Patents

Literature

103results about How to "Increase full rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

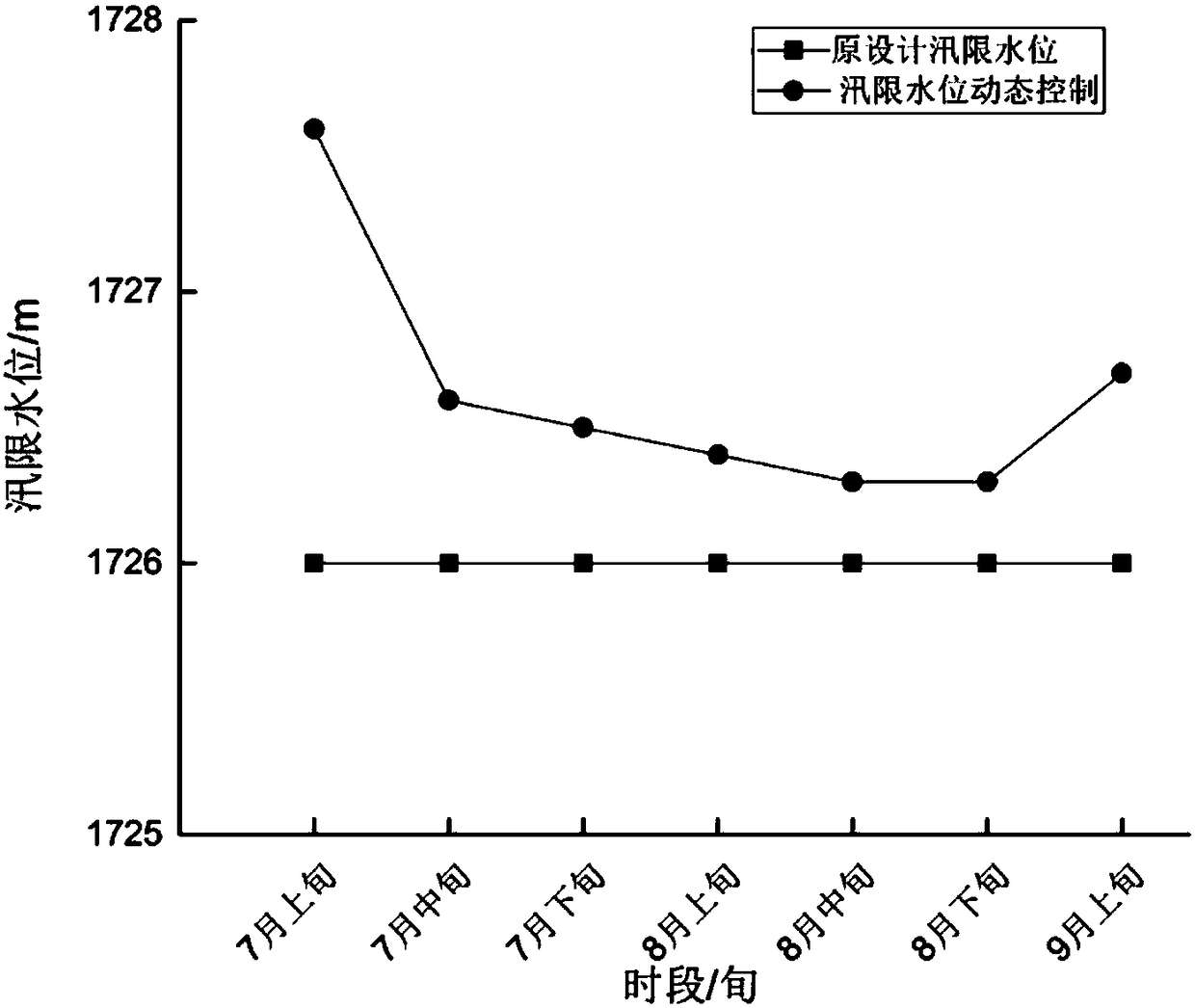

Reservoir real-time water storage scheduling method based on ensemble forecast

ActiveCN107248015AAchieve couplingIncrease full rateForecastingResourcesWater storageOptimal scheduling

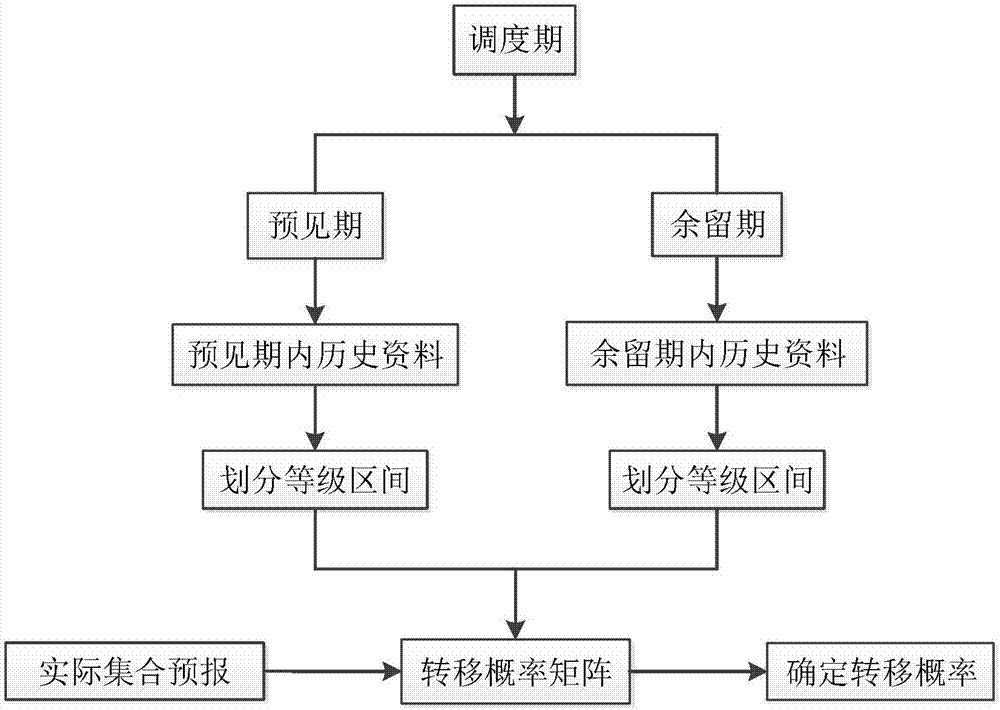

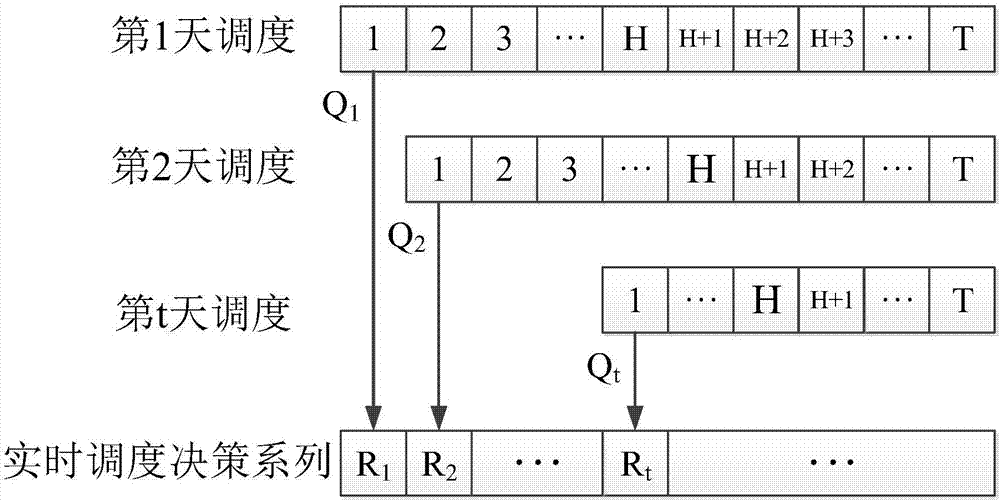

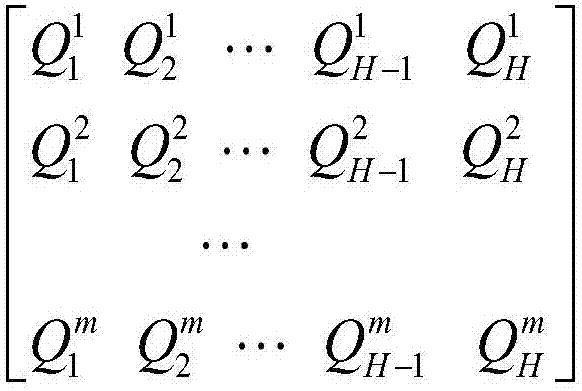

The present invention provides a reservoir real-time water storage scheduling method based on ensemble forecast, the utilization efficiency of various runoff data can be improved, and a scheduling result is optimized. The method is characterized in that the method comprises the following steps of (1) determining a total time length from a facing period to the end of a water storage period in a current scheduling period, determining a forecast period length of the ensemble forecast, and dividing the whole scheduling period into a forecast period and a remaining period, (2) determining runoff input data in the forecast period and the remaining period, (3) establishing a reservoir optimal scheduling model, (4) obtaining a scheduling decision table of the current facing period, (5) consulting the scheduling decision table according to a current reservoir capacity and the inflow condition when an actual inflow situation happens, carrying out interpolation calculation, and obtaining the reservoir capacity at the end of the period, and (6) repeating the steps (1) to (5) day by day for a whole water storage period, updating forecast information, obtaining a scheduling decision table of each day, guiding the real-time scheduling of each day, and then completing the scheduling of the whole water storage period.

Owner:WUHAN UNIV

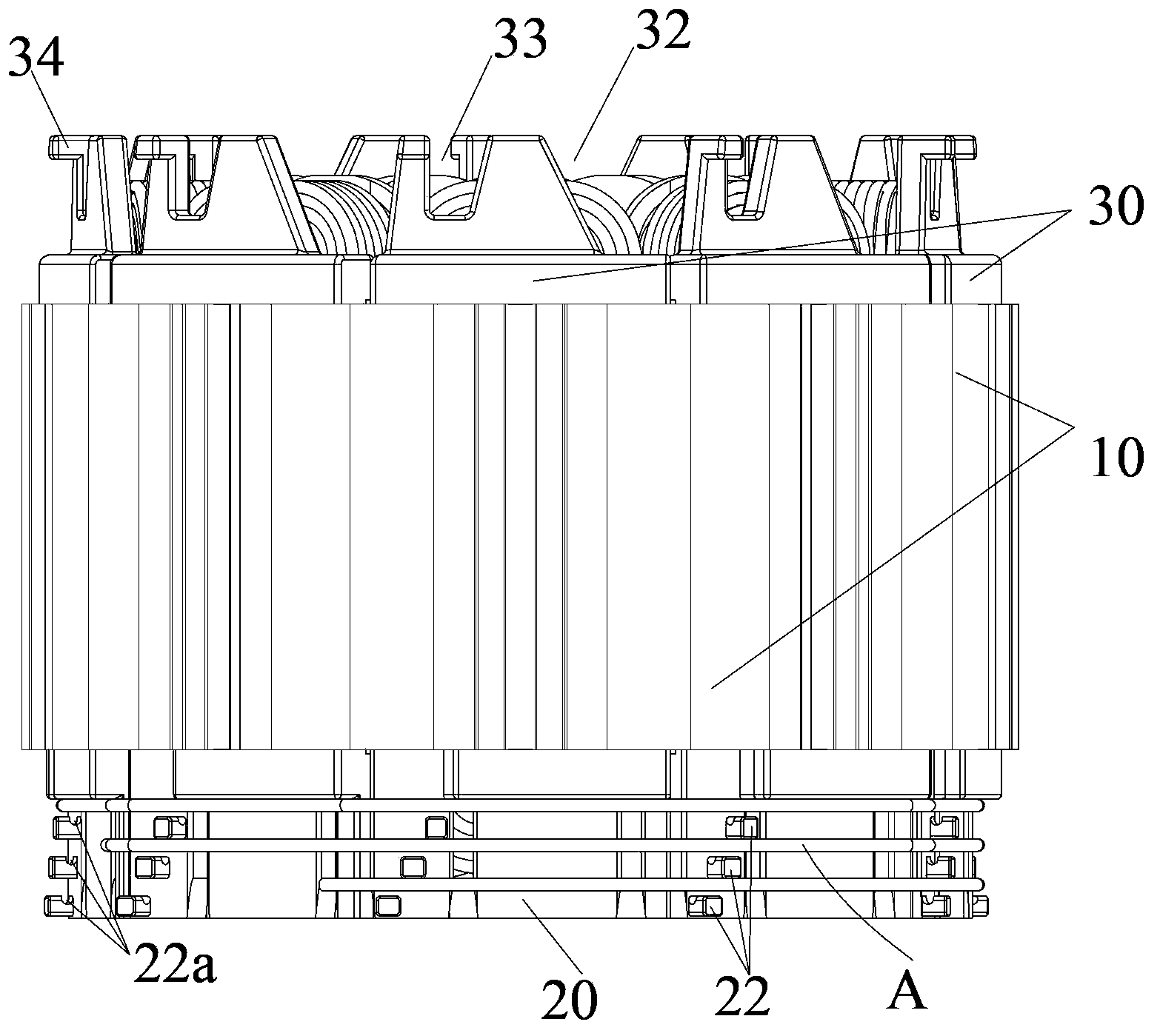

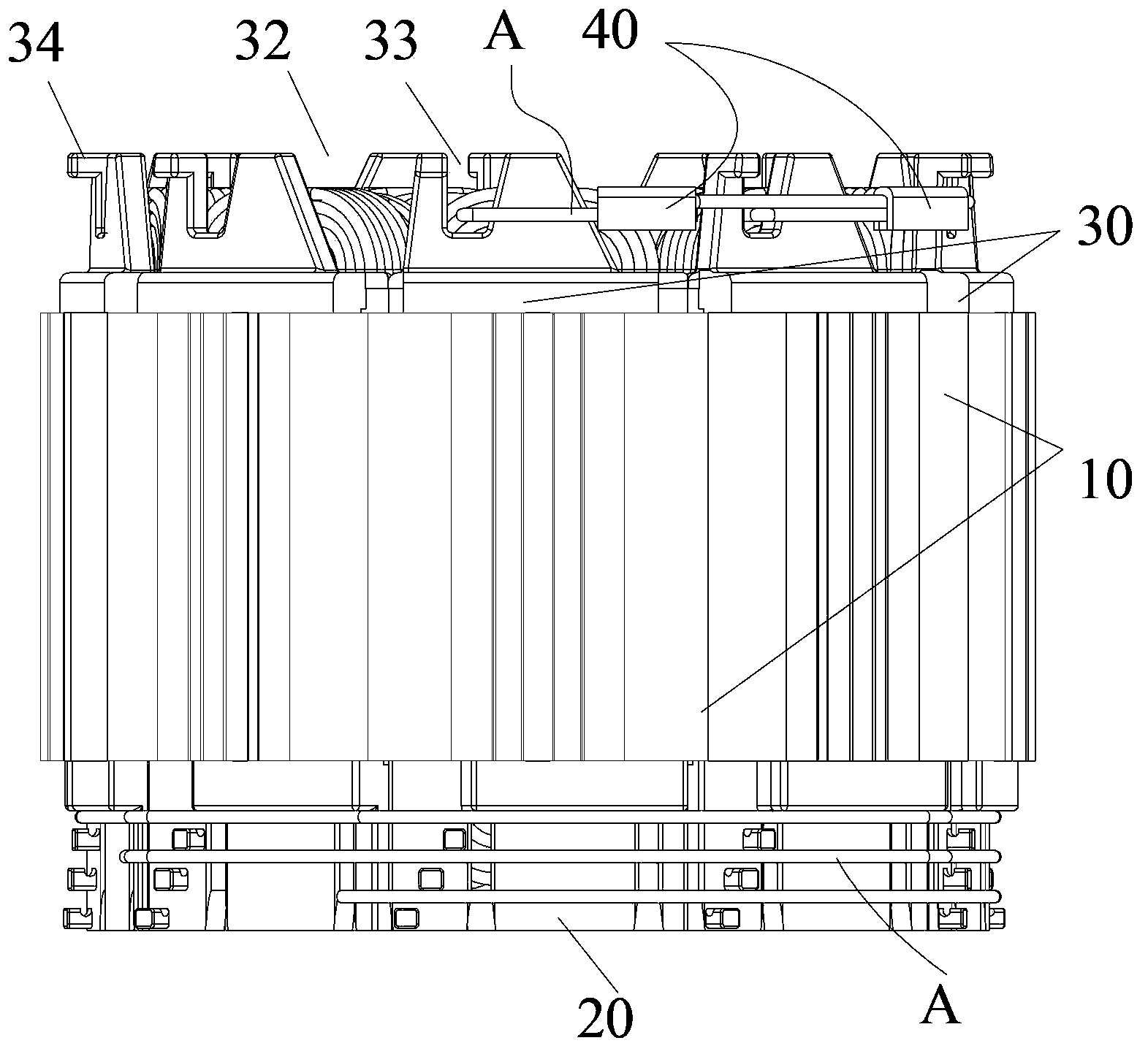

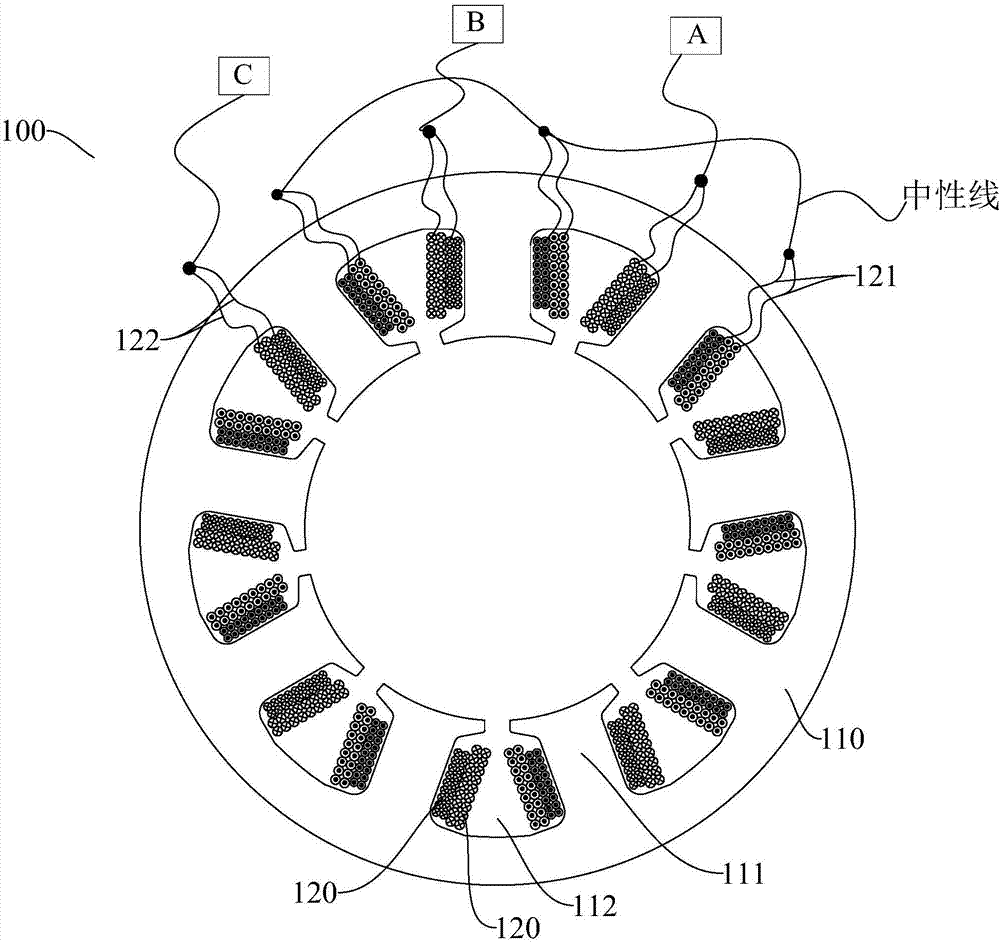

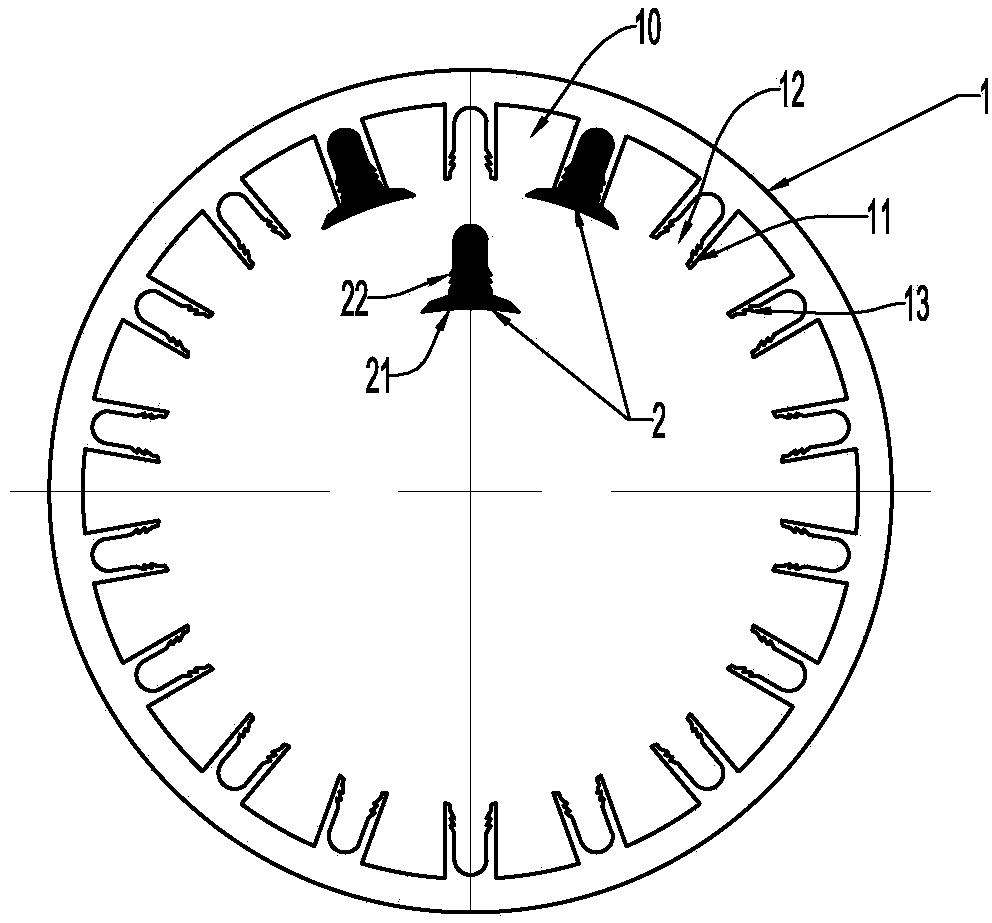

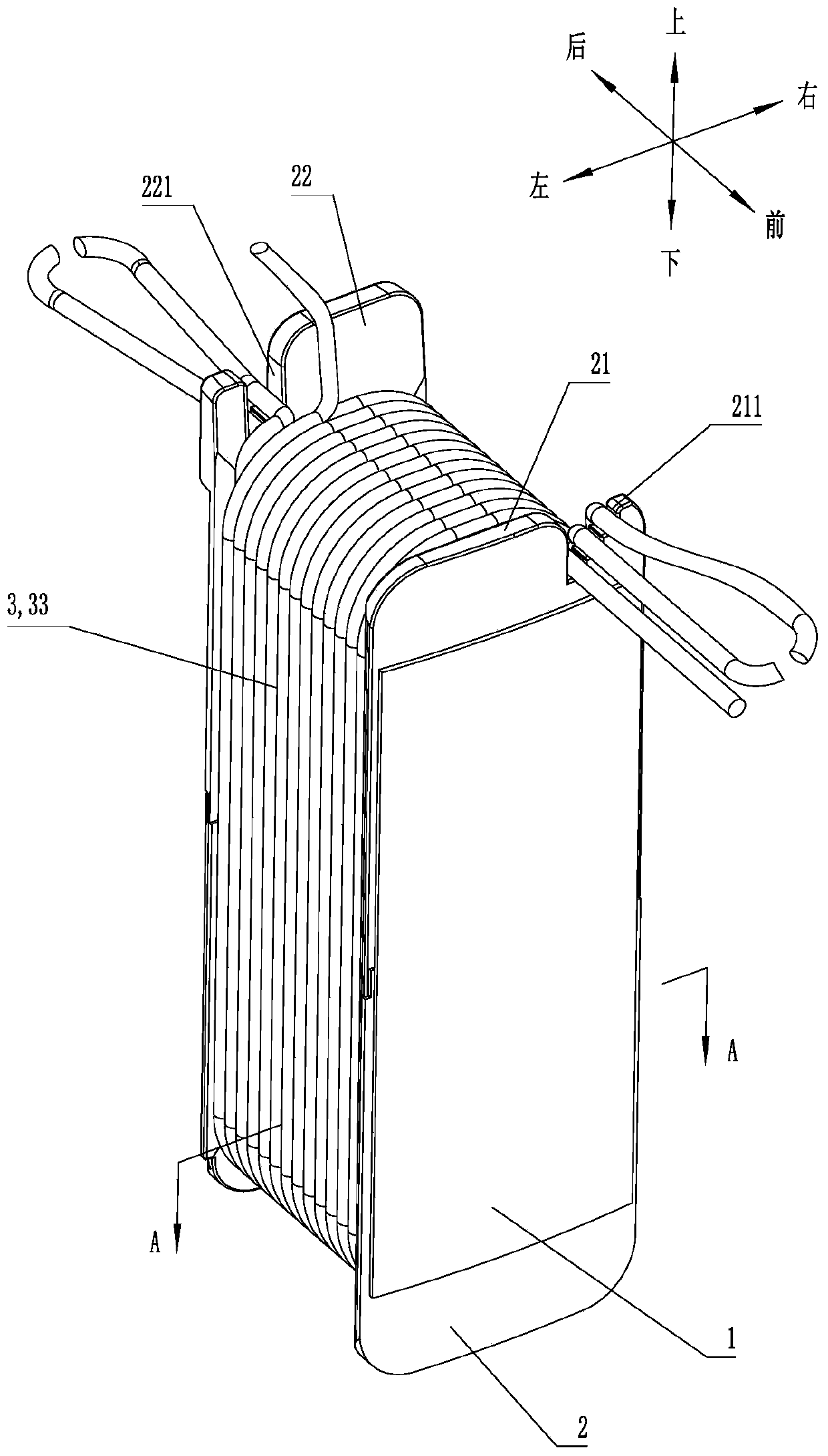

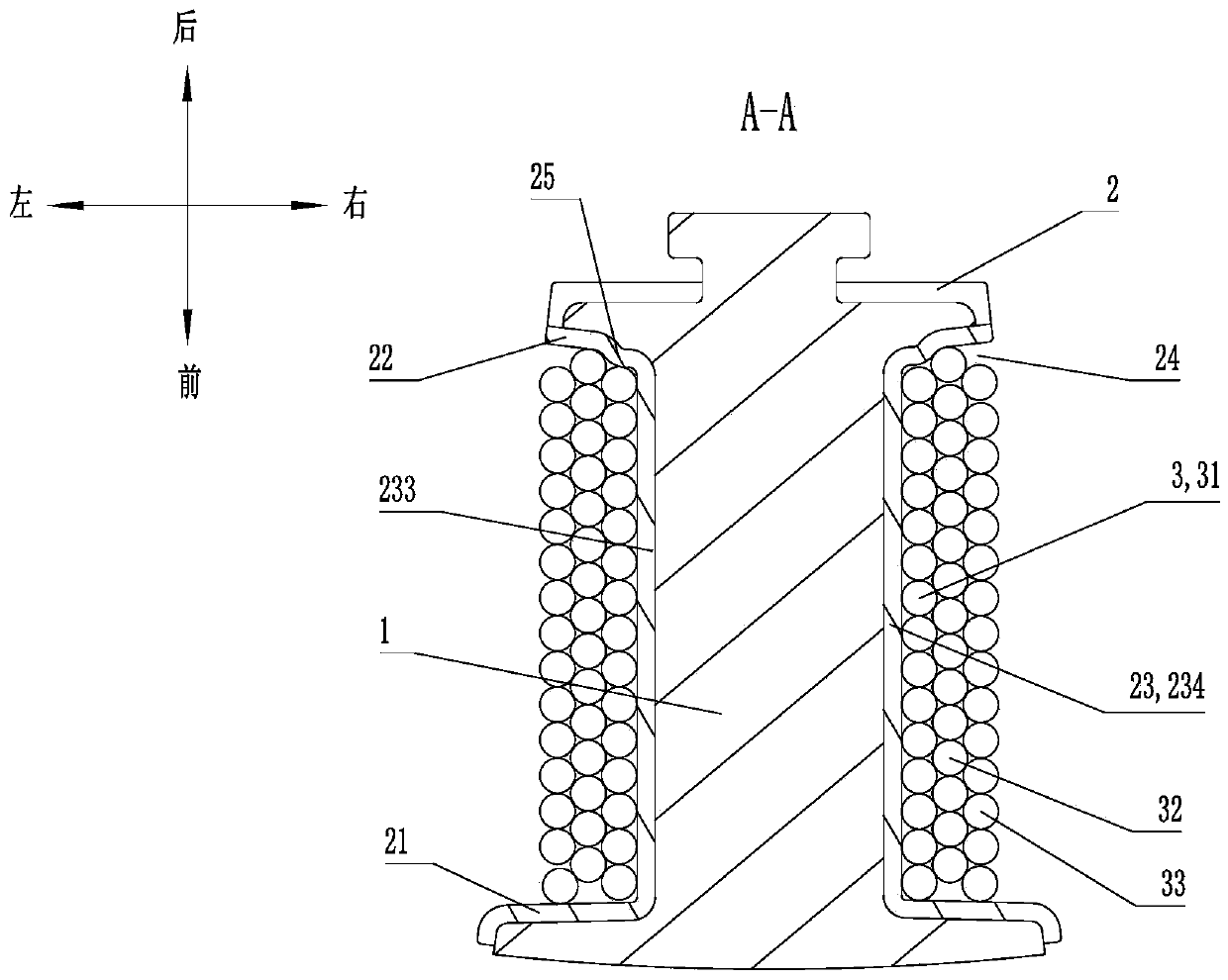

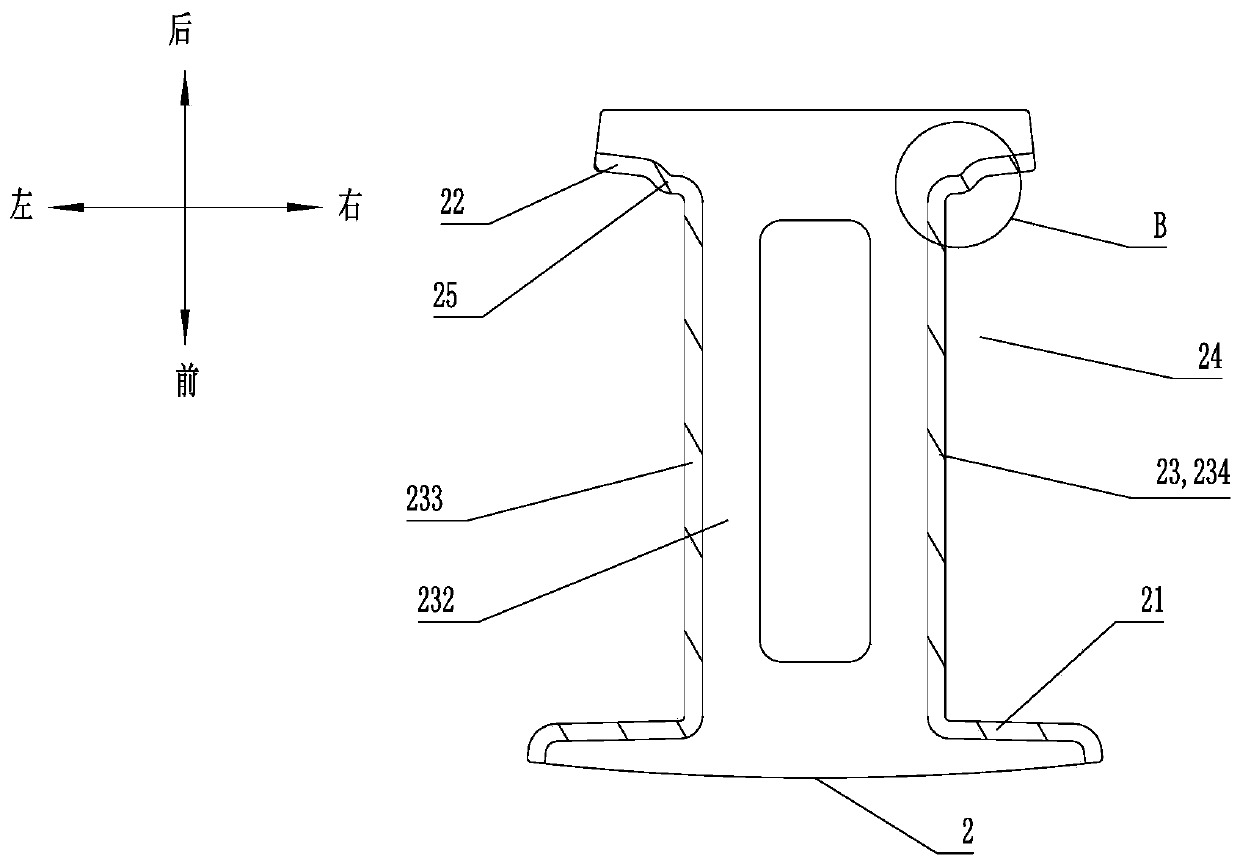

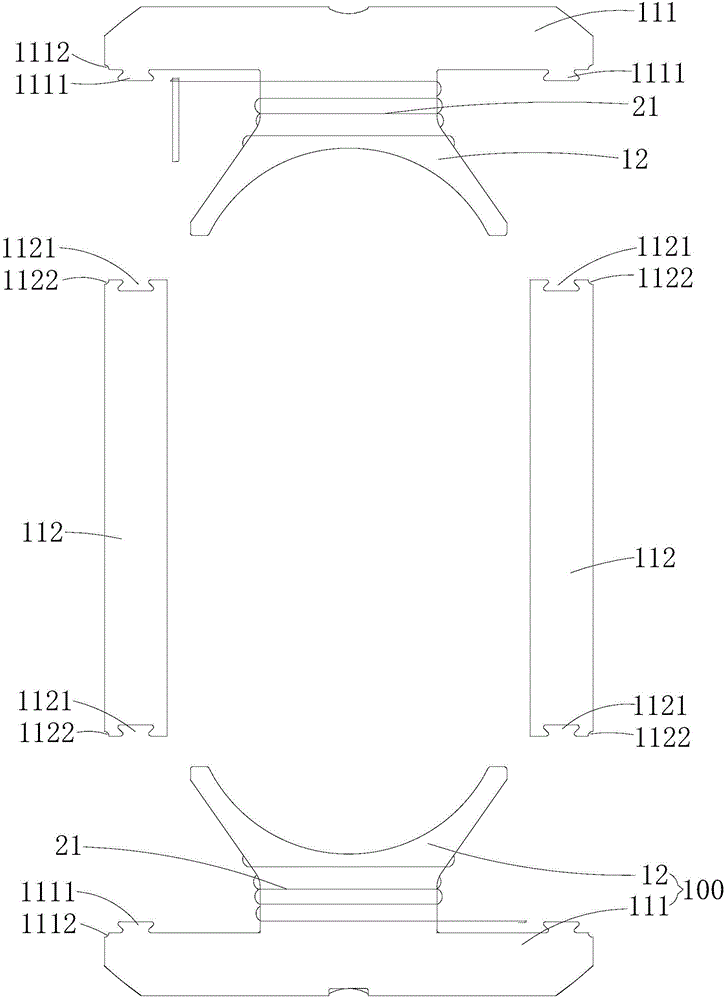

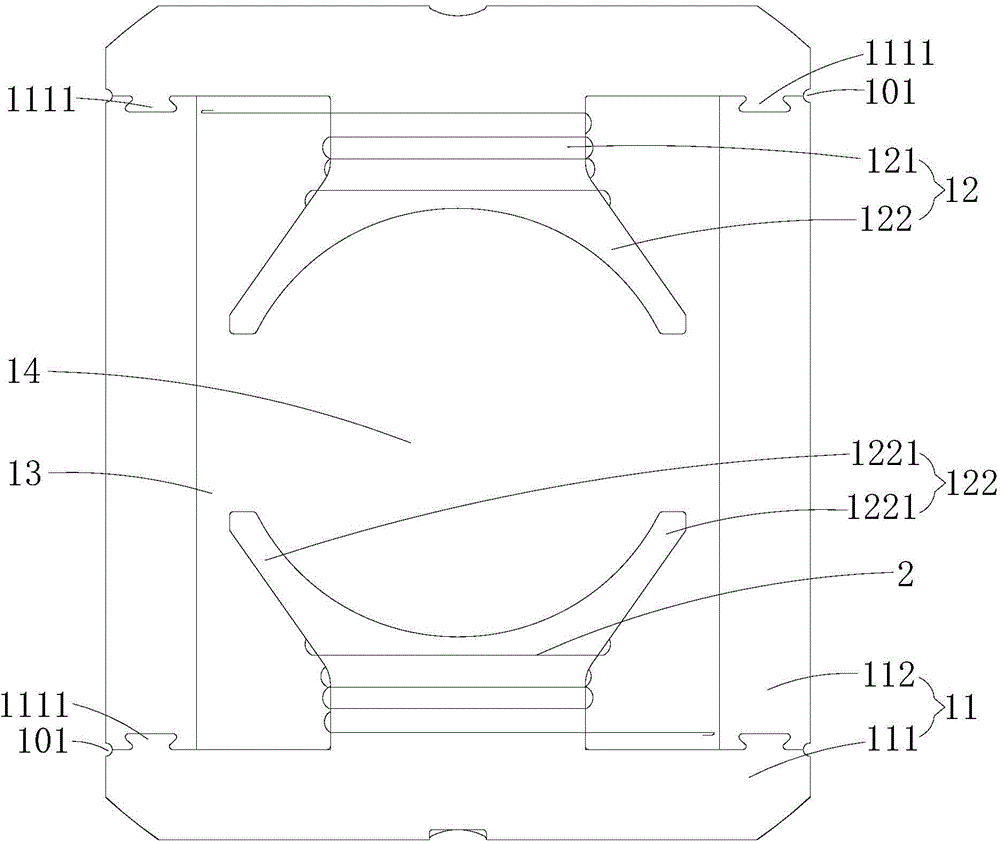

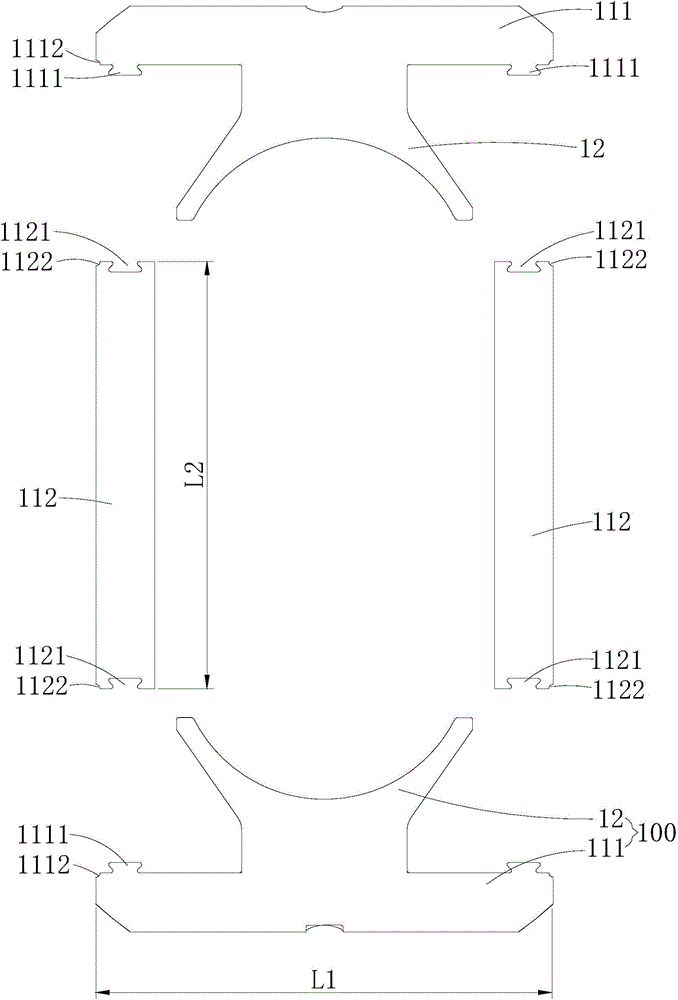

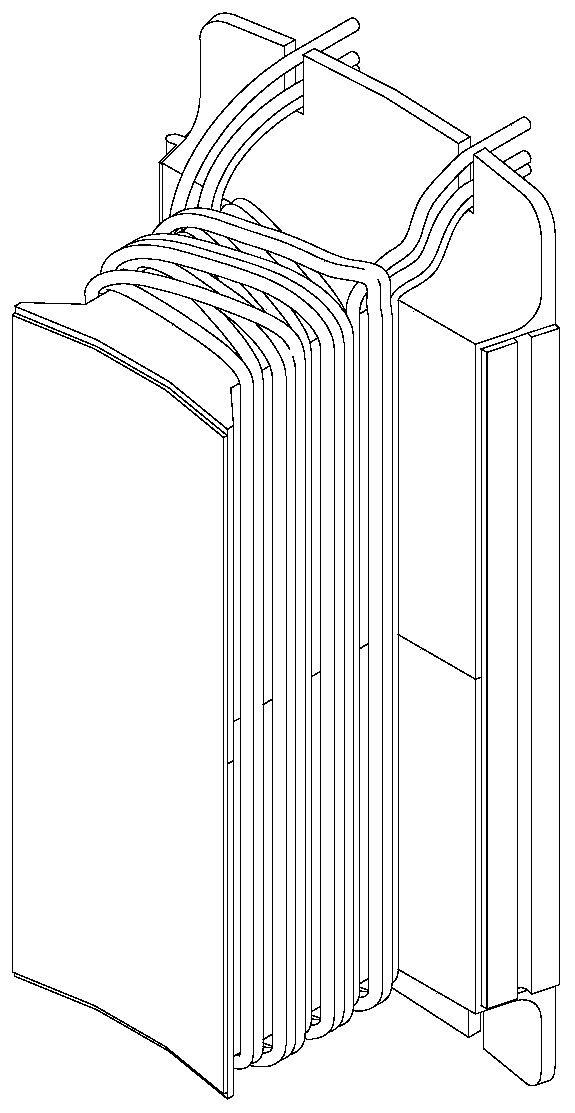

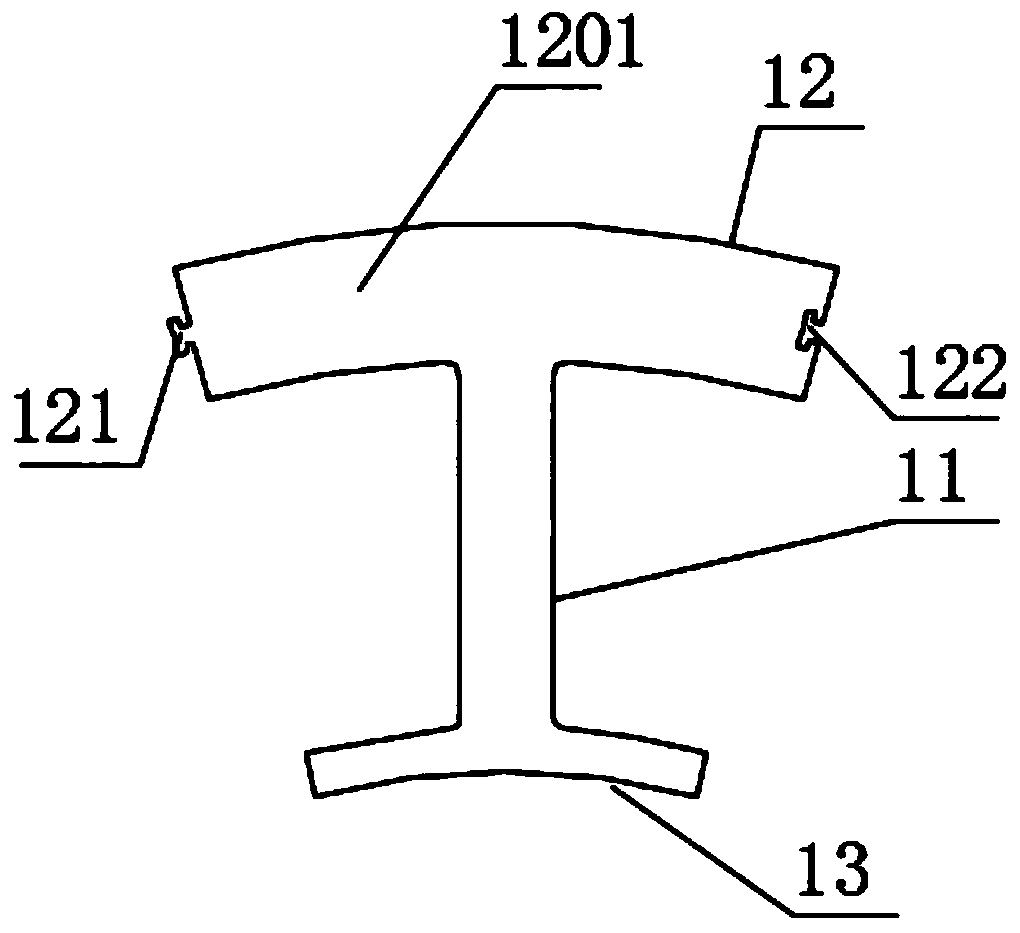

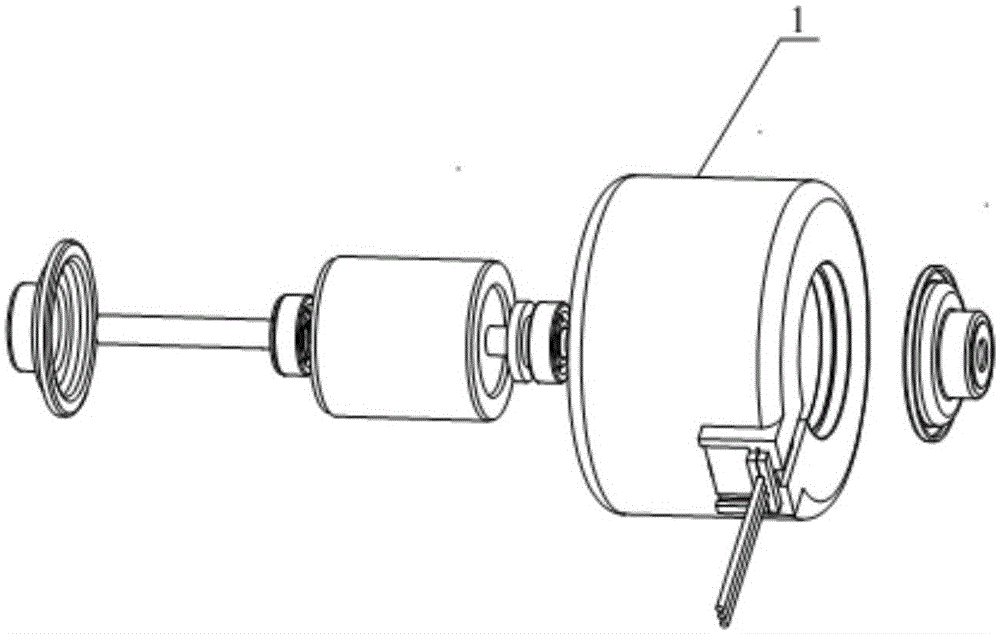

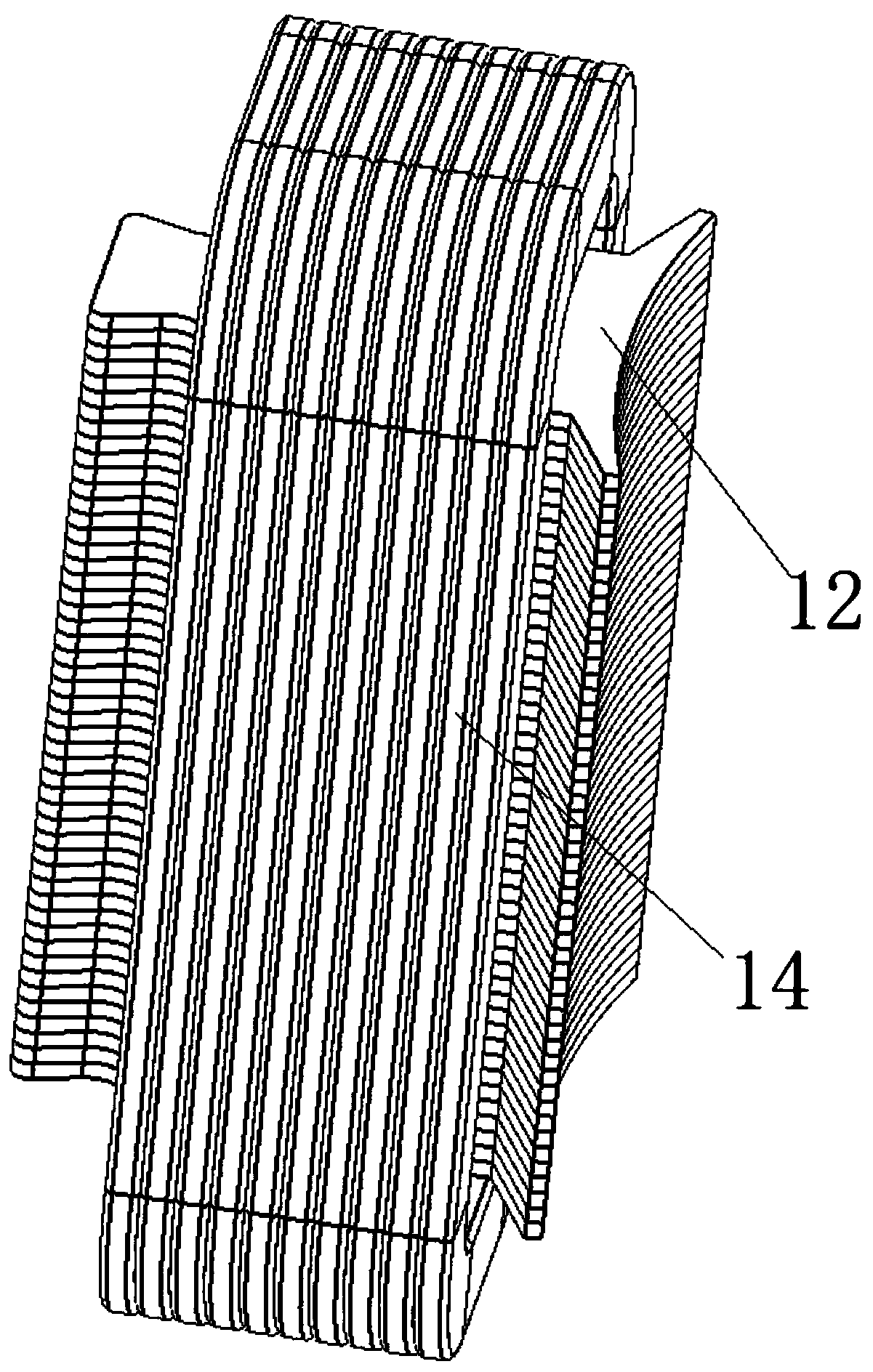

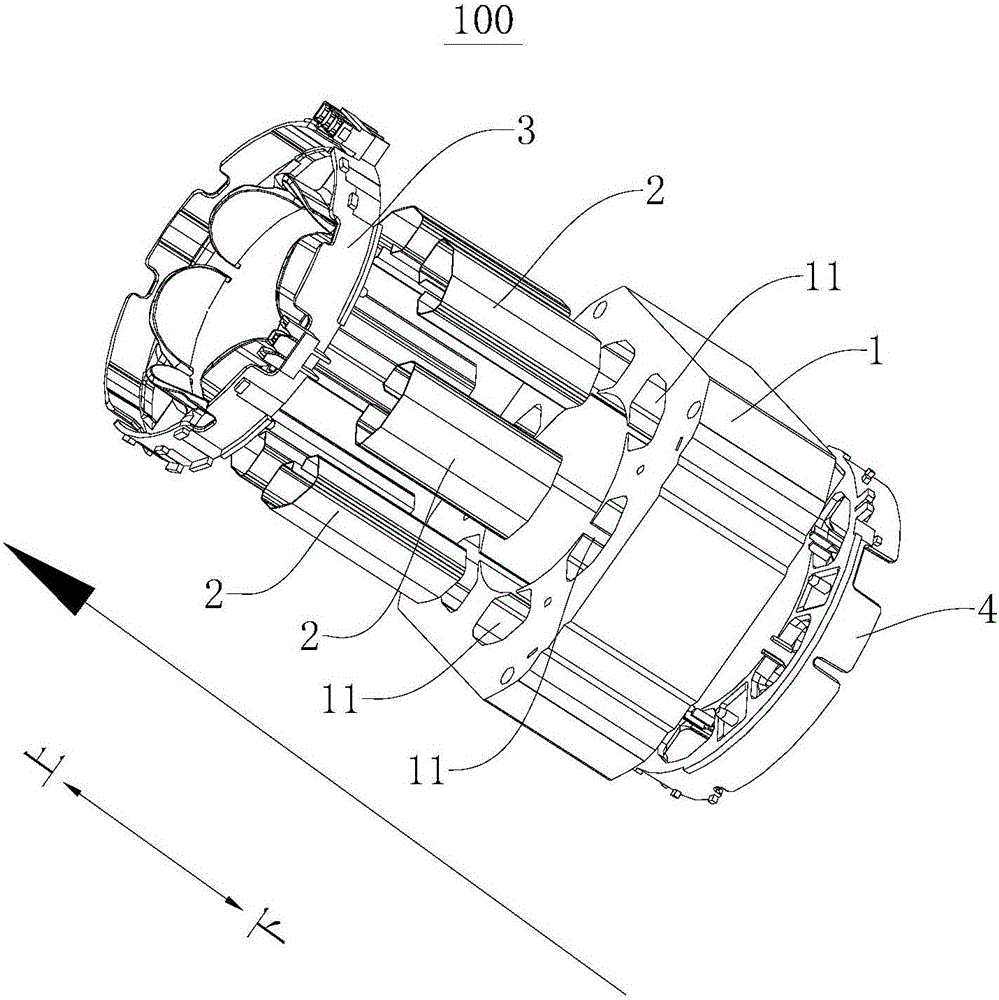

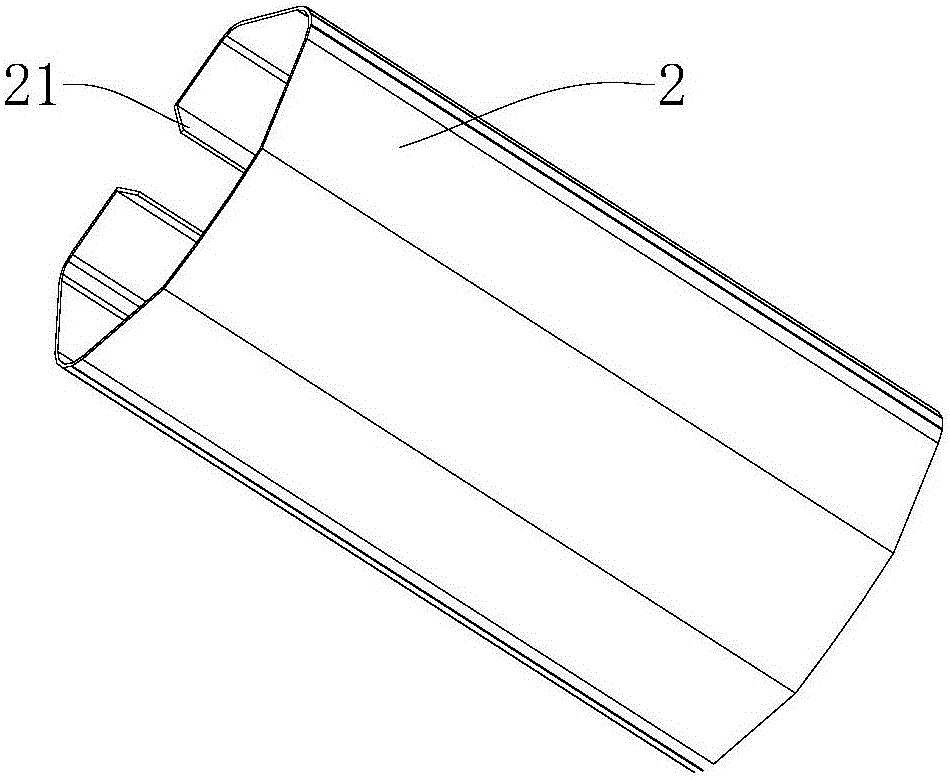

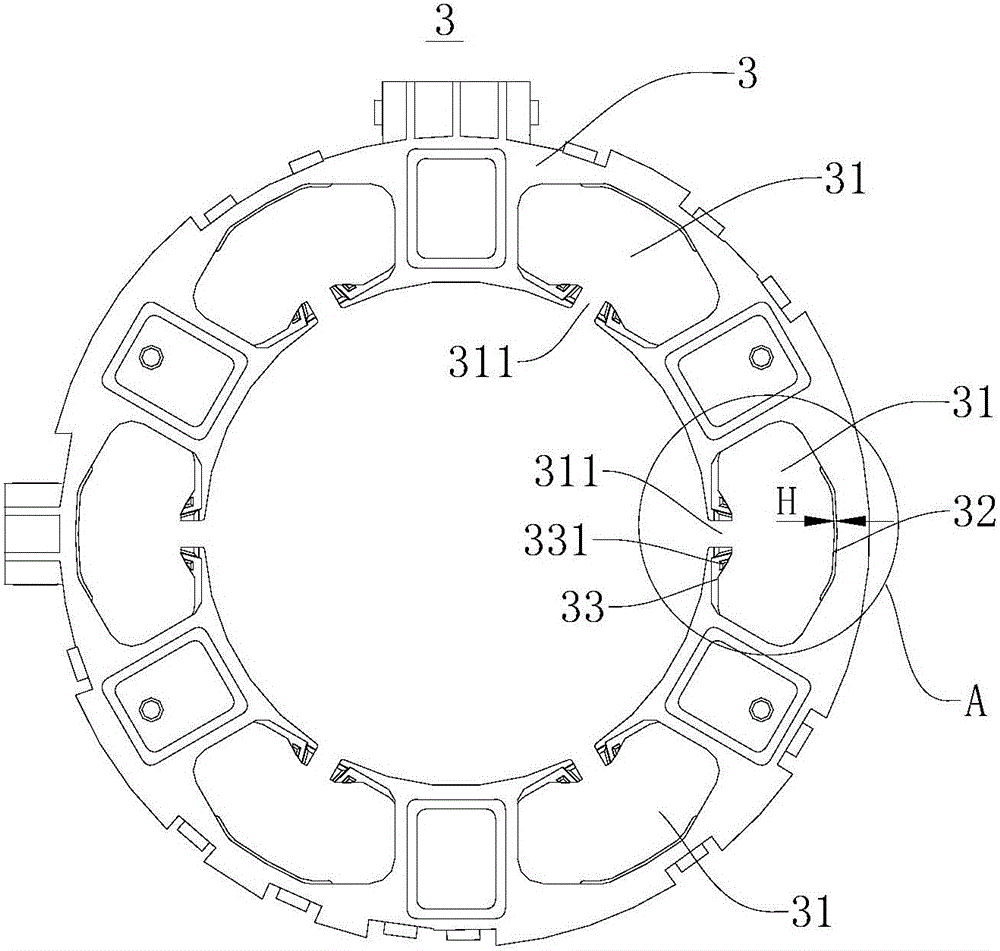

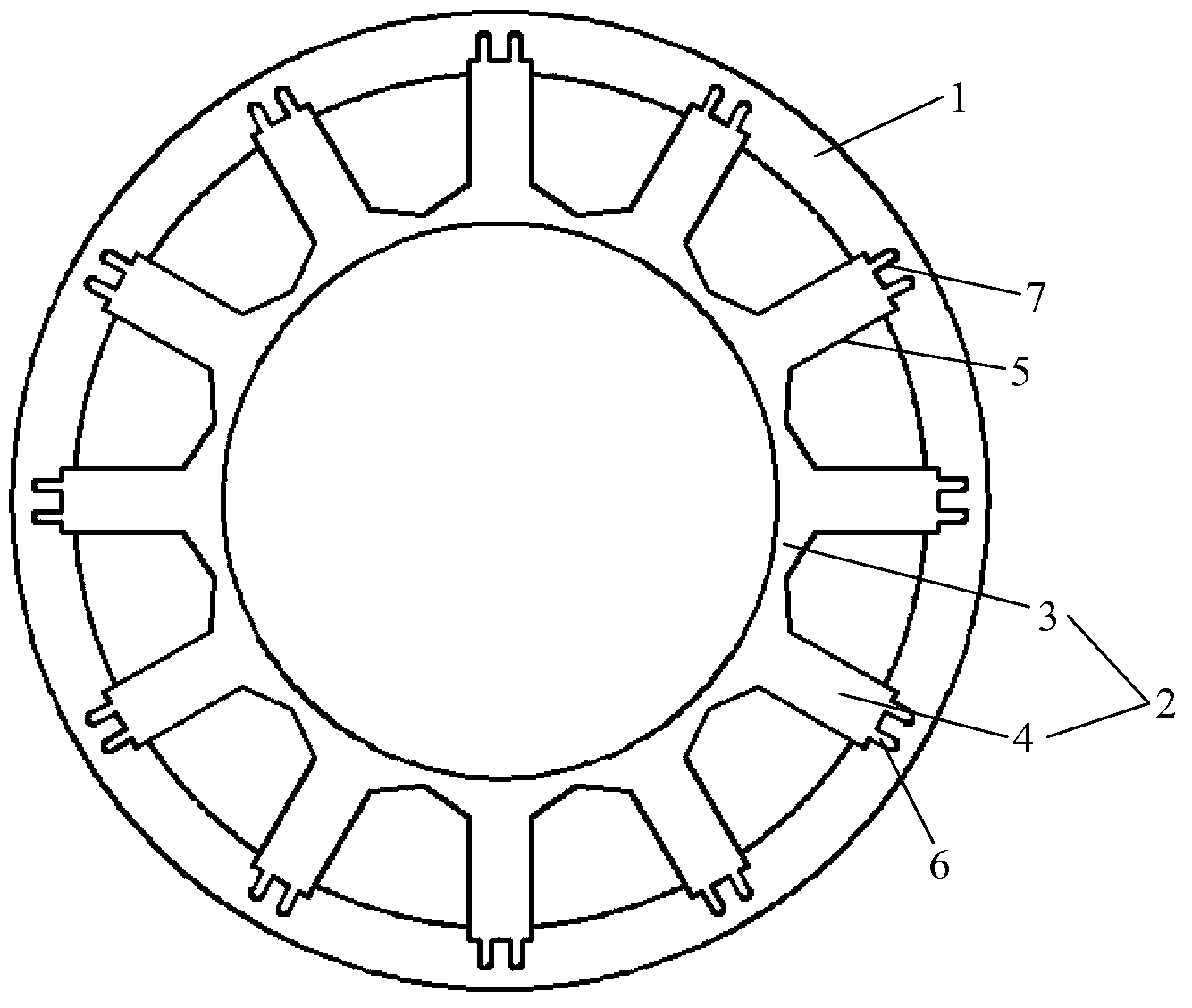

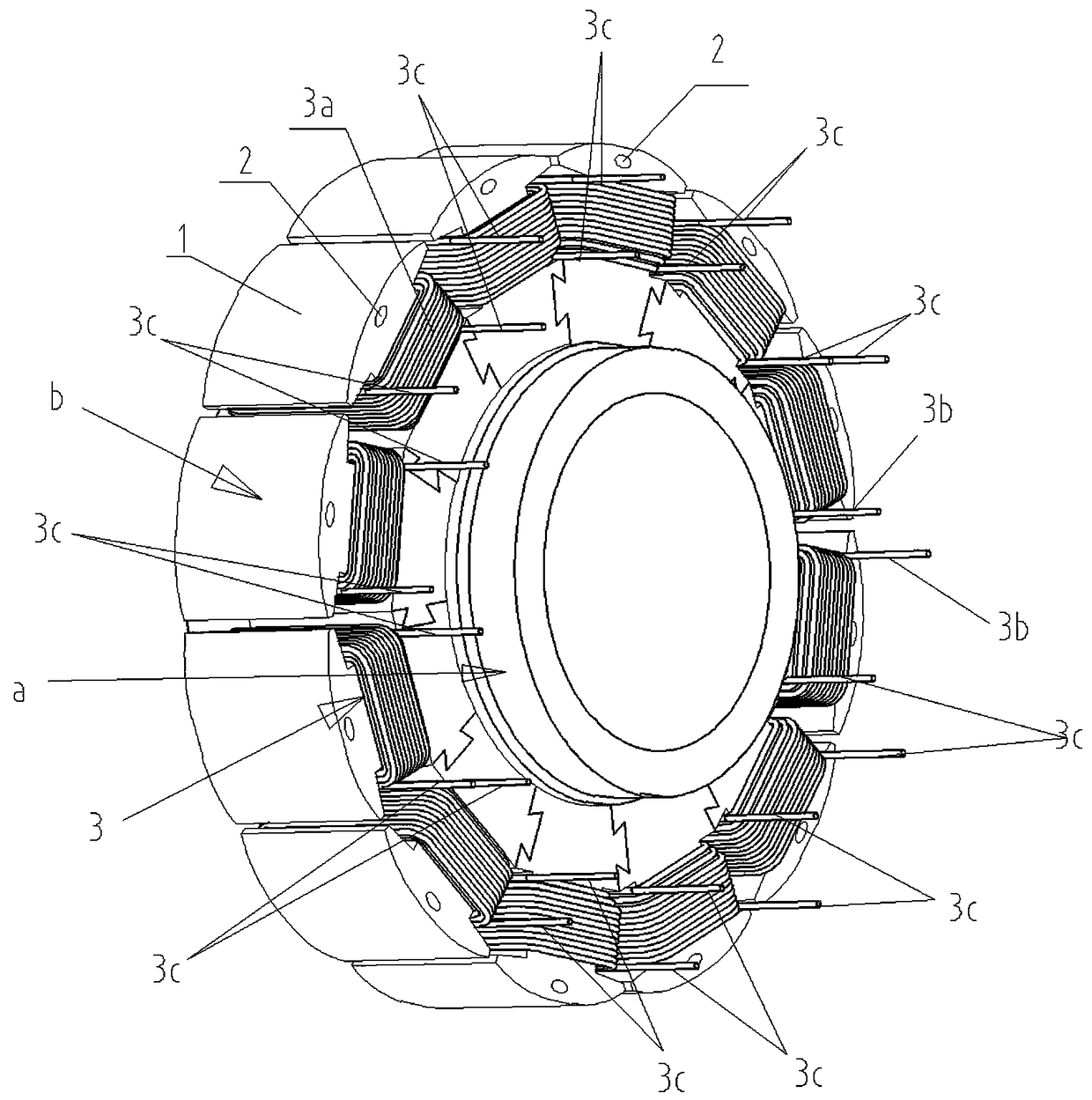

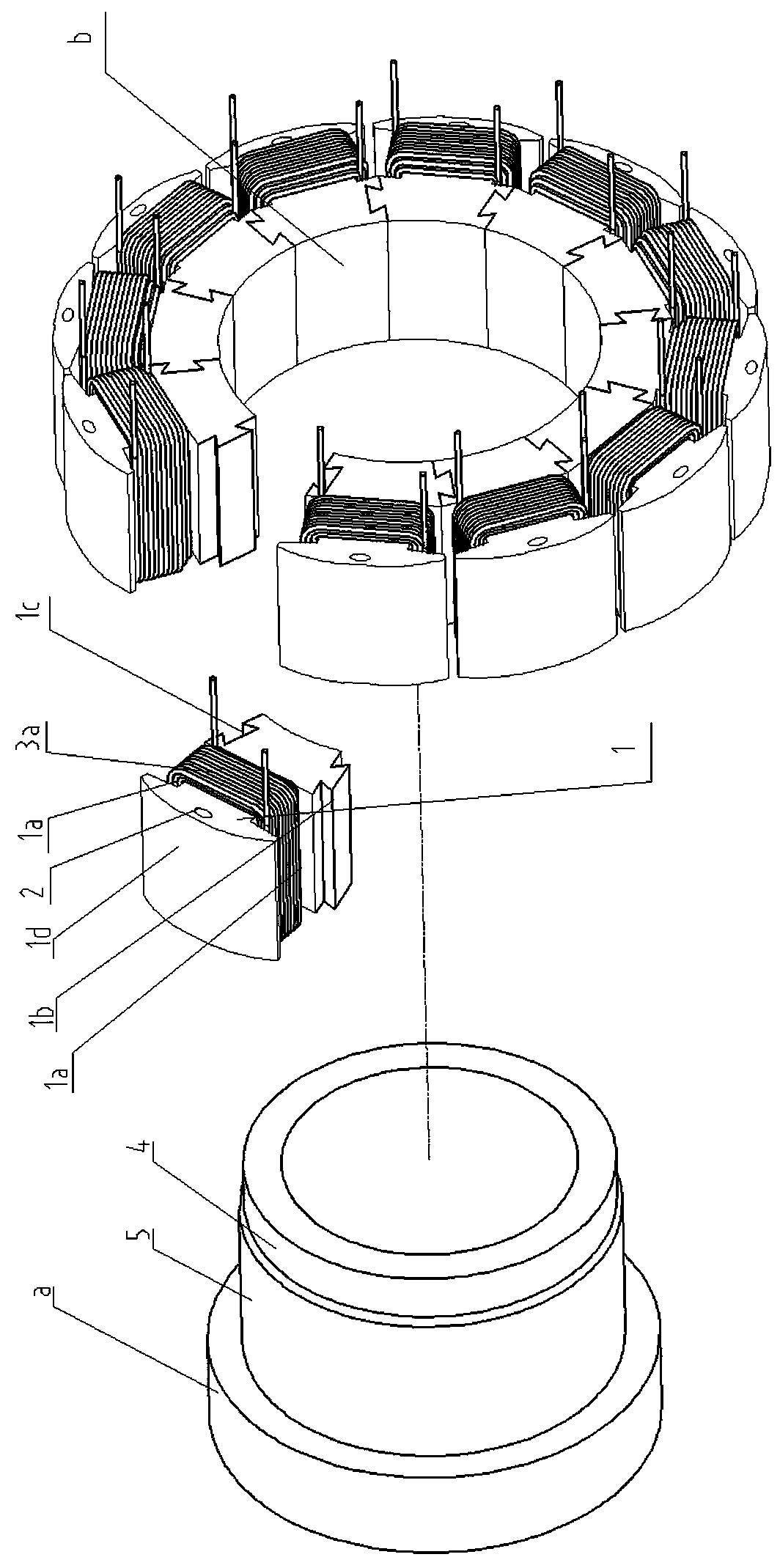

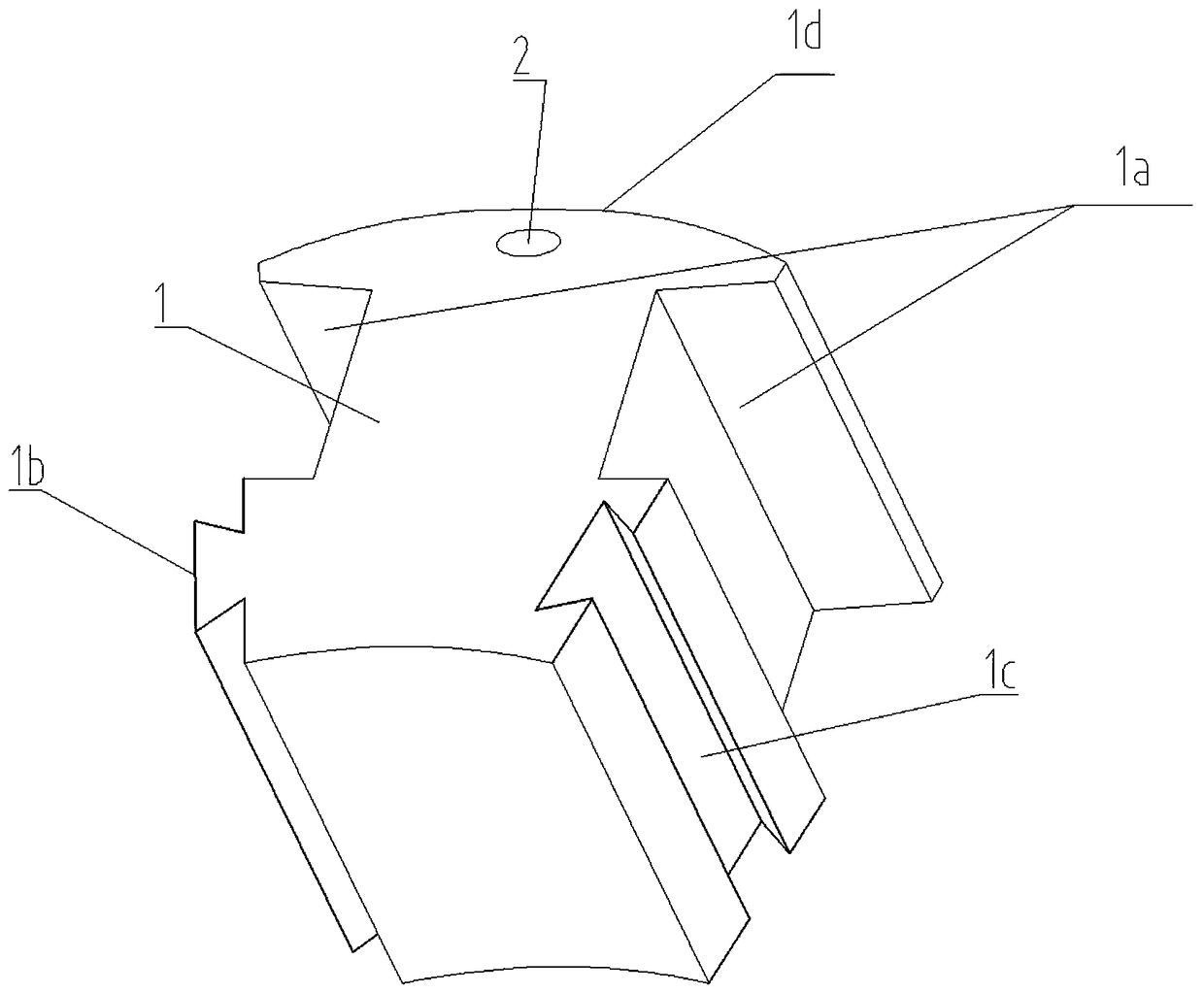

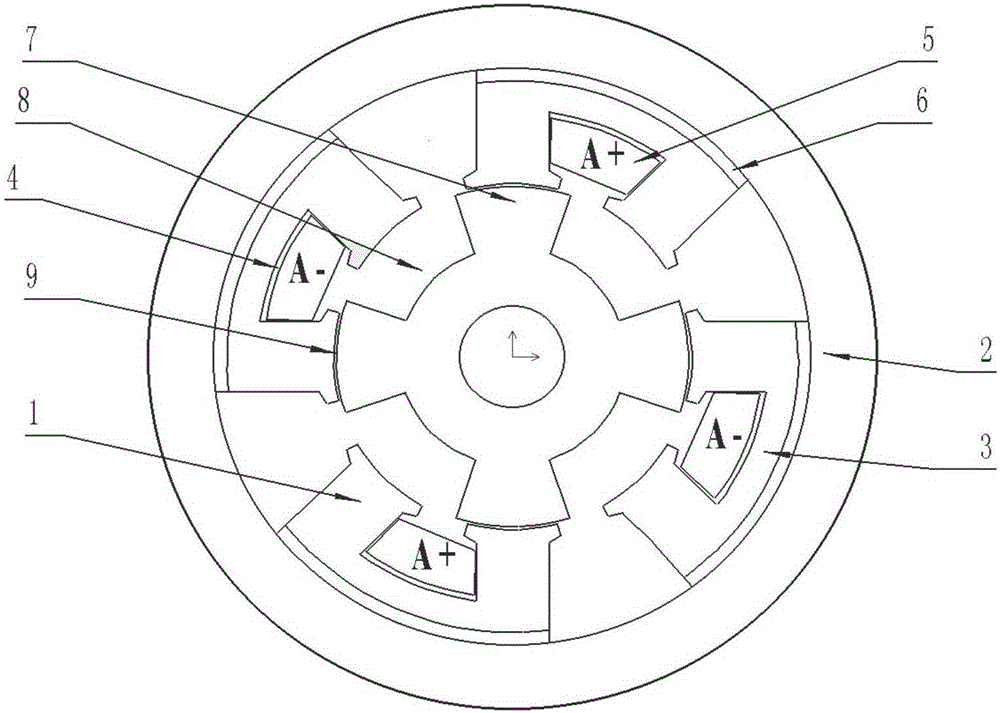

Stator, motor with stator and compressor

InactiveCN104079086AOrderly rowsSolve the wiring confusionMagnetic circuit stationary partsEngineeringConductor Coil

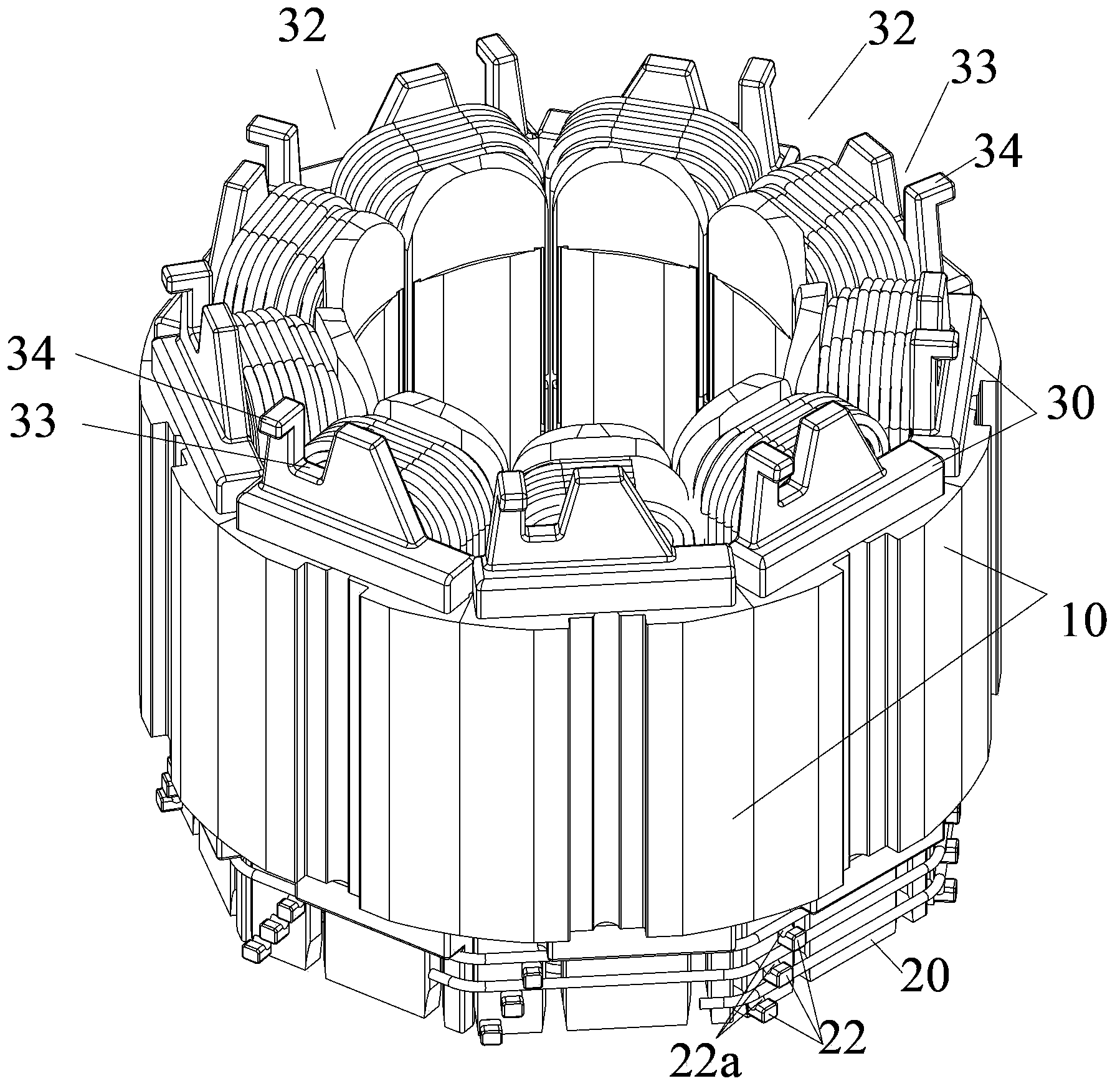

The invention provides a stator, a motor with the stator and a compressor. The stator comprises a plurality of stator iron core blocks, first insulation frames fixed at the first ends of the stator iron core blocks respectively, and second insulation frames fixed at the second ends of the stator iron core blocks respectively. Each first insulation frame comprises a first winding portion which is provided with a first winding groove. Each second insulation frame comprises a second winding portion which is provided with a second winding groove corresponding to each first winding groove in the axial direction of the stator. According to the stator, the motor with the stator and the compressor, the first winding grooves are formed in the first winding portions of the first insulation frames, and the second winding grooves matched with the first winding grooves are formed in the second winding portions of the second insulation frames, so that when winding is started, start flat cables are limited in the first winding grooves and the second winding grooves, the start flat cables are orderly arranged, and the problem of disorder of the start flat cables is solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

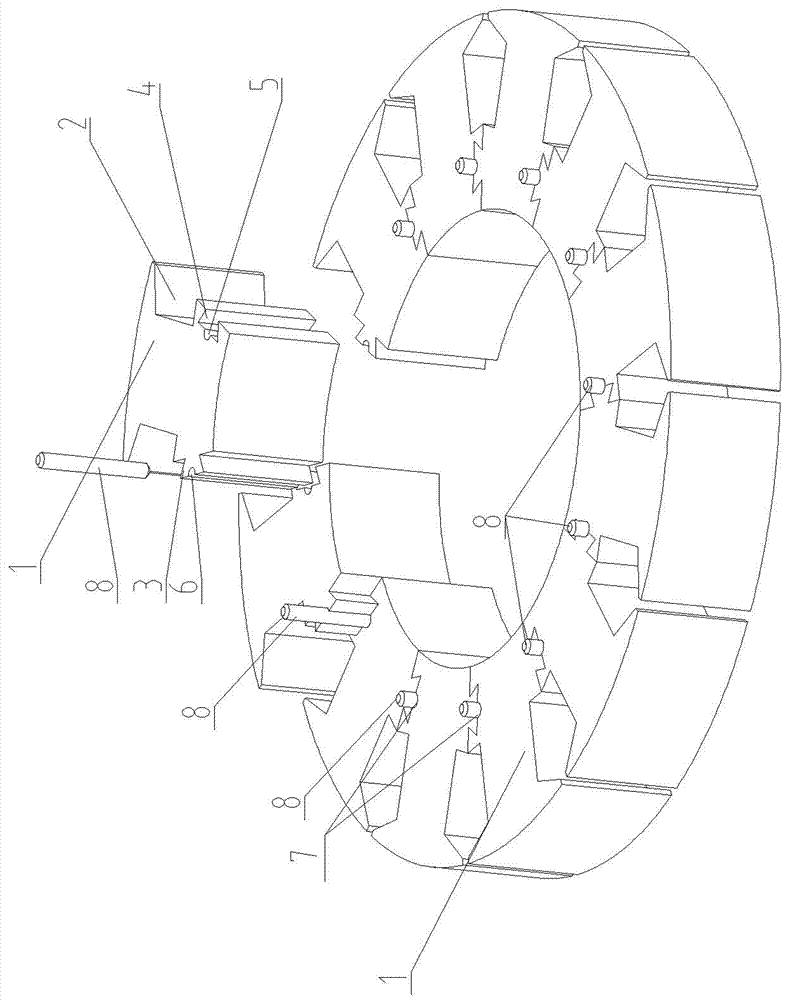

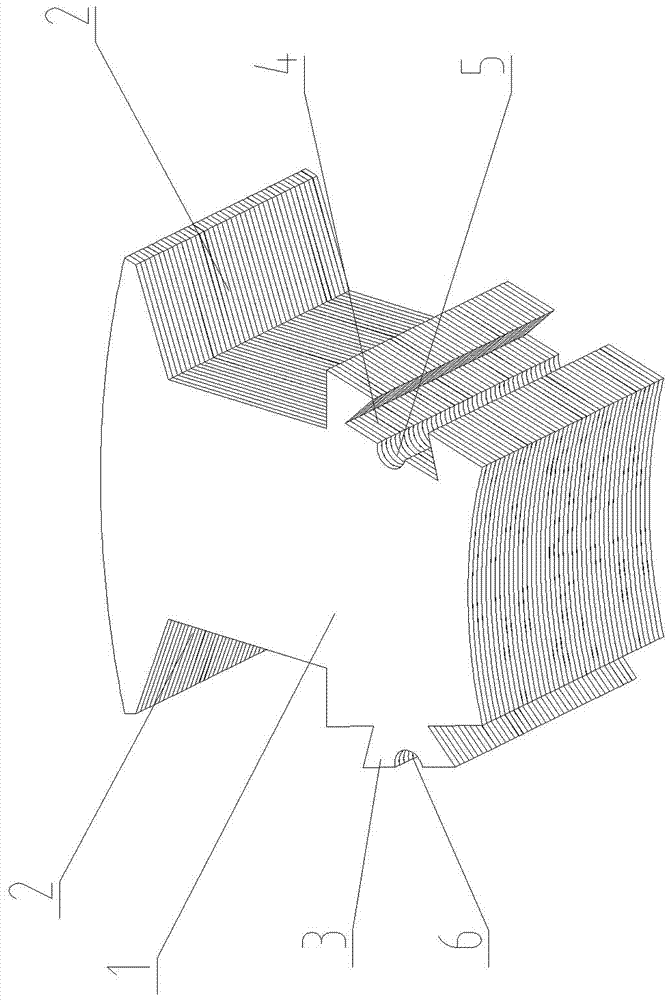

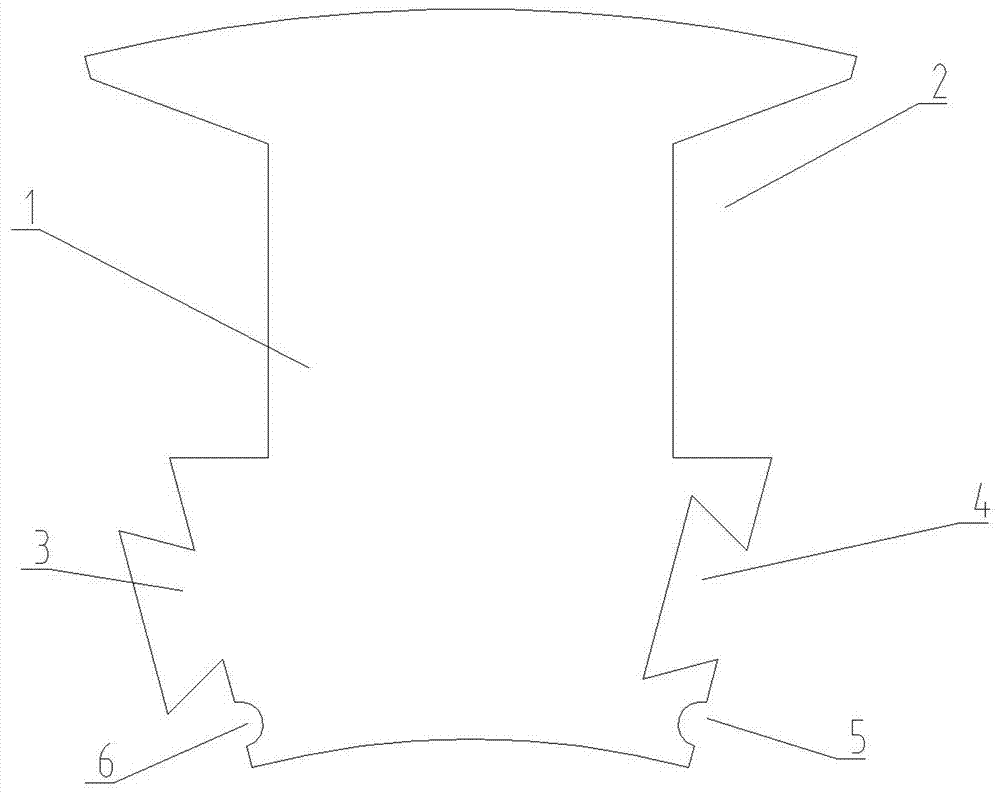

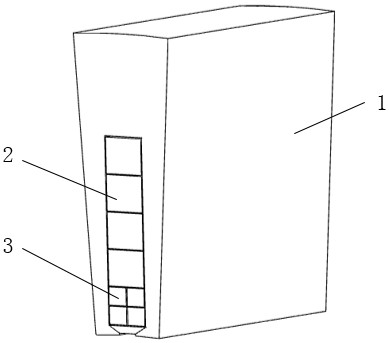

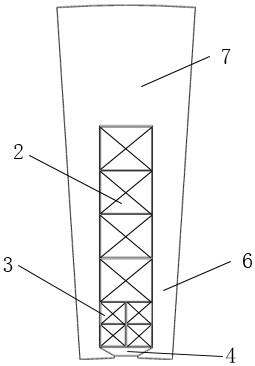

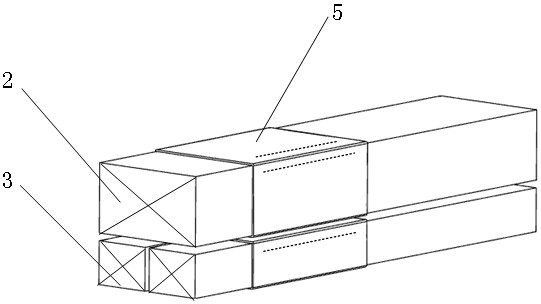

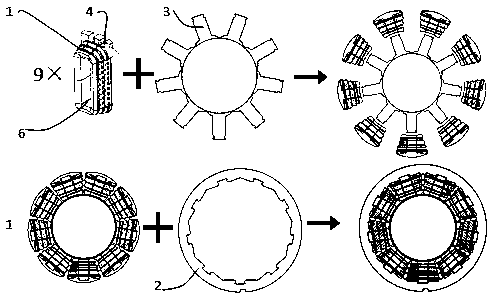

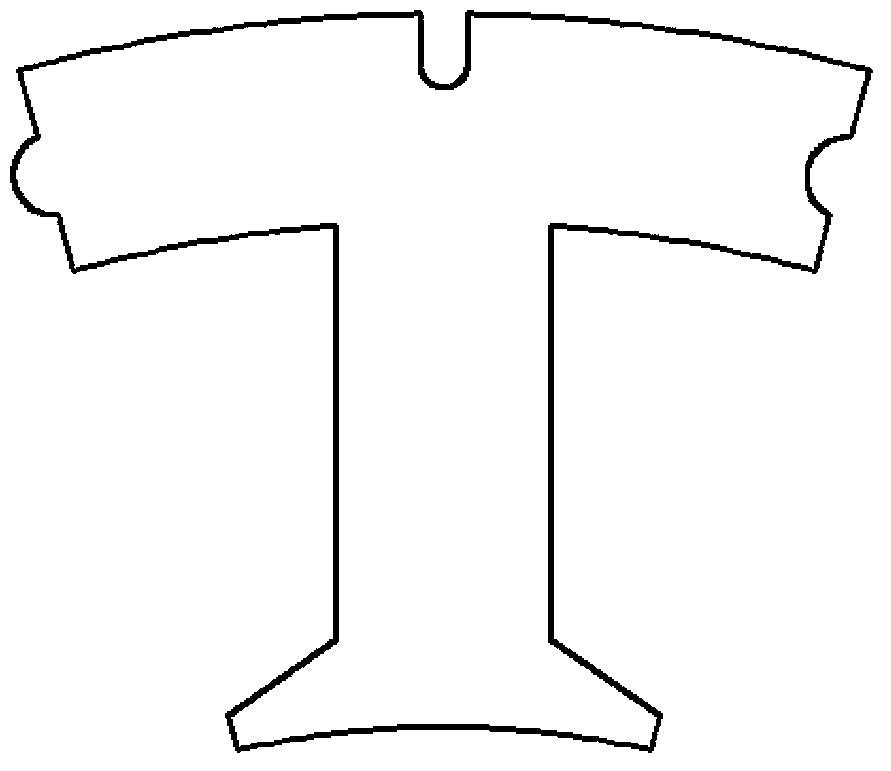

Fastening structure for split stator iron core

PendingCN107332366ASmall sizeLow input costMagnetic circuit stationary partsManufacturing stator/rotor bodiesInterference fitStator coil

A fastening structure for a split stator iron core comprises a plurality of fan-shaped iron core units which are connected in series to form an annular stator core. Grooves are arranged in the upper two sides of each fan-shaped iron core unit, and a tenon and a mortise are respectively arranged on the two lower sides of the fan-shaped iron core unit. Two adjacent fan-shaped iron core units are connected together through tenons and mortises embedded together, and the grooves of the two adjacent fan-shaped iron core units are in abut joint to form a wire duct for winding stator coils. Each fan-shaped iron core unit is formed by punching sheets laminated together. Cylindrical gaps are formed on the connecting surfaces of the tenons and the mortises, the cylindrical gaps of the tenons and the mortises form a cylindrical hole after connection, and a wedge is embedded in the cylindrical hole in an interference fit manner. Compared with the prior art, the fastening structure is convenient for assembly, realizes fastening connection of the split stator iron core after assembly, and prevents unreliable work of a motor due to loosening of the split stator iron core.

Owner:GUANGDONG HEPU POWER TECH

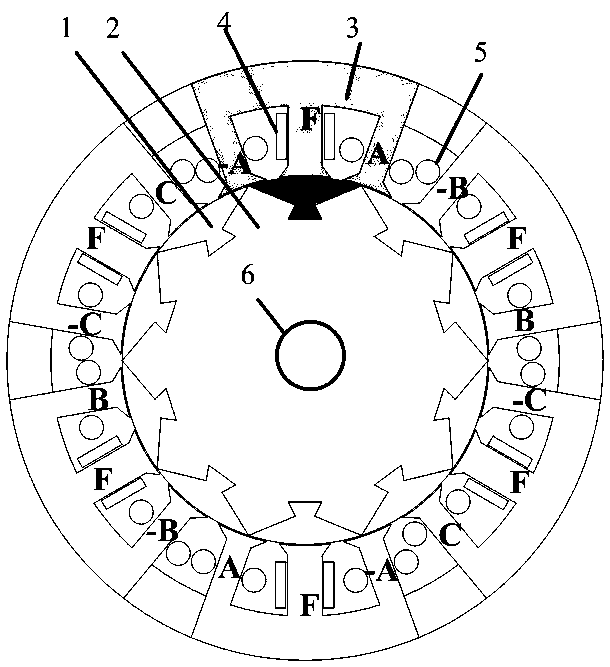

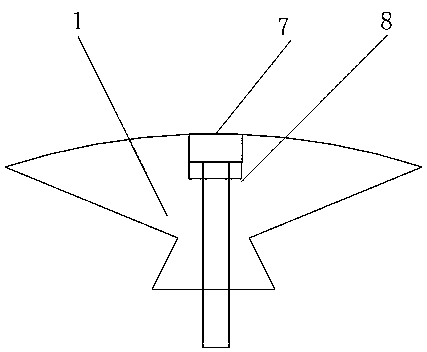

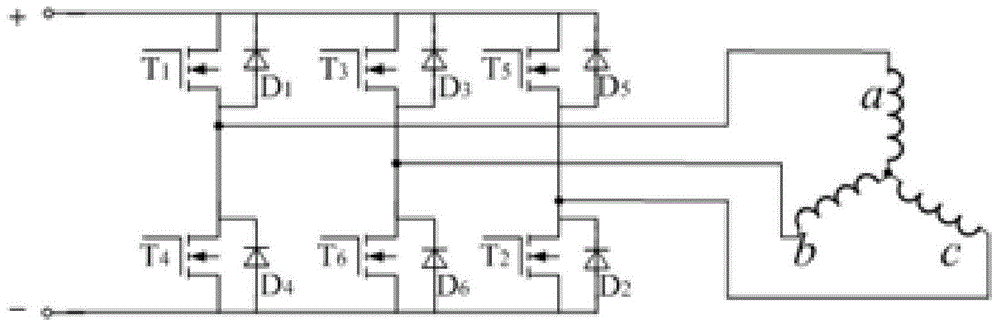

Electric automobile modular stator and rotor motor

ActiveCN109347288APrevent Fault PropagationStable structureMagnetic circuit rotating partsElectric machinesElectric machineNon magnetic

The invention provides an electric automobile modular stator and rotor motor, and belongs to the technical field of automobile motors. The electric automobile modular stator and rotor motor is characterized by comprising a convex lens-shaped iron core, a non-magnetic-conduction rotor iron core, a stator iron core, an excitation winding, an armature winding and the like, wherein the stator iron core is divided into six stator modules which are E-shaped; three unequal-width stator poles are arranged on the inner side of each stator module, wherein an excitation pole is arranged in the middle, and armature poles of the same width are arranged on the two sides; the non-magnetic-conduction rotor iron core has 10 fan-shaped grooves; and fan-shaped iron cores formed by silicon steel sheets in a laminated mode are embedded in the fan-shaped grooves. By virtue of the technology of the invention, a magnetic field can be provided for two armature windings through a short-moment excitation winding, so that the winding groove fullness and the isolation performance of each phase are improved, and the design of modularization of the stator and the rotor is realized.

Owner:SHANDONG UNIV OF TECH

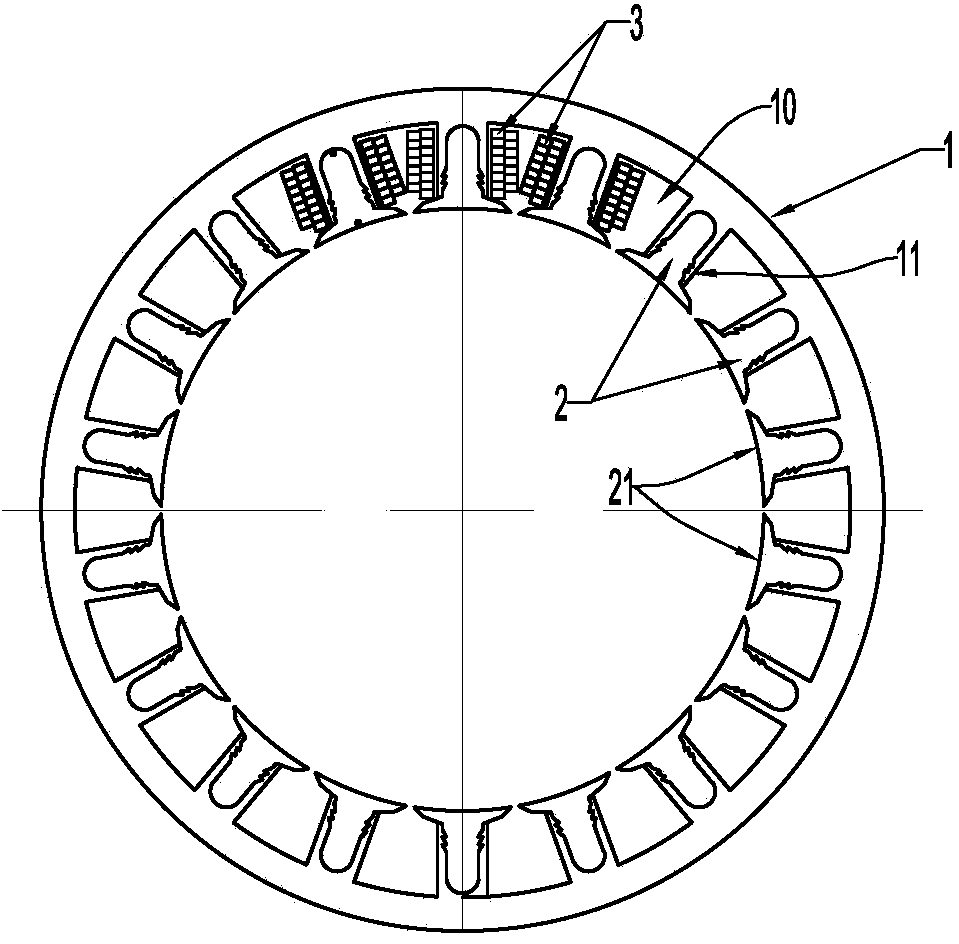

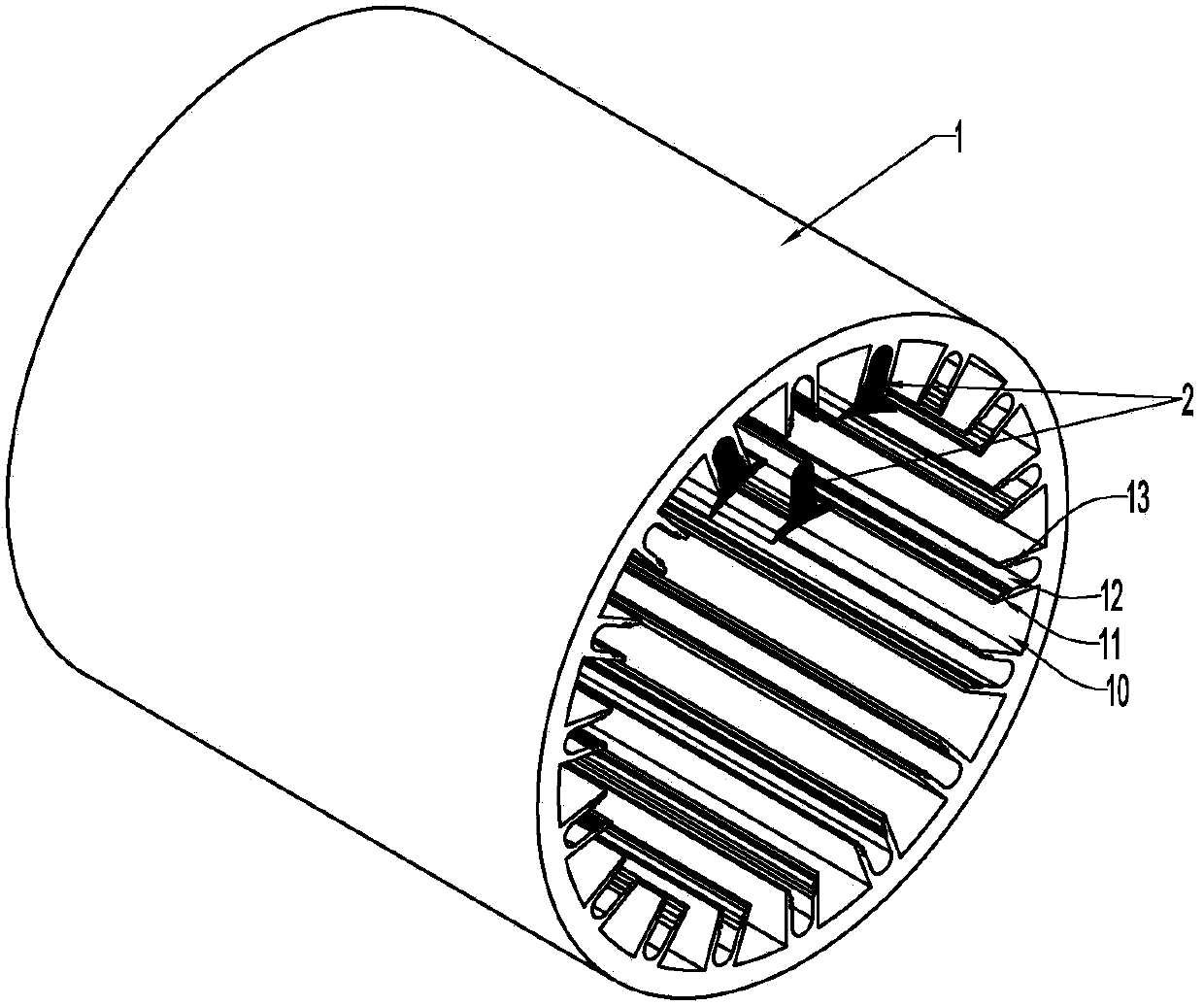

Compressor stator, permanent magnet motor, compressor and stator coil winding method

PendingCN107017710ANot easy to scratch or tangleNeatly arrangedMagnetic circuit stationary partsManufacturing dynamo-electric machinesPhysicsMagneto

The present invention discloses a compressor stator, a permanent magnet motor, a compressor and a stator coil winding method. The stator comprises a stator iron core and coils. The stator iron core is provided with a plurality of circumferentially spaced winding teeth and a winding slot is formed between every two adjacent winding teeth. M coils are sequentially wound onto each winding tooth from the inside to the outside, wherein the line outgoing taps of the m coils for each winding tooth are connected, and the line incoming taps of the m coils for each winding tooth are connected. M is larger than or equal to 2. According to the technical scheme of the invention, during the winding process, coils are not easily scratched or knotted, and are arranged more orderly. Meanwhile, the production efficiency is high, and the manufacturability is improved. The slot fullness rate of the motor is improved.

Owner:GUANGDONG MEIZHI COMPRESSOR

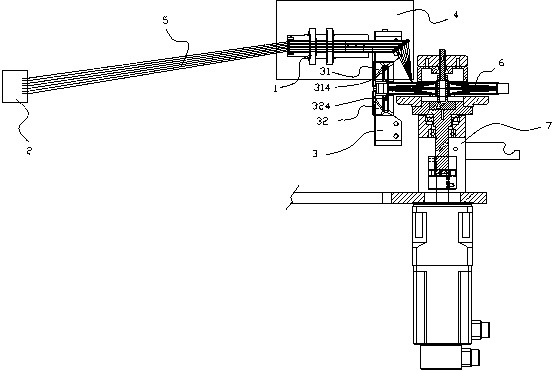

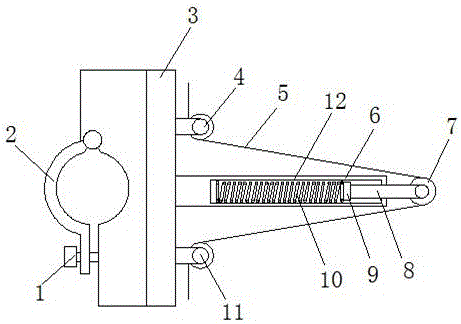

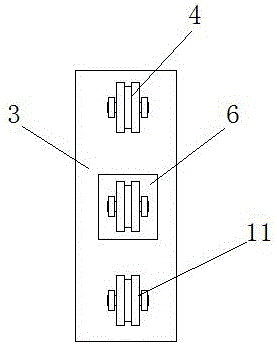

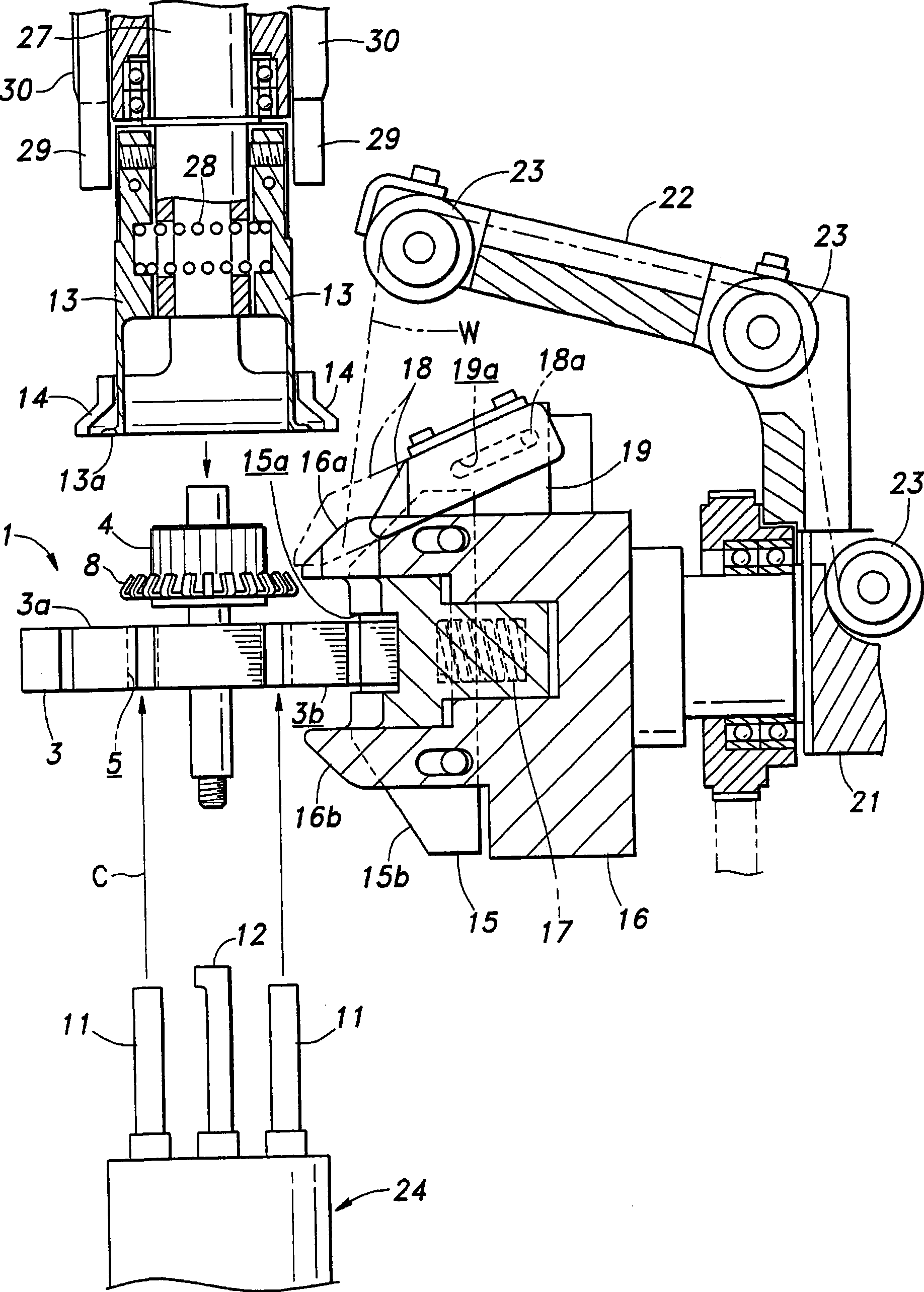

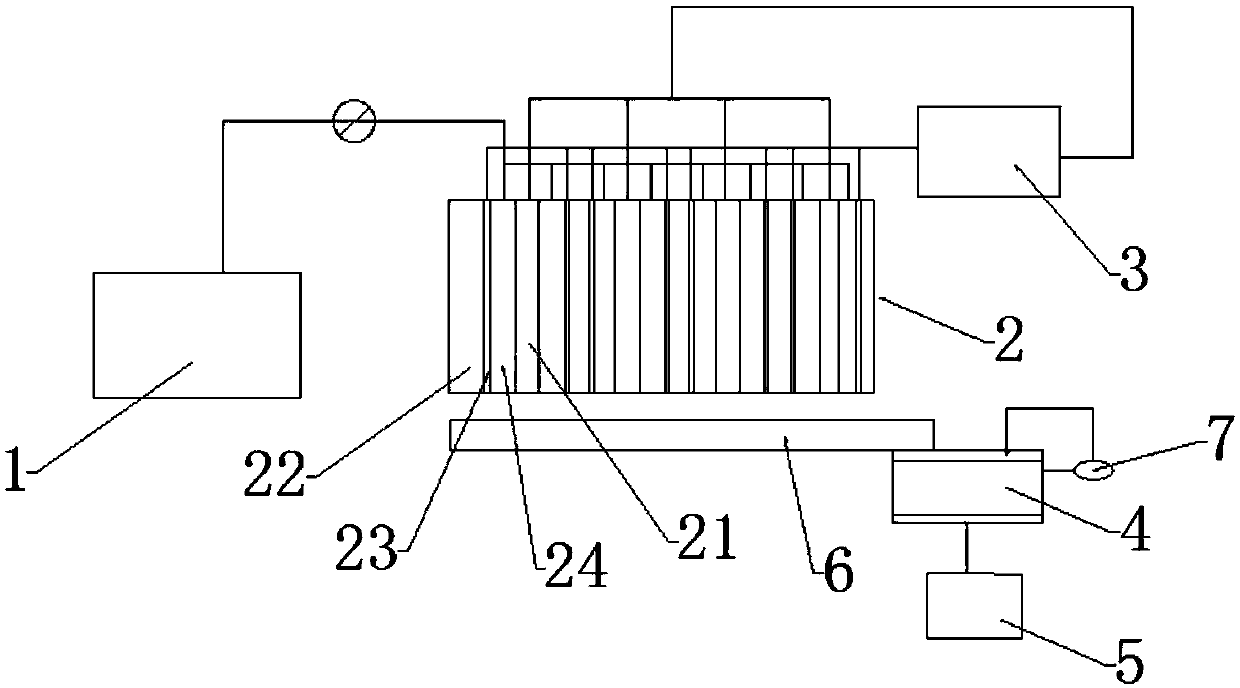

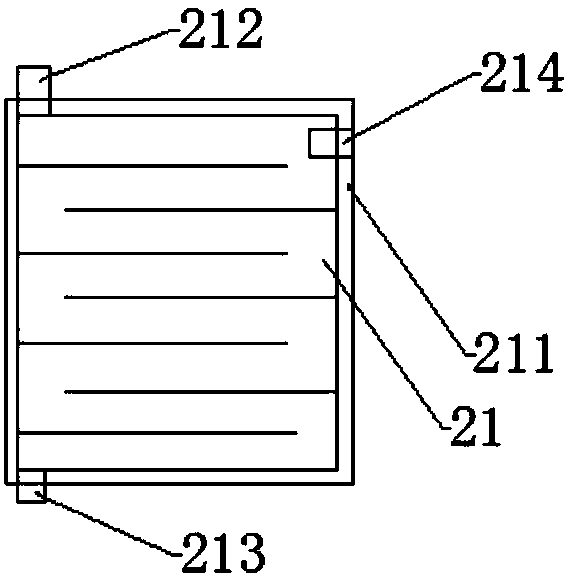

Automatic wire winding device of motor stator

InactiveCN103346648AIncrease full rateImprove work efficiencyManufacturing dynamo-electric machinesVertical planeMaterial consumption

The invention discloses an automatic wire winding device of a motor stator. The automatic wire winding device of the motor stator comprises a wire winding mechanism and a stator positioning mechanism, wherein the wire winding mechanism is composed of a moving wire nozzle, a wire compressing device and a wire-embedding guiding device, the moving wire nozzle can revolve on the axis and is arranged on a double-axis moving device which enables the moving wire nozzle to make planer motion relative to the vertical plane, the entire moving wire nozzle is hollow, and a single-row wire inlet hole and a single-row wire outlet hole which are used for arranging wires in a single row are respectively formed in the two ends of the moving wire nozzle. The automatic wire winding device of the motor stator is designed by imitating manual wire winding operational motions, automatically enables a plurality of the wires to pass through a wire inlet interval between an upper guiding device and a lower guiding device while the wires are arranged one by one, further guides the wires into a stator winding groove, and has the advantages of being high in work efficiency, low in labor intensity, high in groove filling rate of finished stators, high in pass percentage, free of damage to the wires, and small in material consumption.

Owner:李宗智

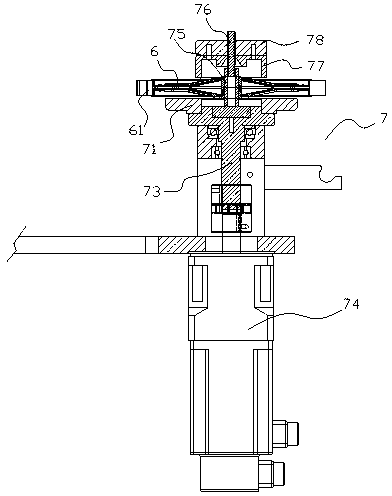

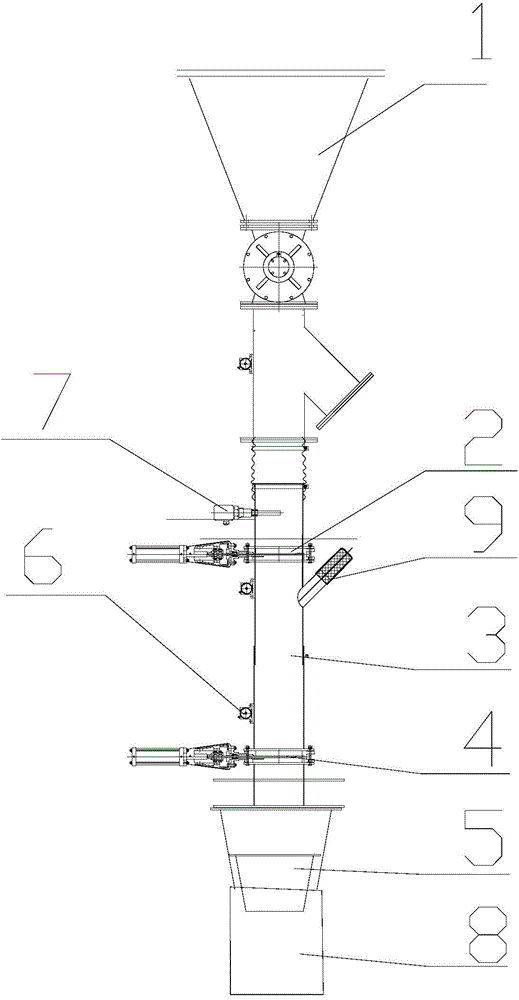

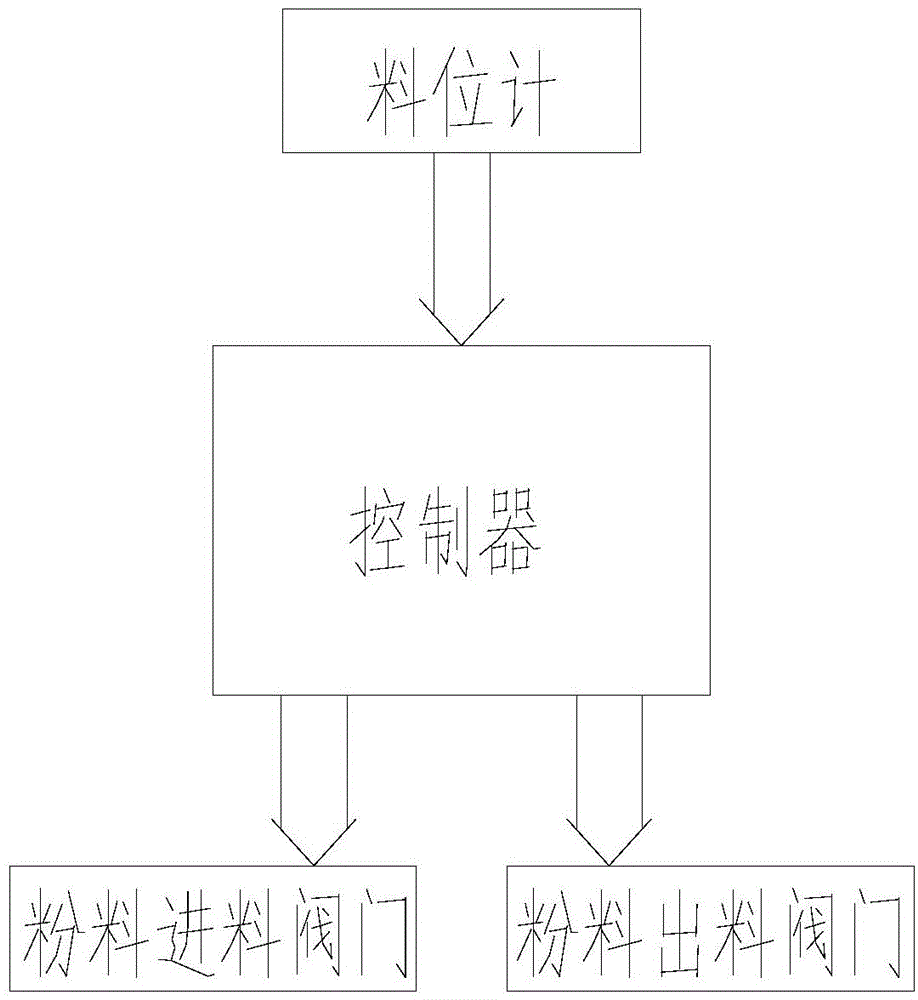

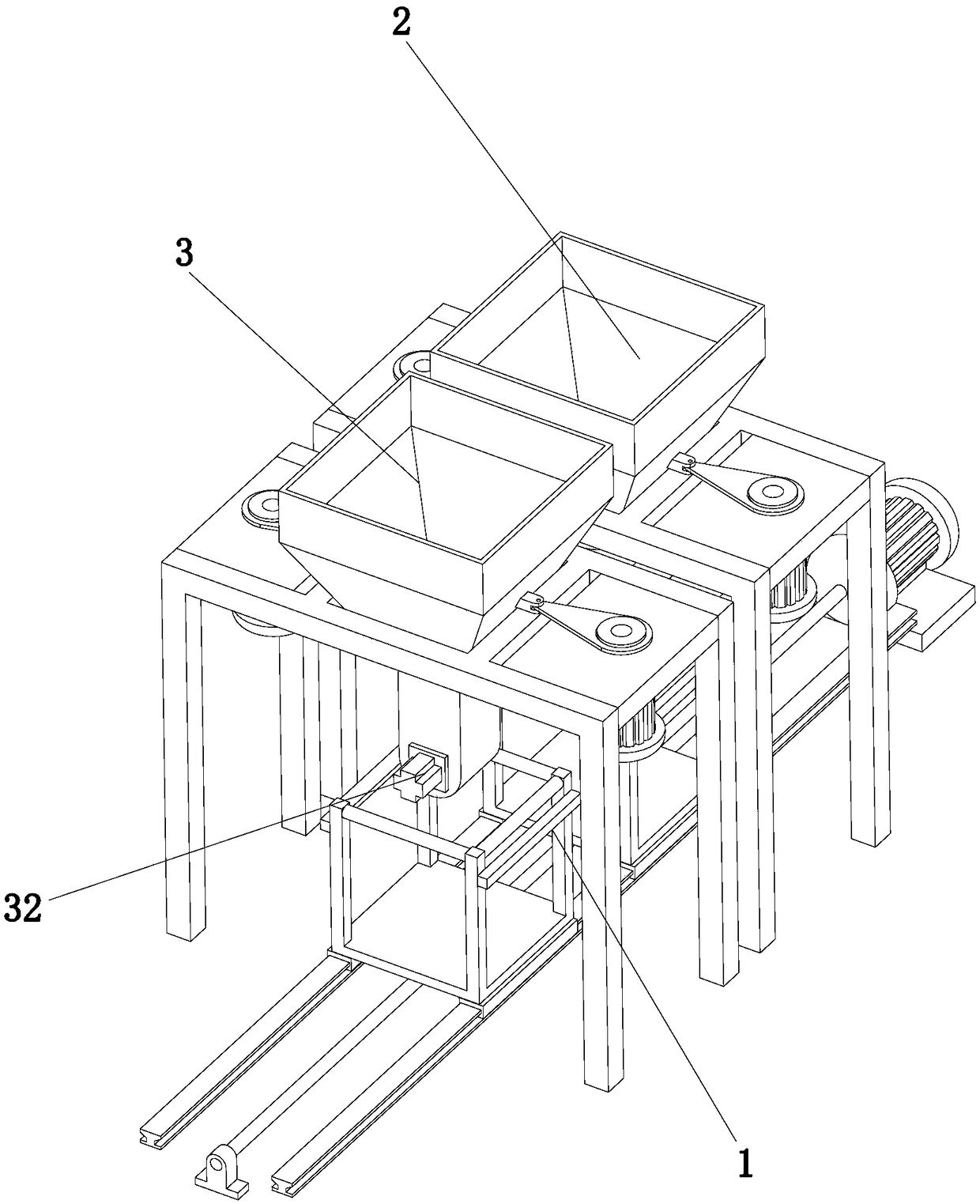

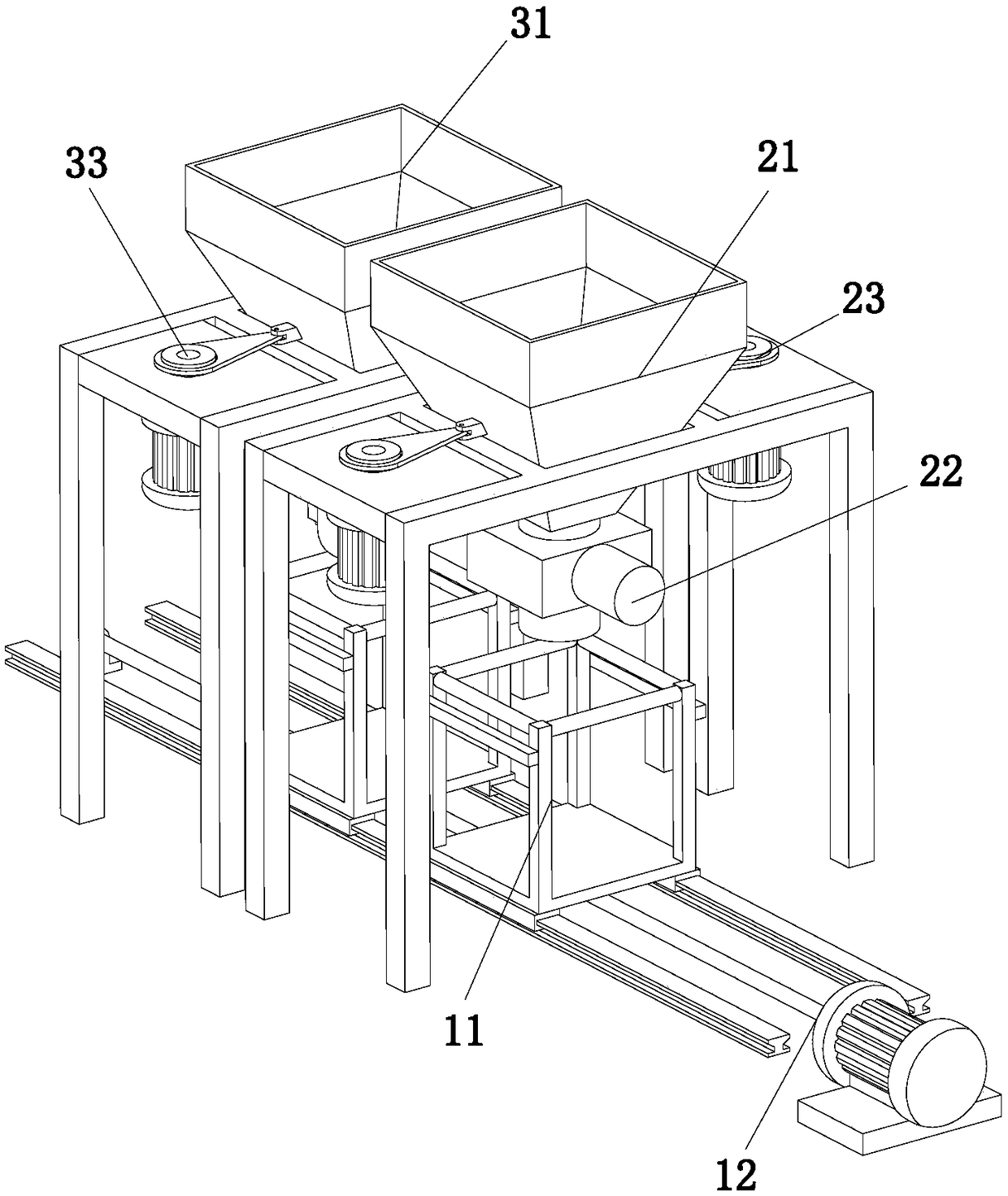

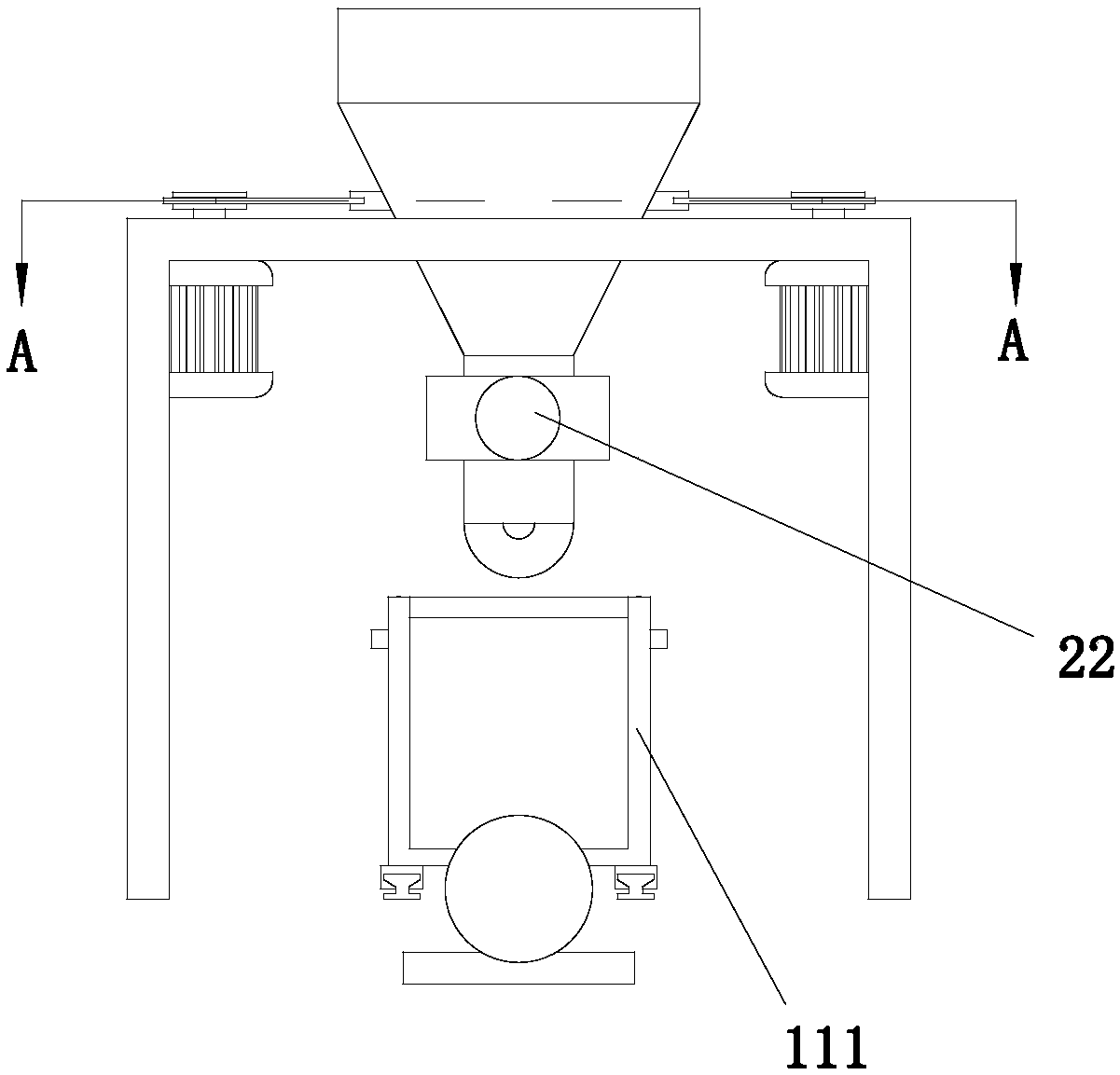

Powder packing and measuring device and method

InactiveCN104670536AIncrease full rateReduced flash rateSolid materialFilling rateVolumetric Mass Density

The invention discloses a powder packing and measuring device and method; the powder packing and measuring device is adopted to measure and pack powder with non-constant stacking density and comprises a vertical tubular measuring container; the upper opening of the measuring container is connected with an ash hopper connected with a feeding device, and the lower end is a discharging opening connected with a packing bag; a powder feeding valve and a powder discharging valve are arranged in the measuring container from top to bottom; the volume of the measuring container between the powder feeding valve and the powder discharging valve matches with that of the packing bag; and a level gauge is arranged above the powder feeding valve. The measuring and packing manner for a constant volume is realized; the device is compact in structure, smooth in discharging, low in fault rate, stable in running and accurate in measuring; the high fill rate of the packing bag and the clean environment during packing are ensured; in combination of the disclosed and matched powder packing and measuring method, the fill rate of the packing bag is improved effectively and the overflow rate of the packing bag is reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Yarn guide board device with buffer gear

The invention discloses a yarn guide board device with a buffer gear. The device comprises a mounting plate and yarns. One side of the mounting plate is provided with a first yarn guide roller, a second yarn guide roller and a buffer gear. The first yarn guide roller is fixedly arranged above the mounting plate through screws. The second yarn guide roller is fixedly arranged below the mounting plate through screws. The buffer gear is located between the first yarn guide roller and the second yarn guide roller. The buffer gear comprises a shaft sleeve, an expansion link and a movable yarn guide roller. One end of the expansion link is located in the shaft sleeve. And the end of the expansion link which is located in the shaft sleeve is provided with a baffle plate. A spring is arranged in the shaft sleeve. The movable yarn guide roller is movably arranged at one end of the expansion link. The yarn guide board device with the buffer gear is capable of making effective buffer for the yarns, preventing the textile yarns breaking, reducing outer yarn breakage and increasing full spindle ratio. Besides, the device has the advantages of simple structure, convenience in use, good effect and the like.

Owner:XIANGSHUI BAOJI TEXTILE

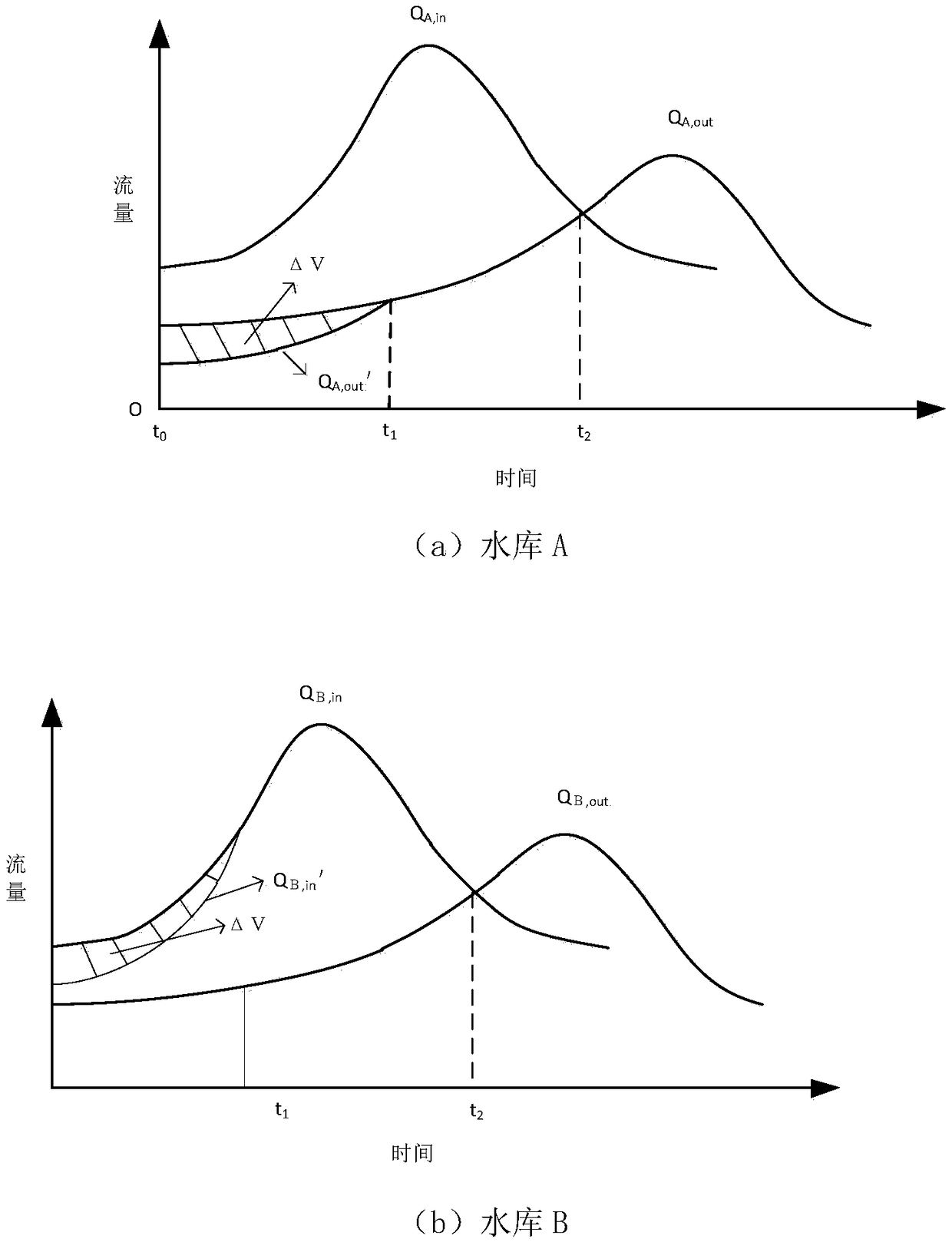

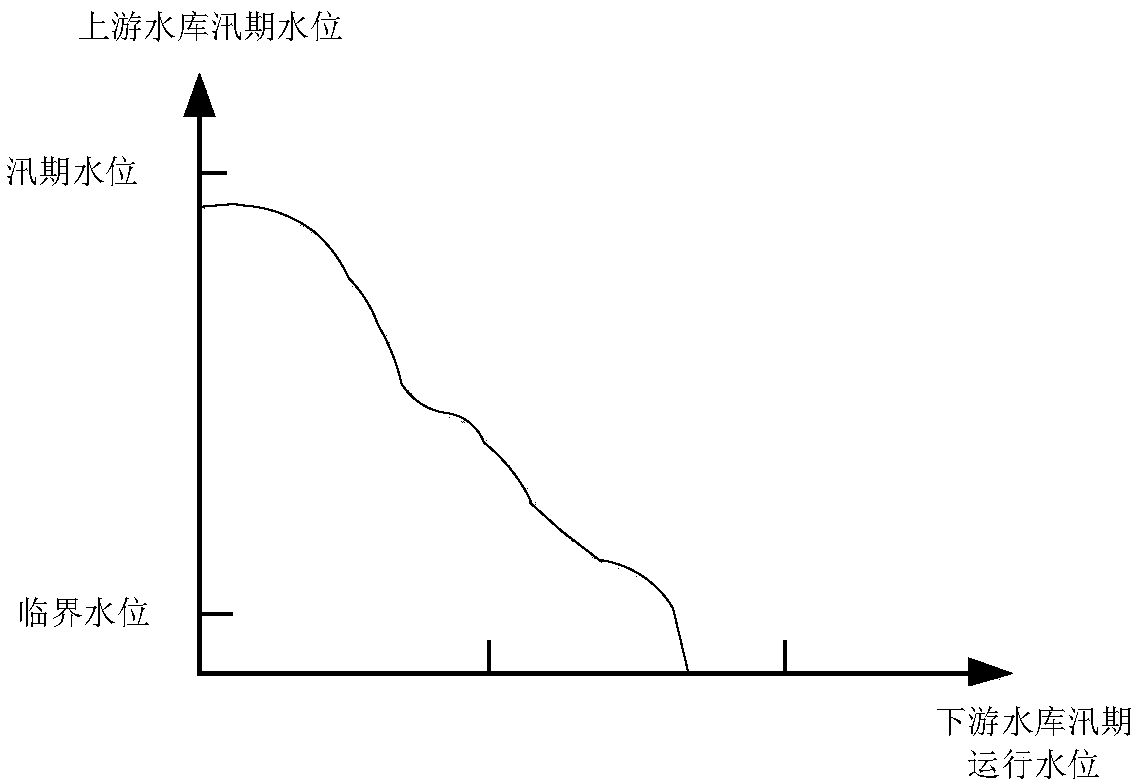

Reservoir-capacity-compensation-method-based method for flood resource utilization of cascade reservoirs

InactiveCN108596417ANo need to worry about uncertaintyEasy to operateClimate change adaptationResourcesResource utilizationEngineering

The invention discloses a reservoir-capacity-compensation-method-based method for flood resource utilization of cascade reservoirs. The method comprises: step one, calculating the surplus storage capacity of an upstream reservoir; step two, according to a water level running state of the upstream reservoir, determining a water level running state of a downstream reservoir; and step three, realizing flood resource utilization based on a compensation relationship between flood control capacities of cascade reservoirs. According to the invention, the requirement on the flood forecasting is low; the occurrence time of the next flood does not need to be considered; the water level running state of the downstream reservoir is determined only based on the water level running state of the upstreamreservoir; the worry about uncertainty caused by the flood forecasting is avoided; the full rate of the reservoir is increased; the flood resources in a flood season can be utilized as much as possible; the power generation efficiency is increased; and the operability is enhanced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

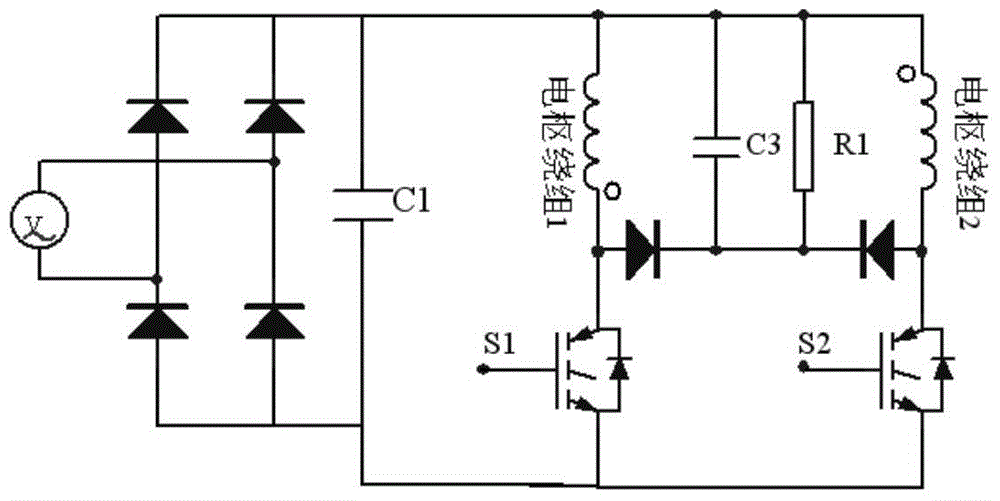

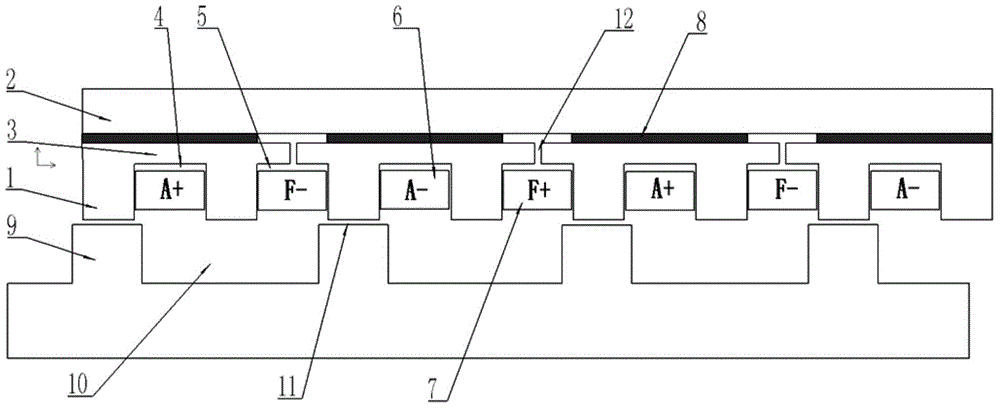

Double-winding high-powder-density mixed excitation permanent-magnet linear generator

ActiveCN105186733ASimple off-line processIncrease profitMagnetic circuit stationary partsDc currentPermanent magnet linear generator

The invention discloses a double-winding high-powder-density mixed excitation permanent-magnet linear generator which comprises a stator, wherein an even number of stator teeth are uniformly arranged on the stator; a stator slot is formed between two adjacent stator teeth; a permanent magnet is arranged between each stator slot yoke and a corresponding stator back yoke; a main gap is formed between each stator tooth and the corresponding rotor tooth of a rotor; each stator slot comprises armature slots and excitation slots which are arranged at an interval in an alternated manner; a set of excitation winding is arranged in the two adjacent excitation slots in a surrounding manner; direct current without changed direction is introduced into the excitation windings; additional gas gaps are formed in the middles of the yokes of the stator slots on which the excitation windings are positioned; one part of magnetic flux generated by two adjacent permanent magnets enters the rotor by the main gas gaps to form main magnetic flux, and the other part of the magnetic flux generated by the two adjacent permanent magnets passes through the additional gas gaps to form leaked magnetic flux. The double-winding high-powder-density mixed excitation permanent-magnet linear generator can be used for adjusting the leaked magnetic flux by adjusting the direction and the size of the current in the excitation windings, so that effects of magnetism enhancing and magnetism removing can be realized.

Owner:SHANDONG UNIV

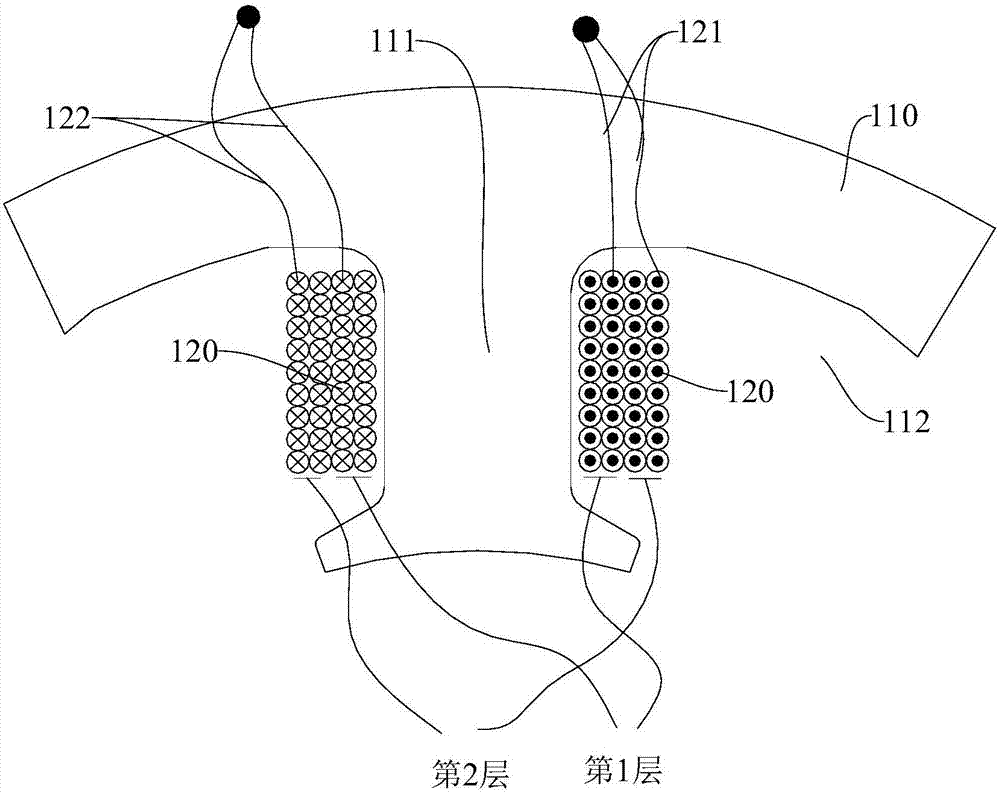

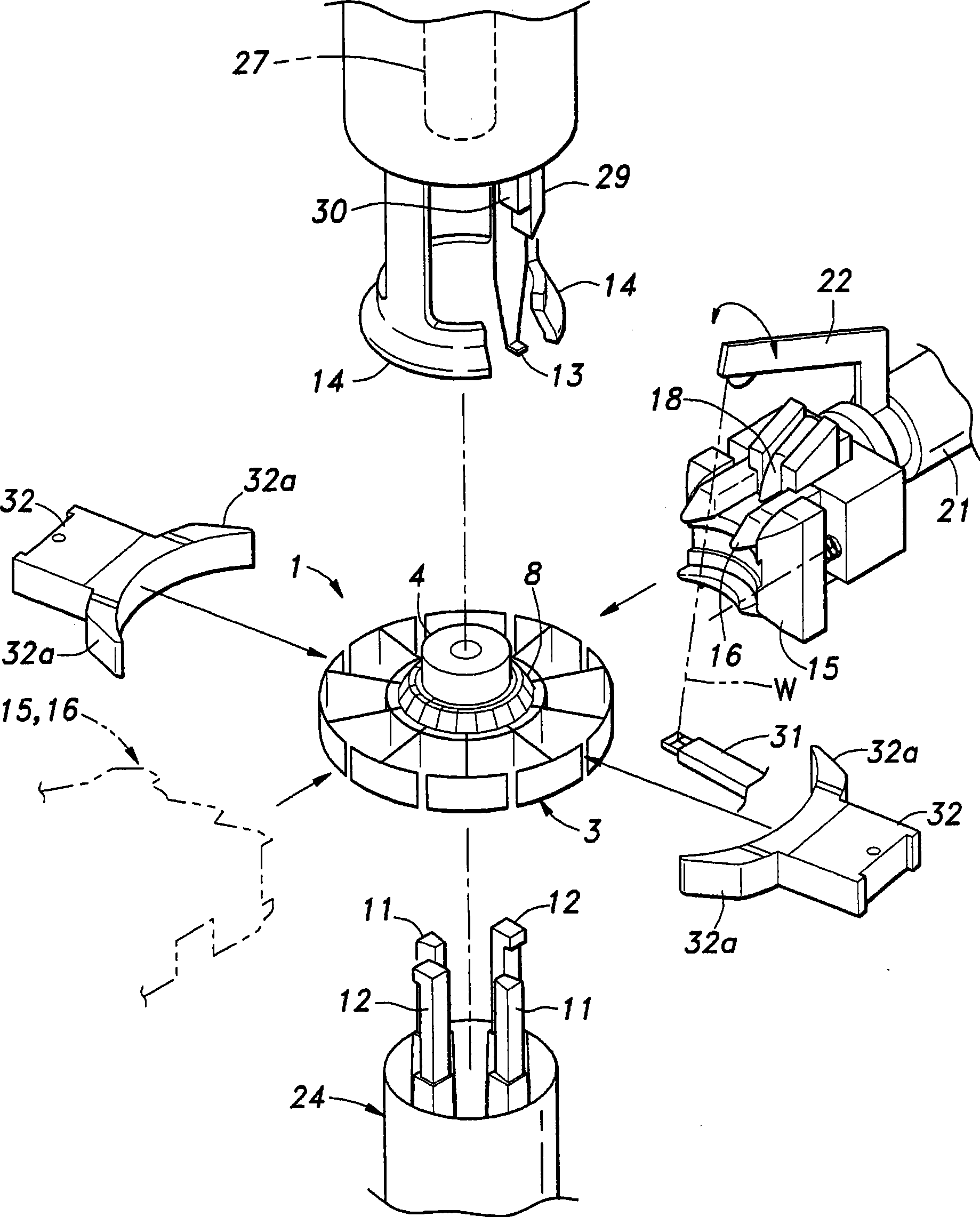

Winding device of armature and method

ActiveCN101425729AIncrease full rateEasy to hookManufacturing dynamo-electric machinesSpring forceConductor Coil

The invention provides a winding device and method of an armature to improve slot fullness rate aiming at a pancake motor. The winding device is provided with: a variable guiding part having an arc groove having an arc abutting surface abutted with the outer peripheral face of an iron core; and a guide portion that guides the wire from the outer peripheral surface of the core to a pair of slots; and a movable guiding part that supports the variable guiding part so as to be freely moved in the radial direction of the iron core. Moreover, a spring force is applied on the movable guiding part bya compressed spiral spring; the movable guiding part is provided with the guide portion; the end face of the guide portion along the axial direction of the iron core is extended out more inwardly to the iron core than the variable guiding part. As the position of the variable guiding part guiding metal wires into the slot can be freely set in the radial direction of the iron core, the position ofthe initial winding relative to the slot is as inward the semi-diameter direction of the iron core as possible in the condition of double-layer winding, thereby being capable of improving slot fullness rate.

Owner:MITSUBA CORP

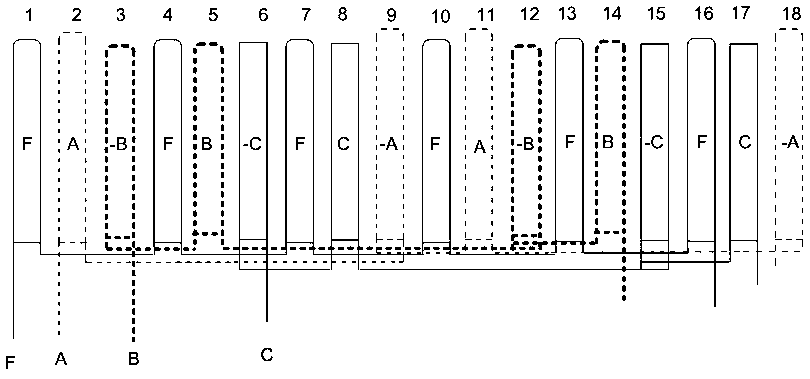

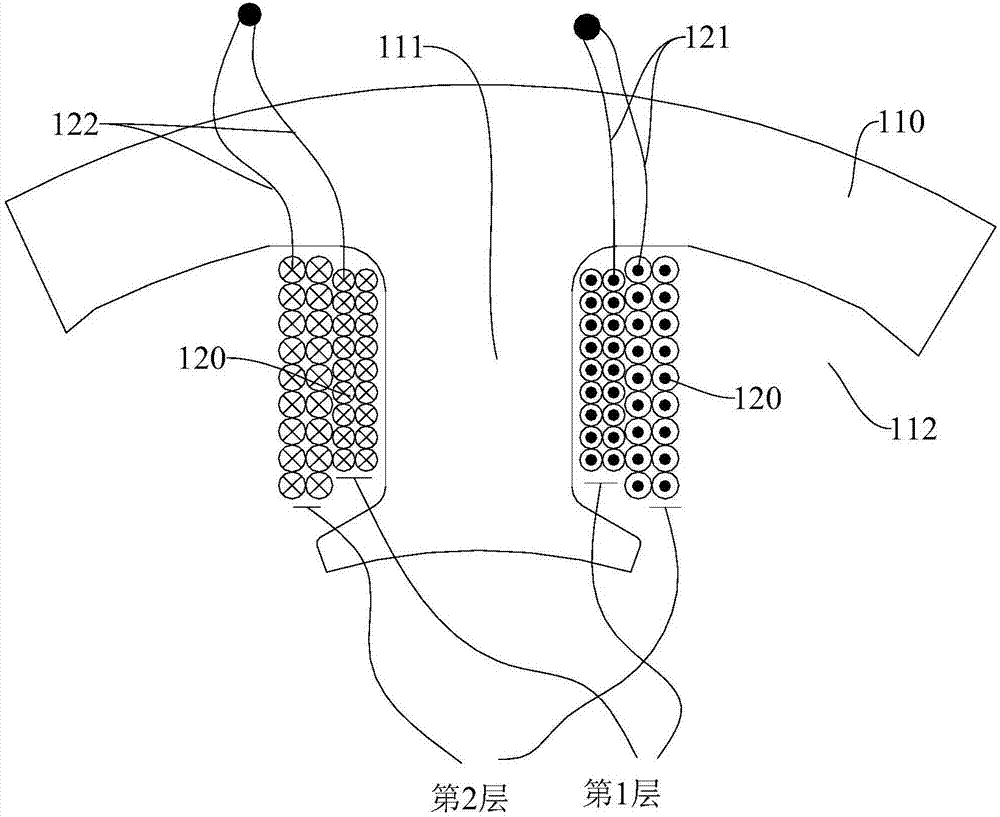

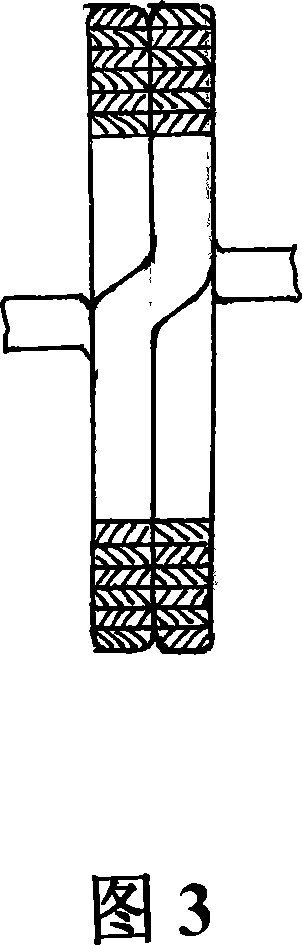

Stator winding of cylinder submersible linear electric machine with oil and its winding method

ActiveCN101090214AIncrease the cross-sectional areaReduce reactive power lossManufacturing dynamo-electric machinesWindings conductor shape/form/constructionElectric machineStator coil

This invention relates to a stator winding of a cylinder-submersible oil linear motor and its winding method characterizing that the stator coil winding is composed of multiple serial single-coke coils and each one is a double-layer structure, one layer is winded clockwise and the other is winded anticlockwise, which is advantaged that the winding structure of the coil is special, and the lead out wires at the two ends are set outside of the coil increasing the power of a linear motor to the utmost and the coil is winded with flat electromagnetic wires so the space of a disk core is fully utilized and the filling rate of the motor groove and section area of the wire are increased greatly and powerless loss of the motor is reduced.

Owner:SHENYANG XINCHENG PETROLEUM MACHINERY MFG

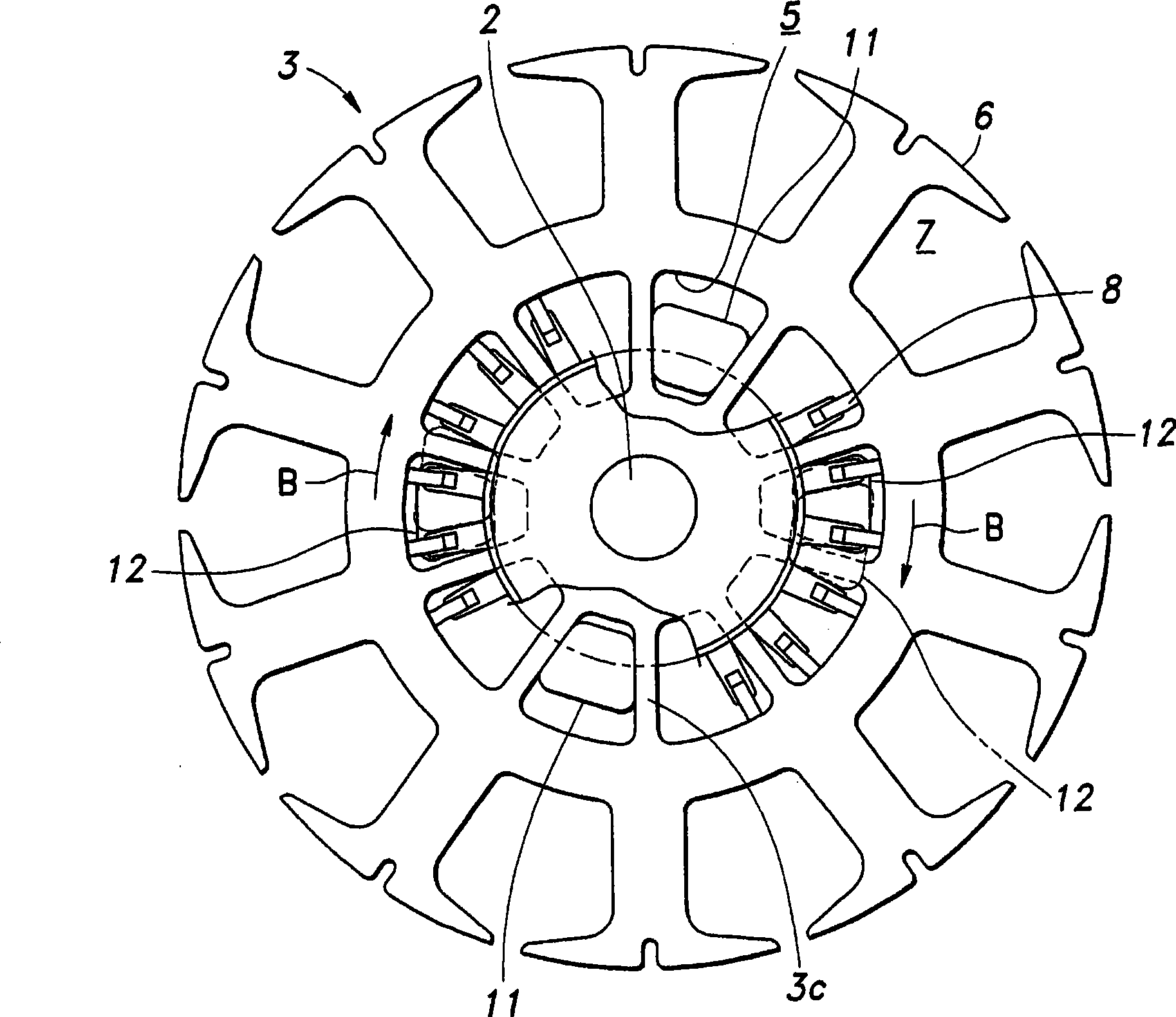

Gear shaping stator and assembling technology thereof

InactiveCN103595155ASatisfy automatic offlineImprove performanceMagnetic circuit stationary partsManufacturing dynamo-electric machinesEngineeringSilicon

The invention relates to a motor gear shaping stator. The motor gear shaping stator is characterized in that each stator tooth of a silicon steel sheet stator is provided with an tooth inserting groove, each tooth inserting groove is provided with an insertion tooth of a silicon steel sheet, each insertion tooth is provided with a T-shaped head with a circular-arc-shaped face and is inserted into a corresponding tooth inserting groove, the T-shaped head respectively seals open guide line grooves on the two sides, clearance exists between T-shaped heads of adjacent insertion teeth so as to form a notch, circular-arc-shaped faces of a plurality of T-shaped heads form an inner circle or outer circle structure of the stator. At assembling time, the silicon steel sheets are respectively stamped to form the stator sheets with tooth inserting grooves and insertion tooth sheets, the stator sheets and the insertion tooth sheets are respectively aligned and stacked to form the stator and insertion teeth, the stator and the insertion teeth are placed into formed windings one by one, and the stator can be formed as long as the insertion teeth are hit into the tooth inserting grooves. The motor gear shaping stator has the advantages of being exquisite in conception, reasonable in structure and simple in inserting coil technology. Especially, the stator guide line notch can be opened larger, automatic inserting coil of machines can be met, and the groove full rate is improved, subsequently, the insertion teeth are used for blocking open guide line grooves, so that the clearance between adjacent stator teeth is reduced, and the motor performance is improved.

Owner:叶羽纺

Double drying process sludge treatment apparatus

InactiveCN107777853AEliminate transportEliminate a series of problems such as storageSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeFiltration

The invention belongs to the technical field of sludge treatment, and relates to a double-dry sludge treatment device. A plate and frame filter press drier is provided with several independent filter press drying units. The filter press drying unit includes a heating plate, and the two sides of the heating plate A tympanic plate is provided, filter cloths are provided on both sides of the tympanic plate, and several protrusions are provided on the side of the tympanic plate close to the filter cloth to support the filter cloth. The cavity between the heating plate and the heating plate is a drying chamber; the stirring tank is connected with the sludge chamber of the filter press drying unit one by one through branch pipes, and feeds in parallel. There is a screw conveyor under the filter press drying unit, the screw conveyor is connected to the inlet of the retort furnace, and the retort furnace is respectively connected to the gas storage tank and the biochar storage bin; the gap between the tympanum plate and the filter cloth is connected to the steam collection pipe , the steam collection pipe is connected to the steam compressor, the output of the steam compressor is connected to the inlet of the heating plate, and the bottom of the heating plate is provided with a condensed water outlet; the secondary steam compression is used to reduce the boiling point, and the resource utilization rate is high, occupying an area The area is small.

Owner:王政峰

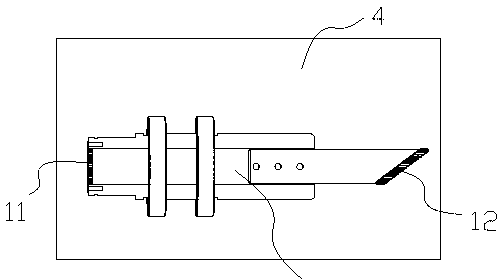

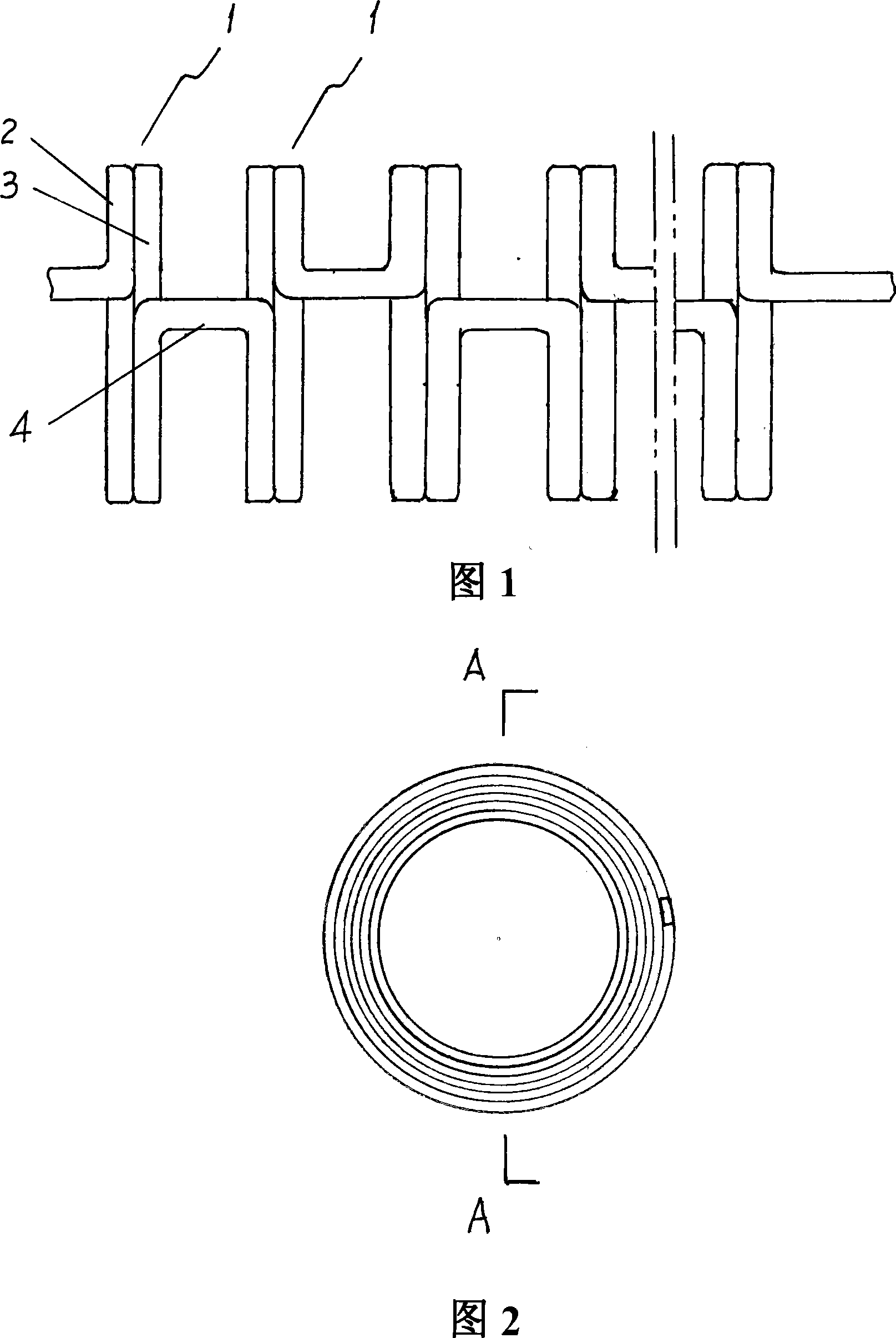

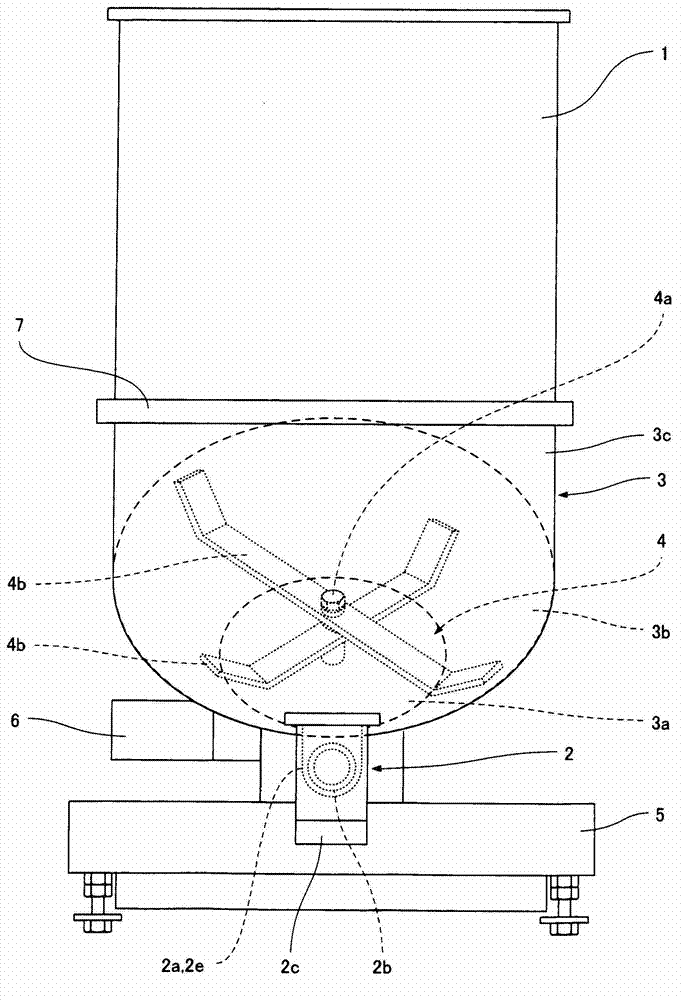

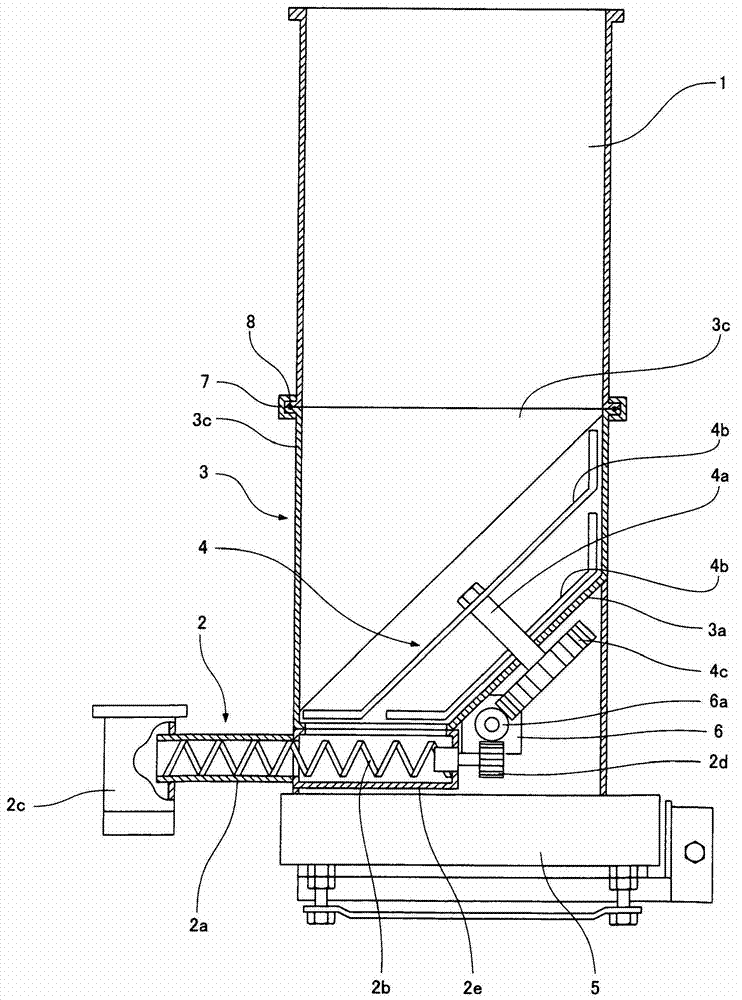

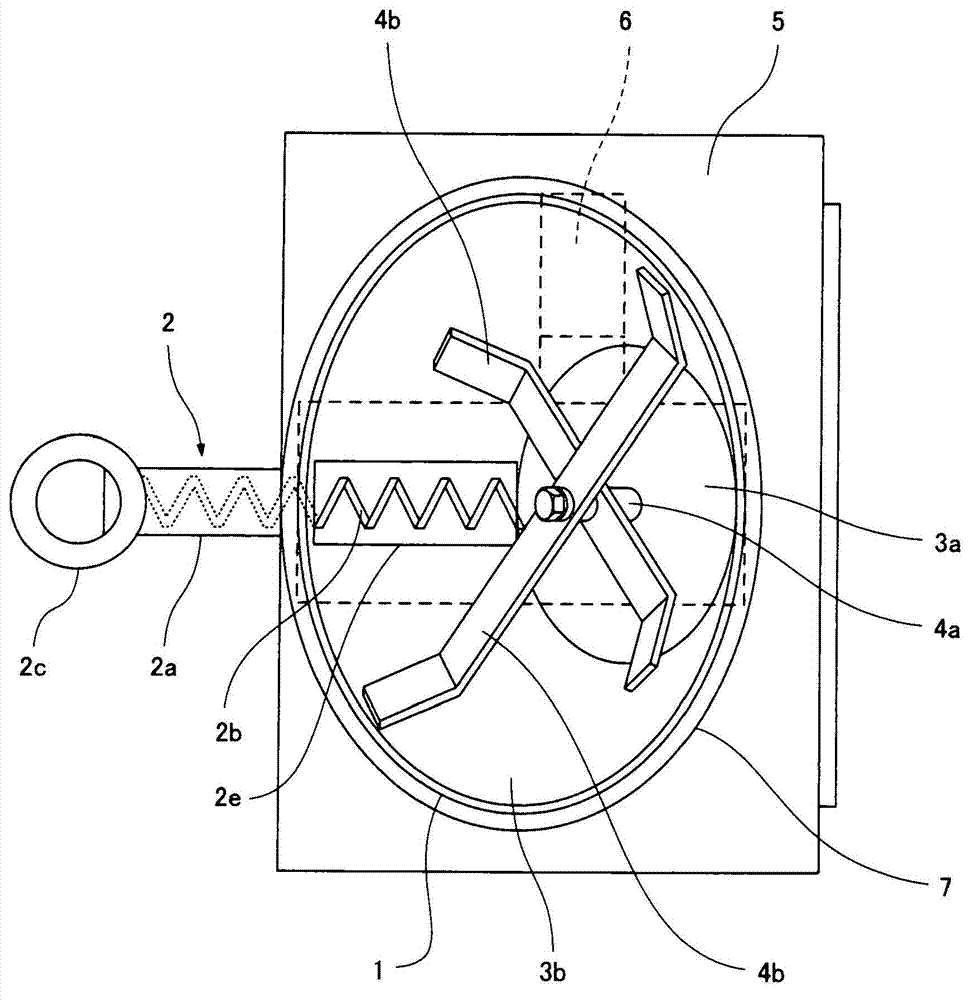

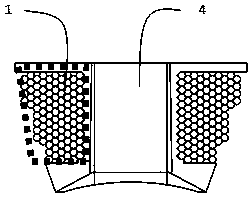

Powder/granular material feeding device

ActiveCN103159042AWell formedAvoid it happening againAnimal feeding devicesLarge containersMechanical engineeringGranular material

A provided powder / granular material feeding device fully satisfies the function of sufficiently preventing bridges and ratholes and the function of favorably stabilizing the filling rate of an outlet portion. Moreover, the powder / granular material feeding device does not require consumable items such as a flexible chute or leave a large amount of powder / granular material in a specific region inside a chute. The powder / granular material feeding device includes: a hopper 1 that receives powder / granular material; an outlet portion 2 that discharges powder / granular material; a chute 3 that guides, into the outlet portion 2, powder / granular material dropped from the hopper 1; and a stirring part 4 that rotates stirring members 4b about a shaft 4a protruding so as to tilt diagonally upward from the lower part of the interior of the chute 3.

Owner:KUBOTA CORP

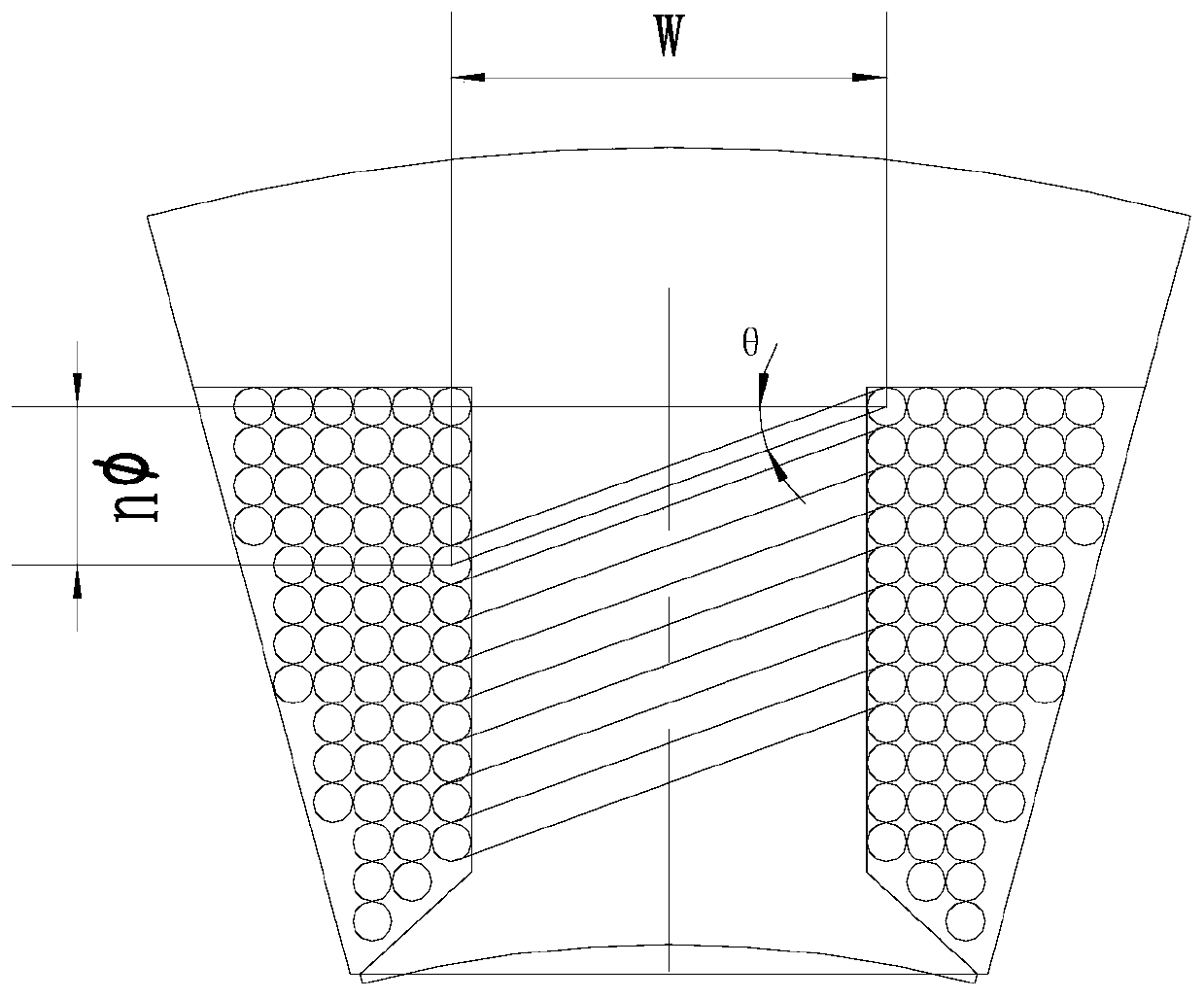

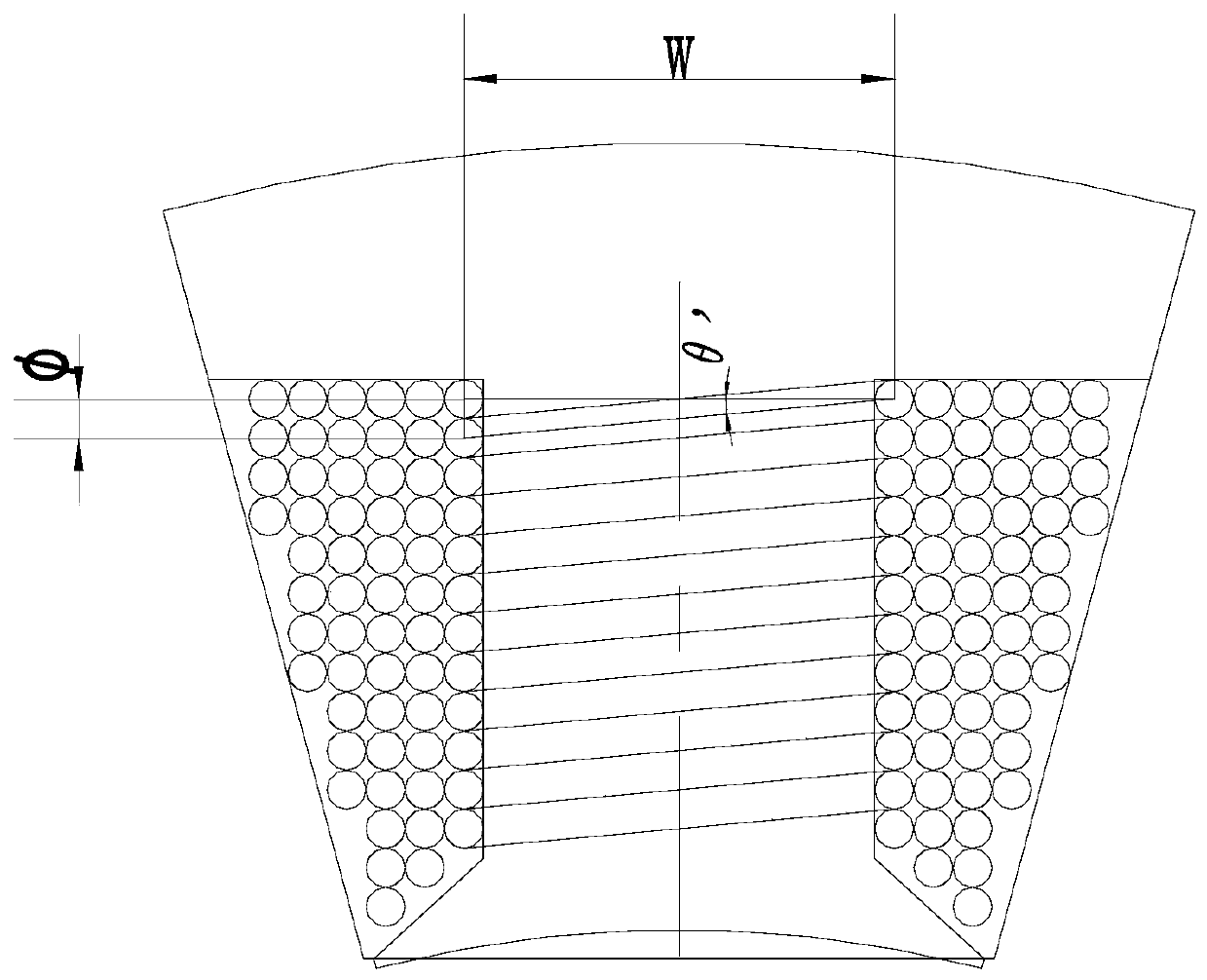

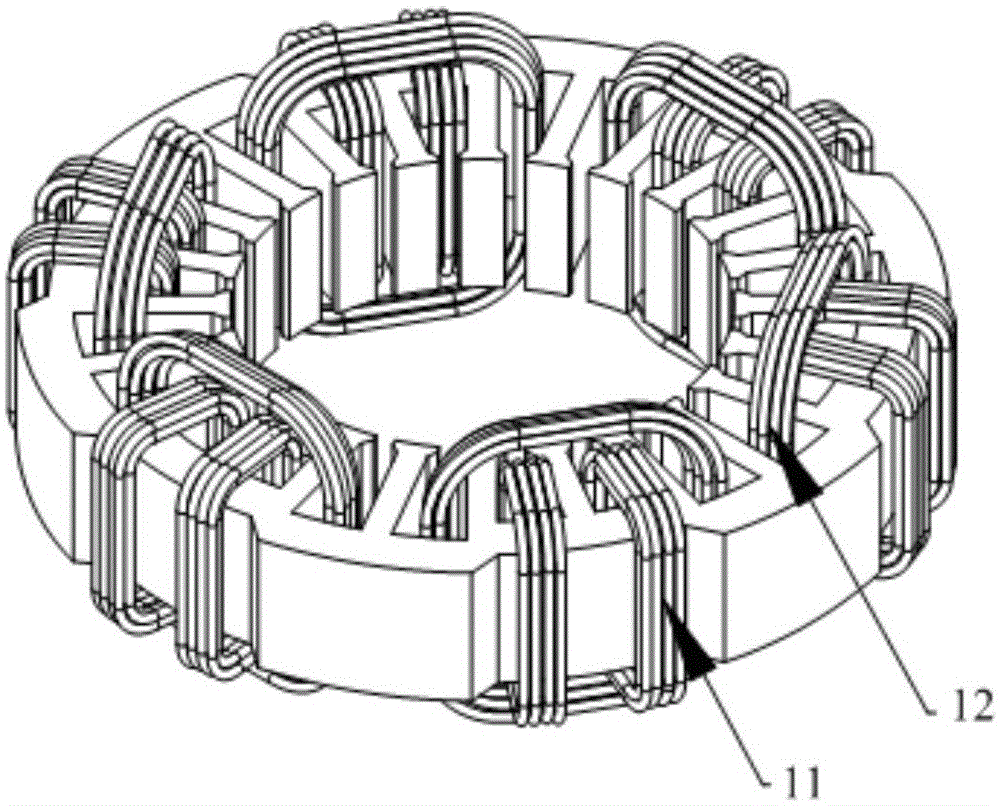

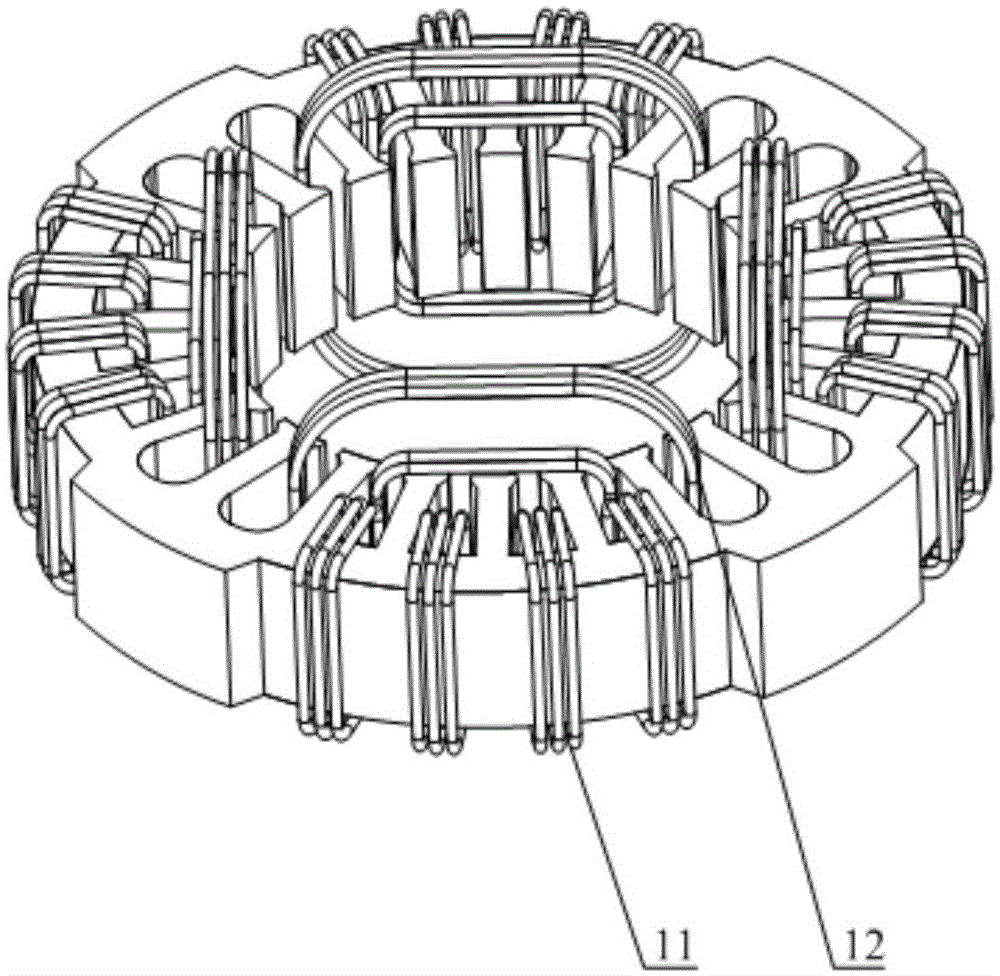

Stator tooth module, stator, motor and winding method of winding in stator tooth module

PendingCN109756039AEasy to windLower requirementWindings insulation shape/form/constructionMagnetic circuit stationary partsWinding machineStator

The invention relates to a stator tooth module. The stator tooth module comprises stator teeth, an insulation framework and a winding, wherein a winding groove is formed in the insulation framework, and the winding is wound in the winding groove; a vertical convex strip is arranged at each of the rear ends of the outer surfaces of a left supporting plate and a right supporting plate of a supporting sleeve; the first coil group of the winding is wound on the supporting sleeve between the vertical convex strip and a front baffle; the second coil group of the winding is wound on the first coil group; the coil at the last end in the second coil group is tightly pressed on the coil at the last end in the first coil group and a rear baffle plate and / or the vertical convex strip; and any other coil in the second coil group is tightly pressed on two adjacent coils in the first coil group. The invention further relates to a stator comprising the stator tooth module, a motor comprising the stator and a winding method for the winding in the stator tooth module. The invention has the advantages that the requirement for the winding machine is low, the manufacturing cost of the winding can be effectively reduced, the full rate of the motor groove is high, and the performance of the motor is good.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

Series excitation motor, stator core thereof, stator and manufacturing method of stator

InactiveCN104600883AReduce the impactIncrease slot fill rateMagnetic circuit stationary partsManufacturing stator/rotor bodiesPhysicsMotor efficiency

The invention is suitable for the field of a series excitation motor and discloses a series excitation motor stator core, a series excitation motor stator, a manufacturing method of the series excitation motor stator and a series excitation motor. The series excitation motor stator core comprises a stator yoke and a plurality of stator teeth arranged on the stator yoke, wherein the stator yoke comprises first sub-yokes and second sub-yokes which are alternately arranged along a circumferential direction, each first sub-yoke is respectively connected with each stator tooth, each second sub-yoke is respectively connected with each stator tooth, both ends of the first sub-yoke are respectively provided with two first inserting parts, both ends of the second sub-yoke are respectively provided with two second inserting parts, said two first inserting parts on both ends of the first sub-yoke are respectively connected with said two inserting parts of said two second adjacent sub-yokes in an inserting way. Filling ratio, motor efficiency, winding efficiency, automation production degree and low-voltage start ability of the series excitation motor are improved, meanwhile vibration and noise at the junction of the stator tooth and the stator yoke can be avoided and vibration and noise of the series excitation motor are further reduced.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

Stator winding iron core and winding method thereof

InactiveCN110571966ASolve the complex problem of winding manufacturingSolve the problem that multi-strand parallel winding cannot be carried outWindings insulation shape/form/constructionManufacturing dynamo-electric machinesEngineeringPower equipment

The invention discloses a stator winding iron core and a winding method thereof, and belongs to the field of power equipment. The stator winding iron core comprises an iron core and a winding, whereinthe iron core comprises a core body and an insulating framework which are connected with each other; a plurality of winding areas which are sequentially distributed in the direction from a first endto a second end are defined in the core body; the insulating framework is provided with a wire inlet and a wire outlet; the winding comprises a plurality of wires in one-to-one correspondence with theplurality of winding areas, the starting winding section of each wire in the plurality of wires jointly forms a wire inlet end matched with the wire inlet, and the ending winding section of each wirein the plurality of wires jointly forms a wire outlet end matched with the wire outlet. The stator winding iron core in the embodiment of the invention adopts a multi-strand parallel winding mode, and the production efficiency and quality can be improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Block type stator core, stator and motor

PendingCN108718121AEasy to operateIncrease full rateMagnetic circuit stationary partsConductor CoilFilling ratio

The invention relates to the technical field of motors, in particular to a block type stator core, a stator and a motor. The block type stator core provided by the invention comprises multiple arc iron core blocks which are connected end to end; two adjacent arc iron core blocks are connected by virtue of a sliding splicing mechanism; each arc iron core block comprises the outer ring arc slab, theinner ring arc slab and the wrapping post connected between the outer ring arc slab and the inner ring arc slab; and each arc iron core block respectively carries out wire winding and then is splicedand connected, and compared with the traditional whole circle iron core, a wire winding operation on each arc iron core block is easy, filling ratio can be increased, width of a notch can be reduced,and cogging torque can be beneficially reduced.

Owner:BEIDOU AEROSPACE AUTOMOBILE BEIJING CO LTD

Air processor and alternating current plastic-sealed motor and stator thereof

ActiveCN105141061AImprove efficiencyIncrease full rateWindings conductor shape/form/constructionElectric machineAir handler

The invention discloses a stator of a motor, which comprises a winding and a stator iron core with a groove, wherein the winding comprises a plurality of sub-windings distributed along the periphery of the stator; the sub-windings comprise a first phase windings and a second phase windings; the first phase windings comprise even numbers of windings; each of the windings is wound in a groove of a yoke portion of the stator iron core; the second phase windings comprise at least a groove-crossing coil; and the groove-crossing coil is wound inside the groove of the stator iron core by crossing the groove. The stator of the invention comprises the first phase windings wound on the yoke portion of the stator iron core and the second phase windings located inside the groove of the stator iron core by crossing the groove; the first phase windings are distributed on the outer circumference of the stator iron core; the outer circumference space that can be occupied is wound with large amount of vanished wires and the groove on which the second phase windings are located won't be blocked; the number of coils of the groove-crossing coil inside the groove to which the second phase windings are located are added; and the two phase windings are not interfered with each other, thus the rate of filling the groove with windings is improved and further the efficiency of the motor is improved. The invention also comprises an alternating current plastic-sealed motor and an air processor that are provided with the stator.

Owner:ZHUHAI KAIBANG MOTOR MFR +4

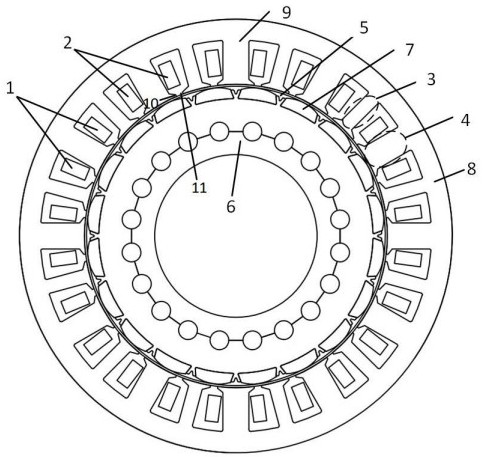

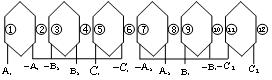

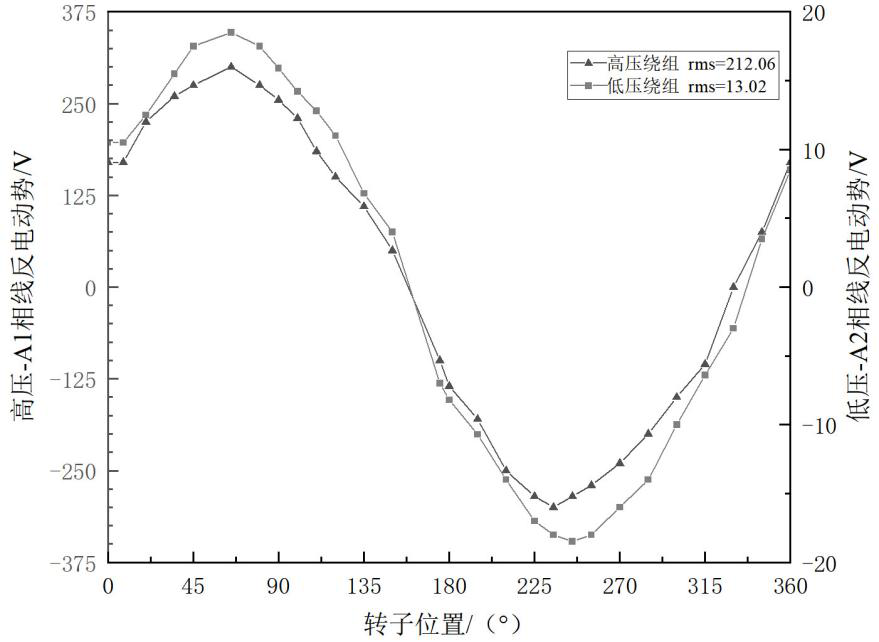

High-reliability permanent-magnet fault-tolerant steering motor

InactiveCN113708522AAchieve electrical isolationAchieve magnetic isolationMagnetic circuit rotating partsElectric machinesElectric machineShort circuit fault

The invention discloses a high-reliability permanent-magnet fault-tolerant steering motor, and belongs to the technical field of fault-tolerant motors, the motor adopts a 20-pole 24-slot matched structure, a winding mode adopts a tooth-separated winding mode of fractional-slot single-layer concentrated windings, armature teeth are provided with high-voltage windings and low-voltage windings in a crossing manner, fault-tolerant teeth are not provided with windings, and a magnetic loop is provided; a stator adopts a large and small tooth distribution mode, and stator teeth are in a parallel tooth type; a rotor adopts a semi-embedded SPM topological structure, the rotor comprises permanent magnets and a rotor iron core, the permanent magnets are of surface-mounted structures, the rotor iron core is of a dovetail groove type design, circular holes are uniformly formed in a rotor punching sheet at intervals, and the number of the circular holes is the same as that of the permanent magnets. The problem that the switching time of switching the high-voltage winding to the low-voltage winding is too long due to the fact that the high-voltage winding and the low-voltage winding cannot operate at the same time in a traditional double-winding motor applied to a double-source steering system is solved, the inter-phase mutual inductance and the high-voltage winding and low-voltage winding mutual inductance of the motor are almost zero, the fault-tolerant capability of the motor is improved, and the inter-phase short-circuit fault probability is reduced.

Owner:NANJING UNIV OF SCI & TECH

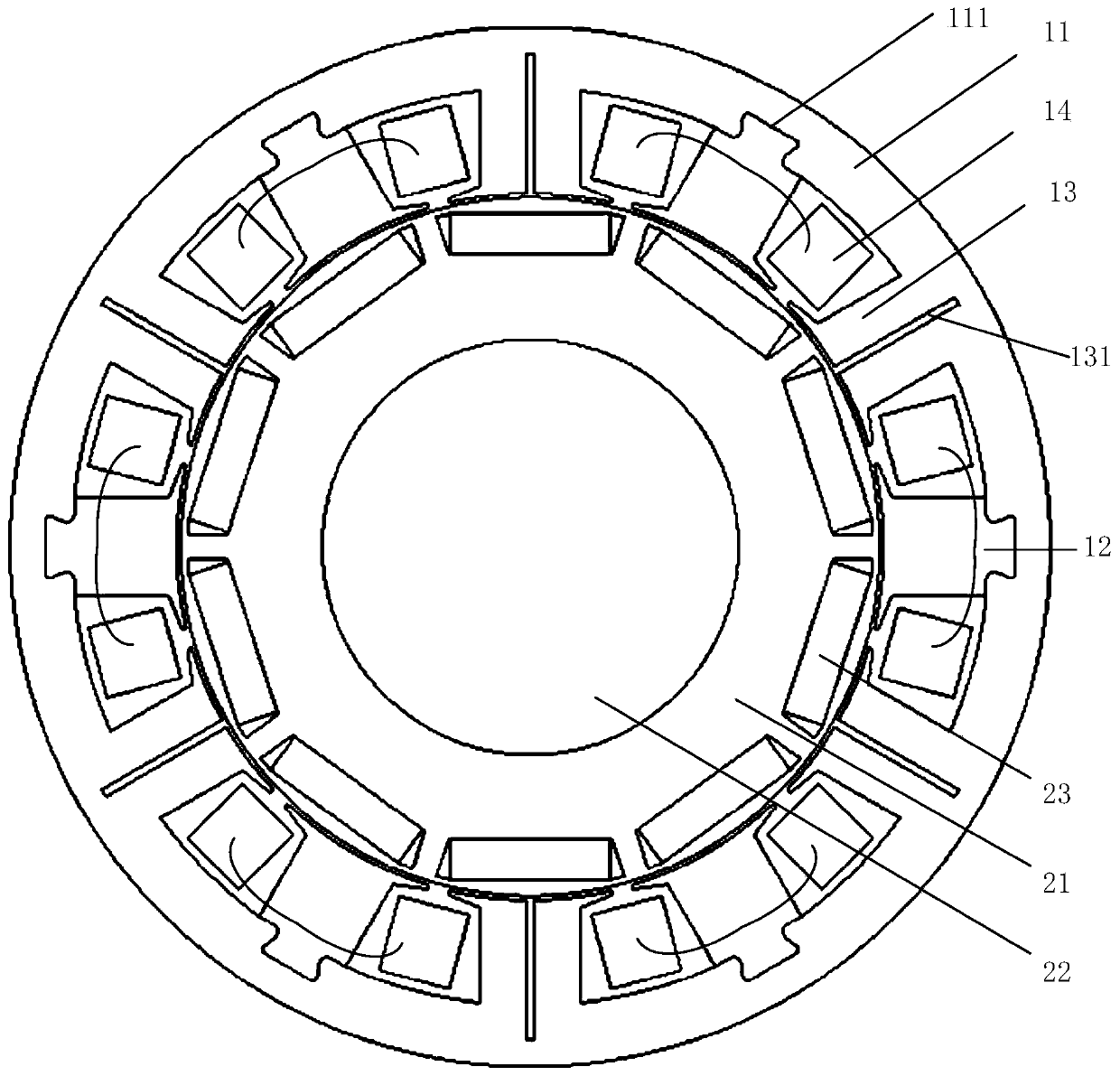

Magneto-thermal isolation type stator structure and motor

ActiveCN111404289AImprove the ability of heat insulation and magnetic insulationIncrease flexibilityWindings insulation shape/form/constructionMagnetic circuit rotating partsThermal isolationElectric machine

The invention discloses a magneto-thermal isolation type stator structure and a motor. The magneto-thermal isolation type stator structure comprises a stator yoke and a plurality of stator teeth. Wherein the stator yoke and the rotor are sleeved with each other; the stator teeth comprise mounting stator teeth and isolation stator teeth; the mounting stator teeth and the isolation stator teeth arealternately arranged on the circumferential wall surface of one side, close to the rotor, of the stator yoke; any stator tooth protrudes towards one side of the rotor. Winding coils are wound on the peripheries of the mounting stator teeth; the isolation stator teeth are provided with a plurality of isolation grooves, the isolation grooves are recessed from the side close to the rotor to the sideaway from the rotor, and the bottoms of the isolation grooves extend into the stator yoke. Winding phase-to-phase thermal field isolation is achieved, and therefore the phase-to-phase thermal isolation effect is achieved when a motor operates in a fault mode. Moreover, the inter-phase mutual inductance of the windings is effectively reduced, and the self-inductance of the windings is increased, sothat the influence of a fault winding short-circuit magnetic field on the normal winding magnetic performance is shielded, and the inter-phase electromagnetic field isolation effect of the windings during motor fault operation is further improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Motor stator assembly and compressor having the same

InactiveCN105846583AImprove insulation performanceIncrease slot fill rateWindings insulation shape/form/constructionEngineeringElectrical and Electronics engineering

The invention discloses a motor stator assembly and compressor having the same. The motor stator assembly comprises a stator core, an insulating layer, a first insulated framework and a second insulated framework; the first insulated framework is arranged at one end of the stator core; the first insulated framework is provided with a first slot corresponding to the position of a stator core slot; one side of the first slot close to the outer periphery of the first insulated framework is provided with a first stopping part; a second stopping part is arranged on the first insulated framework adjacent to an opening of the first slot; one end of the insulating layer leans against the first stopping part and the second stopping part; the second insulated framework is arranged at the other end of the stator core; the second insulated framework is provided with a second slot corresponding to the position of the stator core slot; and the other end of the insulating layer leans against the second insulated framework. According to the motor stator assembly of the embodiment of the invention, movement of the insulating layer can be defined, and the space utilization in the slot can be improved and the spacer factor can be promoted.

Owner:ANHUI MEIZHI COMPRESSOR +1

Novel unequal-area transposition flat wire winding permanent magnet motor

PendingCN112421816AReduce temperature riseImprove efficiencyWindings insulation shape/form/constructionMagnetic circuit stationary partsElectric machinePermanent magnet motor

The invention discloses a novel unequal-area transposition flat wire winding permanent magnet motor and belongs to the technical field of permanent magnet motors. The motor is characterized by comprising a stator iron core, a flat wire winding and an insulator, wherein the stator iron core and the flat wire winding jointly form a permanent magnet motor stator part, the stator winding comprises a large-area flat wire winding and a stranded flat wire winding which are placed in a stator core groove, the thickness of the stranded flat wire winding is smaller than that of the large-area flat wirewinding, and the insulation is divided into groove insulation arranged in the stator core groove and winding insulation arranged between adjacent windings; The unequal-area transposition flat wire winding not only can solve problems of low slot filling rate and low power density of the traditional round strand winding motor, but also can reduce the eddy current loss and the circulation loss of theflat wire winding, and can effectively reduce the temperature rise of the motor and improve efficiency of the motor on the premise of ensuring high power density.

Owner:HARBIN UNIV OF SCI & TECH

Electric compressor motor stator and manufacturing method thereof

PendingCN109672277AEasy windingImprove winding efficiencyWindingsMagnetic circuit stationary partsElectric machineEngineering

The invention provides an electric compressor motor stator and a manufacturing method thereof. The electric compressor motor stator comprises a stator winding, stator tooth parts, a stator yoke part and a stator framework, and is characterized in that a stator iron core comprises the stator tooth parts and the stator yoke part, which are separated from each other; the stator tooth parts are connected through bridges; the stator winding is orderly wound on the stator framework; lead wires at two ends of the winding are fixed on a fixed pin; a winding process can be independently finished; afterthe winding is finished, assembling holes on the stator winding and the stator framework are directly assembled on teeth; after each tooth on a stator part is assembled, a tooth root of each of the stator tooth part and a clamping groove of the stator yoke part are matched to finish installation. The electric compressor motor stator provided by the invention has the advantages that a production technology of the motor stator is simplified; the stator winding is independently wound on the framework, the arrangement is ordered and the production efficiency is high; the slot space factor of thestator is high and the energy density of a motor is improved; a closed groove is designed so that the flux leakage is reduced and the operation vibration and noises are reduced.

Owner:苏州新智机电工业有限公司

Permanent magnet motor stator structure

InactiveCN102801231AHigh mechanical strengthIncrease capacityMagnetic circuit stationary partsFilling ratePermanent magnet motor

The invention relates to a permanent magnet motor stator structure which comprises a stator yoke part and a stator toothed ring, wherein the stator toothed ring comprises a ring base part and a plurality of stator teeth outwards extending from the radial direction of the ring base part, the stator yoke part is sleeved outside the stator toothed ring, and the inner surface of the stator yoke part is provided with fixed grooves which is same with the stator teeth in quantity and shape, the stator teeth are inserted in the fixed grooves and are mutually tightly contacted. Preferably, the tops of the stator teeth are provided with convex parts, the bottoms of the fixed grooves are provided with concave parts adapted to the convex parts in shapes, and the convex parts are inserted in the concave parts and are mutually tightly contacted. The stator yoke part is integrally formed, or is formed by connecting a plurality of sections. The ring base part is integrally formed or formed by connecting a plurality of sections. The permanent magnet motor stator structure has the advantages of being skilled in structure design and simple in structure, improving mechanical strength, lowering influence to a magnetic chain, and increasing the groove filling rate, thereby increasing the capacity and the efficiency of a motor, and the integral mechanical strength of the motor, and being suitable for being popularized and applied.

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

Differential supplementing device for metal powder bagging

The invention belongs to the technical field of metal powder production and particularly relates to a differential supplementing device for metal powder bagging. The differential supplementing devicecomprises a positioning transferring device, a filling mechanism, a supplementing device body and a control device. The positioning transferring device comprises a plurality of positioning jigs and adriving electric cylinder. The filling mechanism comprises a first material falling hopper, a solenoid valve and a first shaking mechanism. The supplementing device body comprises a second material falling hopper, a limiting assembly and a second shaking mechanism. The second shaking mechanism and the middle section of the second material falling hopper are hinged. The packaging bag filling rate is increased, the packaging bag overflow rate is decreased, the semi-automatic powder accurate packaging progress is achieved, a packaging bag is charged continuously, powder falling precision is improved, and the packaging efficiency is improved.

Owner:芜湖市晨睿建材有限公司

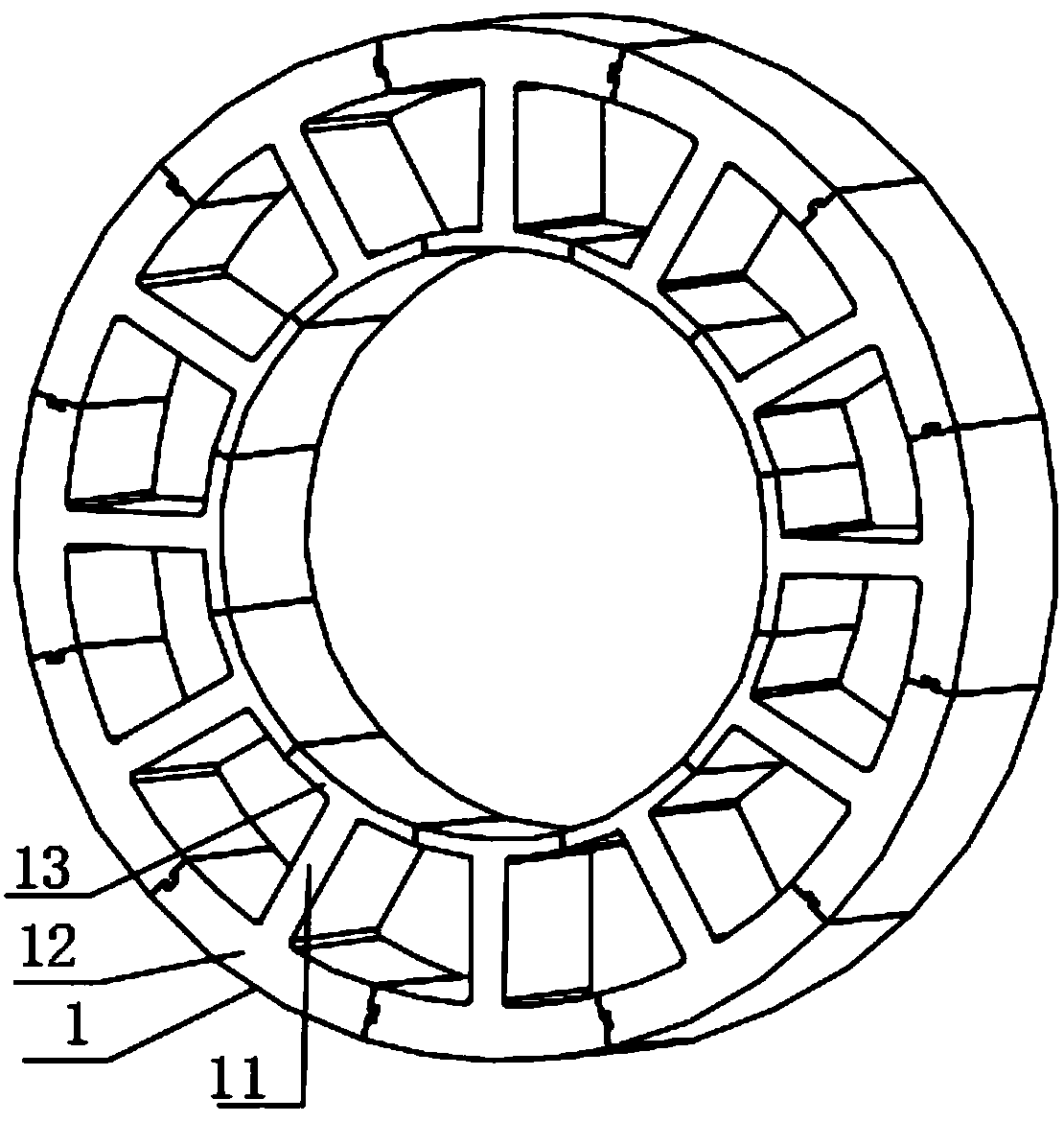

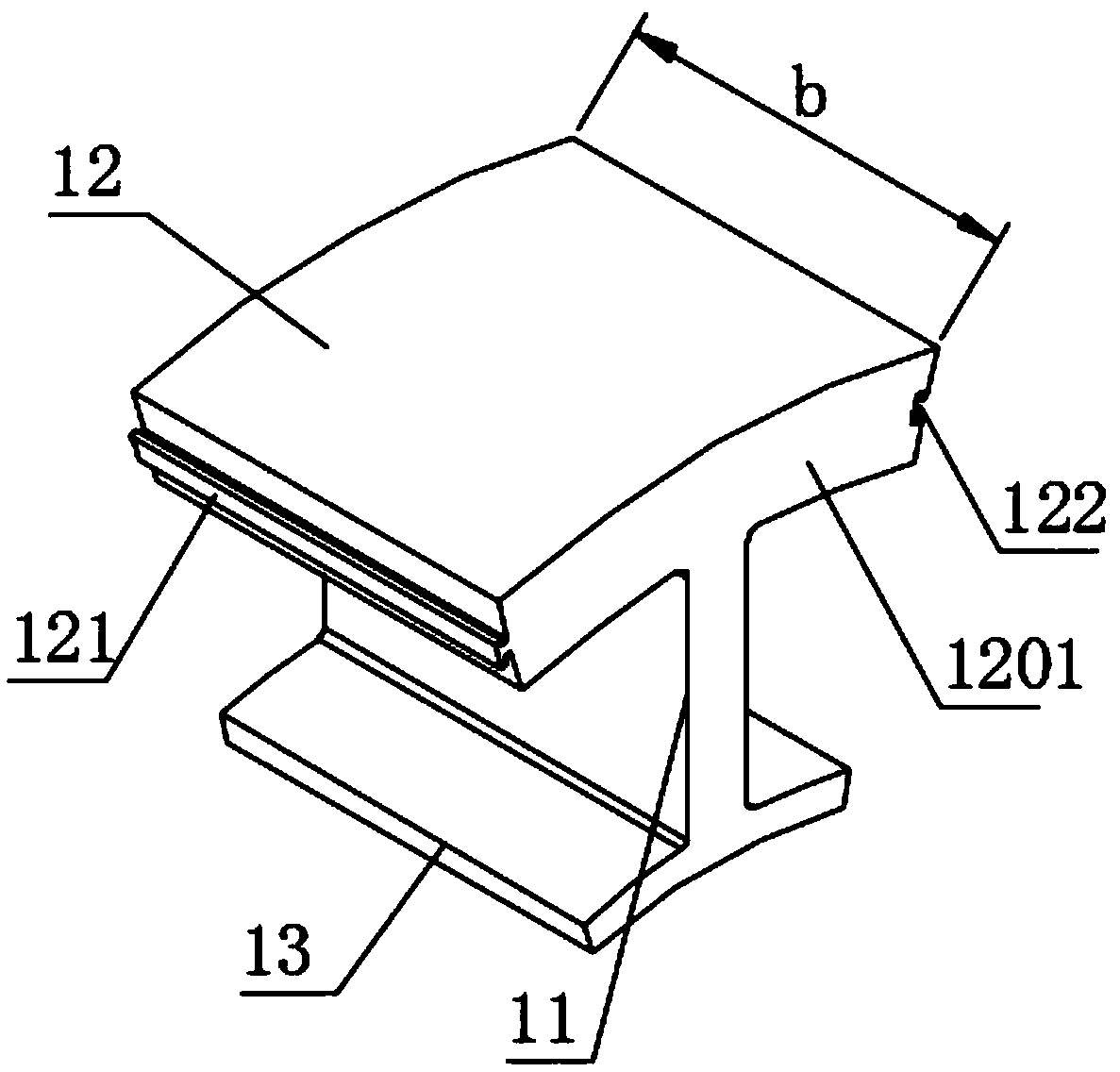

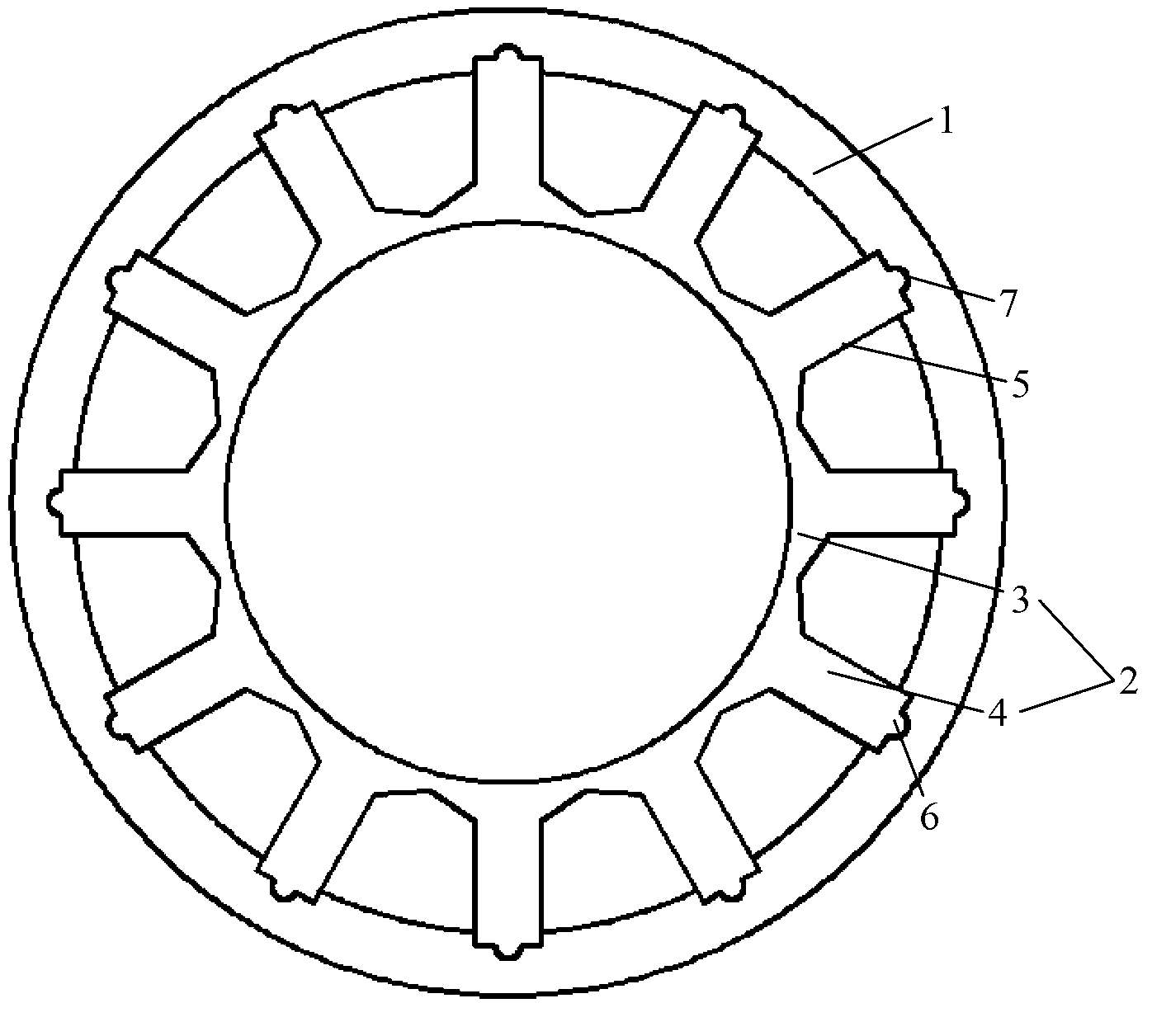

A lobe split combination stator

PendingCN109245346ASmall sizeReduce vibrationMagnetic circuit stationary partsWindings conductor shape/form/constructionRelative VolumeStator coil

A lobe split combination stator includes an annular expansion sleeve, an annular stator iron core formed by a plurality of sector iron core units connected in series with each other, the middle of both sides of the sector core unit is provided with grooves, the two sides of the lower part of the sector-shaped iron core unit are respectively provided with a tenon and a tenon groove, As that two adjacent sector core unit are are inlaid with each other to form an annular stator core through the tenon, and grooves;, the stator coil windings with several turns are wound on the grooves of each sector-shaped iron core unit by wires, and then adjacent sector-shaped iron core units are embedded together to form an annular stator core wound with the stator coils, and the annular expansion sleeve interference mosaic is embedded into the combined annular stator core inner hole. Compared with the prior art, The invention has the advantages that the stator notch need not be very large, the slot full rate is high, the relative volume of the motor is small, the enameled wire can be effectively avoided from touching the notch, the material utilization rate is high, the torque ripple and the noiseare low.

Owner:GUANGDONG HEPU POWER TECH

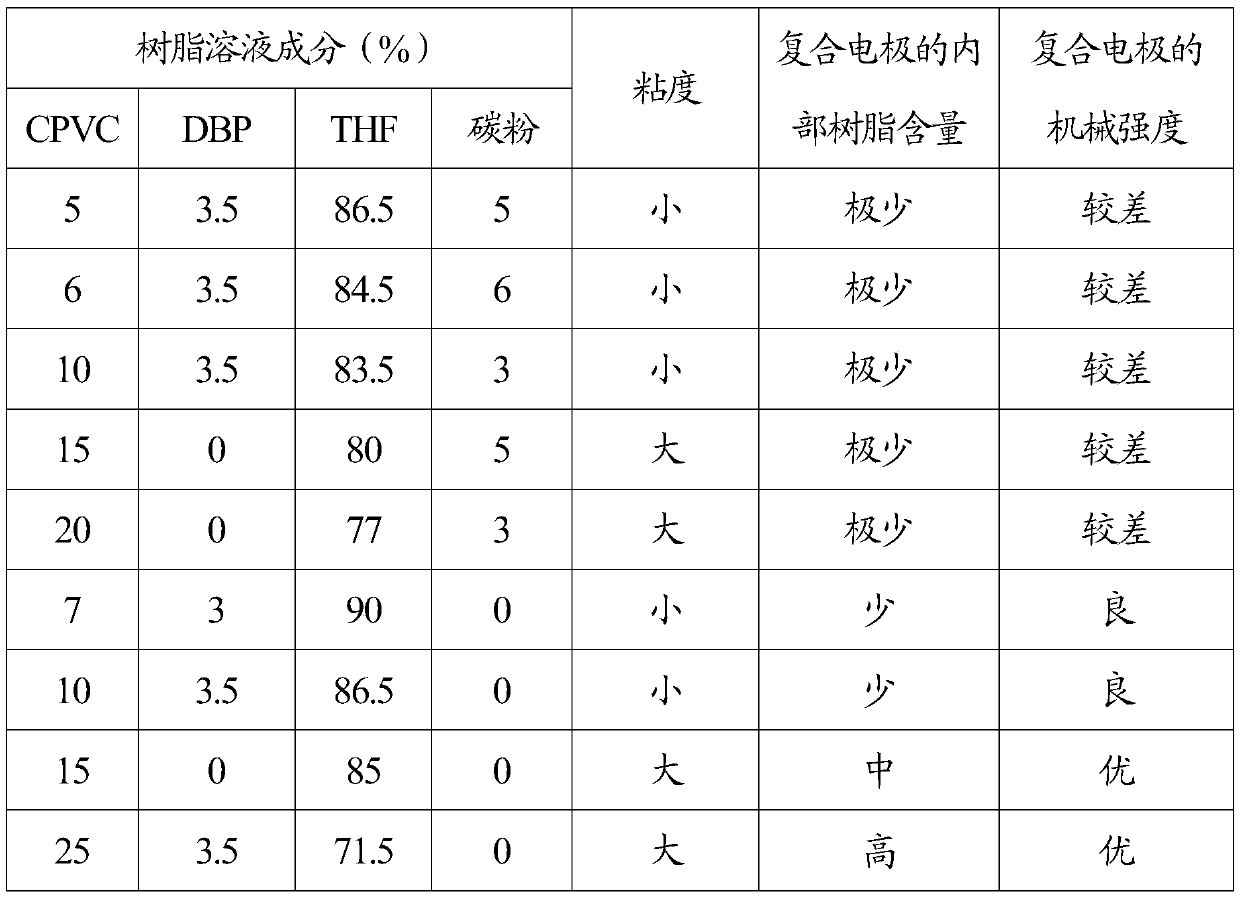

Preparation method of composite electrode of flow battery

InactiveCN111525149AImprove performanceIncrease internal resin contentRegenerative fuel cellsComposite electrodeConductive materials

The invention discloses a preparation method of a composite electrode of a flow battery. The preparation method comprises the following steps: dissolving thermoplastic resin in a solvent I to preparea resin solution; putting the porous conductive material layer into a resin solution for vibration impregnation, so that pores of the porous conductive material layer are filled with the resin solution to obtain an intermediate product I; removing the resin solution on the surfaces of the two sides of the porous conductive material layer of the intermediate product I to obtain an intermediate product II; removing the solvent I from the intermediate product II to obtain an intermediate product III; and coating conductive agents on the surfaces of the two sides of the porous conductive materiallayer of the intermediate product III, and then heating and pressurizing the intermediate product III to obtain the composite electrode. The pores of the porous conductive material layer can be effectively filled with the resin, meanwhile, the resin covering the surface of the porous conductive material layer is reduced, the mechanical strength of the composite electrode is improved, the resistivity is effectively reduced, and the performance of the flow battery is effectively improved.

Owner:乐山创新储能技术研究院有限公司

Single-winding low-cost high-power-density permanent magnet motor

ActiveCN105207435ASimple off-line processLow costSynchronous machinesMagnetic circuit stationary partsPermanent magnet motorHigh power density

The invention discloses a single-winding low-cost high-power-density permanent magnet motor which is characterized by comprising a stator and a rotor, wherein the stator comprises a stator yoke composed of a stator back yoke and a plurality of stator slot yokes; a permanent magnet is arranged between the stator back yoke and each stator slot yoke; a stator tooth is arranged at each of the two ends of each stator slot yoke; an armature slot is formed between every two stator teeth; a set of armature winding is arranged in each armature slot; the rotor comprises a plurality of rotor teeth; a rotor slot is formed between every two adjacent rotors; a main air gap is formed between each rotor tooth and the corresponding stator teeth. The single-winding low-cost high power-density permanent magnet motor is simple in manufacturing technique and low in cost.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com