Adjustable-feeding greige cloth dual unwinding machine

A double unwinder, adjustable technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve problems such as prone to sagging and affecting the quality of unwinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

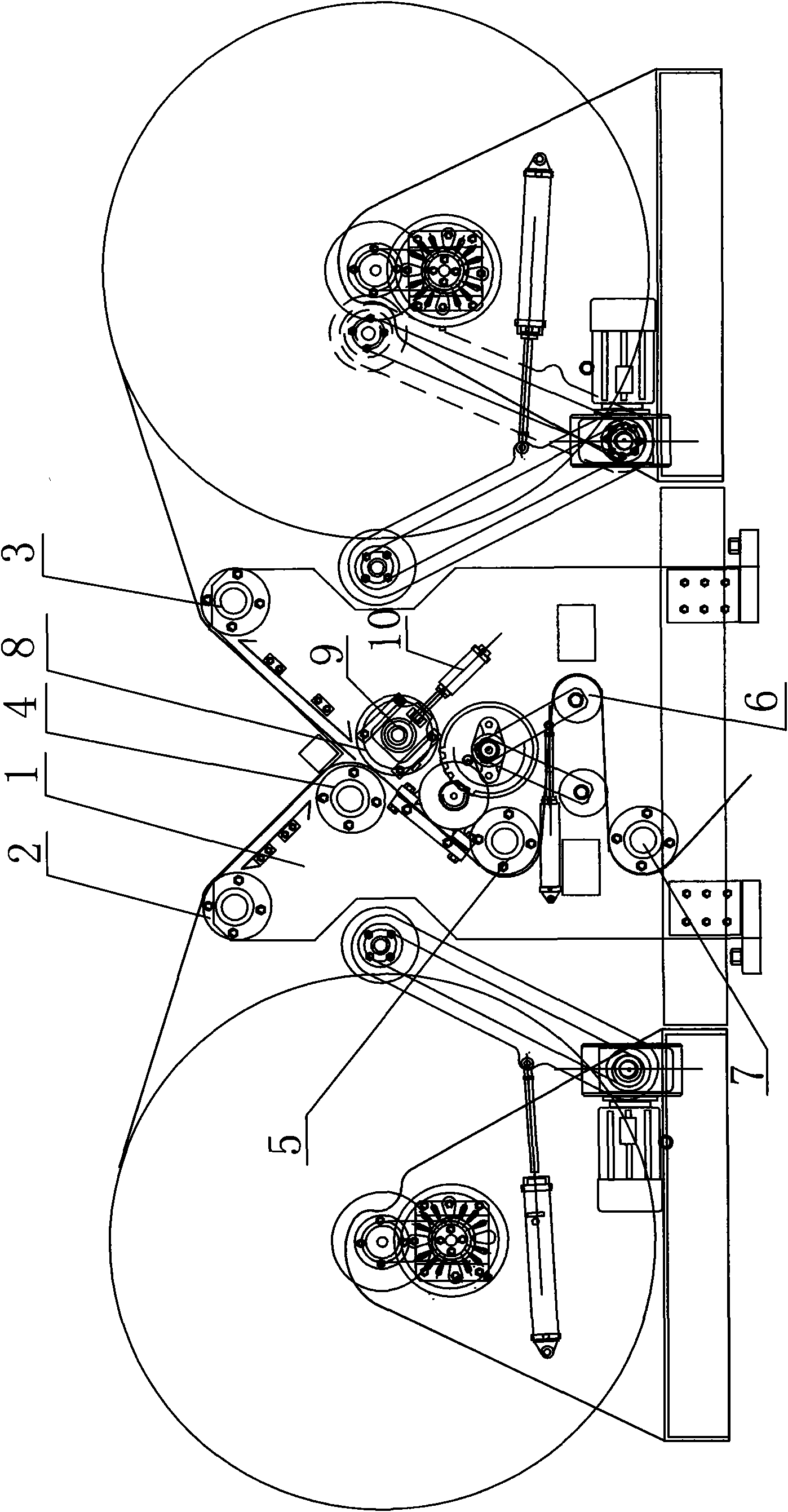

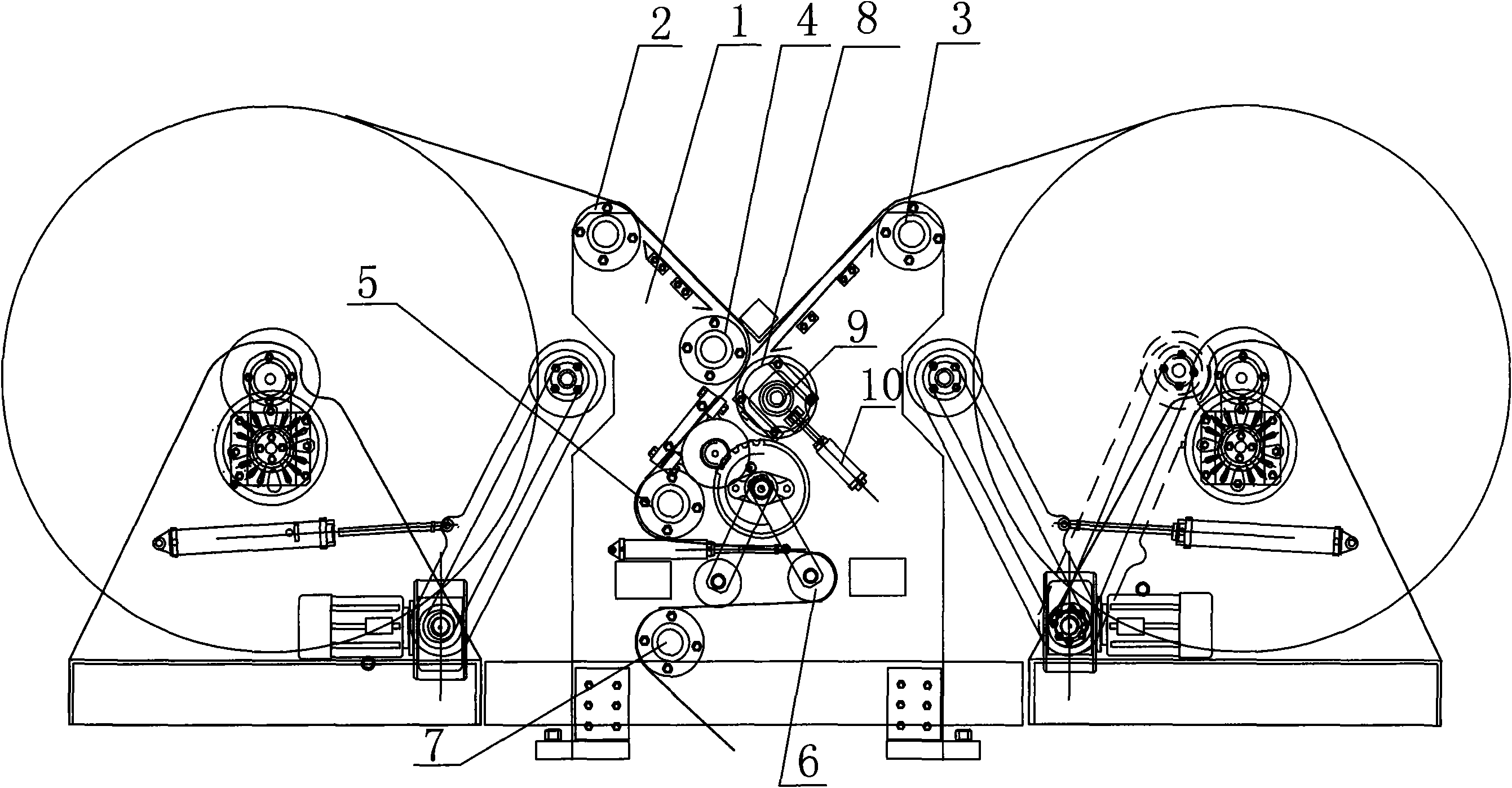

[0008] Such as figure 1 As shown, the present invention is provided with two groups of frames 1 arranged in pairs, and two upper cloth guide rollers 2, 3 are symmetrically arranged on each group of frames 1 respectively through bearings, and a middle cloth guide roller 4 is also arranged through bearings. , a bottom cloth guide roller 5, a balance cloth guide roller 6 and a bottom cloth guide roller 7.

[0009] A telescopic cloth guide roller 8 is arranged obliquely below the middle cloth guide roller 4, and the two ends of the telescopic cloth guide roller 8 are respectively supported on a pair of movable bearing seats 9, and the two groups of movable bearing seats 9 are connected to two groups of cylinders 10 respectively. Two groups of cylinders 10 are fixedly supported on two groups of frames 1 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com