Metal framework discharge tool

A metal frame and tooling technology, applied in the field of metal frame feeding tooling, can solve the problems of easily scalding the operator's arm and low feeding efficiency, and achieve the effect of eliminating potential safety hazards, simple structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

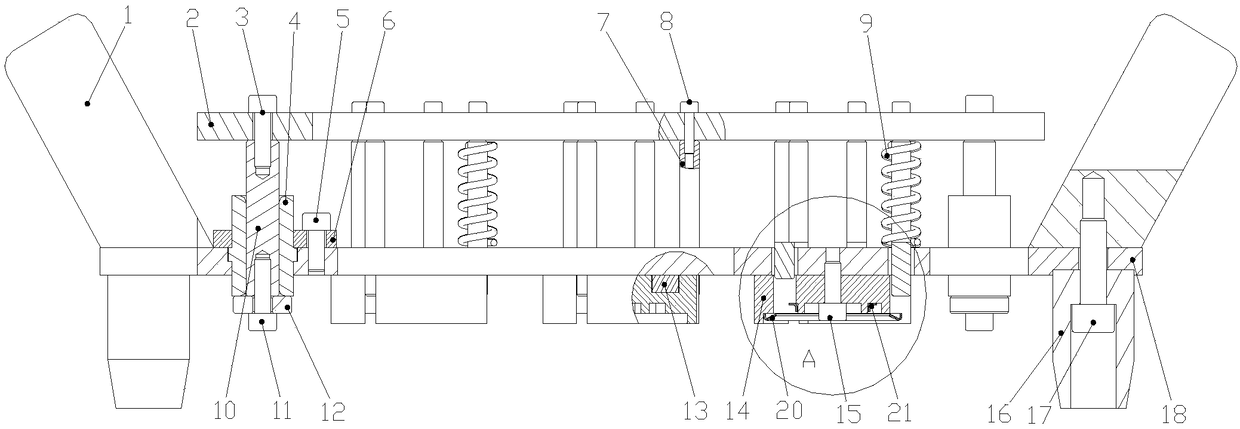

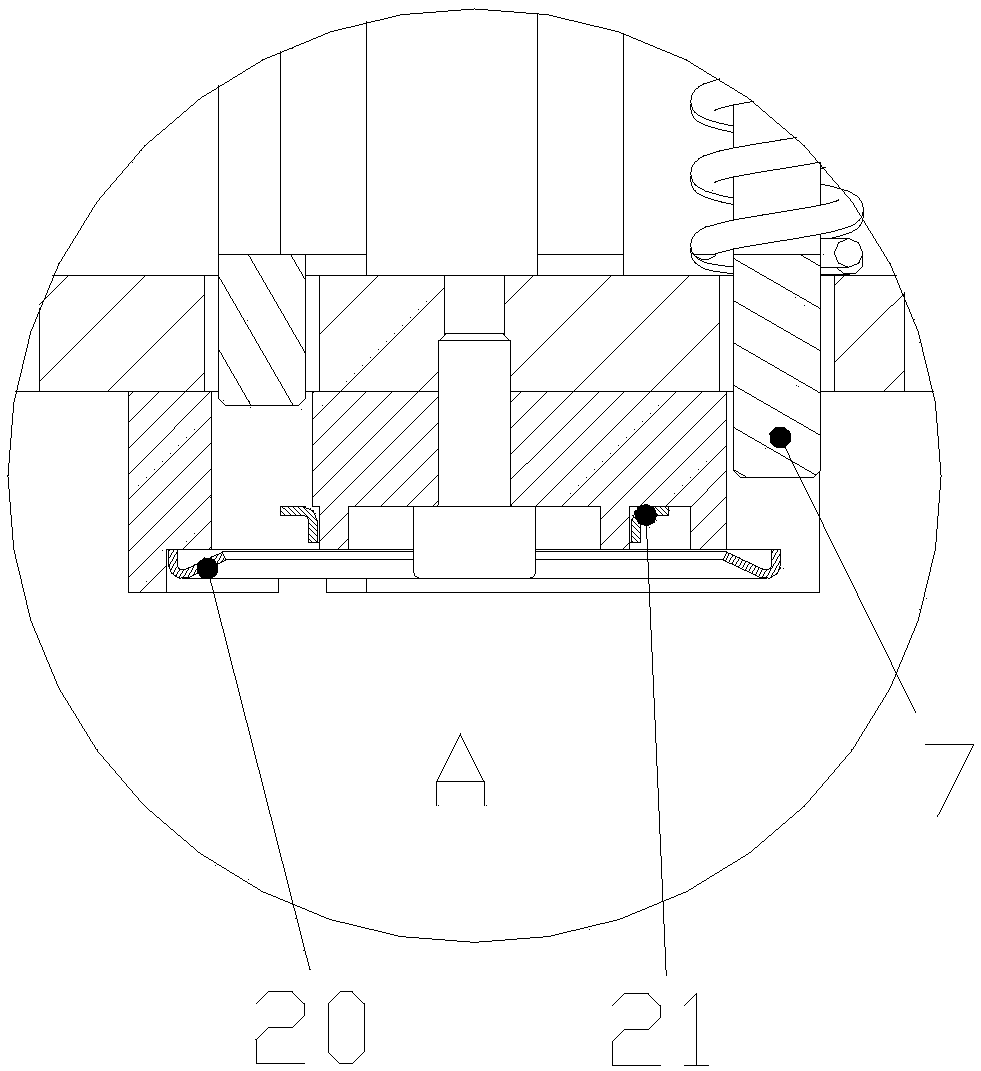

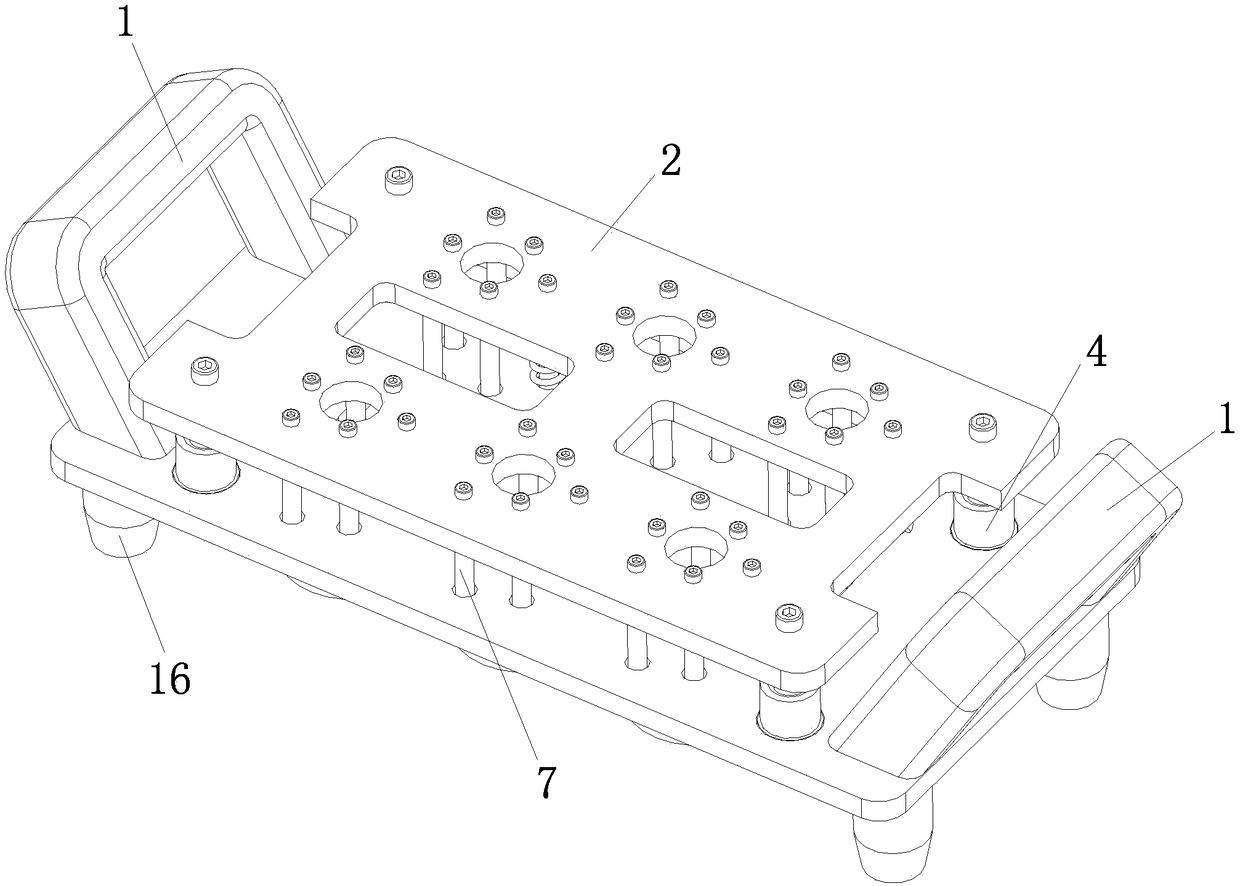

[0026] Such as Figure 1-5 As shown, the metal skeleton unloading tool provided by the present invention has simple structure, scientific and reasonable design, and is easy to use. high. The present invention includes a fixed plate 18 arranged horizontally, a pair of handrails 1 respectively fixed on the two ends of the top surface of the fixed plate 18, two pairs of handrails 1 respectively fixed on the four corners of the bottom surface of the fixed plate 18 and matched with the photos of the four positioning holes on the mould. Locating pins 16, two or more positioning seats 14 for absorbing and positioning metal skeletons 20, 21 equidistantly distributed on the bottom surface of the fixing plate 18, and horizontally located directly above the fixing plate 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com