Preparation method of composite electrode of flow battery

A composite electrode and liquid flow battery technology, which is applied in fuel cells, regenerative fuel cells, circuits, etc., can solve the problems of poor conductivity and mechanical strength of bipolar plates, so as to improve conductivity, improve mechanical strength, and reduce resistivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

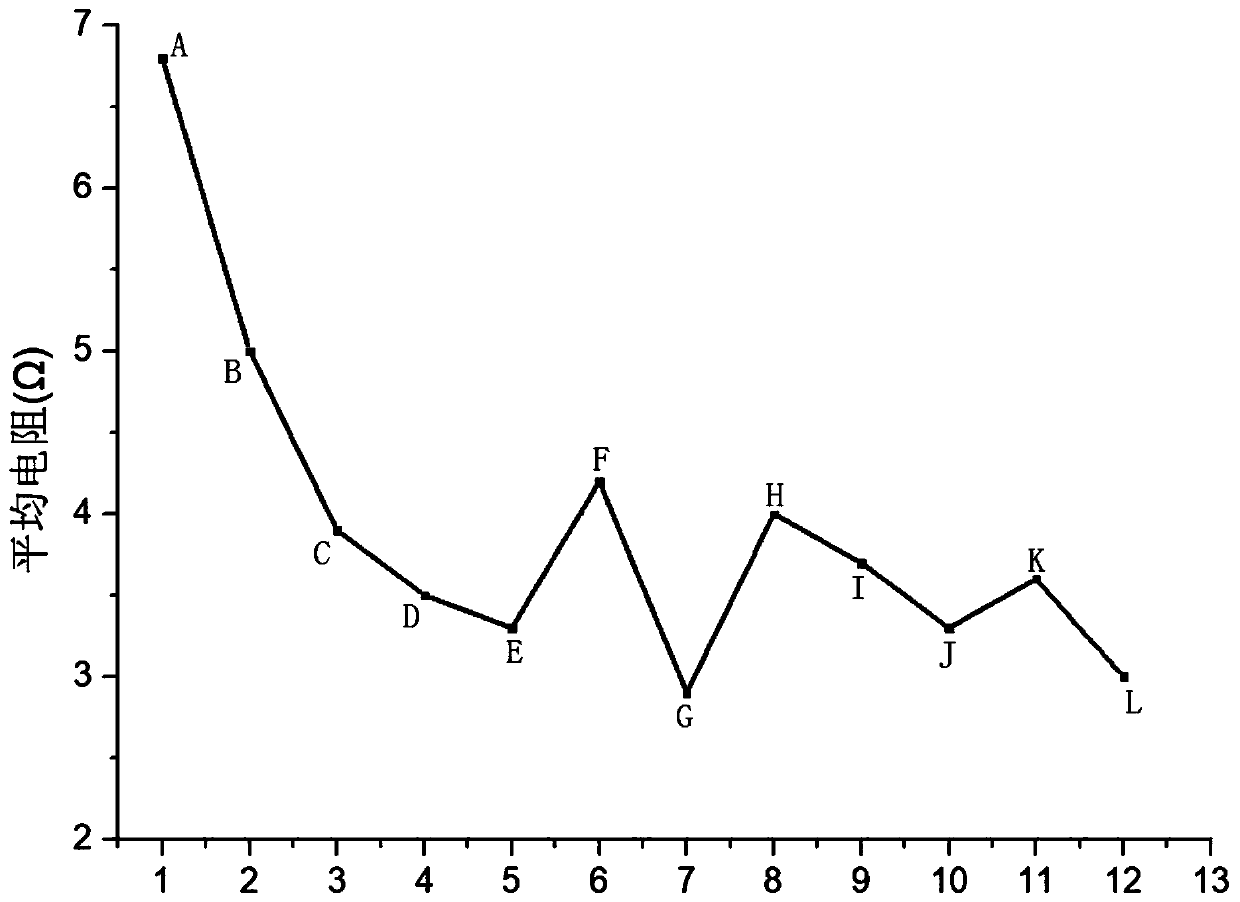

Image

Examples

Embodiment 1

[0030] A preparation method for a composite electrode of a flow battery, the steps mainly comprising:

[0031] A, thermoplastic resin is dissolved in solvent one and makes resin solution;

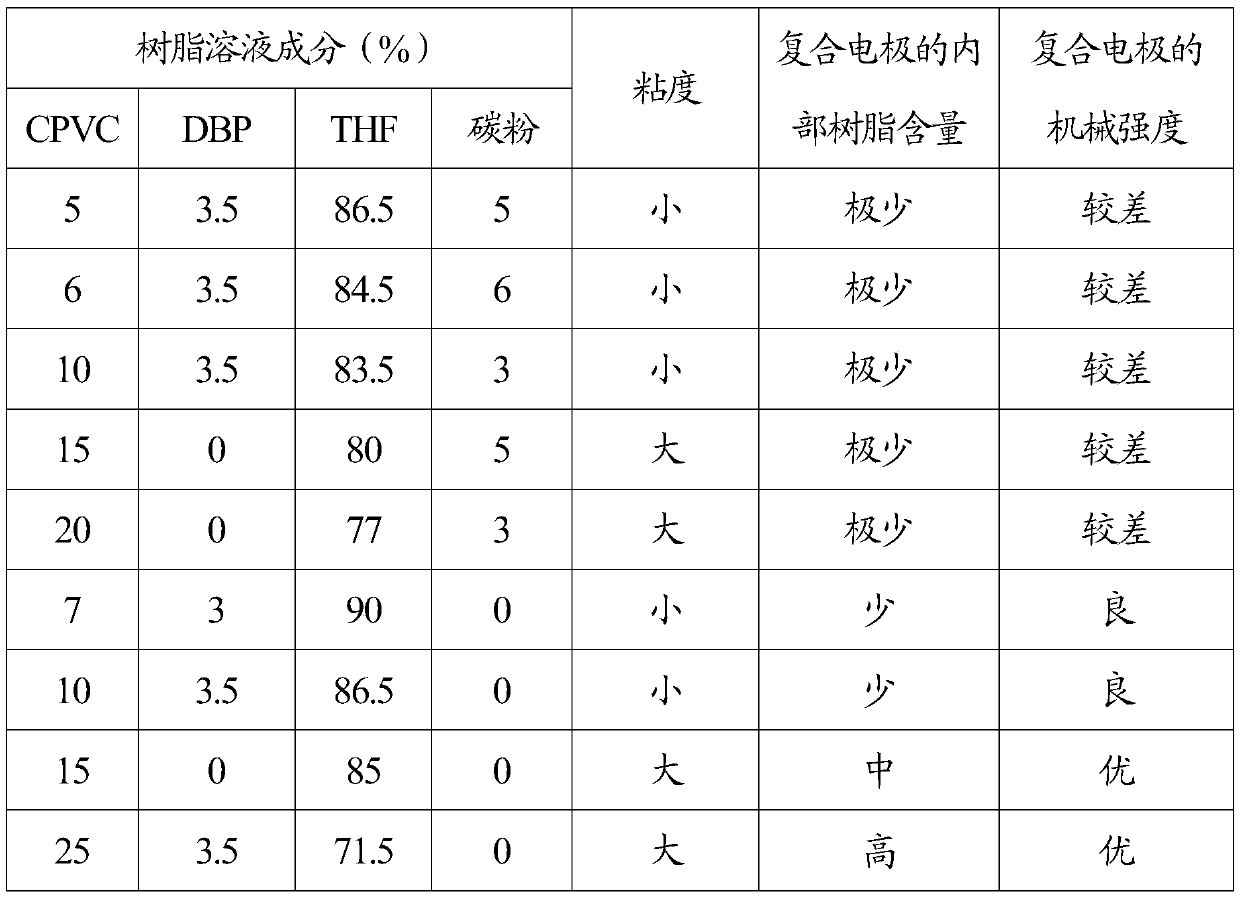

[0032] The thermoplastic resin can be mixed with one or more of chlorinated polyvinyl chloride, fluorinated polyvinyl chloride, polystyrene, ethylene-tetrafluoroethylene copolymer, and the solvent one is tetrahydrofuran, toluene, xylene, chloroform, tetrachloro One of carbon dioxide and dichloromethane, the weight percentage of the thermoplastic resin is 5-25%, preferably 20-25%, more preferably 22%-25%, and a plasticizer can also be added to make the composite electrode in the While guaranteeing strength, it has certain toughness, reduces brittleness, and improves bending strength. The plasticizer can specifically use dibutyl phthalate; in this embodiment, the thermoplastic resin only uses chlorinated polyvinyl chloride, chlorinated poly The weight percentage of vinyl chloride (CPVC) is 2...

Embodiment 2

[0051] A preparation method for a composite electrode of a flow battery, the steps mainly comprising:

[0052] A, thermoplastic resin is dissolved in solvent one and makes resin solution;

[0053] In this embodiment, the thermoplastic resin is formed by mixing fluorinated polyvinyl chloride and polystyrene at a ratio of 1:1, the solvent one is toluene, the thermoplastic resin is 22% by weight, and the toluene is 78% by weight;

[0054] When preparing the resin solution, accurately weigh the toluene and add it to the container first, then slowly add the thermoplastic resin into the container and keep stirring during the addition process, and finally ensure that the thermoplastic resin is completely dissolved and stirred to obtain a resin solution;

[0055] B. Putting the porous conductive material layer into the resin solution obtained in step A for vibration impregnation, so that the resin solution is filled into the pores of the porous conductive material layer to obtain an i...

Embodiment 3

[0067] A preparation method for a composite electrode of a flow battery, the steps mainly comprising:

[0068] A, thermoplastic resin is dissolved in solvent one and makes resin solution;

[0069] Thermoplastic resin adopts polystyrene and ethylene-tetrafluoroethylene copolymer 1:1 to form, solvent one adopts chloroform, and adds plasticizer, plasticizer adopts dibutyl phthalate, in the present embodiment, When the weight percentage of thermoplastic resin is 20%, the weight percentage of dibutyl phthalate can be 3.5%, and the weight percentage of chloroform is 76.5%;

[0070] When preparing the resin solution, accurately weigh the chloroform and dibutyl phthalate and add it into the container for stirring and mixing, then slowly add the thermoplastic resin into the container and keep stirring during the addition process to ensure that the thermoplastic resin is dissolved Completely and stir and mix to finally obtain the resin solution;

[0071] B. Putting the porous conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com