Car-following synchronous side-tipping grain conveying device of corn ears

A technology of corn ears and conveying devices, which is applied in the direction of agricultural machinery and implements, applications, harvesters, etc., can solve the problems of long vehicle body, unsatisfactory harvesting efficiency, and limited use, so as to reduce the number of times of unloading grain and save unloading costs. Grain time, the effect of improving harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

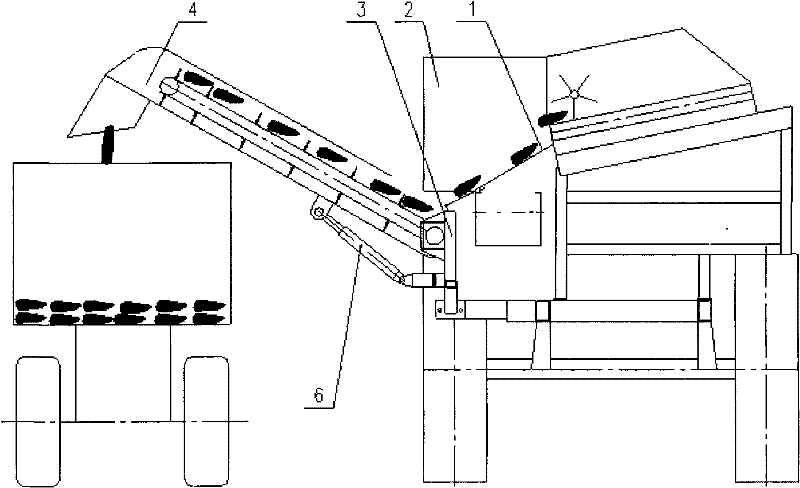

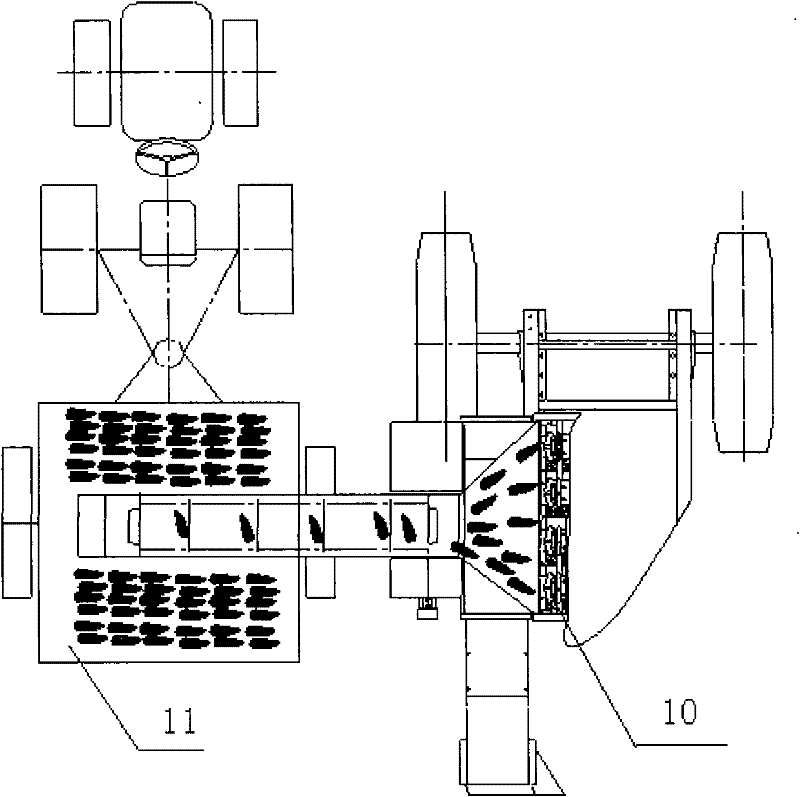

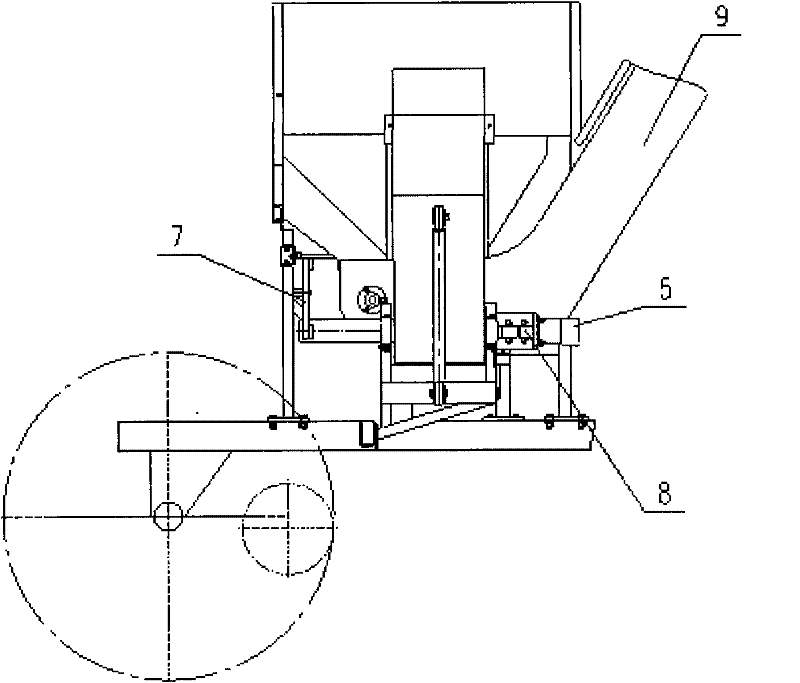

[0013] Such as Figure 1-Figure 3 As shown, the synchronous side unloading conveying device for corn ears following the car is mainly composed of the ear distribution lower plate 1, the scion groove 2, the secondary elevator bracket 3, the ear lateral conveyor 4, the hydraulic drive 5, the oil cylinder 6, and the connecting rod 7 , universal joint 8, and secondary elevator 9, the ear lateral conveyor 4 is installed in the "U"-shaped seat of the secondary elevator bracket 3, and one end of the oil cylinder 6 is installed on the ear lateral conveyor 4 On the support, the other end is installed on the support of the secondary elevator bracket 3, the scion groove 2 is installed on the horizontal section of the secondary elevator 9, and the ear distribution lower plate 1 is installed on the secondary elevator 9 In the horizontal section sleeve pipe, one end of the connecting rod 7 is connected with the upper rotating shaft support arm of the fruit ear distribution lower plate 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com