High-reliability permanent-magnet fault-tolerant steering motor

A permanent magnet fault-tolerant, steering motor technology, applied in the direction of motors, magnetic circuit rotating parts, magnetic circuits, etc., can solve the problems of long switching time, double-winding motors cannot realize the simultaneous operation of high and low voltage windings, and achieve short switching time, The probability of phase-to-phase short-circuit fault is small, and the weakening effect of cogging torque is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

[0027] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

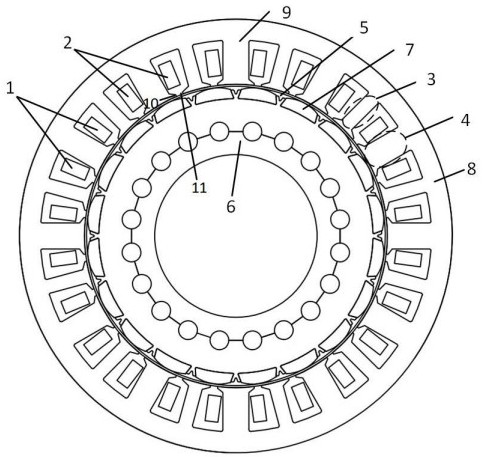

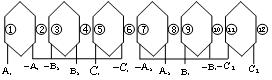

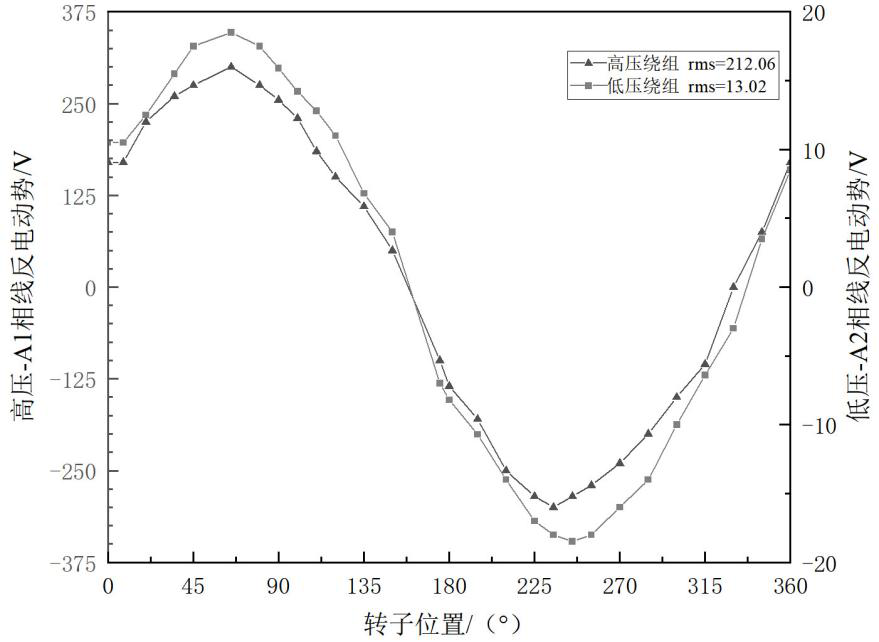

[0028] Such as figure 1 Shown is a schematic diagram of the structure of a highly reliable permanent magnet fault-tolerant steering motor. The motor adopts 20 poles and 24 slots, high-voltage side winding 1, low-voltage side winding 2, fault-tolerant teeth 3, armature teeth 4, and rotor core 5 with dovetail slots The rotor 6 adopts a semi-embedded SPM topological structure, and the rotor adopts a segmented method. The number of rotor segments is 3 segments, each segment is 30mm, and the stagger angle of adjacent segments is 0°. The rotor inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com