Patents

Literature

61results about How to "Good softness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dip-forming composition, dip-formed article and process for making same

InactiveUS20050171272A1Good softnessHigh tensile strengthSpecial tyresEmulsion paintsKetoneWater soluble

A dip-forming composition comprising a conjugated diene rubber latex prepared by copolymerizing 30-90 wt. % of a conjugated diene monomer, 0.1-20 wt. % of an ethylenically unsaturated acid monomer and 0-69.9 wt. % of other copolymerizable ethylenically unsaturated monomer, wherein a copolymer constituting the conjugated diene rubber latex exhibits a content insoluble in methyl ethyl ketone of not larger than 30 wt. % at a latex pH value of 10, and the dip-forming composition has a pH value of at least 8.5 and is substantially free from a sulfur-containing vulcanizer, a vulcanization accelerator for the sulfur-containing vulcanizer, and zinc oxide. A dip-formed article made therefrom, which has been crosslinked with a water-soluble polyvalent metal salt used as a coagulant for latex, has an extremely reduced number of pinholes, good softness to touch, high tensile strength and high fatigue resistance to repeated use.

Owner:ZEON CORP

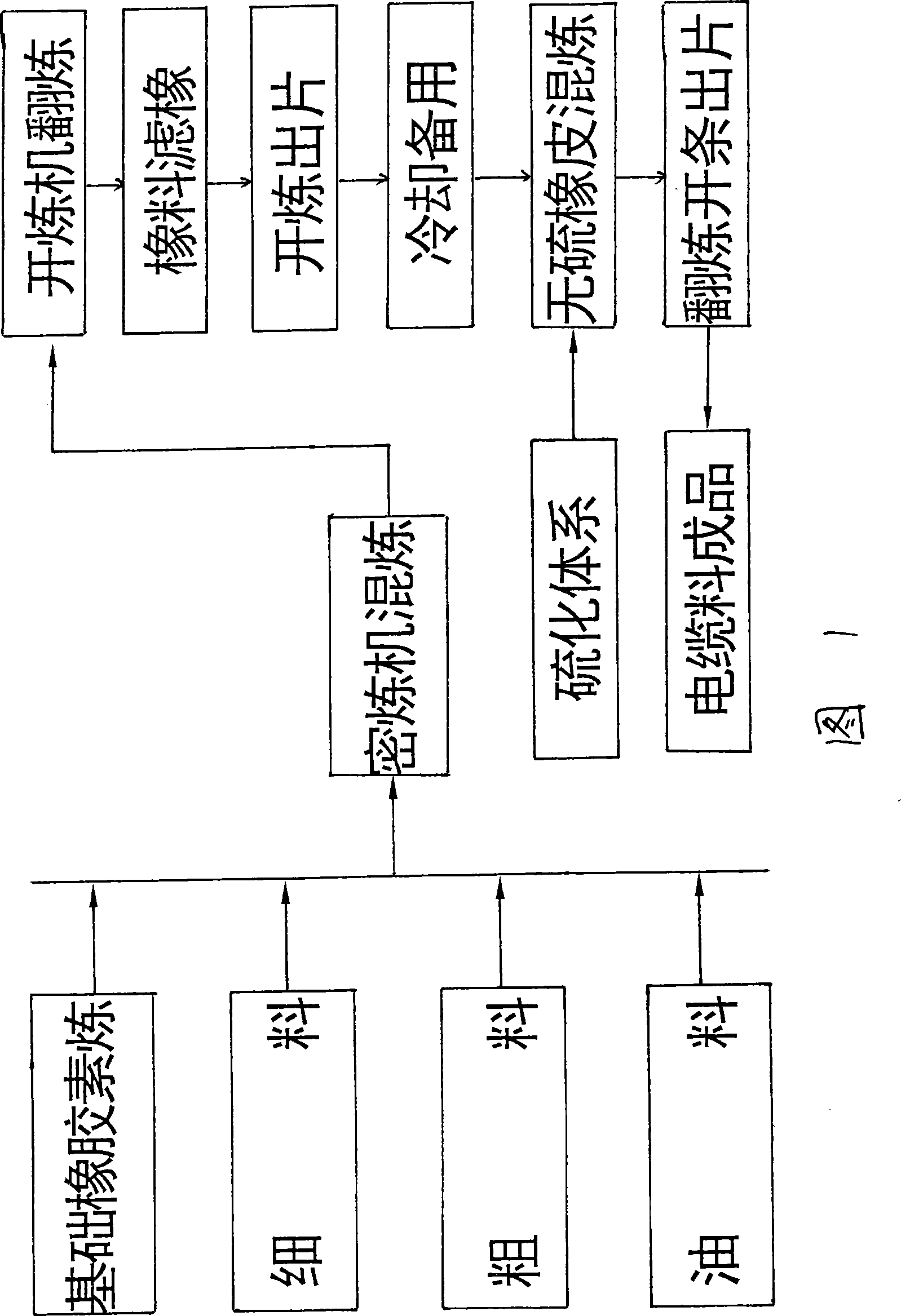

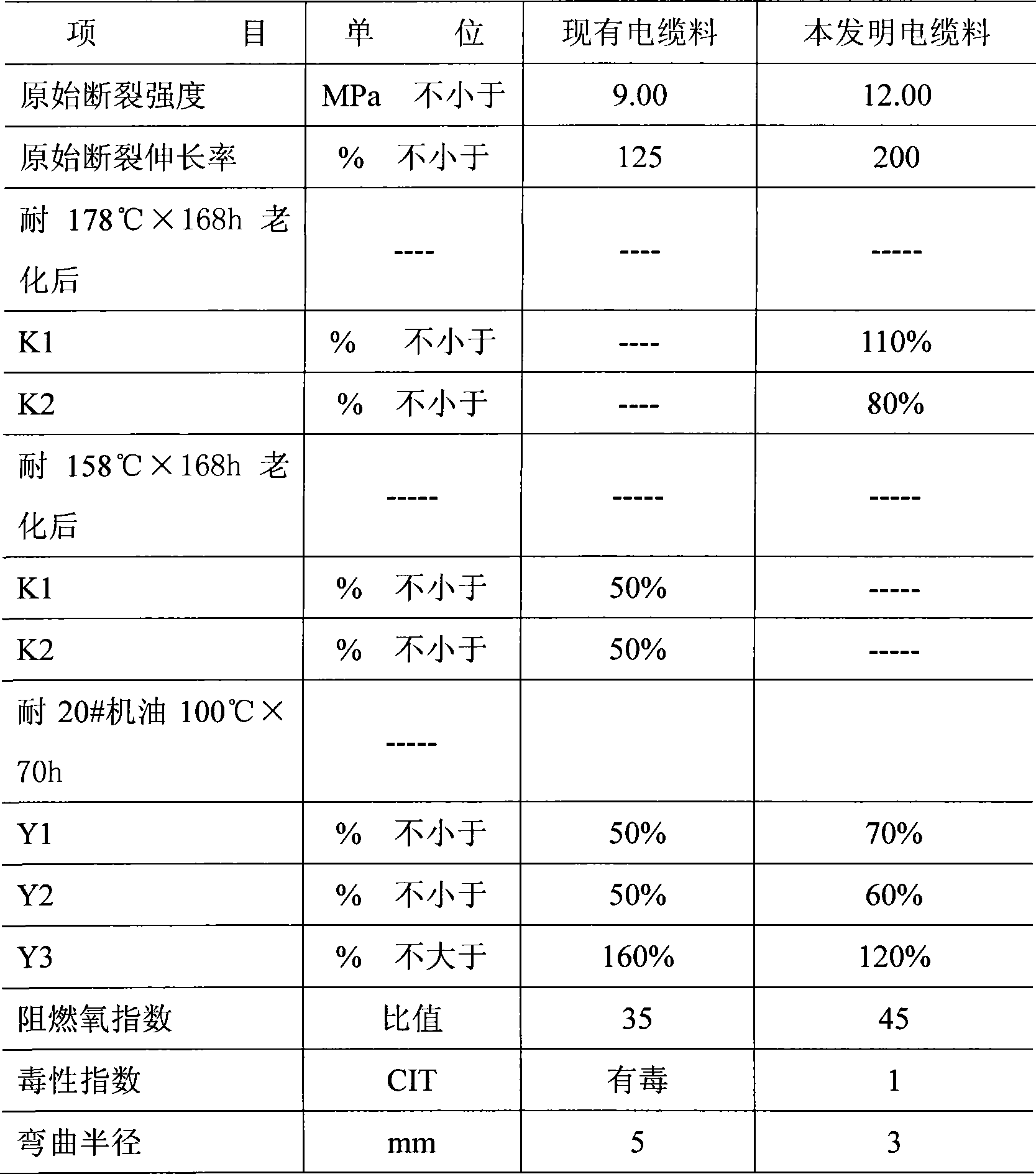

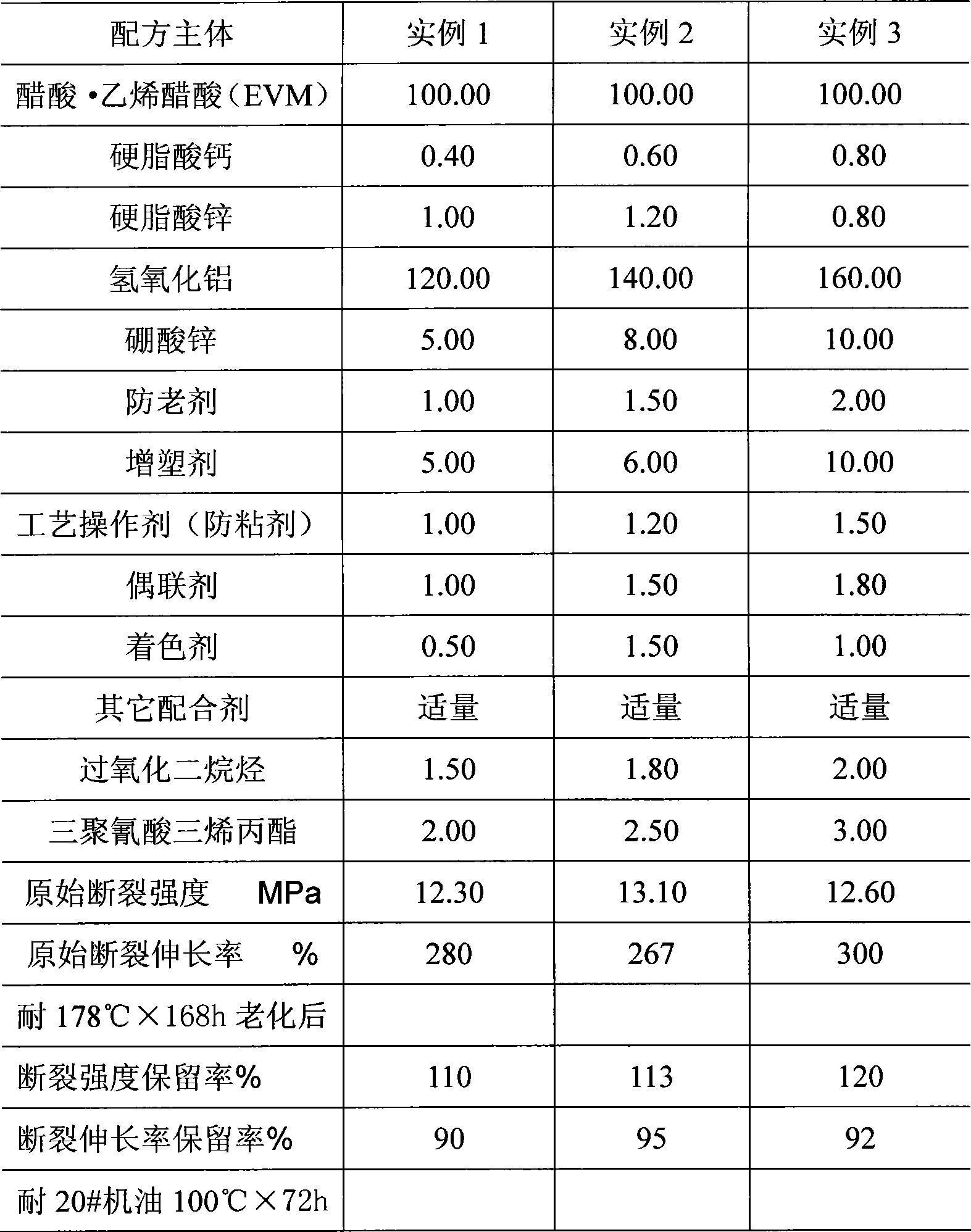

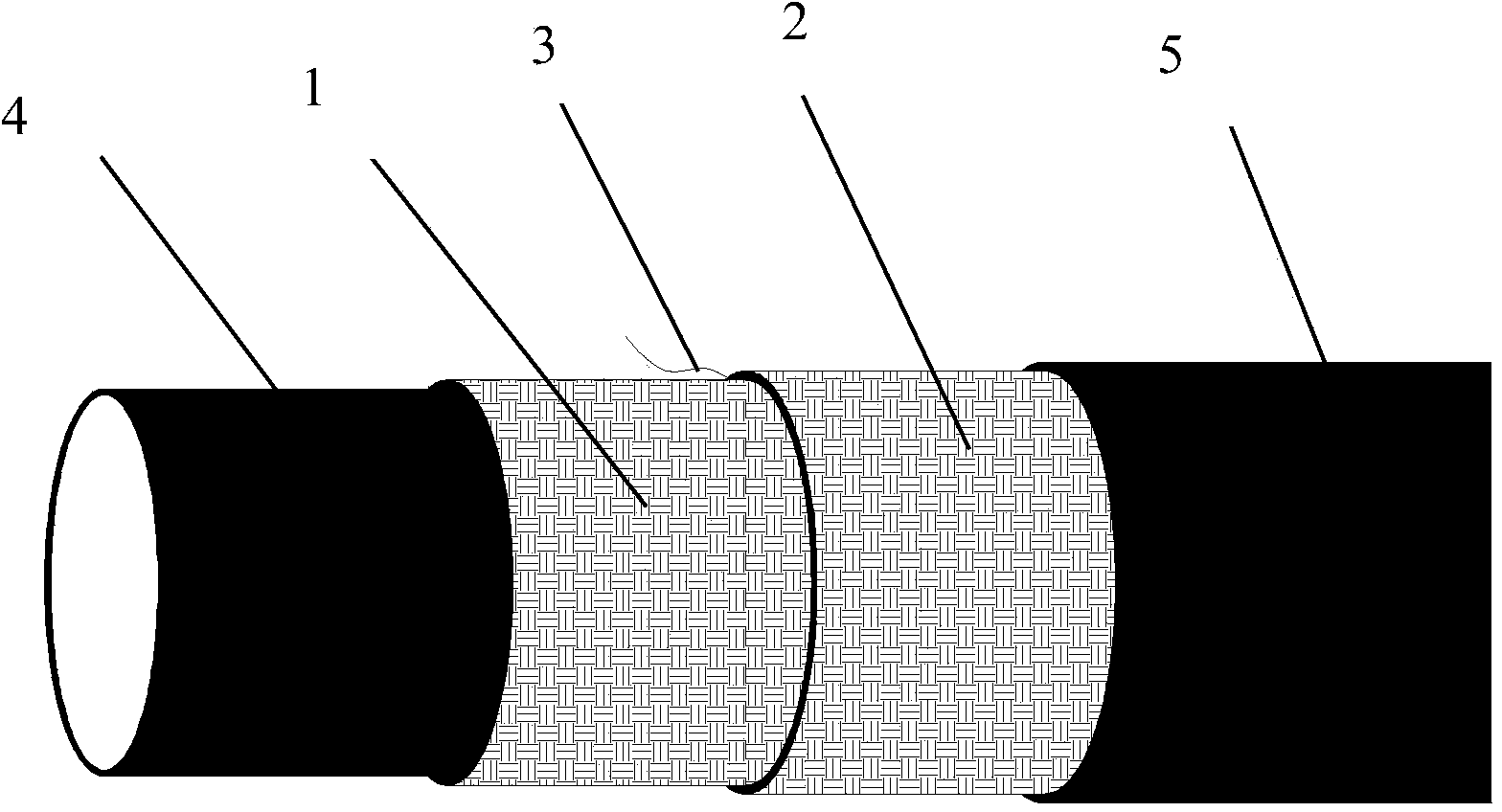

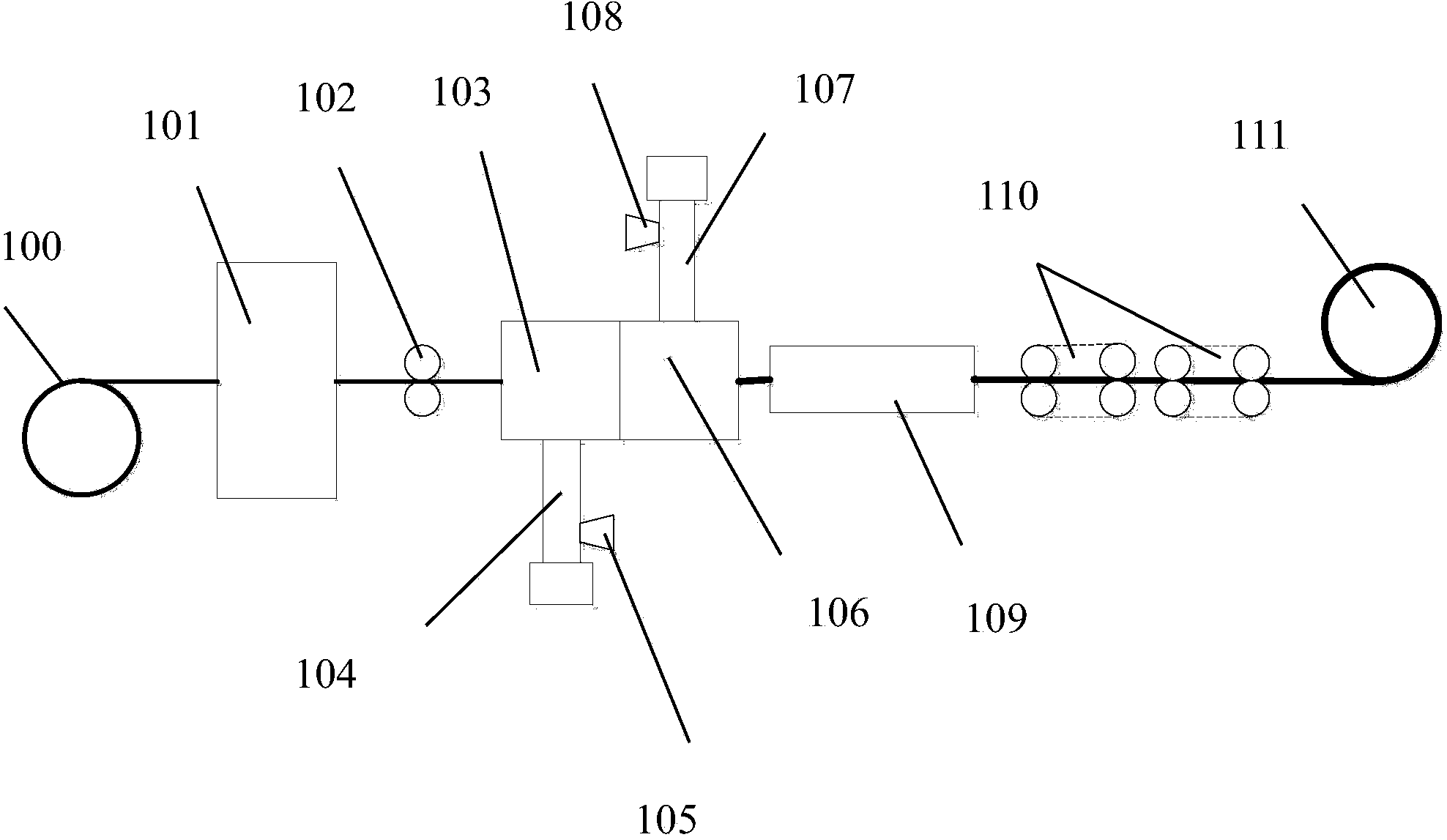

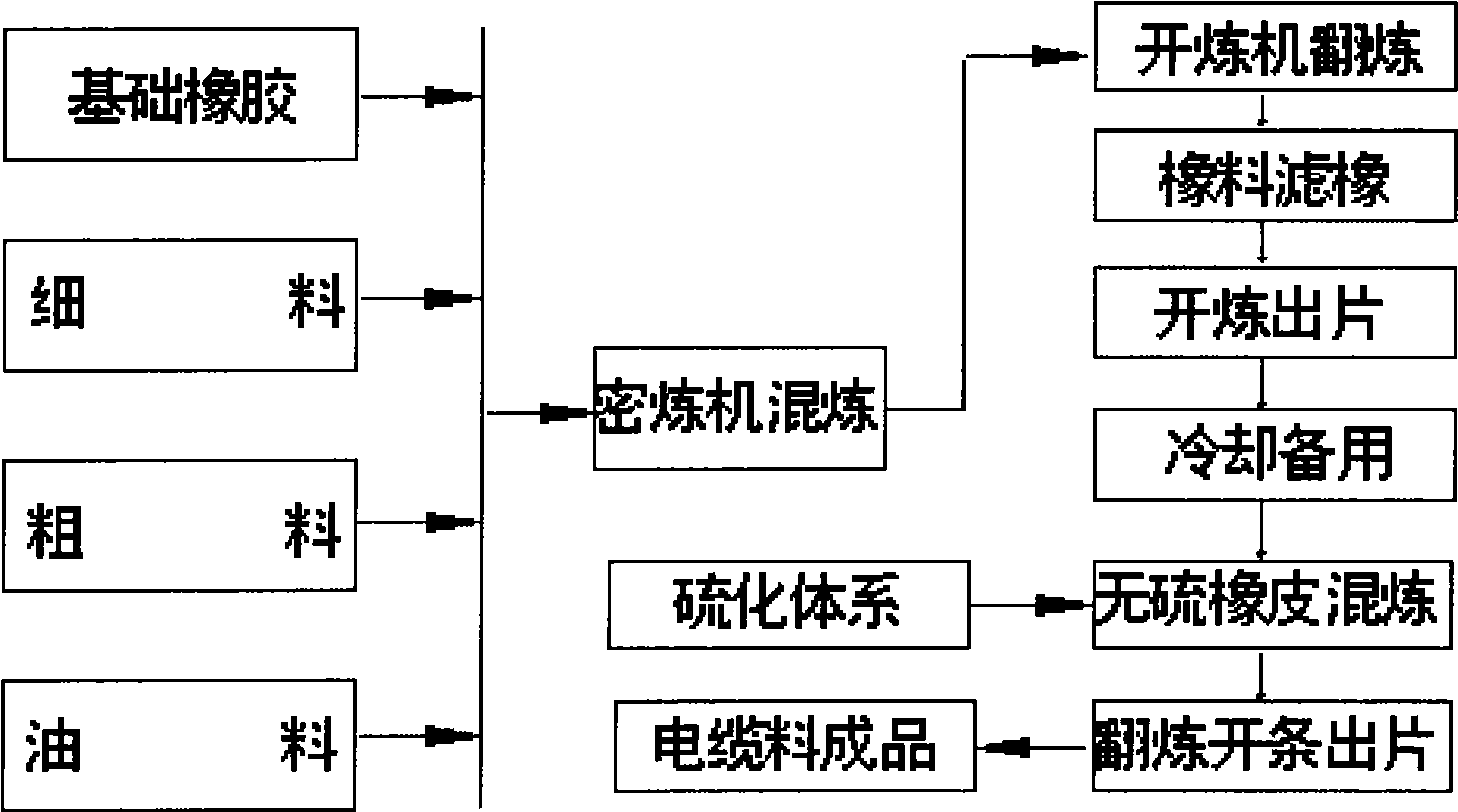

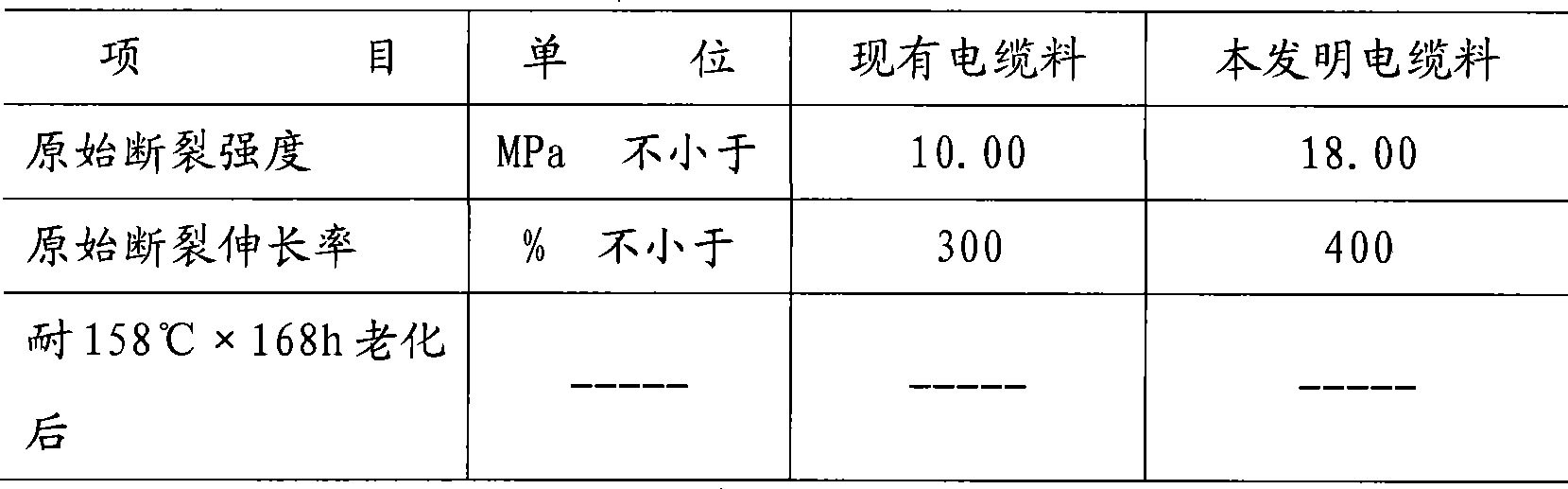

scable material for high-strength and ultra-soft oil-proof rubber elastic body, and preparation method thereof

InactiveCN101445630APromote environmental protectionGood softnessPlastic/resin/waxes insulatorsElastomerFuel oil

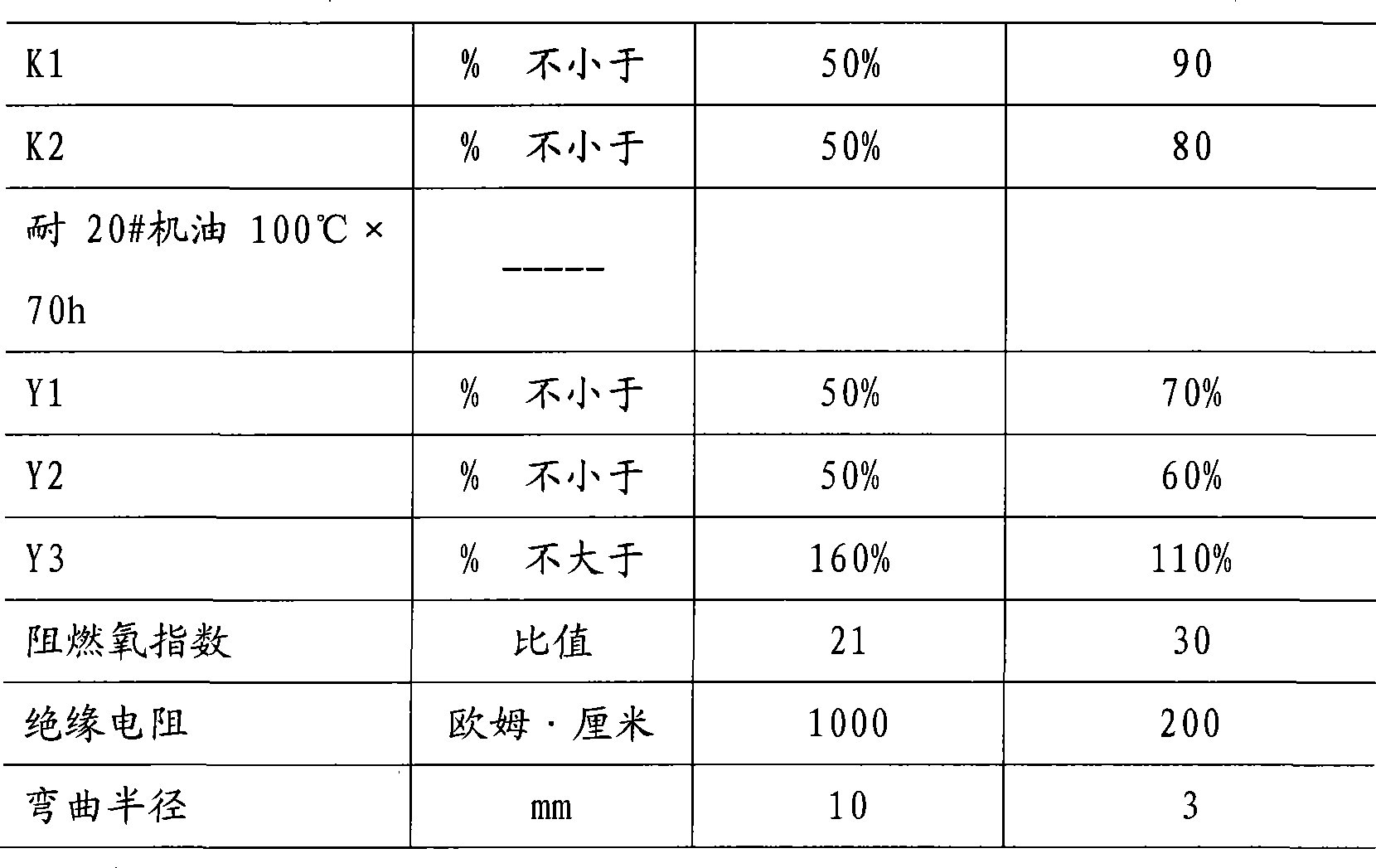

The invention provides a cable material for 140 DEG C high-temperature resistant, high-strength and ultra-soft oil-proof rubber elastic body, and a preparation method thereof. The invention is characterized in that the polar ethylene, the vinyl acetate (EVA) and the environmental-friendly high molecular material are taken as the foundational rubber formula, and the corresponding curing system is added with environmental-friendly aluminum hydroxide, boron-zinc flame retardant, calcium or zinc stabilizer, high-temperature resistant silicone oil plasticizer, and the like, therefore, the cable material for the rubber elastic body is formed. The cable material has the characteristics that the cable material is 140 DEG C high-temperature resistant and mineral oil and fuel oil resistant, and is ultra-soft, conforms to the requirement of the railway motor train cable and provides convenience for the users of the railway motor train cable.

Owner:ANHUI ZONGHENG HI TECH CABLE +1

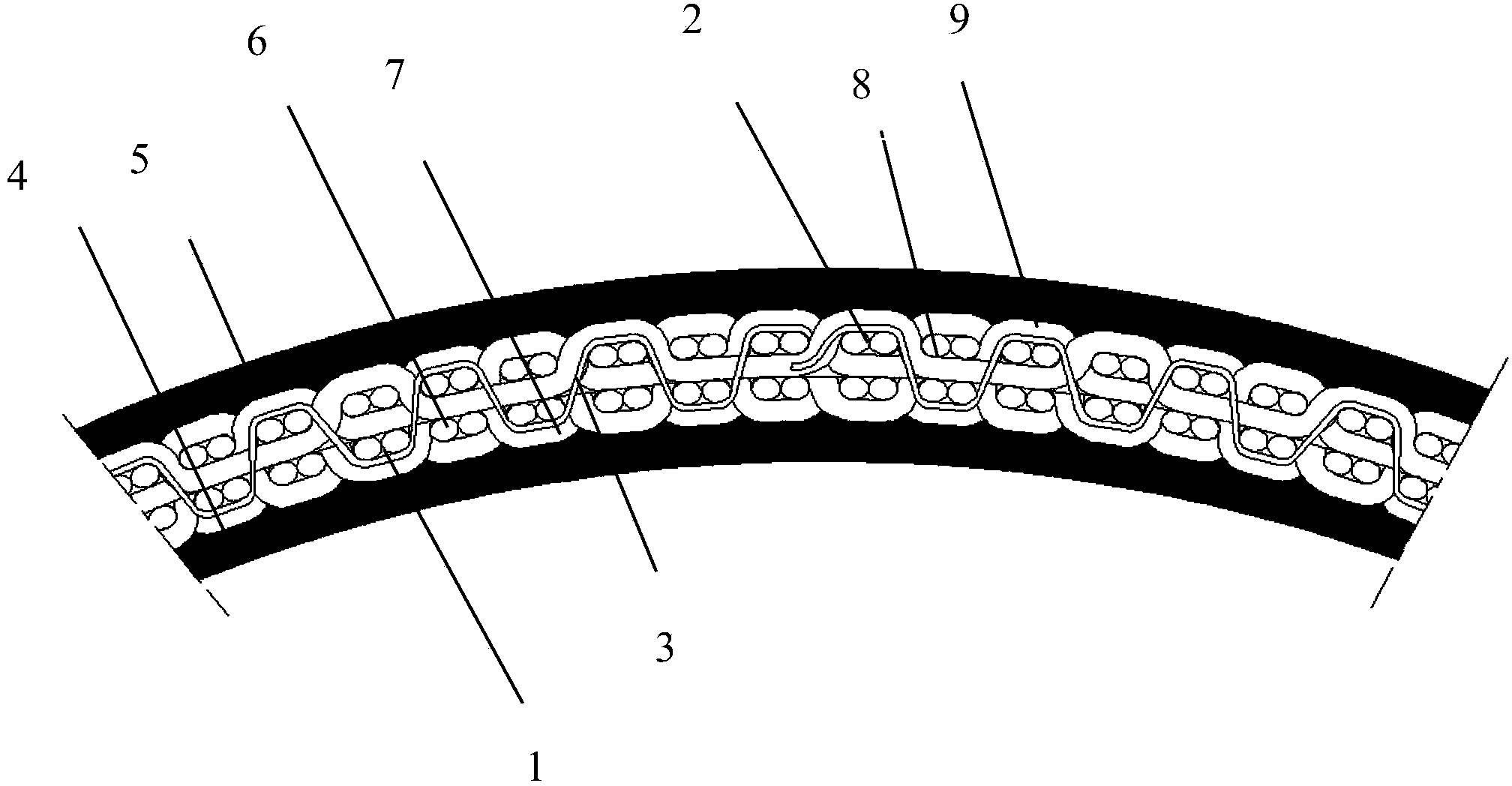

Hose capable of being flattened and manufacturing method thereof

InactiveCN104235530AIncrease delivery flowGood softnessFlexible pipesMulti-ply fabricsLiquid pressureWeft yarn

The invention discloses a hose capable of being flattened. The hose capable of being flattened comprises an inner rubber layer, an outer rubber layer and a cylindrical fabric layer which is positioned between the inner rubber layer and the outer rubber layer, wherein the inner rubber layer and the outer rubber layer are made of a thermoplastic polyurethane or polyvinyl chloride material; the cylindrical fabric layer comprises an outer enhancement layer and an inner enhancement layer; the outer enhancement layer and the inner enhancement layer are of independent plain, twill or satin weave structures which are formed by weaving warp yarns and weft yarns; the outer enhancement layer and the inner enhancement layer are bound by using the weft yarns. The invention also provides a manufacturing method of the hose capable of being flattened. The hose capable of being flattened can bear high conveying liquid pressure to further improve the conveying flow of the hose; the hose capable of being flattened has good softness under a storage condition and is convenient to coil or fold to store.

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA

125 DEG C resistance low smoke non-halogen rubber-sheathed cable shielding material

InactiveCN101544790AIt has the characteristics of green environmental protectionGood softnessShielded cableActive agent

The present invention discloses a 125 DEG C resistance low smoke non-halogen rubber-sheathed cable shielding material, including 100.00 shares of ethylene / ethylene acetic acid rubber, 60.00 to 100.00 shares of conductive carbon black, 40.00 to 60.00 shares of light calcium carbonate, 10.00 to 15.00 shares of plasticizer, 0.50 to 1.00 shares of active agent, 1.50 to 2.00 shares of anti-aging agent, 0.50 to 1.00 shares of technology operating agent, 1.50 to 2.00 shares of Di(tert-butylperoxyisopropyl)benzene, and 1.00 to 3.00 shares of triallyl isocyanurate. The rubber shielding cable material has characteristics of high temperature resistance, high conductivity, low smoke, non halogen, oil resistance, very plasticity and the like.

Owner:ANHUI ZONGHENG HI TECH CABLE +1

Inductance capacitance integrated structure implemented by flexible circuit board in EMI filter

InactiveCN101206947AGood softnessReduce volumeMultiple-port networksWound capacitorsMagnetic coreCopper foil

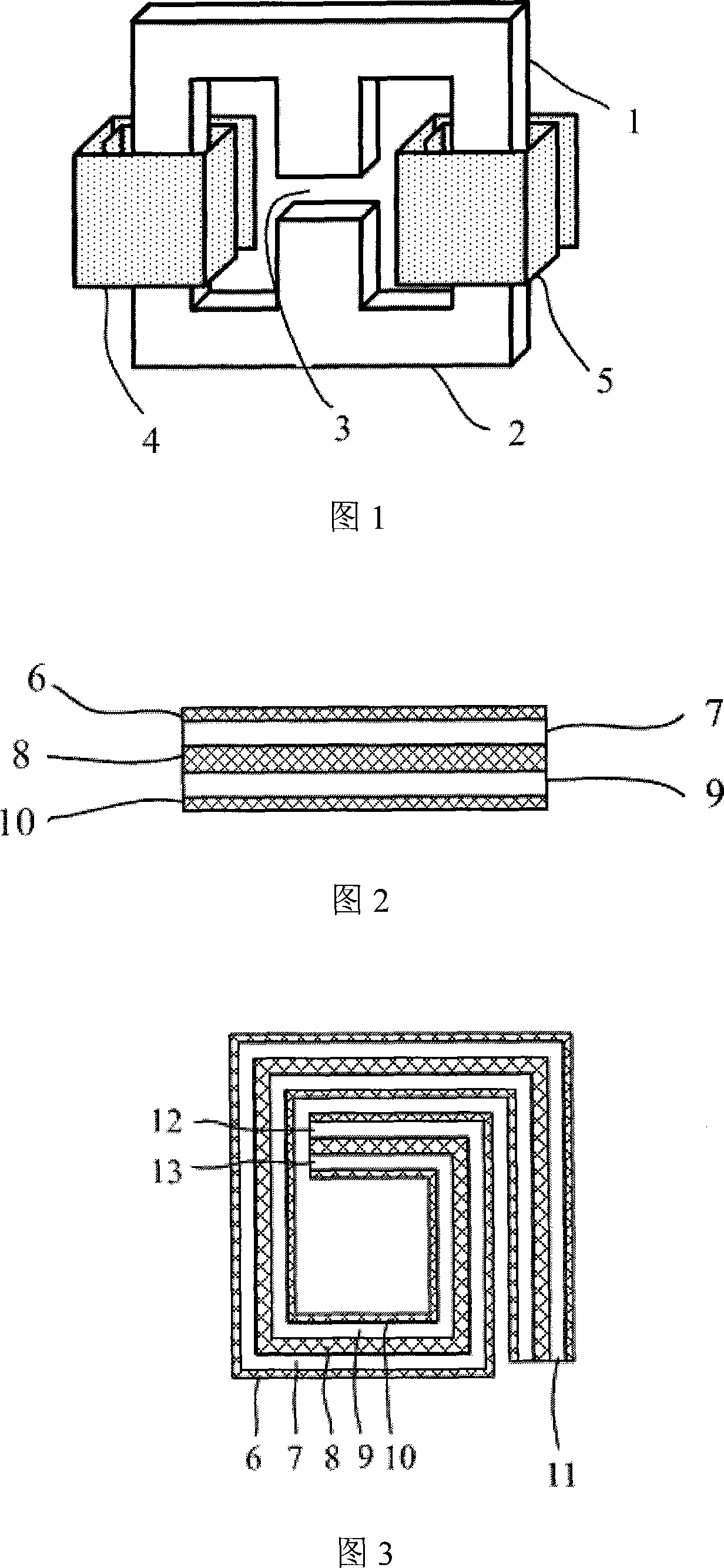

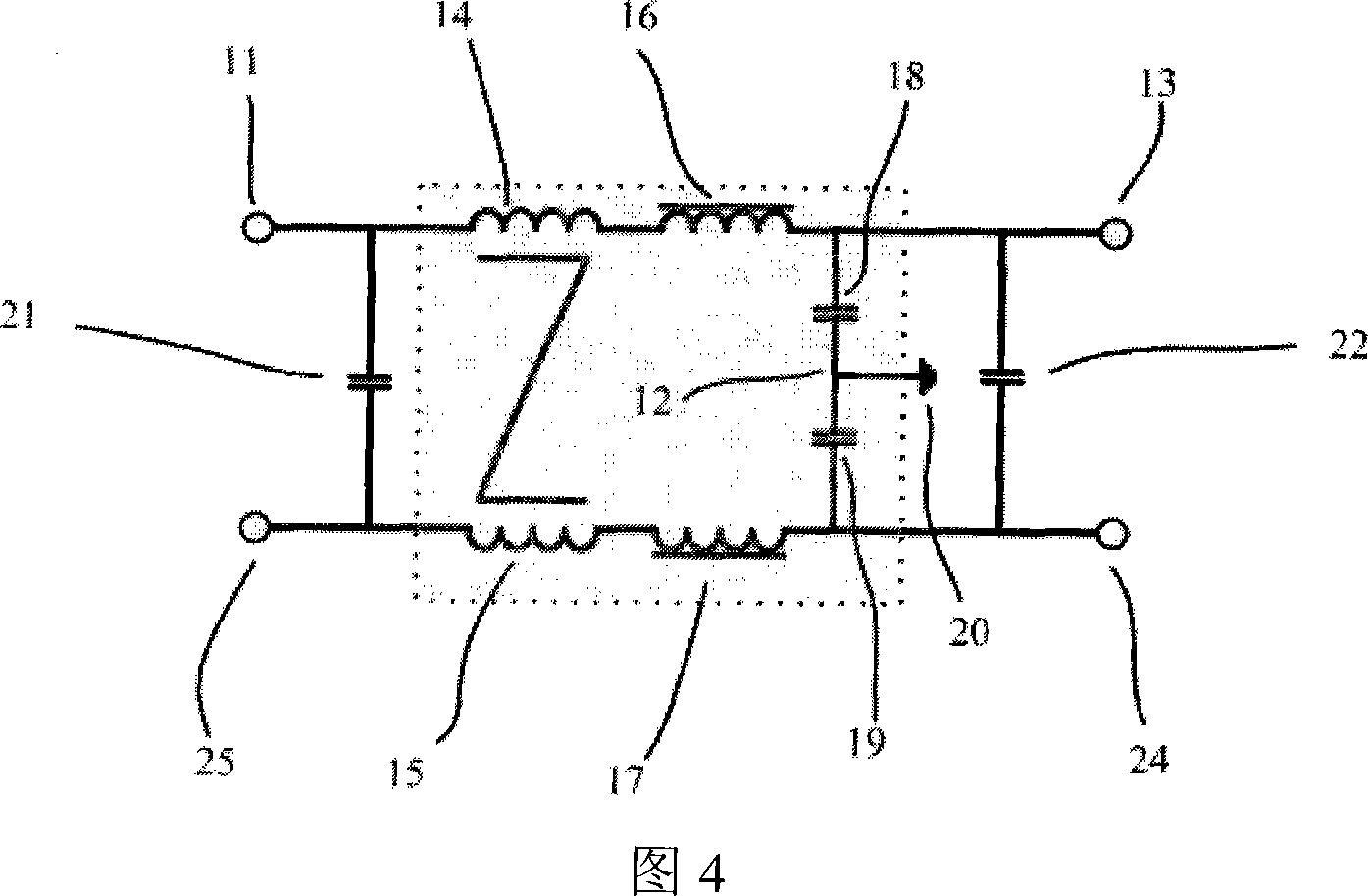

The invention discloses an integrated structure of an inducer and a capacitor in an EMI wave filter realized through a flexible circuit board, the integrated structure comprises a three magnetic core column closed magnetic circuit. An air gap is arranged on the middle magnetic core column of the closed magnetic circuit, a cylindrical dual-surface flexible circuit board is respectively wound on two side magnetic core columns and is composed of a first insulating layer, a first copper foil, an isolation medium layer, a second copper foil, and a second insulating layer which are overlapped. The first copper foil, the isolation medium layer and the second copper foil of the cylindrical dual-surface flexible circuit board form a common mode capacitor in the EMI wave filter, two cylindrical dual-surface flexible circuit boards form a common mode inductor in the EMI wave filter through a coupling inductor formed by the side magnetic core columns, two cylindrical dual-surface flexible circuit boards form a difference mode inductor in the EMI wave filter respectively through a magnetic circuit composed of the side magnetic core columns and the middle magnetic core column. The integrated structure of the inducer and the capacitor provided by the invention is favorable for decreasing the volume of the EMI wave filter, and improving the power intensity of a power electronic convertor.

Owner:ZHEJIANG UNIV +1

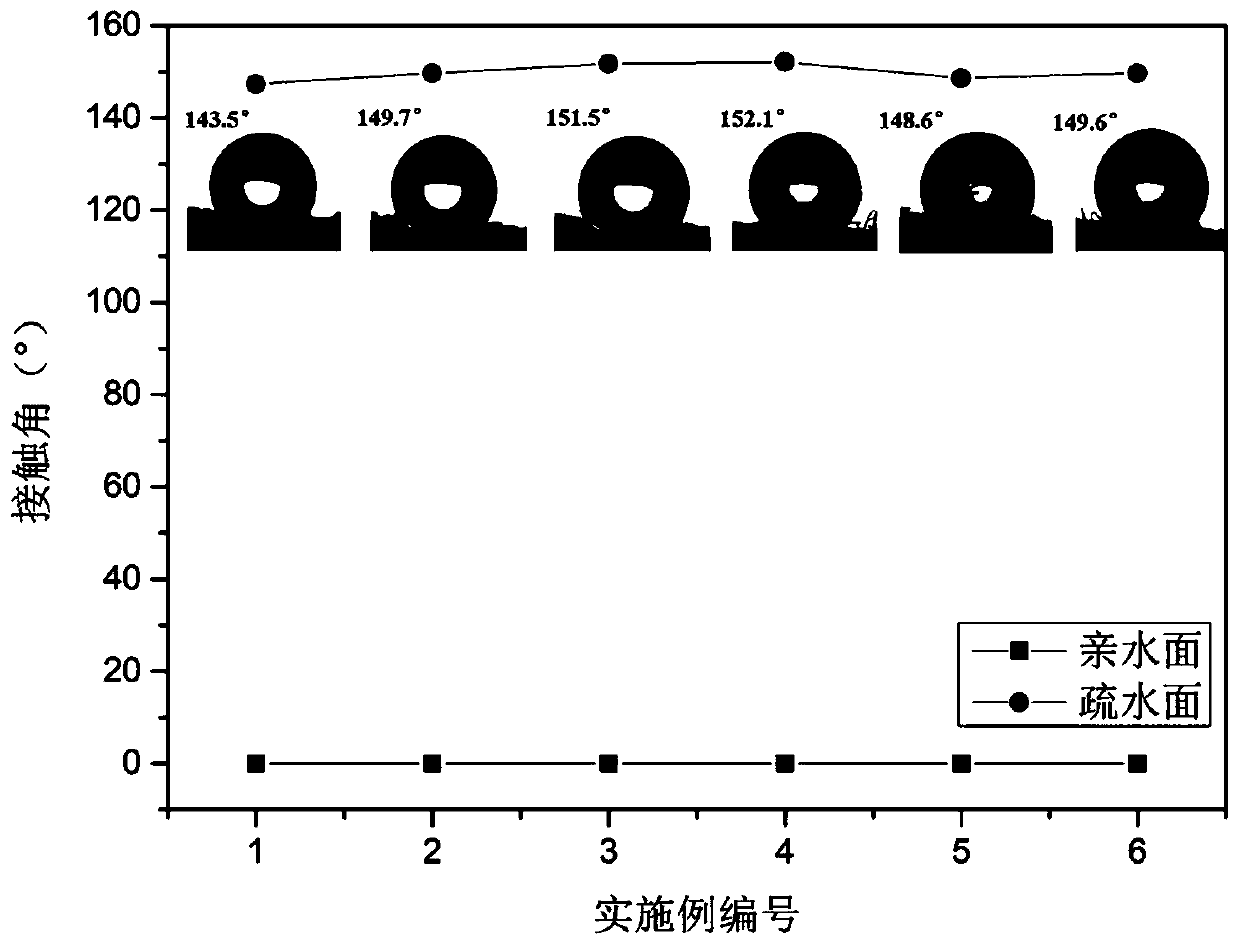

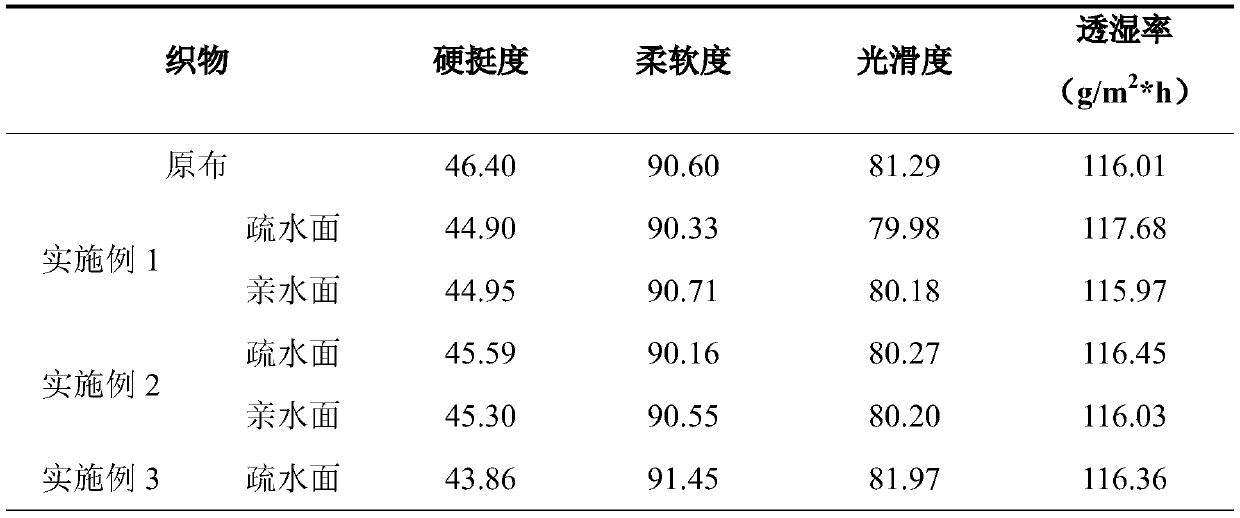

Making method of single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric

InactiveCN109706735AGood softnessGood performanceUltrasonic/sonic fibre treatmentVegetal fibresGlow dischargeWoven fabric

The invention relates to a making method of a fabric, in particular to a making method of a single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric and belongs to the field of textile function arrangement. The method comprises the following steps that 1, the fabric is cleaned and then dried for use; 2, the single face of the fabric is protected, under the condition of constantoxygen pressure intensity, plasma glow discharge treatment is conducted on the single face of the fabric, after oxygen is switched off, under the condition of constant steam pressure intensity of a grafting monomer, plasma glow discharge treatment is conducted again, and the single-face-super-hydrophobic and single-face-hydrophilic Janus-type fabric is obtained. According to plasma glow dischargetreatment, a cold plasma treatment instrument is used for generating plasma glow, the plasma treatment power is within 30-120 W, and the time is within 1-10 min. According to the method, the technology is simple and easy to control, the method is suitable for single-face treatment of various cotton fabrics and acetate fiber non-woven fabrics, the functionality demand is met, and the method also has good wearing performance.

Owner:ZHEJIANG SCI-TECH UNIV

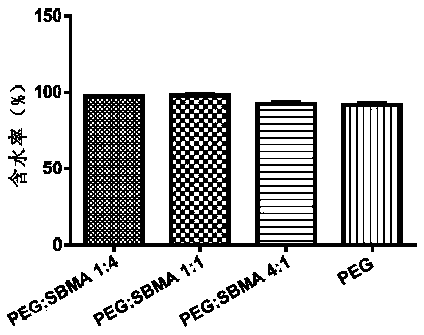

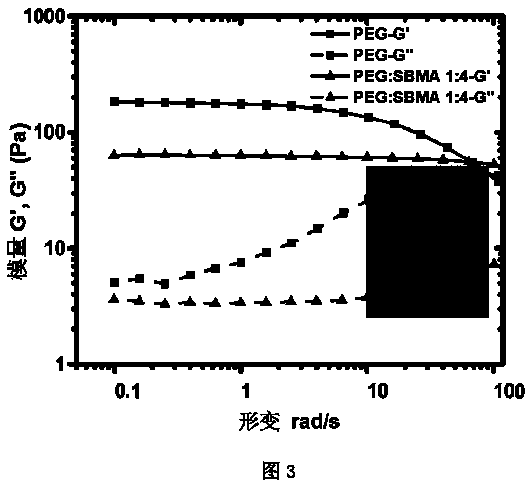

Composite hydrogel and preparation method thereof

InactiveCN105367712AGood antibacterial propertiesGood softnessPharmaceutical non-active ingredientsAbsorbent padsProtein proteinChemistry

The invention discloses a composite hydrogel and a preparation method thereof, which utilize polyethylene glycol dimethyl acrylic esters as cross-linking agents, utilizes 2-hydroxyl-4-(2-hydroxyl ethoxy)-2-methyl propiophenone as an initiator, utilizes [2-( methacryloyloxyethyl) ethyl] dimethyl-(3-sulfopropyl) ammonium hydroxide (SBMA)) and polyethylene glycol methacrylate (polyethylene glycol (PEG)) as monomer light to trigger crosslinking and compound hydrogel. The composite hydrogel with different network structures can be prepared by adjusting and controlling different radios of SBMA and PEG monomers, thereby supplying an appropriate environment (wettability, breathability and low inflammation and the like) for late delivery or tissue-engineered repair. The method for preparing the composite hydrogel is simple, and the used SBMA and the PEG are all protein non-absorbed materials and are easy for long-term preservation and long-distance transportation.

Owner:WENZHOU MEDICAL UNIV

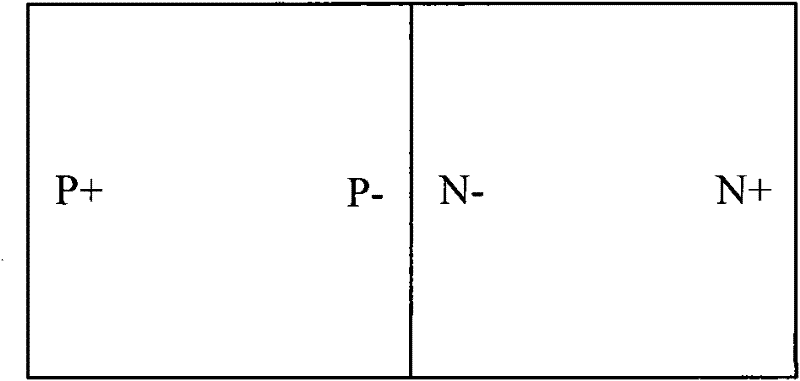

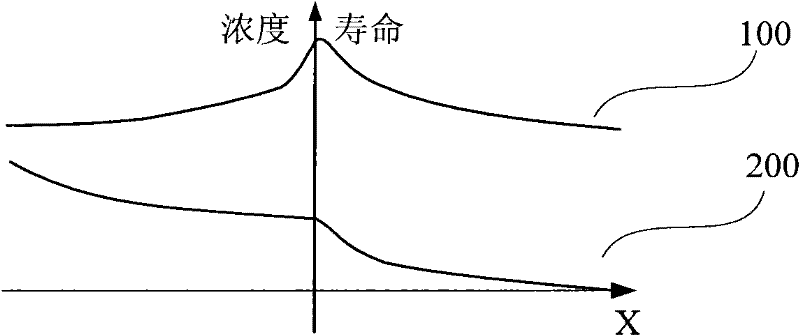

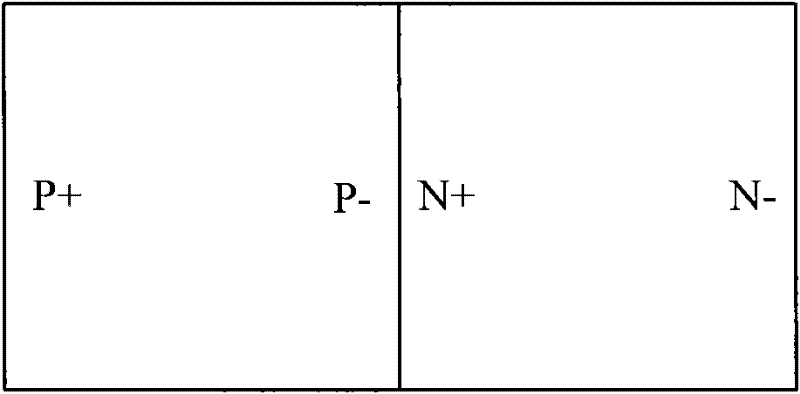

Fast recovery diode

The invention provides a fast recovery diode, which comprises a p-type semiconductor layer and an n-type semiconductor layer which is contacted with the p-type semiconductor layer, wherein in the transverse direction, the service life of a minority carrier in the p-type semiconductor layer is gradually prolonged and the doped concentration is gradually reduced from an outer surface of the p-type side to a metallurgical junction, and the service life of the minority carrier in the n-type semiconductor layer is gradually shortened and the doped concentration is gradually increased from the metallurgical junction to an outer surface of the n-type side. The fast recovery diode has higher forward recovery characteristics by controlling the doped concentration and the service life of the minority carrier. The invention also provides another fast recovery diode, which has higher reverse recovery characteristics by controlling the doped concentration and the service life of the minority carrier in the p-type semiconductor layer and the n-type semiconductor layer. The invention also provides another fast recovery diode, which has higher forward recovery characteristics and reverse recoverycharacteristics by controlling the doped concentration and the service life of the minority carrier in the p-type semiconductor layer and the n-type semiconductor layer.

Owner:BYD SEMICON CO LTD

Production process for bamboo charcoal polyester staple fibre

InactiveCN102517686ARealize resource reuseReduce manufacturing costFilament forming substance formingArtificial filament heat treatmentPolyesterPolyethylene terephthalate glycol

The invention discloses a production process for a bamboo charcoal polyester staple fibre. In the production process, regenerative PET (Polyethylene Terephthalate) material is used as the material, and the finished product is acquired by pre-treating, rotary drum drying, melt spinning, cooling and forming, winding, drafting, curling, oil applying, thermosetting and cutting-off in sequence, wherein the rotary drum drying comprises the steps of firstly drying the regenerative PET material for 5.5h-6.5h and then adding bamboo charcoal master batches with the final mass fraction of 6%-8% and including bamboo charcoal with the mass fraction of 22%-27%; and the total drying time is 9.5h-10.5h; both the screw rod and the spinning beam of a screw extruder in the melt spinning step are at the temperature from 278 DEG C to 282 DEG C; cooling forming is realized through circular air blow, the temperature of the circular air is 22 DEG C to 26 DEG C, and the air velocity of the circular air is 4.0m / s-5.0m / s; the total draft multiple is 3.1-3.3 times; and the thermosetting temperature is 162 DEG C to 168 DEG C, and the thermosetting time is 13 minutes to 17 minutes. The production process can save the cost and is helpful for environmental protection; the produced product has a better smooth and comfortable hand feeling and moisture-absorption air permeability than those of a normal polyester staple fibre.

Owner:HANGZHOU BEST CHEM FIBER

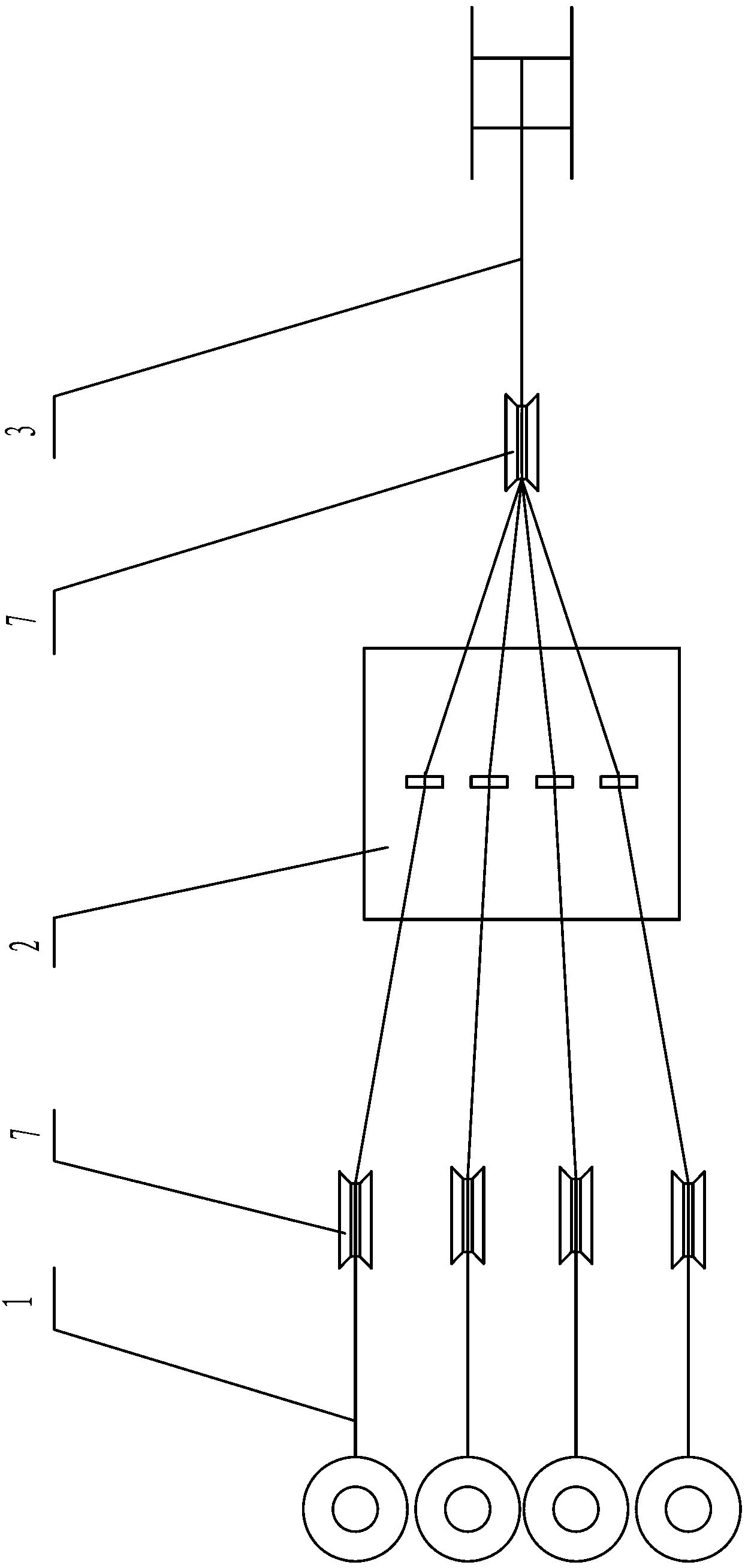

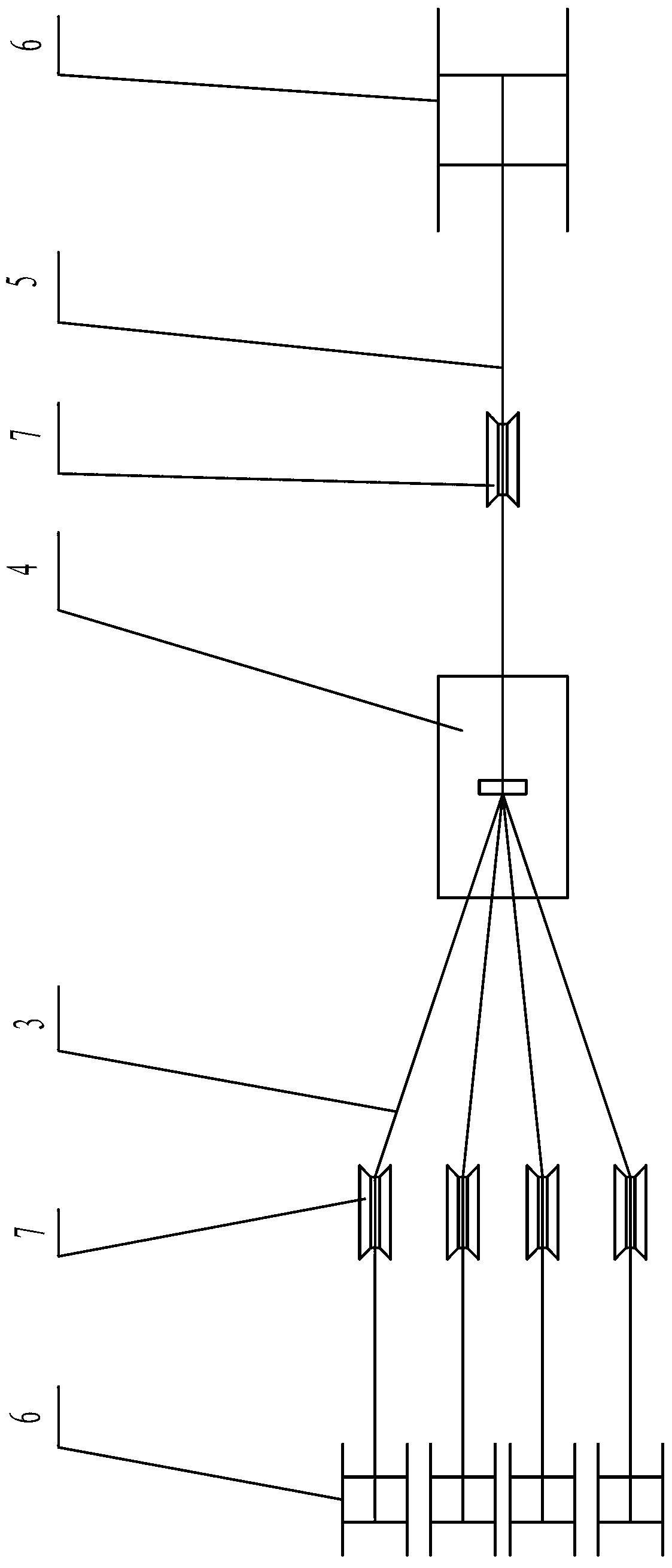

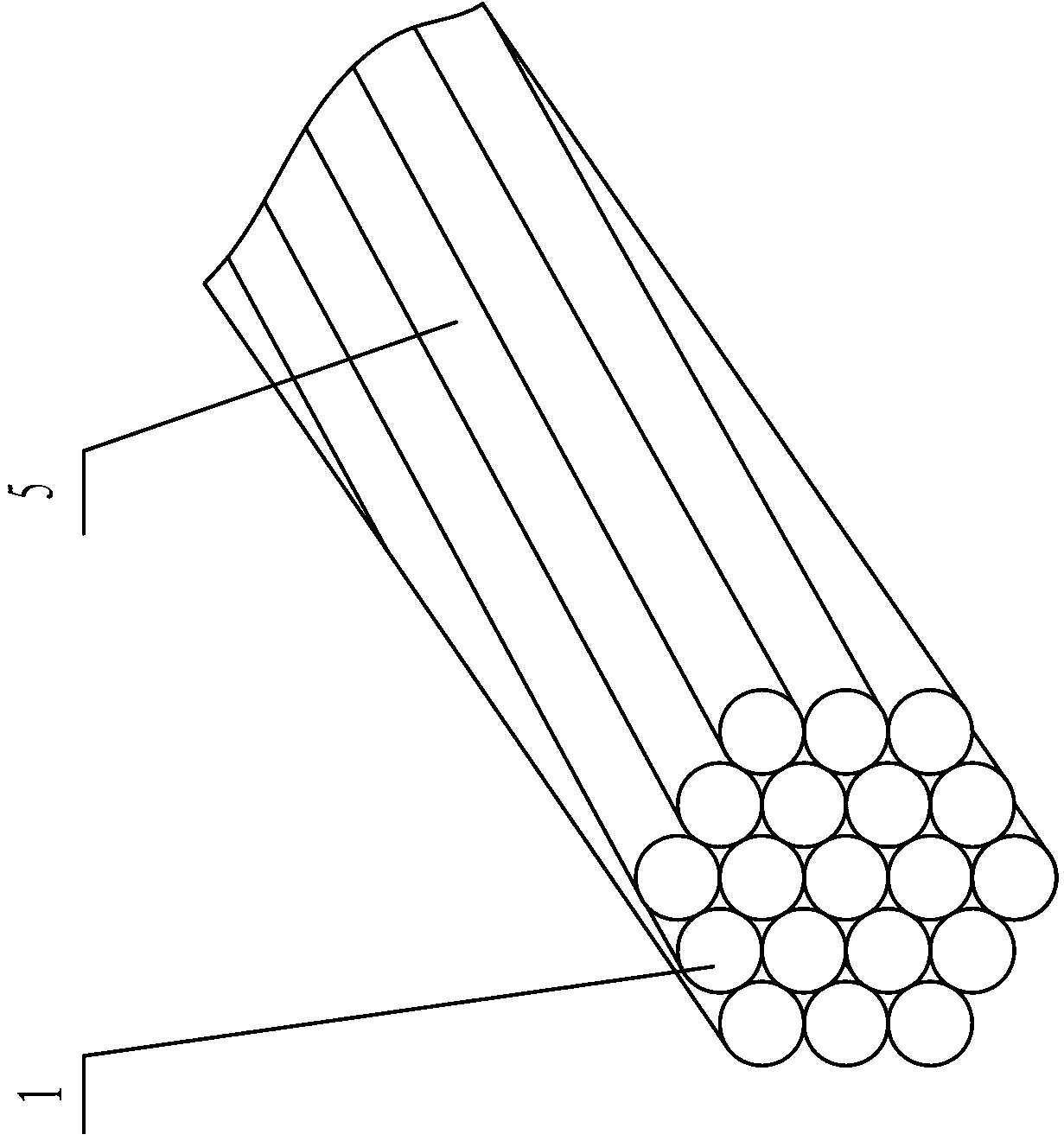

Multi-drawing-wire conductor wire-stranding method

The invention discloses a multi-drawing-wire conductor wire-stranding method. The method includes the working procedure of wire drawing and the working procedure of wire stranding. According to the wire drawing working procedure, a plurality of metal wires are formed by drawing on a multi-wire drawing machine in a one-time mode, and the formed metal wires are combined into a strand of metal wires which is wound on a bobbin; according to the wire stranding working procedure, a plurality of strands of metal wires are stranded on a wire stranding machine in a one-time mode, and the strands of metal wires after the stranding are combined into a metal conductor which is wound on a bobbin. The product produced with the method is round and normal in appearance, good in flexibility and reduced in outer diameter, and the method saves raw material and labor, reduces production field area and energy consumption and promotes production efficiency.

Owner:GUILIN INT ELECTRIC WIRE & CABLE GROUP

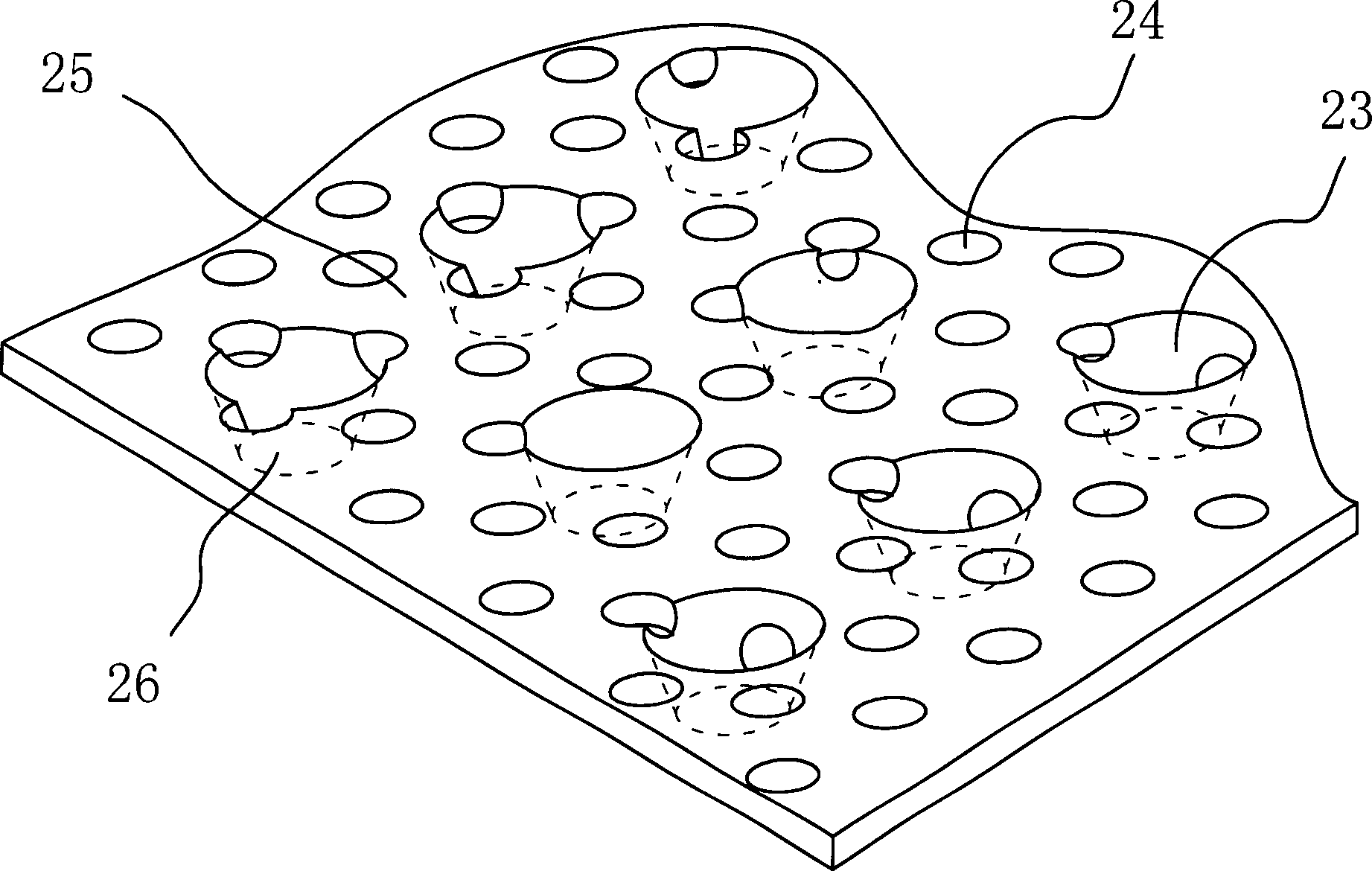

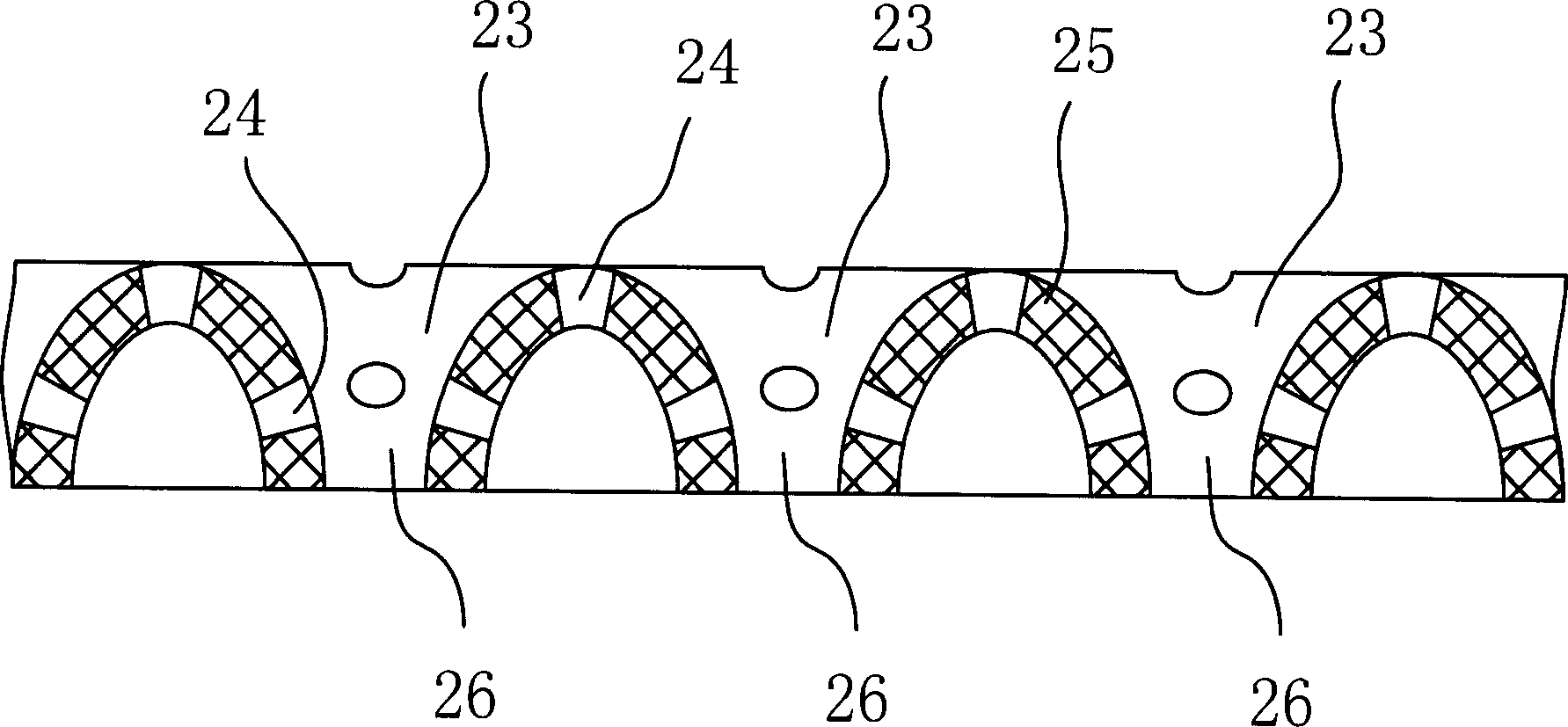

Secondary mesh combined plastic punched film and method for making same

InactiveCN1875899AGood air permeability and permeabilityGood softnessDomestic netsBandagesSpecial effectsPlastic film

The invention relates the twice mesh combined type plastic making hole film and preparing method. The method comprises the following steps: using mono-layer plastic foil as base material, carrying out twice mono-layer technology, forming the small hole in the first making holes technology, and forming big hole in the second making holes technology. The diameter of small hole is less than the half of the big hole, the perforated density of small hole is 170-500 holes / cm2, the perforated density of big hole is 30-150 holes / cm2; the perforated rate of small hole is 10-35%, and the perforated rate of big hole is 10-32%. The twice making hole uses vacuum making hole and mechanical making hole. The invention has the advantages of good air permeability, penetrability, softness and three-dimension effect.

Owner:蔡子辛 +1

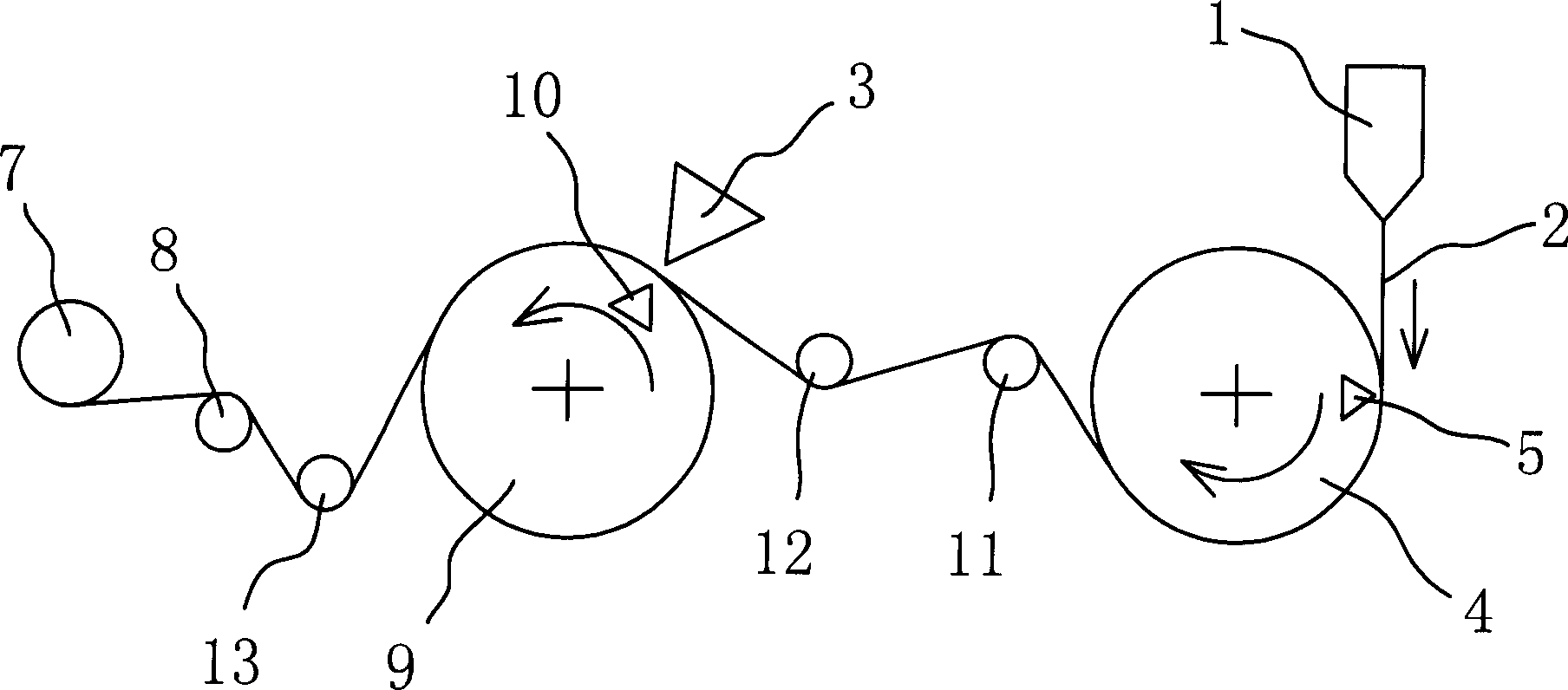

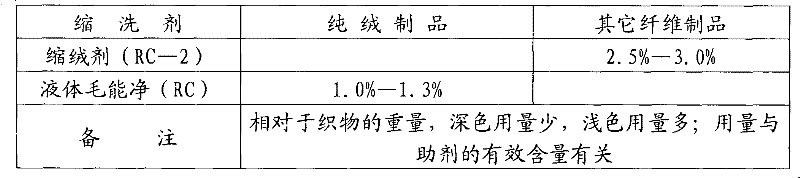

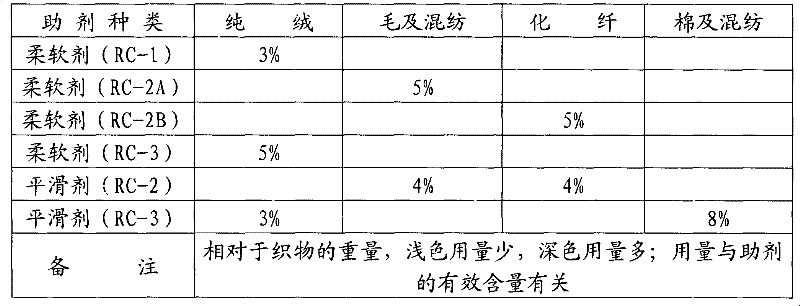

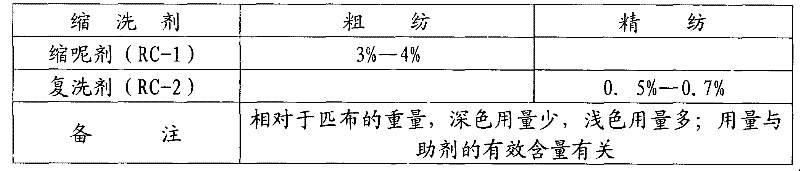

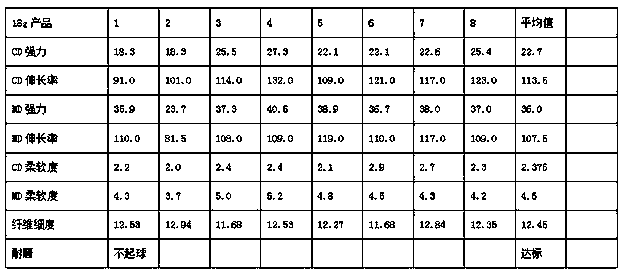

Low-temperature after finishing method of textiles

ActiveCN102392342AGood softnessReduced pillingFibre treatmentDry-cleaning apparatus for textilesChemistryCarbon dioxide

The invention provides a low-temperature after finishing method of textiles. The method comprises the following steps: (1) washing and milling treatment in an industrial washing machine: adding 0.5-4.0% of washing and milling agent, firstly soaking the textiles for 0-30 minutes, then stirring the textiles for 2-40 minutes, then carrying out deep dehydration and rinsing for 1-10 minutes and then carrying out deep dehydration, wherein the weight ratio of water to the textiles is (1:1)-(1:25) according to the types of the textiles and the water temperature is 0-20 DEG C (normal temperature); (2) softening treatment in the industrial washing machine: adding 3.0-5.0% of softening agent and 2.0-8.0% of smoothening agent, firstly soaking the textiles for 0-30 minutes, then stirring the textiles for 0-40 minutes and carrying out moderate dehydration, wherein the weight ratio of water to the textiles is (1:15)-(1:25) and the water temperature is 0-20 DEG C (normal temperature); (3) drying the textiles at 70-90 DEG C in a special oven for spinning; and (4) ironing (decatizing) and setting the textiles. The method has the following beneficial effects: energy consumption and carbon dioxide emission can be reduced, the fibers can be protected, weight loss of the textiles can be reduced and the production efficiency can be improved; the method is simple and practical; and the textiles have good softness, bulkiness and smooth and glutinous feel and are seldom subjected to pilling. The method plays an active role in promoting increase of economic benefits in the cashmere processing industry and green development of the spinning industry.

Owner:INNER MONGOLIA RIHONGKE IND TRADE

Fire-resistant fiber fabric and preparation method thereof

The invention discloses a fire-resistant fiber fabric and a preparation method thereof. The fabric comprises broken filaments, central filaments and base filaments; the mass ratio of the broken filaments to the fabric is 50-80%, and the mass ratio of the central filaments and the base filaments to the fabric is 20-50%, wherein the broken filaments adopt polyester fibers of 120-150 D, the central filaments and the base filaments adopt fire-resistant fibers, and the fabric is woven by utilizing a two-needle-bar 288 / 292 warp knitting machine. According to the fire-resistant fiber fabric and the preparation method thereof, the fabric adopts the fire-resistant fibers and the polyester fibers, is woven by utilizing five guide bars, and has the permanent fire resistance, reduction of the fire resistance caused by the times of washing does not occur, and the fabric also has the characteristic of soft hand feeling.

Owner:CHANGSHU XINXIN WARP & KNITTING

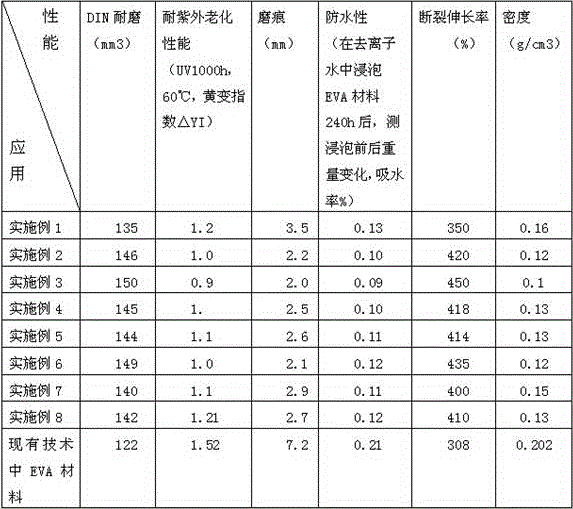

Light, waterproof and abrasion-resistant EVA material

The invention belongs to the field of EVA materials, and particularly relates to a light, waterproof and abrasion-resistant EVA material. The light, waterproof and abrasion-resistant EVA material is prepared from, by weight, 30-45 parts of EVA, 10-15 parts of natural rubber, and 1-5 parts of polyvinylpyrrolidone. The light, waterproof and abrasion-resistant EVA material further comprises an abrasion-resistant phase which is an abrasion-resistant agent or white carbon black or zinc hydroxystannate; when the abrasion-resistant phase is an abrasion-resistant agent, the number of parts by weight is 10-15; when the abrasion-resistant phase is white carbon black or zinc hydroxystannate, the number of parts by weight is 20-30. The light, waterproof and abrasion-resistant EVA material further comprises a foaming phase which is a foaming agent or a small-density inert gas; when the foaming phase is a foaming agent, the number of parts by weight is 3-10; when the foaming phase is a small-density inert gas, the number of parts by weight is 10-15, and the small-density inert gas is hydrogen or helium or nitrogen or argon. The hardness and abrasion resistance of the light, waterproof and abrasion-resistant EVA material are effectively improved, and meanwhile the softness of the EVA material is also maintained.

Owner:FUJIAN PROVINCE JINJIANG CITY HUAYIN SHOE MATERIALS

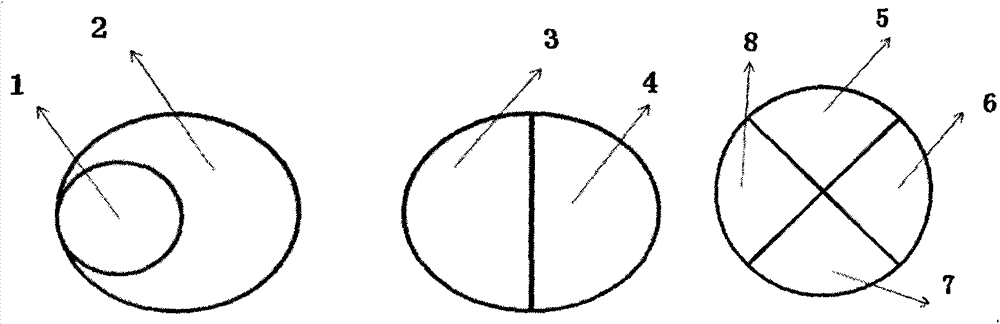

Crimping fiber elastic non-woven fabric and manufacturing method thereof

The invention discloses crimping fiber elastic non-woven fabric and a manufacturing method thereof. The cross section of each crimpled fiber contains two thermoplastic raw materials with different melting points, the two thermoplastic raw materials refer to polyisoprene and polyethylene, and the melting point deviation exceeds 100 DEG C. The two raw materials are distributed in the cross section direction according to a parallel structure or an eccentric core sheath structure or an orange section structure. A melt spinning tubular drafting technology is adopted, and in the fiber spinning process, for the reason that the heat shrinkable properties of the two raw materials are different, the fibers can be twisted in the cooling process. In the cooling drafting process, a high-speed rotating electrode is used for enabling a drafting tube with a thread structure to be rotated, the fibers are further driven to rotate, and accordingly high crimpiness fibers can be obtained. After the fibers are laid to form a net, the fibers are solidified to form the non-woven fabric through a needle-punched or hydroentangled technology. The crimping fiber elastic non-woven fabric has excellent elasticity and can be widely applied to the fields of medical treatment, sanitation, clothing, industry and the like.

Owner:JIAXING UNIV +1

Damp-proof PVC injection moulding material

The invention belongs to the technical field of cable injection moulding materials and discloses a damp-proof PVC injection moulding material. The damp-proof PVC injection moulding material is prepared from the raw materials including PVC resin, PE resin, inorganic filler, composite rubber, a fluidity modifier, plasticizers, a lubricant, a heat stabilizer and the like, wherein the inorganic filleris modified white mica; the composite rubber includes nitrile butadiene rubber, ethylene-propylene-diene monomer, silicone rubber and chloroprene rubber; the plasticizers are dioctyl terephthalate and dioctyl phthalate. The damp-proof PVC injection moulding material disclosed by the invention has moisture-proof and damp-proof characteristics as well as the characteristics of smooth and delicate product surface, relatively high softness and the like.

Owner:ZHEJIANG WELLSCOM PLASTIC CO LTD

Preparation method and application of hollow fiber non-woven fabric

InactiveCN111364167AReduce weightGood softnessHollow filament manufactureNon-woven fabricsWoven fabricYarn

The invention discloses a preparation method and application of a hollow fiber non-woven fabric. The preparation method comprises the following steps that 20% high melt index elastomer, 1.5% soft masterbatch, 2.5% whitening masterbatch and 76% conventional spunbonded material are used as raw materials, the selected raw materials are mixed, the mixed raw materials are added into a hopper, the mixedraw materials are fed to a screw rod through a feeding system for extruding and melting to obtain a hot melt, filtering, measuring and distributing are conducted on the hot melt, spinning is conducted on the distributed and measured hot melt through a hollow spinning board, and the spun yarn is cooled through side cold air to obtain a primary filament; and drawing is conducted on the primary filament to obtain fiber, the fiber touches a mesh curtain to form a fiber web, and hot rolling is conducted on the fiber web to obtain the nonwoven fabric. By means of the preparation method, the hollowspinning board is adopted to replace a conventional spinning board, special raw material ratio is adopted, the produced non-woven fabric is lower in gram weight and higher in softness and is more suitable for using of a bottom membrane and waist circumference of a diaper, and meanwhile, the production costs are lower.

Owner:山东恒鹏卫生用品有限公司

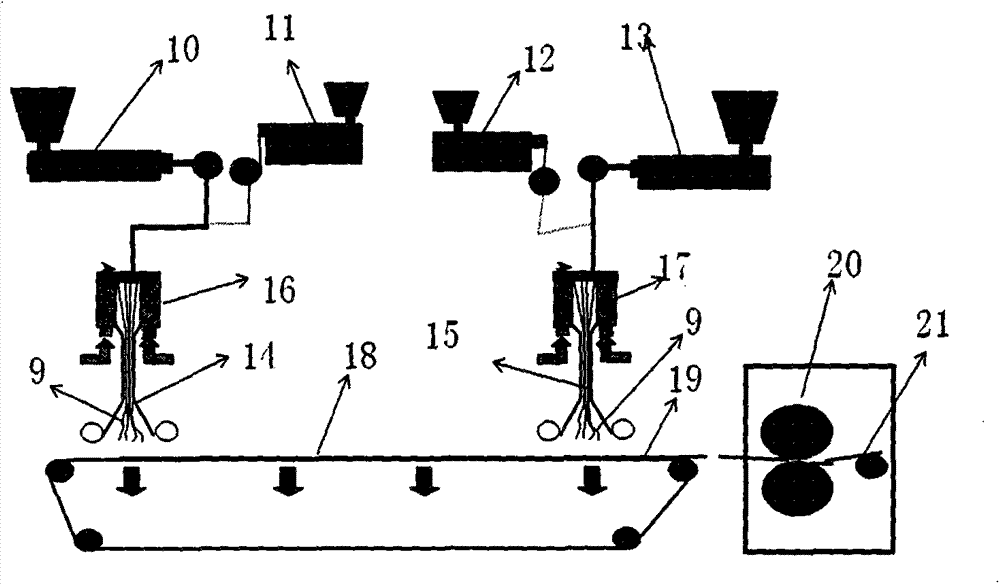

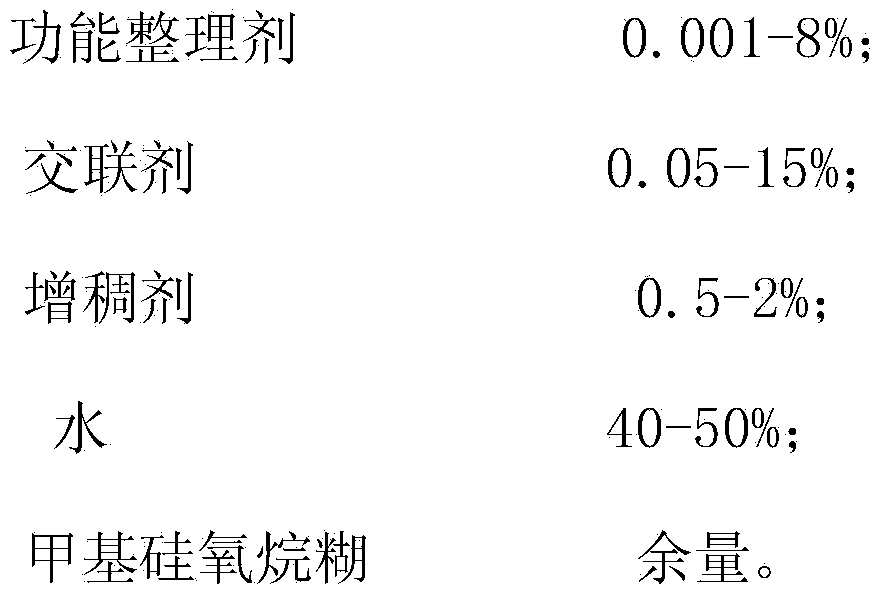

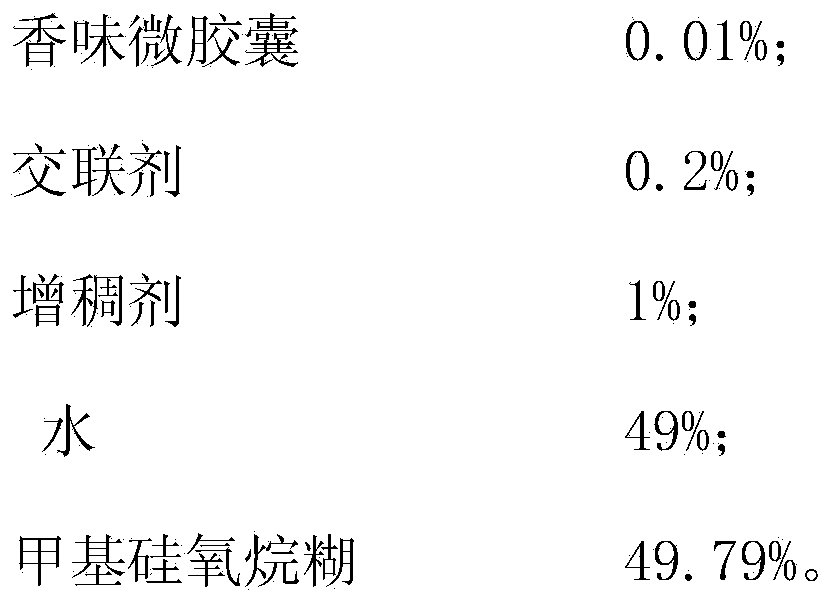

Textile finishing liquid adopting stamping method, and finishing technology thereof

InactiveCN104109973AIncrease productivityHigh utilization rate of raw materialsFibre treatmentTextile parts treatmentEngineeringTextile

The invention discloses a textile finishing liquid adopting a stamping method, and a finishing technology thereof. The textile finishing liquid comprises, by mass, 0.001-8% of a functional finishing agent, 0.05-15% of a cross-linking agent, 0.5-2% of a thickening agent, 40-50% of water, and the balance methylsiloxane paste. The finishing technology has the advantages of simple method, easy operation, high raw material utilization rate, low cost, energy saving and emission reduction, and obtains a similar finishing effect with present technologies.

Owner:ZHEJIANG SCI-TECH UNIV +1

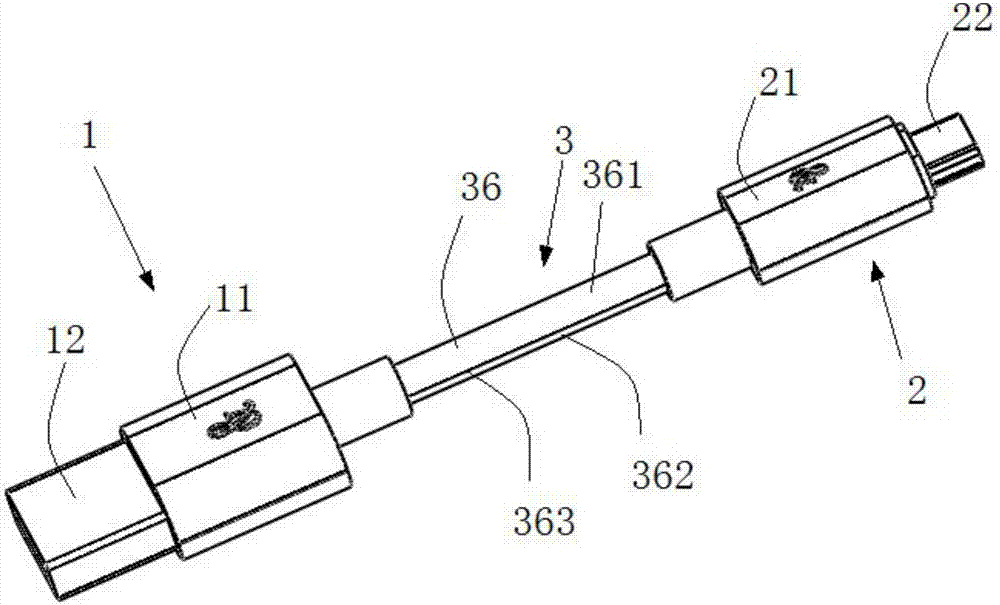

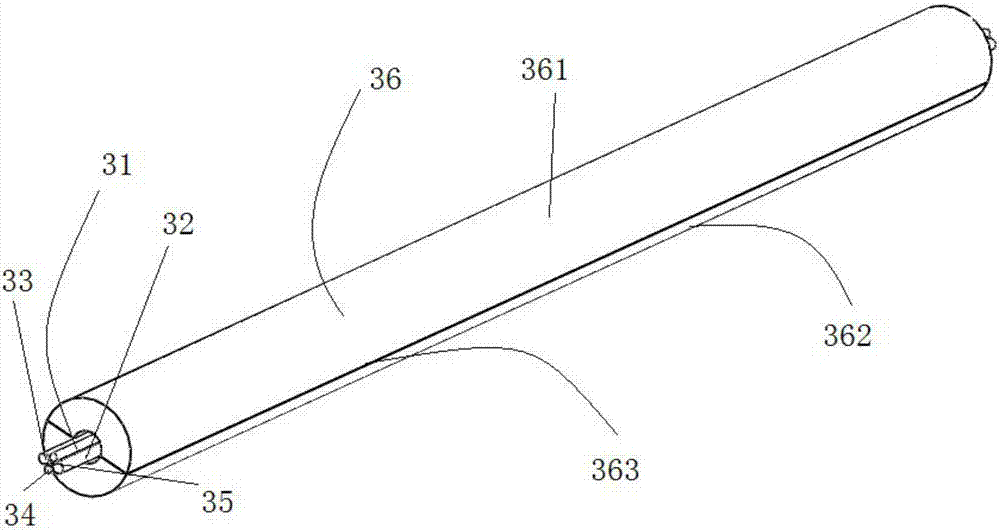

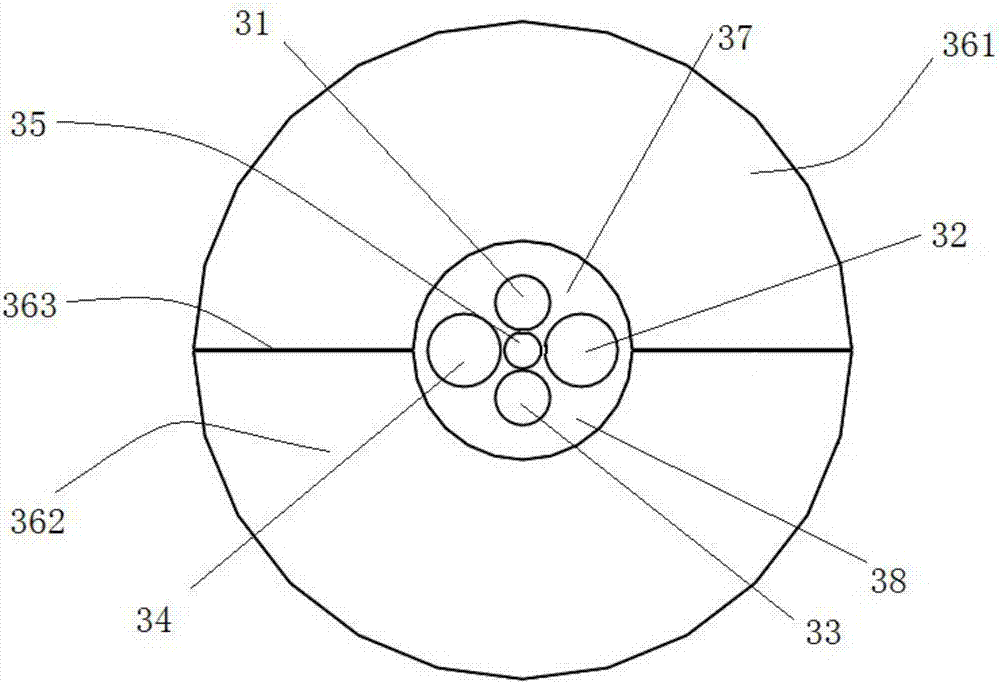

Multicolor silica gel coated USB data charge cable

PendingCN107204555ADoes not affect conductionImprove flexibilityCoupling device connectionsFlexible cablesEngineeringSilica gel

The invention discloses a multicolor silica gel coated USB data charge cable. The multicolor silica gel coated USB data charge cable comprises a USB connecting terminal, a data transmission interface and a connecting wire; the connecting wire comprises a multicolor silica gel coating layer, a power positive wire, a negative voltage data wire, a positive voltage data wire, a grounding wire and a Kevlar wire, wherein the multicolor silica gel coating layer coats the power positive wire, the negative voltage data line, the positive voltage data line, the grounding wire and the Kevlar wire; the Kevlar wire is shorter than other wires of the connecting wire, the USB connecting terminal comprises a USB terminal silica gel shell and a USB terminal coated with the USB terminal silica gel shell, the data transmission interface comprises an interface silica gel shell and a data interface coated with the interface silica gel shell, the two ends of the connecting wire are respectively connected with the USB connecting terminal and the data interface, and the USB terminal silica gel shell and the interface silica gel shell respectively coat the USB terminal and a joint of the data interface and the connecting wire. The multicolor silica gel coated USB data charge cable provided by the application of the invention is high in flexibility and good in hand feeling, does not become hard at low temperature, is not knotted, is not easy to break, is skin-friendly, and is high in tensile property.

Owner:戴明

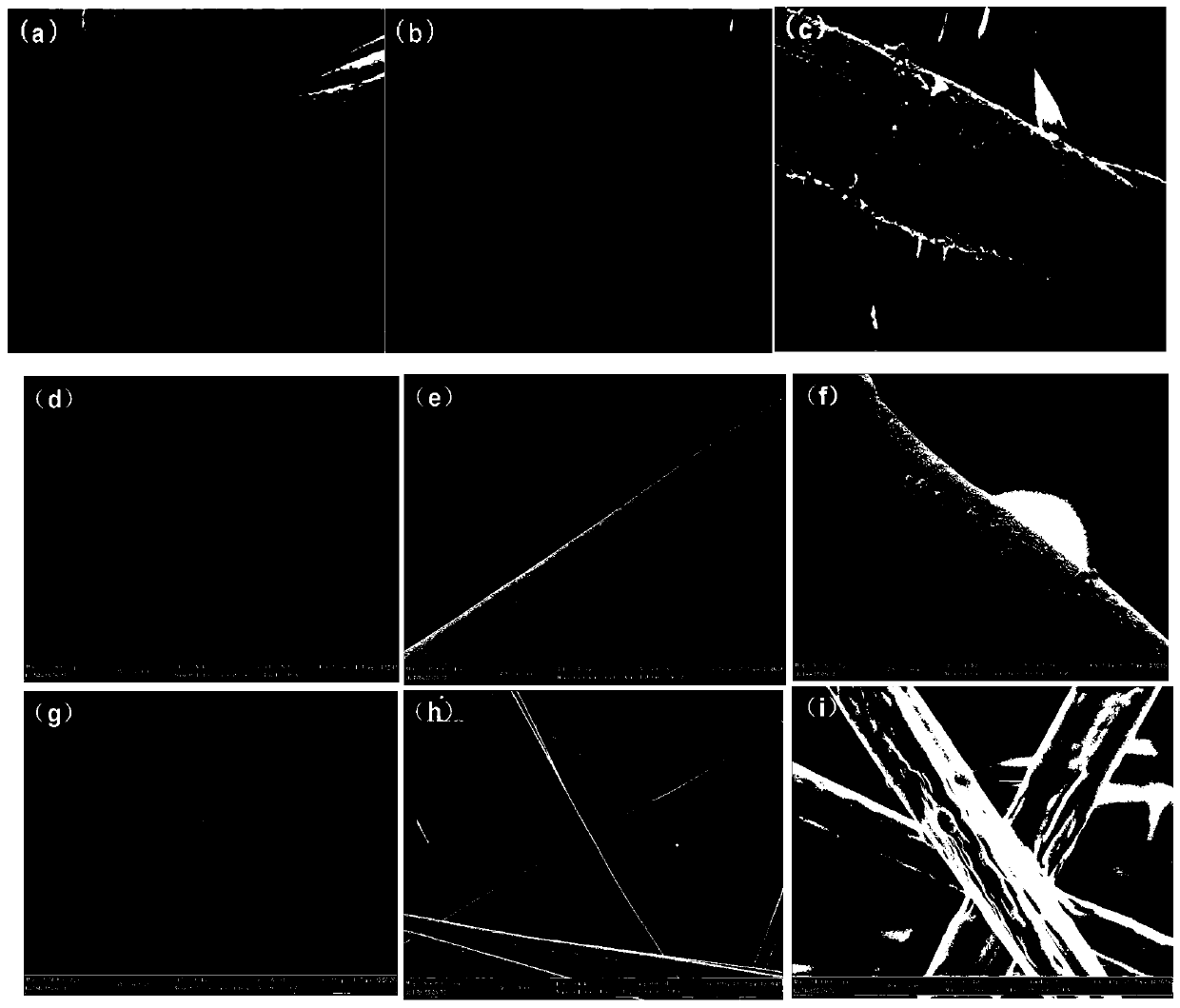

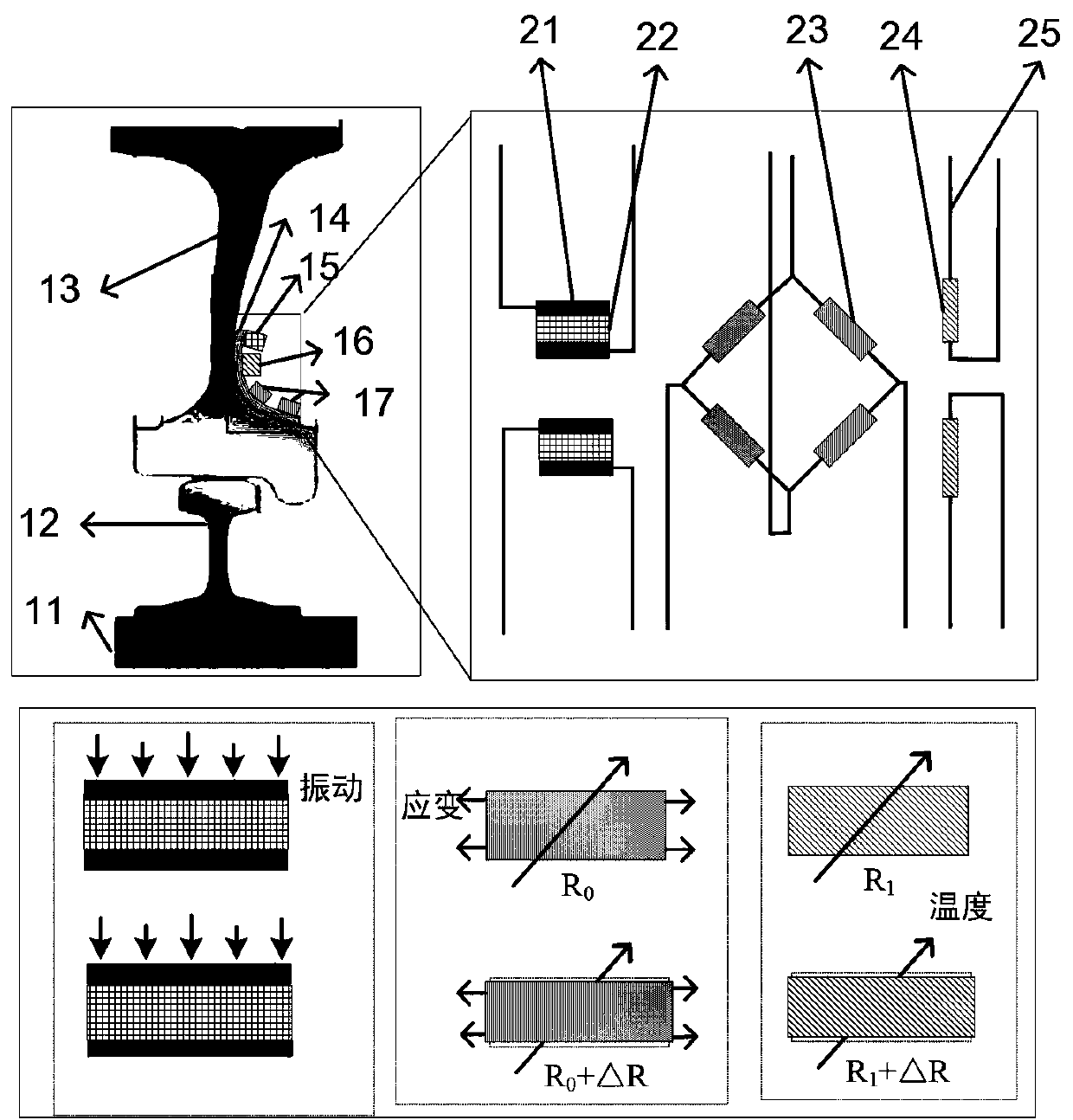

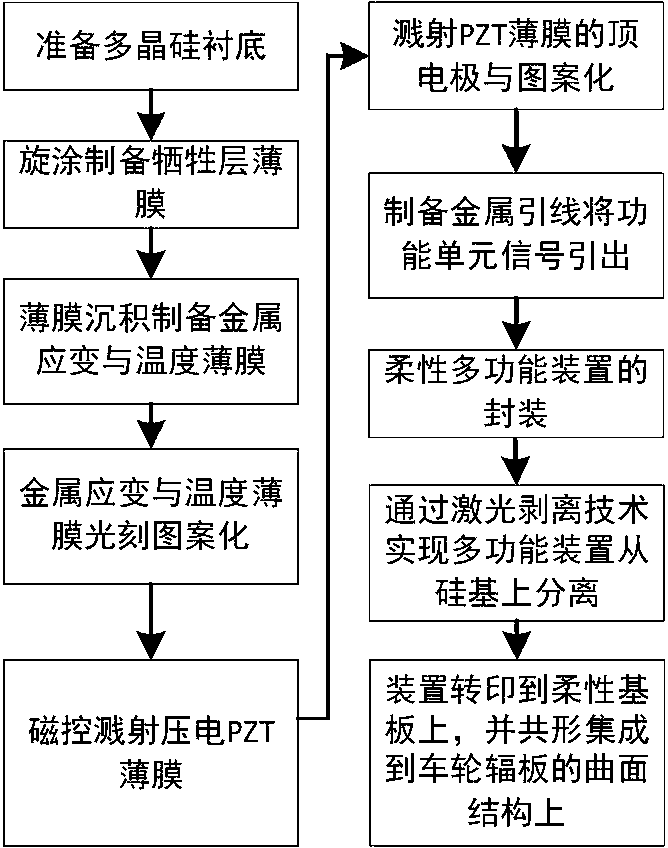

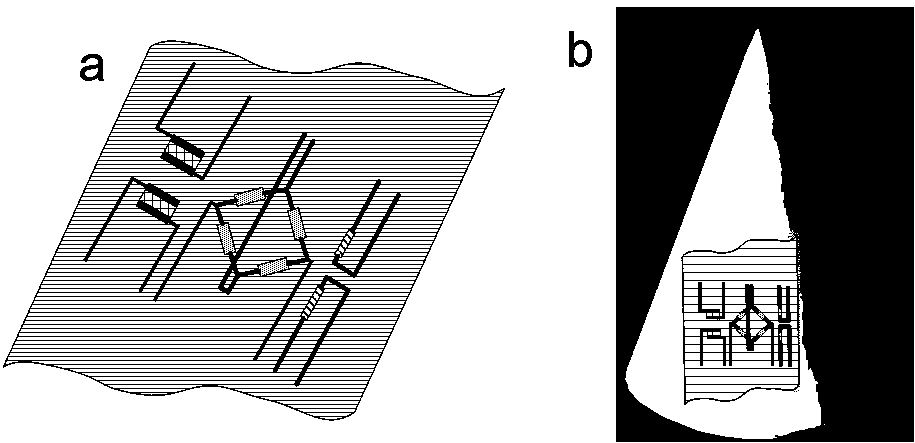

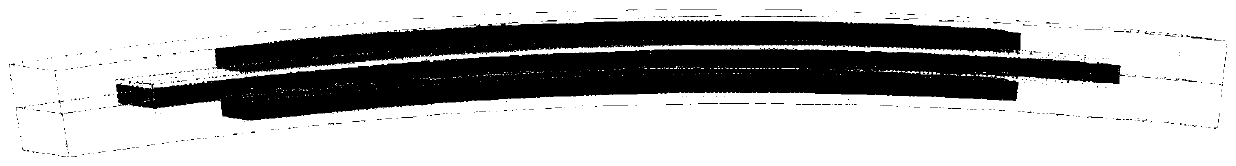

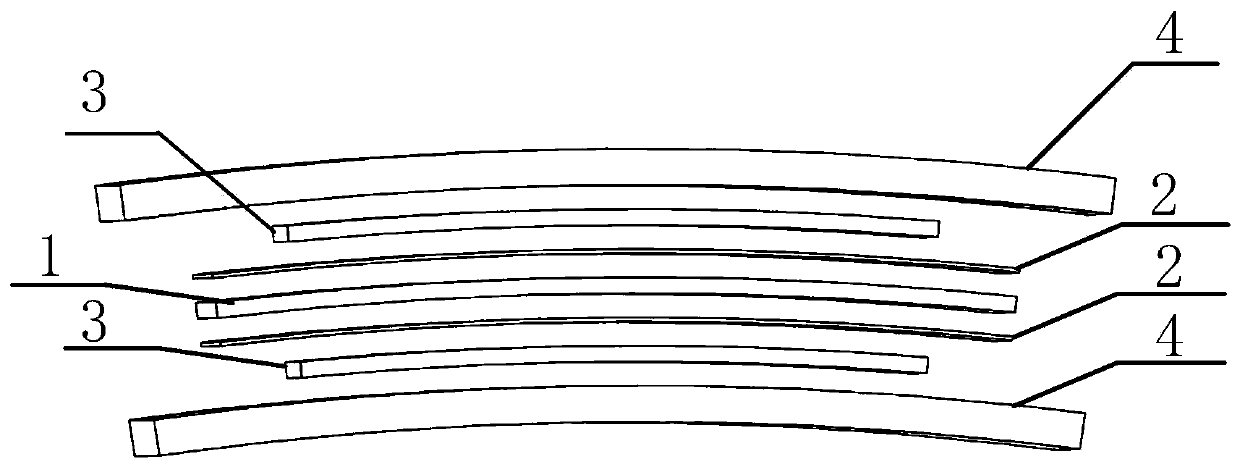

Flexible electronic device for wheel-rail force testing, and preparation method thereof

InactiveCN111439290AImprove driving safetyImprove driving comfort performanceWheel-rims surveying/measuringEngineeringStructural engineering

The invention discloses a flexible multifunctional electronic device for wheel-rail force online monitoring, and relates to the field of rail transit wheel-rail relation and flexible electronics. Thedevice comprises a temperature sensing function module, a dynamic strain sensing function module and a piezoelectric vibration sensing function module. All the modules are integrated on the same flexible substrate, the device is installed on a wheel spoke curved surface, and keeps conformal contact with the wheel spoke curved surface, and the acting force between wheel rails is calculated by utilizing dynamic strain and vibration information of spoke plates, so real-time monitoring of the wheel-rail contact state (temperature, dynamic strain and vibration information) of the high-speed train is achieved, the flexible multifunctional electronic device is prepared through micro electro mechanical machining and a laser lift-off technology, and technical guarantee is provided for monitoring application of the flexible electronic technology in the wheel-rail relation.

Owner:EAST CHINA JIAOTONG UNIVERSITY +1

Two-step finishing process of jacquard fabric fibers

InactiveCN104452149AColor becomes smallerGood softnessSucessive textile treatmentsFibre treatmentEngineeringFiber

The invention relates to a two-step finishing process of jacquard fabric fibers. The finishing process jacquard fabric obtained by spinning on a loom is directly fed to a hot air tenter, temperature is controlled to be 150-200 DEG C, speed is controlled to be 20-60m / minute, thermal processing is performed on the fabric, the fabric is put into clean water in a material tank and then dried by a padder, an infrared weft straightener is used to straighten wefts, softener solution padding is performed through the padder, the fabric is placed on full-loosening drying equipment for drying and loosening, the temperature is controlled to be 20-4-140 DEG C, the speed is controlled to be 15-30m / minute, and fabric discharge is performed by hot air constantly beating and drying the fabric so as to complete fabric drying and loosening. Compared with the prior art, the two-step finishing process has the advantages that the fabric processed by process is good in softness, good in elasticity and drapability, and good in shrinkage rate.

Owner:SHANGHAI SKYTEX FASHION TECH CO LTD

Soft waterproof fabric

InactiveCN106072939AImprove waterproof performanceGood softnessBiochemical fibre treatmentLiquid repellent fibresPolyvinyl alcoholHot-melt adhesive

The invention discloses a soft waterproof fabric. The soft waterproof fabric is prepared from, by weight, 30-40 parts of viscose flax, 15-20 parts of bamboo charcoal fibers, 15-20 parts of polyurethane resin, 5-12 parts of polyvinyl alcohol fibers, 10-15 parts of nano antibacterial powder, 3-5 parts of hot melt adhesive and 2-5 parts of zinc borate. High softness of the fabric is achieved while excellent waterproof performance of the waterproof fabric is kept, and accordingly comfort of clothes made of the fabric is improved greatly, and great convenience is brought to people.

Owner:YIXING ZHENYANG GARMENT CO LTD

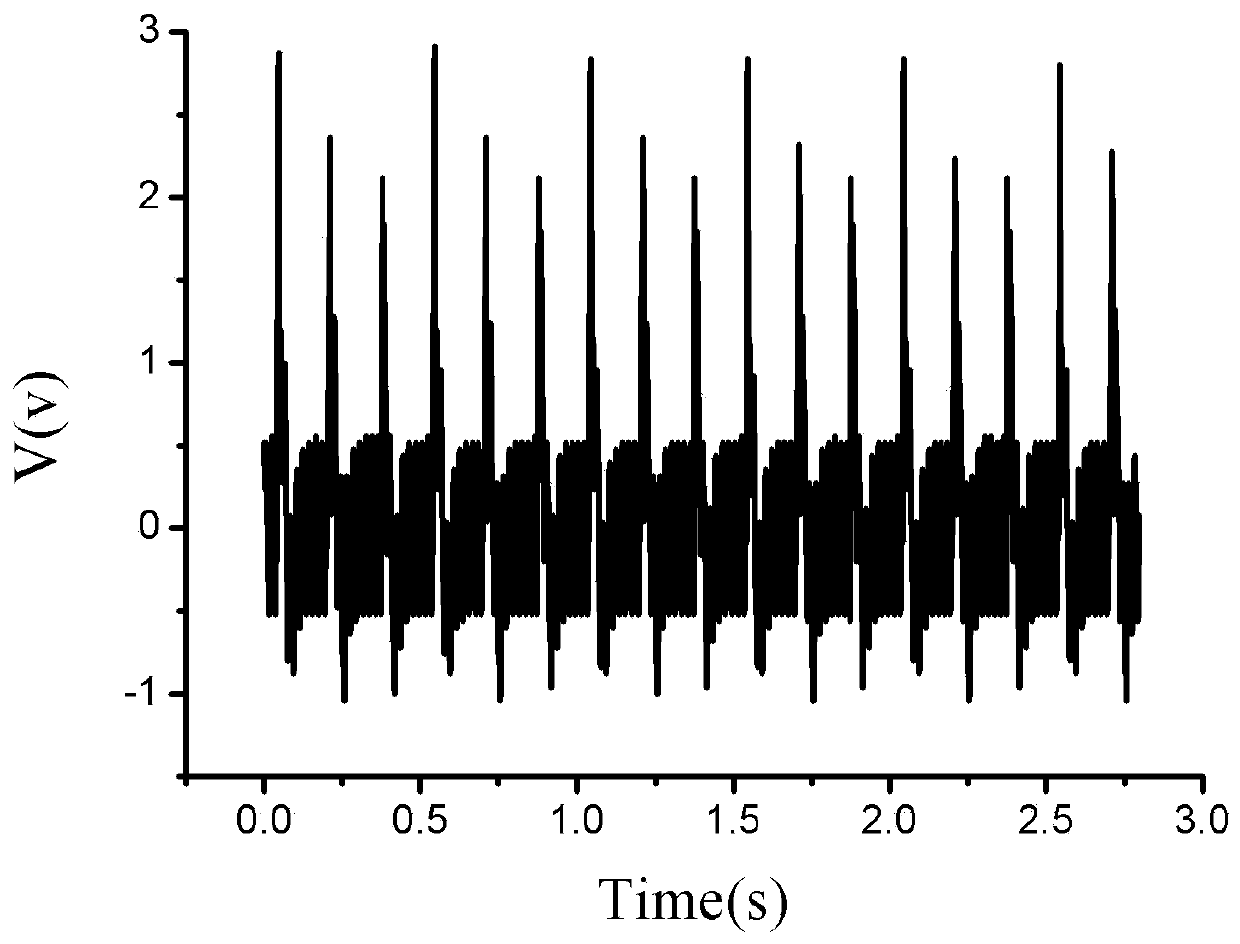

Flexible piezoelectric energy acquisition device based on plant fibers and preparation method thereof

ActiveCN110190179AHas biocompatible propertiesPossesses biodegradable propertiesPiezoelectric/electrostrictive device manufacture/assemblyFiberElectricity

The invention discloses a flexible piezoelectric energy acquisition device based on plant fibers and a preparation method thereof. The flexible piezoelectric energy acquisition device comprises a fiber-based piezoelectric functional film, an insulating layer, a fiber-based electrode and a packaging layer; the upper surface and the lower surface of the fiber-based piezoelectric functional film arerespectively attached with a first insulating layer and a second insulating layer, a first fiber-based electrode is attached to the upper surface of the first insulating layer, and a second fiber-based electrode is attached to the lower surface of the second insulating layer; the packaging layer packages the fiber-based piezoelectric functional film, the first insulating layer, the second insulating layer, the first fiber-based electrode and the second fiber-based electrode; the first insulating layer, the second insulating layer and the packaging layer are made of ECOFLEX-series silicon rubber; the fiber-based piezoelectric functional film, the first fiber-based electrode and the second fiber-based electrode all adopt plant fibers as substrates; and the device has excellent flexibility, can be completely attached to each part of a human body, and has good biocompatibility and comfort.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

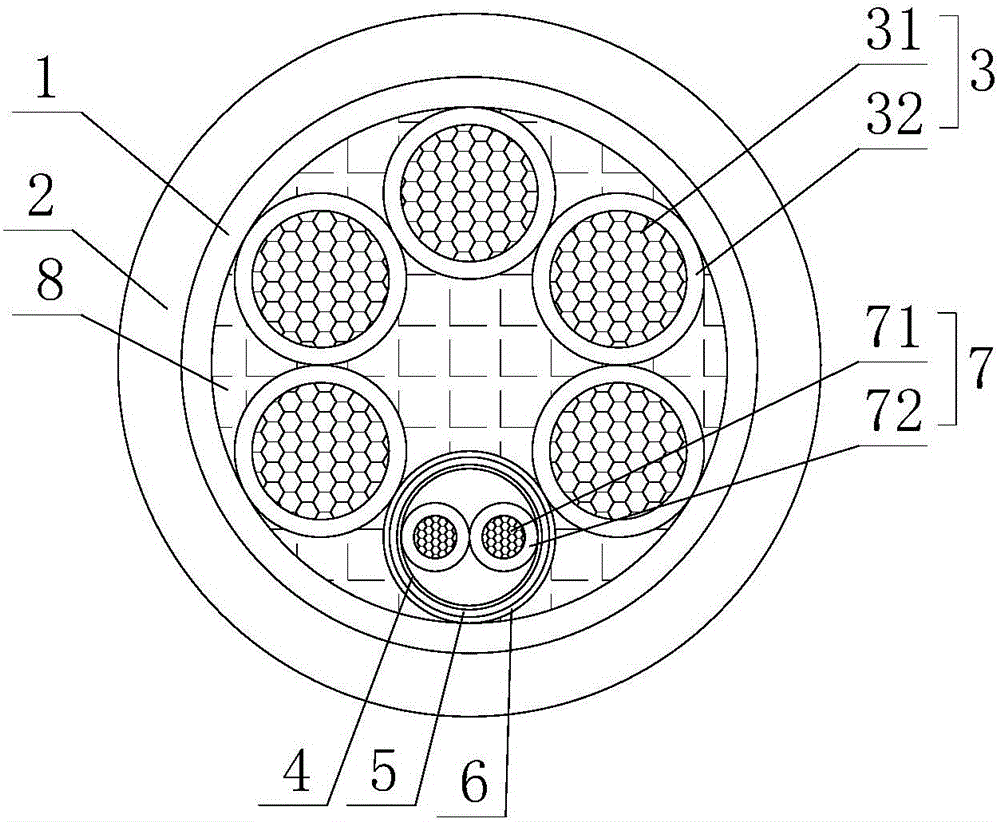

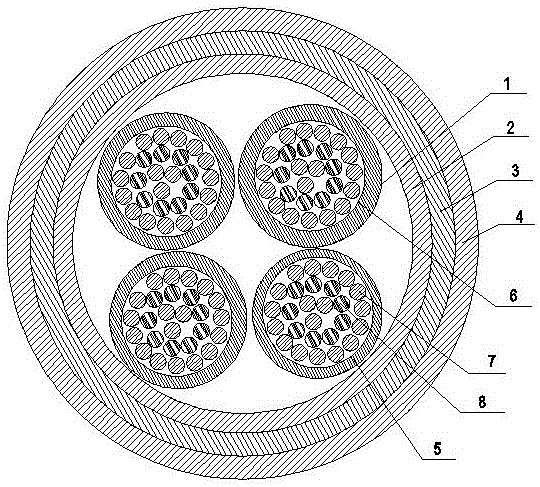

Environment-friendly cable for automobile charging pile

InactiveCN105761787AGood softnessImprove stress resistanceConductive materialDetails of conductive coresCopper wireEngineering

The invention discloses an environment-friendly cable for an automobile charging pile. A cable core is formed by regularly twisting a plurality of power core wires and a control core wire, flexibility of the cable and roundness of the cable core are guaranteed, and both a first conductor and a second conductor are formed by stranding tinned copper wires, thereby enabling the conductors to achieve excellent flexibility and roundness, and improving an anti-pressure capability of the cable; a first insulating layer, a second insulating layer, a main sheath layer and a sub sheath layer adopt irradiation insulating materials, thereby ensuring that the cable has the characteristics of flexibility, oil resistance, alkali resistance, ultraviolet resistance, wear resistance, cracking resistance and the like; and the sheath is extruded outside the cable core, thereby ensuring compactness of a cross section of the cable, and enabling the cable to have excellent anti-rolling performance.

Owner:安徽华海特种电缆集团有限公司

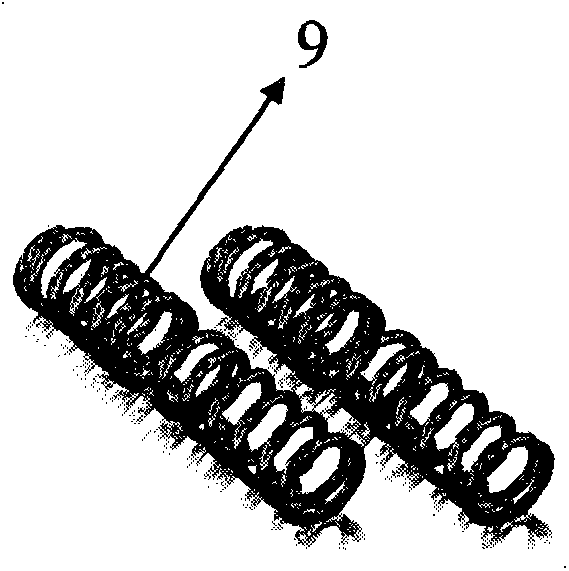

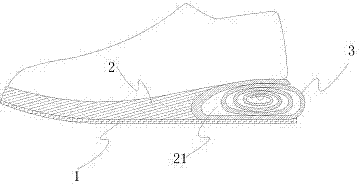

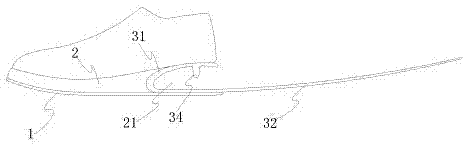

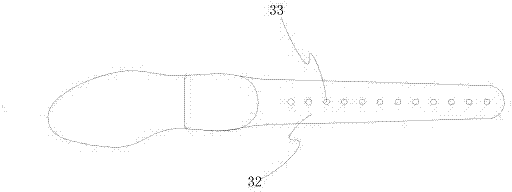

Sole with adjustable damping effect and shoe with sole

ActiveCN104273790AGood shock absorption strengthSimple structureSolesUltimate tensile strengthControl theory

The invention relates to shoes, and provides a sole with an adjustable damping effect. The sole is provided with a damping ring structure, so that the damping strength can be adjusted by adjusting the number of turning circles of a damping ring, and the sole has a simple structure and is convenient to operate. The sole comprises an outsole, an insole on the outsole and the damping ring, wherein the insole is provided with an opening for mounting the damping ring at a position corresponding to the heel of a human foot; the number of turning circles of the damping ring is adjustable; the damping ring consists of a strip-shaped damping adjusting strip; one end of the damping adjusting strip is firmly arranged around the inner wall of the opening as a fastening end, and the other end of the damping adjusting strip is arranged to be a free adjusting end; the free adjusting end is provided with a plurality of fixing ring holes which are spaced from one another in sequence in the extension direction of the length of the damping adjusting strip; the fastening end of the damping adjusting strip is also provided with fixing bumps to be matched with the fixing ring holes for fixation; a revolute ring of the free adjusting end is arranged in the opening in a ring shape; the fixing bumps at the fastening end are used for fixing the fixing ring holes, namely the damping adjusting strip forms the damping ring to be placed in the opening.

Owner:MAOTAI FUJIAN SOLES CO LTD +1

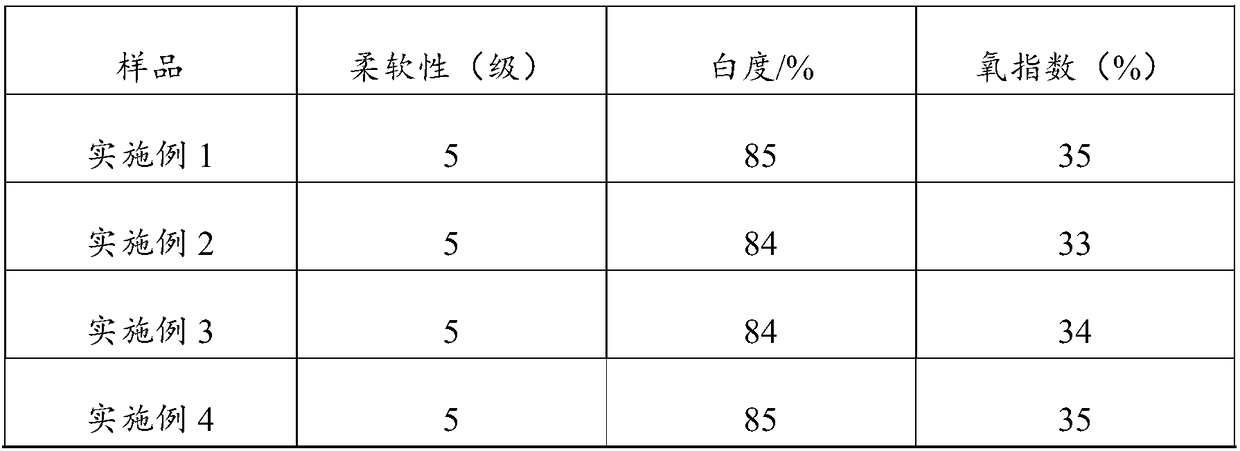

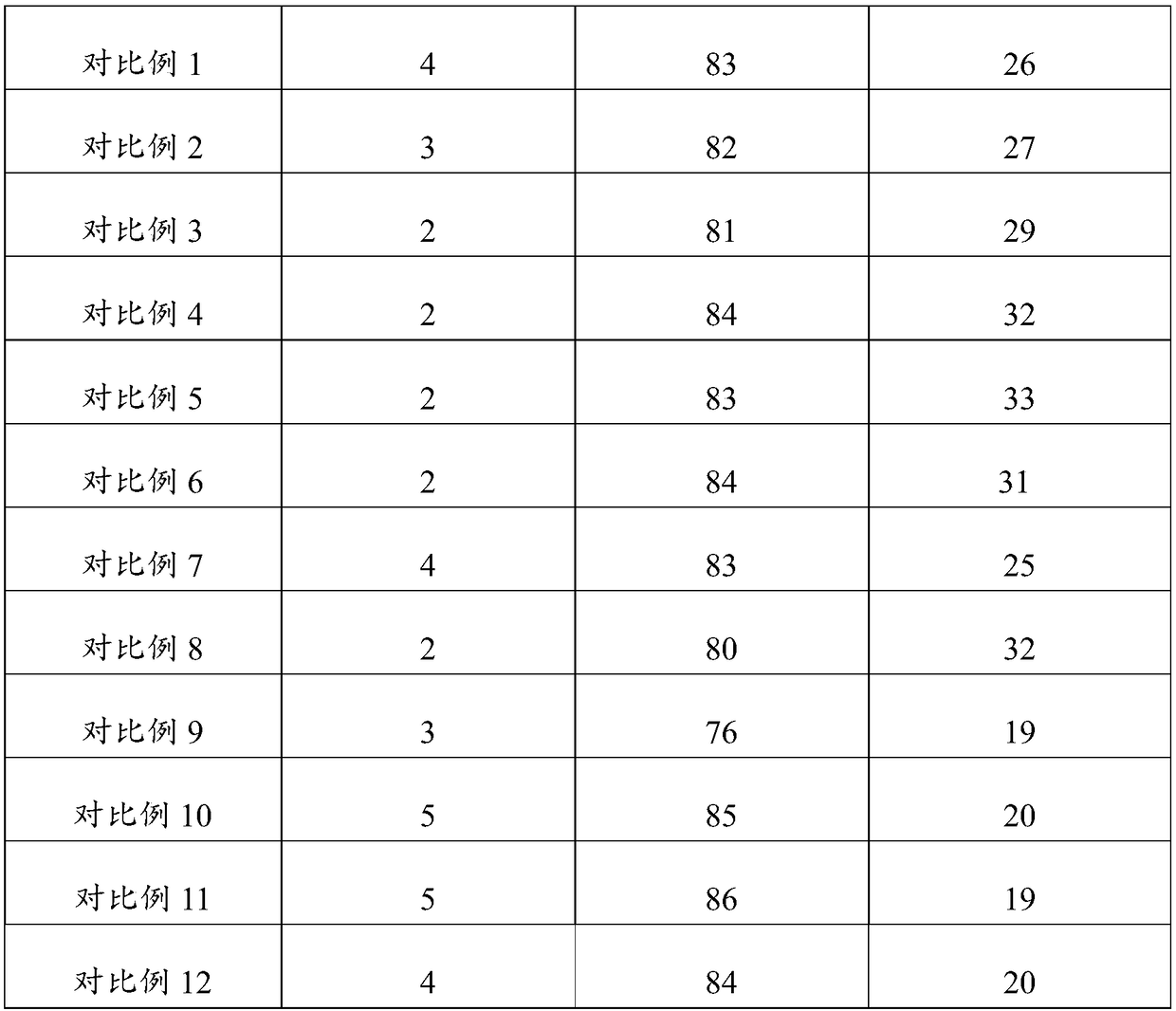

Flame-retardant modified silicone oil, and preparation method and application thereof

ActiveCN109293923AGood softnessGood flame retardant performanceHeat resistant fibresGrip property fibresBromineUrea

The invention belongs to the field of preparation of modified silicone oil, and relates to a flame-retardant modified silicone oil, a preparation method thereof, and an application thereof in textileproduction. The modified silicone oil is mainly prepared through a copolymerization reaction of (perbromo-1,2-phenylene)dimethanol, trimethylol melamine resin, 1,4-dibromo-2,3-butylene glycol, hexaethylcyclotrisiloxane, methyldichlorosilane, 3-aminopropylsilane triol, ethylenediamine tetramethylenephosphonic acid and 1,3-bis(trimethylsilyl)urea. Monomers with high content of flame-retardant elements, such as bromine, nitrogen and phosphorus, comprising (perbromo-1,2-phenylene)dimethanol, trimethylol melamine resin, 1,4-dibromo-2,3-butylene glycol and ethylenediamine tetramethylenephosphonic acid are used as main copolymerization raw materials, and are copolymerized with an organosiloxane raw material to obtain the modified silicone oil. The obtained modified silicone oil has an excellent flexible performance, also has an excellent flame retardant performance due to the high content of the flame retardant elements comprising bromine, nitrogen and phosphorus, can be applied to textiles of machine-made bleached twill pure cotton clothes, and has an oxygen index reaching 32% or above.

Owner:黄山市强力化工有限公司

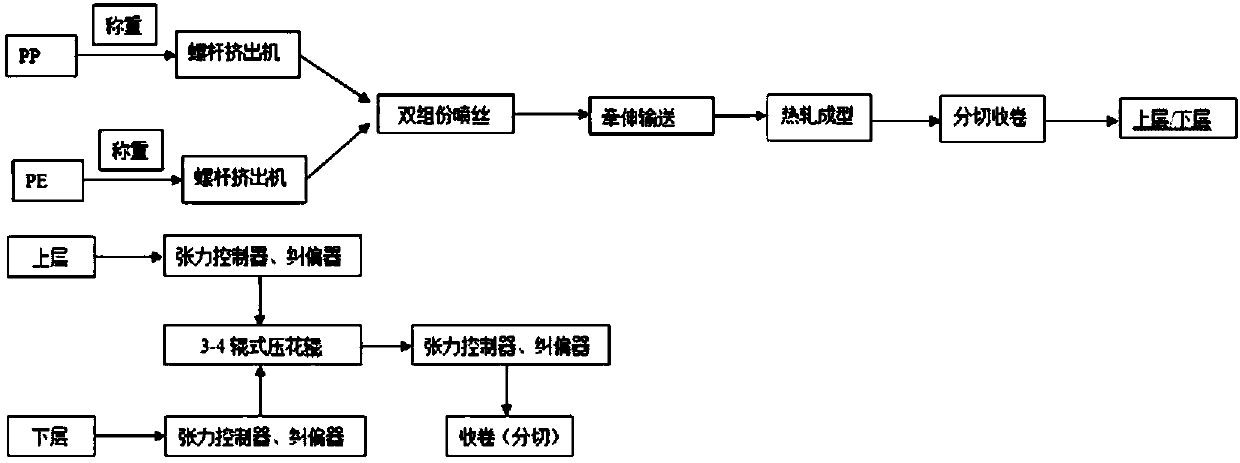

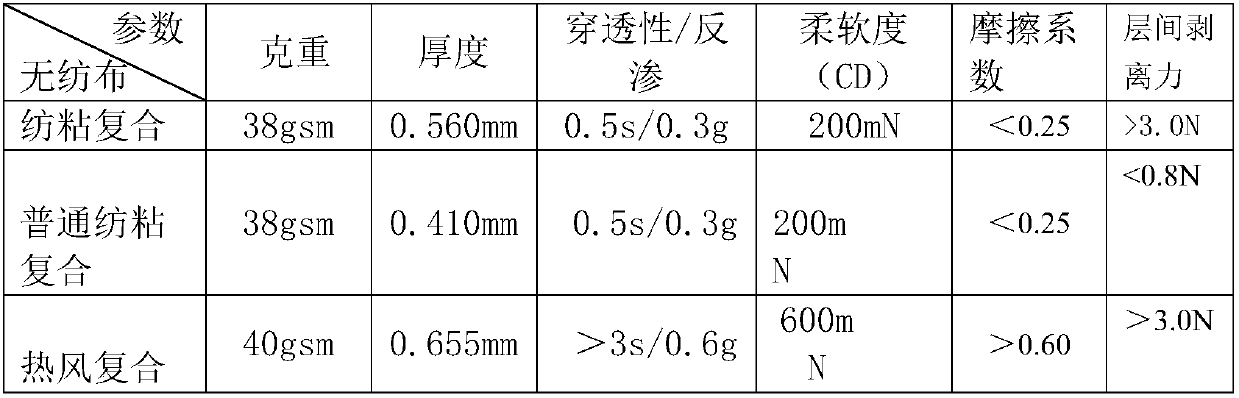

Spunbond two-component fiber non-woven fabric and processing equipment and technology thereof

InactiveCN107761253AFluffiness is goodGood softnessAbsorbent padsNon-woven fabricsWoven fabricSurface layer

The invention discloses a spun-bonded two-component fiber non-woven fabric, which comprises an upper layer and a lower layer, and the upper layer is composed of 48.5% PP particles, 49% PE particles and 2.5% metallocene low-temperature particles passing through a screw extruder After extruding the two component products respectively, the surface layer structure of the surface layer PE with the "skin-core" structure is sprayed out through the two-component spinneret hole. The lower layer is composed of 48.5% PP particles, 49% PE particles and 2.5% metallocene low-temperature particles are extruded through the screw extruder to extrude the two component products, and then sprayed out through the two-component spinneret. The surface layer structure and the bottom layer structure are embossed and heat-sealed by "bump-type" hot rolls. The invention has excellent bulkiness and softness, especially the interlayer peeling force, which can achieve the same effect as that of hot-air composite non-woven fabrics, and the spun-bonded penetrability and reverse osmosis performance are obviously better than hot-air products.

Owner:浙江欣富无纺布科技有限公司

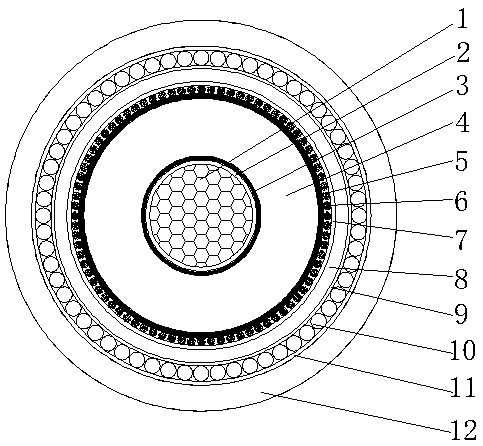

Waterproofing mildew, mice and termite resistant cable for electrified railway and preparation method of cable

PendingCN109300587AExcellent anti-rodent and anti-termite performanceGood radial water blocking propertiesFlexible cablesFlexible conductorsMoistureMetal

The invention relates to a circular power cable for an oil-submerged pump and a preparation method of the cable, and belongs to the technical field of manufacture of cables for electrified railways ofrailway traffic equipment. The cable comprises a conductor, a conductor waterproofing layer, a conductor shielding layer, an insulating layer, an insulated non-metal shielding layer, an insulated metal shielding layer, a first waterproofing layer, an inner sheath layer, a flame-retardant wrapping layer, an armored layer, a second waterproofing layer and an oversheath successively from inside to outside. The provided cable has an excellent radial waterproof performance; the cable is resistant to moisture and prevented from mildew in the wet environment; the cable is characterized by resistantto mice and termites; the cable is convenient to install and operate due to the soft and tensile features; and the cable can meet the reality of continuously development of high-speed railway electrified equipment.

Owner:江苏华远电缆有限公司

High-weather-resistant, torsion-resistant and bending-resistant control cable

InactiveCN106601345AImprove insulation performanceImprove combustion characteristicsQuad constructionsClimate change adaptationFiberInterference resistance

The invention provides a high-weather-resistant, torsion-resistant and bending-resistant control cable, and relates to the technical field of design of towline cables. The high-weather-resistant, torsion-resistant and bending-resistant control cable includes a cable core formed by mutual twisting of a plurality of reinforced insulating wire cores, an inner liner layer, a reinforced braided shielding layer and an outer sheath layer are arranged in sequence outside the cable core, each reinforced insulating wire core includes a conductor externally wrapped by an insulating layer, and the conductor is formed by intertwisting copper wires and Dupont fibers in the same direction; and the reinforced braided shielding layer is formed by braiding copper wires and Dupont fibers in a combined manner, each spindle of copper wires is provided with a piece of Dupont fiber, and the braiding density of the reinforced braided shielding layer is larger than 90%. The high-weather-resistant, torsion-resistant and bending-resistant control cable provided by the invention has the characteristics of excellent interference resistance, torsion resistance, bending resistance and the like, and can meet market requirements.

Owner:江苏安胜电缆有限公司

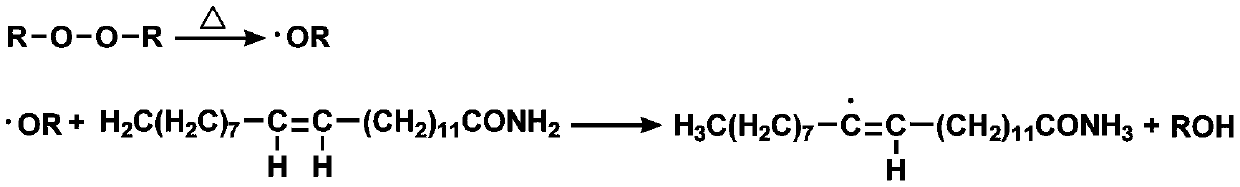

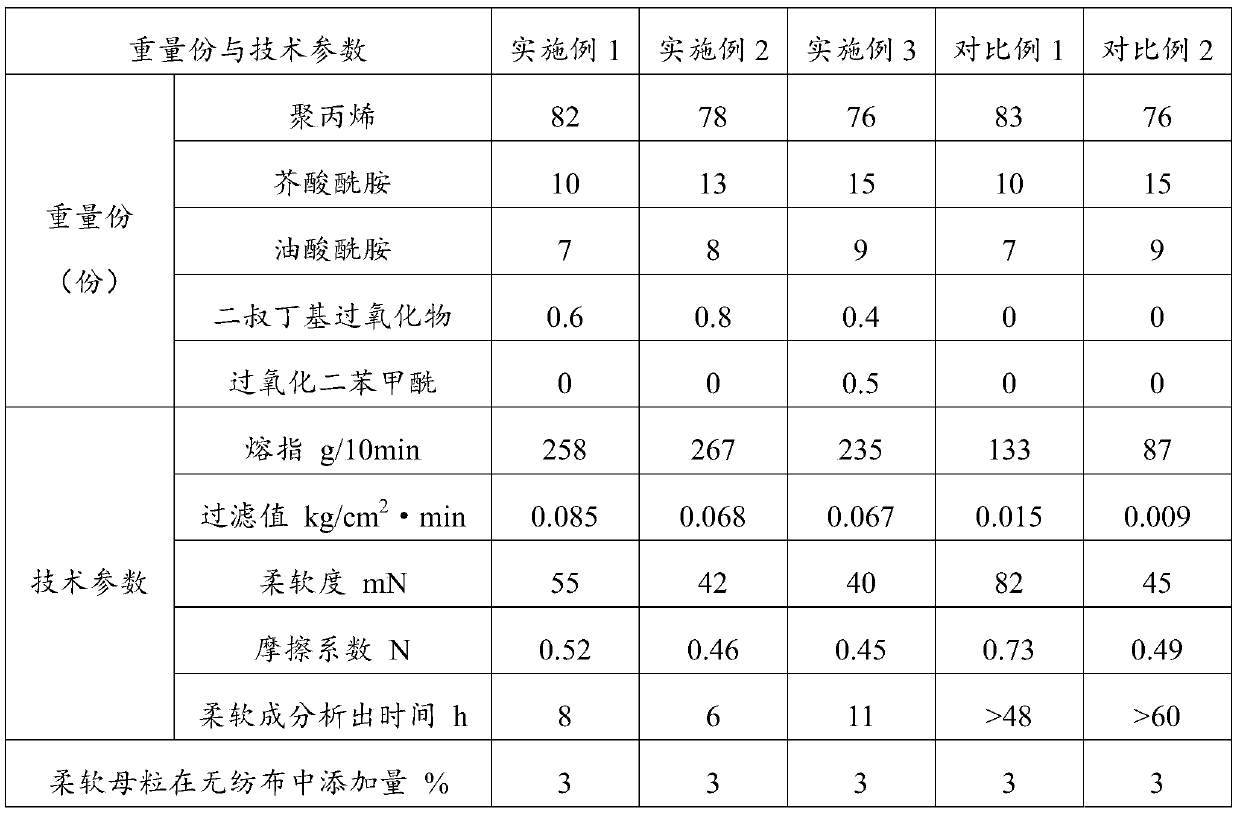

Soft nonwoven master batch and preparation method thereof

ActiveCN110358189AGood soft effectGood softnessMonocomponent polyolefin artificial filamentArtifical filament manufacturePolypropyleneChemistry

The invention discloses a soft nonwoven master batch. The master batch is characterized in that the master batch comprises, by weight, 75-85 parts of a carrier, 14-24 parts of additives and 0.3-0.9 part of an active assistant, the carrier is a polypropylene homopolymer, the additives are oleamide and erucamide, and the active assistant is one or two of di-tert-butyl peroxide and dibenzoyl peroxide. A preparation method of the master batch comprises the following steps: proportioning all above components according to corresponding weight parts, heating and mixing erucamide powder and the activeassistant in a high-speed mixer in advance, adding the obtained mixture and other components into a co-rotating twin-screw extruder, and blending, extruding, drawing and pelletizing the finally obtained mixture to obtain the soft nonwoven master batch. The soft nonwoven master batch prepared in the invention allows the soft components to quickly and stably precipitate and achieves a good softening effect, so the influences brought by the environment and the like are reduced, and the softness of the product can be ensured without increasing the cost of raw materials.

Owner:广东一龙新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com