Granary fruit cluster conveying device

The technology of conveying device and granary is applied to the field of harvesting equipment for growing crops. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

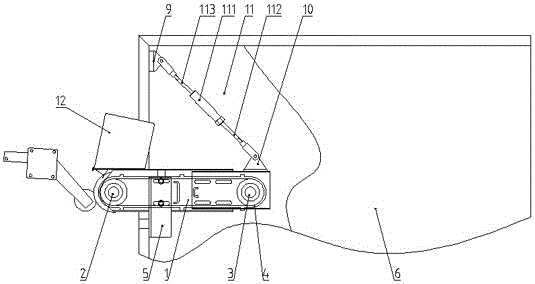

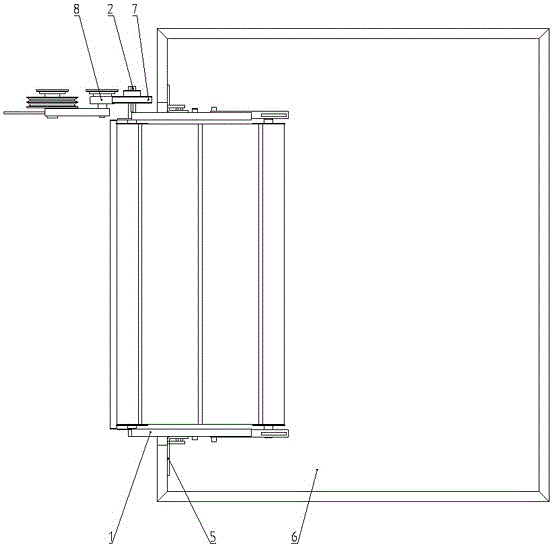

[0013] Such as figure 1 As shown, a granary ear conveying device includes a support frame 1 , a driving conveying roller 2 , a driven conveying roller 3 and a conveying belt 4 . Among them, such as figure 1 , figure 2 As shown, a fixing plate 5 is screwed on both sides of the support frame 1 respectively, and the fixing plate 5 fixes the support frame 1 laterally on the inner side wall of the granary 6 .

[0014] Such as figure 1 As shown, the active conveying roller 2 is rotatably supported on the proximal end of the support frame 1 through conventional bearings, the driven conveying roller 3 is rotatably supported on the far end of the support frame 1 through conventional bearings, and the conveyor belt 4 is rotatably assembled on the active conveying roller 2 , Between the driven conveying rollers 3.

[0015] Such as figure 2 As shown, a driving gear 7 is keyed to the roller shaft end of the driving conveying roller 2, and the driving gear 7 is in floating engagement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com