Air valve one-time forming grinding machine

A valve and grinding machine technology, which is applied in the direction of grinding machines, grinding bed, grinding machine parts, etc., can solve the problems of reduced work efficiency, long operation time, and low work efficiency, and achieve simplified structure, reduced time consumption, and easy work The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

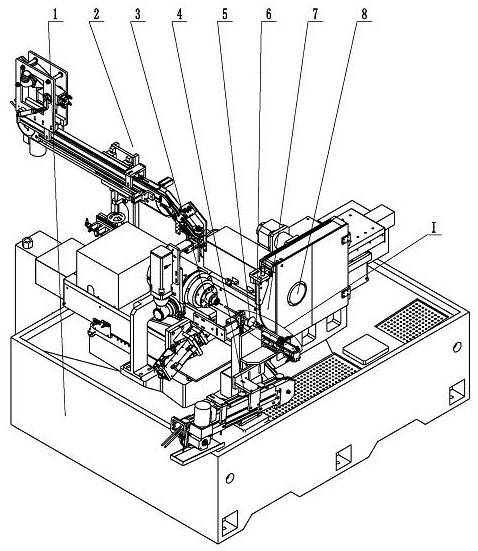

[0033] exist figure 1 In the one-time valve forming grinding machine shown, the frame 1 is the basic support of the valve grinding equipment, and the feeding conveying device 2, the hollow workpiece spindle 3, the grinding wheel spindle 8 and the discharging conveying device are supported on the frame 1 4. The valve 5 to be ground is conveyed to the front end of the workpiece spindle 3 by the feeding conveying device 2, and is positioned, clamped and rotated by the workpiece spindle 3 with the assistance of the loading positioning push rod 6, and is installed on the grinding wheel spindle 8 for forming The emery wheel carries out profile grinding on the head of the valve 5 to be ground, and the valve after grinding is output by the discharge conveying device 4 .

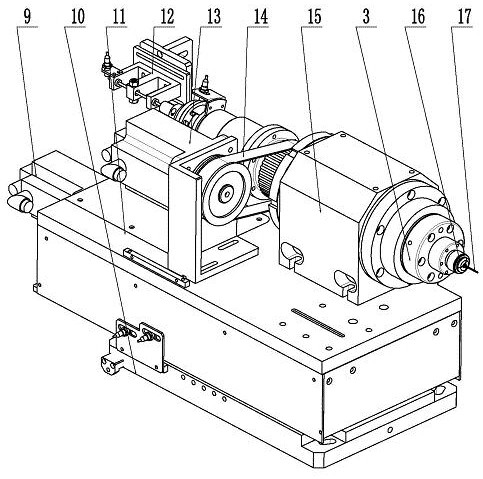

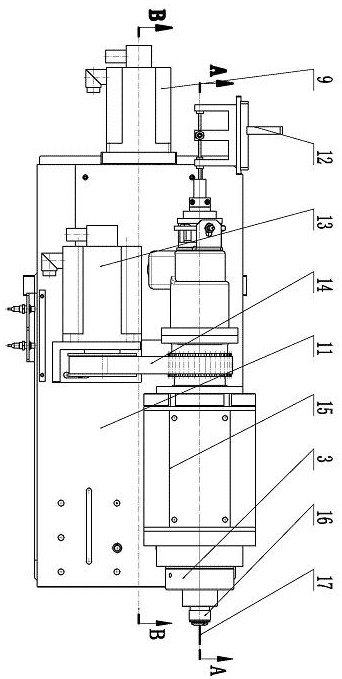

[0034] Such as figure 2 , image 3 with Figure 4 As shown, the workpiece spindle 3 is a hollow tubular member, and an elastic collet 16 is arranged at the front end of the inner hole of the workpiece spindle 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com