Electric compressor motor stator and manufacturing method thereof

A technology of electric compressors and motor stators, applied in the manufacture of motor generators, electromechanical devices, electric components, etc., can solve the problems of increased motor vibration and noise, low stator slot fullness, and reduced work efficiency, so as to reduce vibration and noise, reduce cogging torque, and improve winding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing this patent is described further.

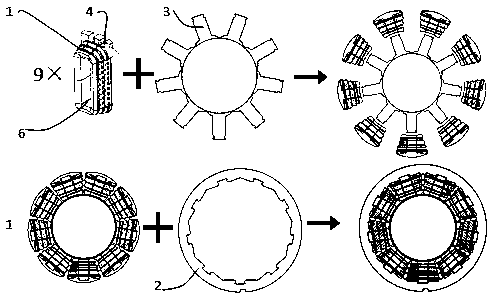

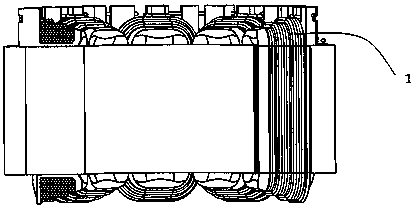

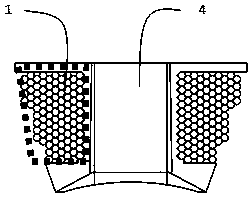

[0026] Such as Figure 1~Figure 8 As shown, an electric compressor motor stator, its structure includes a stator winding 1, a stator yoke 2, a stator tooth 3, a stator skeleton 4, and a stator coil 6; wherein the bottoms of nine stator teeth 3 are connected to each other to form The distance between each stator tooth part 3 on the ring is the same, and the outer part of the stator tooth part 3 is covered with a circular stator yoke part 2; each stator tooth part 3 is provided with an independent stator Coils 6 , each independent stator coil 6 is formed by winding three turns of stator winding 1 on one stator skeleton 4 .

[0027] The number of the stator teeth 3 is 9, and each stator tooth 3 includes a tooth 30, a bridge 31, a tooth root 32, a tooth crown 33, and a tooth 34; wherein the top of the tooth 30 is provided with a tooth root 32, and the teeth Both sides of the root 32 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com