High-weather-resistant, torsion-resistant and bending-resistant control cable

A bending control and high weather resistance technology, which is applied in the direction of bendable cables, insulated cables, communication cables, etc., can solve the problems of inability to resist bending and torsion at the same time, the copper wire of the shielding layer is broken, and the sheath is wrinkled and deformed. , to achieve a wide range of elastic deformation, improve smoothness, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

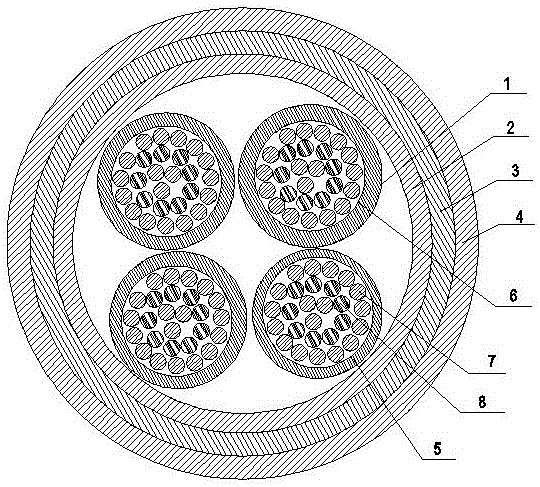

[0015] Such as figure 1 As shown, the present invention includes a cable core formed by twisting a plurality of reinforced insulated cores 1 with each other, and an inner liner 2, a reinforced braided shielding layer 3 and an outer sheath layer 4 are sequentially arranged outside the cable core; each strand Reinforced insulated wire cores 1 respectively include conductors 6 wrapped with insulating layers 5 on the outside, conductors 6 are twisted in the same direction by first copper wires 7 and first DuPont fiber wires 8; reinforced braided shielding layer 3 is made of second copper wires Wire and the second DuPont fiber wire are braided in combination, one DuPont fiber wire is arranged in each copper wire, and the braiding density of the reinforced braided shielding layer 3 is greater than 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com