LNG or gas unloading method

A technology for liquefied natural gas and natural gas, which is applied in the method of container discharge, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve problems such as pump cavitation, reduce production costs, save gas discharge time, and improve The effect of the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

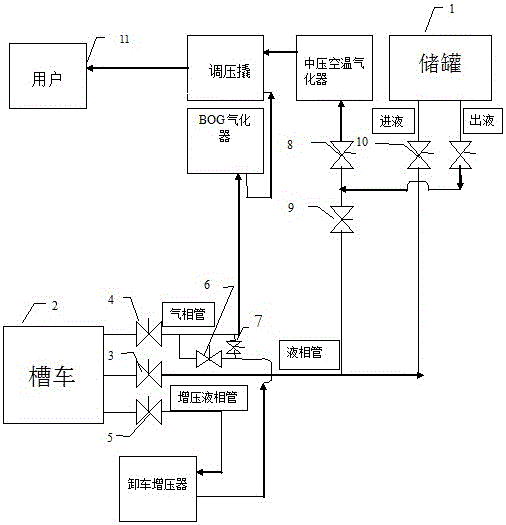

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] During the unloading process of liquefied natural gas (LNG), the tank car 2 is pressurized by the unloading supercharger to form a pressure difference between the tank car 2 and the LNG storage tank 1, and the LNG is unloaded into the LNG storage tank 1 for reuse. The compressed air supply system discharges the residual air from the tanker to the user's pipe network.

[0023] 1) Park the liquid tanker 2 at the designated place, and check and record the tanker 2 according to the regulations.

[0024] 2) Connect the electrostatic grounding wire of the tank car 2 and the unloading platform firmly, and check the status of all relevant valves.

[0025] 3) Connect the gas and liquid phase hoses of the unloading platform and the liquid tanker 2.

[0026] 4) Slowly open the pressurized liquid phase valve 5 on the tank car, open the gas-liquid communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com