Wire disassembling device for small linear cutting machine tool

A wire-cutting machine tool, small-scale technology, applied in the direction of attachments, electric processing equipment, metal processing equipment, etc., can solve the problem of broken wires, easy hooking of equipment parts, affecting the efficiency of wire-cutting processing, production progress and processing surface quality And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

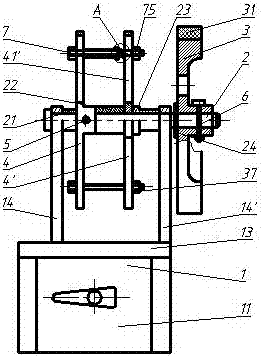

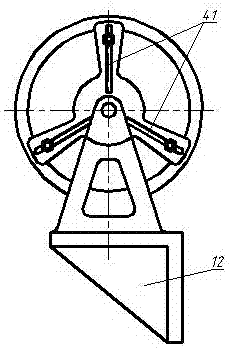

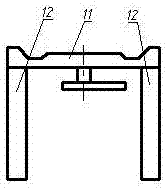

[0017] Below in conjunction with accompanying drawing, the wire removing device of a kind of small wire cutting machine tool of the present invention is further described:

[0018] Depend on figure 1 , figure 2 , image 3 and Figure 4 It can be seen that the wire removal device of the small-sized wire cutting machine tool includes a mounting base 1, a transmission shaft 2, a friction wheel 3, a receiving reel 4 and a receiving reel 2 4', and the installation base 1 includes a V-shaped magnetic suction plate 11, Rib 12, mounting plate 13, left support plate 14 and right support plate 14', described V-shaped magnetic suction plate 11 is arranged on the rear plane below the mounting plate 13, and both sides of mounting plate 13 are respectively provided with ribs 12. Both sides of the upper plane of the mounting plate 13 are provided with a left support plate 14 and a right support plate 14'; above the left support plate 14 and the right support plate 14', a transmission sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com