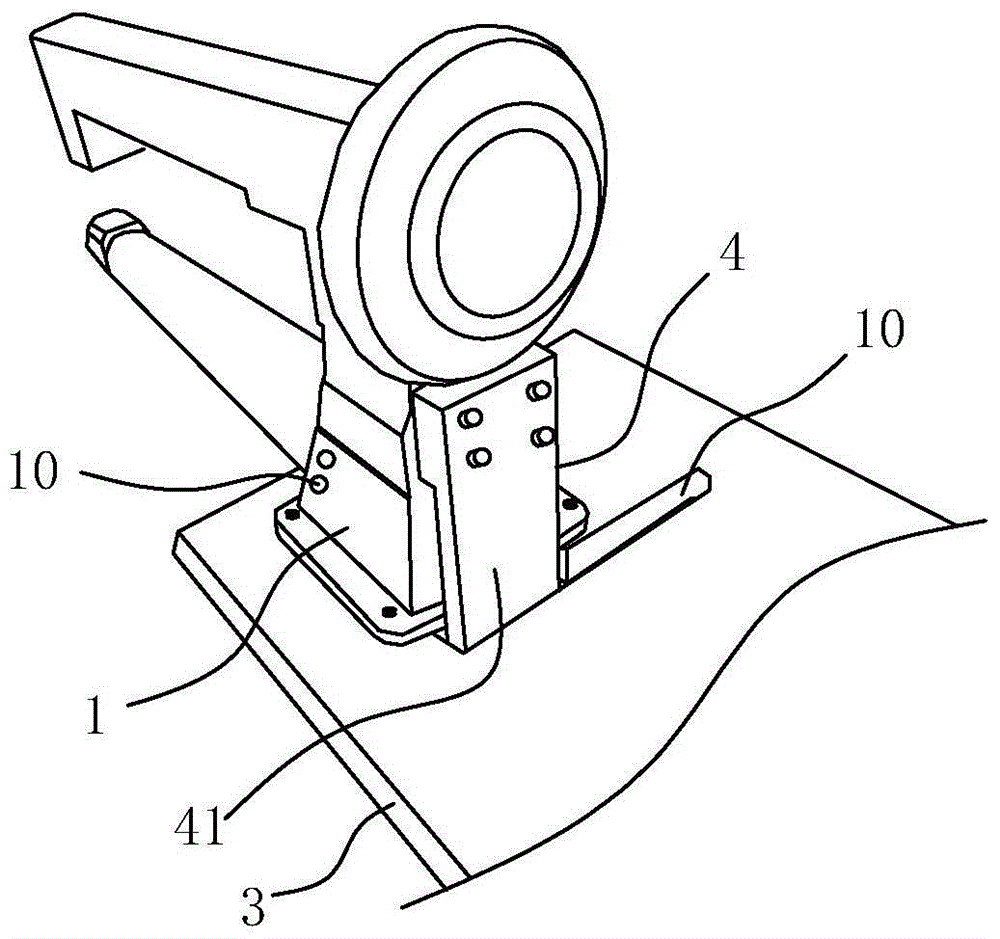

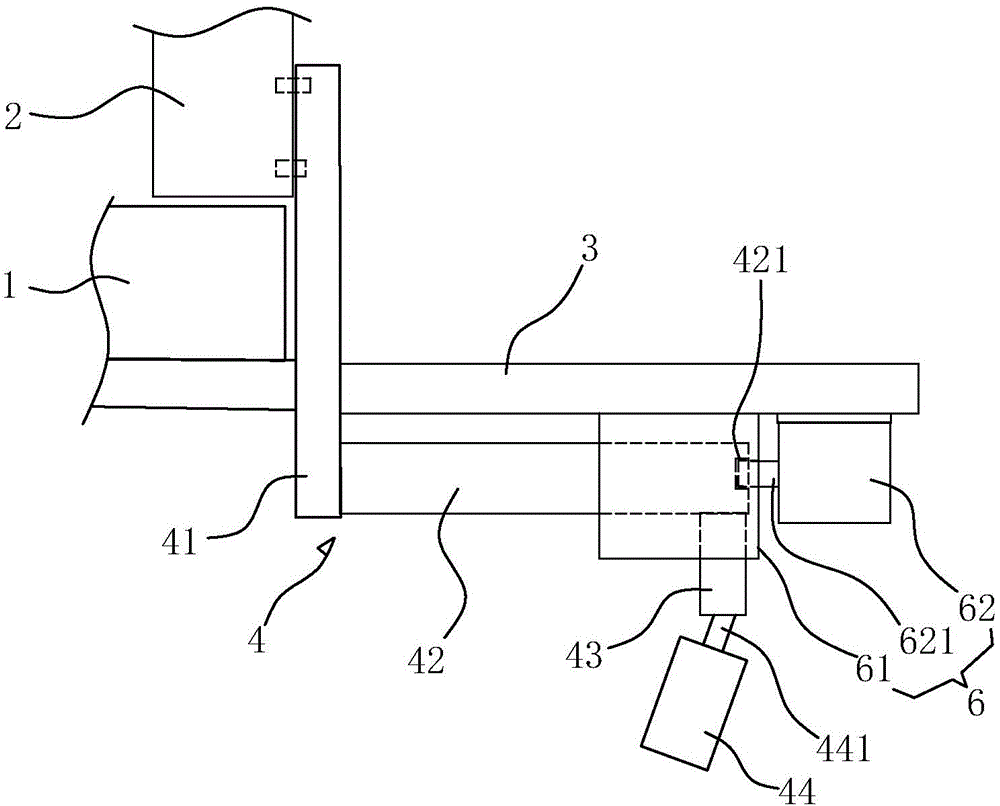

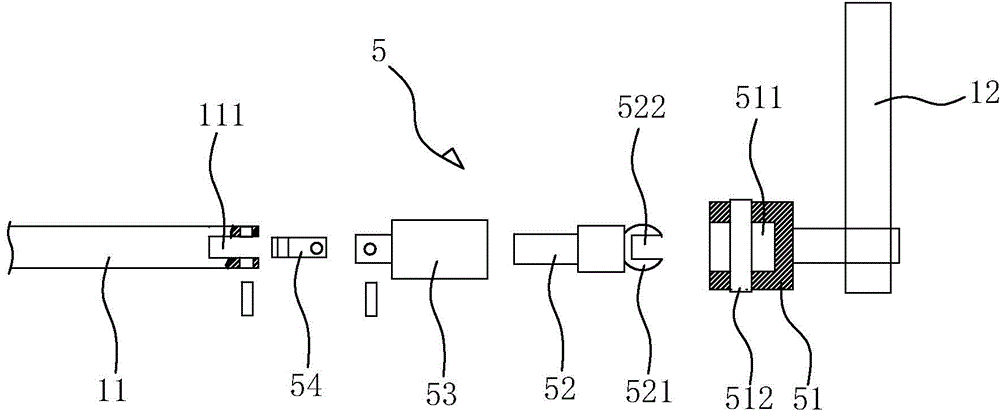

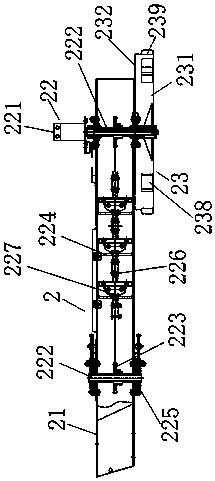

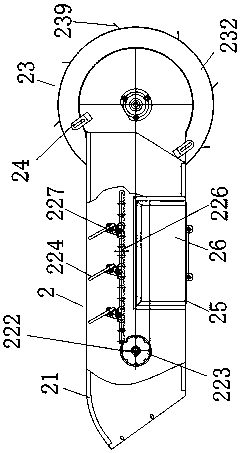

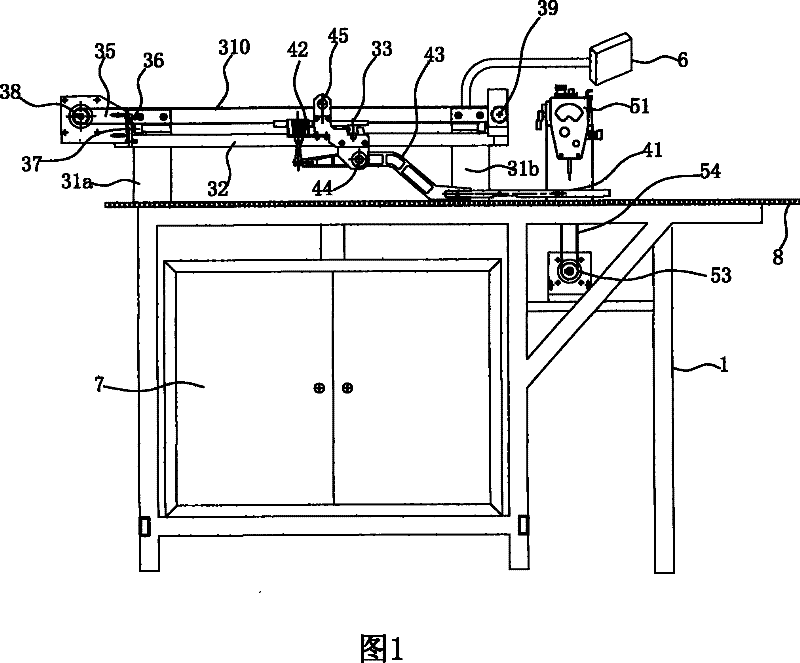

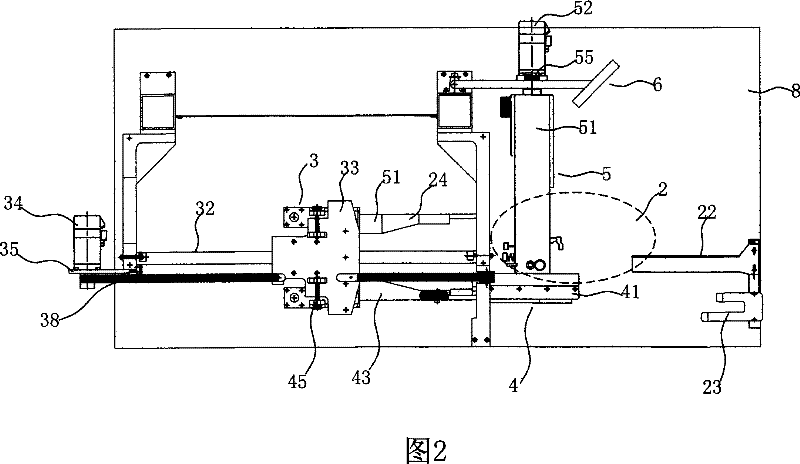

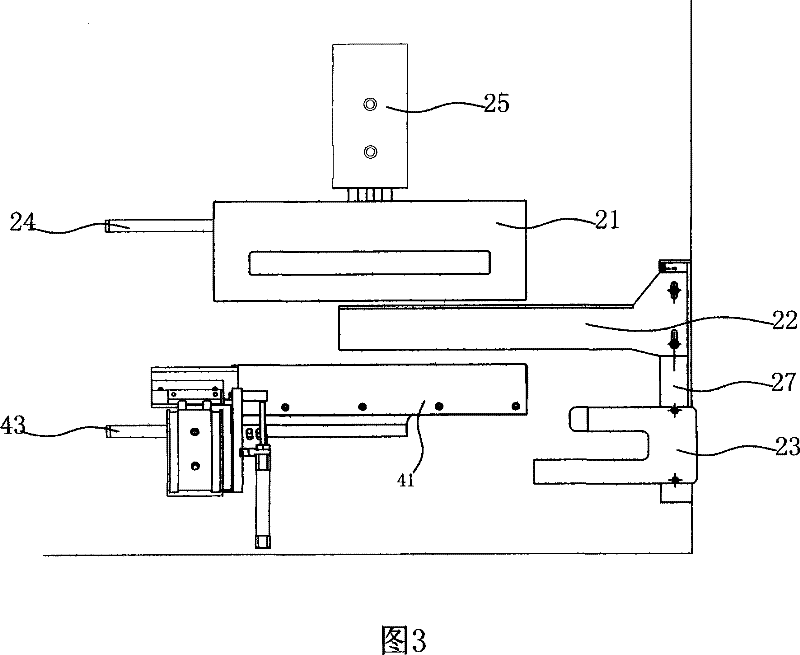

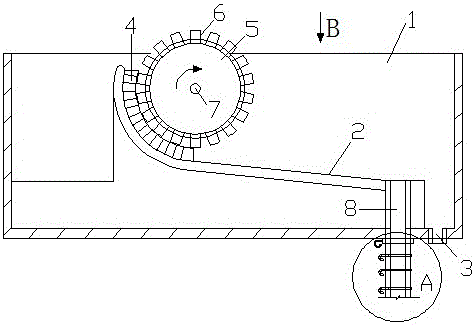

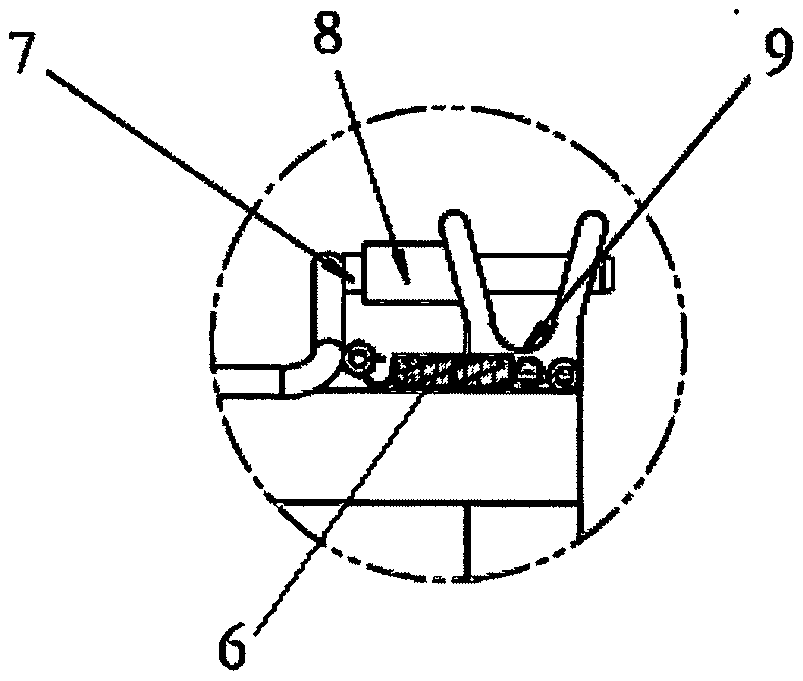

Digital control edgefold sewing machine

InactiveCN101067261APrecise length controlSave unloading timeProgramme-controlled sewing machinesWork-feeding meansEngineeringDigital control

The present invention discloses one kind of numerically controlled hemming sewing machine, which includes a sewing assembly, a driving mechanism, a presser foot mechanism, and a hemming mechanism. The hemming mechanism consists of mainly a pushing cutter, a locating cutter and a locating rod. The pushing cutter and its driving cylinder are mounted on a link rod, which is mounted on the driving mechanism; and the locating cutter is mounted on a seat, which is fixed on the work platform; with one locating clip being mounted beside the locating cutter. The present invention has the integrated automatic functions of seizing cloth, shifting cloth, hemming and sewing and thus high production efficiency.

Owner:龚培云

Method for closed-ring synthesizing anthraquinone from o-benzoylbenzoic acid

InactiveCN1683305AIncrease the feeding speedSave unloading timeOrganic compound preparationQuinone preparationChemistrySpent acid

The process of close-ring synthesizing anthraquinone from o-benzoylbenzoic acid includes the following steps: A. heating o-benzoylbenzoic acid in close-ring reactor to eliminating surface water; B. adding fuming sulfuric acid with SO3 content of 16-24 % in 1.3-1.8 times weight of o-benzoylbenzoic acid and close-ring reaction at 138-200 deg.c for 1 hr; C. separating the reaction product in separating reactor, filtering, water washing, drying, etc. to obtain dry anthraquinone product. The present invention has less sulfuric acid consumption, low production cost, less exhausted waste acid, low power consumption and short reaction time.

Owner:赵振国

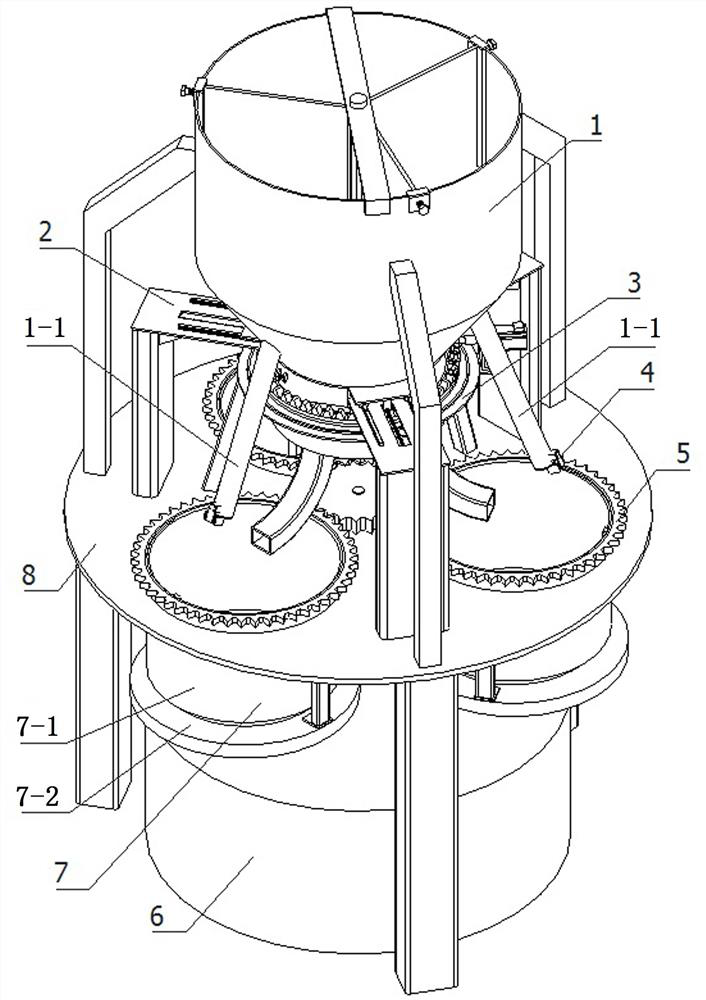

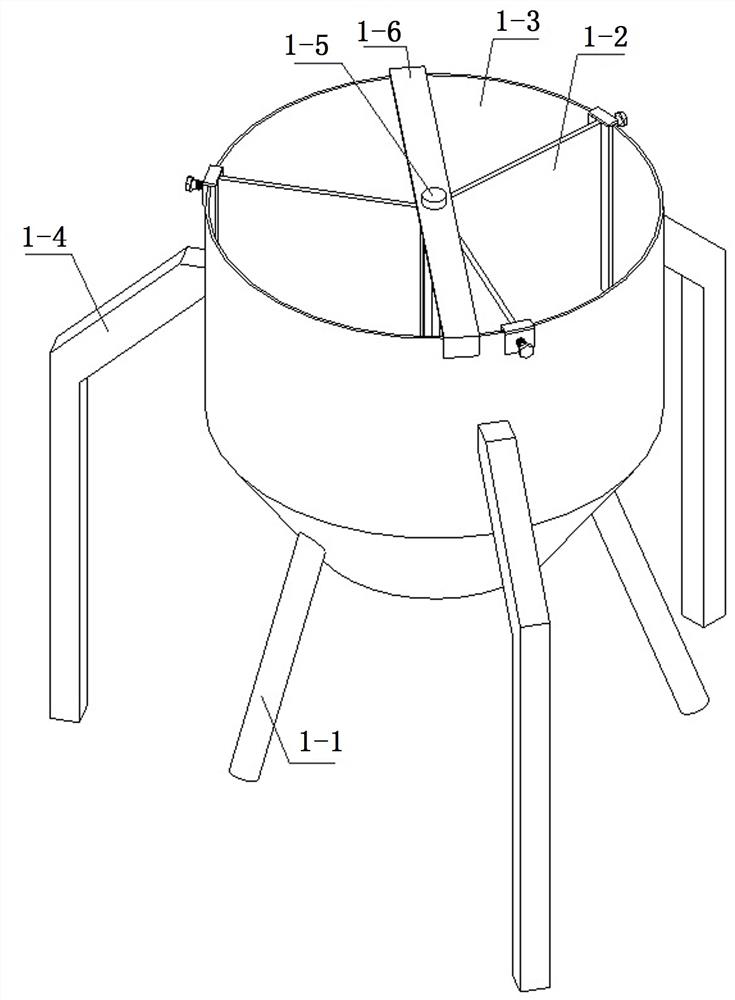

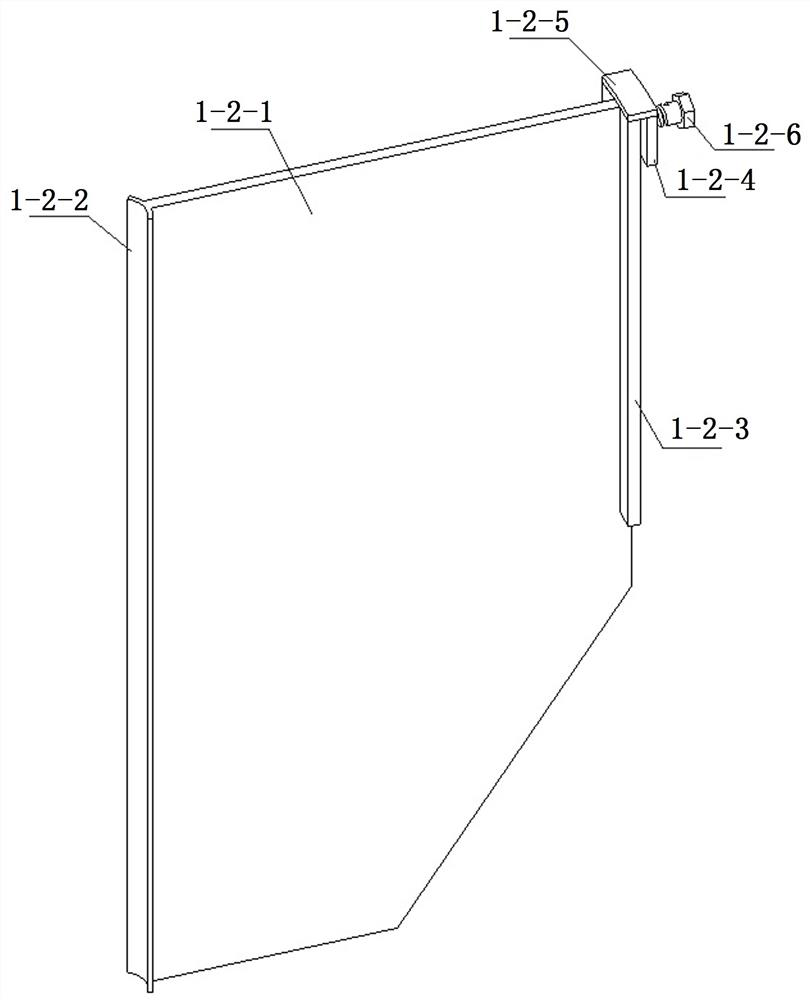

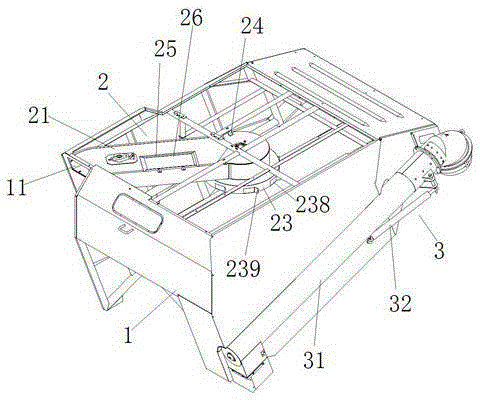

Mine powder accurate proportioning and mixing device and use method

InactiveCN112316841ASave unloading timeImprove the ratio accuracyTransportation and packagingMixer accessoriesProcess engineeringMaterial distribution

The invention relates to the field of accurate proportioning of mine powder, in particular to an mine powder accurate proportioning and mixing device and a use method. The mine powder accurate proportioning and mixing device comprises a proportioning mechanism, a gate mechanism, a material distributing barrel, a micro-proportioning gate mechanism, a scraping mechanism, a mixing barrel and three weighing barrels. According to the mine powder accurate proportioning and mixing device and the use method, The effect of adjusting the outflow volume of raw materials of different proportions is achieved through the material distribution gate plate, the effect of dividing one cylinder is further achieved, one gate mechanism can conveniently control outflow of the three raw materials to be closed atthe same time, the device can be suitable for various raw materials, and it is guaranteed that the raw materials of various proportions can flow out according to the needed raw material proportion atthe same time; a large amount of discharging time of the equipment is saved, a large amount of raw materials remaining in the three conical barrels are cleaned in time through the effect of the scraping mechanism, the proportioning precision of the raw materials is improved, the three conical barrels are synchronously cleaned, and the situation that the next proportioning speed is affected due tothe fact that the conical barrels are not synchronously cleaned up is avoided.

Owner:BACKFILL ENG LAB SHANDONG GOLD MINING TECH CO LTD

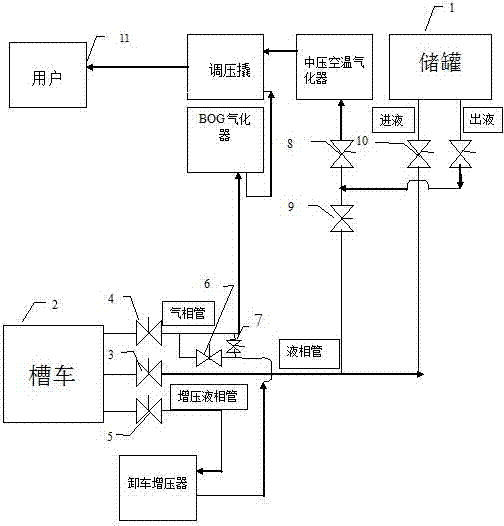

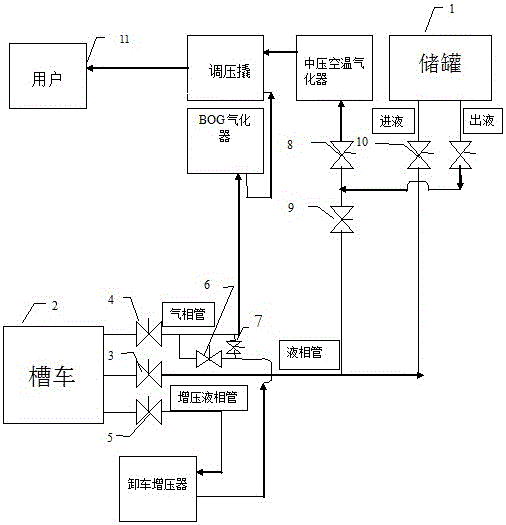

Liquid unloading method for liquefied natural gas or coal gas

ActiveCN104763875AFulfil requirementsSave unloading timePressure vesselsContainer discharging from pressure vesselsEngineeringProcess engineering

The invention discloses a liquid unloading method for liquefied natural gas or coal gas. The liquefied natural gas (LNG) liquid unloading process comprises the following steps: connecting three metal flexible pipes with an unloading platform, pressurizing a cryogenic liquid tanker by using an unloading supercharger to form a pressure difference between the cryogenic liquid tanker and a storage tank, unloading the LNG into the storage tank, and unloading residual gas in the cryogenic liquid tanker to user pipe network by using a medium pressure gas supply system. Compared with the existing liquid unloading method, the invention decreases the residual gas of the cryogenic liquid tanker from 0.4MPa to 0.15Mpa, and the residual gas in the tanker also decreases from 500kg to below 200kg, so as to meet the requirements of customers and save gas unloading time from the original 1 h to 15 min; and the safety coefficient is improved and the production cost is reduced.

Owner:SHANDONG TAISHAN STEEL GROUP

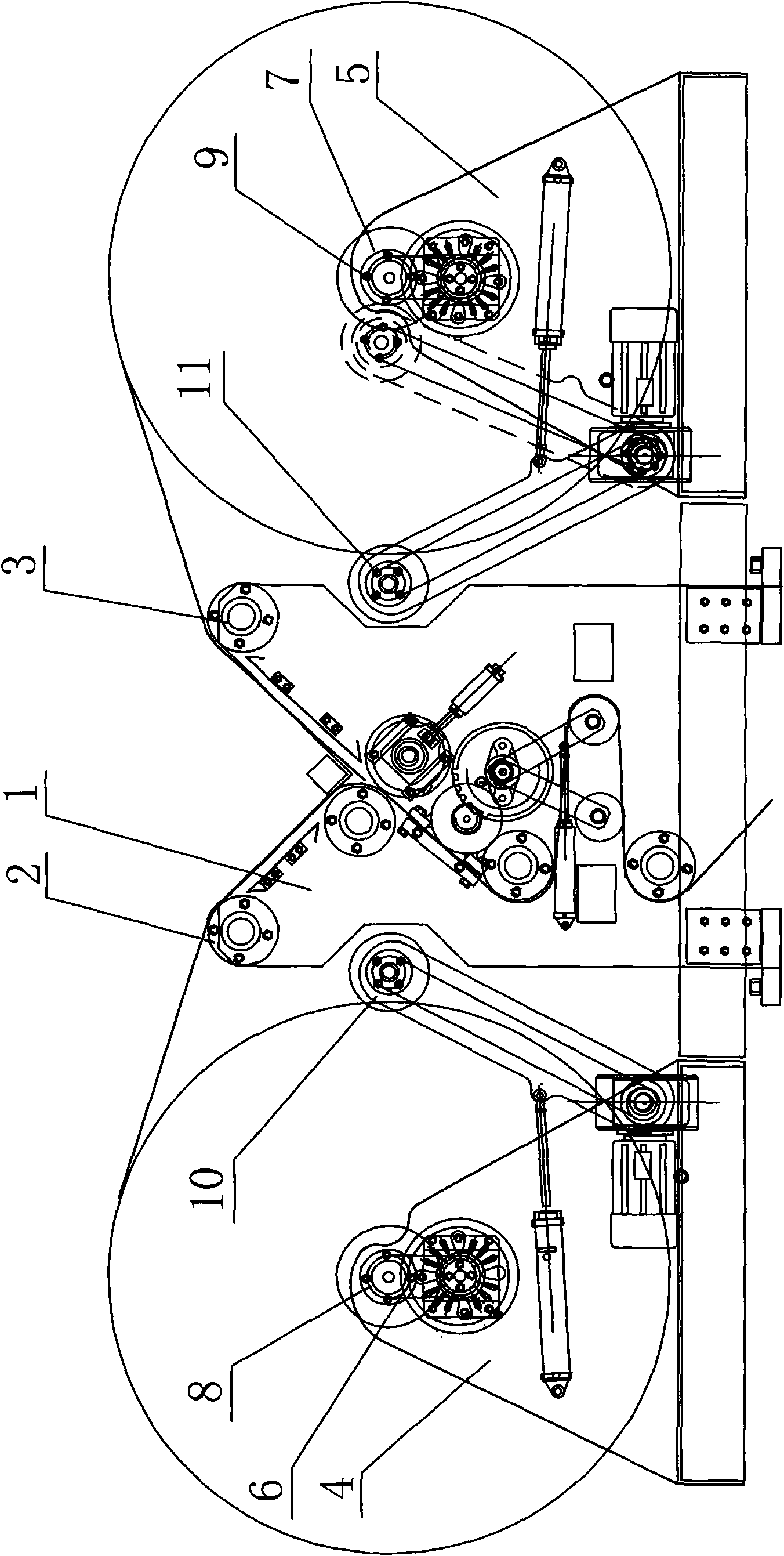

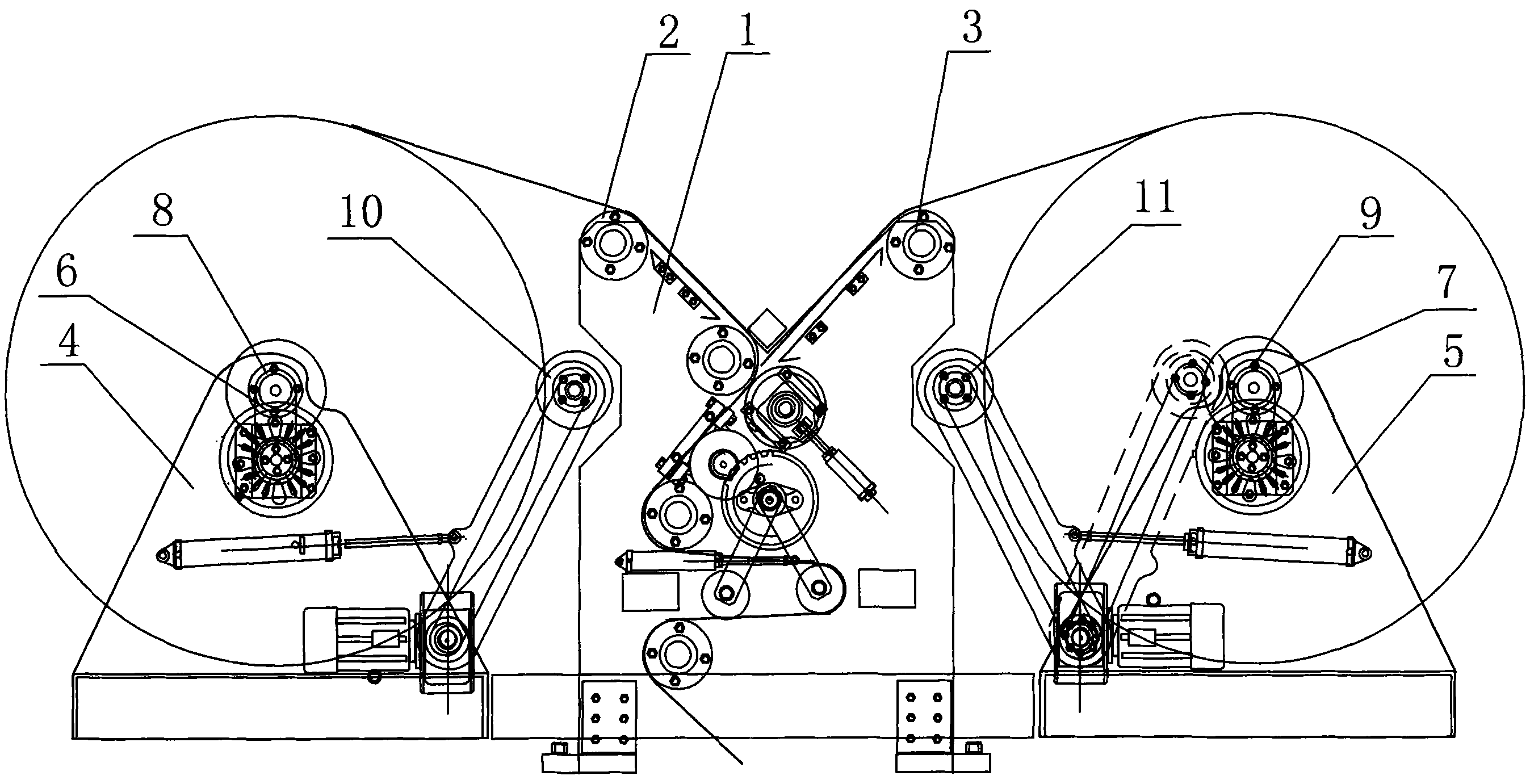

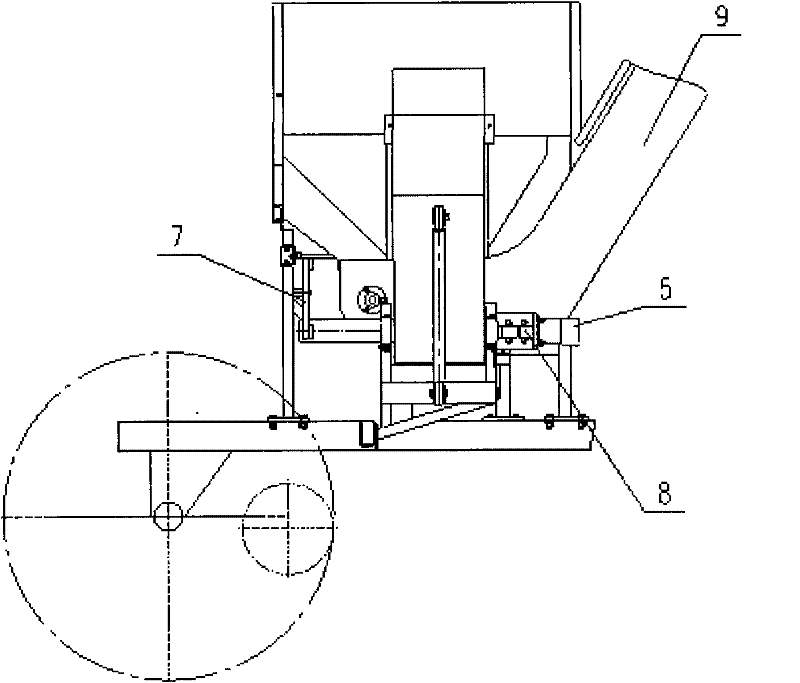

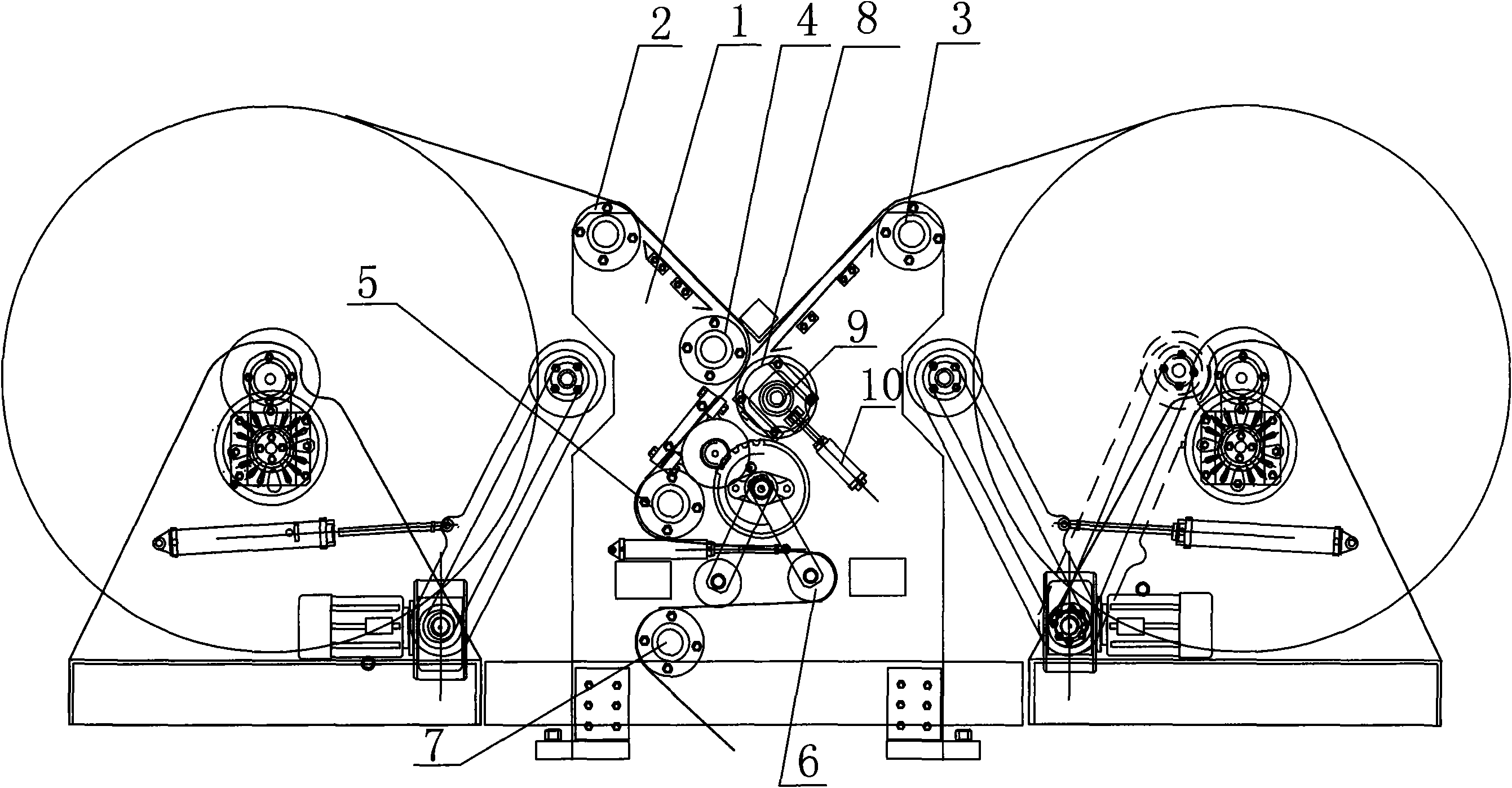

Double rewinding machine of grey cloth

InactiveCN101992962ASave unloading timeImprove feeding efficiencyWebs handlingEngineeringMechanical engineering

The invention discloses a double rewinding machine of grey cloth, relating to the technical field of spinning machinery, in particular to the structure technology of the rewinding machine of the grey cloth. Two upper cloth-guiding rollers are symmetrically arranged on a stand; two groups of discharging frames are respectively placed on the two outer sides of the two upper cloth-guiding rollers; a pair of clothbeam supports are supported against each discharging frame through a bearing; and a group of active discharging rollers is respectively arranged at one side of each discharging frame. When one group of grey cloth is discharged, the other group of grey cloth is arranged on the other discharging frame. The double rewinding machine of the grey cloth can greatly save the discharging time and improve the work efficiency of discharging.

Owner:李龙河

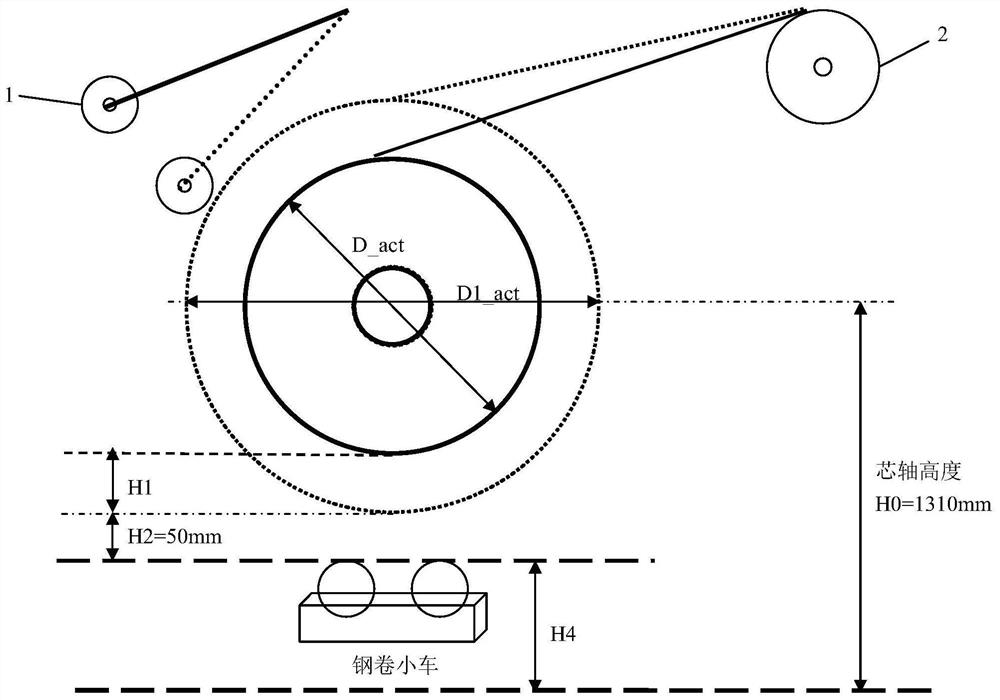

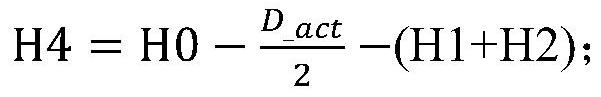

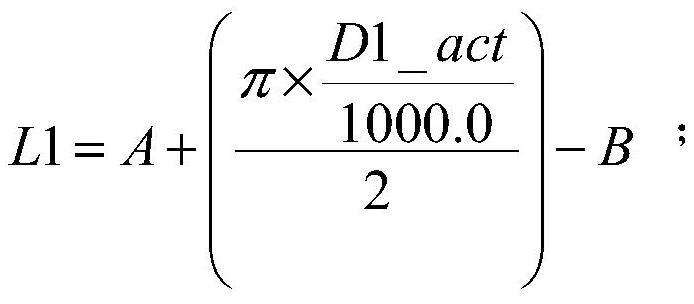

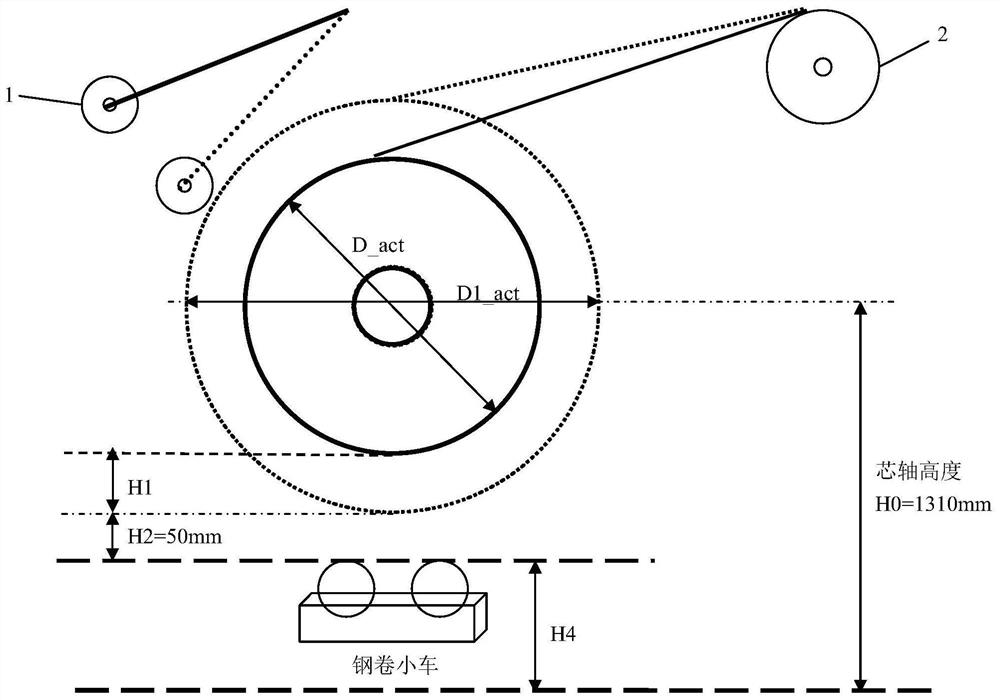

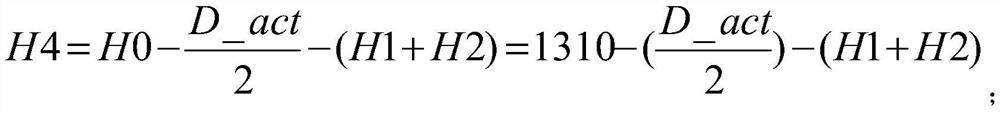

Coiling method of steel coil

ActiveCN112605154ASave unloading timeIncrease production speedMetal rolling arrangementsAutomatic controlStructural engineering

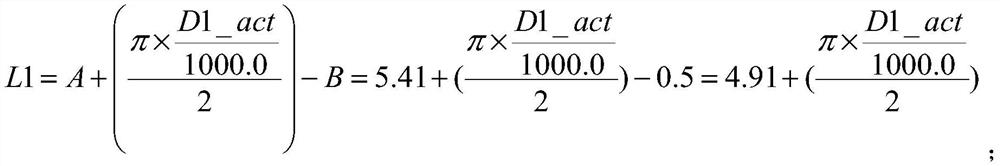

The invention discloses a coiling method of a steel coil, belongs to the technical field of automatic control, and aims to solve the problem that an outer ring of the steel coil is loose. According to the method, three lifting actions of a steel coil trolley are triggered when a certain distance is calculated from a strip tail to a stop position according to a current diameter of the steel coil; and in the drifting process, a residual length of a strip tail of strip steel is calculated in real time, and when the strip tail of the strip steel is about to leave an upper pressing roller of a coiling machine, the steel coil trolley automatically triggers three times of lifting to make contact with the strip steel, so that steel coil coiling is completed. The method has the advantages that the problem that the outer ring of the steel coil is loosened is effectively solved, a coil receiving speed of the steel coil trolley is increased, the labor frequency that an operator needs to frequently and manually inch the coiling machine to rotate by one circle to eliminate loosening of the outer ring of the steel coil is reduced, and continuous and stable high-level automatic production is guaranteed.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

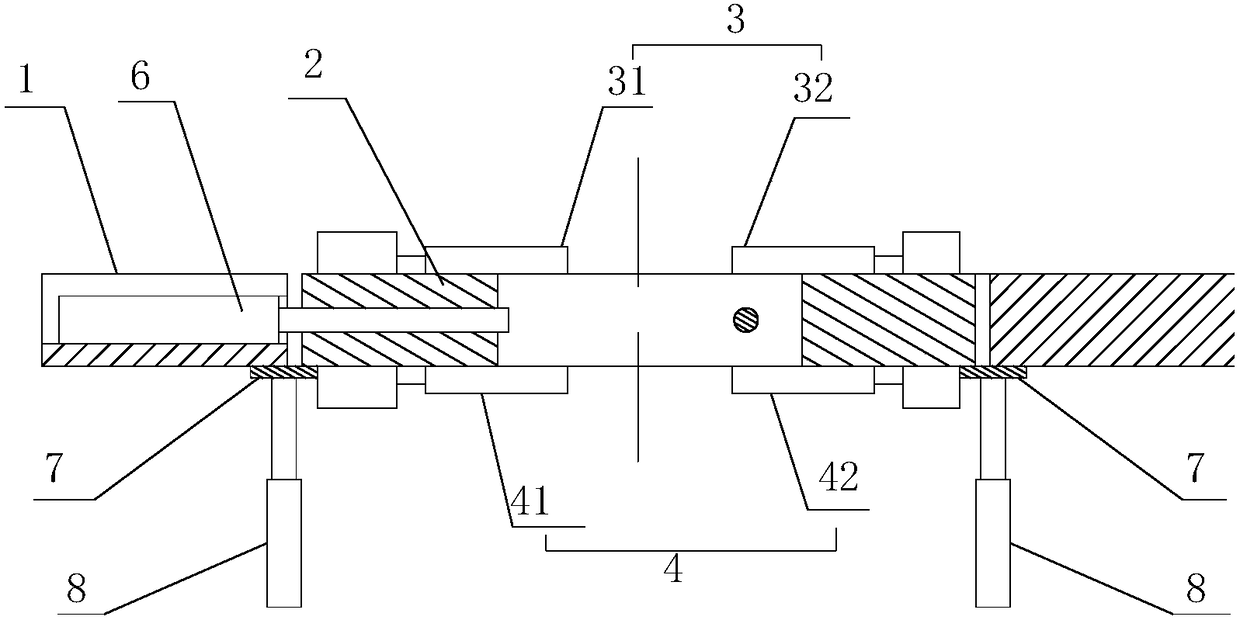

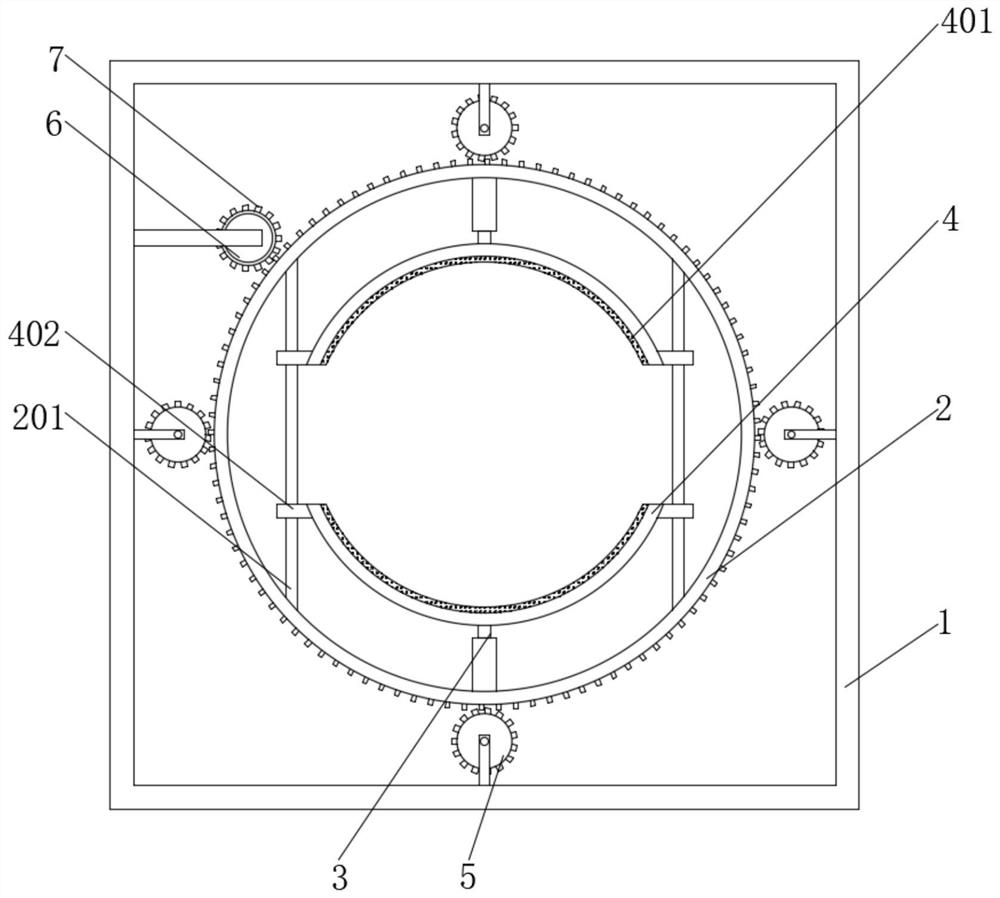

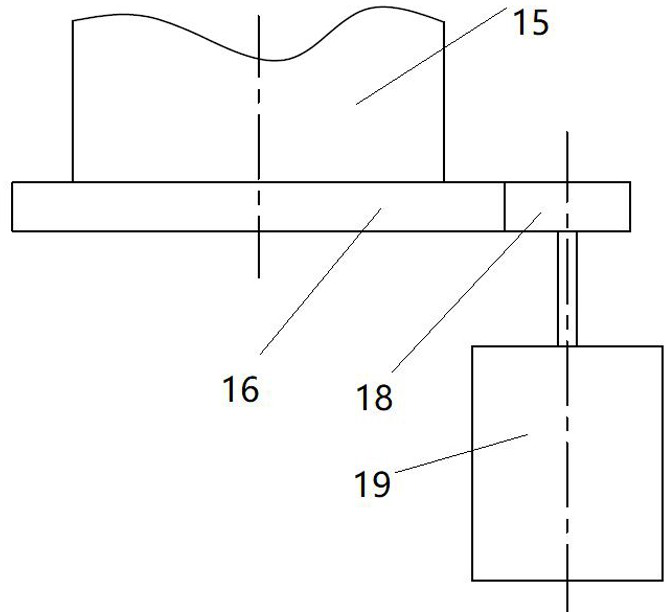

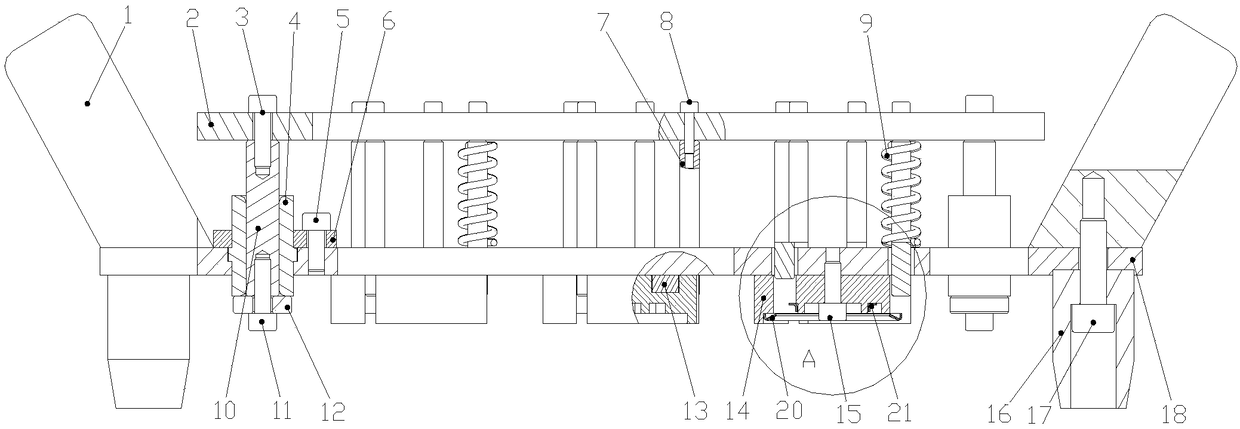

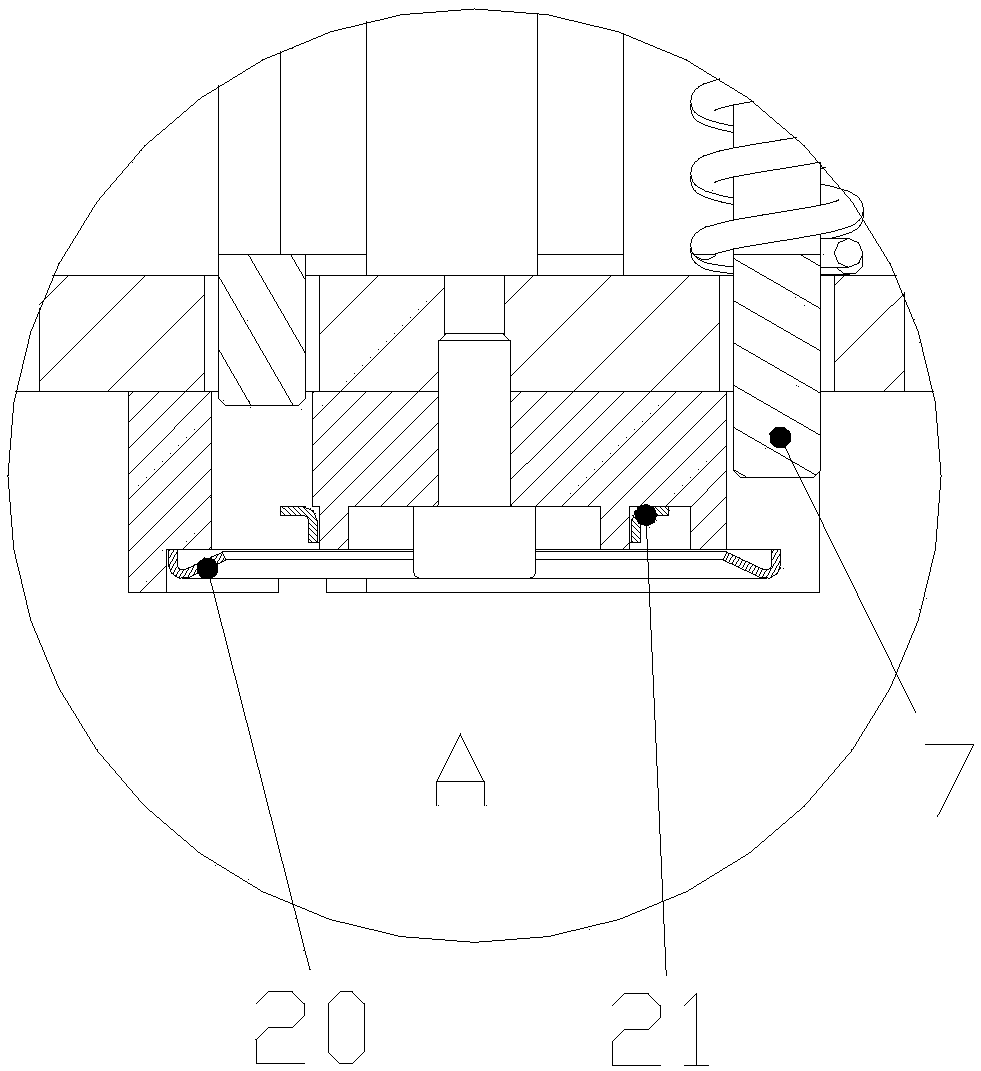

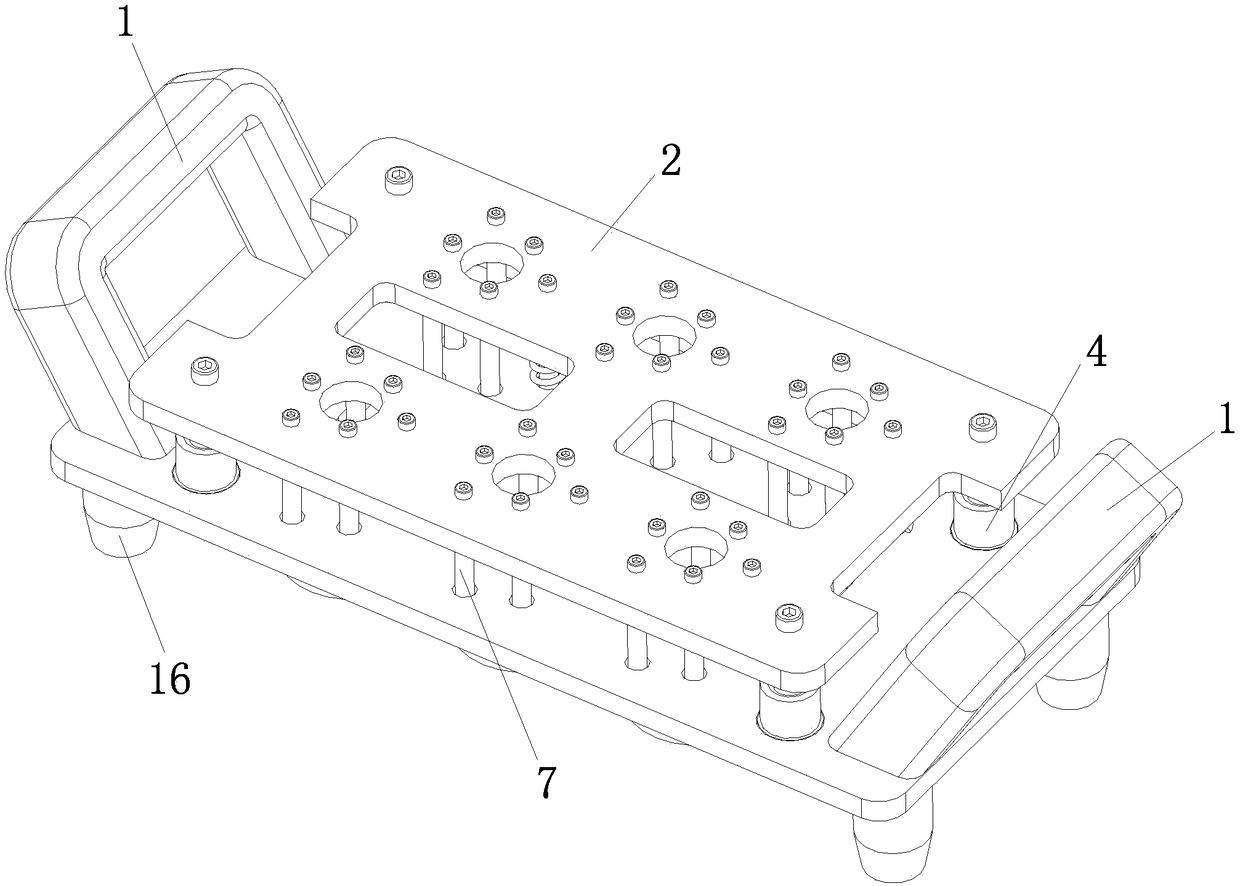

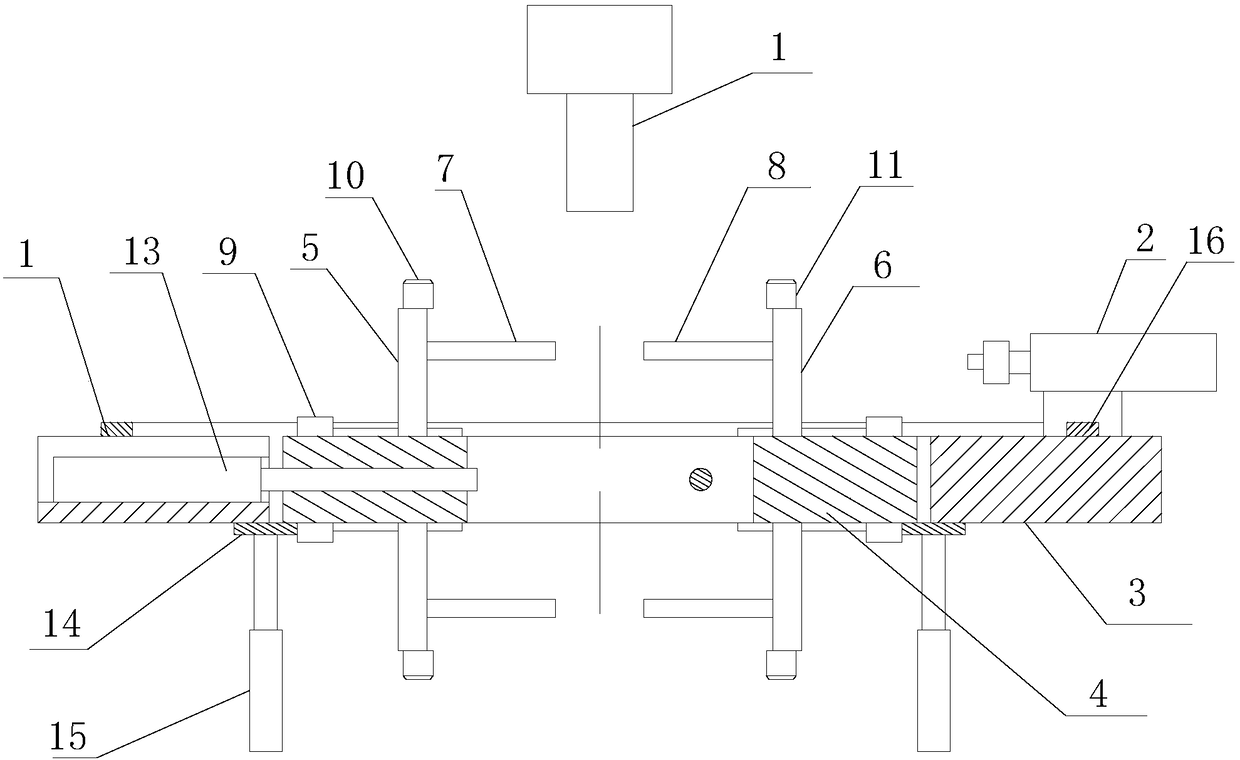

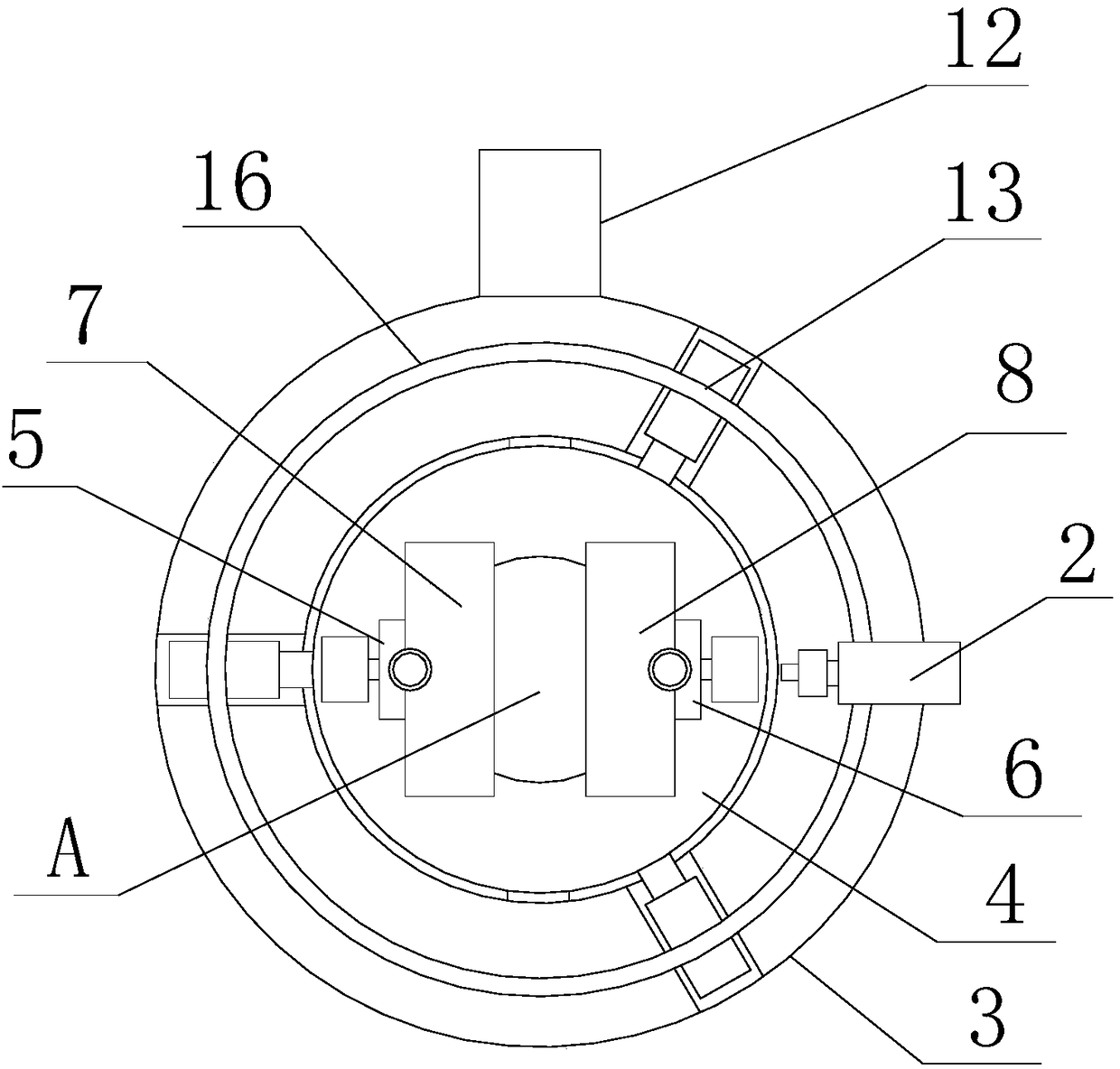

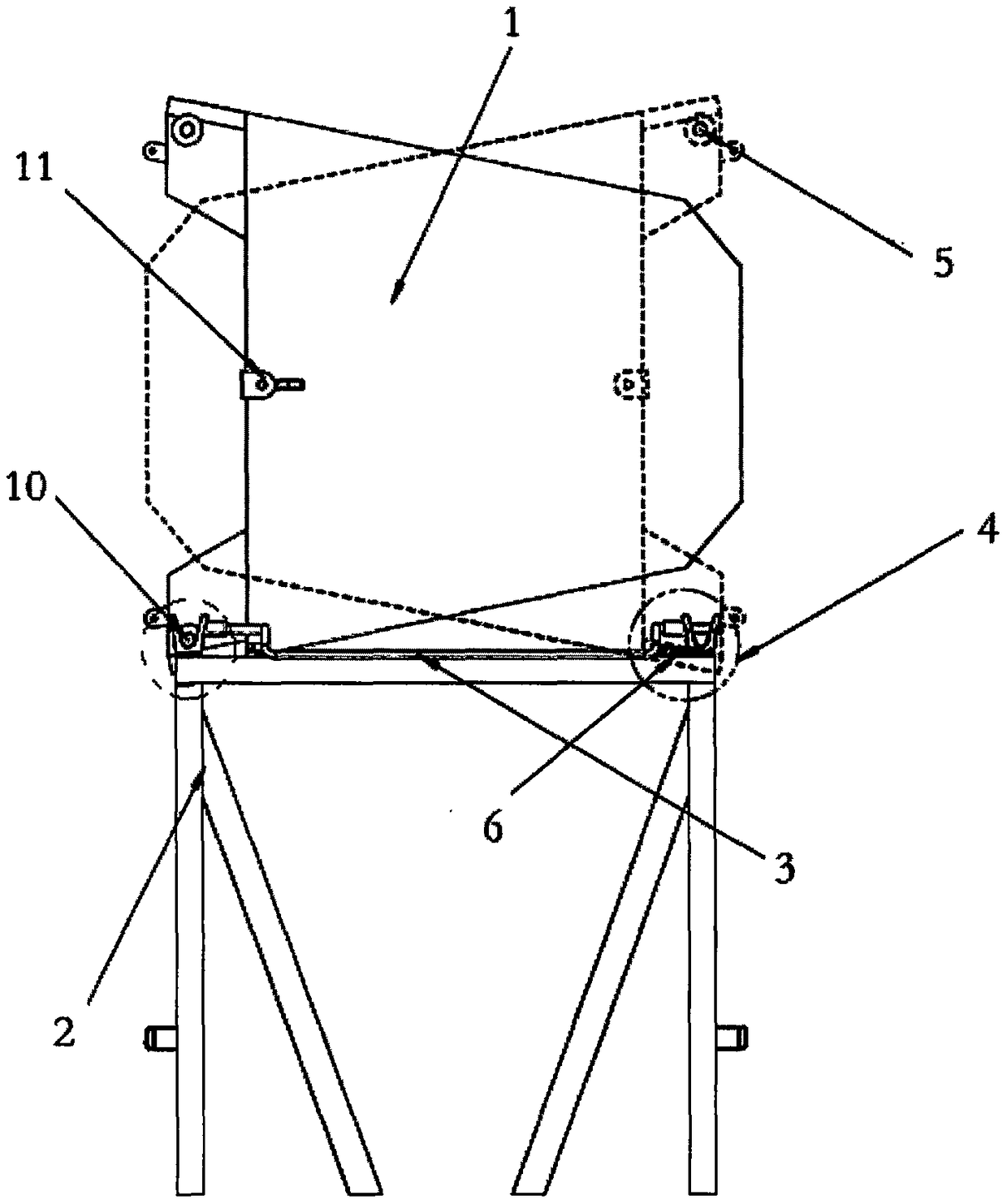

Double open type workbench for double-surface machining of workpieces

ActiveCN108356581AConvenient processing workGuaranteed stabilityMetal working apparatusPositioning apparatusEngineeringPower unit

The invention discloses a double open type workbench for double-surface machining of workpieces. The workbench comprises an outer ring table and a center table, wherein a through groove is formed in the middle of the outer ring table, and the center table is located on the inner side of the through groove; a placement groove is formed in the center table; a first movable plate assembly and a second movable plate assembly which can automatically so as to control opening / closing of a port of the placement groove are arranged on the front side and the reverse side of the center table correspondingly; at least three guide holes which are annularly formed around the placement groove are formed in the center table; a first driving mechanism is arranged on the outer ring table and is used for driving the center table to turn over; every time the first driving mechanism acts, the center table turns over by 180 degrees; a second driving mechanism is arranged at the end, located at any one of the guide holes, of the outer ring table; and each second driving mechanism comprises an ejector rod and a power unit, wherein the ejector rod is coaxially arranged with the corresponding guide hole andcan extend into the corresponding guide hole, and the power unit is used for driving the ejector rod to extend in the direction of the corresponding guide hole. The workbench has the advantage that the production efficiency of double-surface machining of the workpieces can be effectively improved.

Owner:TIANCHANG CYLINDER HEAD

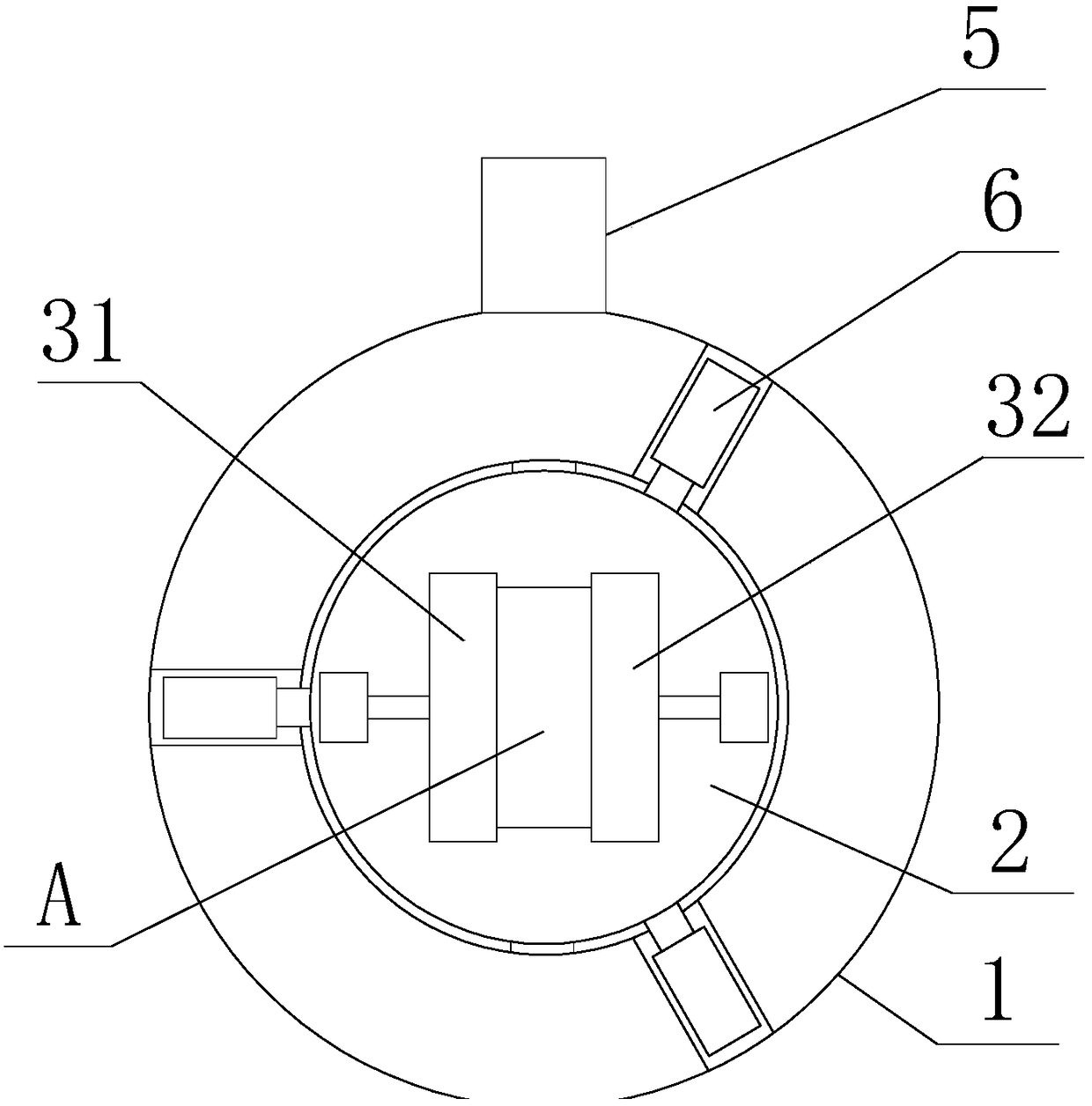

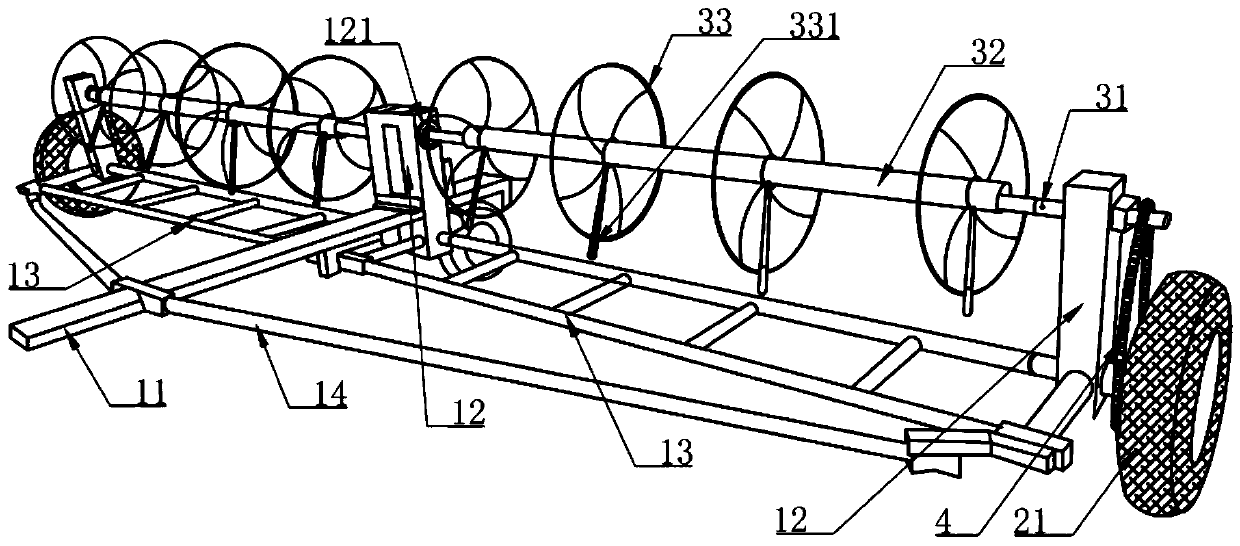

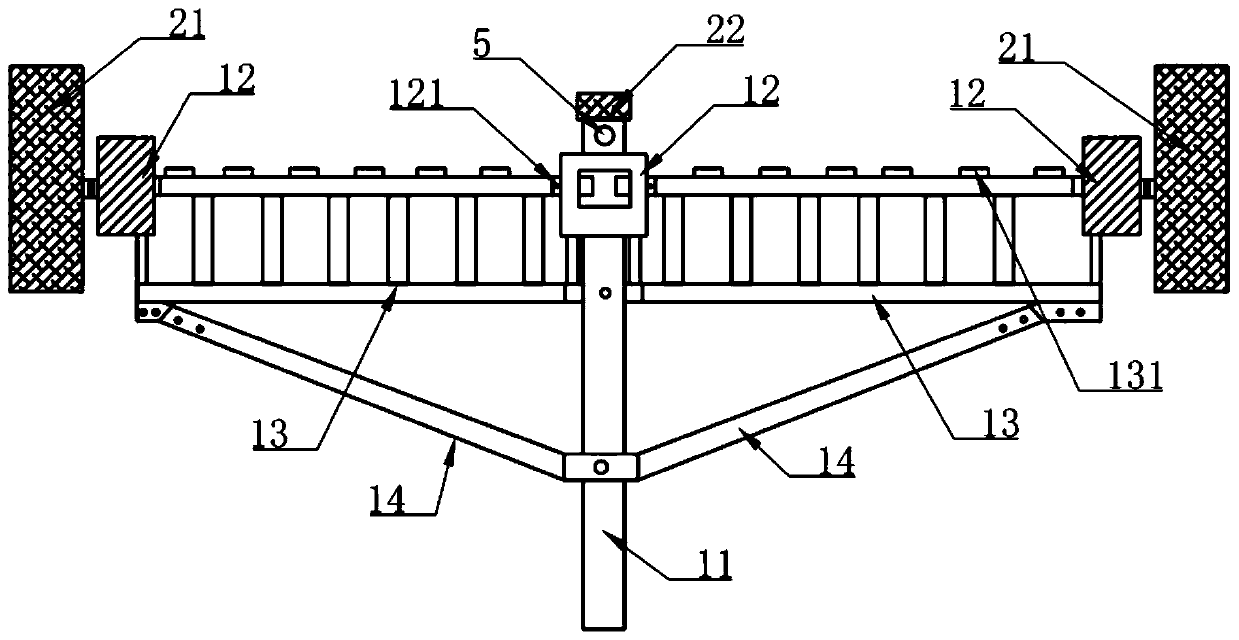

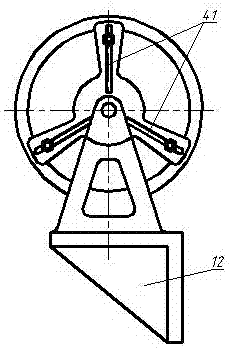

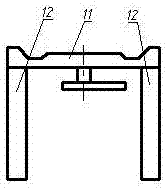

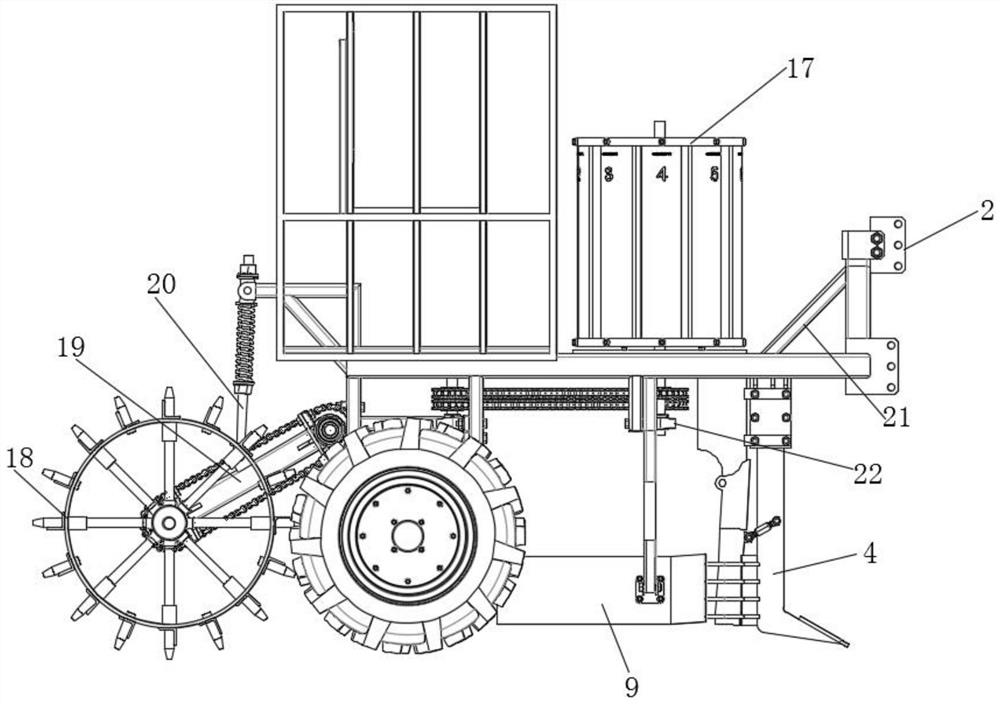

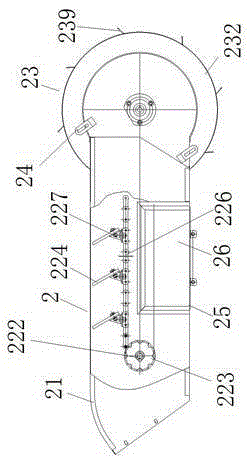

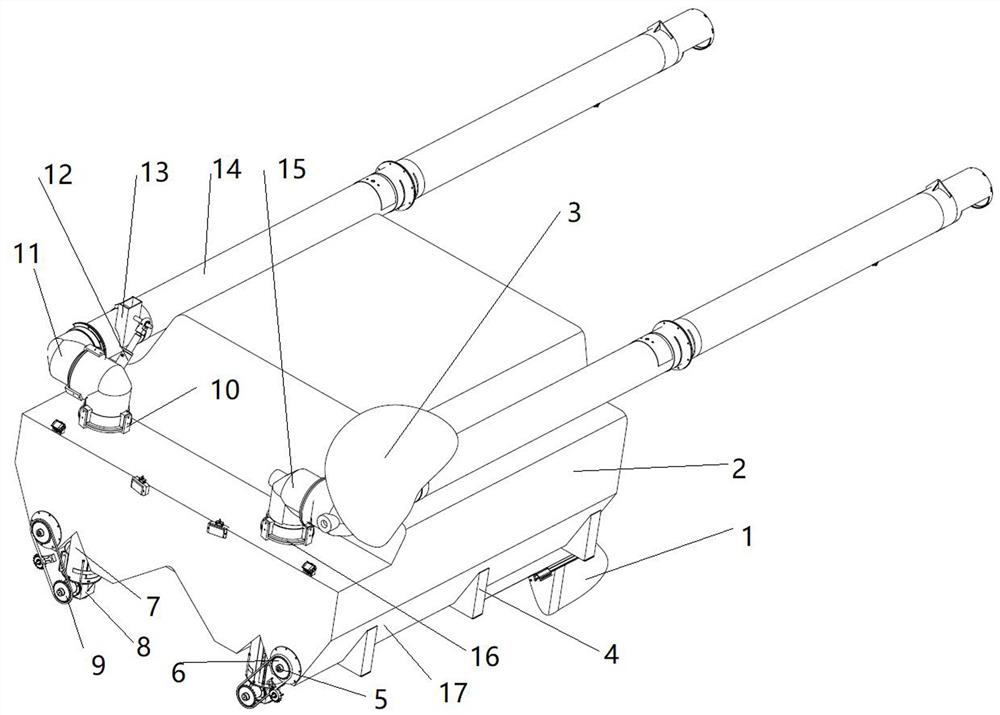

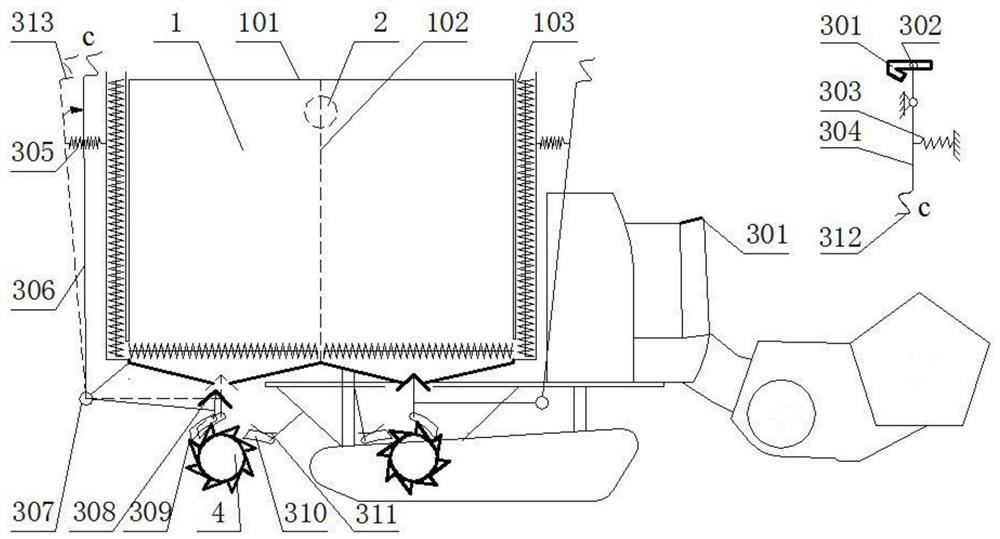

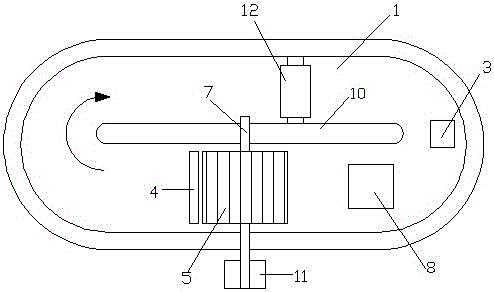

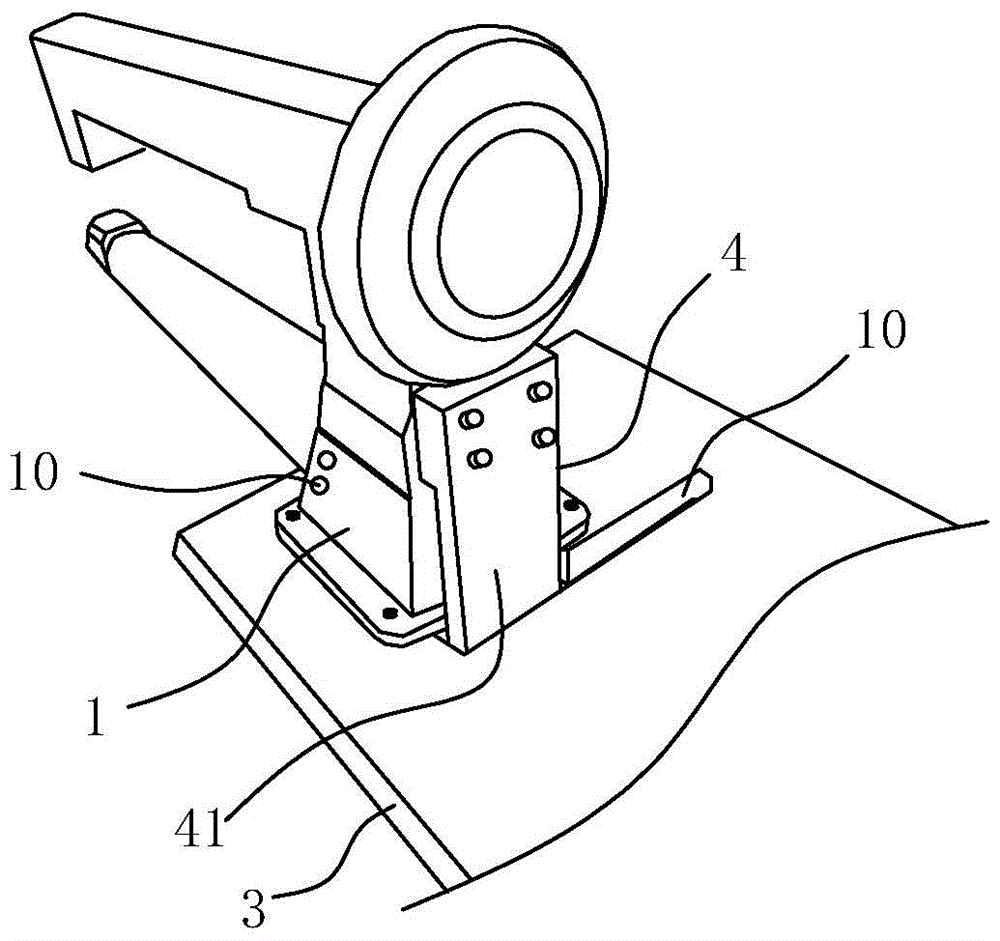

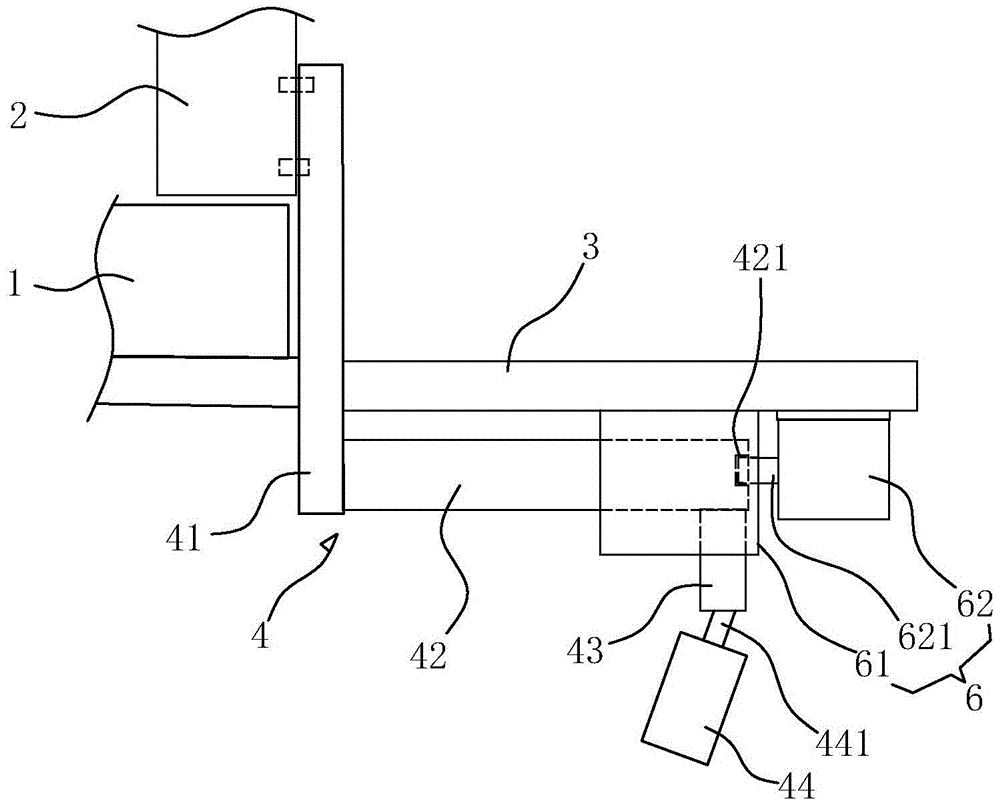

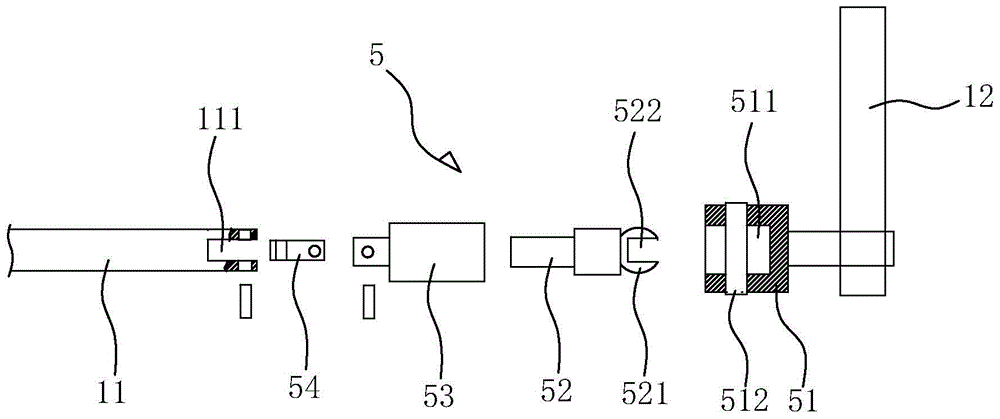

A drip irrigation belt retracting device

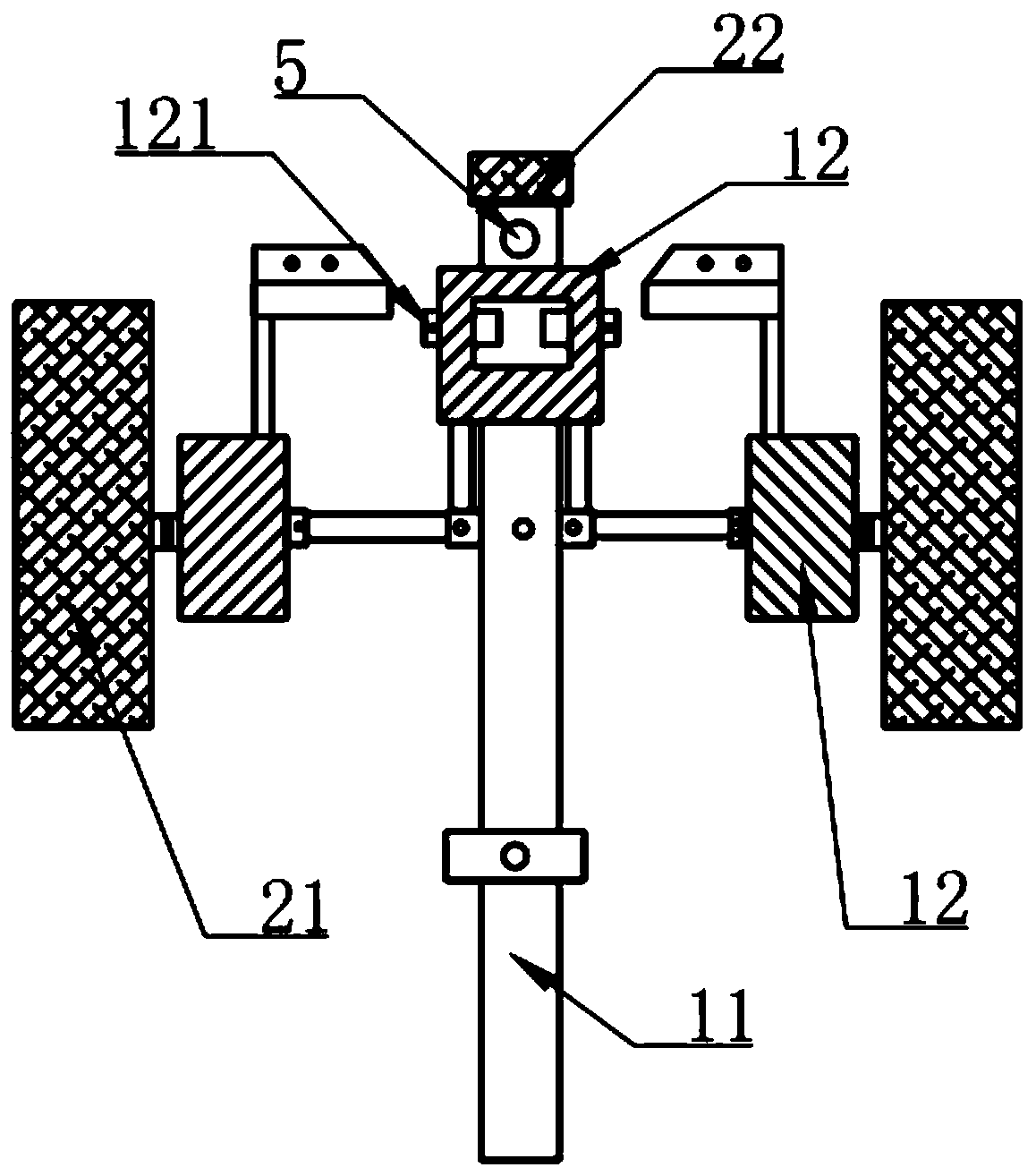

ActiveCN108128669BEasy to assemble and disassembleSimple structureAgricultural engineeringDrip irrigation

The invention discloses a drip irrigation belt winding device. The drip irrigation belt winding device is structurally composed of a supporting mechanism, a winding mechanism and a walking mechanism,wherein the winding mechanism and the walking mechanism are transversely arranged and the total width is 6.5 to 7.5m; the supporting mechanism is composed of a main rod (11), three vertical rods (12),two secondary rods (13) which are fixedly connected with the bottom end parts of the three vertical rods (12) and a connecting rod (14) for connecting the main rod (11) and the vertical rods (12) atthe left and right sides; the winding mechanism is composed of a rotary screw rod (31) which is transversely arranged on the vertical rods (12) of the supporting mechanism, a winding rod (32) and a plurality of round fixed blocking pieces (33); the walking mechanism is composed of walking wheels (21) which are connected with the vertical rods (12) at the left and right sides of the supporting mechanism and a walking wheel (22) at one end of the main rod (11). According to the winding device disclosed by the invention, power is output through a tractor to drag, the recycling speed and recyclingquality of a drip irrigation belt are improved and impurities are reduced.

Owner:付峻岭

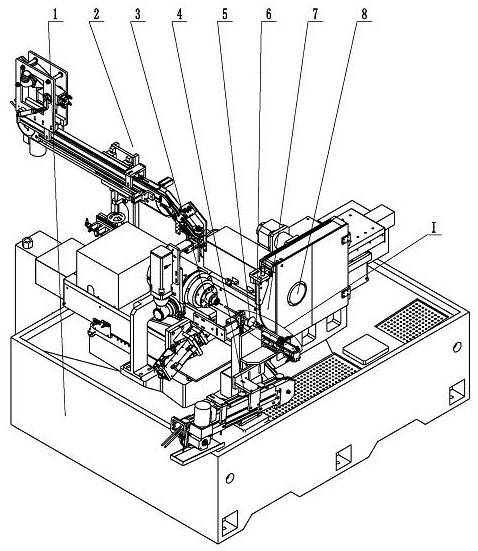

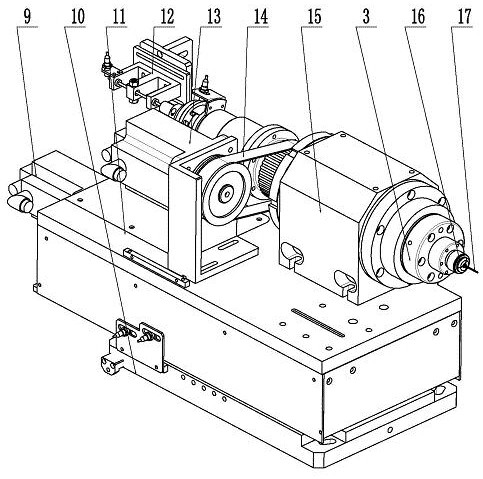

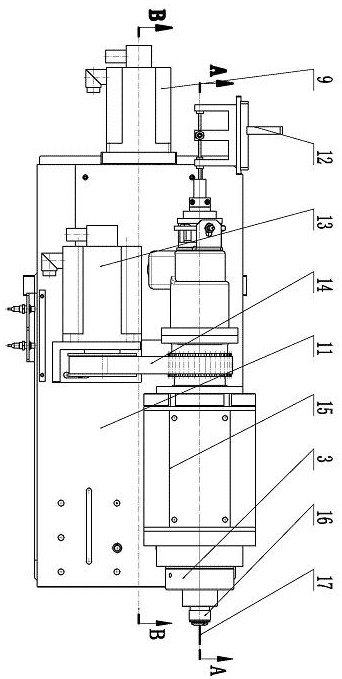

Air valve one-time forming grinding machine

ActiveCN113894656ASimple structureShort timeGrinding carriagesGrinding feed controlStructural engineeringMachine

The invention discloses an air valve one-time forming grinding machine which comprises a rack, a feeding conveying device, a discharging conveying device, a workpiece main shaft, a grinding wheel main shaft and a finishing wheel main shaft. The workpiece main shaft can move front and back in the axial direction through a workpiece main shaft sliding table. A discharging ejector rod limited through an ejector rod support and an elastic telescopic pin on the ejector rod support is inserted into an inner hole of an elastic chuck in the workpiece main shaft, an ejector rod position detection sensor is arranged on the ejector rod support, a charging positioning push rod capable of moving front and back is arranged at the front end of the workpiece main shaft, the grinding wheel main shaft, the finishing wheel main shaft and the workpiece main shaft are arranged in parallel, the grinding wheel main shaft moves and feeds in the radial direction through a grinding wheel sliding seat, and the finishing wheel main shaft is arranged on the grinding wheel sliding seat and can feed in the radial direction. By the adoption of the air valve one-time forming grinding machine, the structure of a clamping mechanism in valve grinding can be optimized, clamping and discharging are rapid and reliable, grinding wheel forming and finishing can be completed in time on the premise that the normal production takt of valve grinding is not affected, and the grinding quality and the production efficiency are improved.

Owner:江苏吉斯特科技有限公司

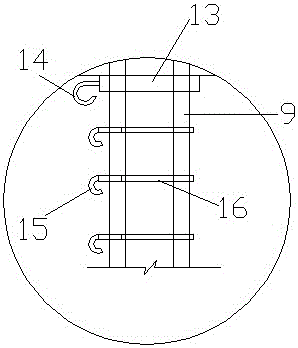

Wire disassembling device for small linear cutting machine tool

InactiveCN107309514ASave unloading timeReduce labor intensityElectrical-based auxillary apparatusDrive shaftEngineering

The invention discloses a wire removal device for a small-sized wire cutting machine tool, which includes a mounting base, a transmission shaft, a friction wheel, a first wire receiving reel and a second wire receiving reel, and the installation base includes a V-shaped magnetic suction plate and a rib plate , a mounting plate, a left support plate and a right support plate, the V-shaped magnetic suction plate is arranged on the lower rear plane of the mounting plate, ribs are respectively provided on both sides of the mounting plate; There are a left support plate and a right support plate; a transmission shaft is arranged above the left support plate and the right support plate, and one end of the transmission shaft is provided with a wire collection disc 1 and a wire collection disc 2, and the wire collection Disk one is connected with the transmission shaft through a transmission pin, and the other end of the transmission shaft is provided with a friction wheel, and the friction wheel is connected with the transmission shaft through a connecting screw. The invention has the advantages of simple structure, fast and efficient disassembly of broken wires, can greatly reduce the wire unloading intensity of wire cutting machine operators, and save wire unloading time.

Owner:潘琴丽

Viburnum flower planting transplanting and fertilizing equipment and use method thereof

InactiveCN111602571AGuaranteed normal rotationAvoid the phenomenon of slipping and non-rotationPlantingGearingAgricultural engineeringEngineering

The invention discloses viburnum flower planting transplanting and fertilizing equipment. The equipment comprises a base and material collecting bins, wherein a station is arranged at one end of the top of the base; the material collecting bins are arranged on the side walls of the base on the two sides of the station; two rotating rods are arranged on one side of the station side by side; mounting frames are arranged on the two rotating rods correspondingly; a plurality of discharging barrels are arranged in the two mounting frames; and a supporting plate is arranged at the bottom of the base. Two third transmission wheels on a third transmission shaft drive rotating gears on the two rotating rods to rotate, and then the mounting frames rotate; viburnum flower rhizomes in one of the discharging barrels in the mounting frames enter an oval plate, so that the placement work of the viburnum flower rhizomes is achieved; and meanwhile, a farmer places the viburnum flower rhizomes and fertilizer in the material collecting bins into the empty discharging barrel, so that the feeding work is achieved, the feeding work is completed while the transplanting work is conducted, the transplanting efficiency is greatly improved, the discharging time is saved, it is guaranteed that the fertilizer makes contact with the viburnum flower rhizomes, and the fertilizer utilization rate is increased.

Owner:SHANDONG PROVINCE FOREST TREE SEEDLING & FLOWER STATION

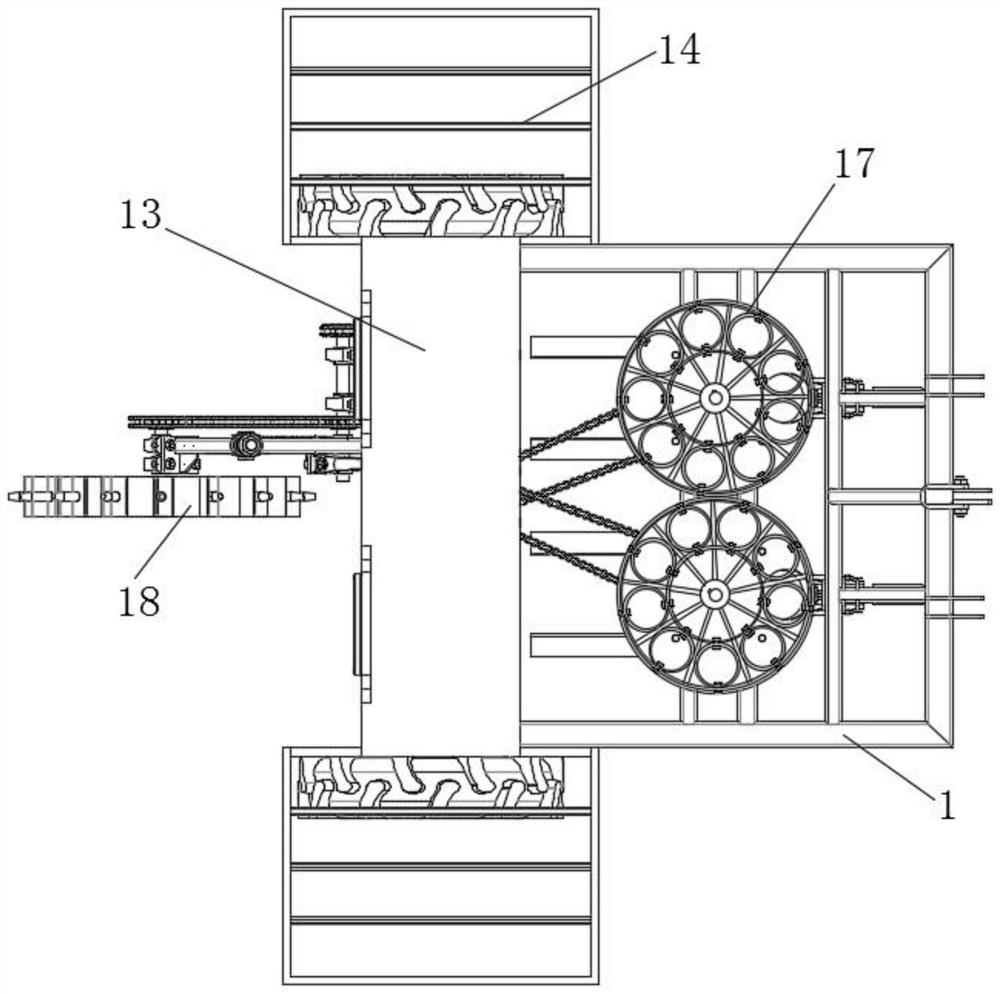

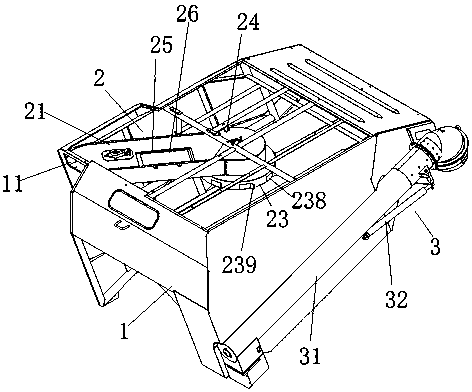

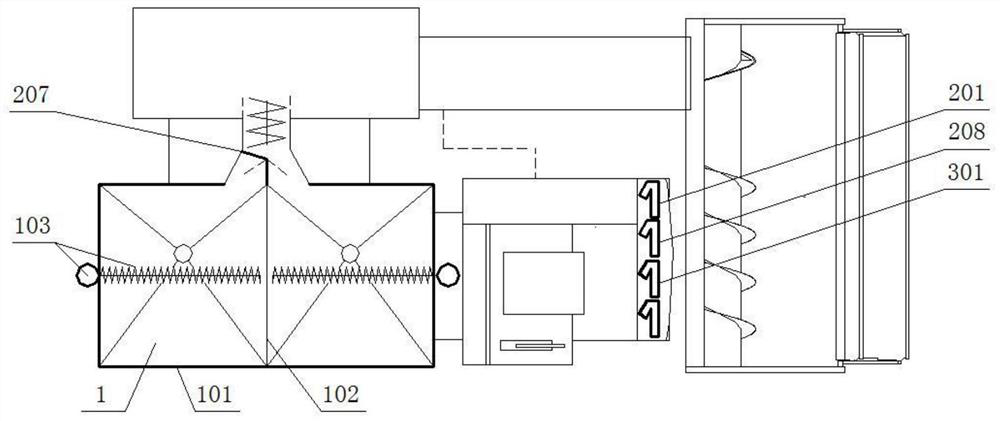

Harvester grain bin

ActiveCN105409432AIncrease grain collection rateAvoid uneven accumulationMowersHydraulic motorDrive shaft

The invention discloses a harvester grain bin. The harvester grain bin comprises a bin body, a transitional conveying mechanism and an externally-extending unloading mechanism; the transitional conveying mechanism is longitudinally arranged in the bin body and comprises a transitional conveying groove, a conveying driving unit and a projecting disc; the conveying driving unit is arranged in the transitional conveying groove and comprises a hydraulic motor, two transmission shafts, a pair of chain wheels and a plurality of scraper plates; the projecting disc is fixedly installed at the lower end of one of the transmission shafts in a sleeving mode, a projecting disc body comprises an inner spreading plate and an outer projecting plate, the disc body is divided into an inner ring area and an outer ring area by the inner spreading plate, multiple spreading openings are evenly formed in the outer circumference of the inner spreading plate, and multiple grain throwing openings are evenly formed in the outer circumference of the outer projecting plate; the externally-extending unloading mechanism is arranged at one side of the bin body. By means of the harvester grain bin, it is guaranteed that grains in the bin body of the grain bin can be distributed uniformly, the grain collection rate of the grain bin is greatly raised, meanwhile, grain discharging times are decreased, and work efficiency is improved. When the bin body of the grain bin is filled up with the grains, the grains can be directly unloaded onto a grain transporting vehicle, time and labor are saved, and grain unloading time is saved.

Owner:JIANGSU WORLD AGRI MACHINERY

Bidirectional cutting machine for natural gas pipeline machining and natural gas pipeline machining technology

ActiveCN113263339AShorten the timeImprove cutting efficiencyLarge fixed membersPositioning apparatusEngineeringMachining process

The invention discloses a bidirectional cutting machine for natural gas pipeline machining and a natural gas pipeline machining technology, and belongs to the technical field of natural gas pipeline machining. The technical solution of the bidirectional cutting machine comprises a frame and two gear rings, wherein the two gear rings are located inside the frame, the surfaces of the gear rings are in meshed connection with annularly-distributed first gears, the first gears are fixedly connected to the inner wall of the frame, first motors are fixedly connected to the back face of the inner wall of the frame, second gears are fixedly connected to output shafts of the first motors, the second gears are in meshed connection with the gear rings, first electric push rods are fixedly connected to the inner top walls and the inner bottom walls of the gear rings correspondingly, the other ends of the first electric push rods are fixedly connected to clamping plates, the top of the frame is fixedly connected to a second motor, and an output shaft of the second motor is fixedly connected to a first lead screw. The the bidirectional cutting machine for the natural gas pipeline machining and the natural gas pipeline machining technology have the advantages that the inner wall and the outer part can be cut at the same time, the required cutting time is short, and the cutting efficiency is high.

Owner:陕西国宏鼎泰能源服务有限公司

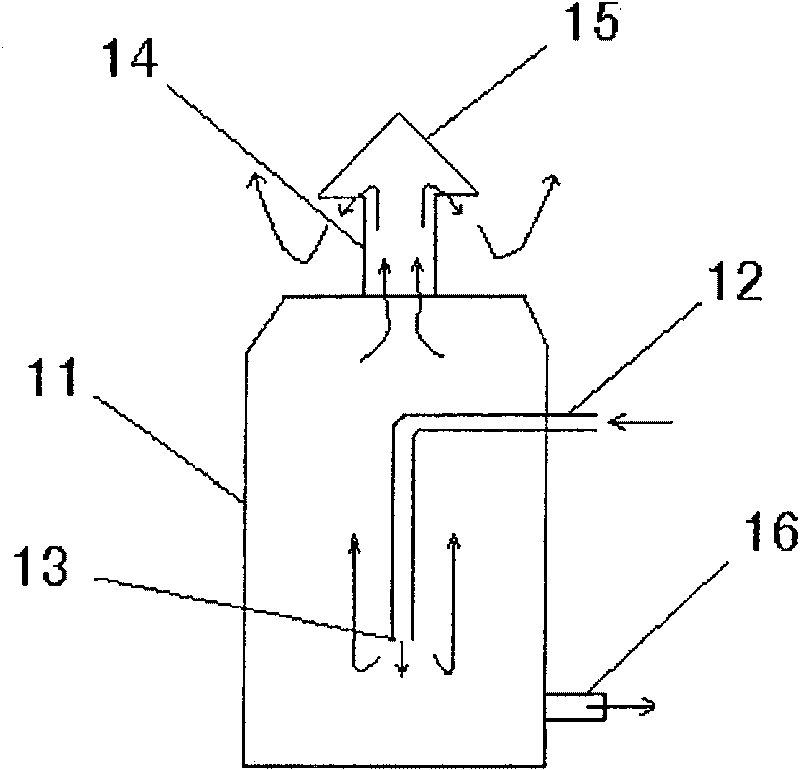

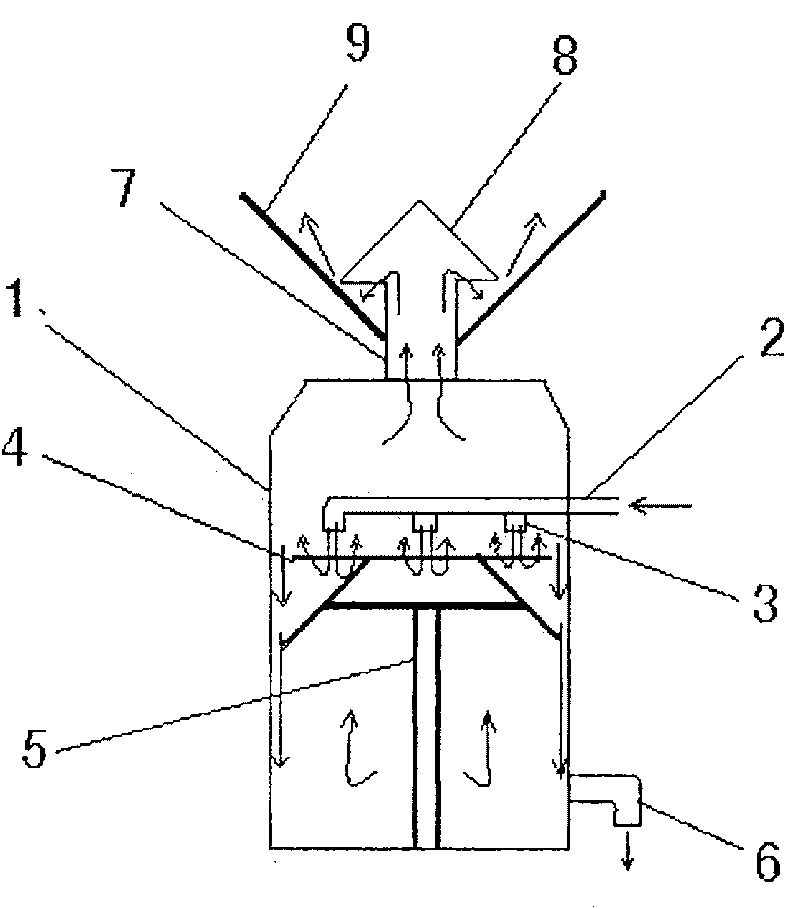

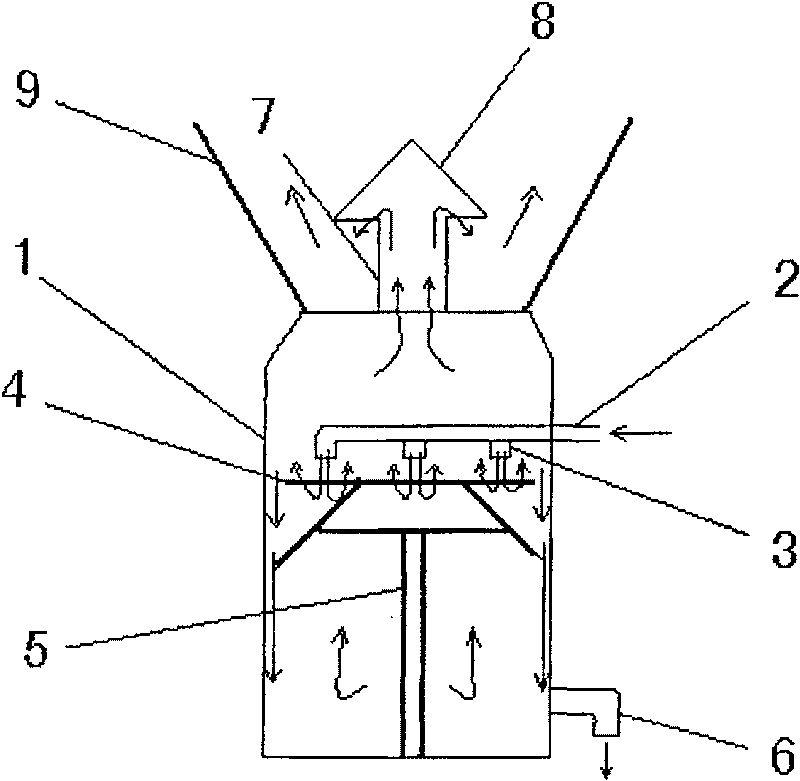

Vapor-liquid separator

InactiveCN101298004BSpread evenlyReduce noise pollutionLiquid degasificationVapor liquidVapor–liquid separator

The invention relates to a vapor-liquid separation device which is characterized in that: the device includes a kettle internally inserted and provided with a feeding tube; one side of the feeding tube is connected with the material source, the other side is provided with a plurality of discharge ports, the lower part of the each discharge port is provided with a baffle, which is provided with a plurality of through holes, and the baffle is fixed in the kettle through the baffle frame; the side wall of the kettle is provided with a discharge fluid tube, the top of the kettle is provided with asteam discharge tube, the top of the steam discharge tube is provided with a baffle cover, and enclosures are arranged around the steam discharge tube and the baffle cover. As the invention is provided with the baffle, the enclosure and the discharge ports, the gas and liquid can be separated more effectively, the noise can be reduced effectively, the environmental pollution can be reduced, and the productivity is increased. The vapor-liquid separation device of the invention is suitable for various vapor-liquid separation processes, especially the production process of the fatty acid products.

Owner:杨解定

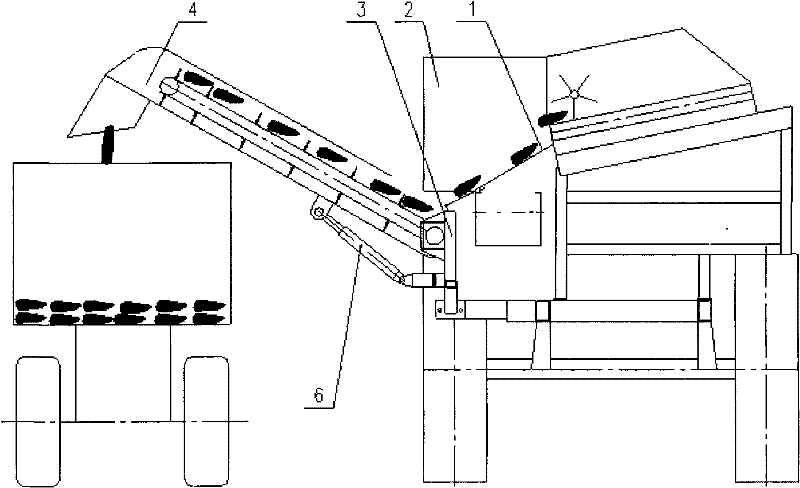

Car-following synchronous side-tipping grain conveying device of corn ears

InactiveCN101796907BReduce the number of unloading grainImprove harvesting efficiencyHarvestersDrive shaftSlide plate

The invention relates to a car-following synchronous side-tipping grain conveying device of corn ears, which mainly comprises a lower ear distribution sliding plate, an ear receiving groove, a secondary lift conveyer bracket, an ear side conveyer, a hydraulic driver, an oil cylinder, a connecting rod, a cardan joint and a secondary lift conveyer. The ear side conveyer is installed in a U-shaped seat of the secondary lift conveyer bracket, the oil cylinder is installed on the ear side conveyer and a supporting seat of the secondary lift conveyer bracket, the ear receiving groove is installed at a horizontal section of the secondary lift conveyer, and the lower ear distribution sliding plate is installed in a sleeve at the horizontal section of the secondary lift conveyer and carries out a reverse fan-shaped motion by taking the sleeve as an axis through the connecting rod along with the motion change of the ear side conveyer. When the travel change of the ear side conveyer along with the oil cylinder is shortest, one end of the lower ear distribution sliding plate is positioned at the ear outlet end of a peeler which is transversely arranged, and the hydraulic driver is connected with a driving shaft of the ear side conveyer by the cardan joint and drives the ear side conveyer to convey the corn ears sliding down from the lower ear distribution sliding plate and the ear receiving groove onto a synchronous transporter, thereby realizing car-following synchronous grain tipping.

Owner:LUOYANG ZHONGSHOU MACHINERY & EQUIP

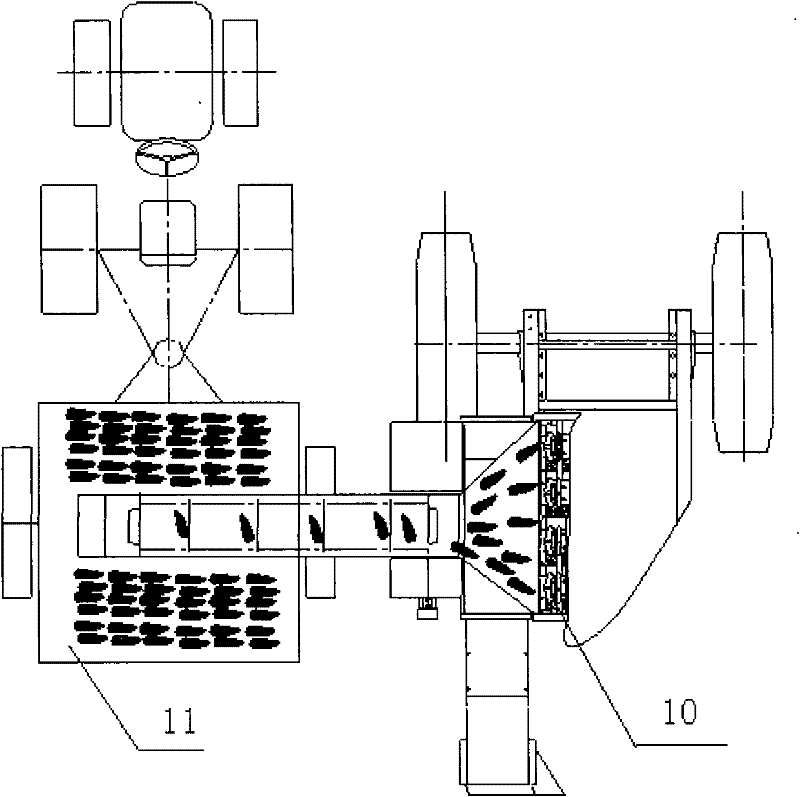

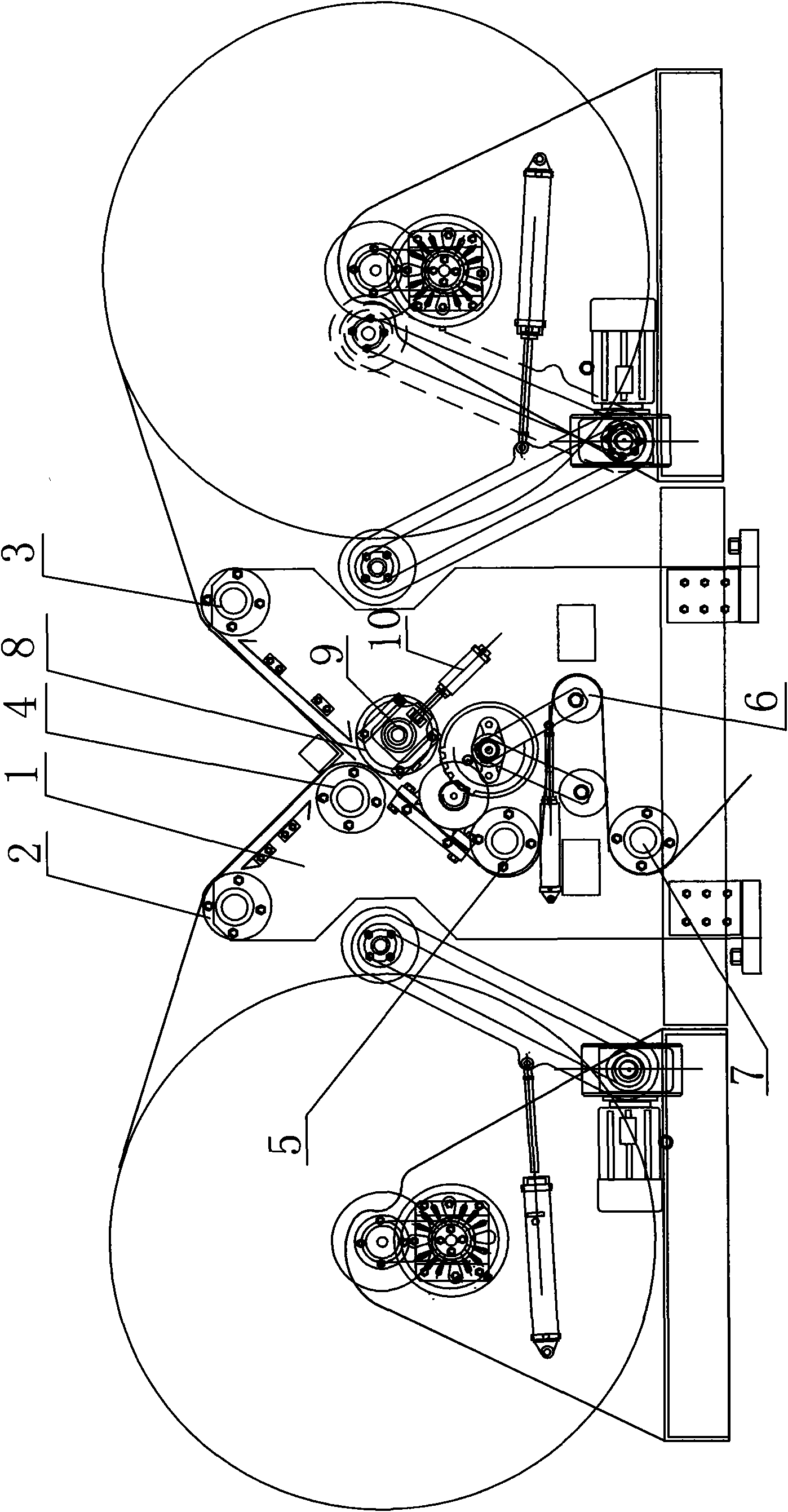

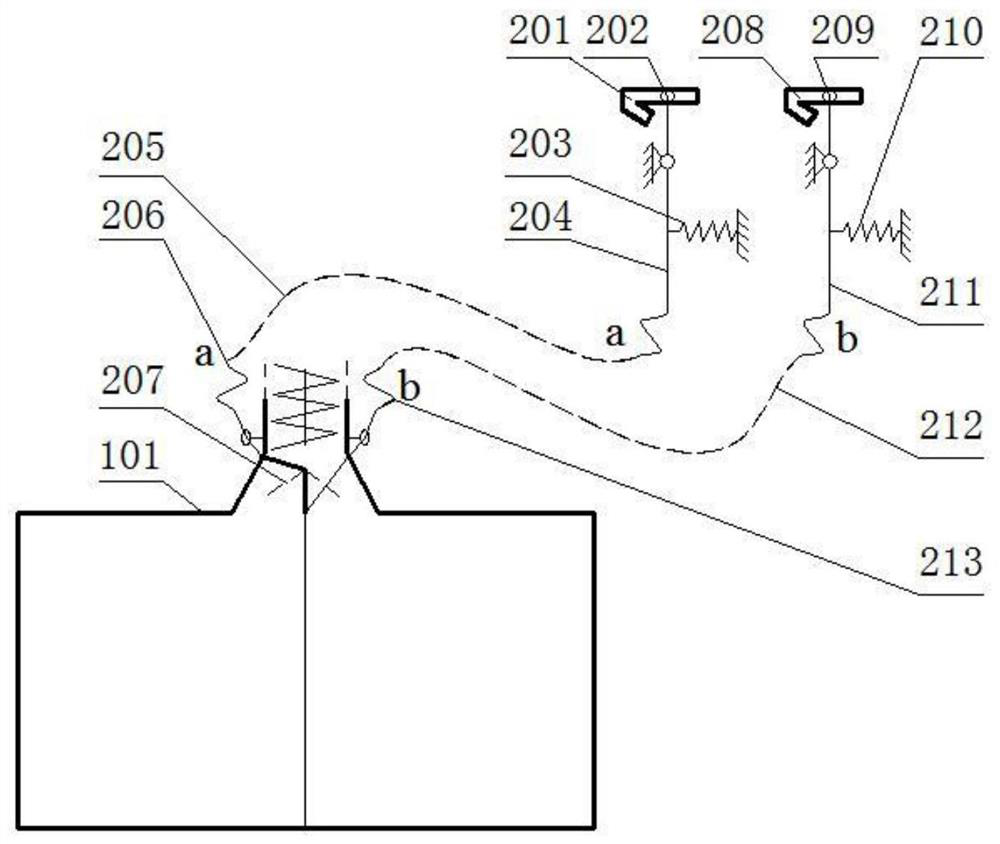

Adjustable-feeding greige cloth dual unwinding machine

InactiveCN101992961AEasy to unloadEasy to adjust the amount of expansion and contractionWebs handlingPulp and paper industryTextile

The invention discloses an adjustable-feeding greige cloth dual unwinding machine and relates to the technical field of textile machinery, in particular to structural technology of a greige cloth unwinding machine. The machine comprises two sets of machine frames in pair, wherein upper cloth guide rollers, a middle cloth guide roller, a lower cloth guide roller, a balance cloth guide roller and a bottom cloth guide roller are arranged on each set of machine frames through bearings respectively; two upper cloth guide rollers are symmetrically arranged on the machine frame; a retractable cloth guide roller is arranged below the middle cloth guide roller; the two ends of the retractable cloth guide roller are supported on a pair of movable bearing blocks respectively; the two sets of movable bearing blocks are connected with the expansion links of two sets of air cylinders respectively; and the two sets of air cylinders are fixedly supported on the two sets of machine frames respectively. The two ends of the retractable cloth guide roller are controlled by the air cylinders, so that the expansion amount of the cloth guide roller can be adjusted conveniently, cloth is fed conveniently, discharge time can be saved greatly, discharge working efficiency can be improved, and unwinding quality can be improved.

Owner:李龙河

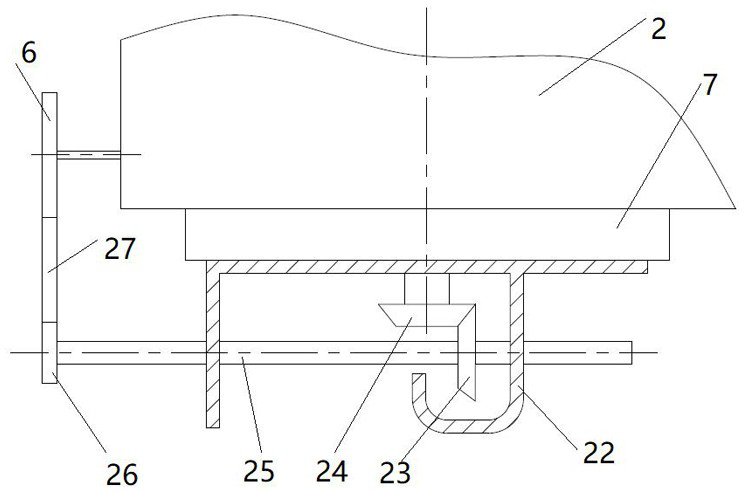

High-speed sewing machine capable of raising machine head

InactiveCN104562483APrevent derailmentEasy to unloadSewing-machine control devicesDrive shaftEngineering

The invention discloses a high-speed sewing machine capable of raising a machine head. The machine comprises a base, and the machine head which is mounted on the base; the base is fixedly mounted on a stand; a rotating shuttle main shaft for driving a rotating shuttle is mounted on the base; a driving shaft for driving the rotating shuttle main shaft is mounted on the machine head, wherein the machine head is pivoted to the base; a cylinder device for raising the machine head is mounted below the stand; a derailing device for preventing the driving shaft and the rotating shuttle main shaft from derailing is arranged on the base. According to the machine, the cylinder device can control the machine head to raise to discharge materials conveniently, and thus the discharging time is reduced, and the production efficiency is increased; in addition, the driving shaft and the rotating shuttle main shaft can be prevented from derailing through the derailing device; therefore, the machine is flexible to operate, and stable in working efficiency; a positioning device mounted at the back of a connecting block in the cylinder device is able to position the cylinder device, so that the safety working coefficients can be increased.

Owner:佛山市科华智缝设备有限公司

harvester granary

ActiveCN105409432BIncrease grain collection rateAvoid uneven accumulationMowersHydraulic motorDrive shaft

Owner:JIANGSU WORLD AGRI MACHINERY

Digital control edgefold sewing machine

InactiveCN101067261BPrecise length controlSave unloading timeProgramme-controlled sewing machinesWork-feeding meansEngineeringDigital control

The present invention discloses one kind of numerically controlled hemming sewing machine, which includes a sewing assembly, a driving mechanism, a presser foot mechanism, and a hemming mechanism. The hemming mechanism consists of mainly a pushing cutter, a locating cutter and a locating rod. The pushing cutter and its driving cylinder are mounted on a link rod, which is mounted on the driving mechanism; and the locating cutter is mounted on a seat, which is fixed on the work platform; with one locating clip being mounted beside the locating cutter. The present invention has the integrated automatic functions of seizing cloth, shifting cloth, hemming and sewing and thus high production efficiency.

Owner:龚培云

LNG or gas unloading method

ActiveCN104763875BFulfil requirementsSave unloading timePressure vesselsContainer discharging from pressure vesselsEngineeringProcess engineering

The invention discloses a liquid unloading method for liquefied natural gas or coal gas. The liquefied natural gas (LNG) liquid unloading process comprises the following steps: connecting three metal flexible pipes with an unloading platform, pressurizing a cryogenic liquid tanker by using an unloading supercharger to form a pressure difference between the cryogenic liquid tanker and a storage tank, unloading the LNG into the storage tank, and unloading residual gas in the cryogenic liquid tanker to user pipe network by using a medium pressure gas supply system. Compared with the existing liquid unloading method, the invention decreases the residual gas of the cryogenic liquid tanker from 0.4MPa to 0.15Mpa, and the residual gas in the tanker also decreases from 500kg to below 200kg, so as to meet the requirements of customers and save gas unloading time from the original 1 h to 15 min; and the safety coefficient is improved and the production cost is reduced.

Owner:SHANDONG TAISHAN STEEL GROUP

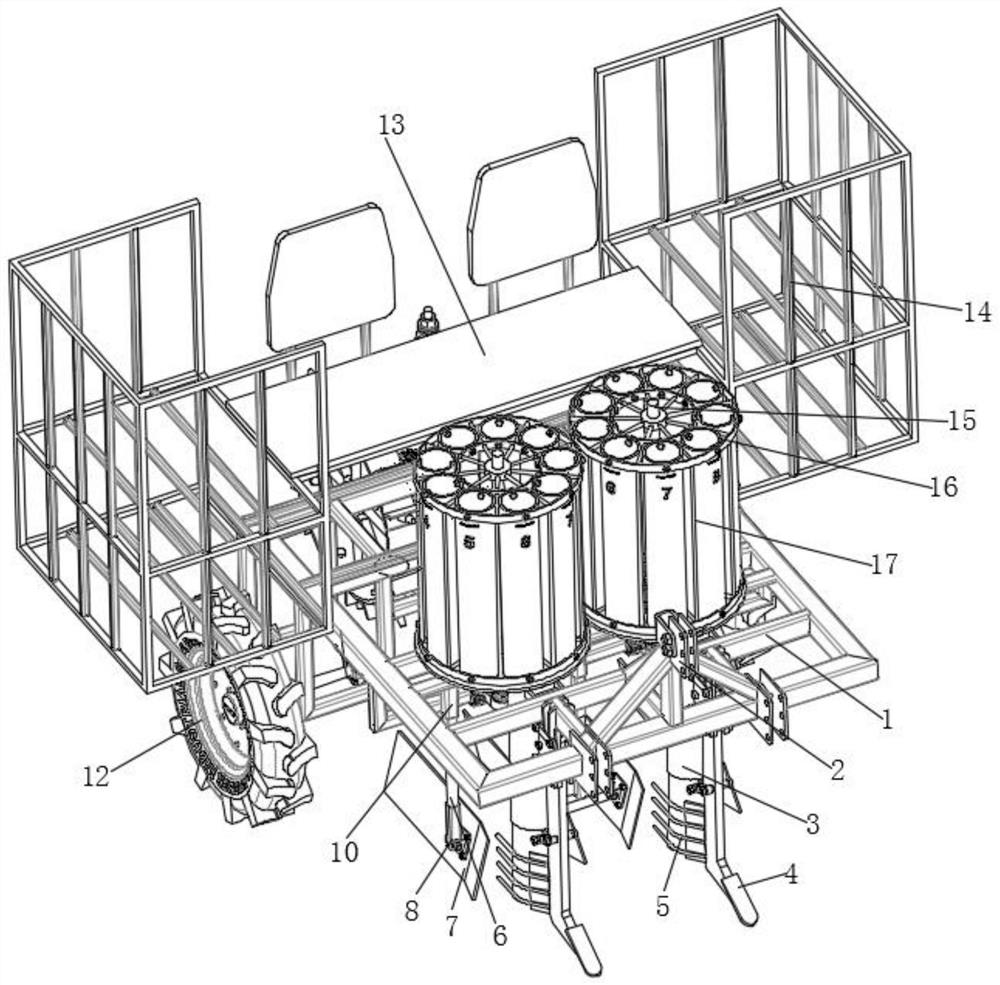

Multidirectional grain unloading device and harvester

The invention discloses a multidirectional grain unloading device and a harvester. The multidirectional grain unloading device comprises a grain tank body, a first conveying auger, a transfer conveying mechanism, a rotating mechanism and a grain unloading barrel; the first conveying auger is installed in the grain tank body, the conveying direction of the first conveying auger in the grain tank body is arranged along a harvester body to be matched with the grain tank body, and the output end of the first conveying auger sequentially communicates with the transfer conveying mechanism, the rotating mechanism and the grain unloading barrel; and the grain unloading barrel is rotationally installed at the top of the grain tank body through the rotating mechanism and can horizontally rotate under the driving of the rotating mechanism. According to the multi-direction grain unloading device, the situation that the side wall of the grain tank body limits the rotation amplitude of the grain unloading barrel can be avoided, the grain unloading barrel can be driven to horizontally rotate through the rotating mechanism, and therefore multi-direction grain unloading is achieved.

Owner:广东皓耘科技有限公司

Metal framework discharge tool

PendingCN108357029ASimple structureScientific and reasonable designDischarge efficiencyMetal framework

The invention discloses a metal framework discharge tool which solves the problems that a potential safety hazard of burning an arm of an operator exists when a metal framework is put into a high-temperature mould, and discharge efficiency is low in the prior art. The metal framework discharge tool comprises a fixed plate, handrails, dowel pins, positioning bases, a movable plate, ejector rods, guide posts and guide sleeves, wherein a return spring is arranged on a position, between the movable plate and the fixed plate, on each ejector rod in a sleeving mode; the guide sleeves vertically penetrate the fixed plate; a pressing plate for fixing each guide sleeve onto the fixed plate sleeves the periphery of the corresponding guide sleeve; and a gasket which is positioned on the bottom of each guide sleeve for preventing each guide column from upwards sliding out of the guide sleeve is arranged on the corresponding guide post. The metal framework discharge tool is simple in structure, isscientific and reasonable in design, is convenient to use, can effectively eliminate the potential safety hazard of burning the arm of the operator in an operation process; and efficiency is high whenthe metal framework is put into the high-temperature mould.

Owner:成都望锦汽车部件有限公司

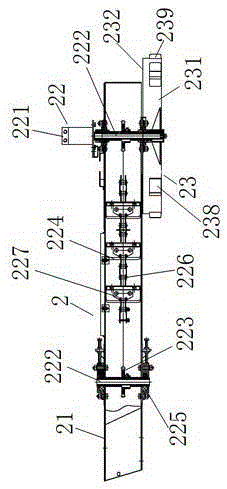

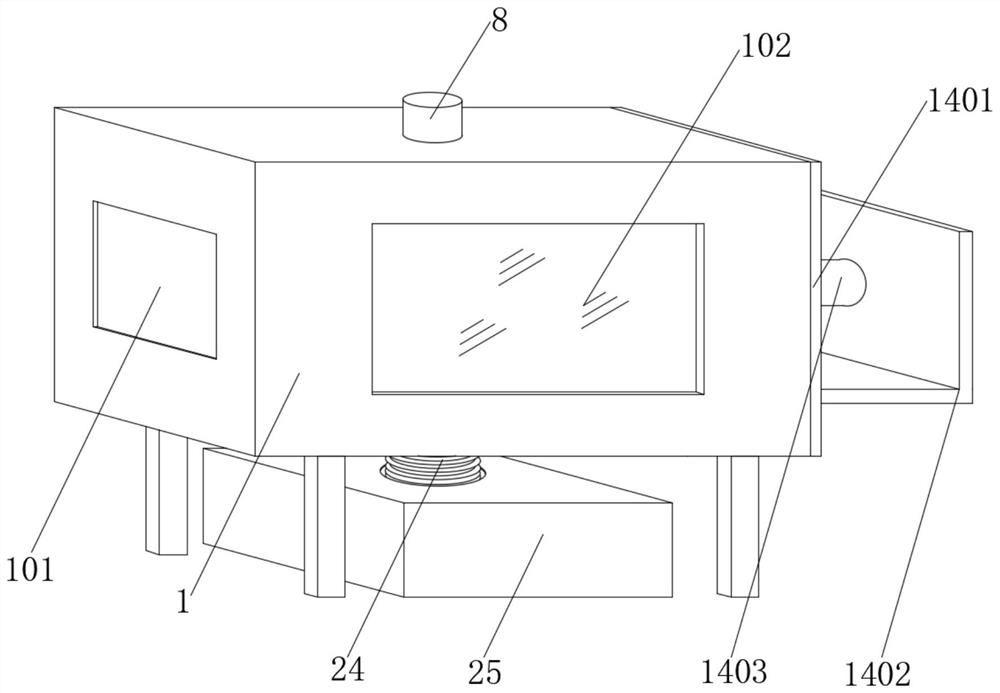

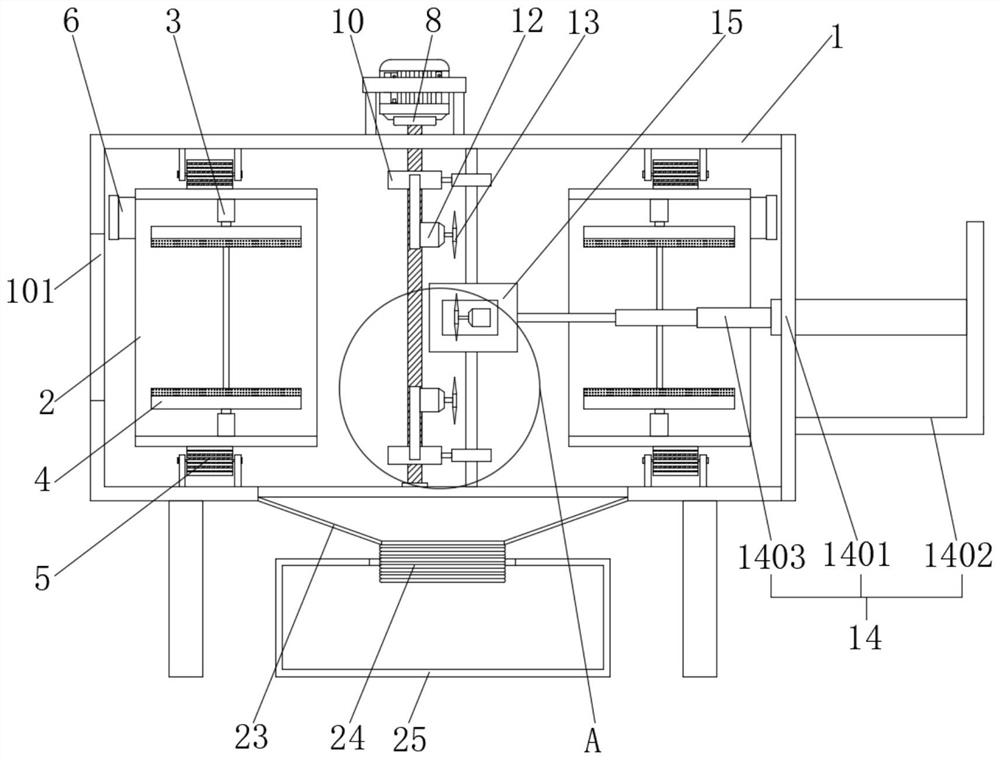

High-efficiency multi-azimuth synchronous machining device

The invention discloses a high-efficiency multi-azimuth synchronous machining device. The device comprises a workbench, a first machining mechanism arranged above the workbench and a second machiningmechanism arranged on one side of the workbench, wherein the workbench comprises an outer ring table and a center table; a storage groove is formed in the center table; a first vertical frame, a second vertical frame and a first driving mechanism are arranged on the upper surface and the lower surface of the central table, a first guide rail, a first movable plate and a second drive mechanism arearranged on the first vertical frame, and a second guide rail, a second movable plate and a third driving mechanism are arranged on the second vertical frame; a guide hole is formed in the center table; and a fourth driving mechanism and a fifth driving mechanism are installed on the outer ring table, the fourth driving mechanism is used for driving the center table to turn over, and the fifth driving mechanism comprises an ejector rod which can extend into the guide hole and a power unit which is used for driving the ejector rod to extend and retract. According to the high-efficiency multi-azimuth synchronous machining device, the workpiece end surface and the side wall are synchronously machined, and the workpiece clamping and discharging time is saved.

Owner:TIANCHANG CYLINDER HEAD

A kind of coiling method of steel coil

ActiveCN112605154BReduce the looseness problemSave unloading timeMetal rolling arrangementsAutomatic controlStructural engineering

The invention discloses a coiling method of a steel coil, which belongs to the technical field of automatic control. In order to solve the problem of the loose outer ring of the steel coil, the present invention calculates the three lifting actions of the steel coil trolley when the strip tail is a certain distance from the stop position according to the current steel coil diameter; length, when the strip tail is about to leave the upper pressure roller of the coiler, the coil trolley automatically triggers three lifts to touch the strip, thus completing the coil coiling. The advantage of the present invention is that it effectively avoids the problem of the loose outer ring of the steel coil, improves the coil receiving speed of the steel coil trolley, and reduces the labor frequency that the operator needs to frequently manually jog the coiler to rotate one circle to eliminate the loose outer ring of the steel coil , to ensure continuous and stable high-level automated production.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

A storage and unloading grain box and a combine harvester

ActiveCN110149892BEasy to harvestEfficient collectionMowersAgricultural scienceAgricultural engineering

The invention provides a grain storage and unloading box and a combine harvester, comprising a grain box shell, a grain outlet control device and a surplus grain collection device, the bottom of the grain box shell is provided with a grain outlet; the grain outlet control device controls the grain box The opening and closing of the grain outlet of the shell; the surplus grain collecting device is located under the bottom of the grain tank shell, and is used to collect different types of surplus grain in the grain tank shell and store them separately. The invention collects the surplus grain through the surplus grain collecting device, and can temporarily store the surplus grain in the grain box, so that the grain combine harvester can continue to harvest other different kinds of grains. The sorting device is used to distribute different kinds of crops into the designated grain storage room of the grain box. The invention solves the problems of unclean grain unloading, mixed species of grain and the like.

Owner:JIANGSU UNIV

Beating machine achieving continuous discharging

ActiveCN106049156ASave unloading timeAvoid cloggingPulp beating/refining methodsWater levelPulp and paper industry

Provided is a beating machine achieving continuous discharging. The beating machine comprises a pulp tank which is internally provided with a partition wall, a wash drum and a beater roll, the bottom of the pulp tank is provided with a drain outlet and a discharge outlet, the discharge outlet is connected with a discharge tube which is perpendicular to the water level, the discharge tube is internally provided with multiple filter screens, a movable and openable cover is arranged at the discharge outlet, and the cover is located above the filter screens. According to the beating machine achieving continuous discharging, paper pulp which achieves the beating degree can be discharged in the beating process of the paper pulp, the discharging time is saved, and the paper pulp achieving the beating degree is prevented from multiple times of beating in the pulp tank.

Owner:安徽丰捷复合材料有限公司

Production process of 5-acetyl acetamino benzimidazolone

The invention relates to a technology for producing 5-acetyl amido benzimidazolone. The condensation process is as follows: o-phenylendiamine, carbamide, water and concentrated sulfuric acid are added into a condensation reaction kettle step by step, the pH value is controlled to between 6 and 7, and benzimidazolone is obtained by drying the mixture; the nitration process is as follows: the benzimidazolone, chlorinated benzene and concentrated sulfuric acid are added into a nitration reaction kettle, the chlorinated benzene is reclaimed and purified by reduced pressure distillation and water boiling, and 5-nitryl benzimidazolone is obtained by drying the mixture; the reduction process is as follows: the 5-nitryl benzimidazolone, iron powder, hydrochloric acid and water are added into a reduction reaction kettle, the mixture is subject to suction filtering, cooling, crystallization and drying after the reaction for producing the 5-amino benzimidazolone; and the acetylization process is as follows: the 5- amino benzimidazolone, Diketene, phosphoric acid, caustic soda liquid and water are added into an acetylization kettle, the pressure inside the kettle is discharged in the temperature rising process, and the mixture is subject to suction filtering and drying to produce the 5-acetyl amido benzimidazolone. The process has the total yield coefficient up to 75 percent, purity quotient more than 99 percent and the product quality which meets the international standards of the same products at home and abroad.

Owner:DONGYING TIANZHENG CHEM

Two-side corn unloading device for corn harvester granary

InactiveCN109417900ASave unloading timeReduce movement distanceMowersRotational axisHydraulic cylinder

The invention provides a two-side corn unloading device for a corn harvester granary, and relates to the technical field of agricultural machinery manufacturing and processing. The device comprises abox body, rotating shafts, a pin connecting rod, pins and a box body turning bracket, wherein the box body is arranged on the box body turning bracket, the rotating shafts are arranged at the four corners of the box body, and the pins are arranged at bottoms of the left side and right side of the box body; the pin connecting rod is disposed between the box body and the box body turning bracket, each pin comprises a spring, a pin body, a pin sliding sleeve and a rotating cavity shaft, and the pins comprises first pins and second pins; and the first pins and the second pins have the same structures but opposite positions, and a hydraulic cylinder is also arranged in the box body. The two-side corn unloading device has a simple structure and reasonable design, two-side corn unloading can be achieved, and movement of a vehicle is reduced, so that saving of oil materials and reduction of wear of the vehicle are achieved.

Owner:LIAONING SHIFENG MACHINERY

A high-speed sewing machine with a raised head

InactiveCN104562483BPrevent derailmentEasy to unloadSewing-machine control devicesDrive shaftEngineering

The invention discloses a high-speed sewing machine capable of raising a machine head. The machine comprises a base, and the machine head which is mounted on the base; the base is fixedly mounted on a stand; a rotating shuttle main shaft for driving a rotating shuttle is mounted on the base; a driving shaft for driving the rotating shuttle main shaft is mounted on the machine head, wherein the machine head is pivoted to the base; a cylinder device for raising the machine head is mounted below the stand; a derailing device for preventing the driving shaft and the rotating shuttle main shaft from derailing is arranged on the base. According to the machine, the cylinder device can control the machine head to raise to discharge materials conveniently, and thus the discharging time is reduced, and the production efficiency is increased; in addition, the driving shaft and the rotating shuttle main shaft can be prevented from derailing through the derailing device; therefore, the machine is flexible to operate, and stable in working efficiency; a positioning device mounted at the back of a connecting block in the cylinder device is able to position the cylinder device, so that the safety working coefficients can be increased.

Owner:佛山市科华智缝设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com