A storage and unloading grain box and a combine harvester

A grain tank and grain storage room technology, which is applied in the directions of harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of unloading grains, complex structure and low reliability, saving grain unloading time and improving economy. Benefit, the effect of reducing the mixing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

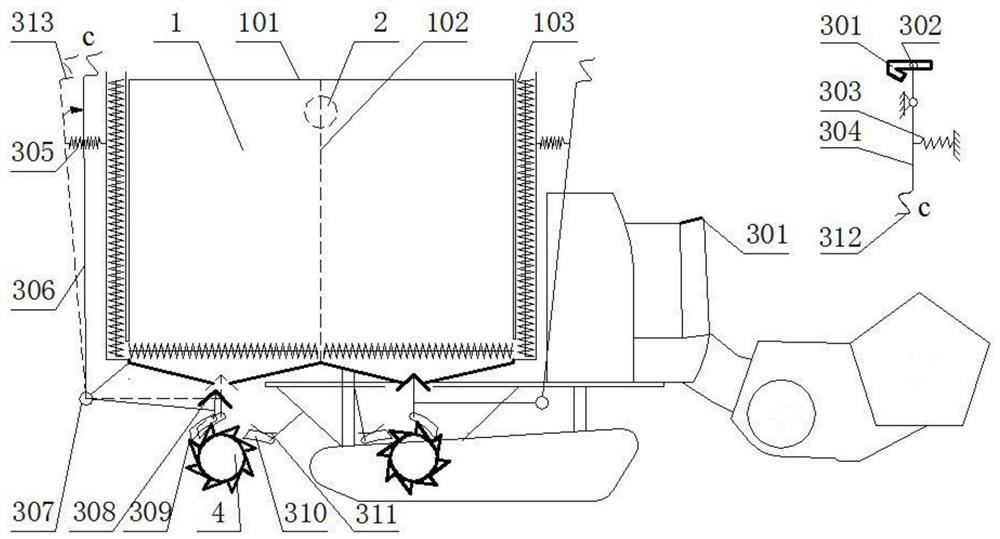

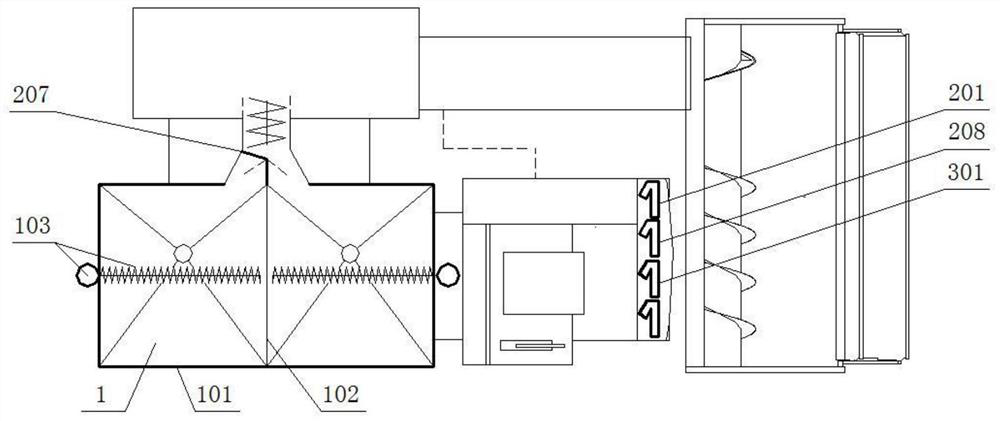

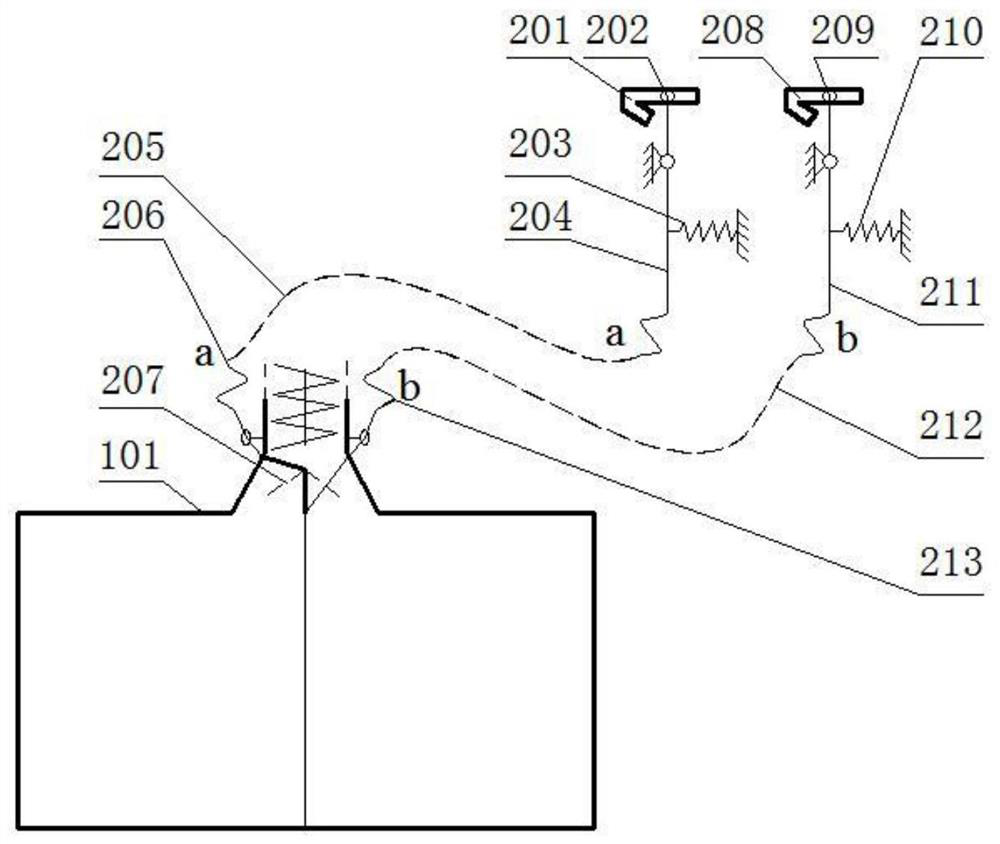

[0046] like figure 1 and 2 Shown is an embodiment of the grain storage and unloading tank of the present invention, the grain storage and unloading tank includes a grain tank housing 101, a grain outlet control device and a surplus grain collection device 4; the bottom of the grain tank housing 101 A grain outlet is provided; the grain outlet control device controls the opening and closing of the grain outlet of the grain tank housing 101; the surplus grain collecting device 4 is located below the bottom of the grain tank housing 101 and is used to collect grain tank housing 101 different Kind of leftovers and store them separately.

[0047] The grain tank shell 101 is provided with several separated grain storage rooms; the bottom of the grain storage room is in the shape of a funnel, and each grain storage room bottom is provided with a grain delivery auger 103 and a grain outlet. The grain inlet of the grain tank housing 101 is provided with a sorting device 2; the sortin...

Embodiment 2

[0073] A combine harvester includes the grain storage and unloading box described in Embodiment 1, so it has the beneficial effects described in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com