Secondary mesh combined plastic punched film and method for making same

A combined, perforated film technology, applied in the field of perforated film, can solve problems such as functional and performance defects, achieve the effect of strong three-dimensional sense, enhanced air permeability and permeability, and improved elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

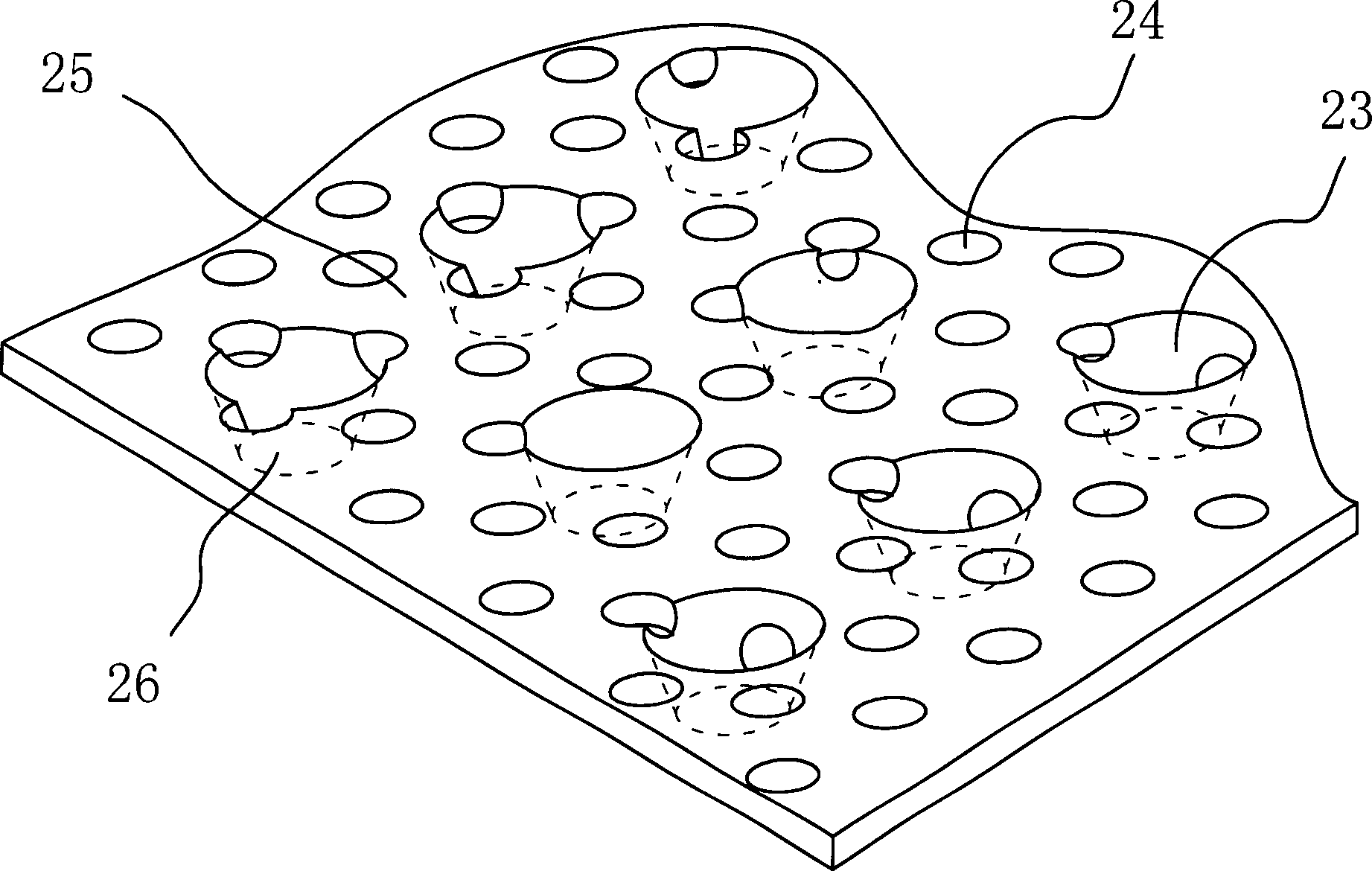

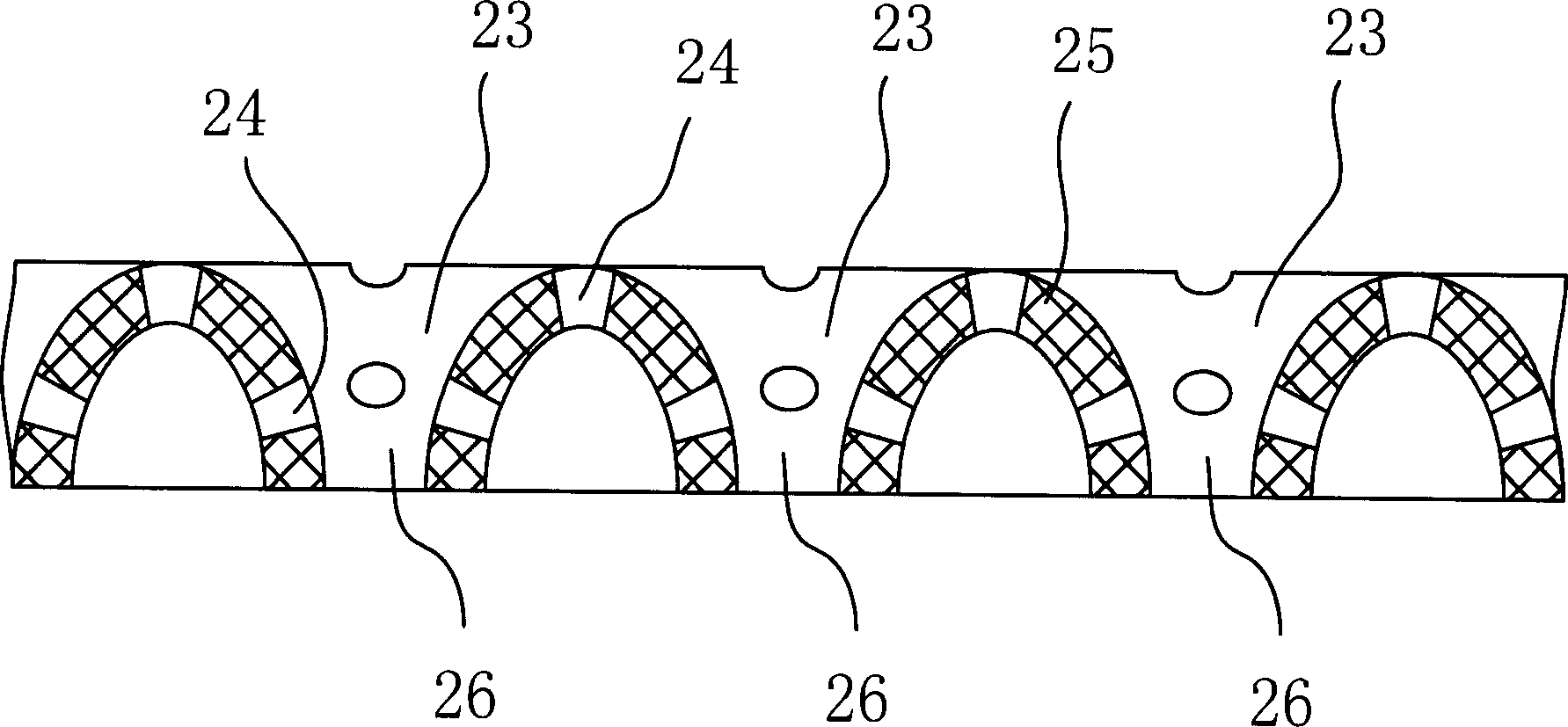

[0038] Embodiment 1: A secondary mesh combined plastic perforated film and its manufacturing method, using a single-layer plastic film as the base material, forming a uniformly distributed small hole mesh by the first punching process , the second punching to form a uniformly distributed large-pore mesh. The aperture of the small mesh is 0.2mm, and the aperture of the large mesh is 0.5mm. The opening density of the small mesh is 230 holes / cm 2 , the hole density of the large mesh is 100 holes / cm 2 ; The opening rate of the small mesh is 30%, and the opening rate of the large mesh is 28%. Both the small hole and the large hole are circular (other geometric shapes are also possible).

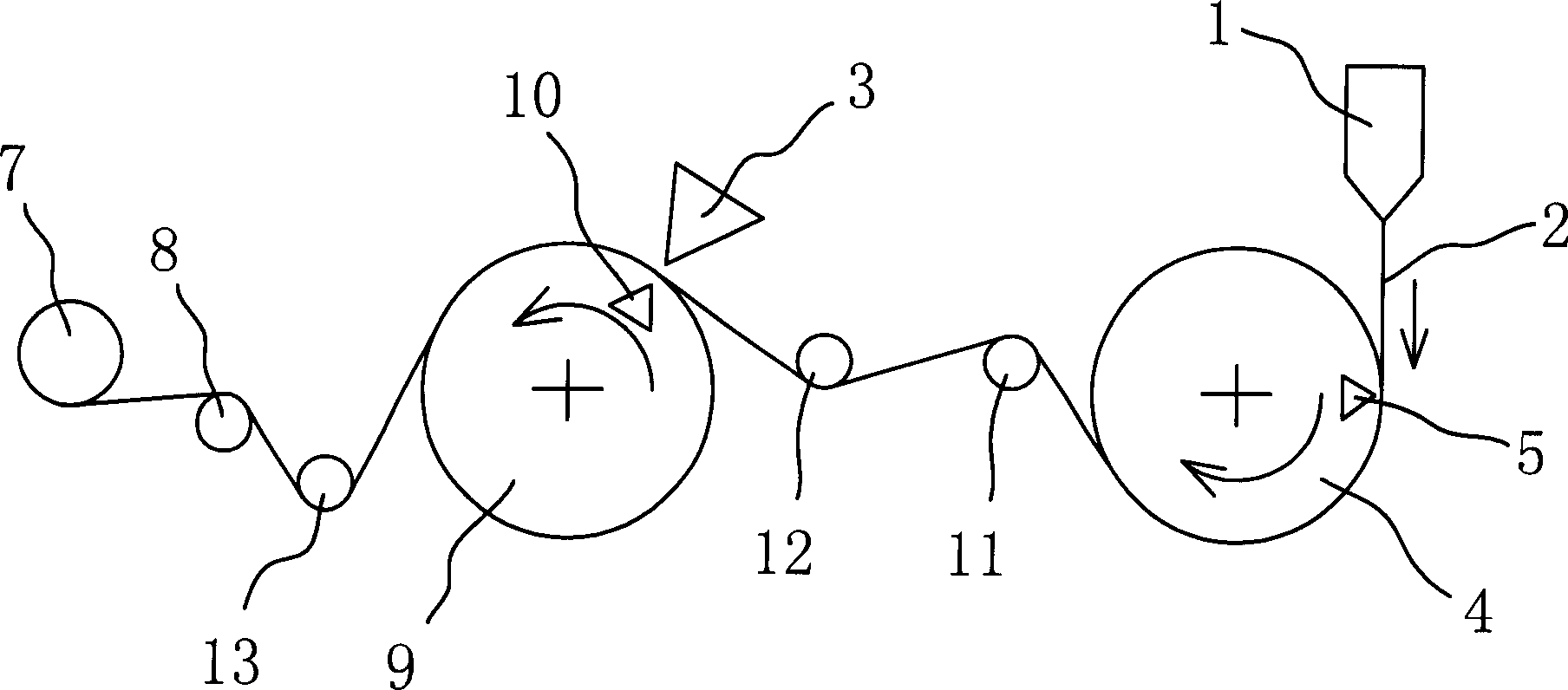

[0039] Depend on image 3As shown, during production, the PE particles and hydrophilic particles are mixed, extruded through the casting machine 1 at high temperature, and the casting film 2 in the high-temperature molten state flows out from the T-shaped die of the casting machine 1, and then...

Embodiment 2

[0040] Embodiment 2: A secondary mesh combined plastic perforated film and its manufacturing method, using a single-layer plastic film as the base material, formed by a secondary punching process, and forming a uniformly distributed small hole mesh for the first time , the second punching to form a uniformly distributed large-pore mesh. The aperture of the small mesh is 0.1mm, and the aperture of the large mesh is 0.5mm. The opening density of the small mesh is 400 holes / cm 2 , the hole density of the large mesh is 130 holes / cm 2 ; The opening rate of the small mesh is 27%, and the opening rate of the large mesh is 31%. Both the small hole and the large hole are pentagonal (other geometric shapes are also possible).

[0041] Depend on Figure 4 As shown, during production, the solid cast film 14 is sent out from the discharge roller 6, and is mechanically perforated by steel rollers 15 and 16. Set hot oil to heat, so as to realize the process of punching small hole mesh f...

Embodiment 3

[0042] Embodiment 3: A secondary mesh combined plastic perforated film and its manufacturing method, using a single-layer plastic film as the base material, formed by a secondary punching process, and forming a uniformly distributed small hole mesh for the first time , the second punching to form a uniformly distributed large-pore mesh. The aperture of the small mesh is 0.25mm, and the aperture of the large mesh is 0.5mm. The opening density of the small mesh is 200 holes / cm 2 , the hole density of the large mesh is 80 holes / cm 2 ; The opening rate of the small mesh is 20%, and the opening rate of the large mesh is 28%. The hole patterns of small holes and large holes are hexagonal (other geometric shapes are also possible).

[0043] Production process: the first punching process in the first embodiment is combined with the second punching process in the second embodiment. Alternatively, the first drilling process in the second embodiment is combined with the second drilli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com