Fastening structure for split stator iron core

A stator core and fastening structure technology, applied in the direction of magnetic circuit shape/style/structure, manufacturing stator/rotor body, manufacturing motor generator, etc., can solve the problems of low material utilization rate, inability to assemble, motor noise, etc. , to achieve the effect of reducing mold investment cost, convenient operation and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

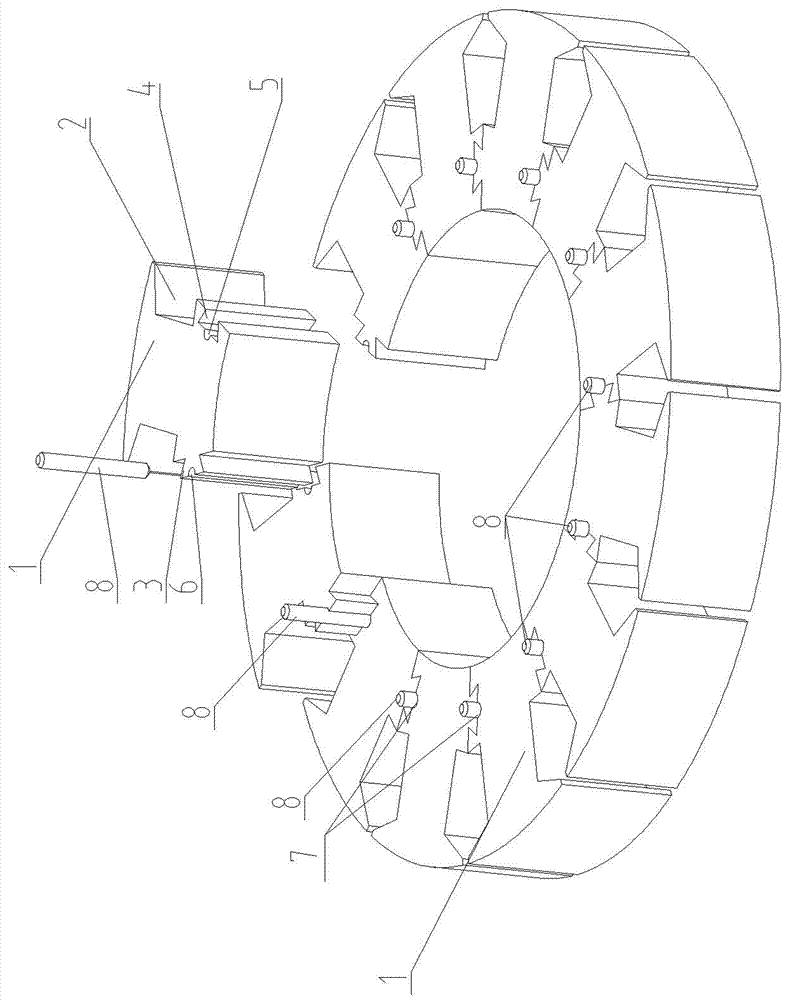

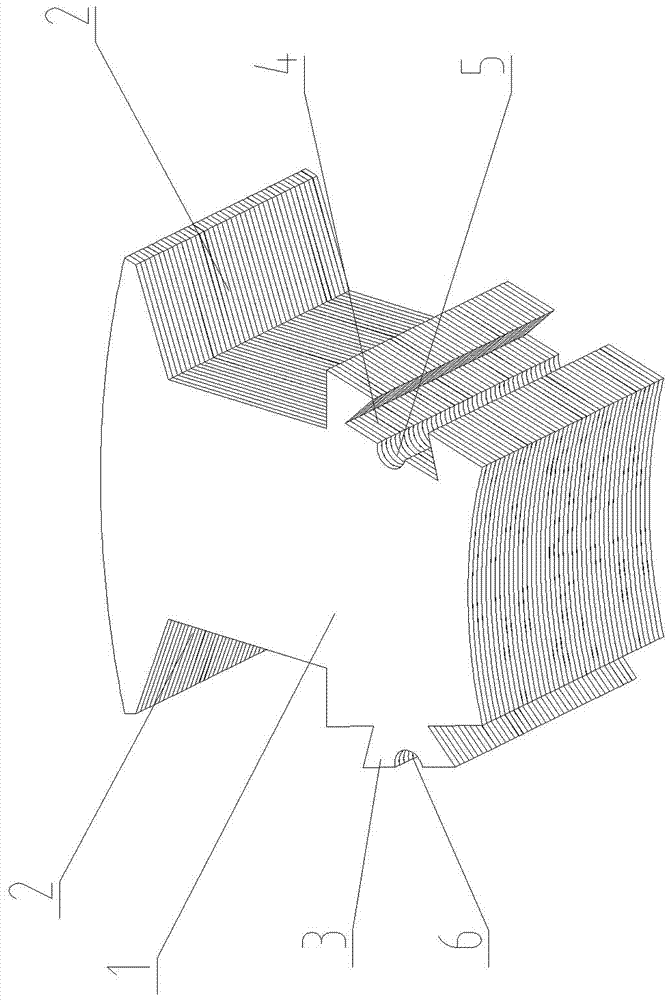

[0021] Embodiment 1: As shown in the figure, the present invention includes several fan-shaped core units 1 connected in series to each other to form a ring-shaped stator core. The upper parts of the fan-shaped core units 1 are provided with grooves 2, and the fan-shaped core units 1 The lower parts of both sides are provided with dovetail-shaped tenons 3 and dovetail-shaped tenon grooves 4 respectively. Two adjacent fan-shaped iron core units 1 are connected by the tenons 3 and tenon grooves 4 embedded together. The two adjacent fan-shaped iron core units 1 The grooves 2 are butted to form a slot for winding the stator coil. The fan-shaped core unit 1 is composed of several laminated punches. The notches 6 and 5, the columnar notch 6 of the tenon 3 and the columnar notch 5 of the tenon groove 4 connect to form a cylindrical hole 7, and a cylindrical wedge 8 is embedded in the columnar hole 7 for interference.

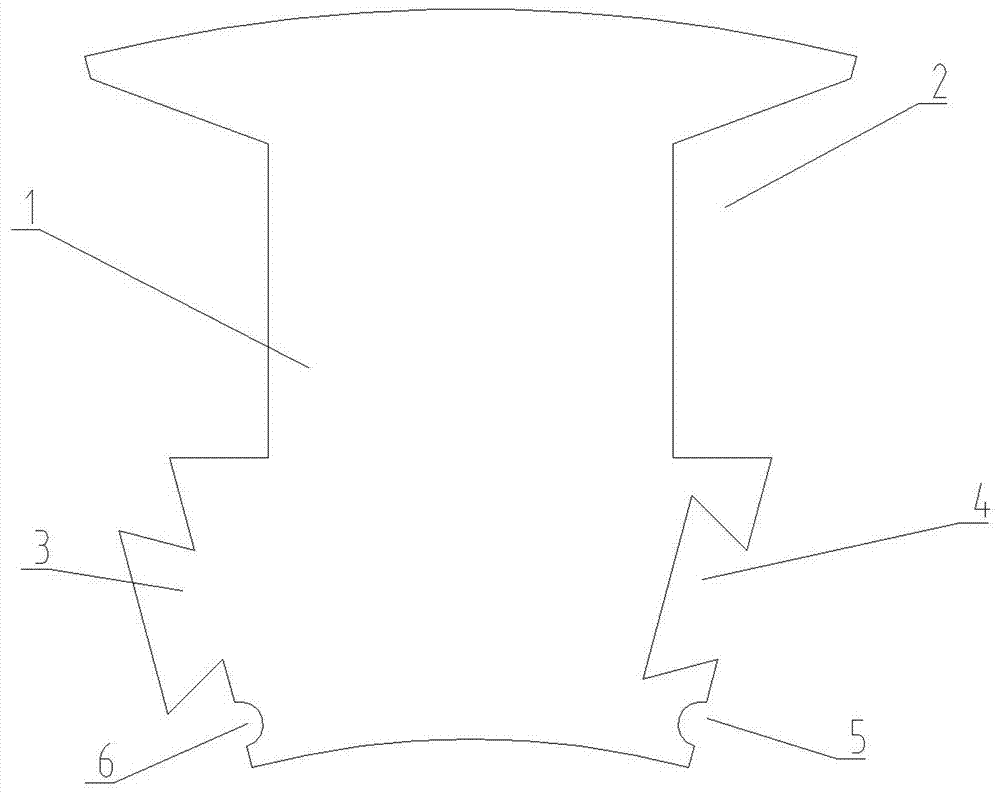

[0022] The cross-section of the columnar hole is one of circular,...

Embodiment 2

[0023] Embodiment 2: as image 3 As shown, the semicircular columnar notches 6 and 5 are respectively provided on the connecting surfaces of two adjacent fan-shaped iron core units 1 except the tenon 3 and the tenon groove 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com