Powder/granular material feeding device

A technology for supplying devices and powders, which is applied in animal feeding devices, packaging, loading/unloading, etc., can solve the problems of poor supply accuracy, low filling performance, and easy adhesion of materials, so as to suppress the deviation of weight value, Effects of defect suppression and manufacturing cost suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, the powder or granular material supply apparatus which concerns on embodiment of this invention is demonstrated based on drawing. In addition, the embodiment shown here is just an example, and this invention is not limited to these embodiment. In addition, in the following description, in a discharge part, the direction which conveys a powder or granular body is called front.

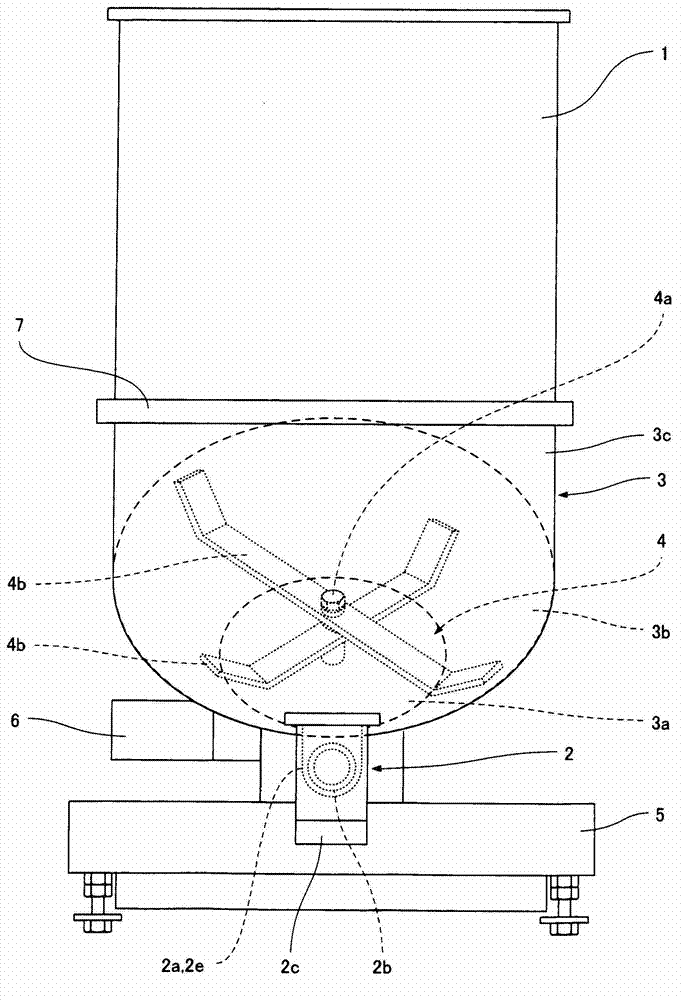

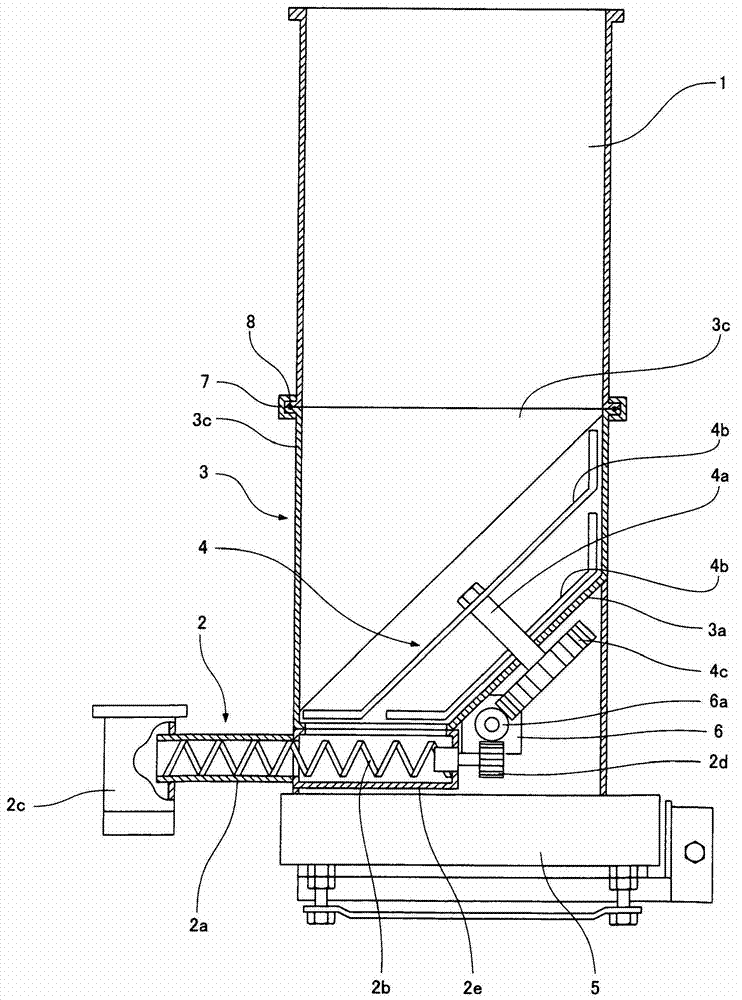

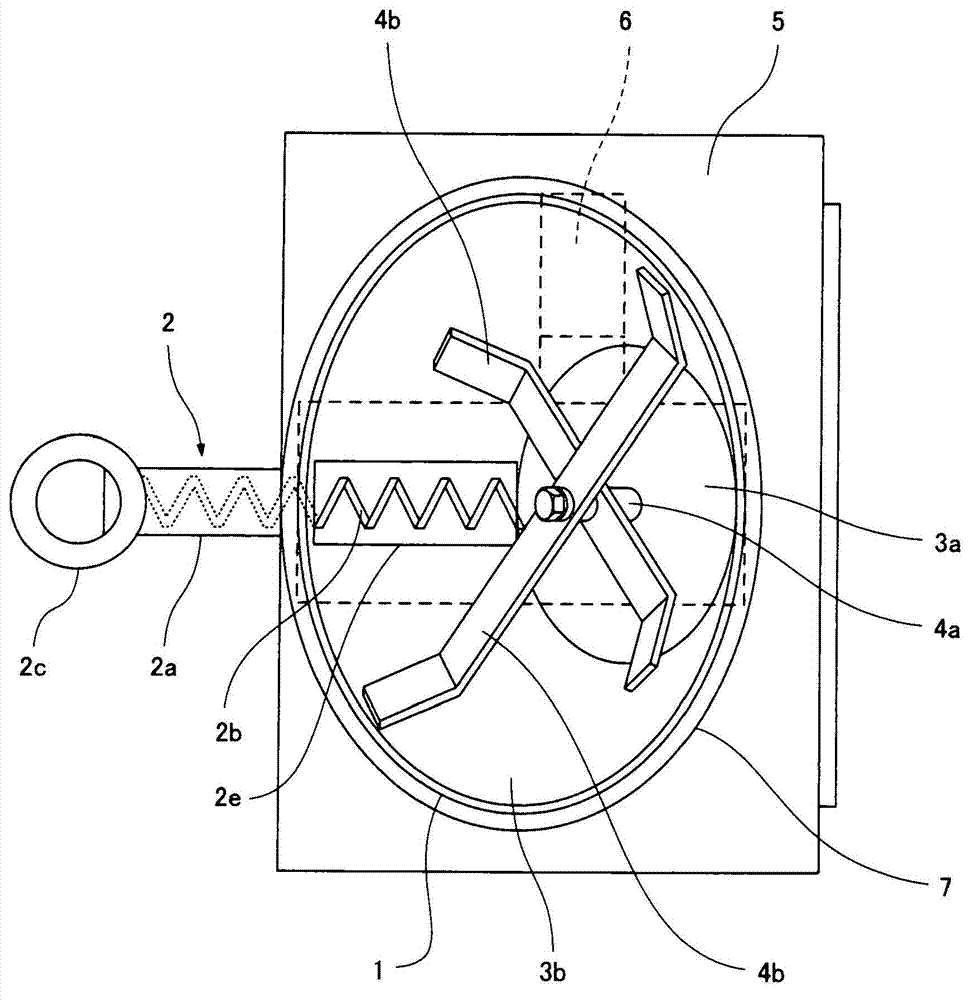

[0066] like Figure 1 to Figure 5 As shown, the powder or grain supply device according to the first embodiment of the present invention has: a hopper 1 into which the powder or grain is thrown; a discharge part 2 for discharging the powder or grain; Tank 3; Stirring part 4, the stirring member 4b of which rotates around the axial center part 4a protruding from the state inclined upward from the lower part in the chute 3 as the center; Measuring part 5 on which they are placed; Not shown control department etc. In addition, although not shown, a cover is placed on the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com