A high-speed sewing machine with a raised head

A sewing machine and machine head technology, which is applied to sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of increasing sewing operation time, reducing production efficiency, and user trouble, and improving work safety factor and improving production efficiency. , The effect of shortening the discharge time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

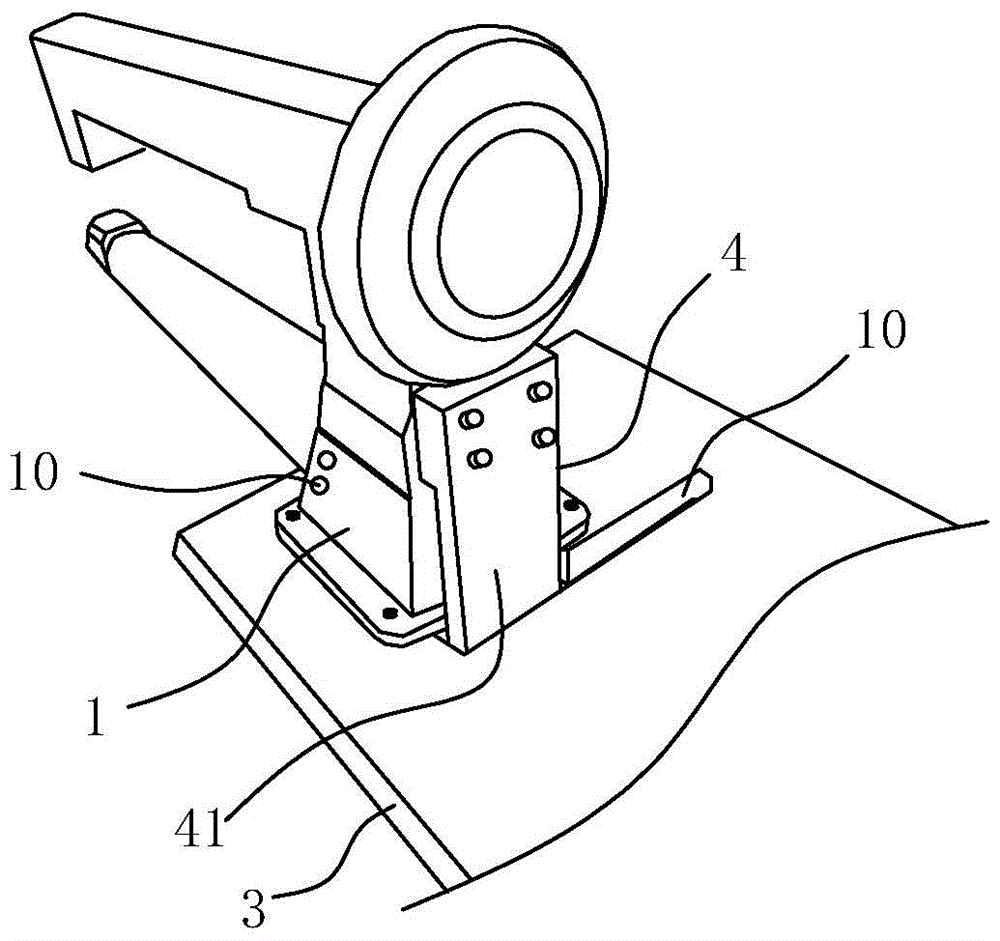

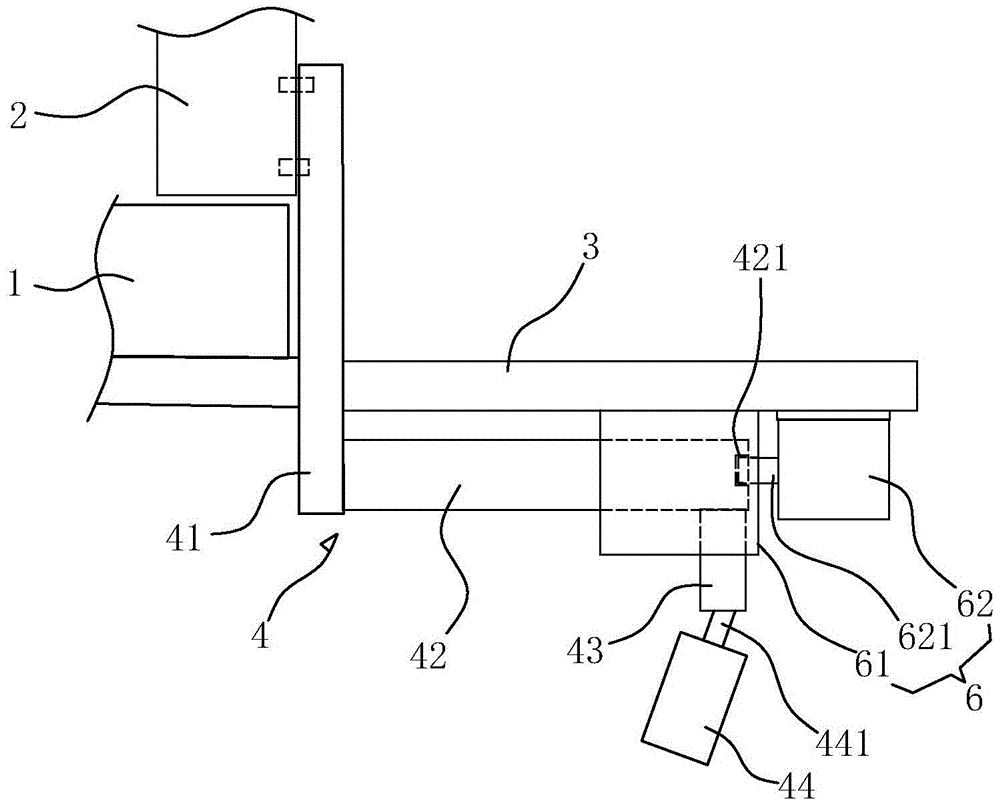

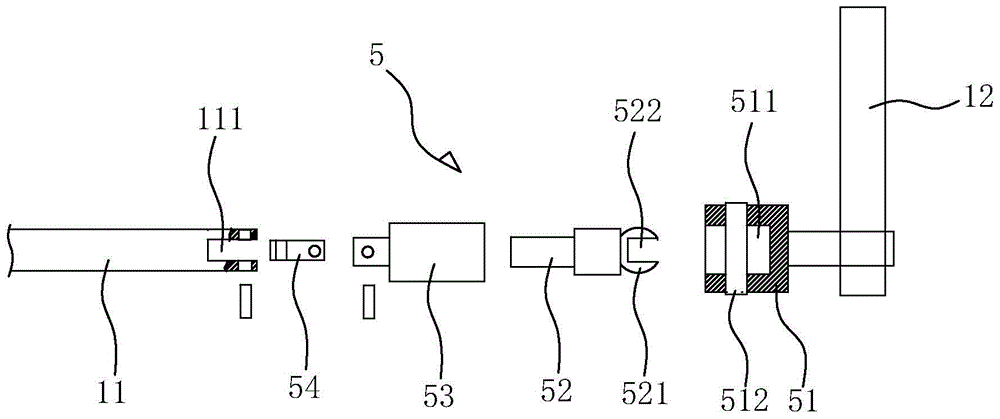

[0030] See Figure 1-3 As shown, a high-speed sewing machine that can raise the machine head includes: a machine base 1 and a machine head 2 installed on the machine base 1, wherein the machine base 1 is fixedly installed on a machine table 3; The base 1 is equipped with a hook main shaft 11 for driving the hook; the head 2 is equipped with a drive shaft 12 for driving the main shaft 11 of the hook; the head 2 is pivotally connected to the base 1, and the machine A cylinder device 4 that can raise the head 2 is also installed below the 3, and an anti-derailing device 5 that can prevent the drive shaft 12 from derailing from the hook main shaft 11 is also provided on the described support 1.

[0031] Specifically, the cylinder device 4 includes a fixed block 41, a connecting block 42, a driving block 43 and a first cylinder 44, wherein the fixing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com