Patents

Literature

308 results about "Industrial automation systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

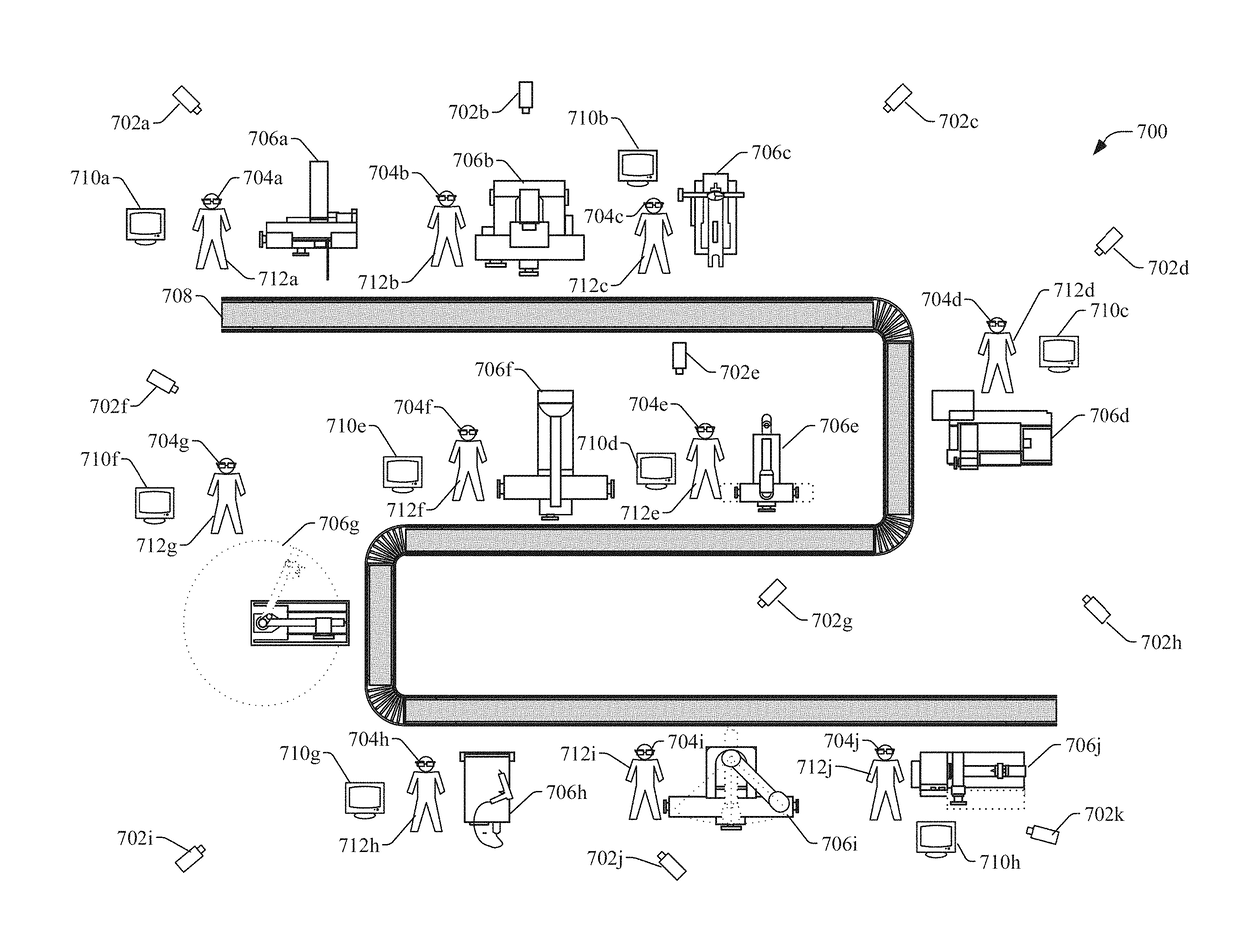

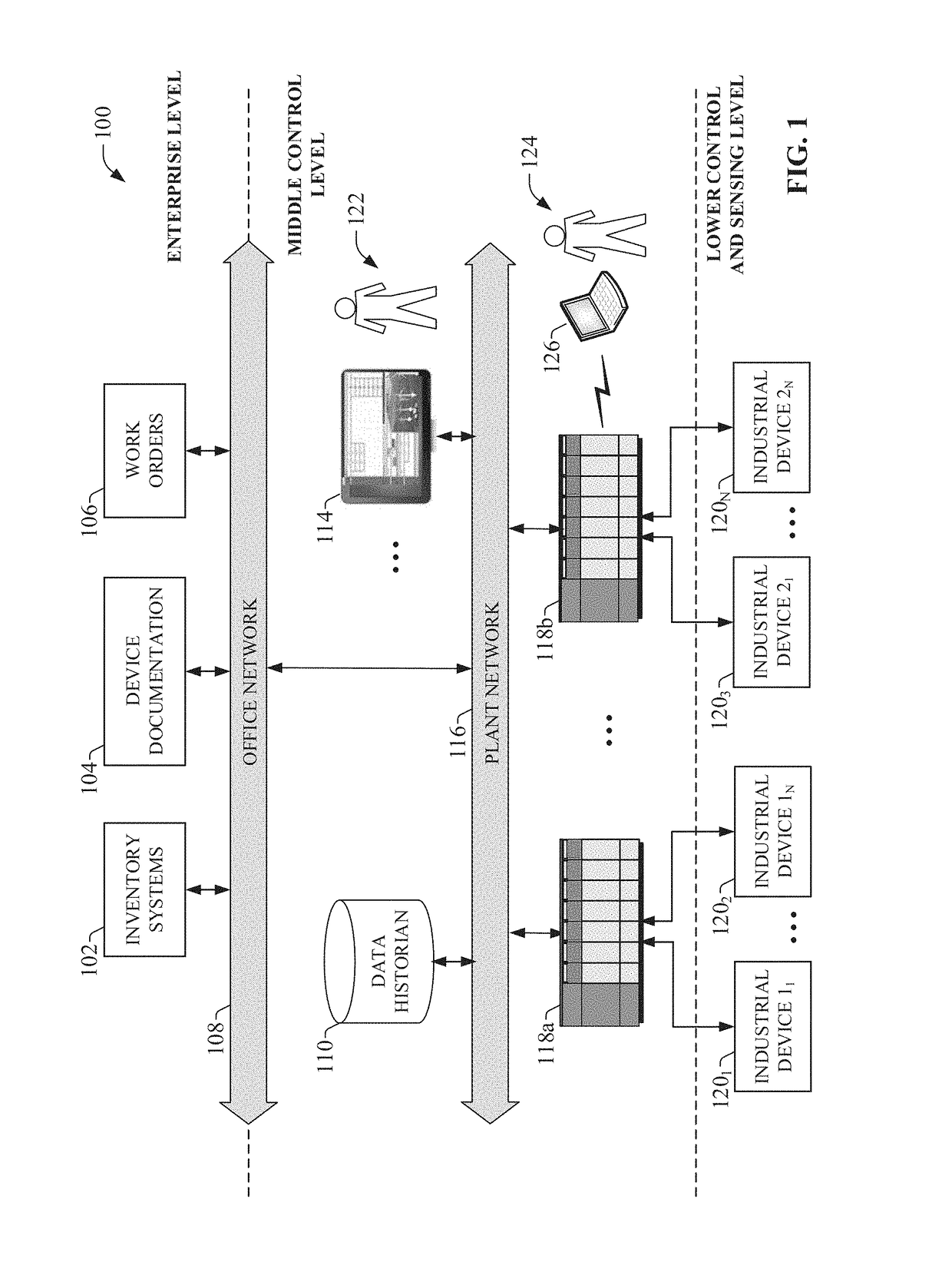

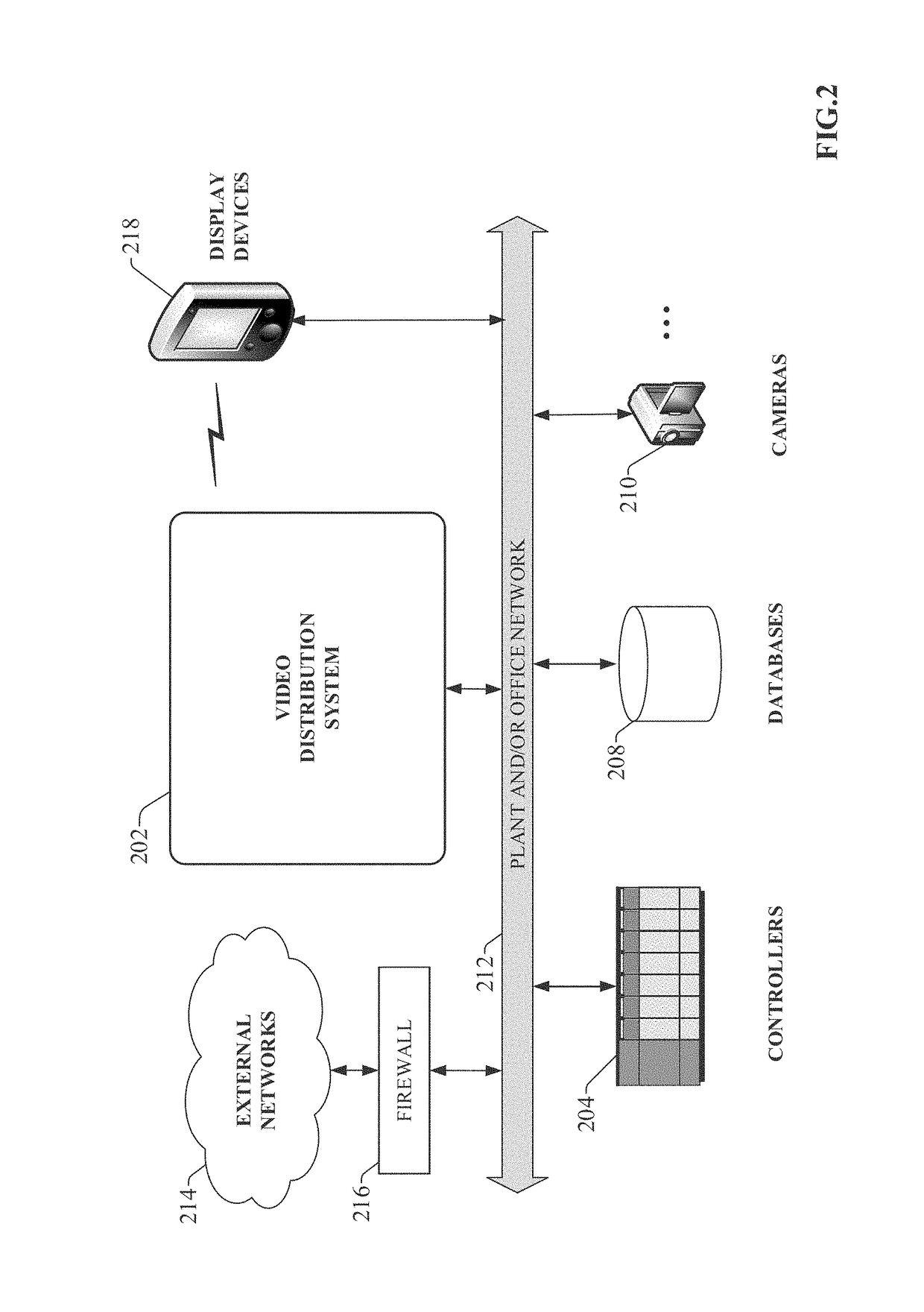

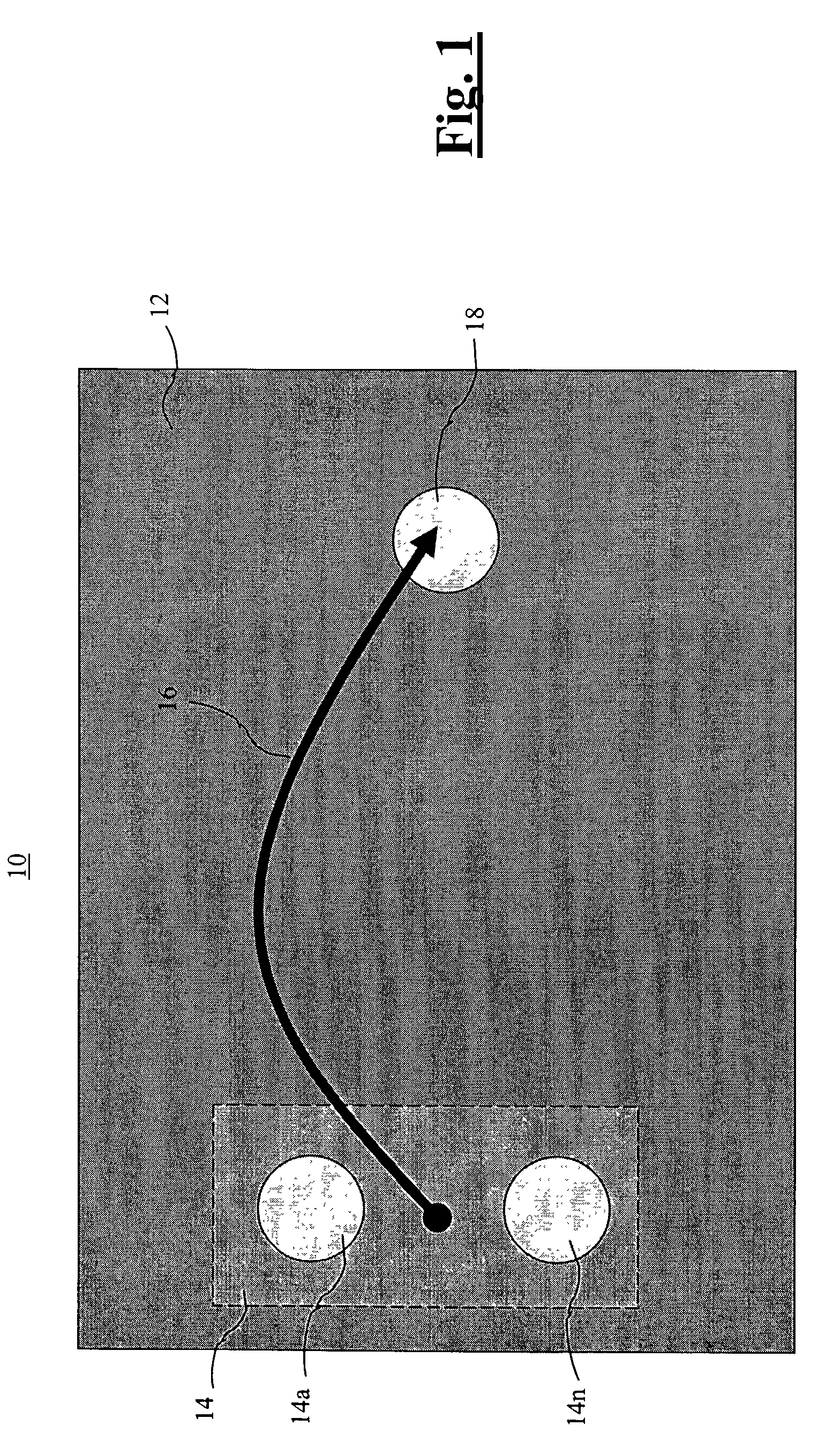

Analyzing video streams in an industrial environment to identify potential problems and select recipients for a display of video streams related to the potential problems

ActiveUS20170300753A1Television system detailsColor television signals processingSubject matterMultimedia

The subject matter disclosed herein relates generally to industrial automation systems, and, more particularly, to collecting video streams from a variety of video devices in an industrial environment, identifying and analyzing potential problems in the industrial environment using the video streams, and presenting the video streams and data associated with the potential problem to appropriate recipients.

Owner:ROCKWELL AUTOMATION TECH

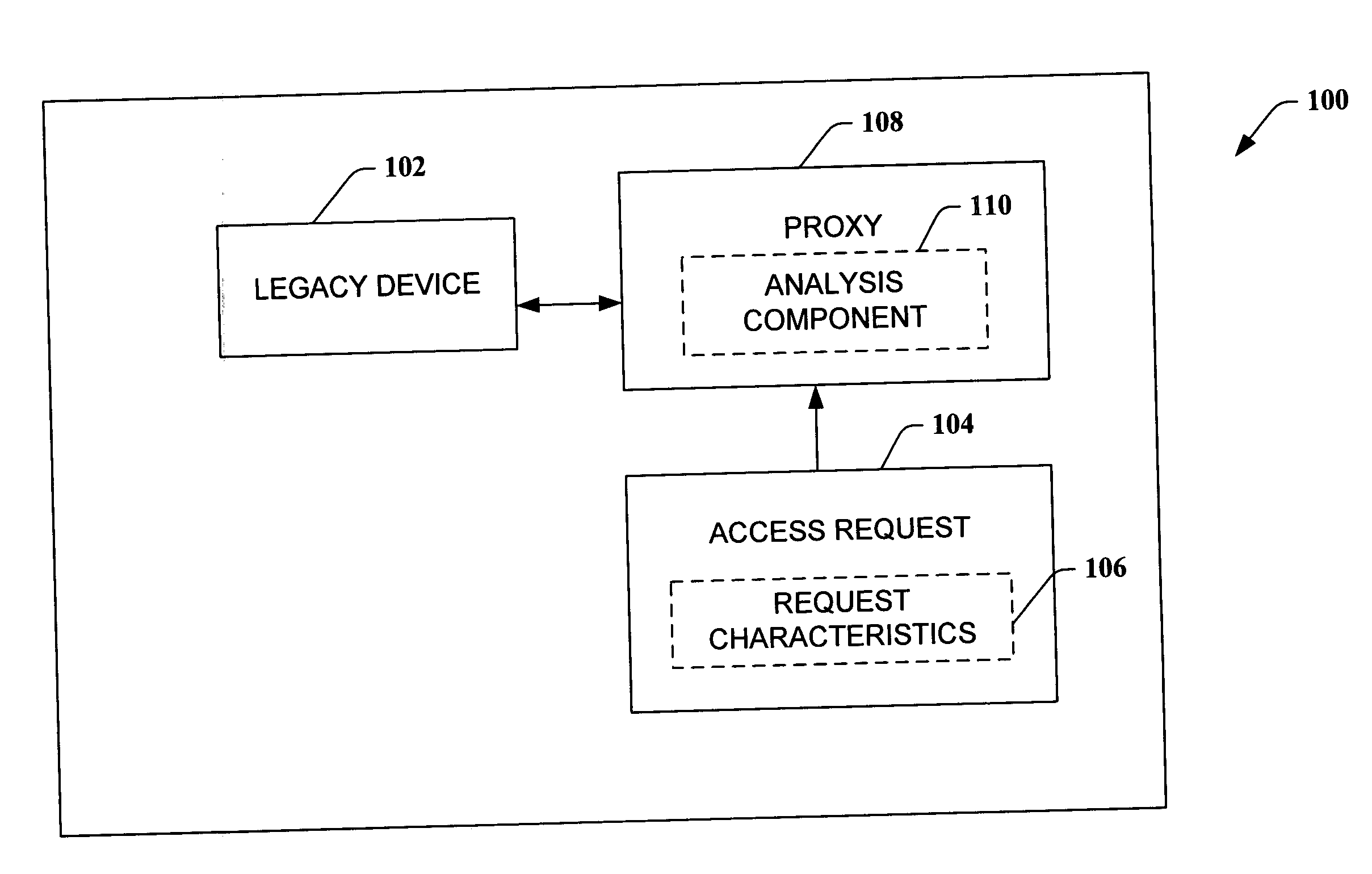

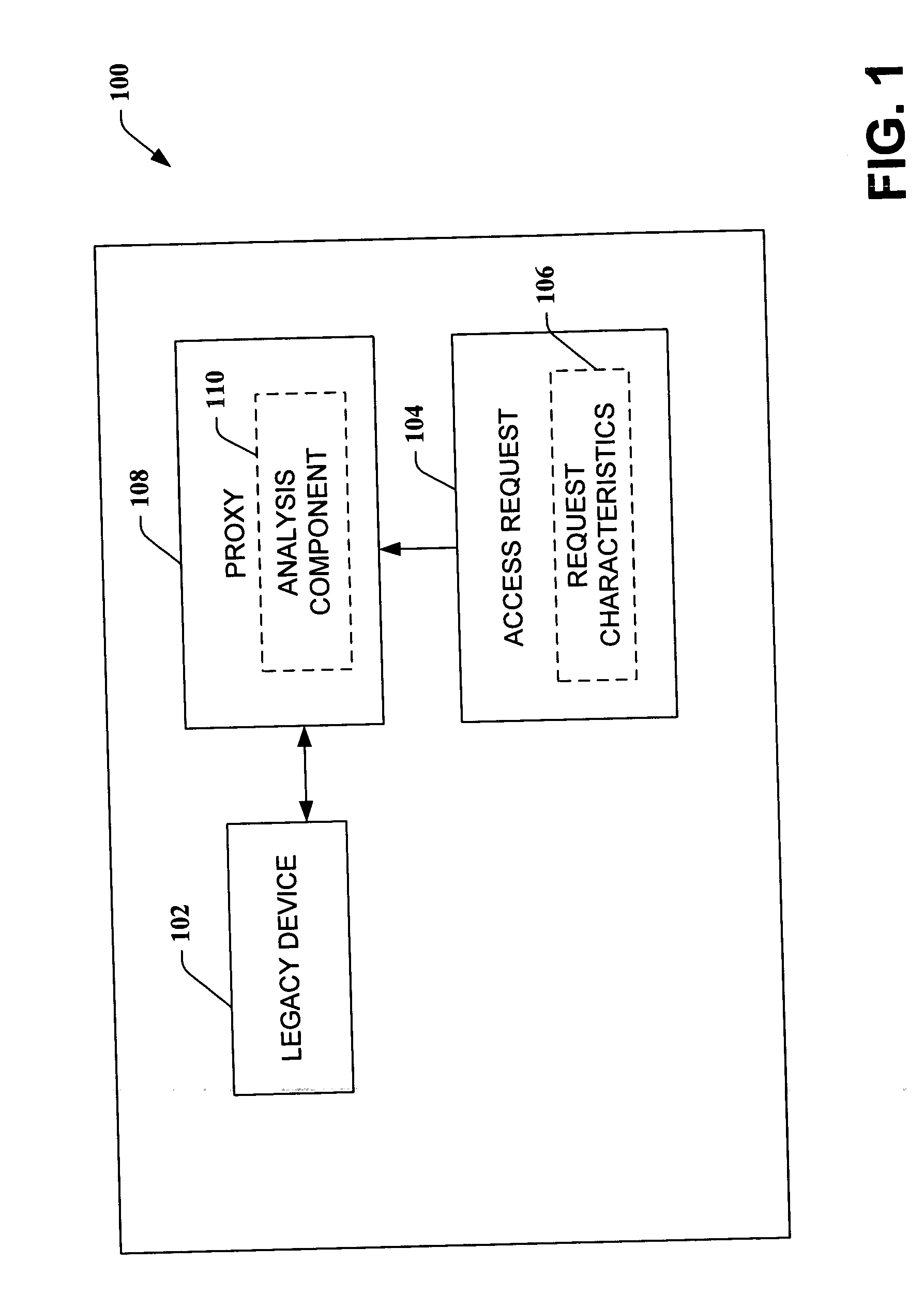

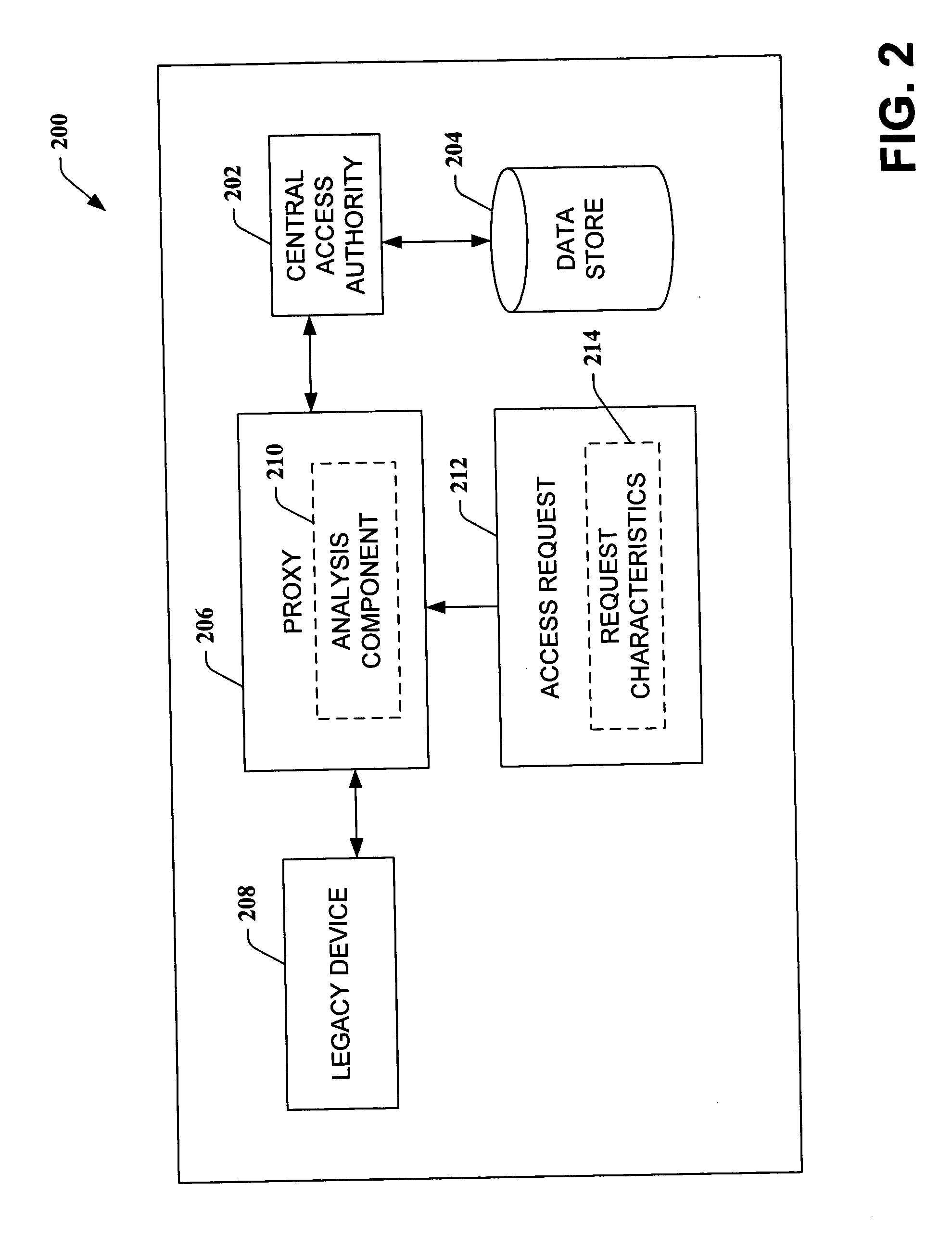

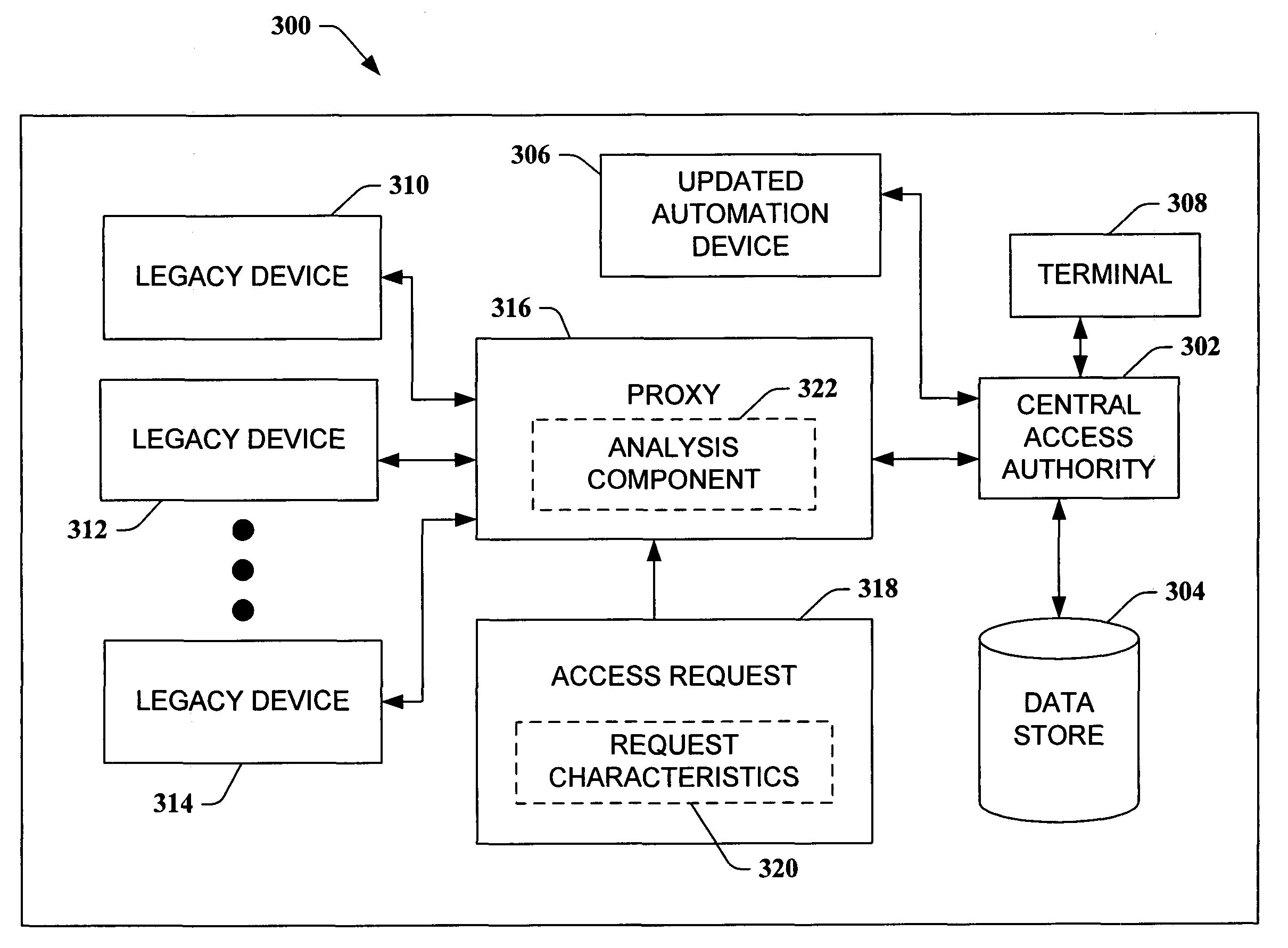

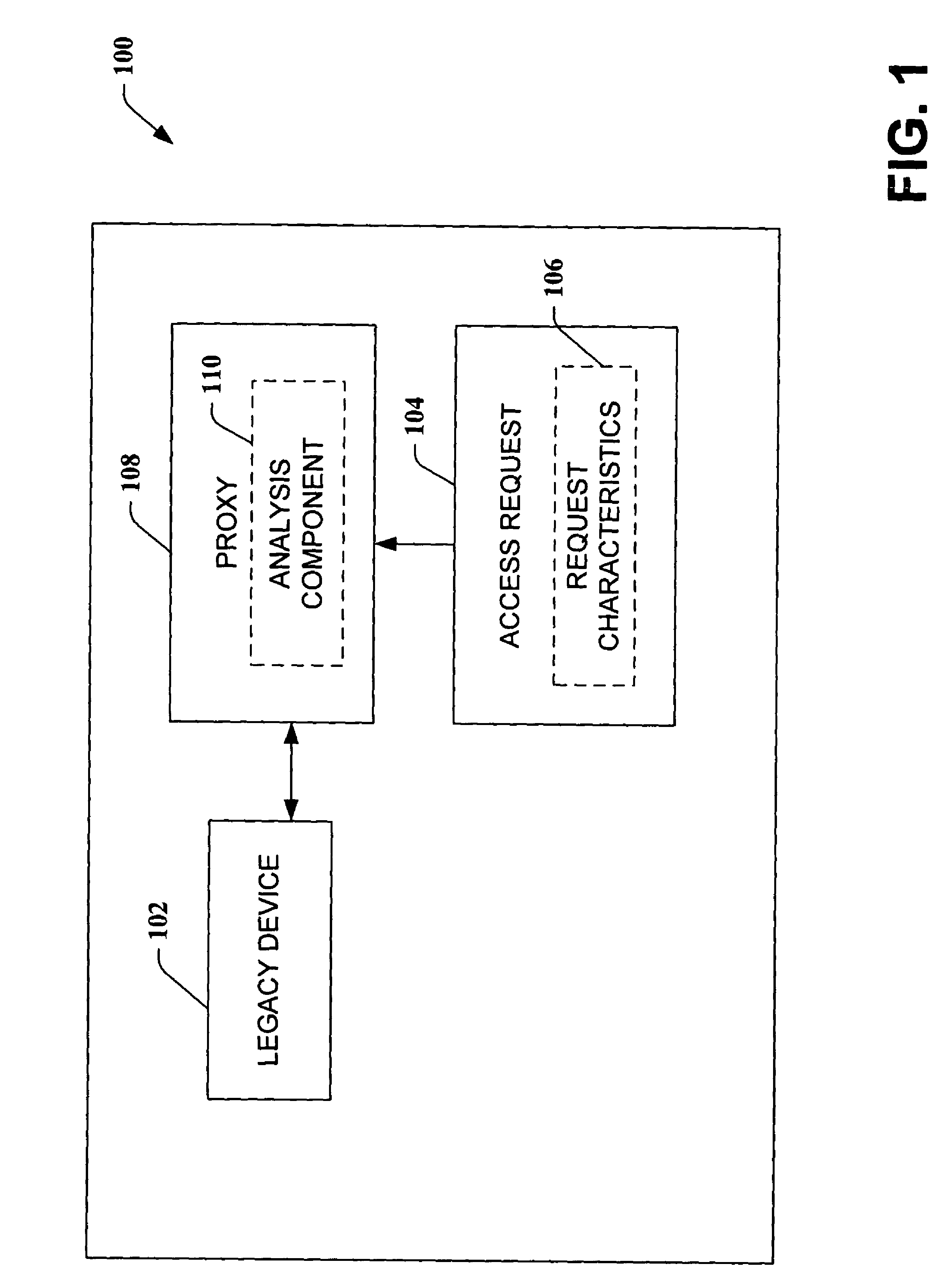

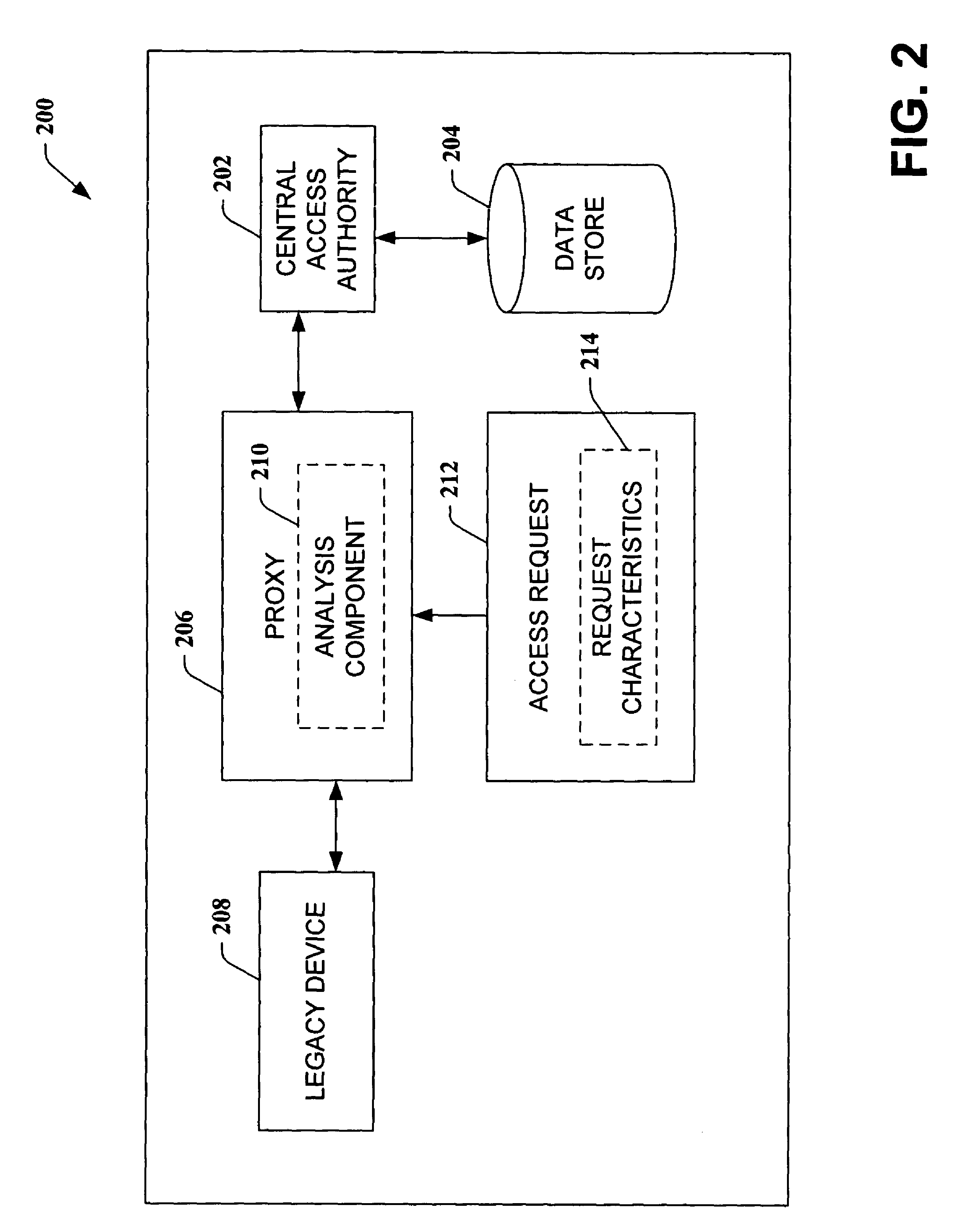

Centrally managed proxy-based security for legacy automation systems

ActiveUS20060085839A1Improve securityAvoid changeProgramme controlDigital data processing detailsCentralized managementDatabase

A system that facilitates enhanced security with respect to an industrial automation environment comprises a legacy device that is existent within an industrial automation system and a central access authority that provides access rules to a proxy. The proxy receives an access request directed to the legacy device and determines whether the access request is permitted based at least in part upon characteristics of the access request and the access rules provided by the central access authority.

Owner:ROCKWELL AUTOMATION TECH

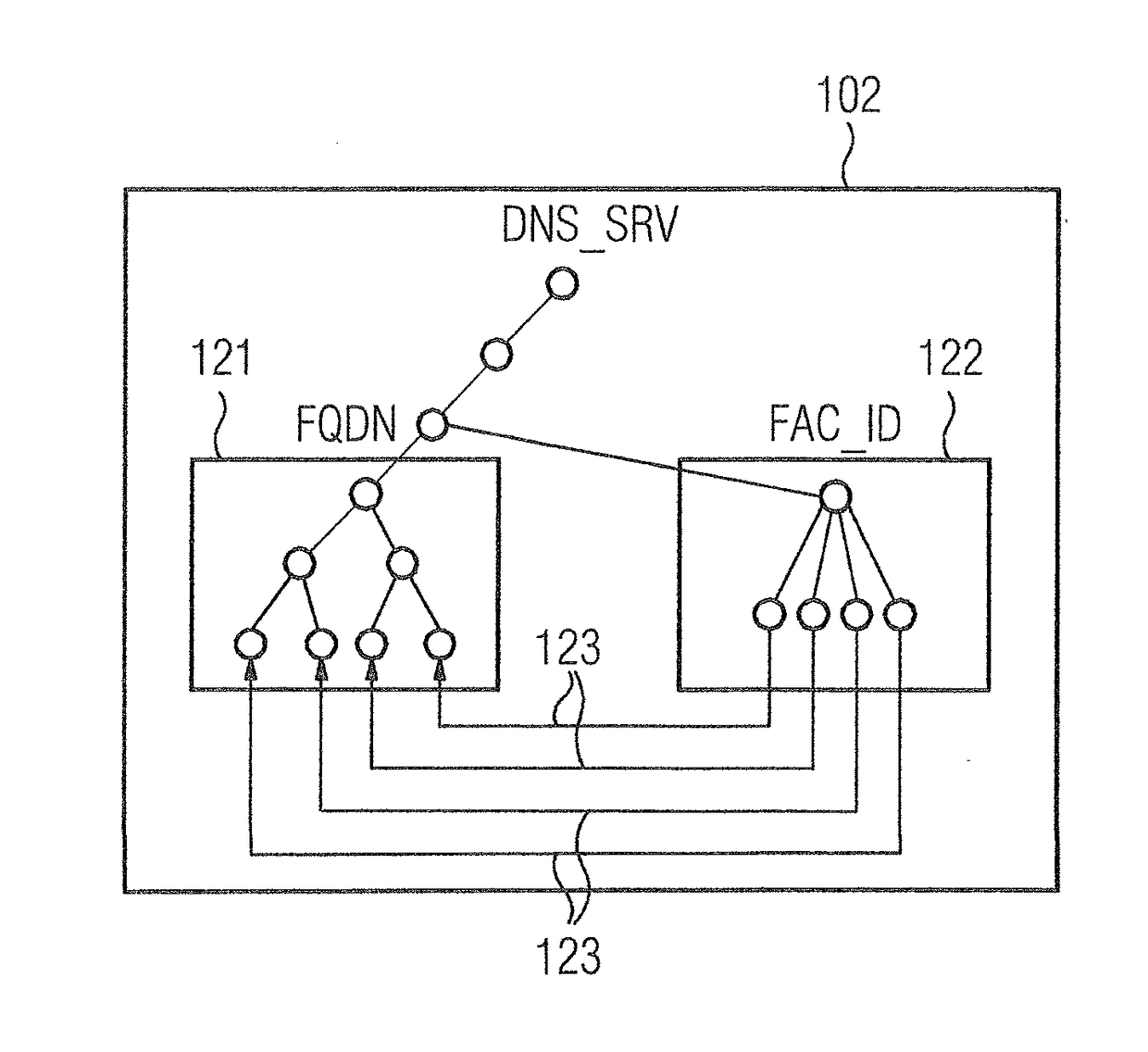

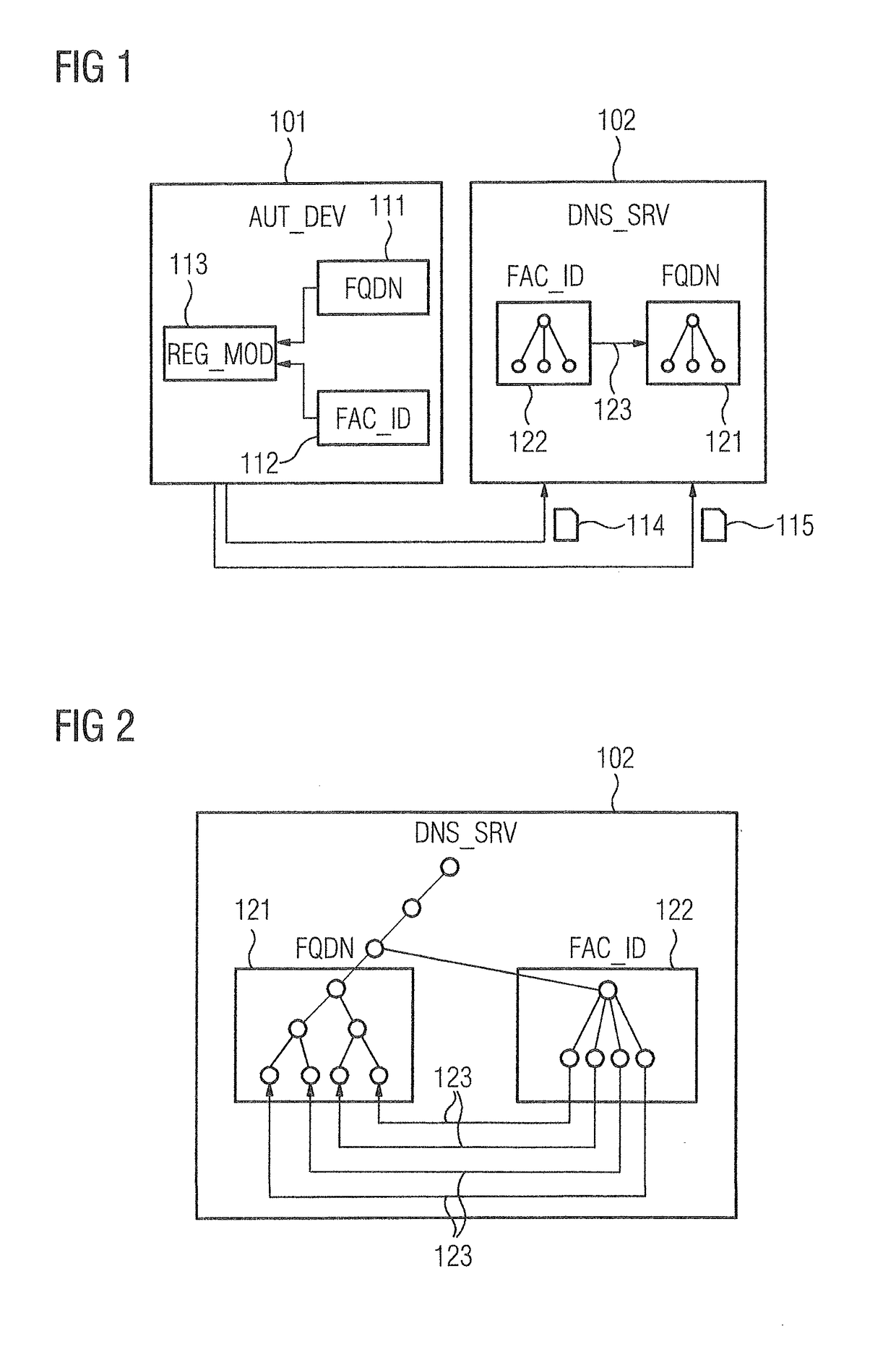

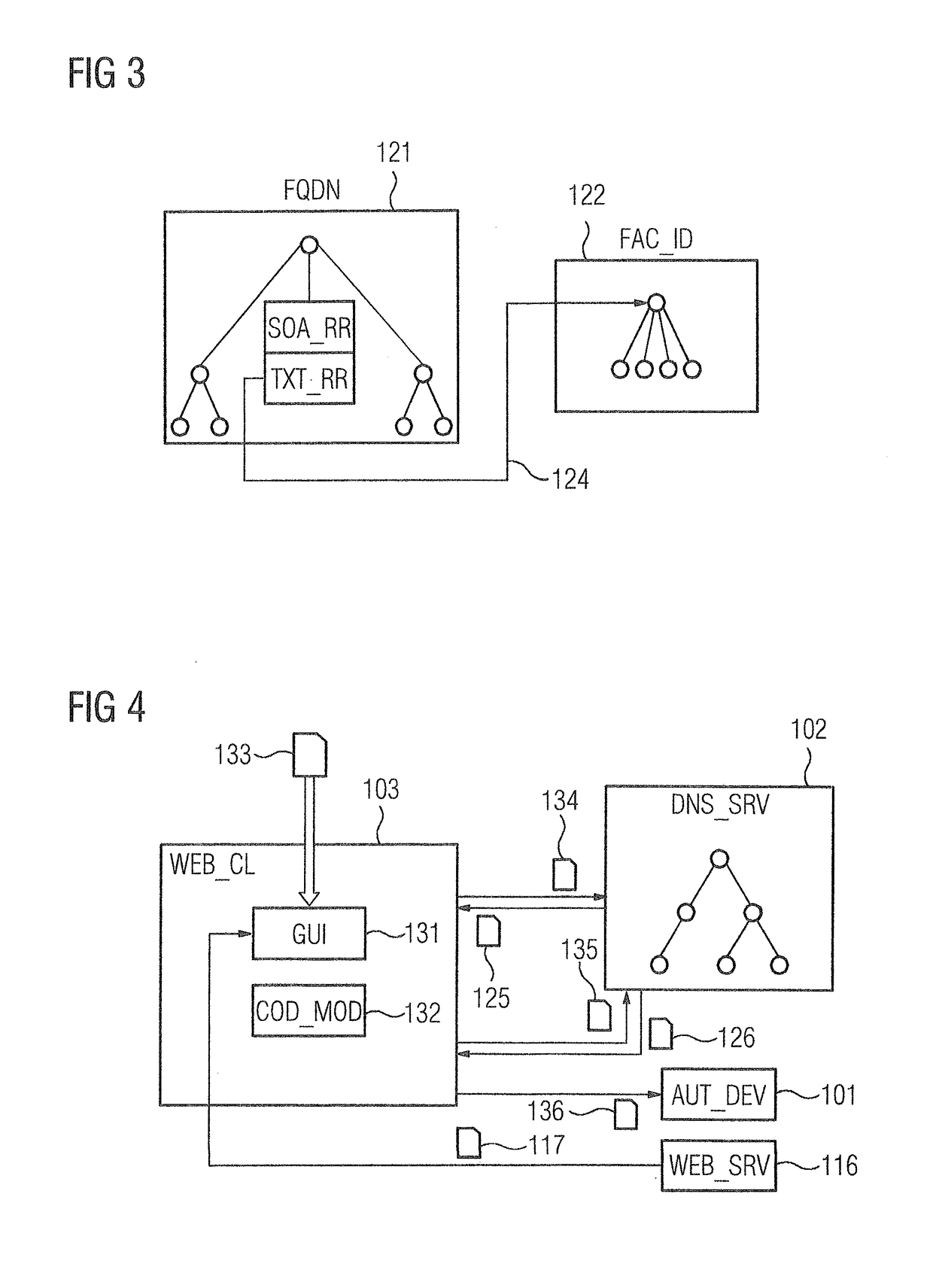

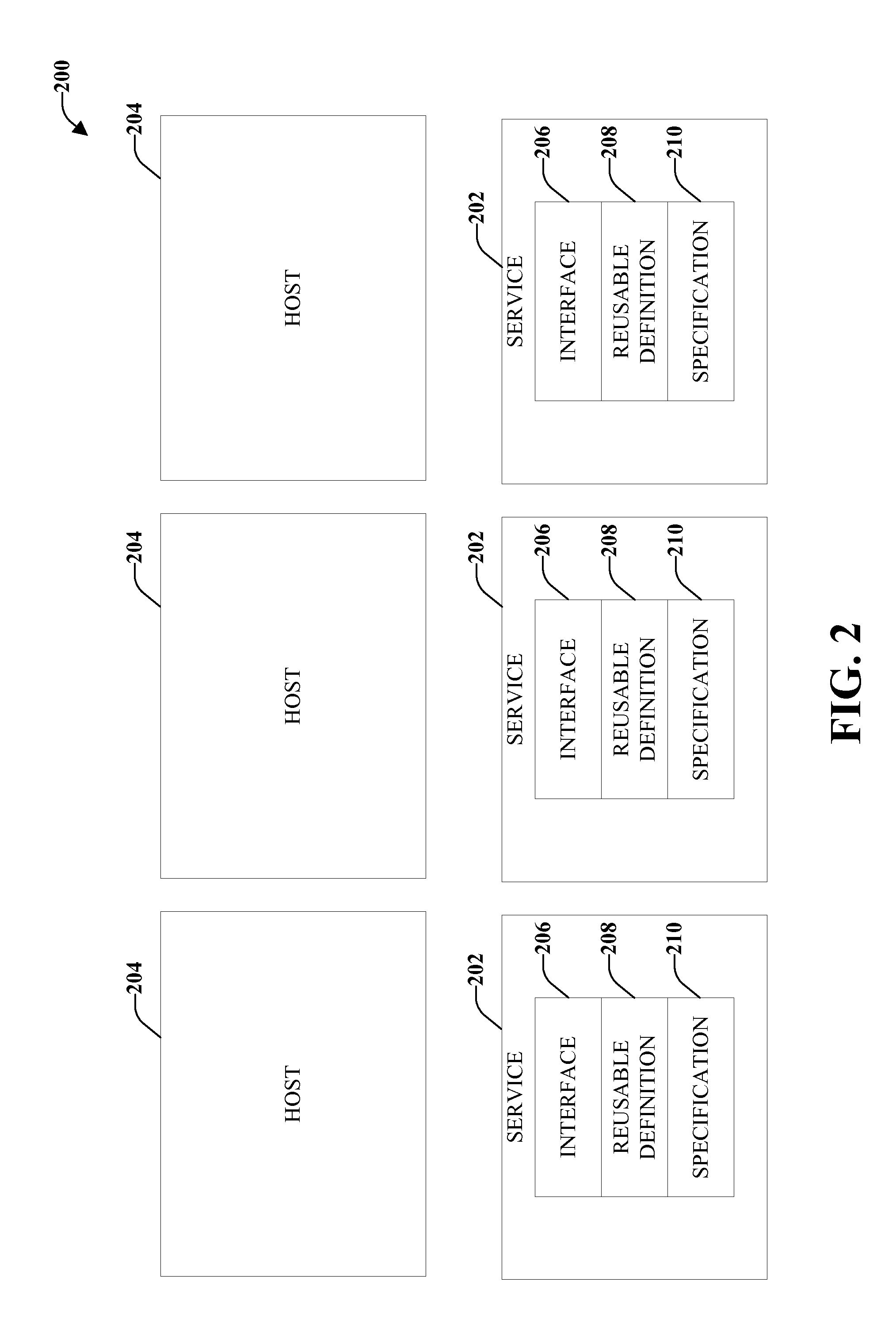

Method for Providing an Expanded Name Service for an Industrial Automation System

ActiveUS20180077109A1Easy to implementReliable responseProgramme controlTransmissionStructure of Management InformationNetwork addressing

A method for providing an expanded name service for an industrial automation system, wherein name-address assignments between device names and communication network addresses are registered in a name service system to provide an expanded name service for an industrial automation system, where device names registered in the name service system have a hierarchical structure represented by a tree structure, where assignments between device names and plant identification codes are additionally registered in the name service system, where the plant identification codes are registered within the same tree structure as the device names, and where end nodes that are respectively assigned to the plant identification codes in the tree structure comprise either a reference to end nodes which are respectively assigned to the device names or intermediate nodes for plant identification codes comprise a reference to intermediate nodes that are respectively assigned to plant units.

Owner:SIEMENS AG

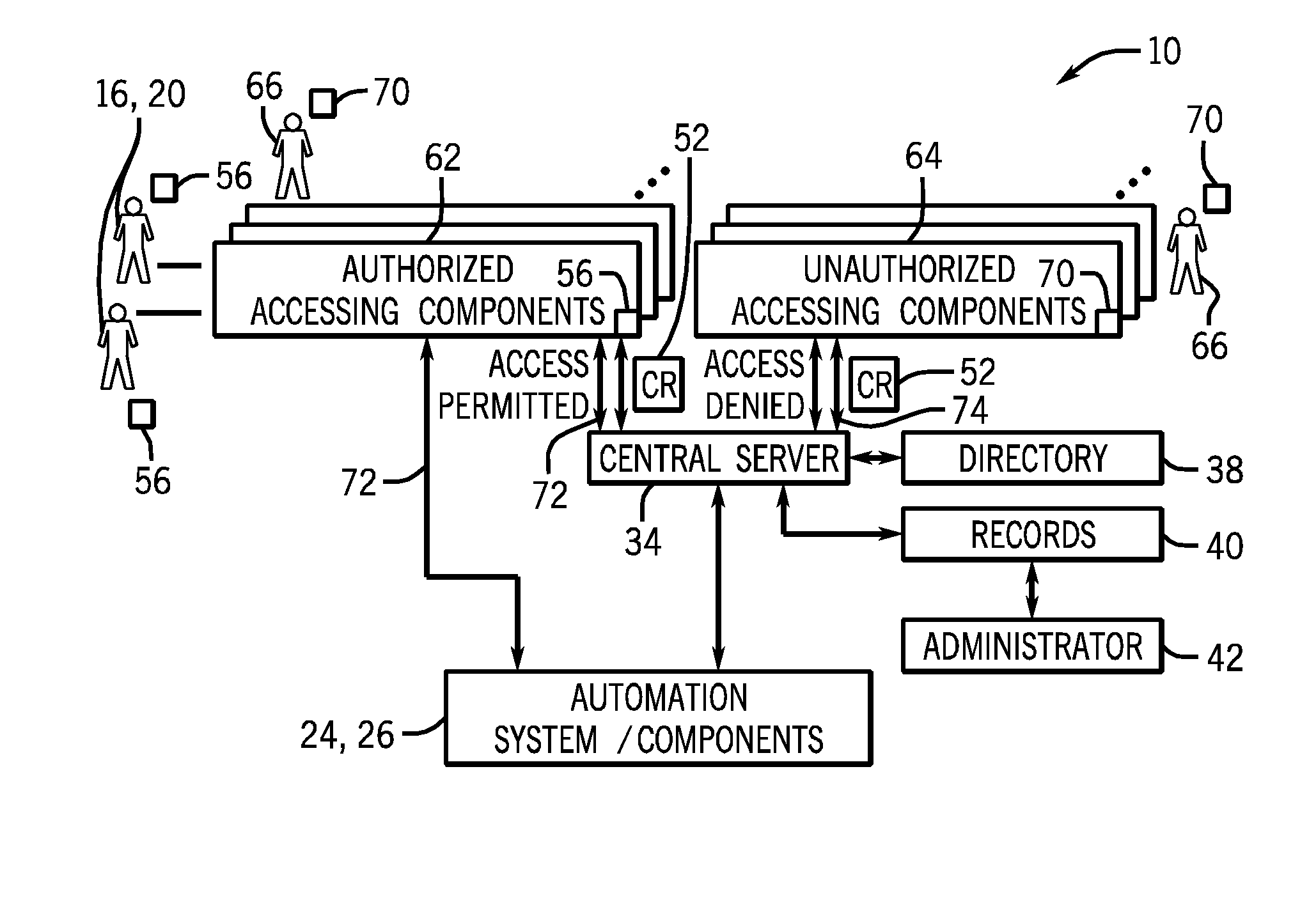

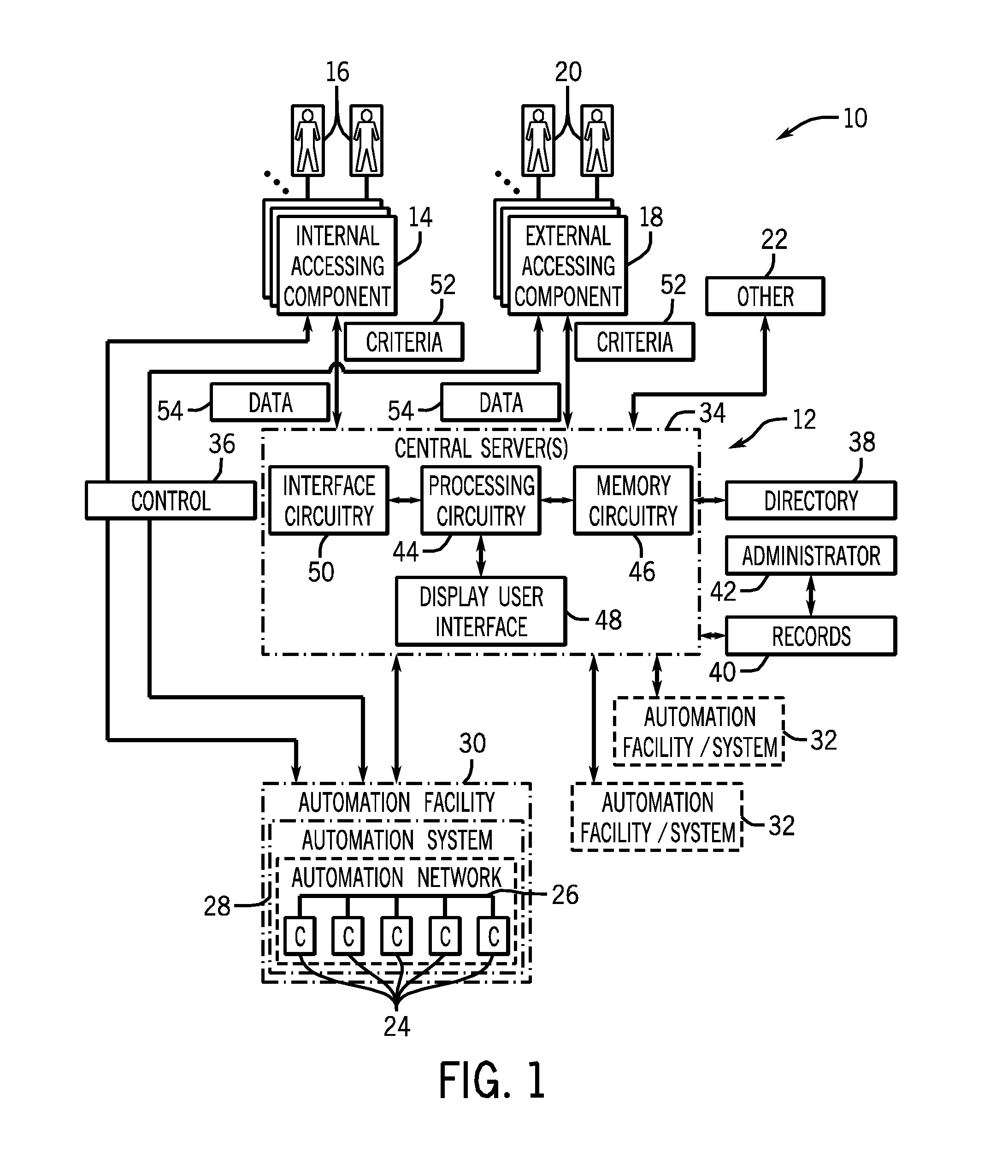

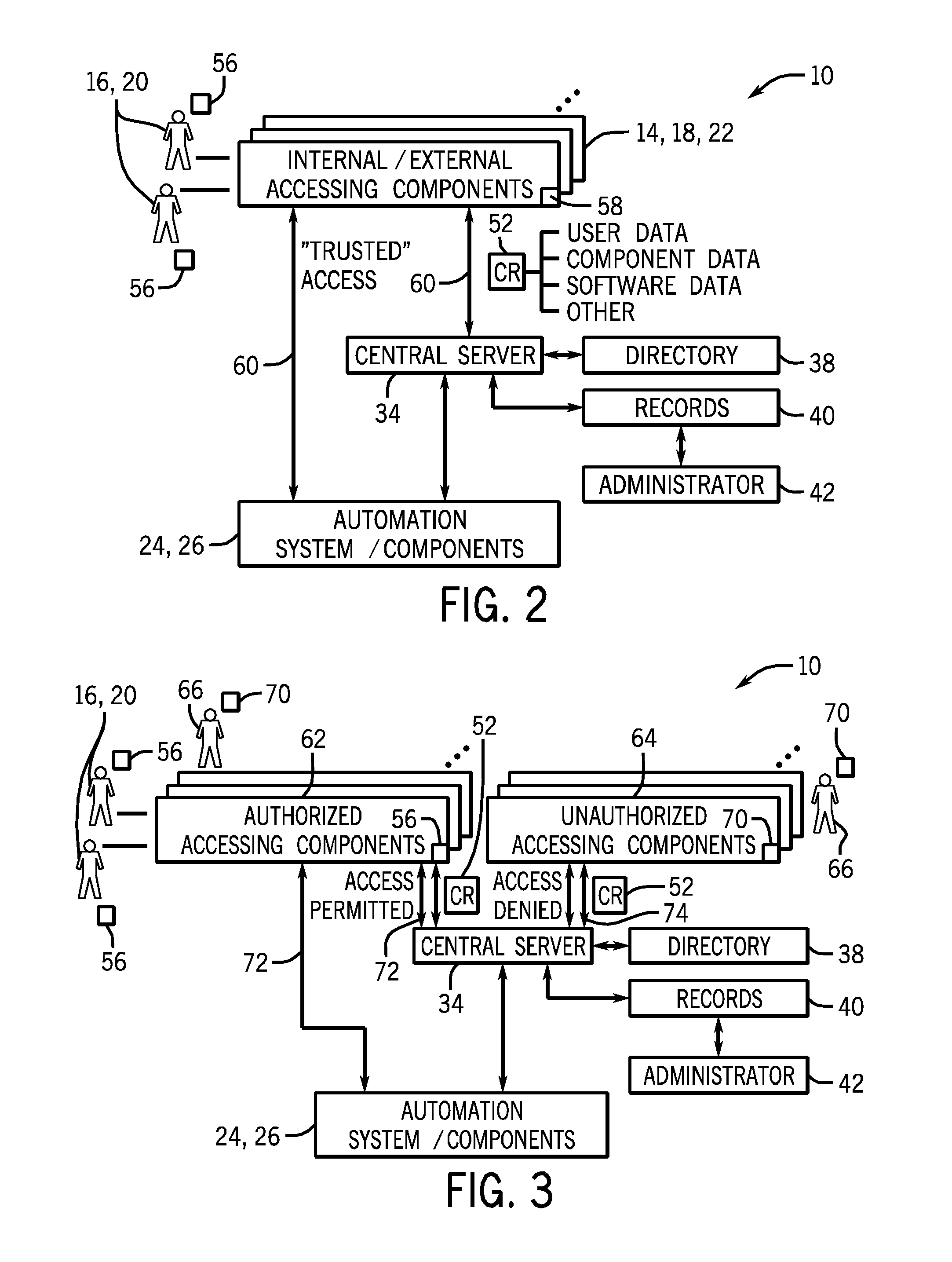

Automation system access control system and method

An improved system and method for controlling access of components to industrial automation system resources by reference to the various operational states of the industrial automation system. A central access control system includes a processing circuitry, interface circuitry configured to receive information pertaining to the operational state of an automation system, memory circuitry, and a display and user interface. In operation, access to automation components are either allowed or denied based on the designation of an operational state of an automation system.

Owner:ROCKWELL AUTOMATION TECH

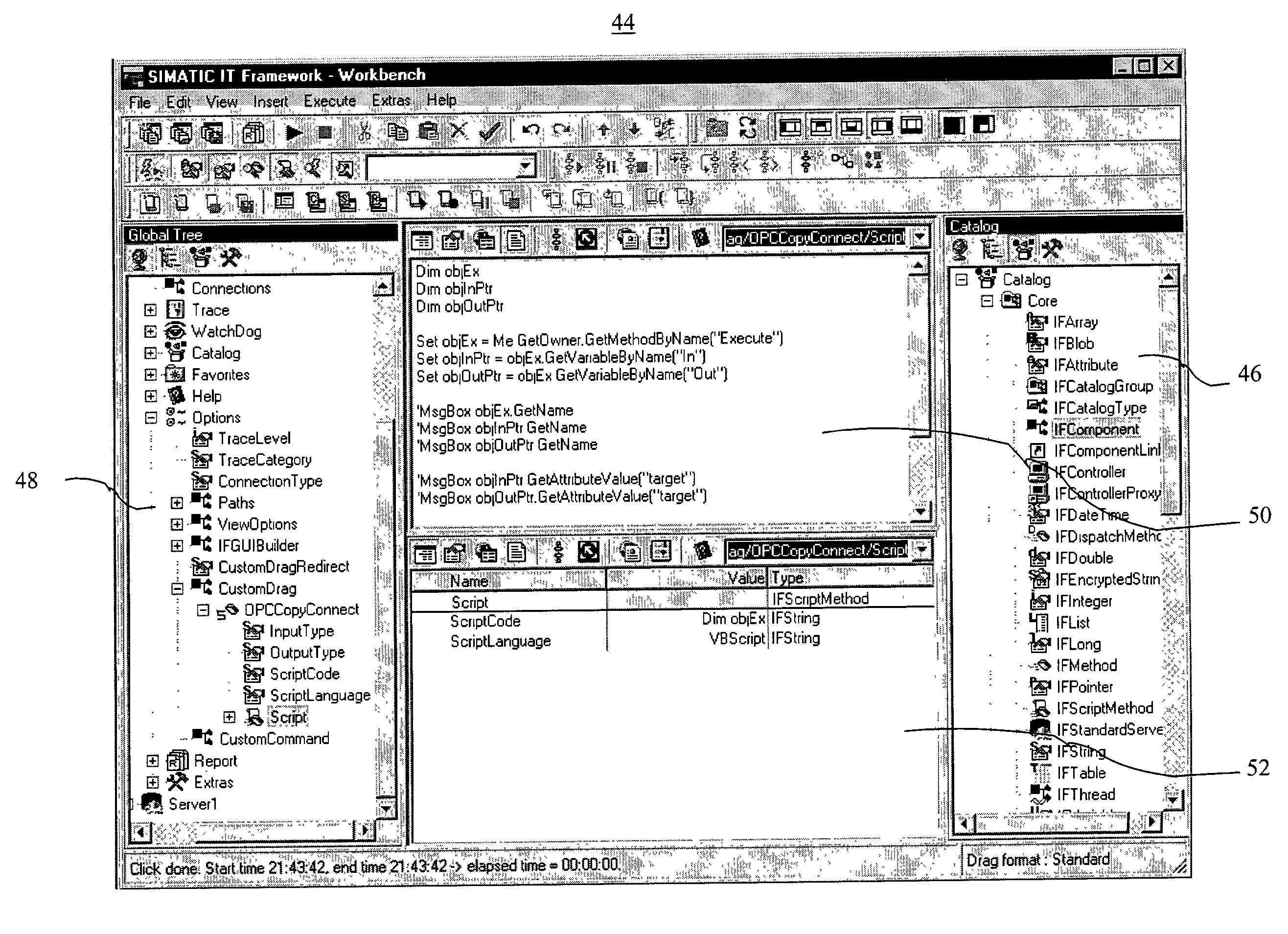

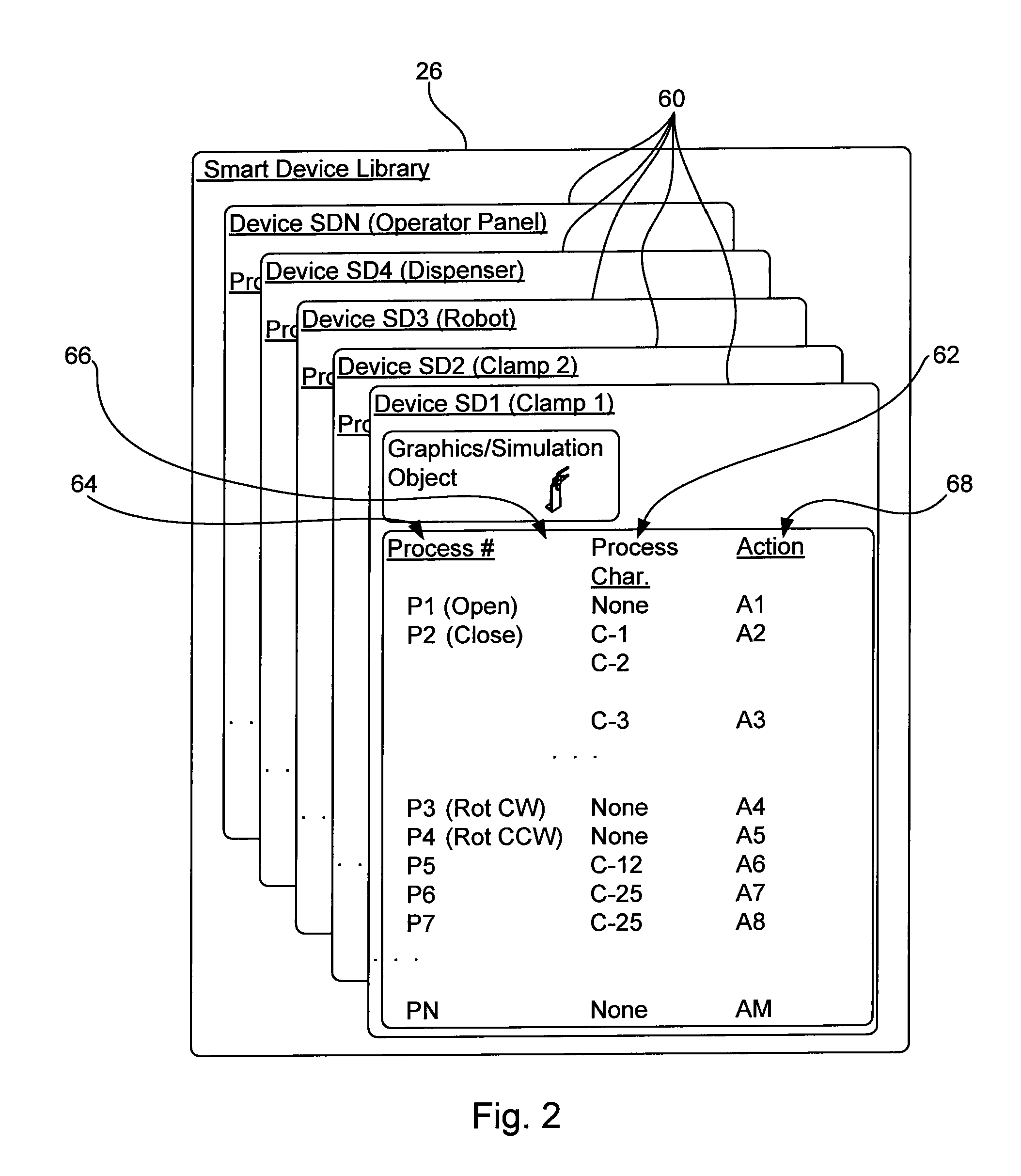

Customizable drag and drop for industrial software applications

ActiveUS7337409B2Extend semanticsCathode-ray tube indicatorsSpecial data processing applicationsDrag and dropSpecific function

Customizable Drag & Drop enables easy activation of user defined or project specific functions concerning two related objects: A user interface graphically displays objects of a particular module. An extending function extends the drag and drop operation to allow the user to define a new set of semantics that is applied when a drag and drop operation is executed. In this way communication can be established using Customizable Drag & Drop extended by a user defined function. Also definition and modification of the deployment of an industrial automation system and hyperlinking of objects in manufacturing execution systems is achieved by Customizable Drag & Drop.

Owner:SIEMENS AG

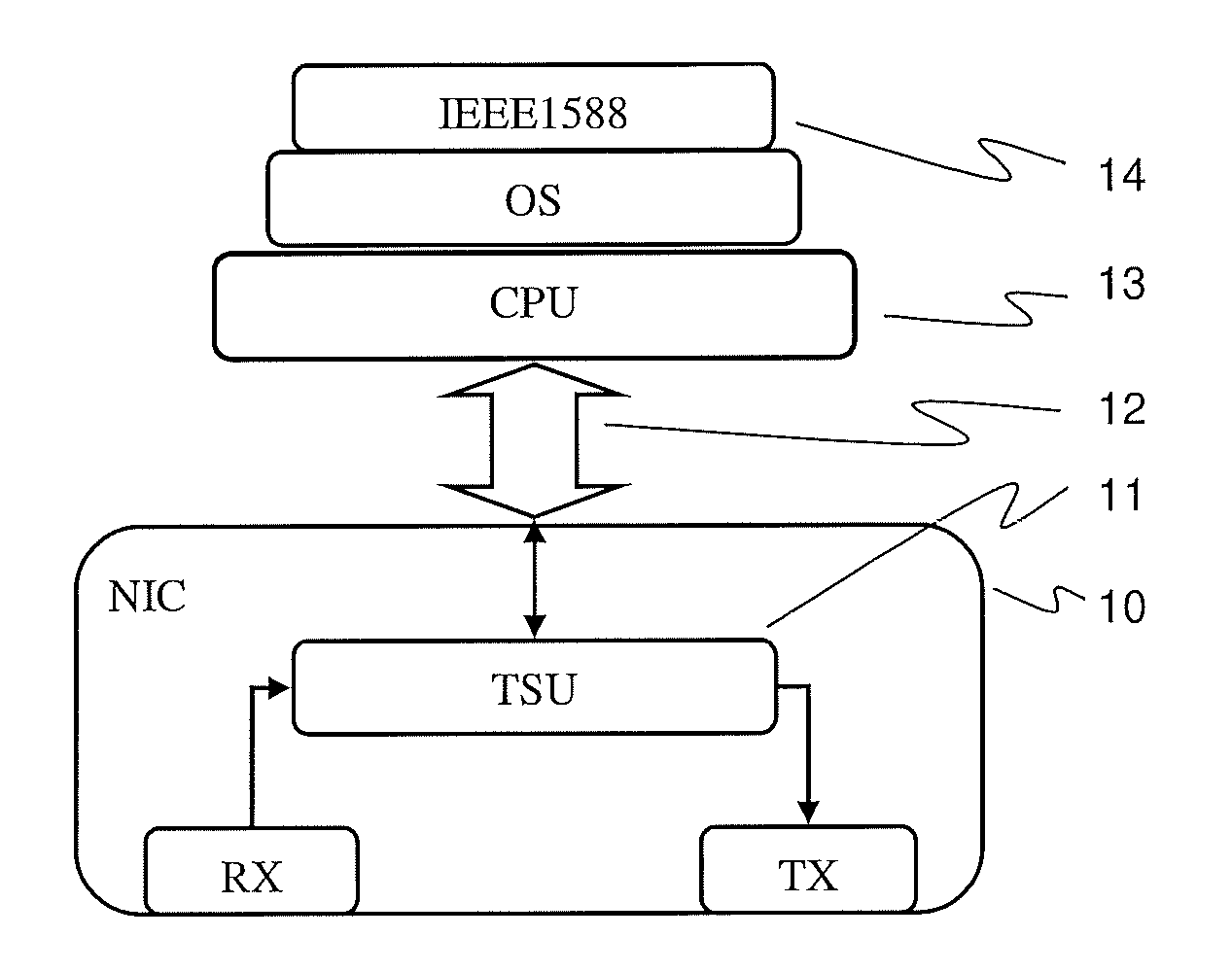

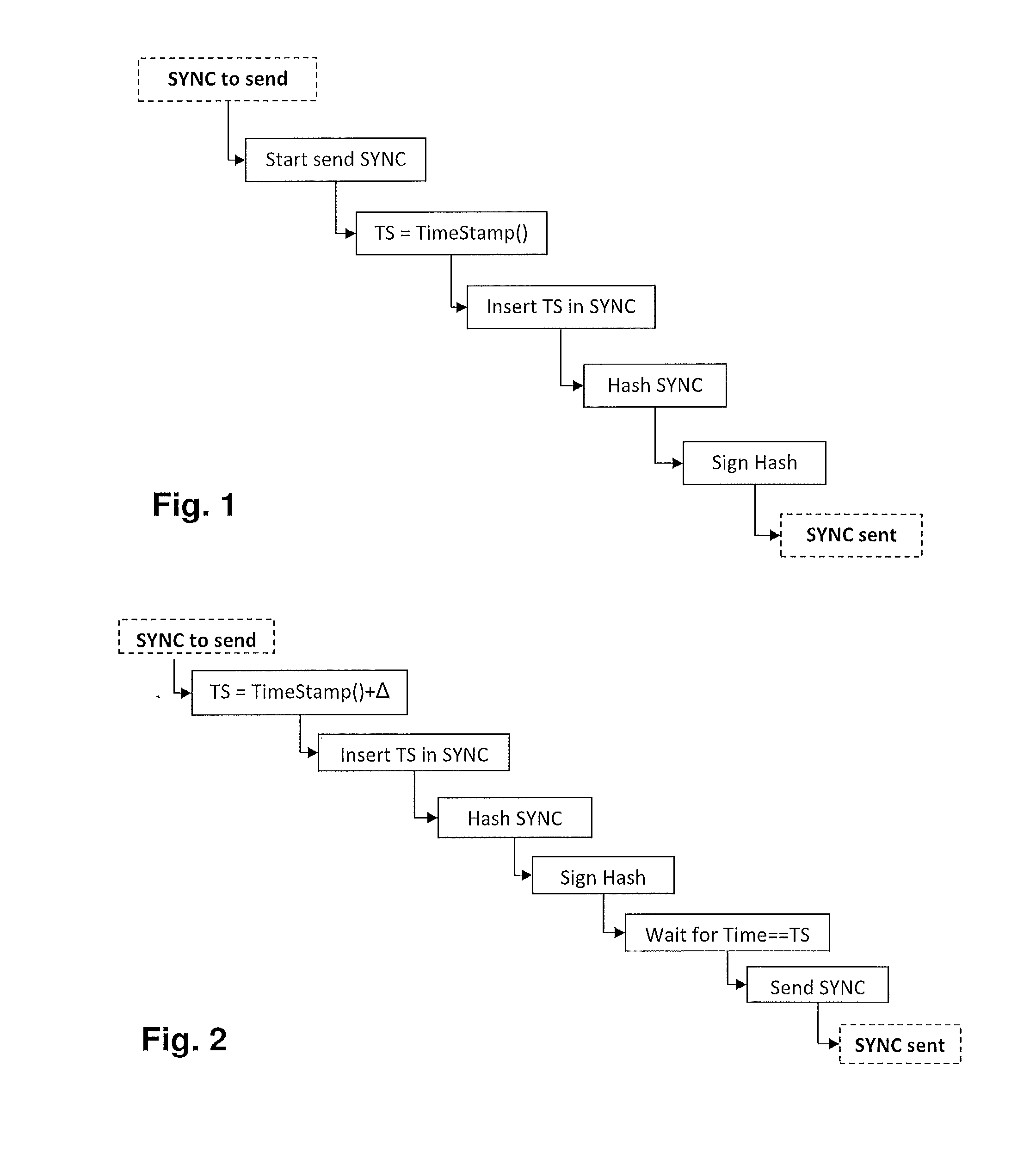

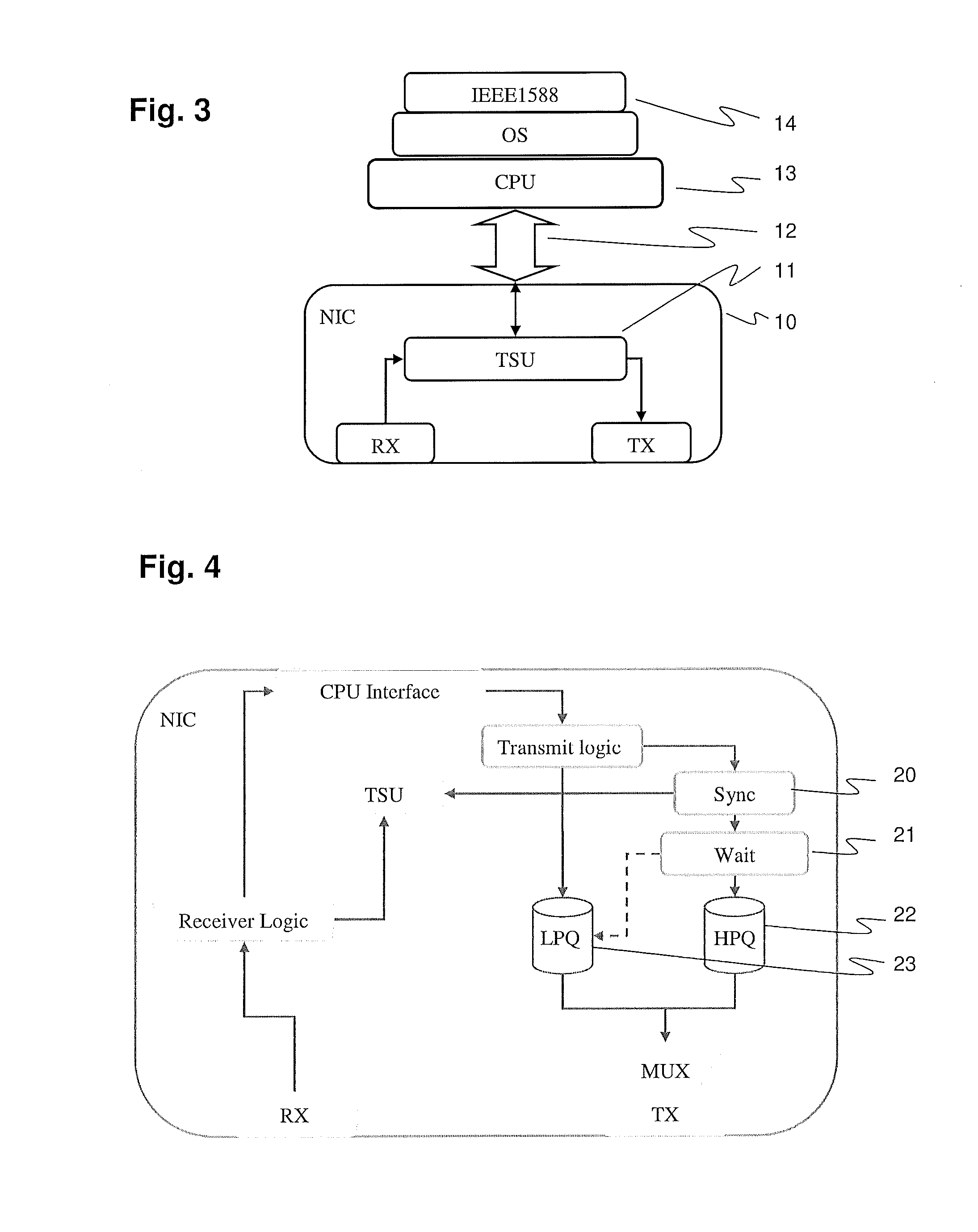

Secure clock synchronization

ActiveUS20120163521A1Synchronisation information channelsTime-division multiplexSlave clockComputer science

The present disclosure provides a secure one-step IEEE 1588 clock using either a symmetric or asymmetric protection scheme. Clocks of mission-critical or highly-available devices in industrial automation systems connected to a communication network are synchronized by sending, by a master clock, a synchronization message, e.g., a single message of the one-step-clock type according to IEEE 1588, including a time stamp, and by receiving and evaluating, by a slave clock, the synchronization message. A synchronization component or module of the master clock prepares, or composes, prior to a projected send time, a synchronization message including a time stamp of the projected send time, and secures the synchronization message in advance of the projected send time. Securing the synchronization message occurs by suitable cryptographic means allowing for authentication of the time stamp at a receiving slave clock. At the projected send time, the secured synchronization message is transmitted.

Owner:HITACHI ENERGY SWITZERLAND AG

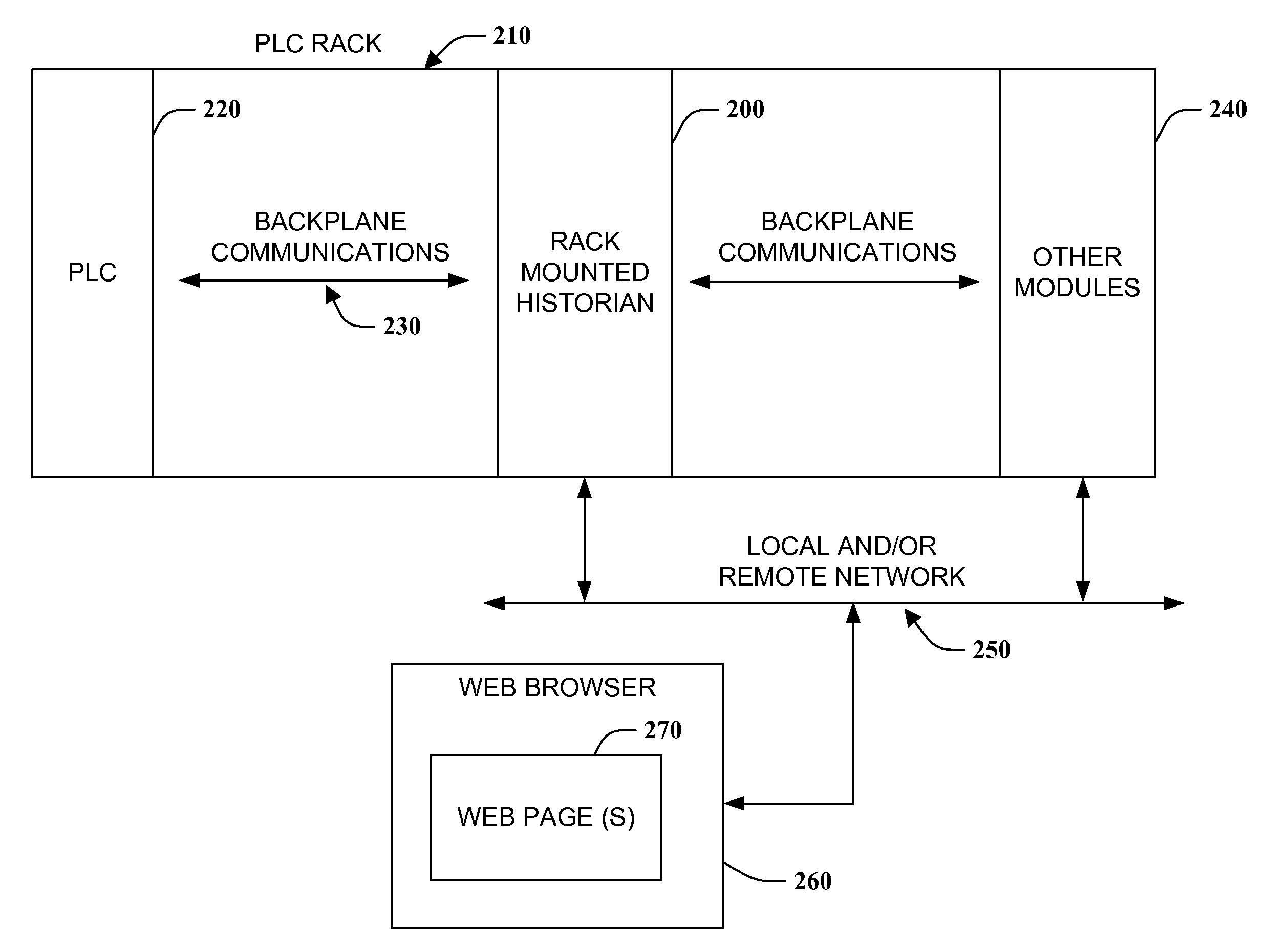

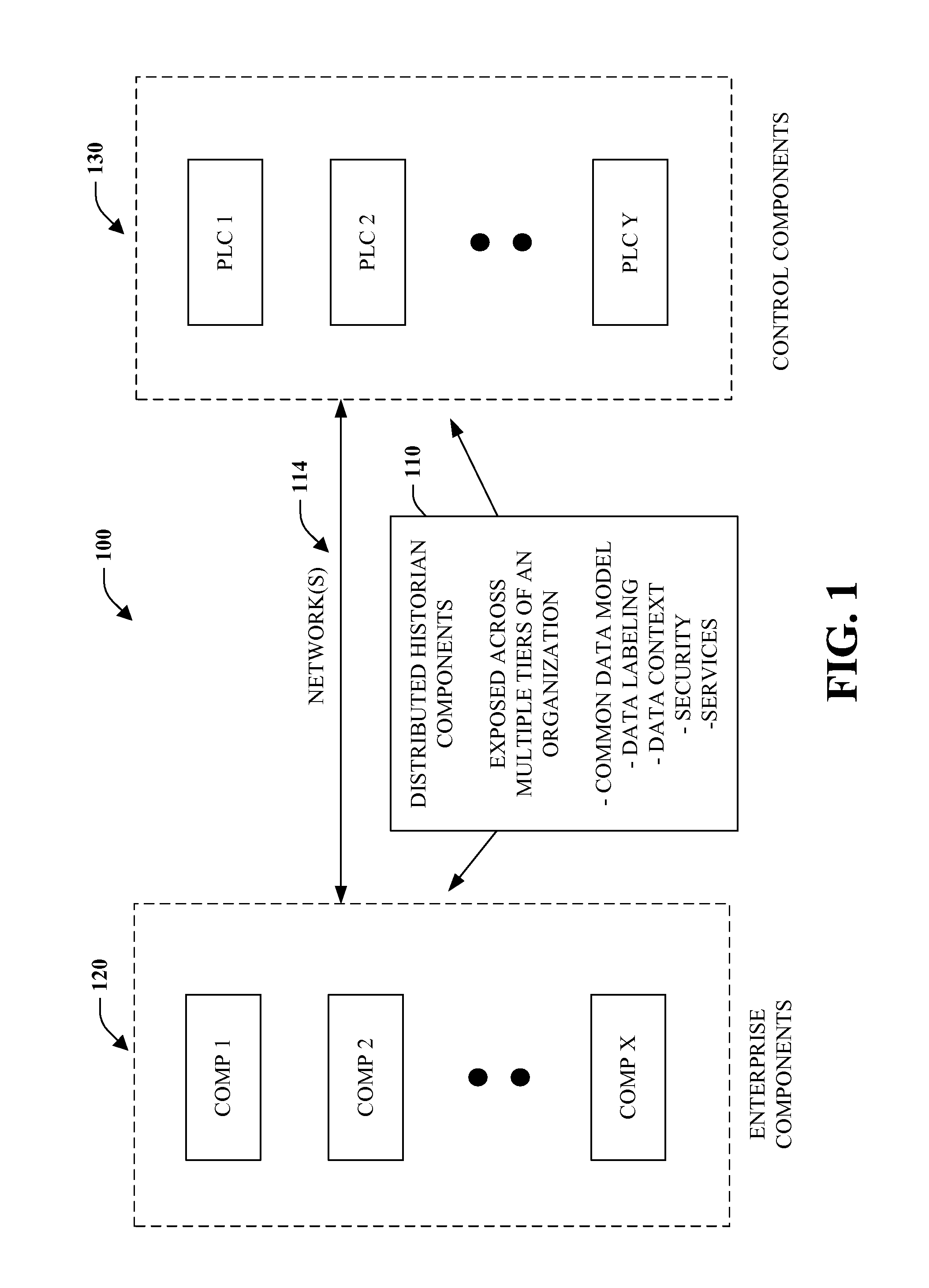

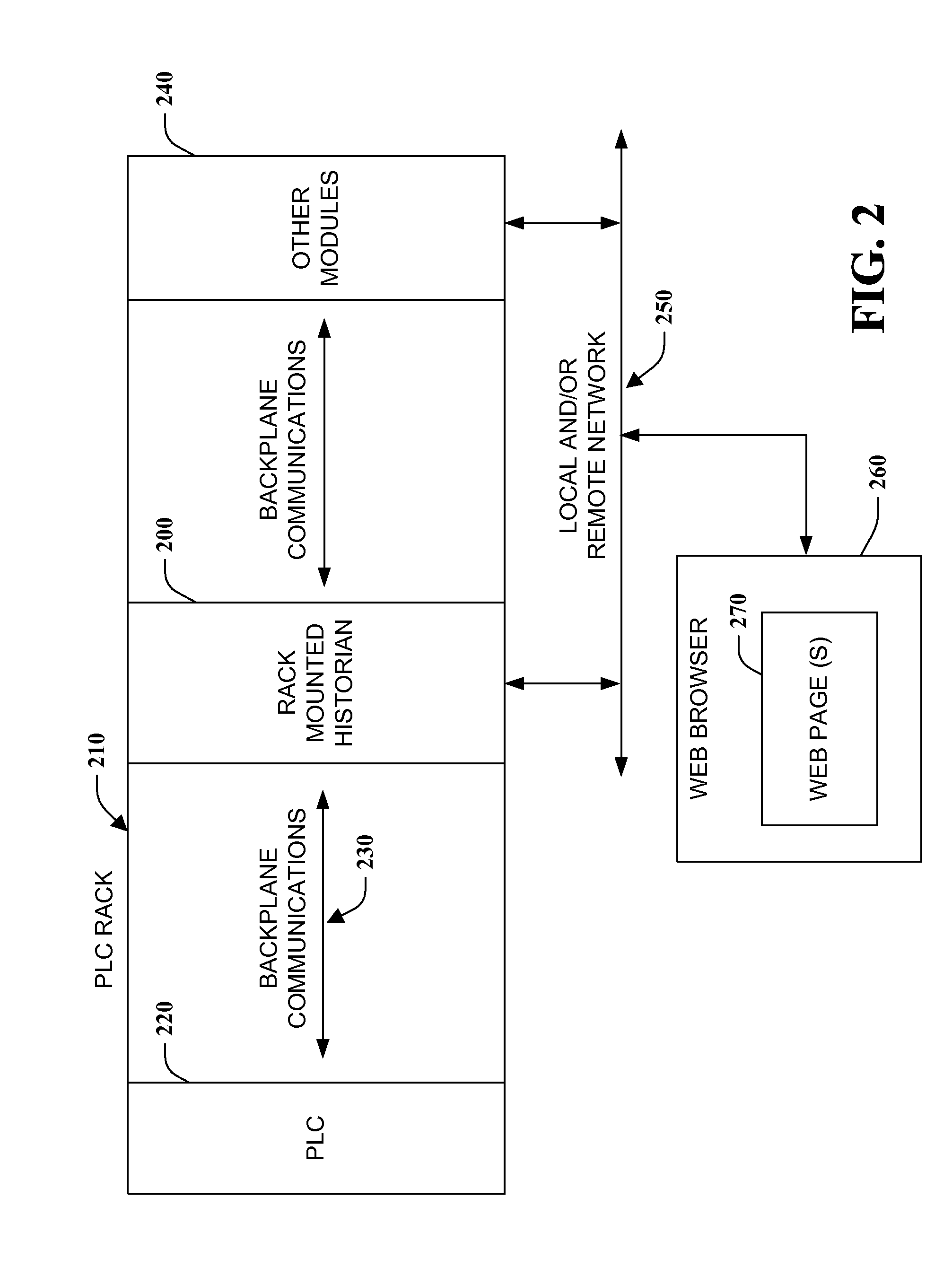

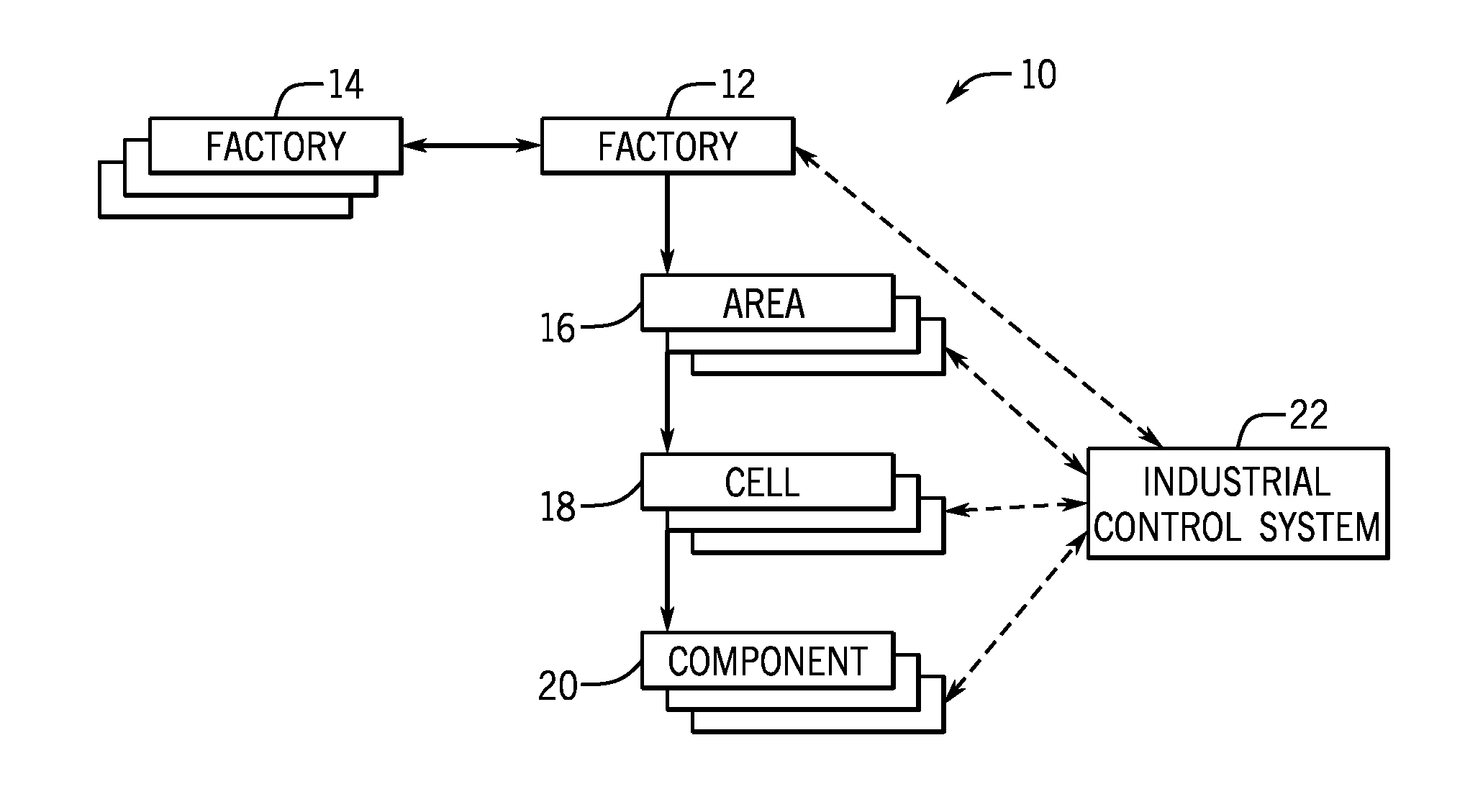

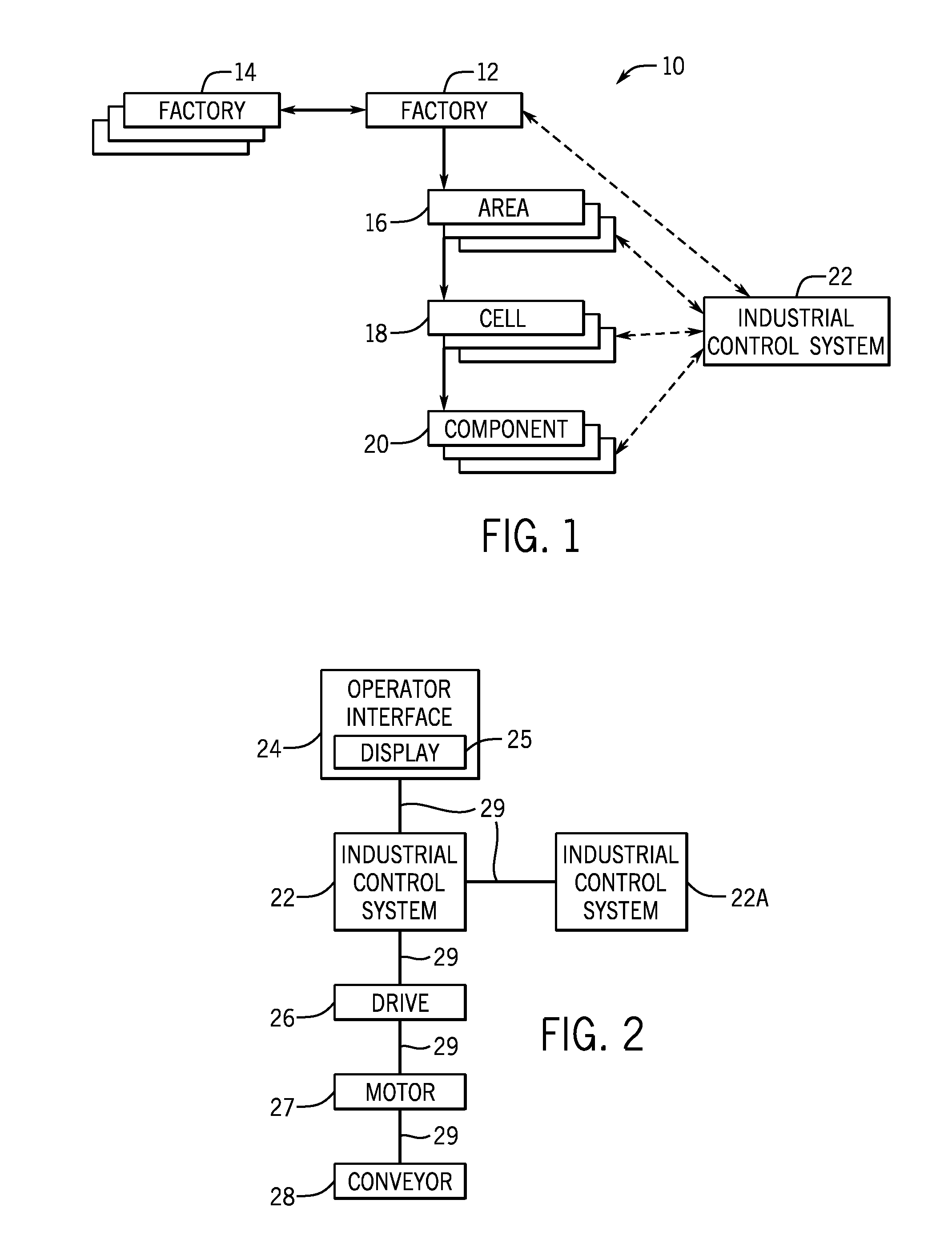

Historian module for use in an industrial automation controller

ActiveUS7627385B2Effective mergerEasy data collectionComputer controlDigital computer detailsData bankDirectory service

A distributed historian framework is provided where historical data is collected in accordance with an organizational model of a hierarchical system that is distributed across various elements of an enterprise. A directory service operates with the organizational model to enable configuration of historian components within the organization and to enable data to be located within the organization. In one aspect, an industrial automation system is provided. The system includes at least one historian component to archive data within an organization. A common data model then exposes functionality and data of the organization to the historian component.

Owner:ROCKWELL AUTOMATION TECH

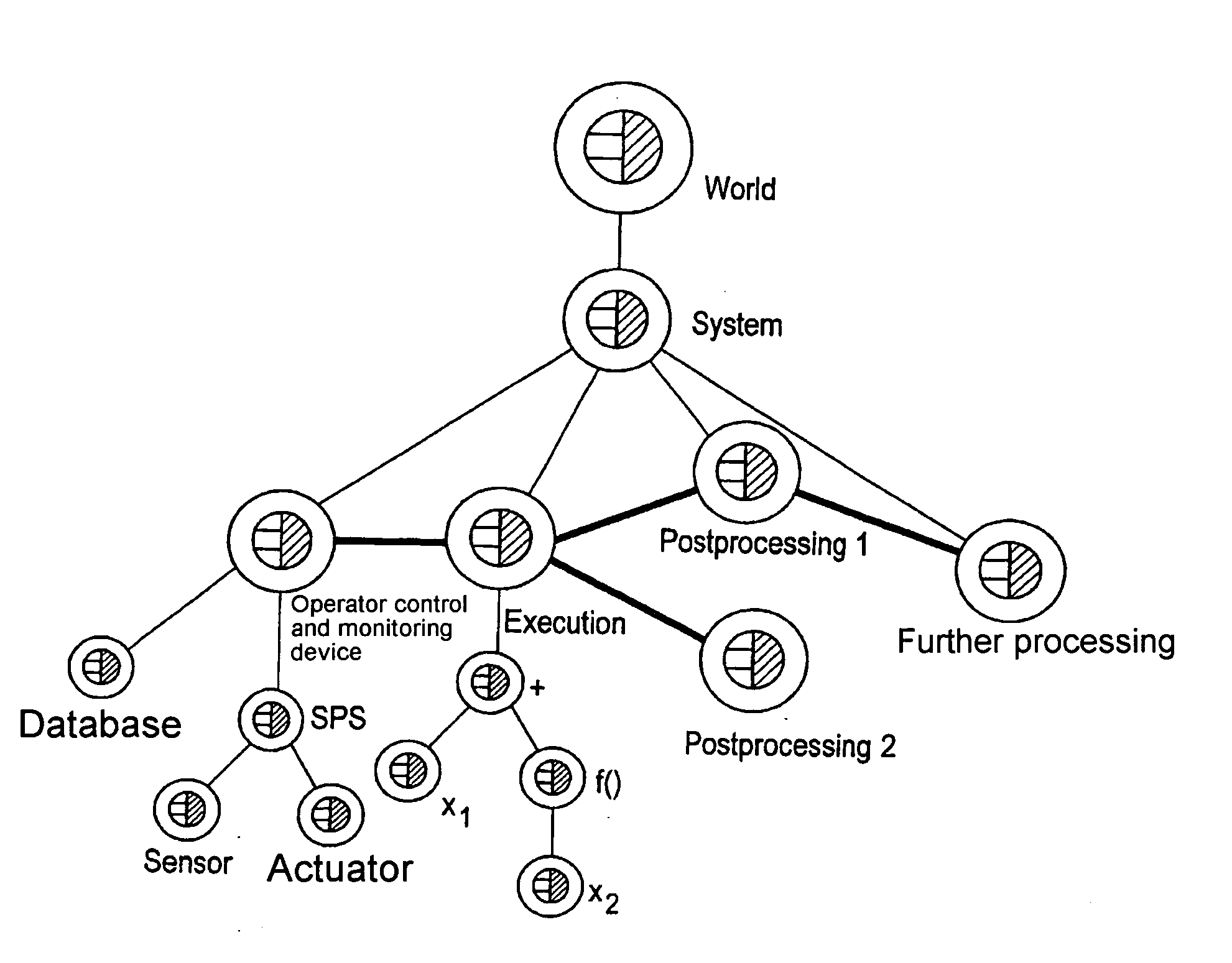

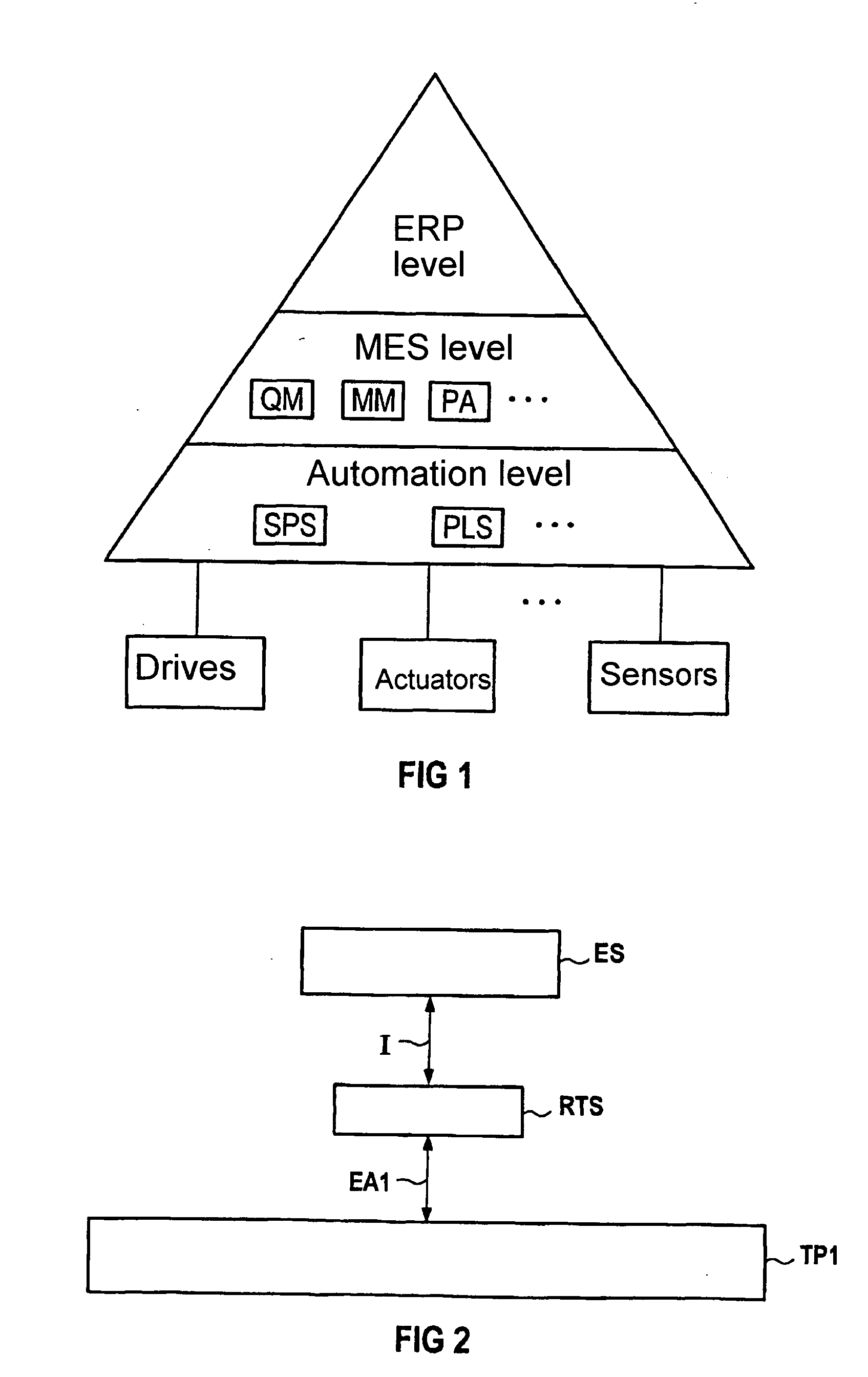

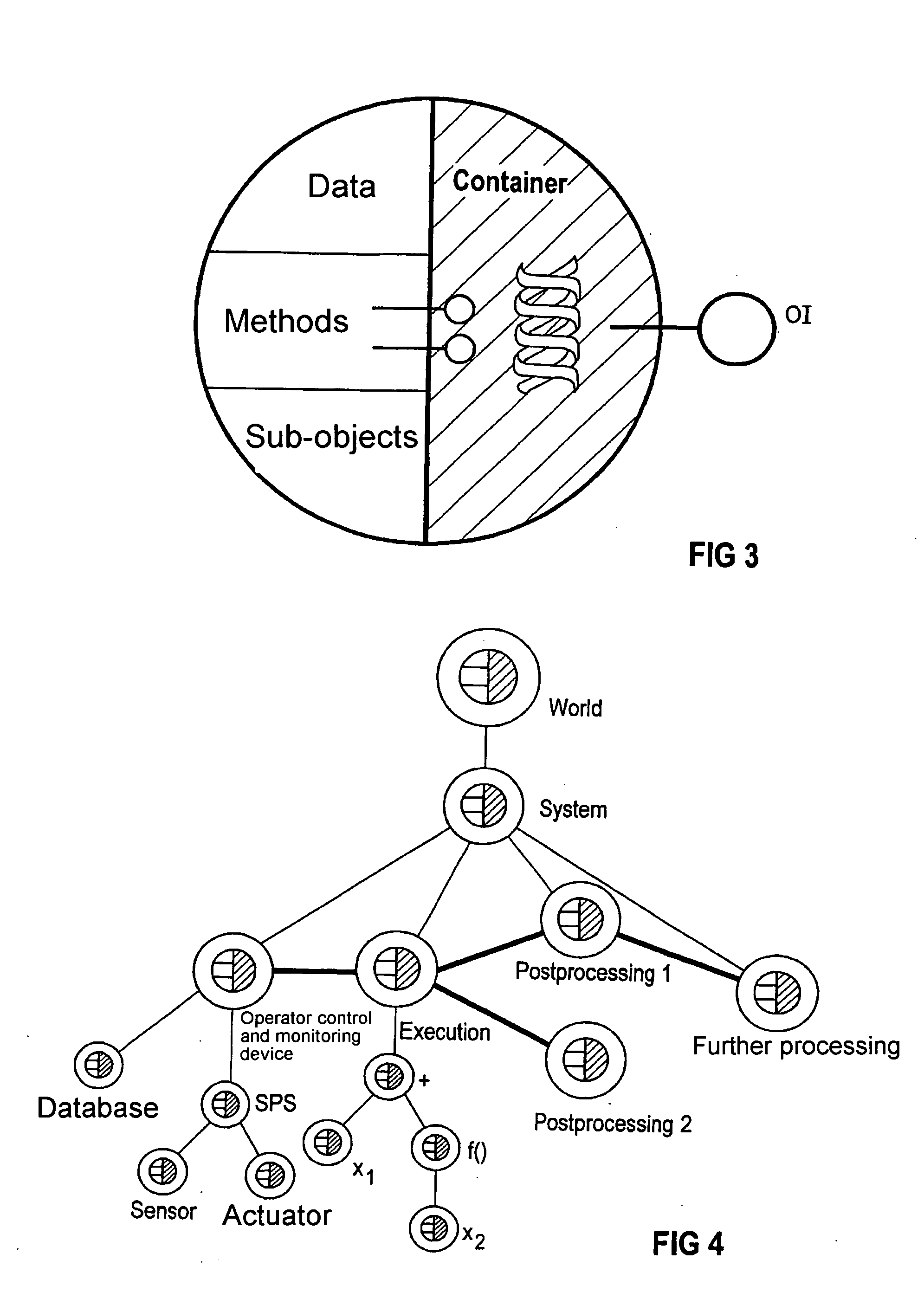

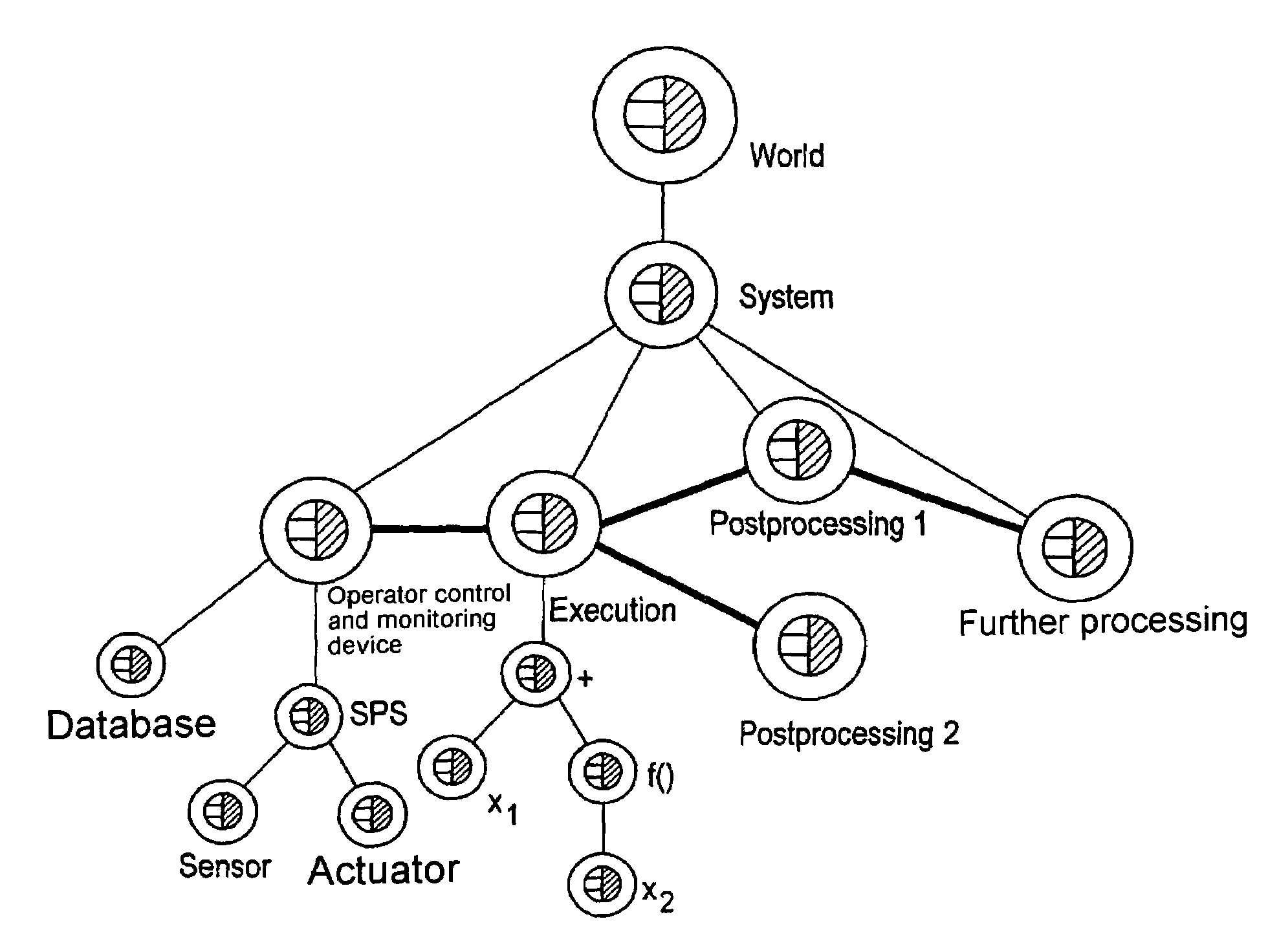

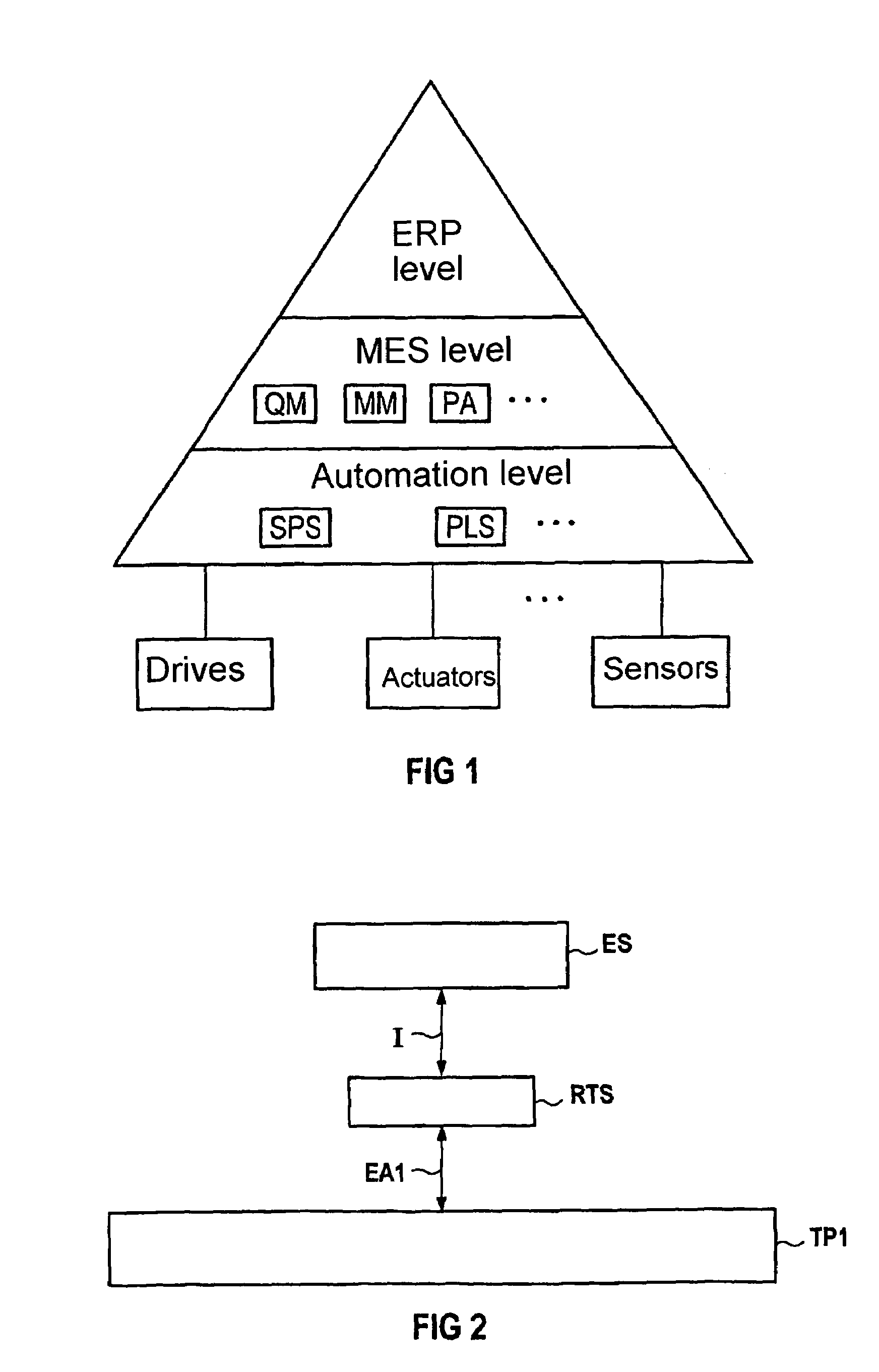

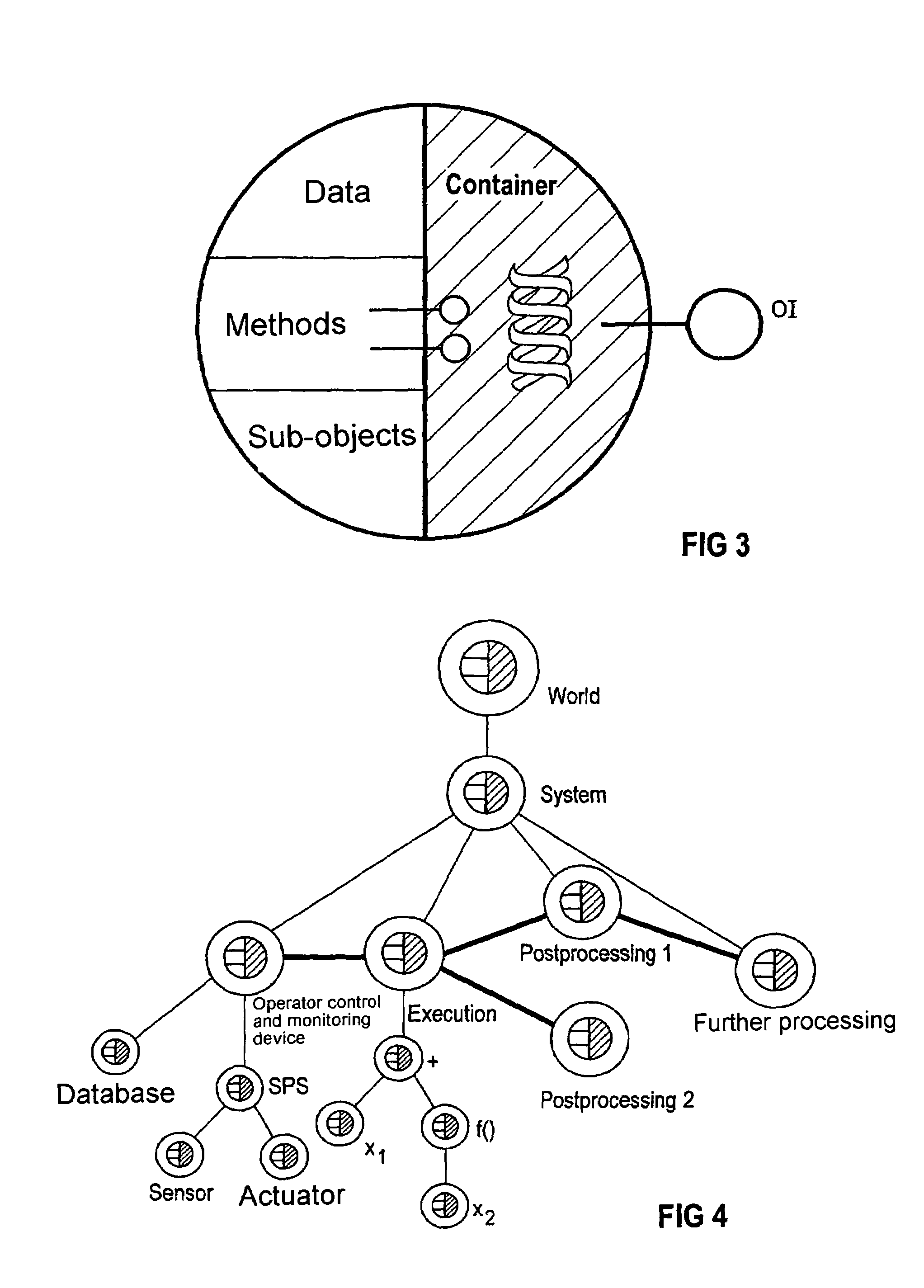

Engineering method and system for industrial automation systems

InactiveUS20050159932A1Minimal timeEasy to carryProgramme controlComputer controlNetwork connectionDisplay device

The invention relates to an engineering method and system for industrial automation systems, in particular for MES systems, based on at least one computational unit with an input auxiliary device, an output auxiliary device, in addition to at least one display device. According to said method, the modelled objects comprise installation structures or installation parts and are linked to meta information. The modelled objects are structured in the engineering method as hierarchical trees and can be interconnected by lateral networking or by means of a cursor. The objects are executed in run-time by evaluating the meta information in a target system, whereby the functions of an installation that has been modelled in the engineering method are determined from the structure of the tree and the networked connections.

Owner:SIEMENS AG

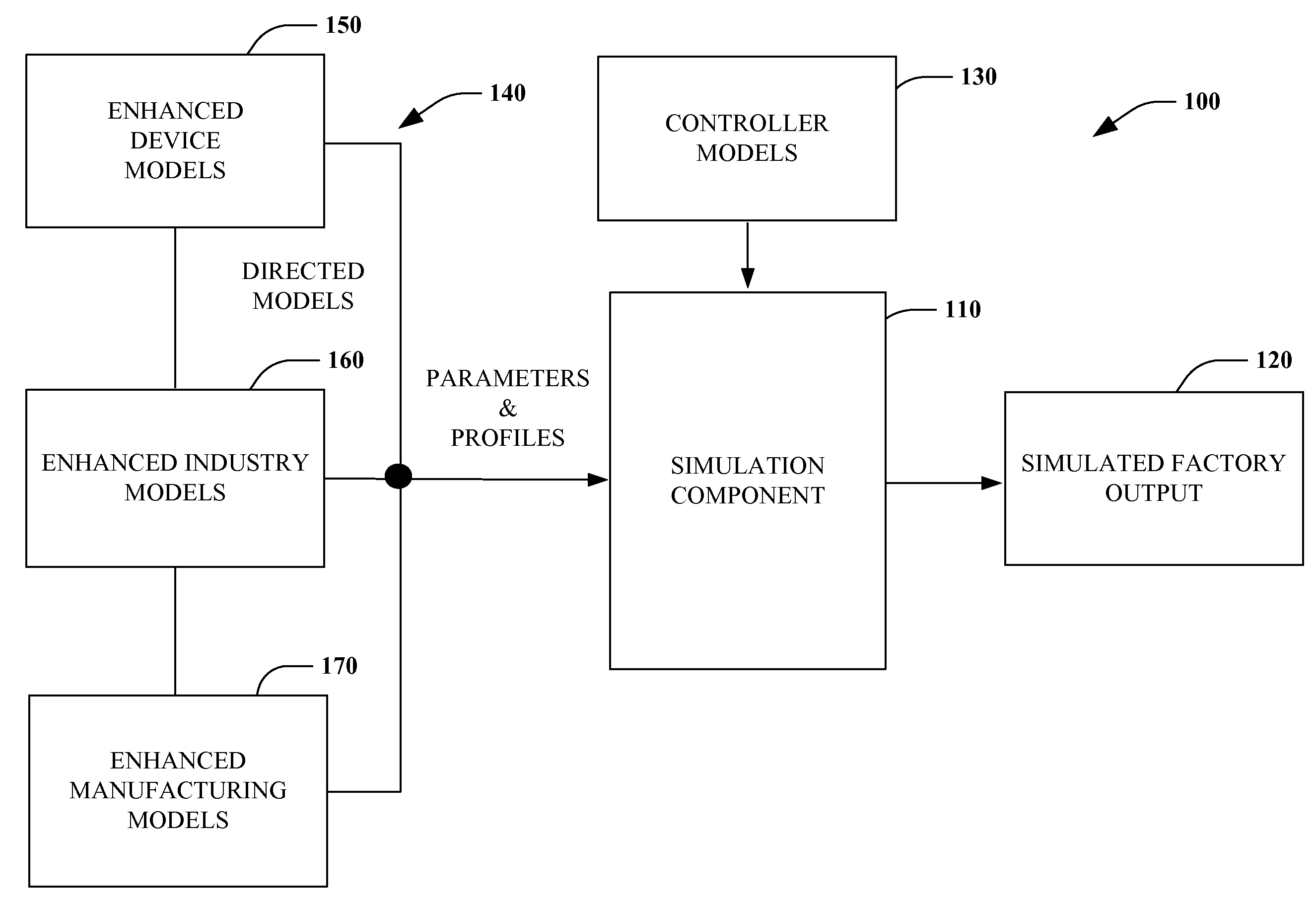

Enhanced simulation models for automation

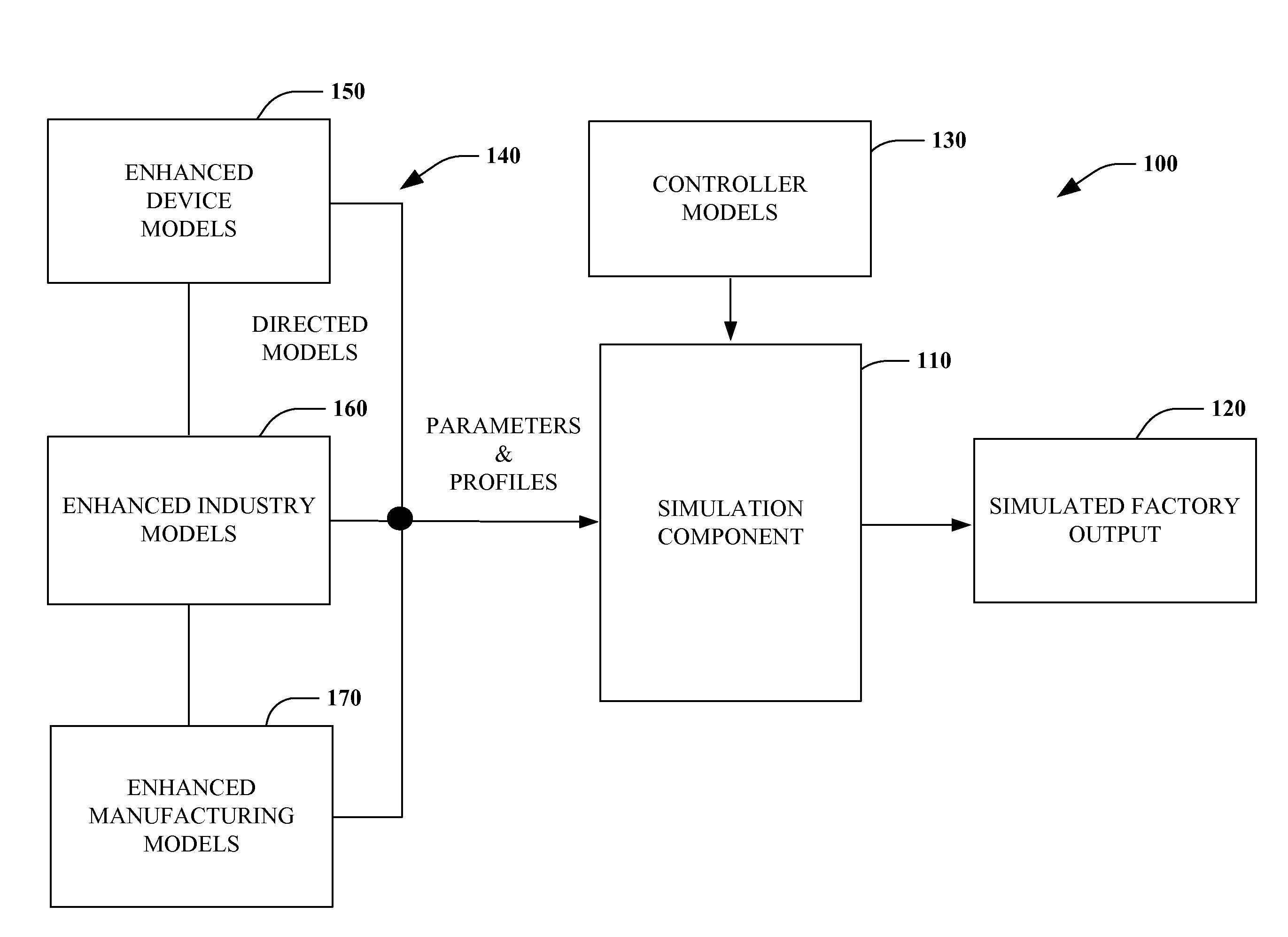

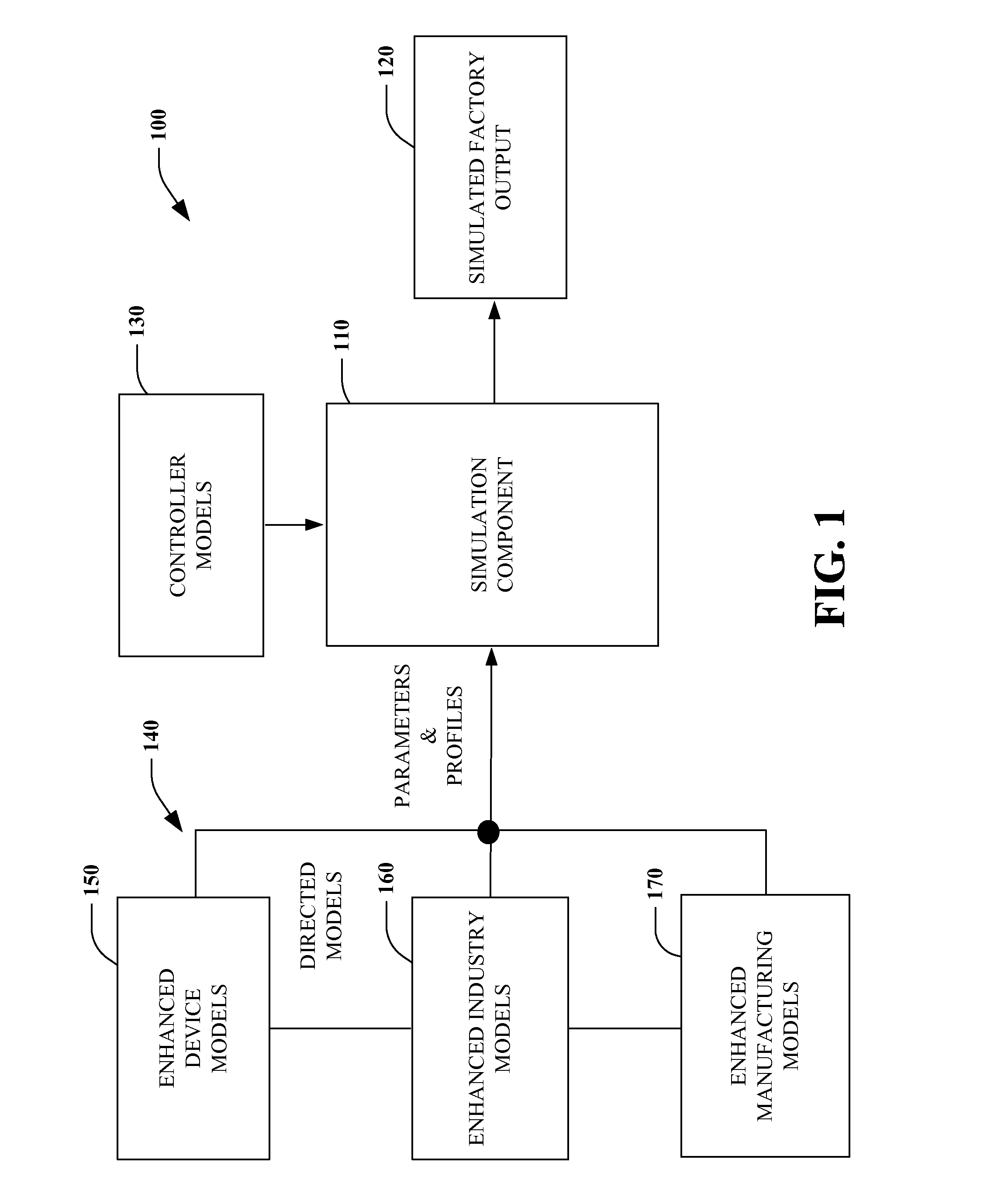

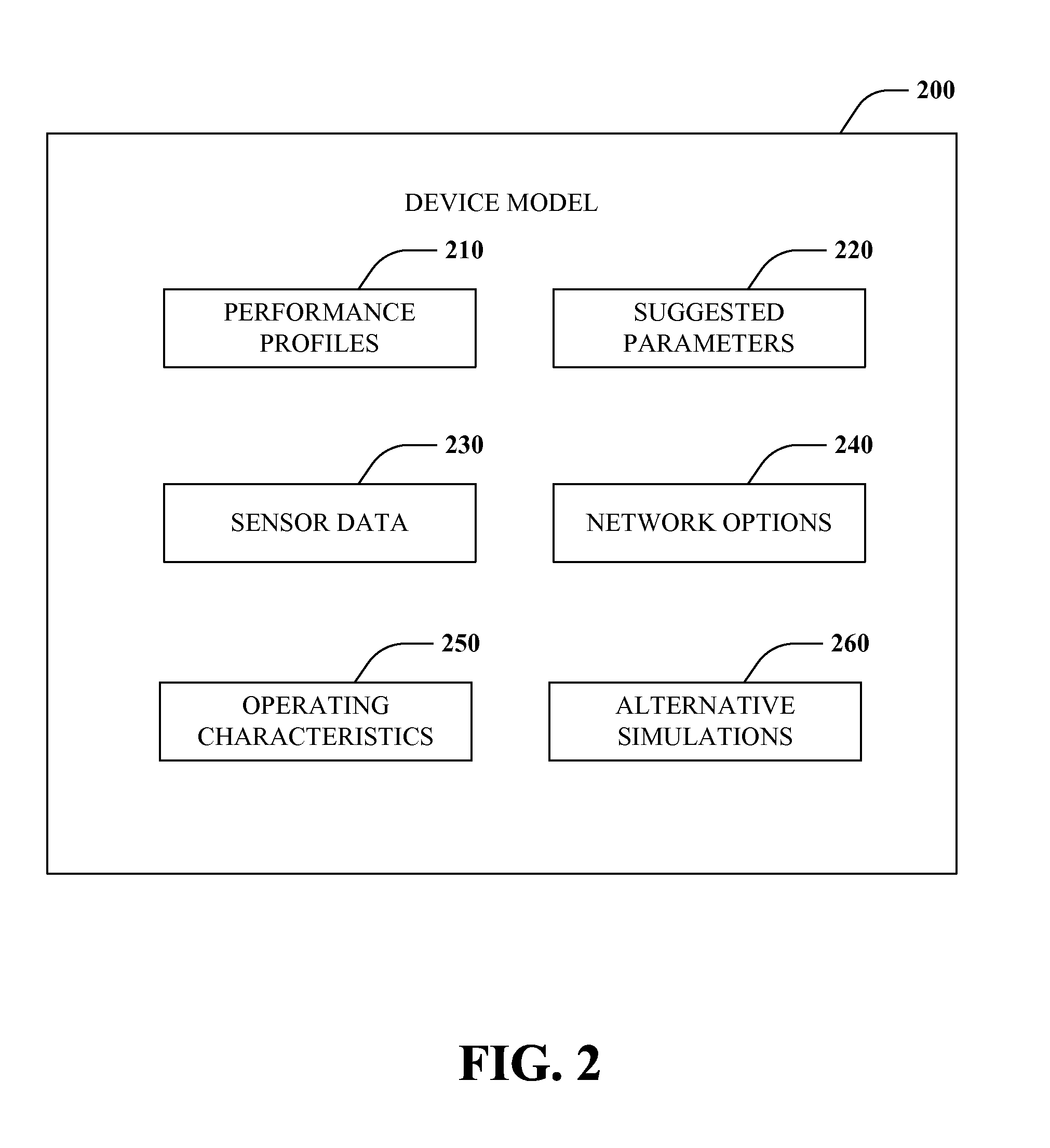

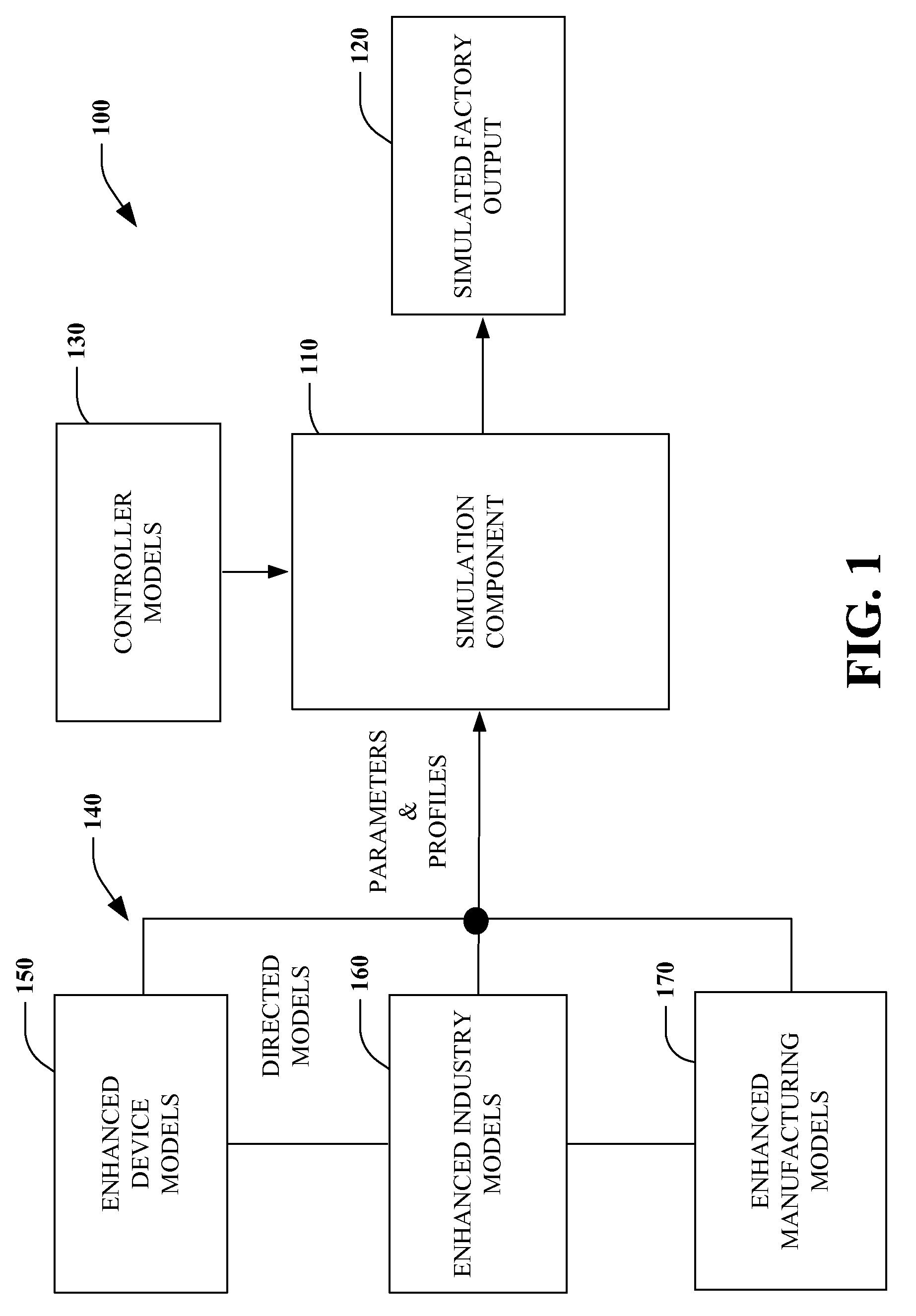

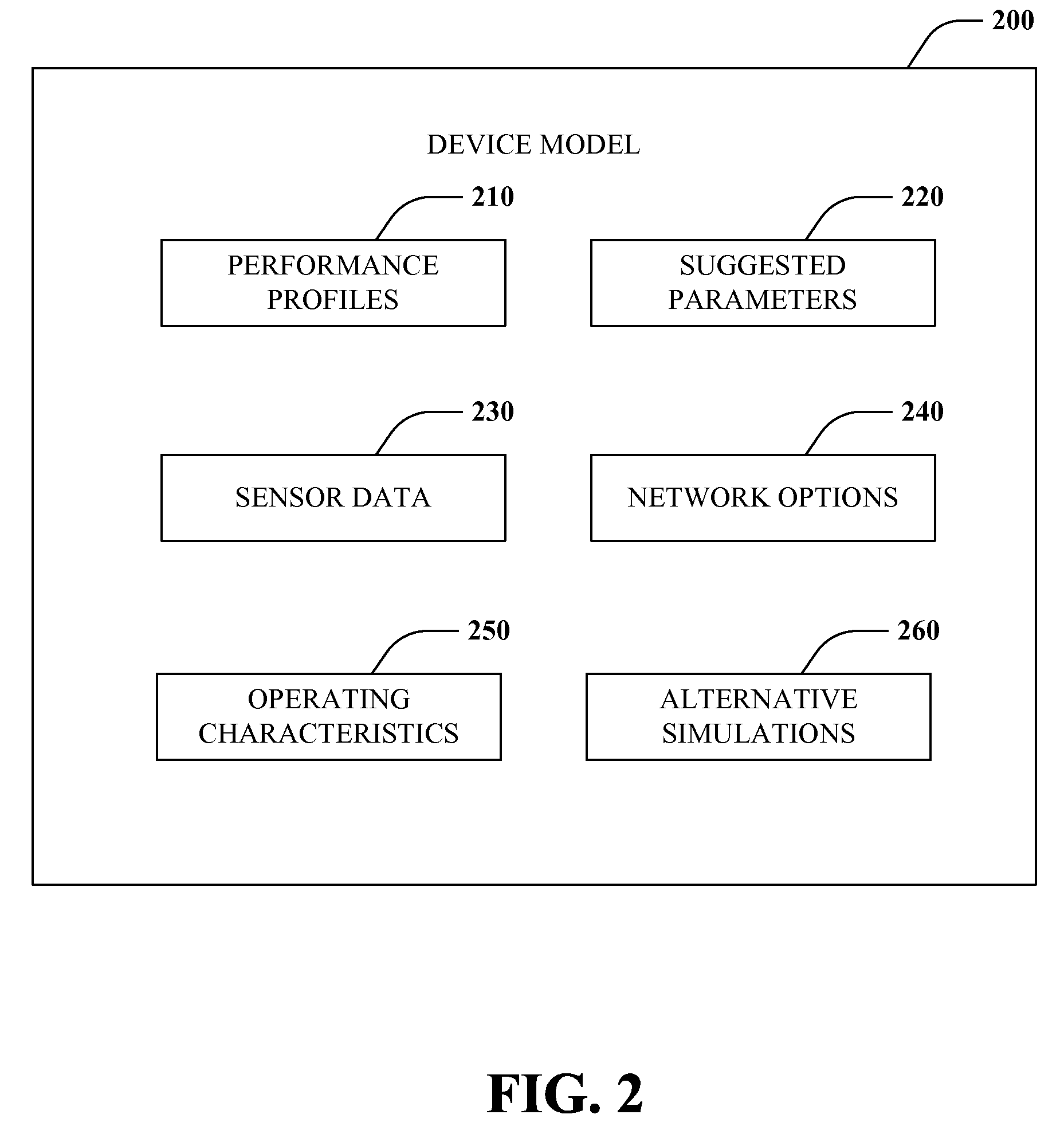

ActiveUS20090089032A1Function increaseHigh simulationSimulator controlComputation using non-denominational number representationSimulationIndustrial control system

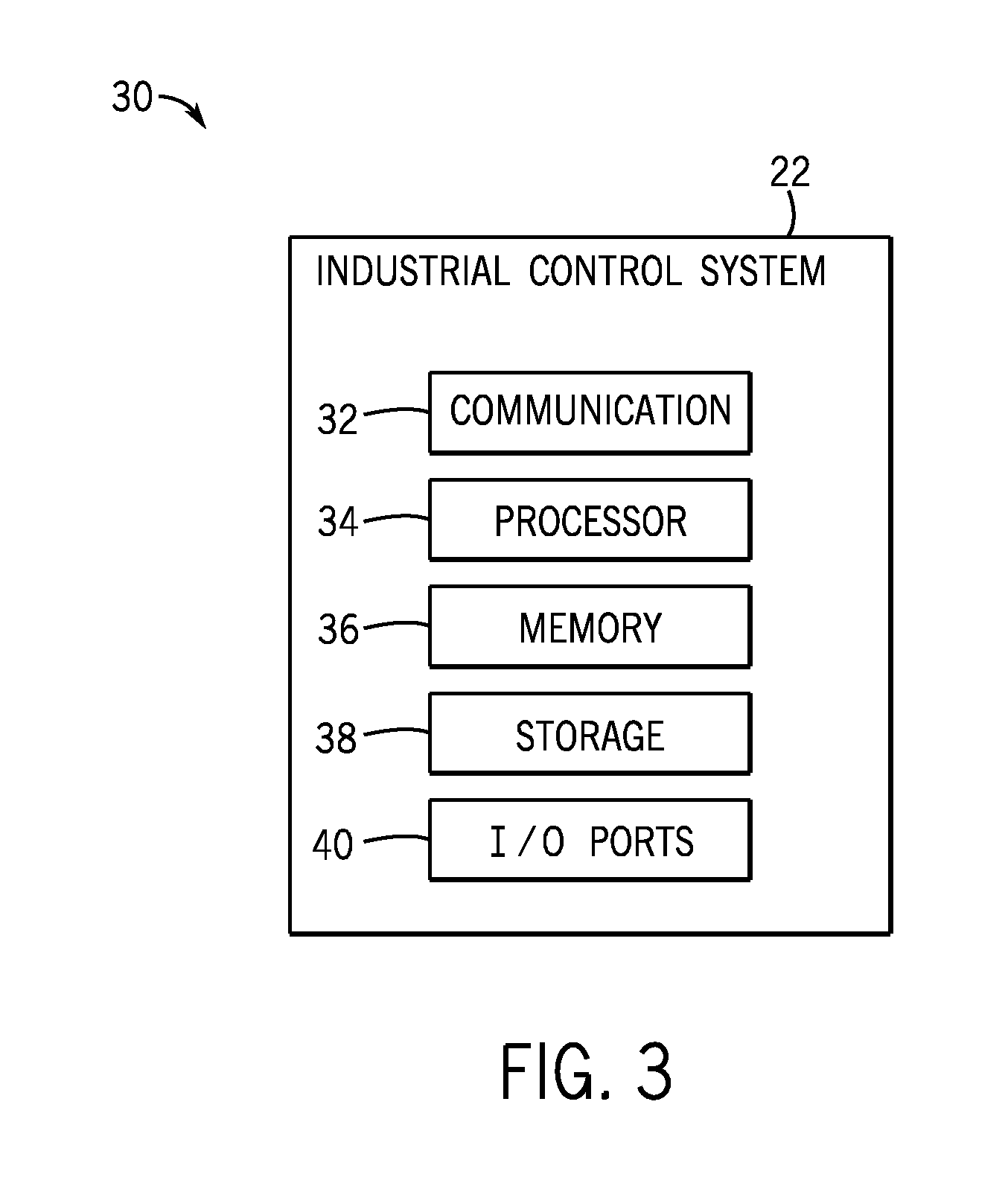

A simulation tool for an industrial automation system is provided. The tool includes a simulation component that simulates one or more components of an industrial control system. At least one directed model provides one or more suggested parameters or profiles to the simulation component, where the suggested parameters or profiles are derived from data relating to an industry or controls application.

Owner:ROCKWELL AUTOMATION TECH

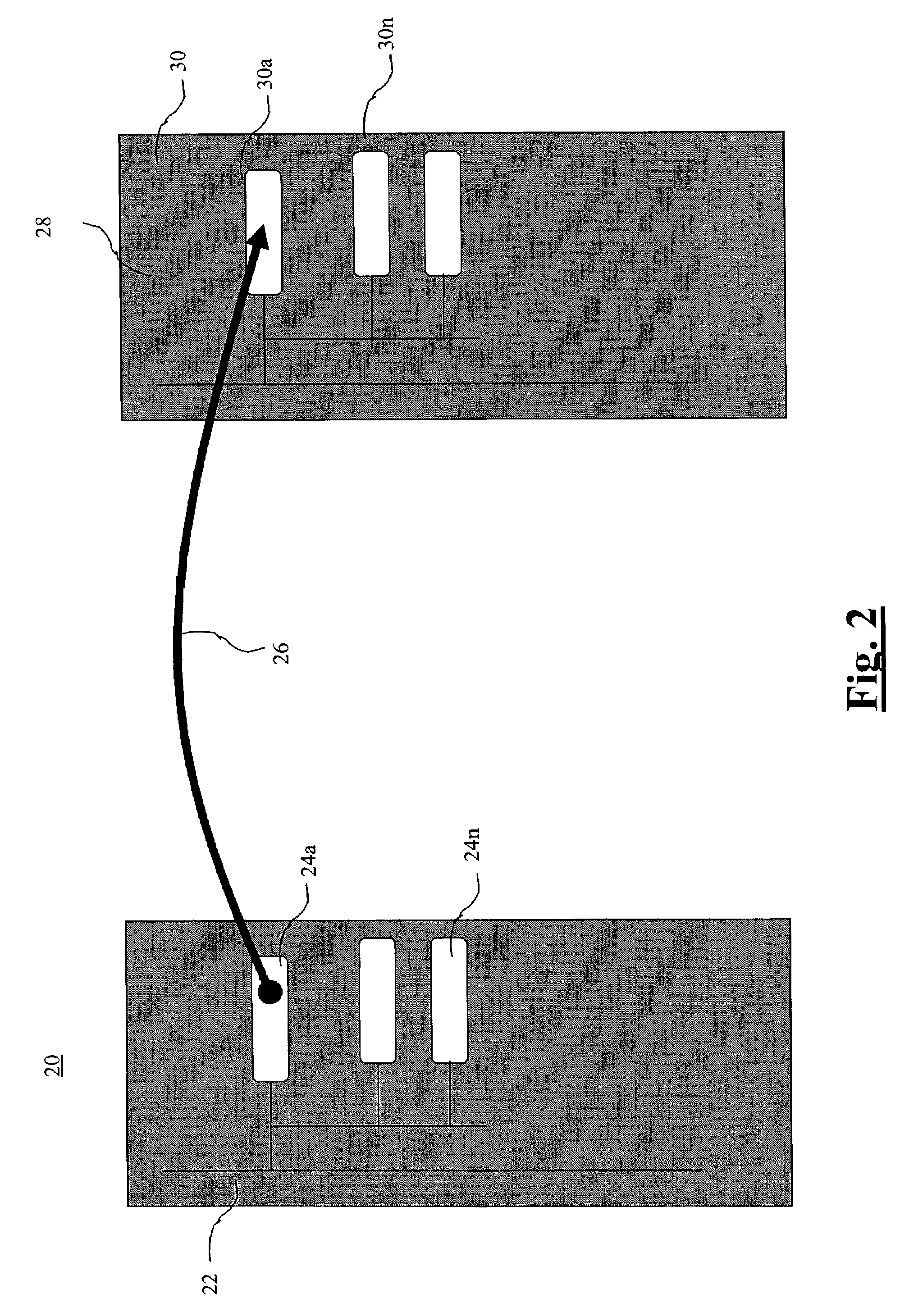

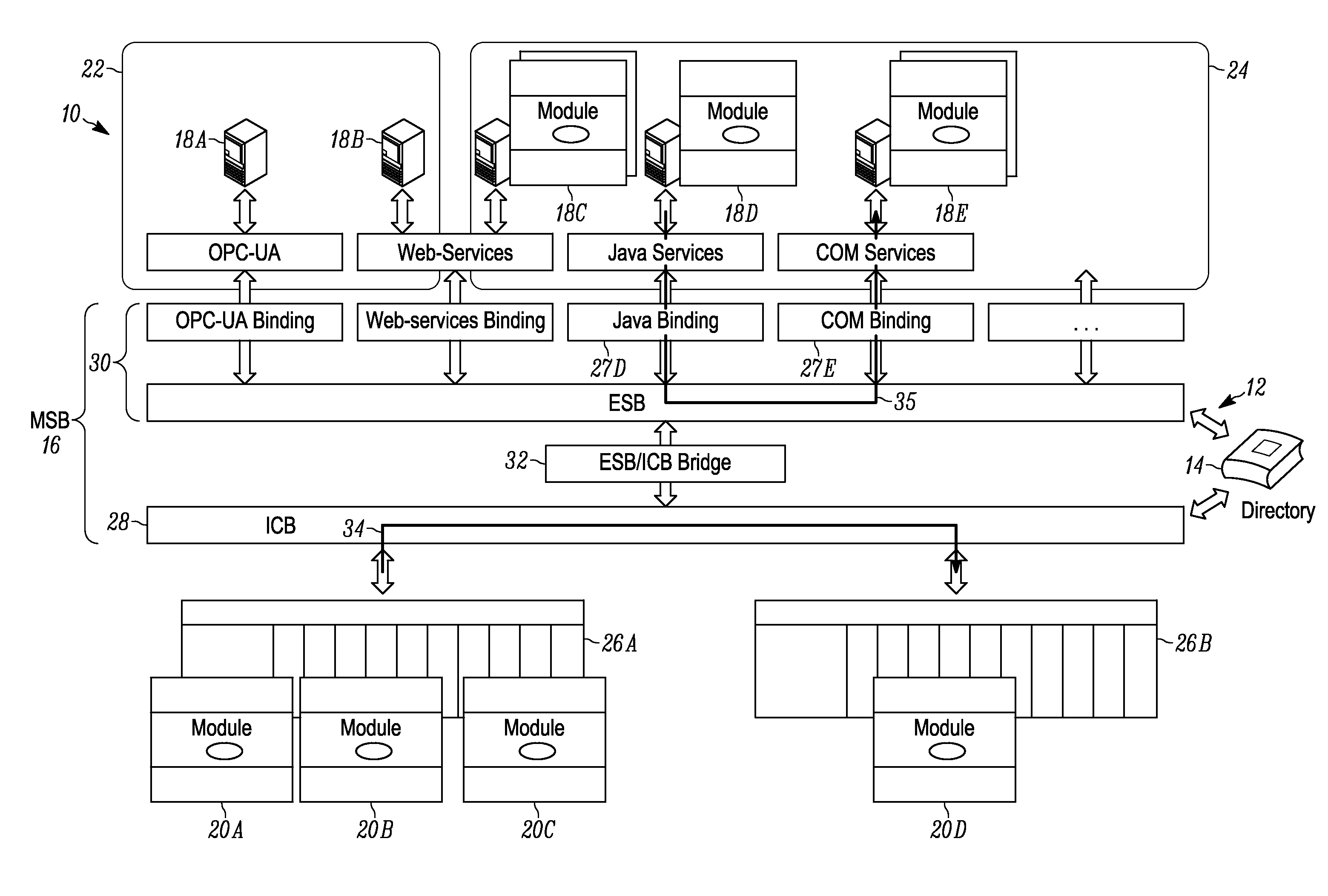

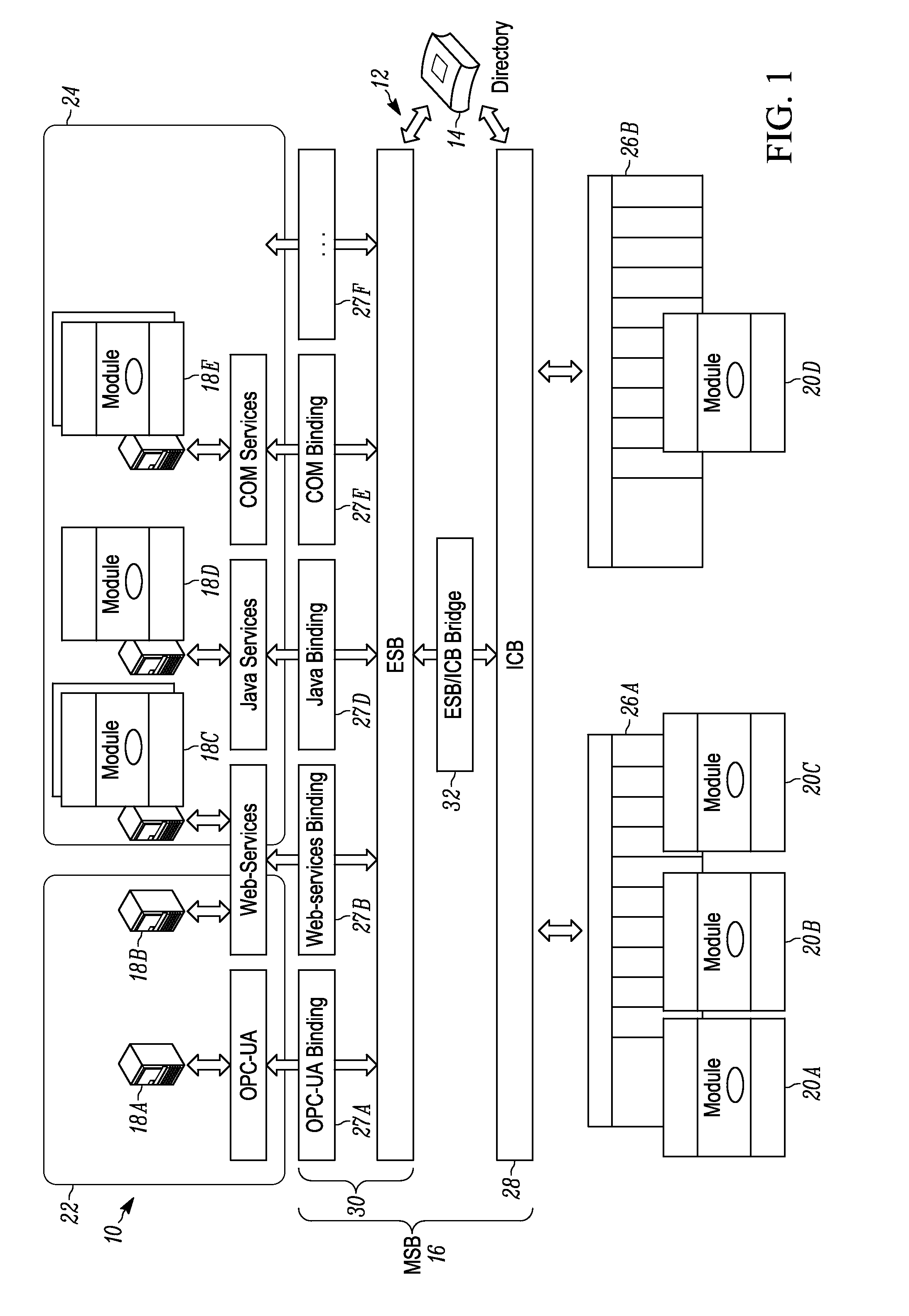

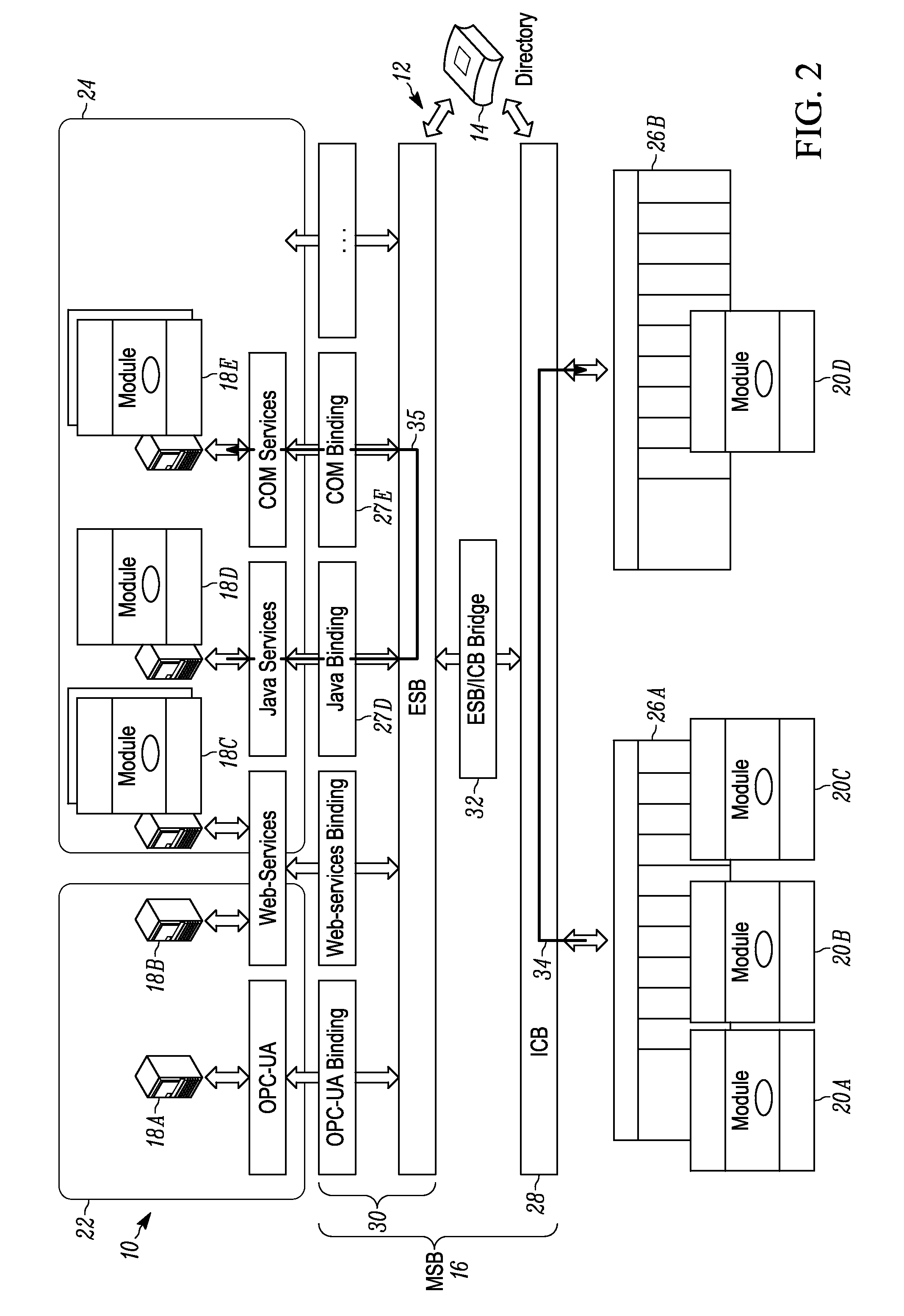

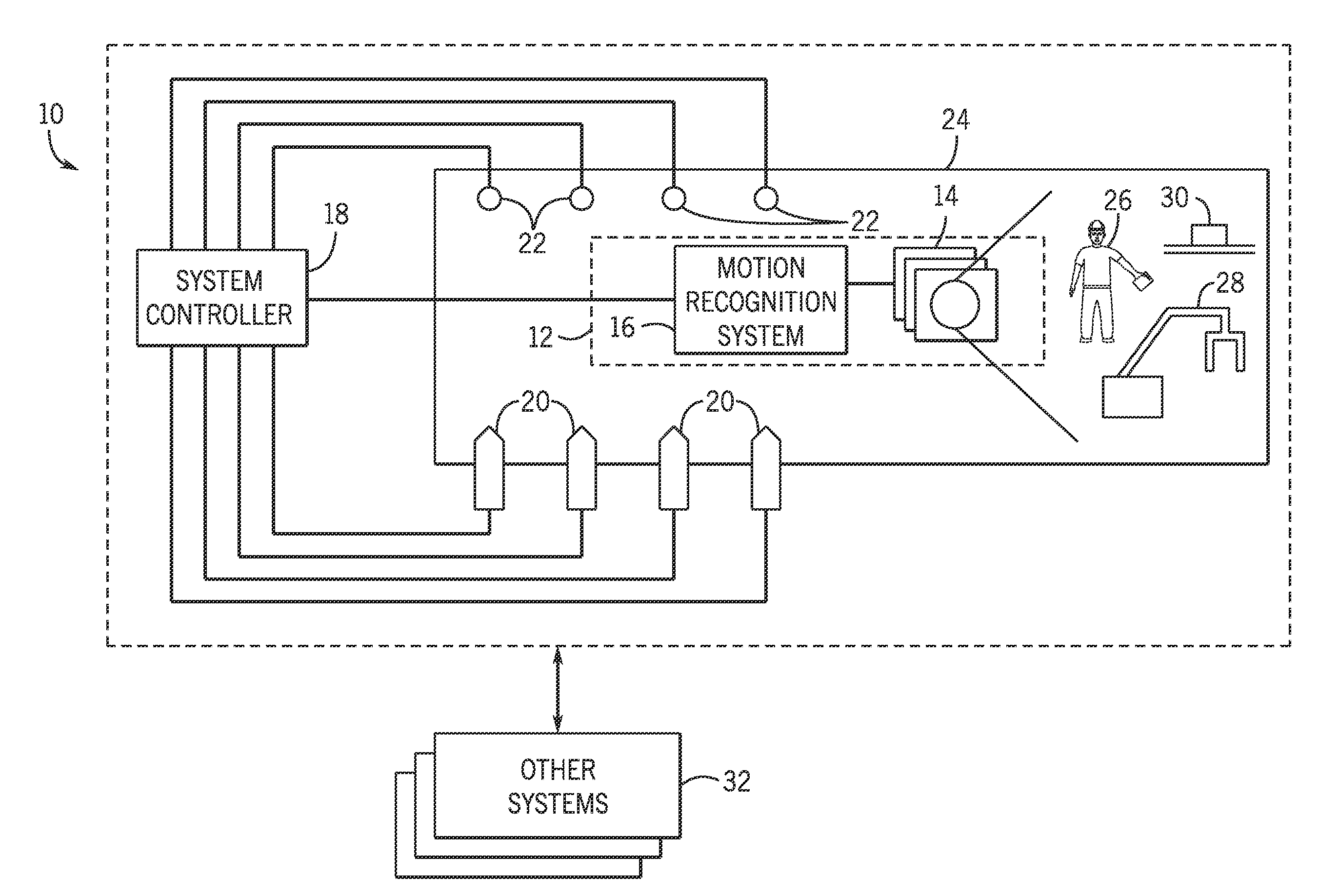

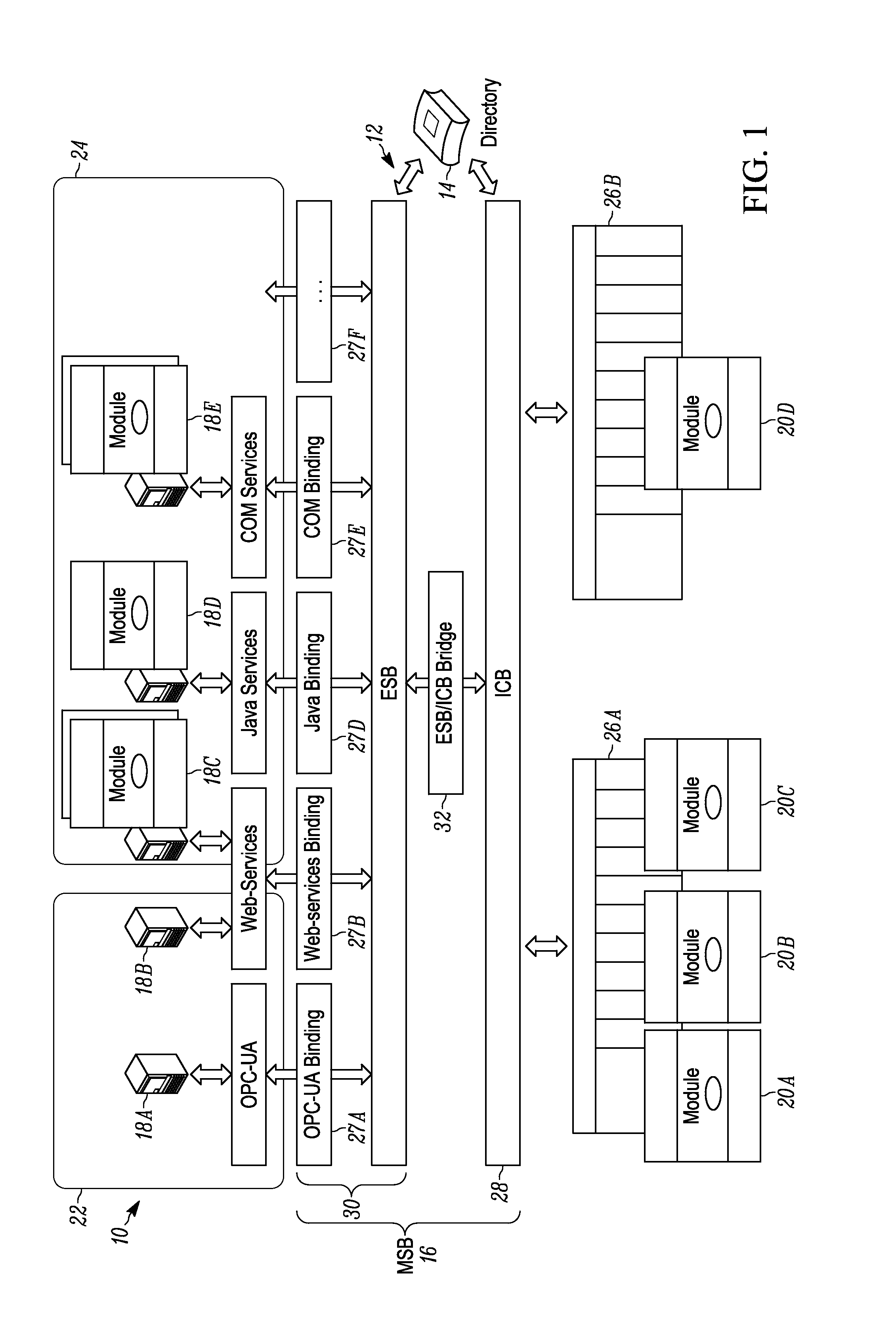

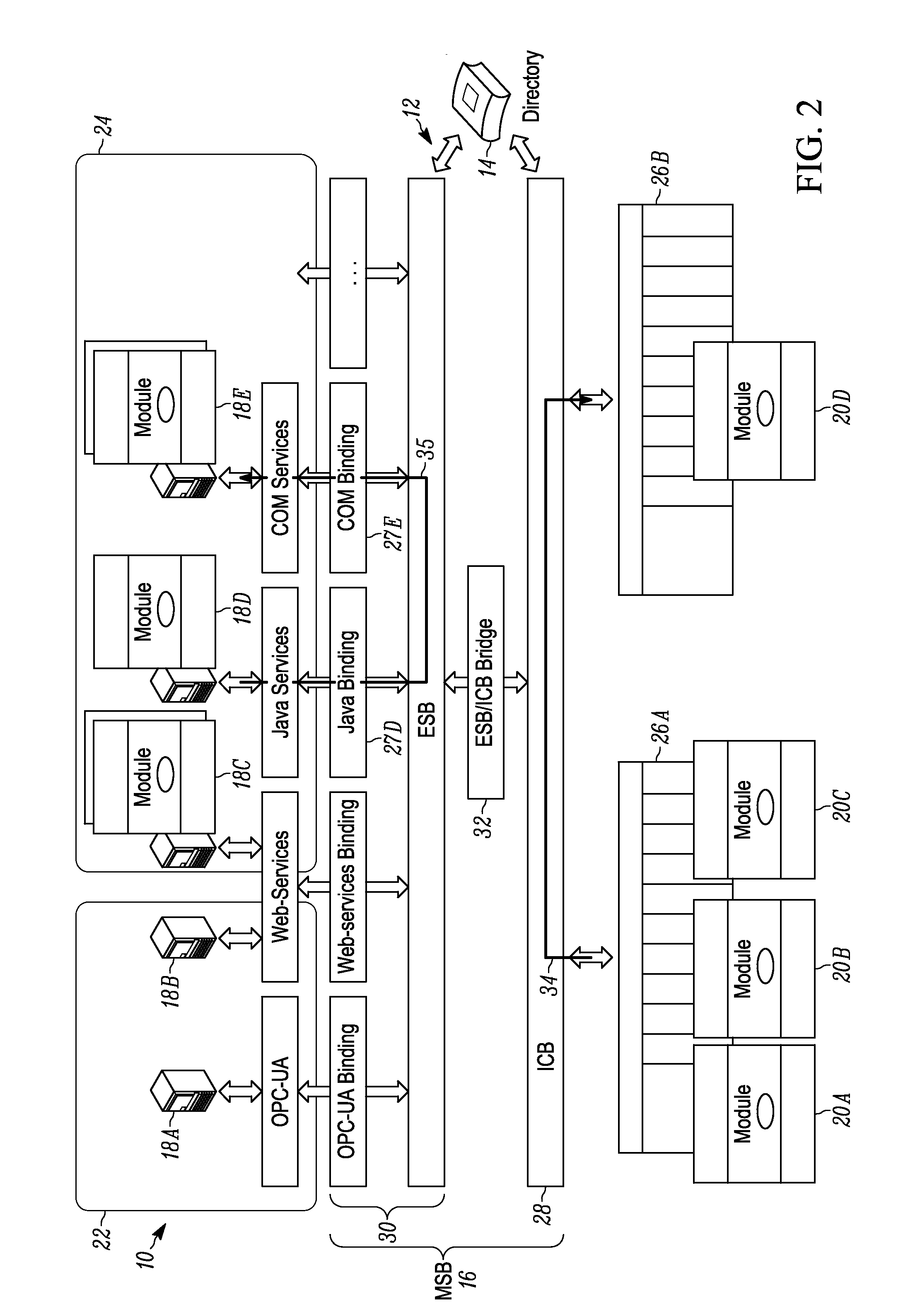

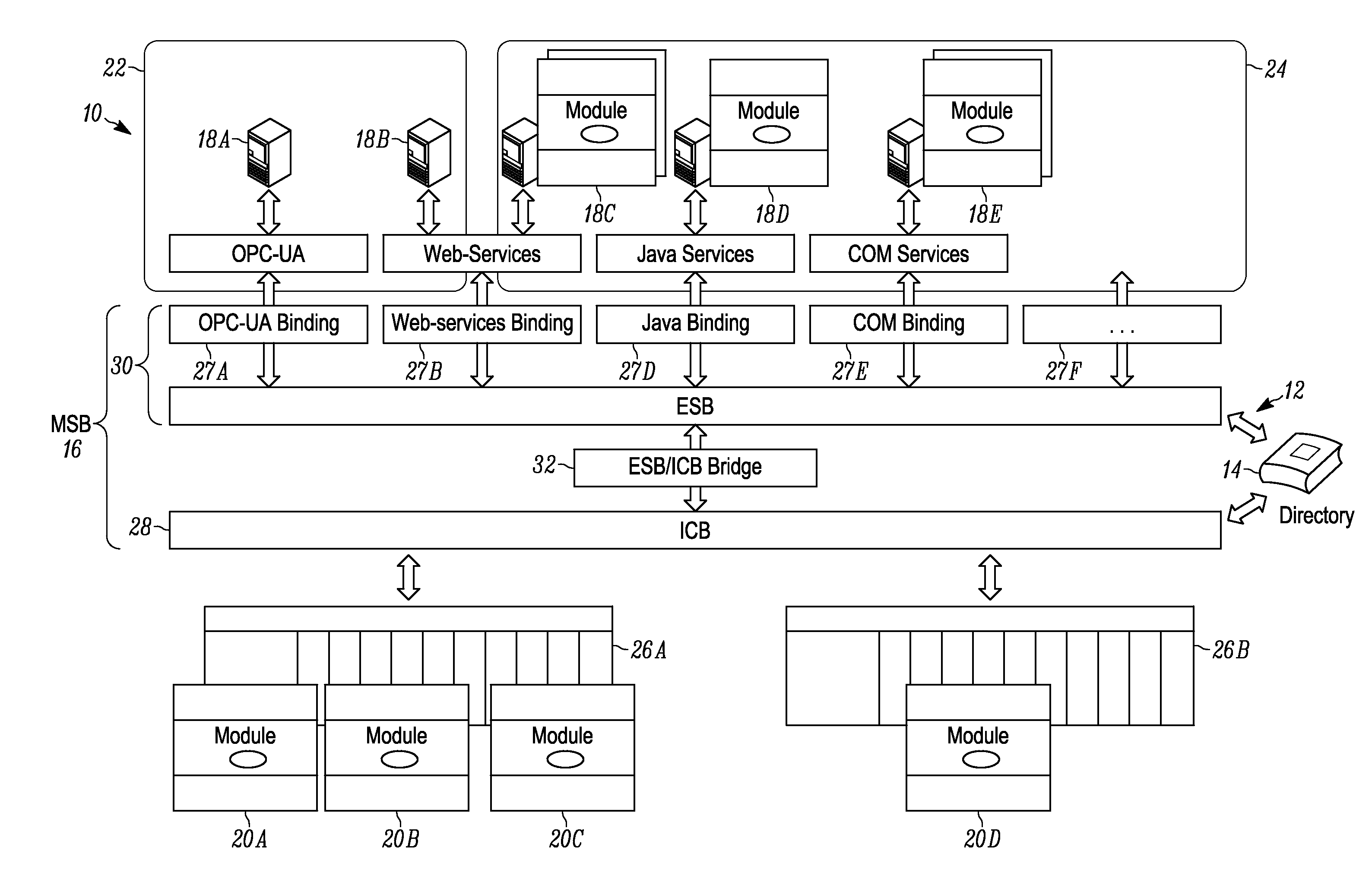

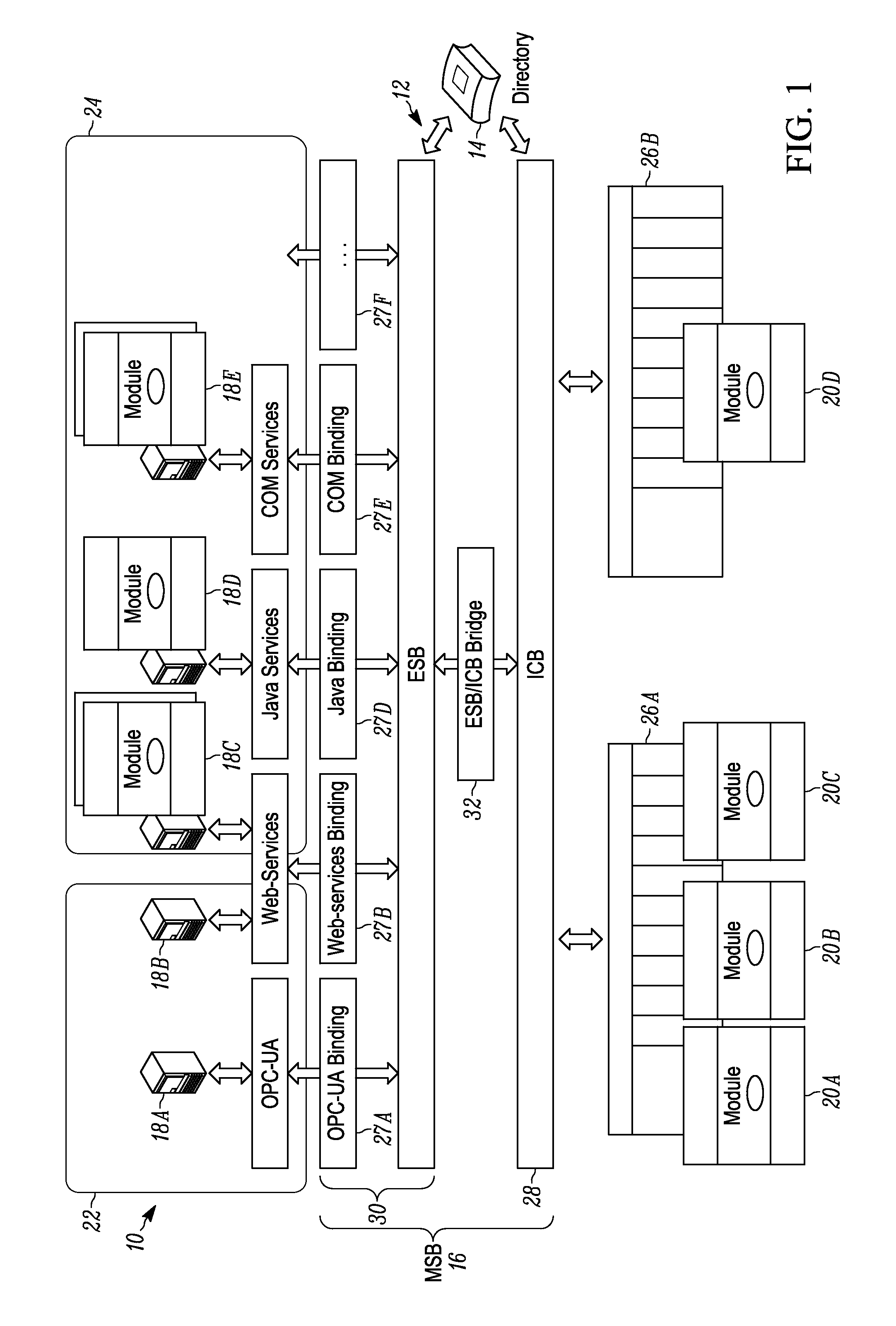

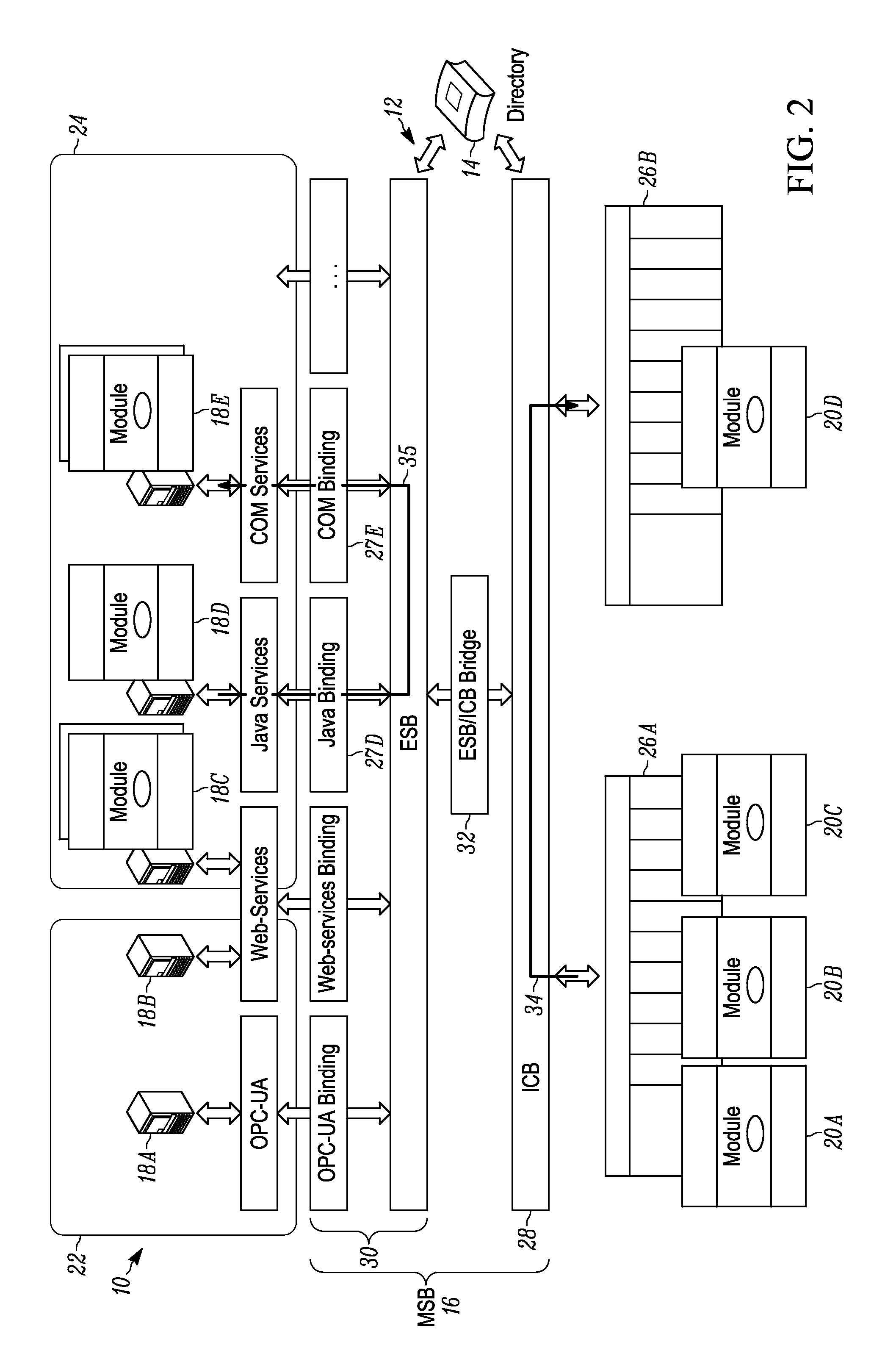

Systems and methods for conducting communications among components of multidomain industrial automation system

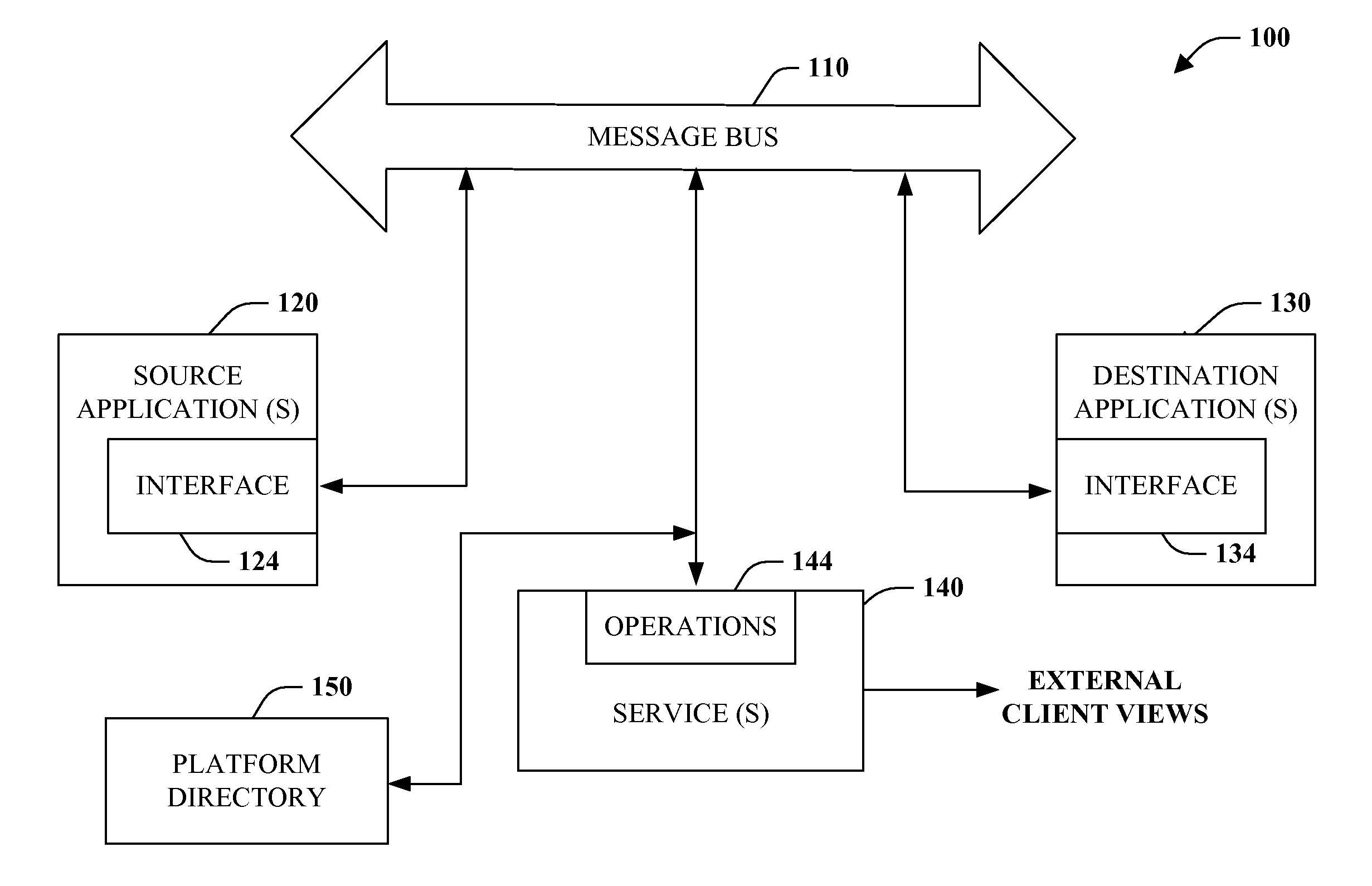

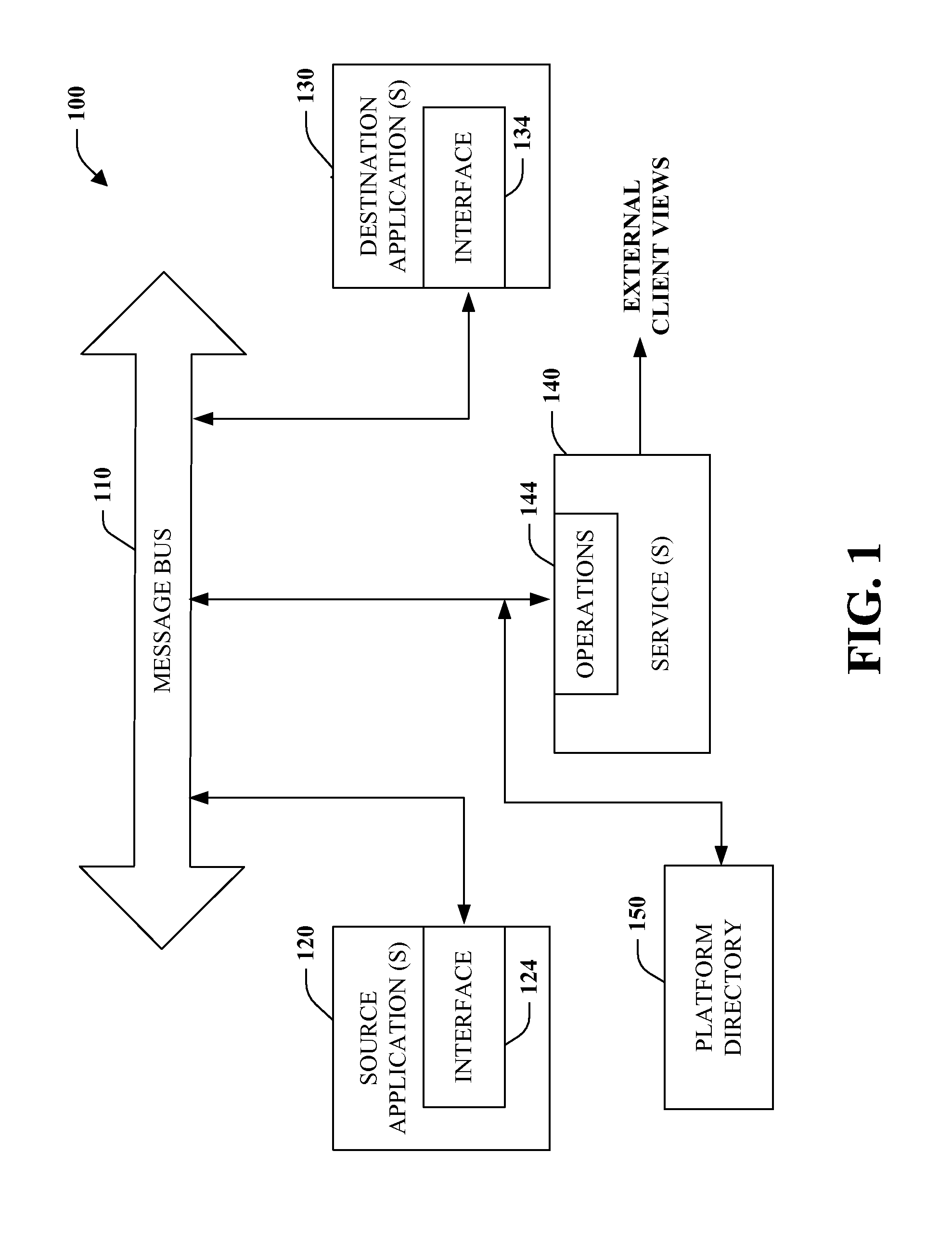

ActiveUS20110258262A1Overcome disadvantagesMultiprogramming arrangementsMultiple digital computer combinationsCommunications systemComputer module

An improved industrial automation system and communication system for implementation therein, and related methods of operation, are described herein. In at least some embodiments, the improved communication system allows communication in the form of messages between modules in different control or enterprise domains. Further, in at least some embodiments, such communications are achieved by providing a communication system including a manufacturing service bus having two internal service busses with a bridge between the internal busses. Also, in at least some embodiments, a methodology of synchronous messaging is employed.

Owner:ROCKWELL AUTOMATION TECH

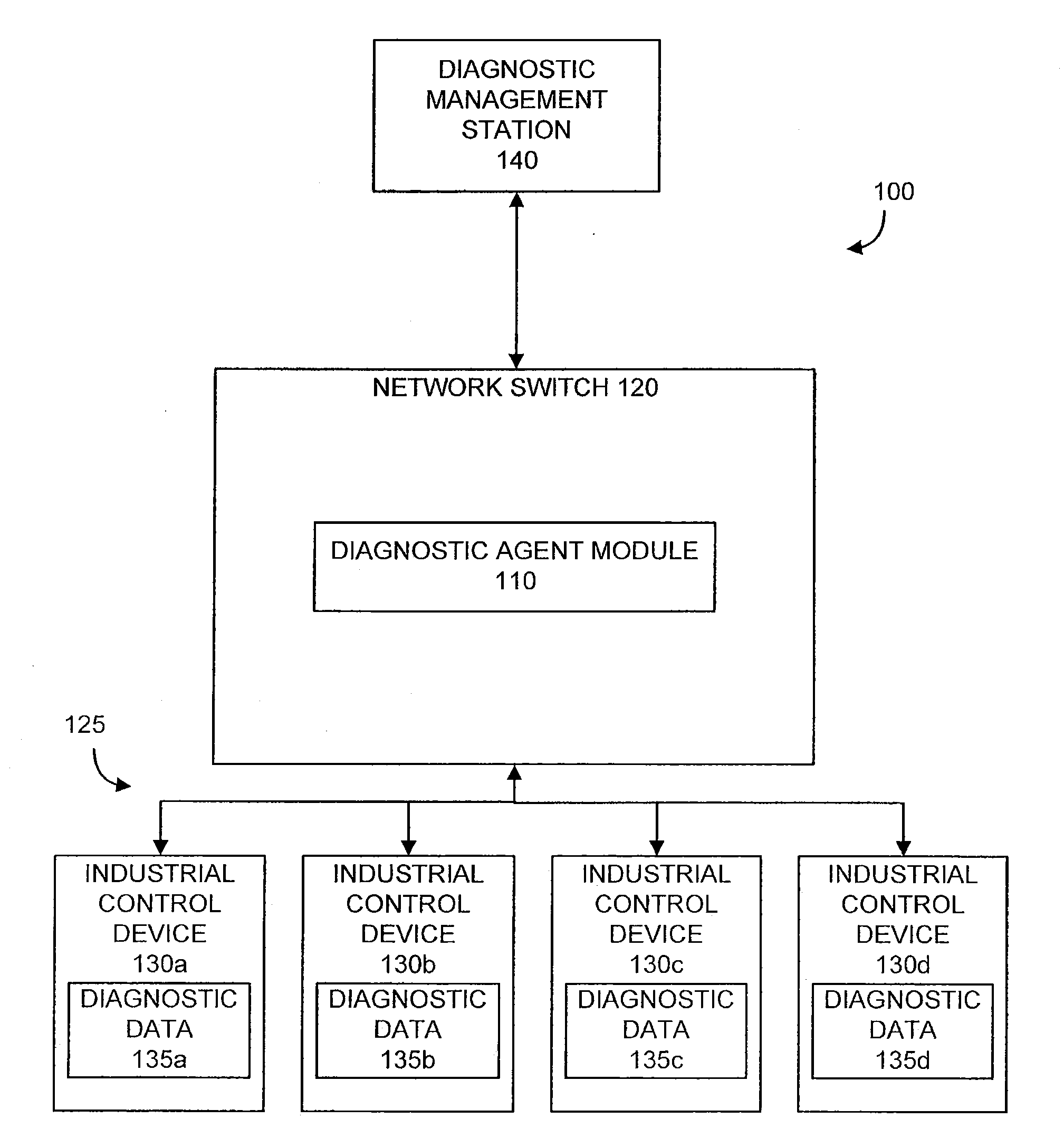

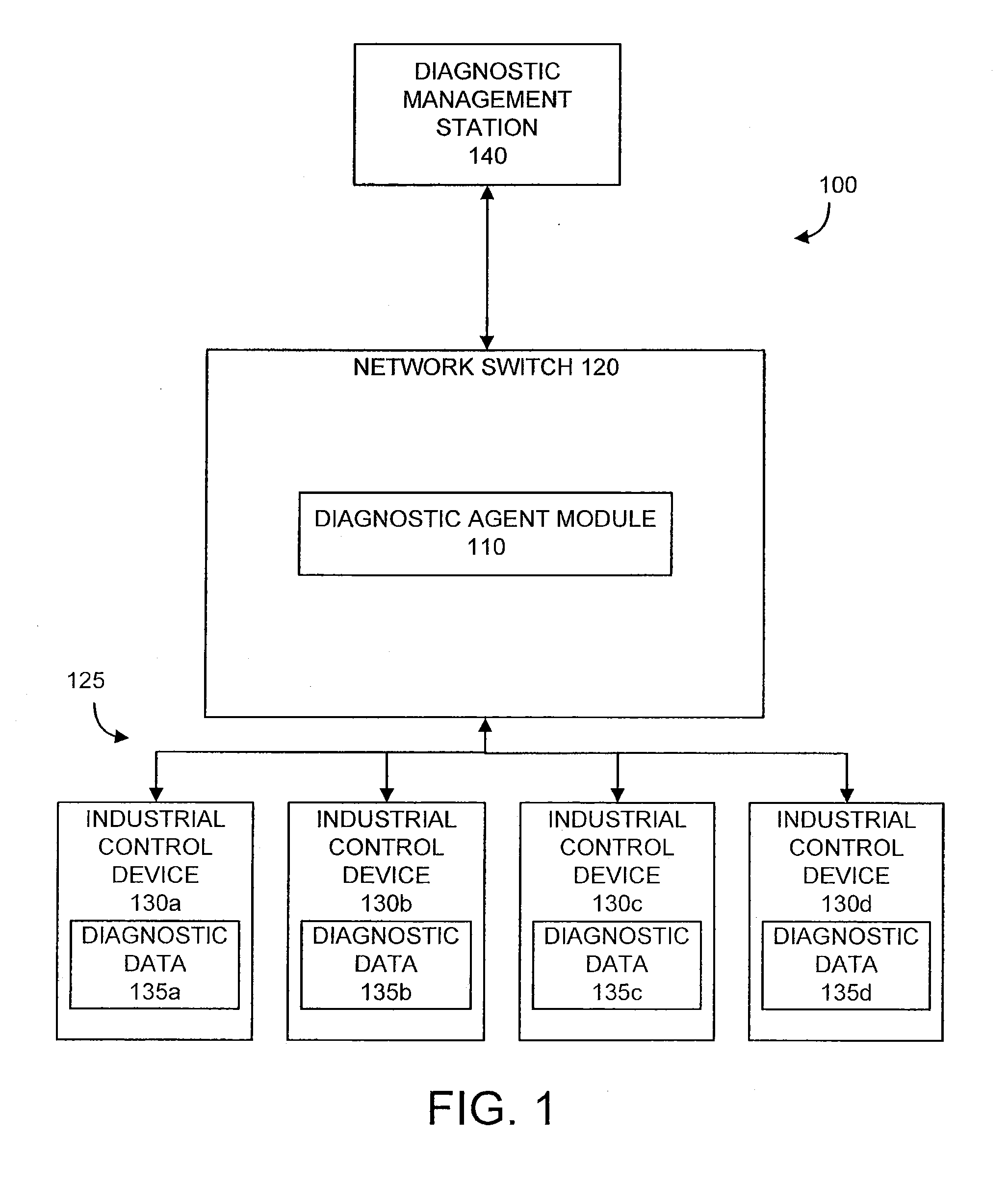

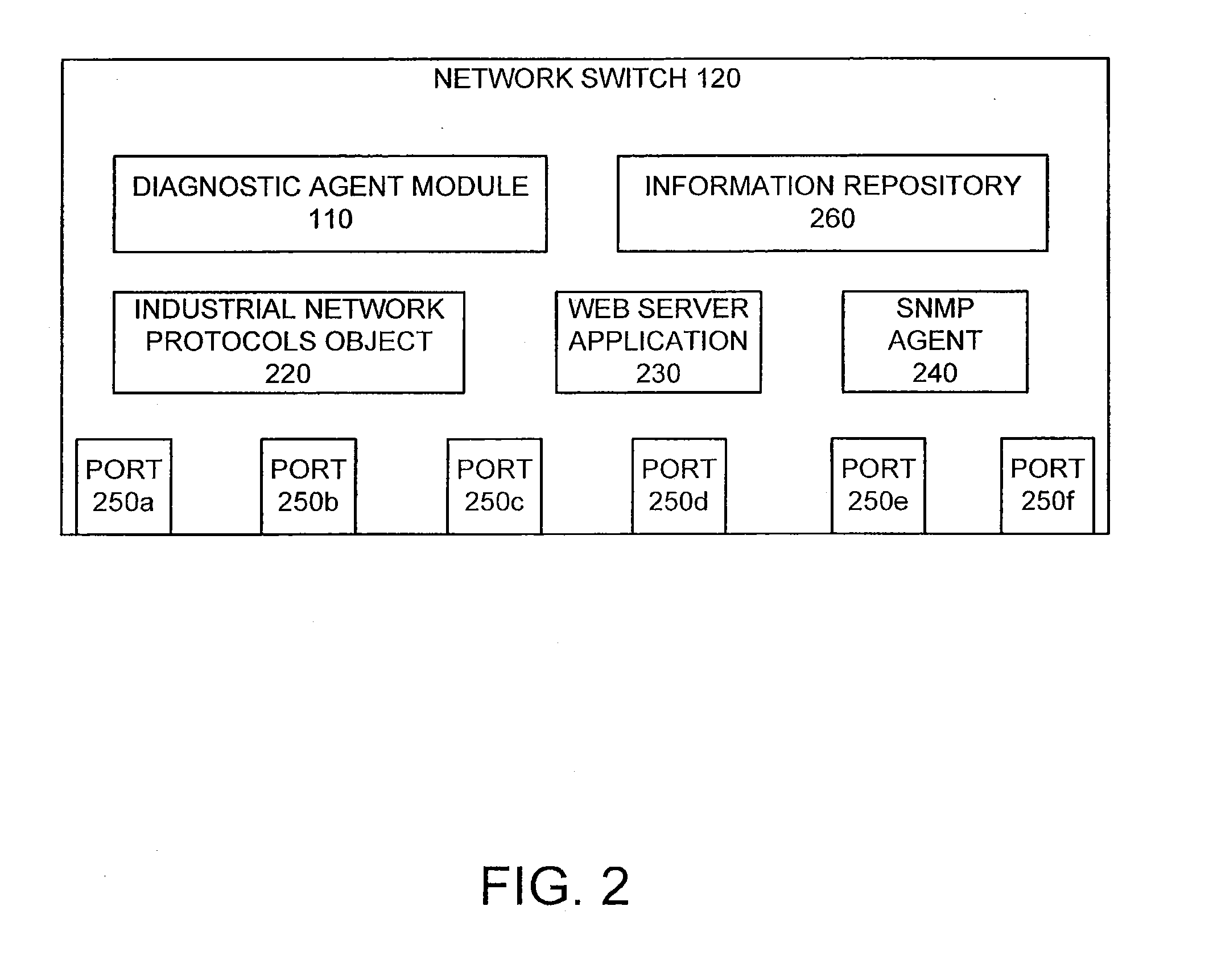

Diagnostic Module For Distributed Industrial Network Including Industrial Control Devices

InactiveUS20110060427A1Easy to processProgramme controlSafety arrangmentsComputer moduleDiagnostic information

A network component for an industrial automation system. The component includes a network switch processor configured to implement a networking switching function, at least one communication port configured to provide a communication channel between the network switch processor and at least one industrial control device over a network, and a diagnostic module configured to be implemented by the network switch processor and configured to retrieve diagnostic information from the at least one industrial control device.

Owner:ROCKWELL AUTOMATION TECH

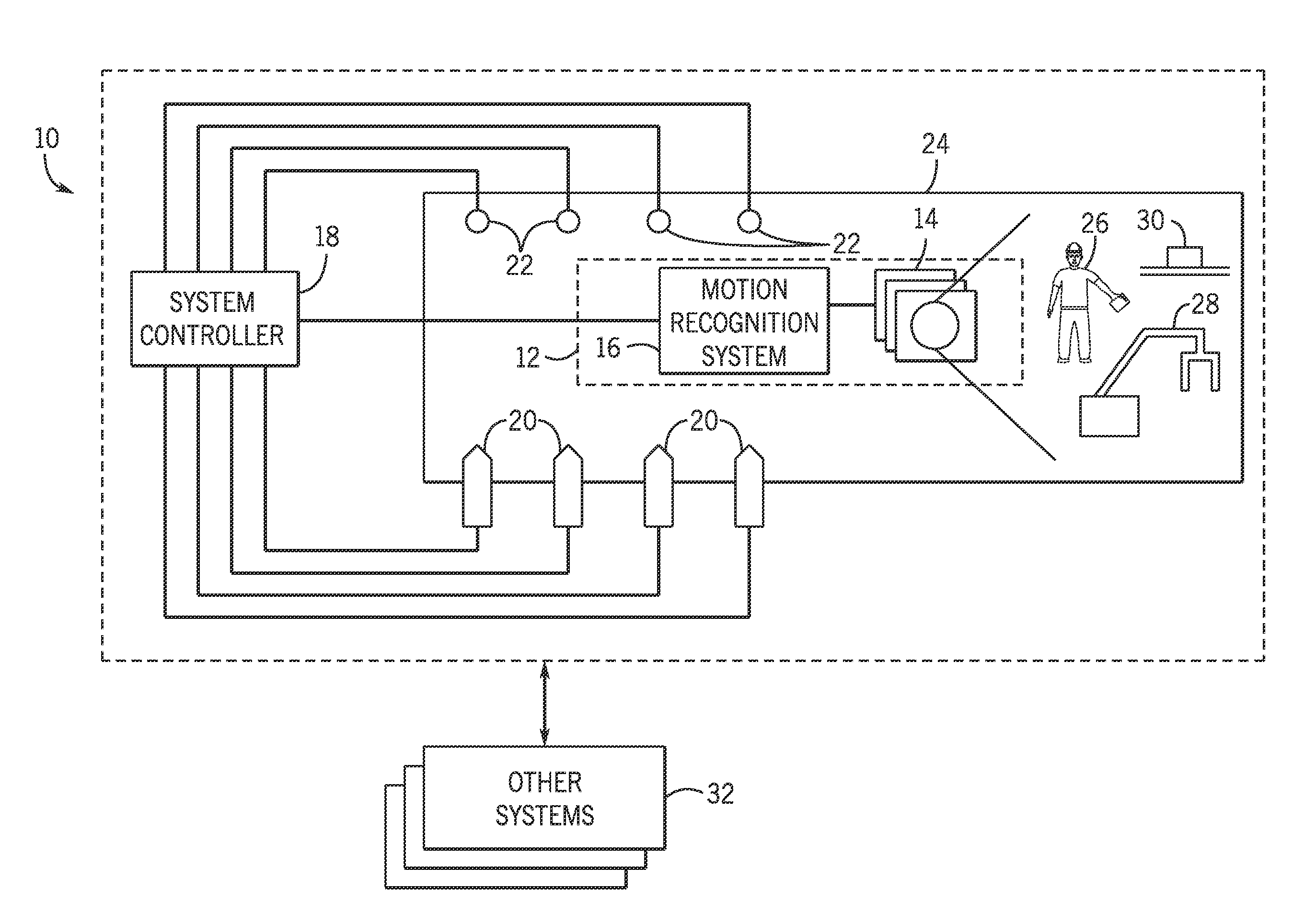

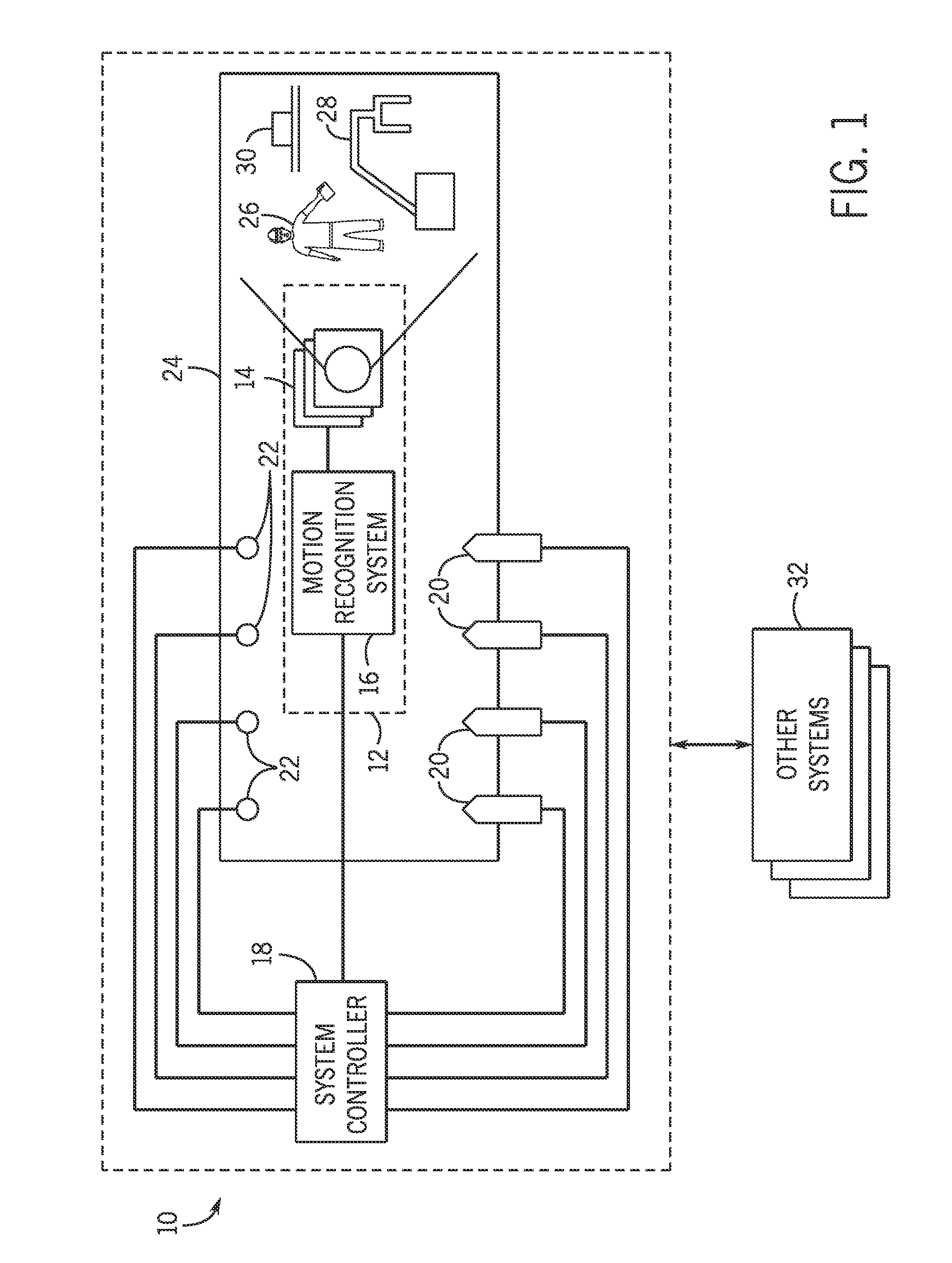

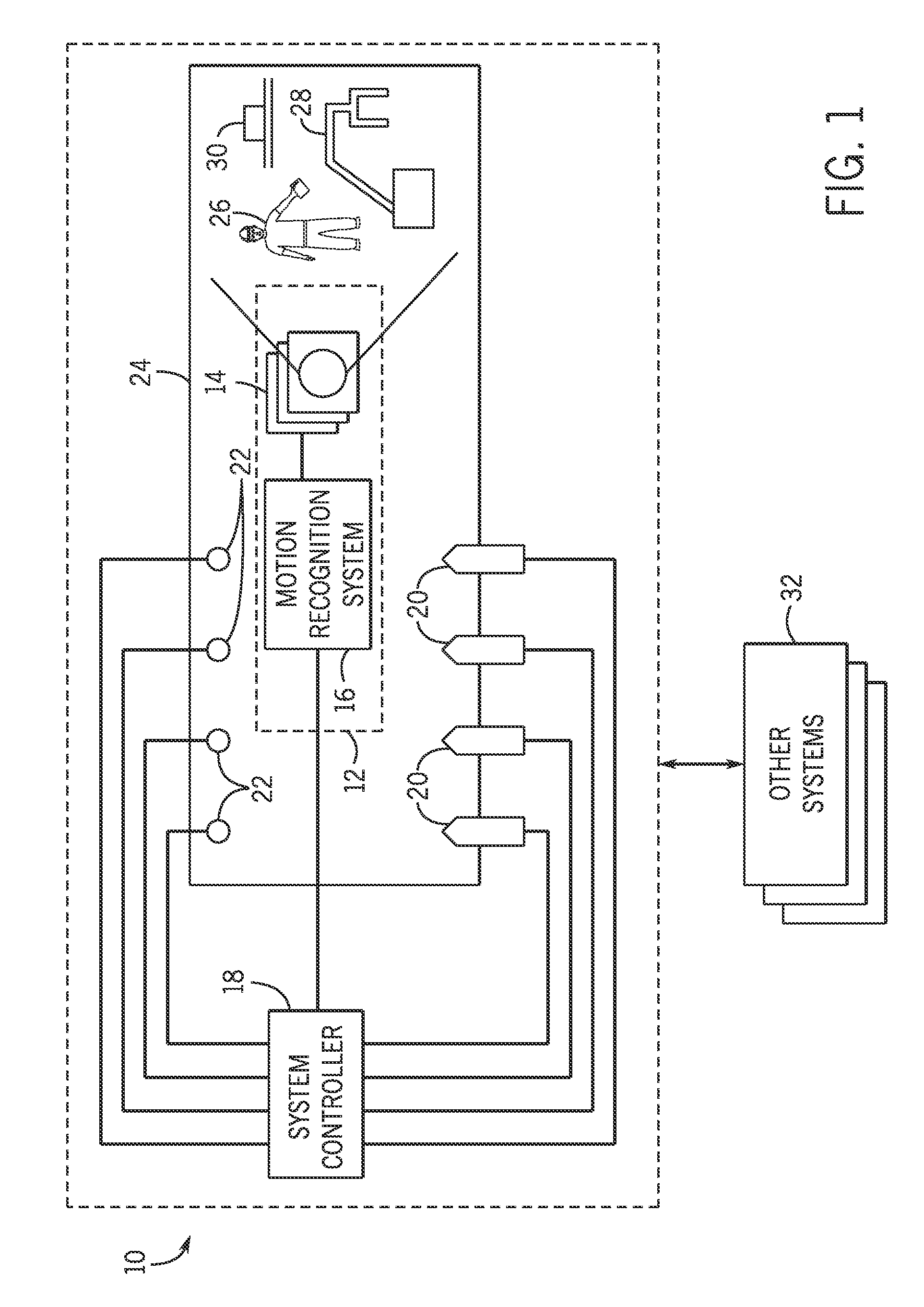

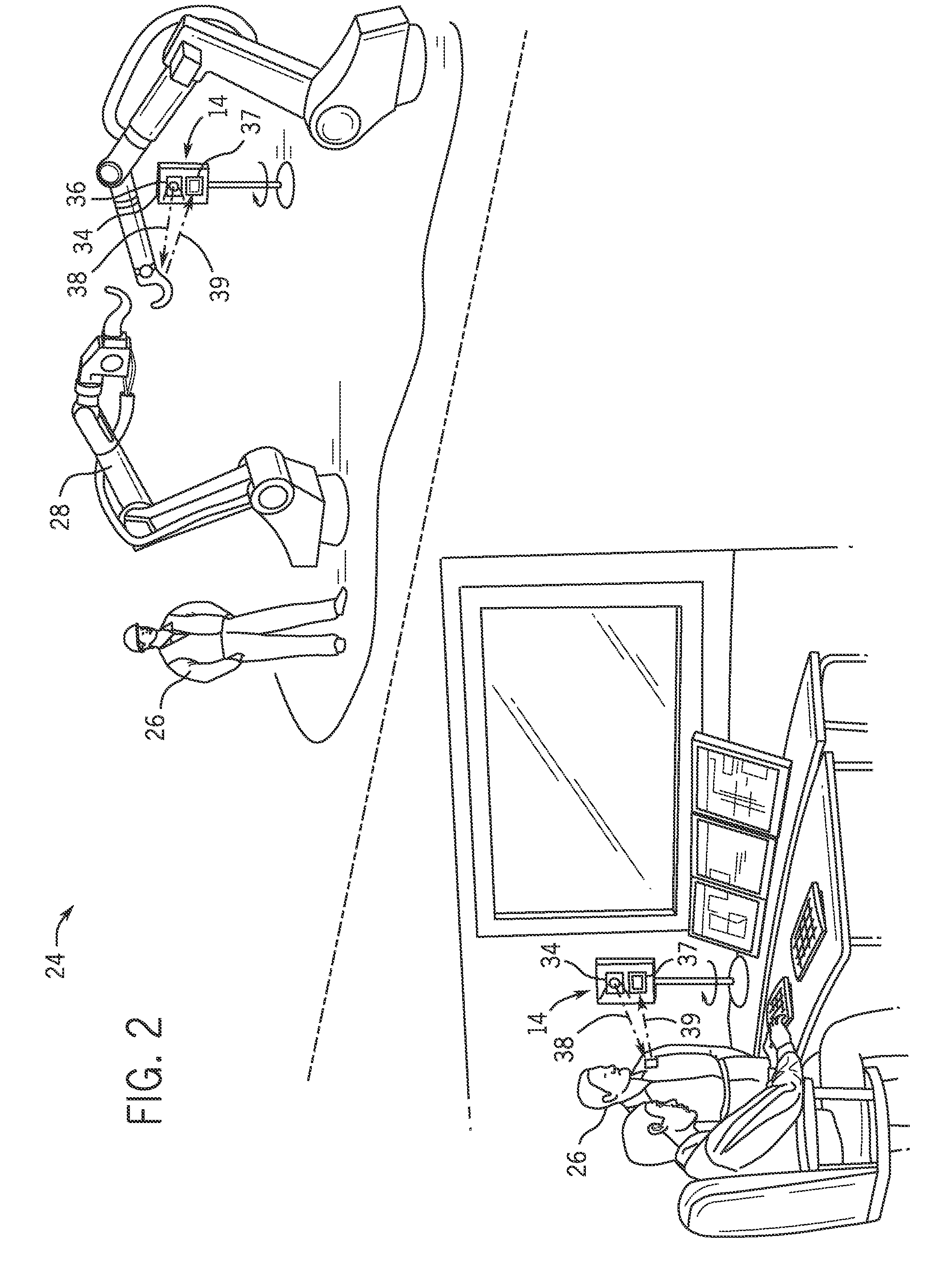

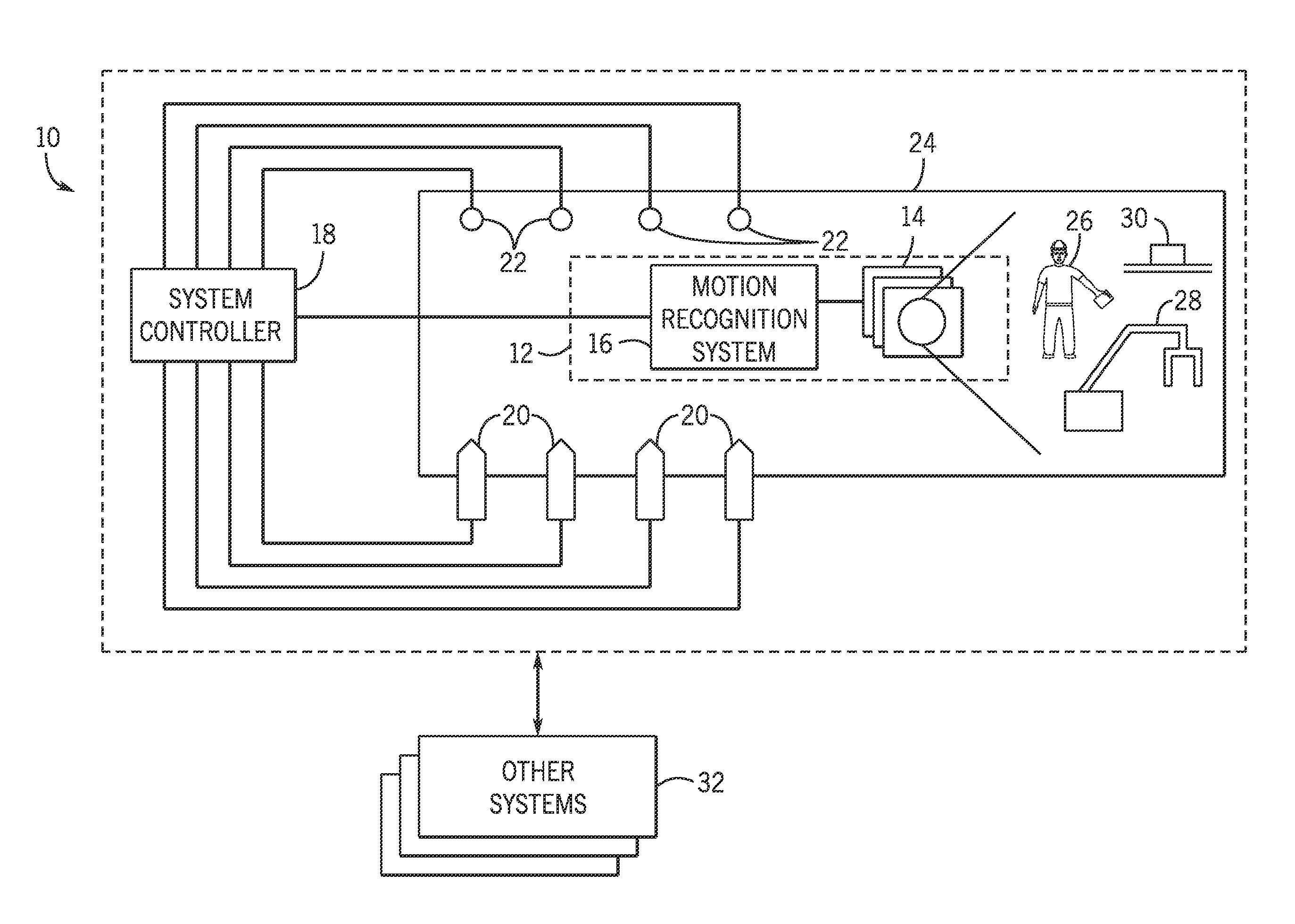

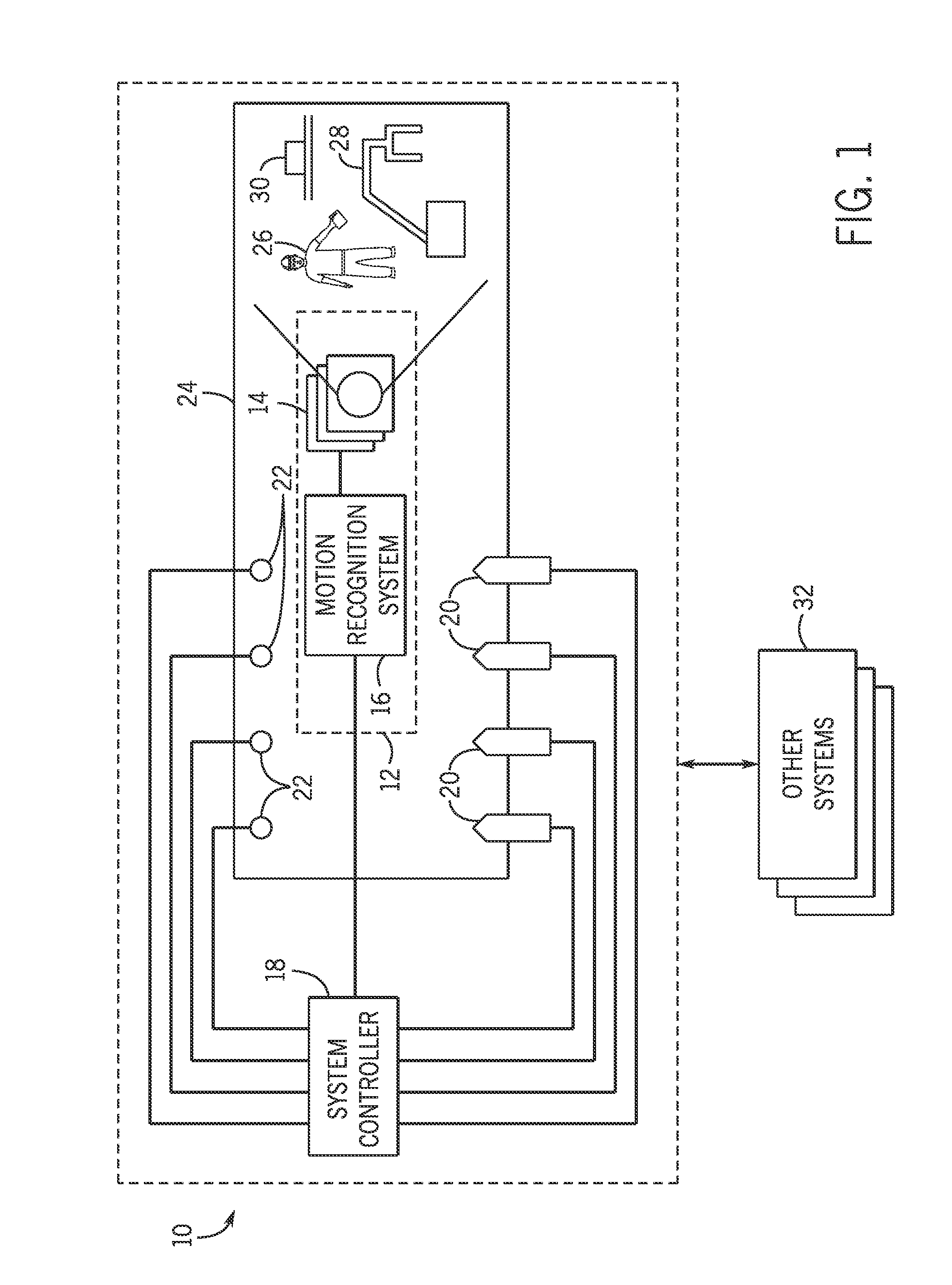

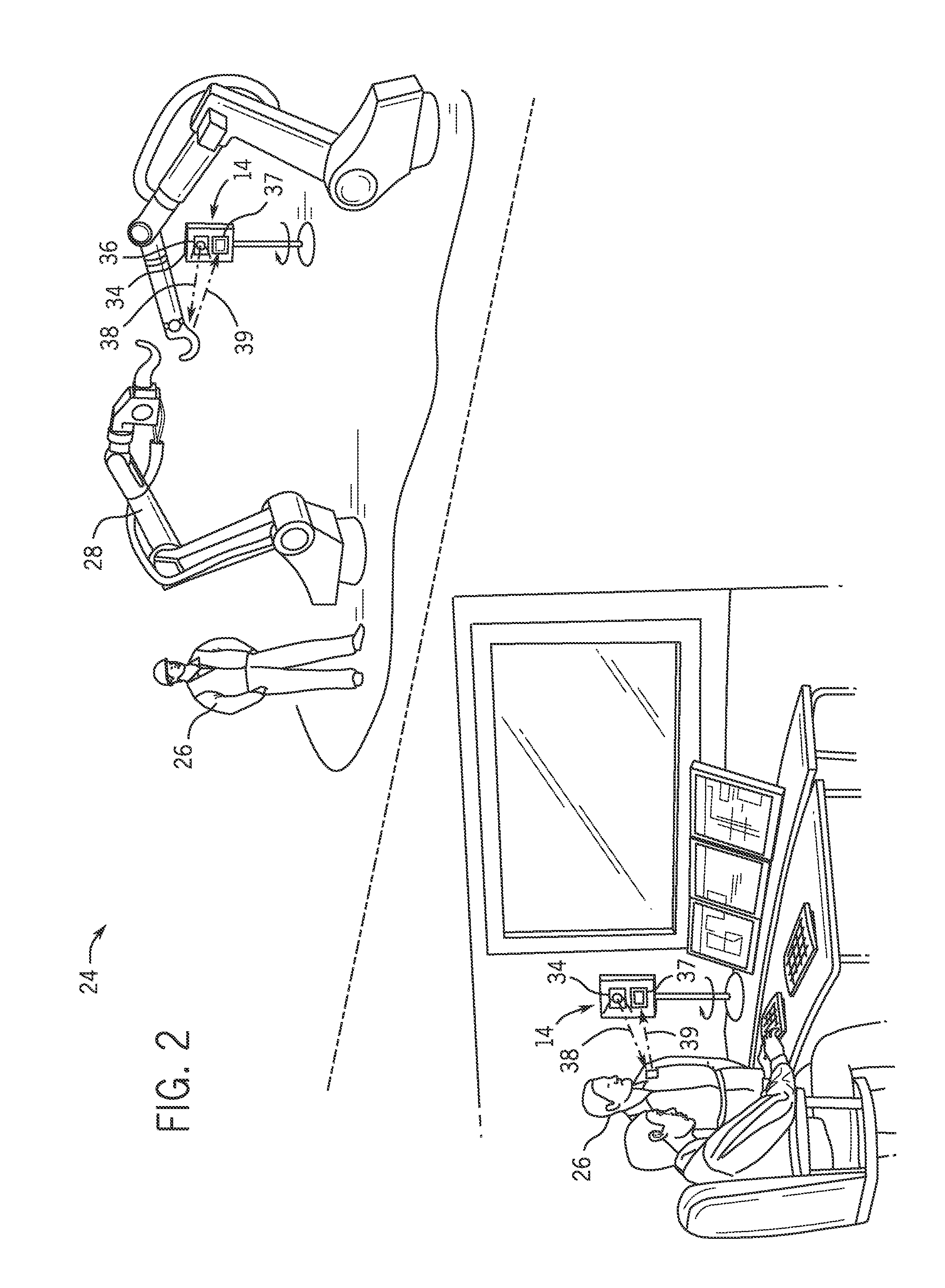

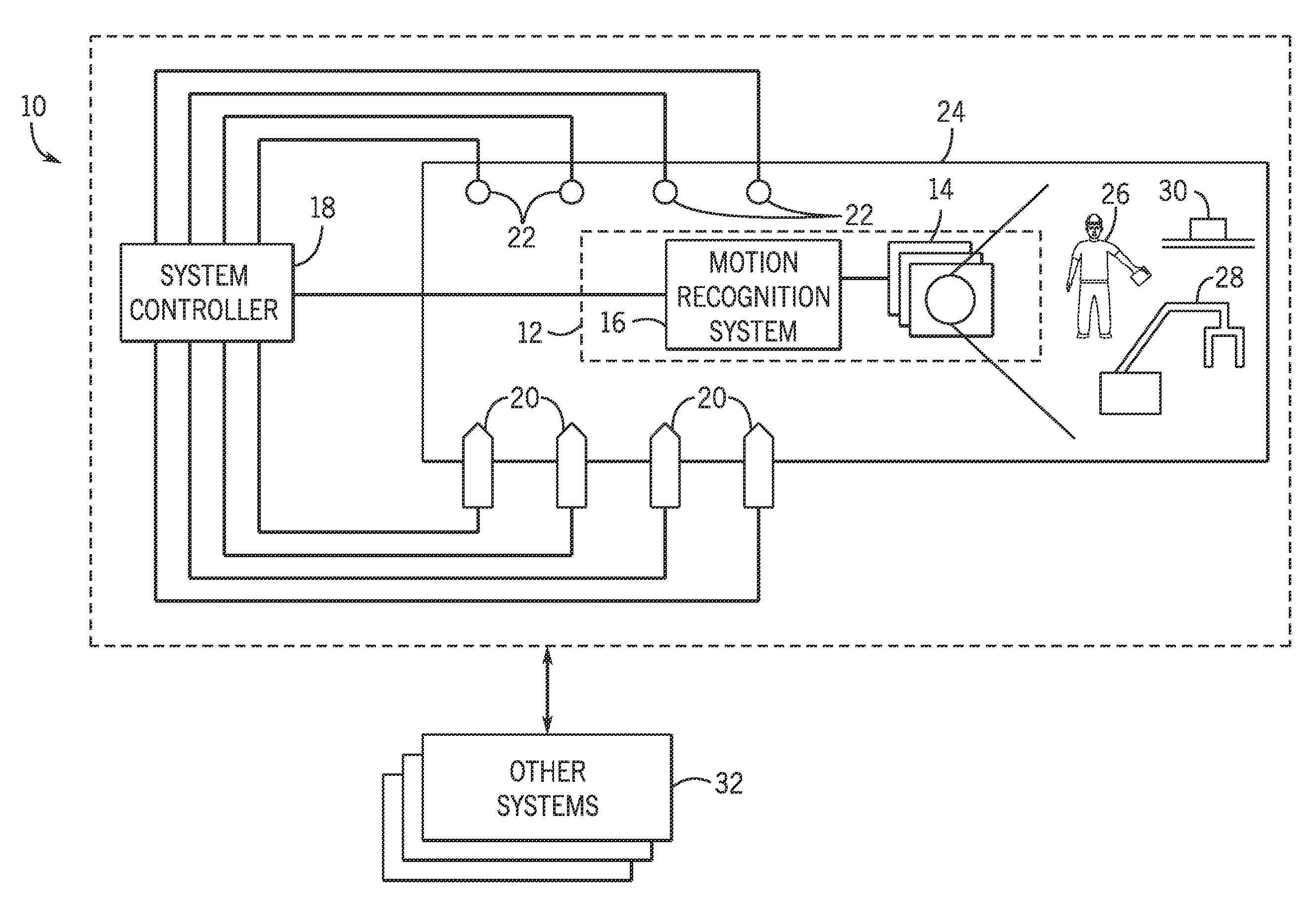

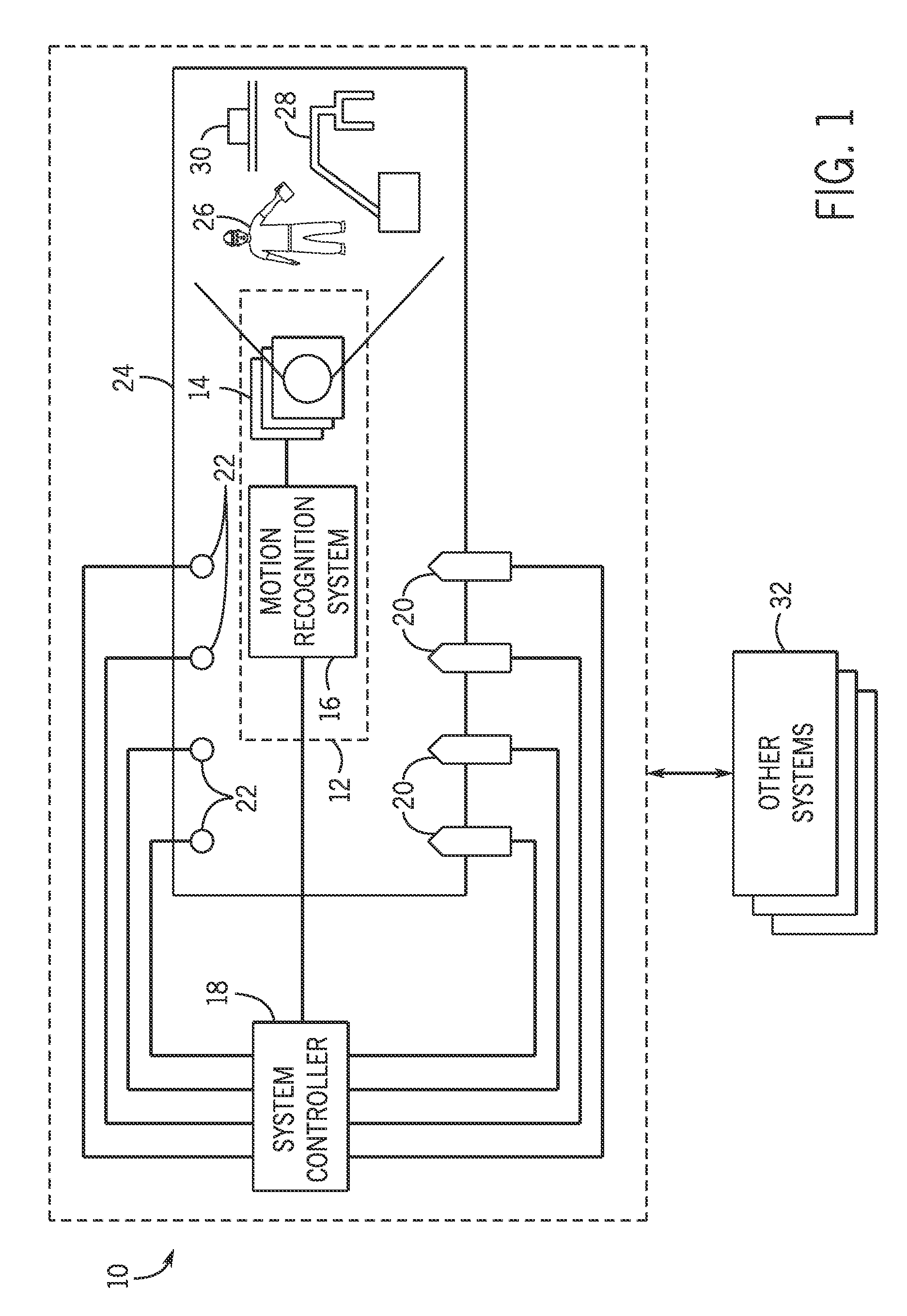

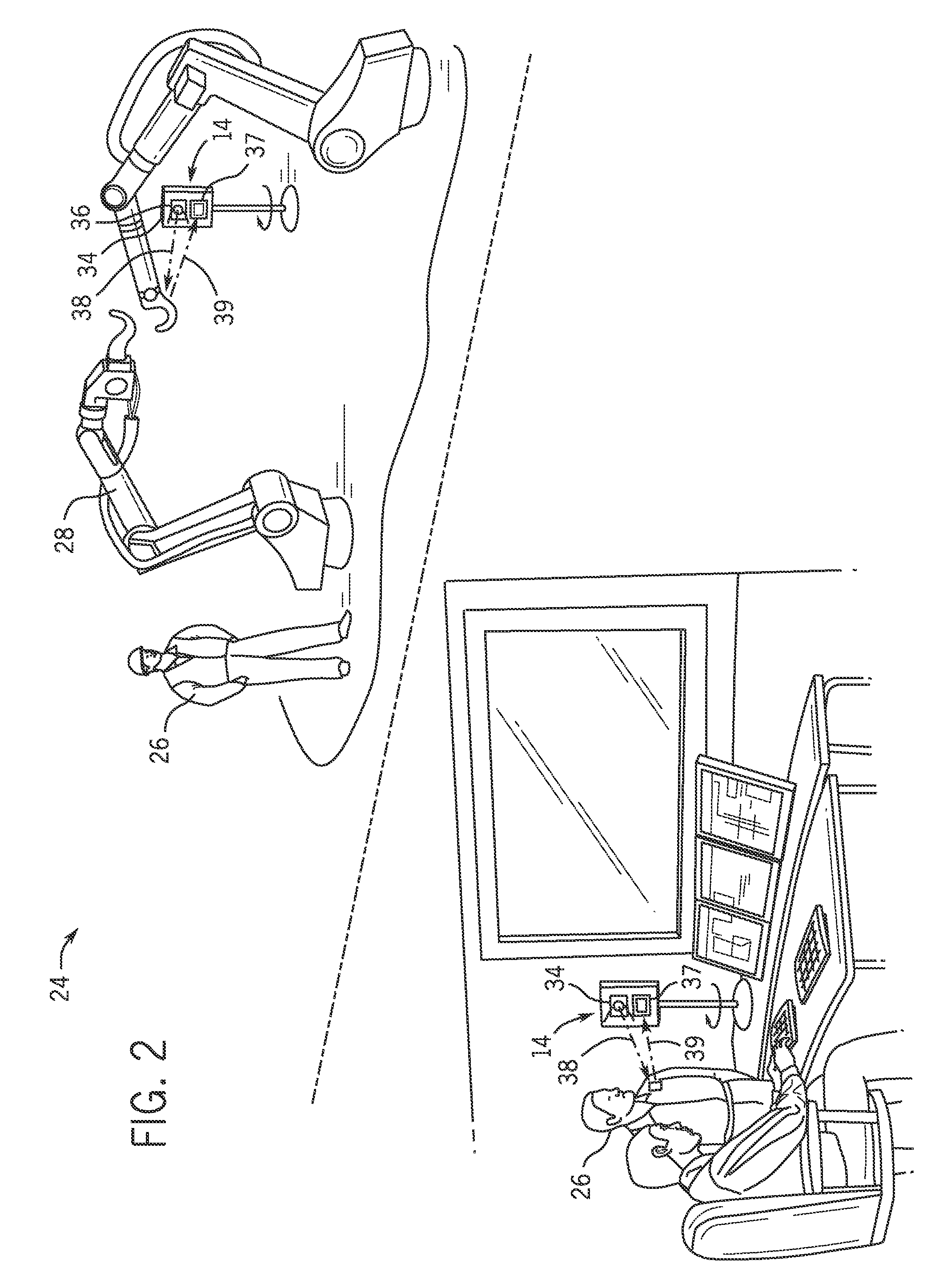

Recognition-based industrial automation control with person and object discrimination

ActiveUS20140244037A1Programme-controlled manipulatorComputer controlObject basedComputerized system

The present disclosure generally relates to a method for performing industrial automation control in an industrial automation system may include detecting, via a sensor system, positions and / or motions of one or more humans and / or one or more objects in an industrial automation system and distinguishing, via a programmed computer system, between one or more humans and one or more objects based upon the detected positions and / or motions. The method may then include implementing a control and / or notification action based upon the distinction.

Owner:ROCKWELL AUTOMATION TECH

Inferred energy usage and multiple levels of energy usage

Owner:ROCKWELL AUTOMATION TECH

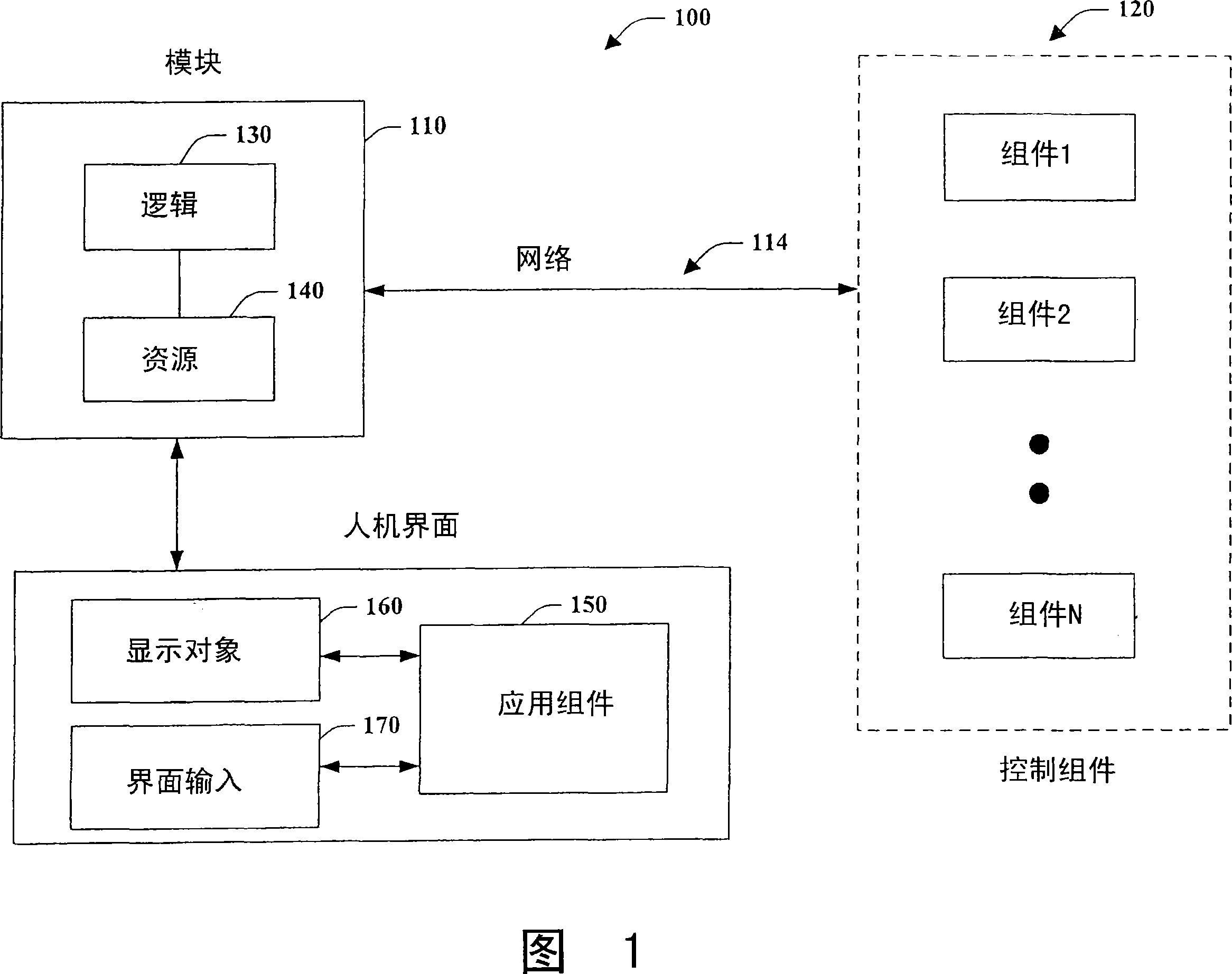

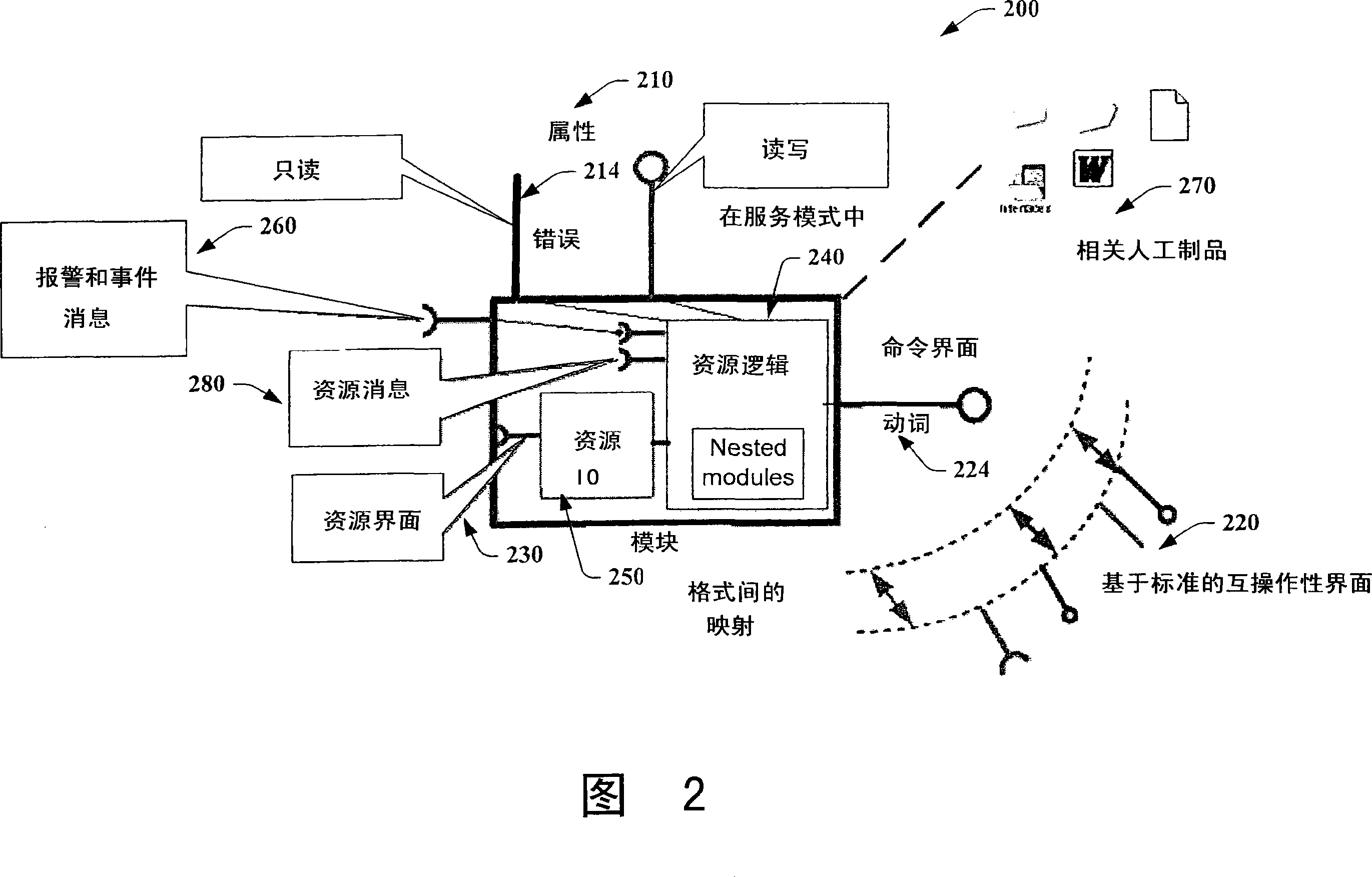

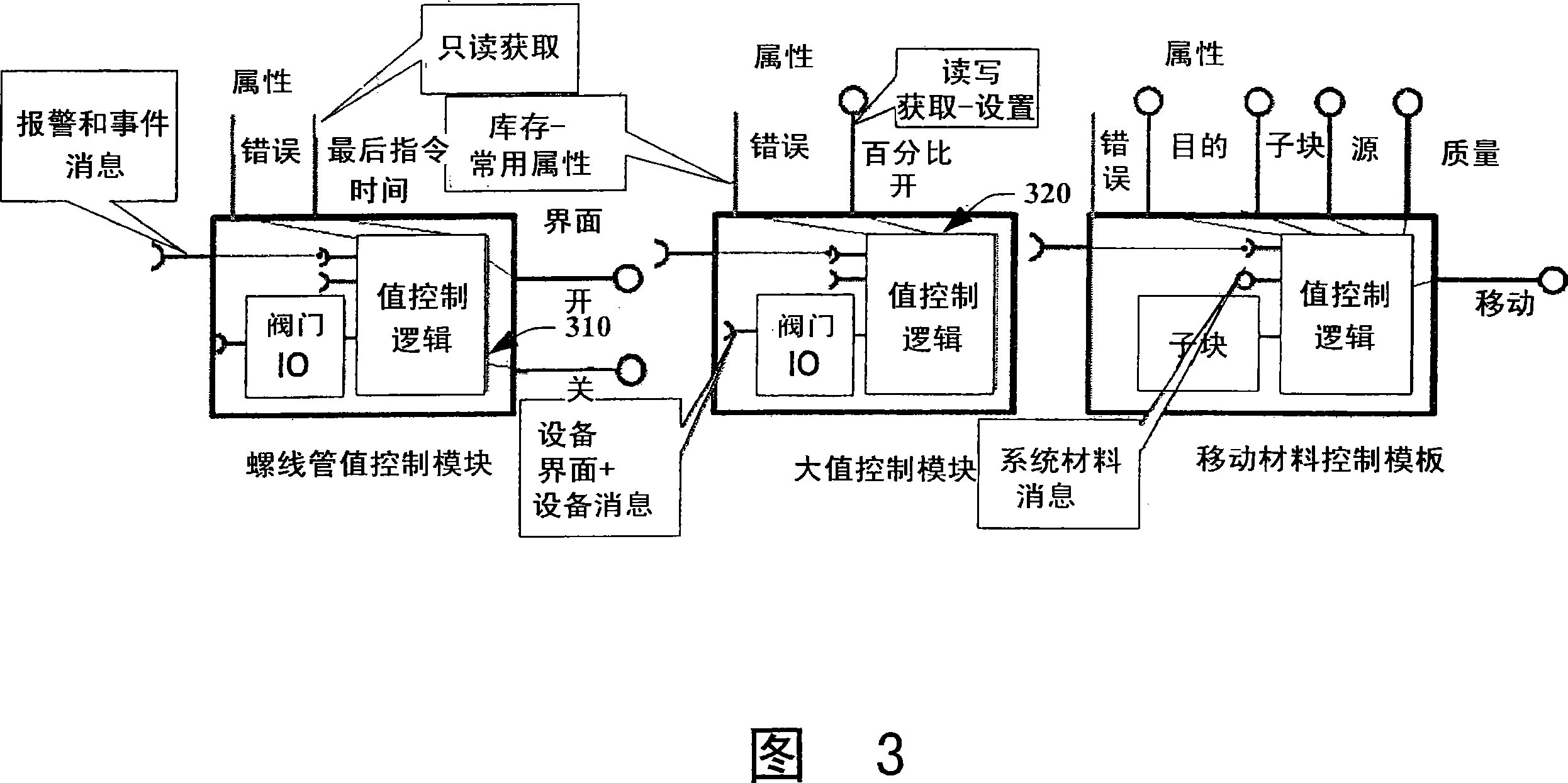

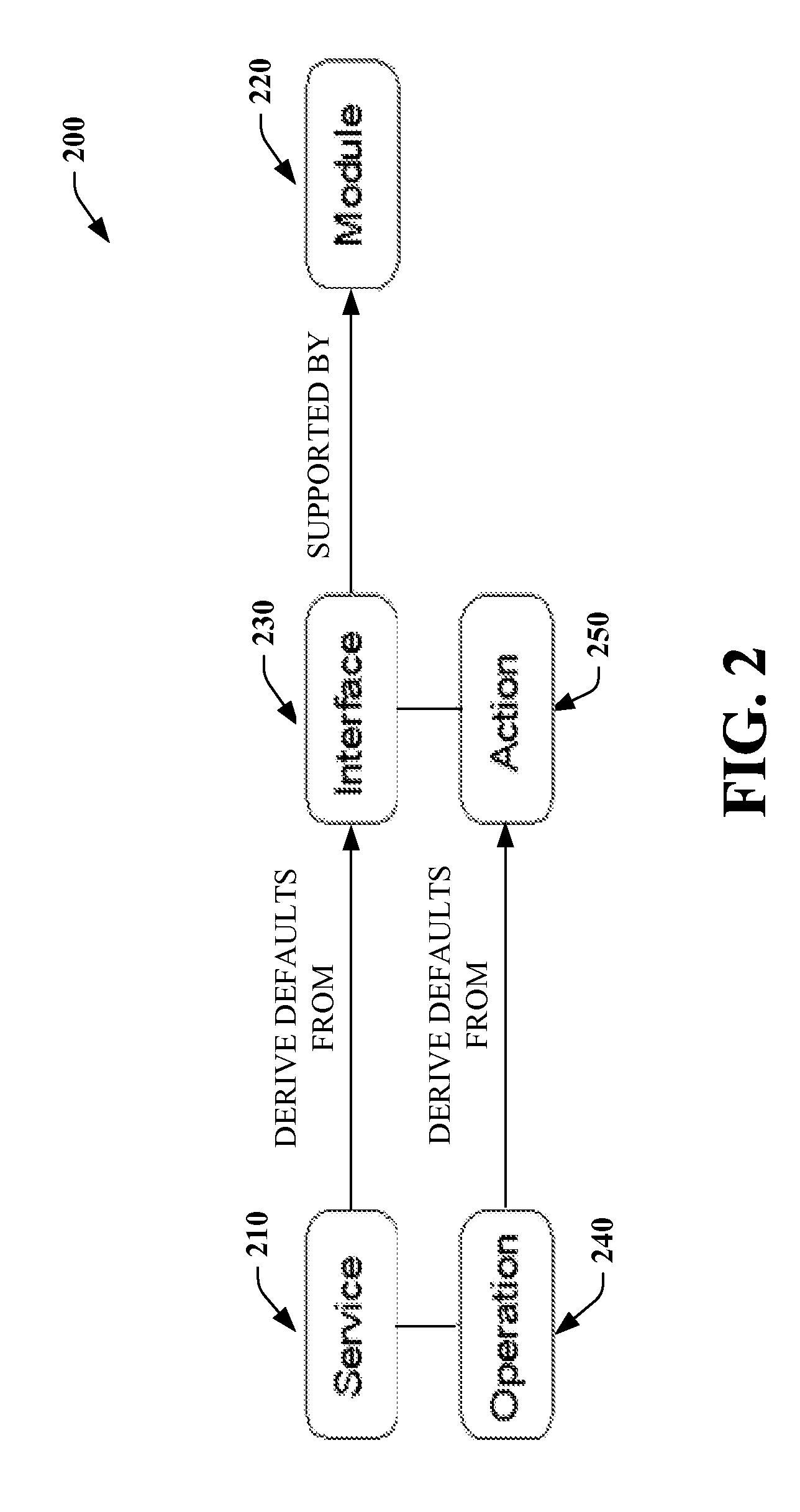

Hmi views of modules for industrial control systems

InactiveCN101201599AProgramme control in sequence/logic controllersHuman–machine interfaceDisplay device

A human machine interface (I-IMI) interface for an industrial automation system is provided. A module is provided that employs resources and logic to expose functionality of the module while providing generic interfaces to external components of the module. A human machine interface (HMI) component associated with the module adapts functionality of a display based at least in part on a type of user or application. In addition to the display, the HMI component adapts functionality of one or more interface inputs based in part on the type of user or application.

Owner:ROCKWELL AUTOMATION TECH

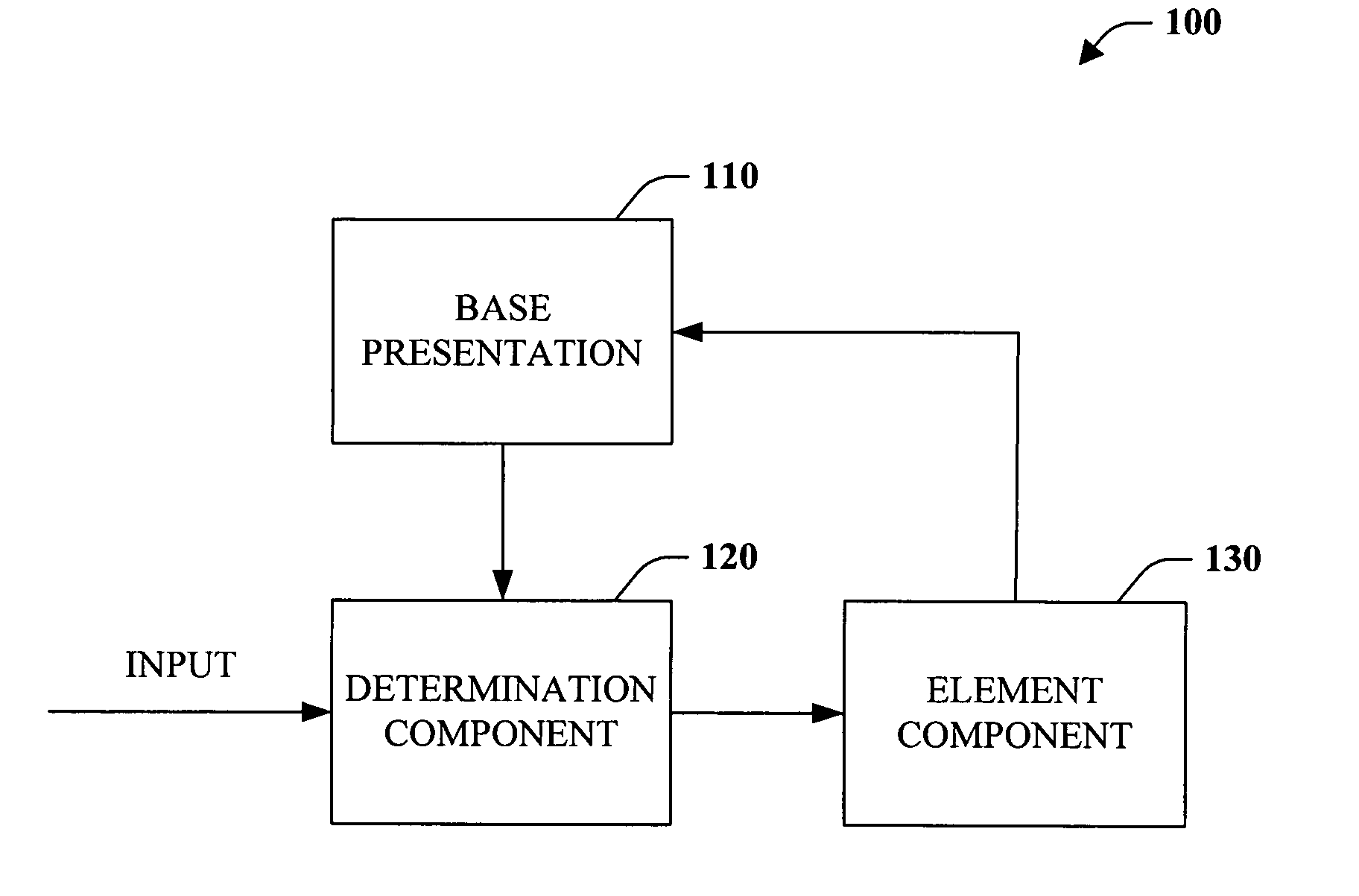

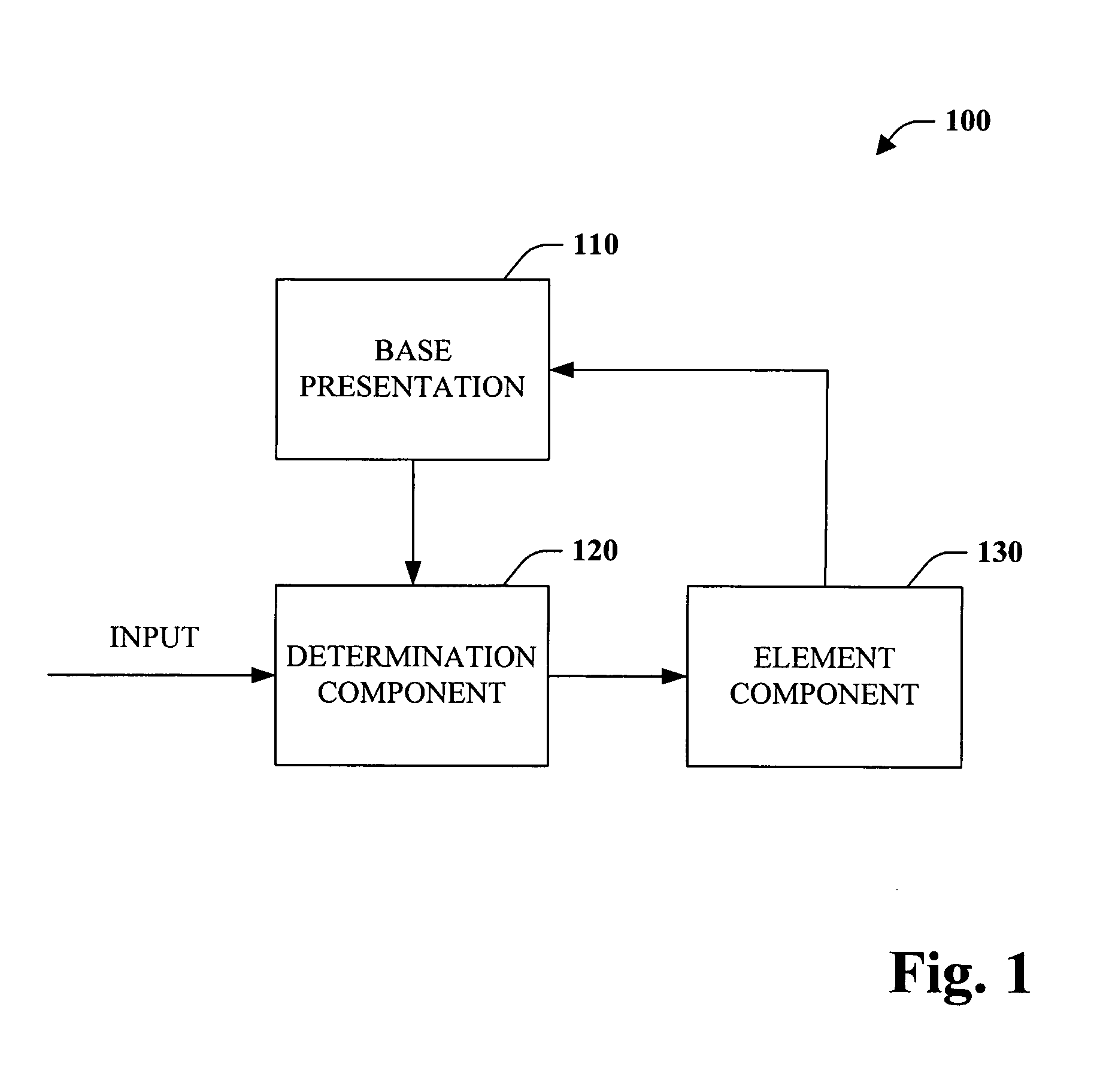

Presentation of automation data

The subject invention pertains to presentation of data. A base presentation can supply coarse data concerning an industrial automation system, for instance. Specific base presentation items can subsequently be identified begetting production of more granular information. In particular, an element can be spawned that provides one or more of text, numbers, graphics, animation, audio and video. The graphical element can remain present and / or active while an item is identified and be removed upon navigation away from the item.

Owner:ROCKWELL AUTOMATION TECH

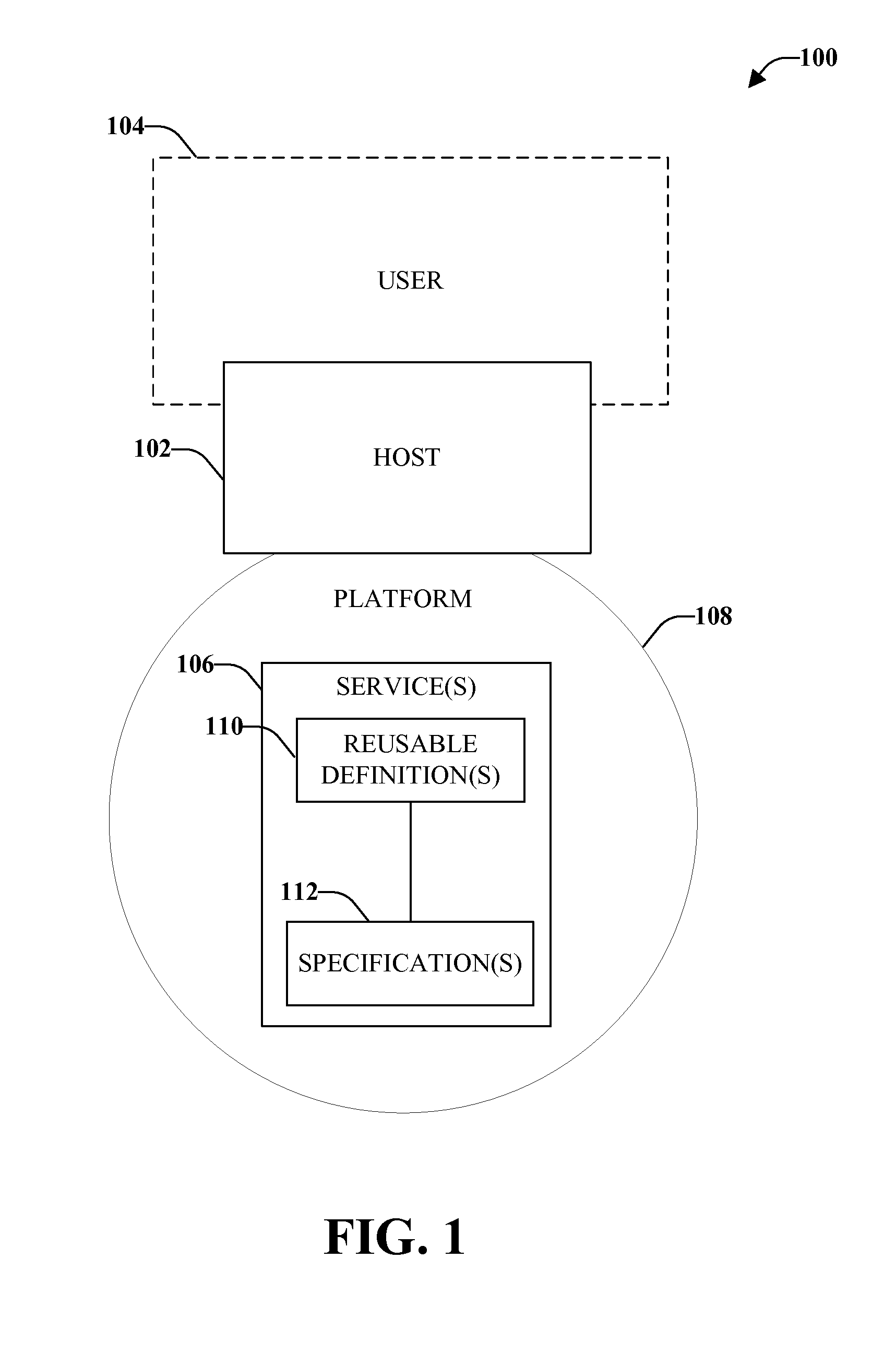

Services for industrial control systems

ActiveUS20080189636A1Efficiently integrated across system componentFirmly connectedElectric controllersIgnition automatic controlApplication softwareService component

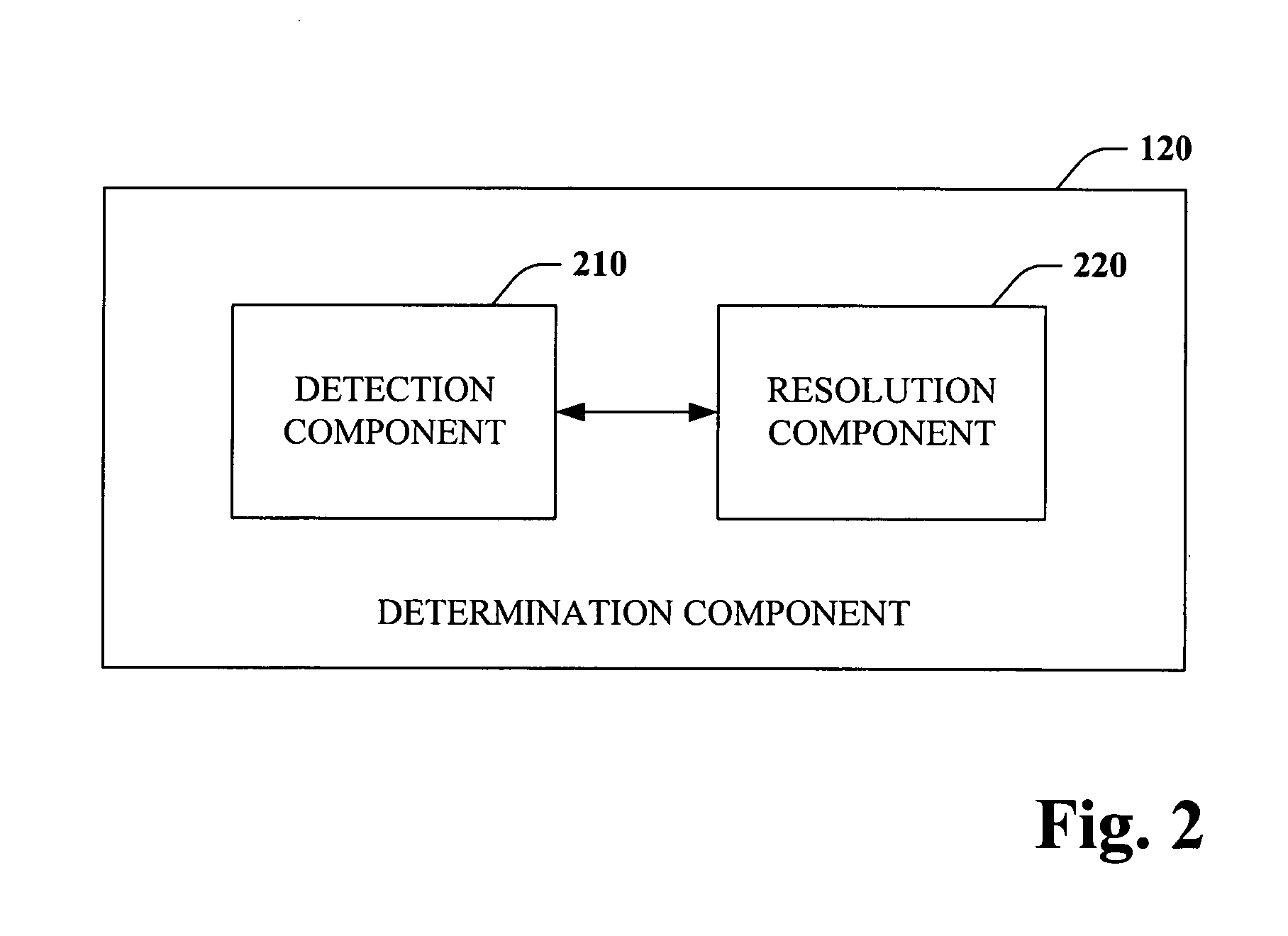

A message component for an industrial automation system is provided. This includes a service component that is employed to locate functionality of applications associated with a control system message bus. An operations component exchanges messages with the message bus, where the service component and the operations component form an external view to facilitate communications between the applications.

Owner:ROCKWELL AUTOMATION TECH

Recognition-based industrial automation control with position and derivative decision reference

ActiveUS20140244004A1Programme-controlled manipulatorComputer controlControl engineeringComputer science

The present disclosure generally relates to a method for performing industrial automation control may include detecting, via a sensor system, positions and / or motions of a human in an industrial automation system, determining at least one derivative value from the detected positions and / or motions, and determining a possible automation command and an undesirable condition based upon the detected positions and / or motions and the at least one derivative value. The method may then include implementing a control and / or notification action based upon the determined possible automation command and the undesired condition.

Owner:ROCKWELL AUTOMATION TECH

Systems and methods for conducting communications among components of multidomain industrial automation system

ActiveUS20110258637A1Programme controlDigital data processing detailsCommunications systemComputer module

An improved industrial automation system and communication system for implementation therein, and related methods of operation, are described herein. In at least some embodiments, the improved communication system allows communication in the form of messages between modules in different control or enterprise domains. Further, in at least some embodiments, such communications are achieved by providing a communication system including a manufacturing service bus having two internal service busses with a bridge between the internal busses. Also, in at least some embodiments, a methodology of synchronous messaging is employed.

Owner:ROCKWELL AUTOMATION TECH

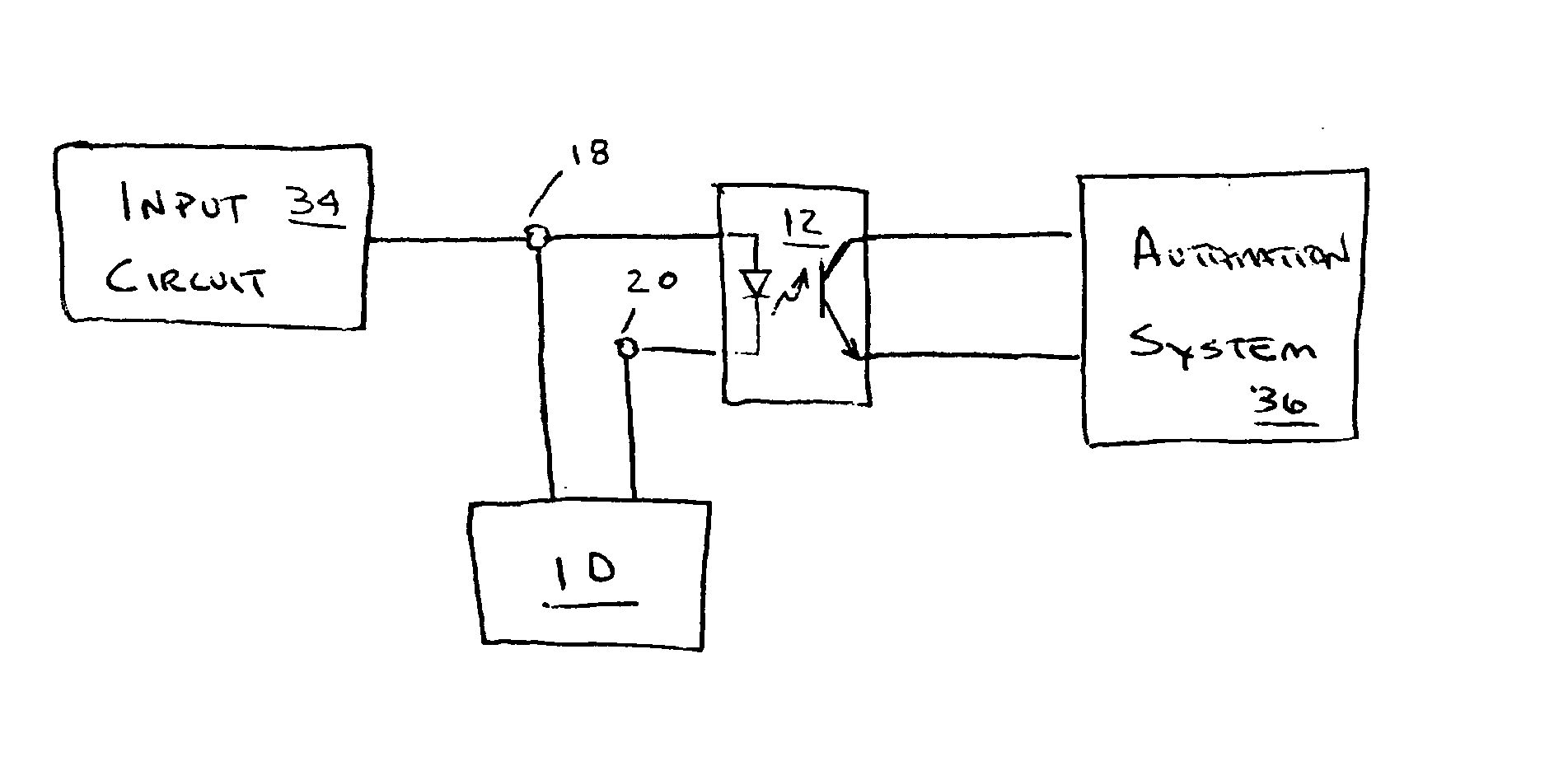

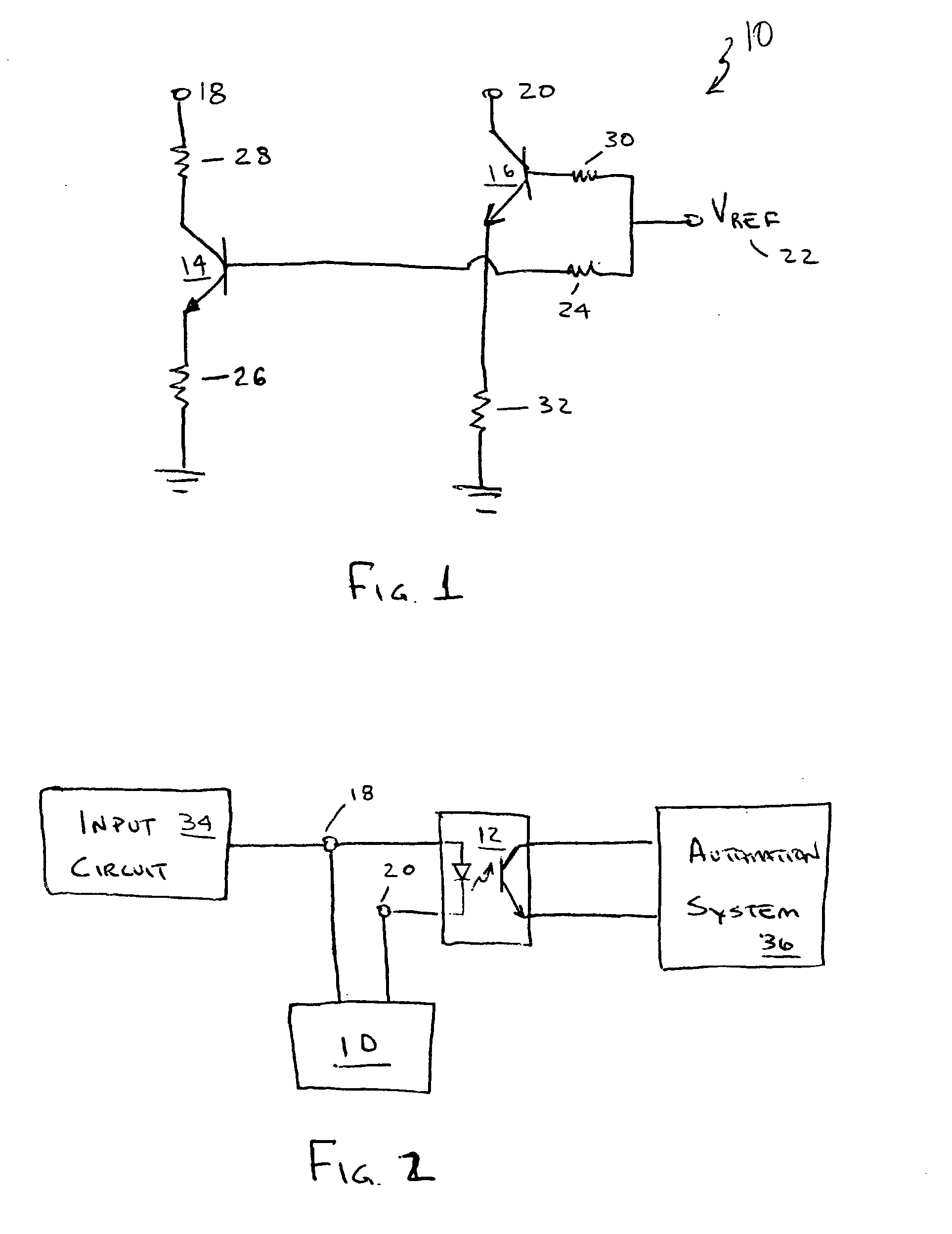

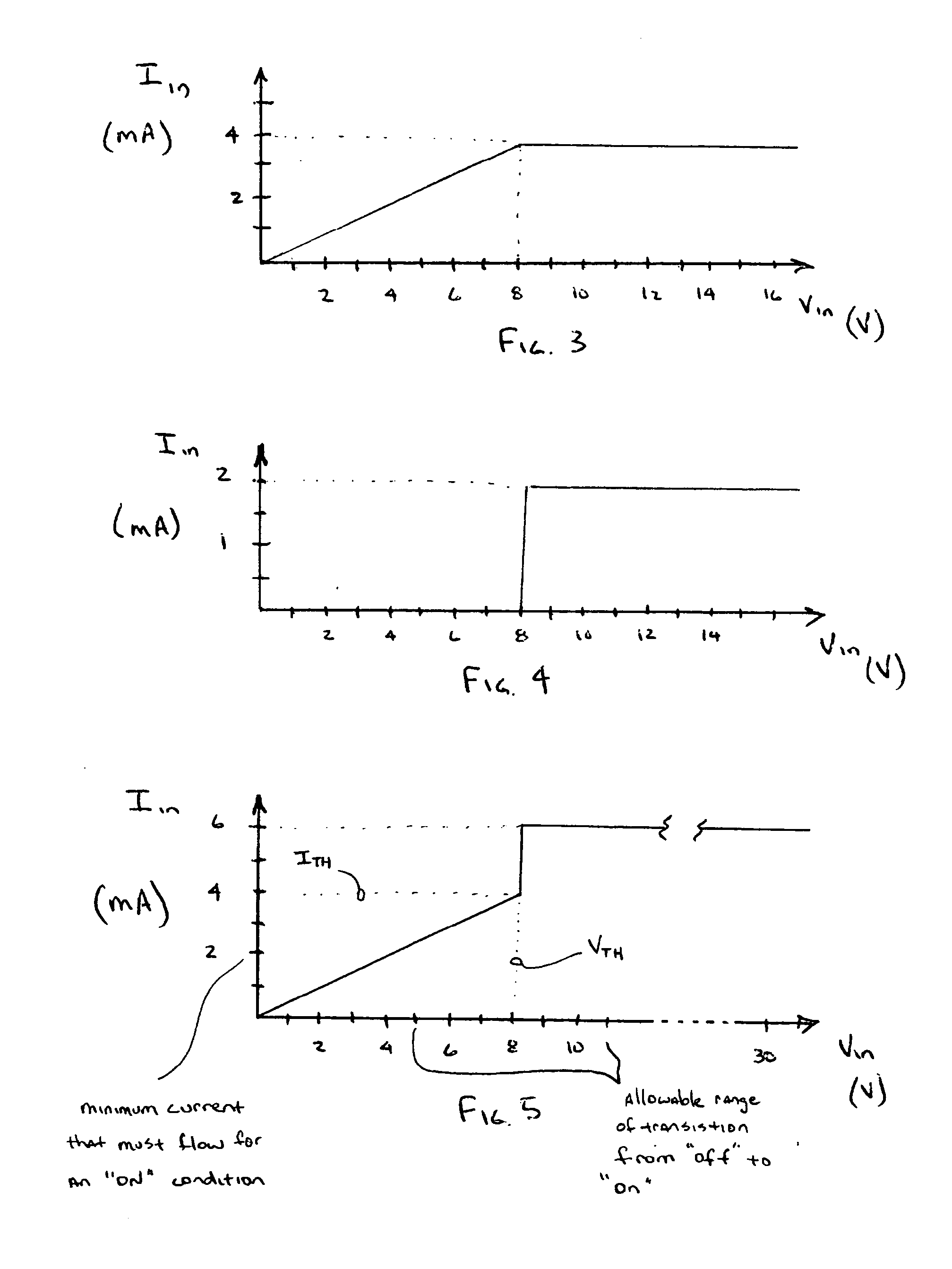

Dual current-source digital-input circuit for an industrial automation system

ActiveUS20050139791A1Low costEasy to controlMaterial analysis by optical meansElectronic switchingElectricityVoltage reference

An interface circuit for use between an input circuit and an industrial automation system is disclosed. The industrial automation system includes an opto-coupler capable of being operably connected to the interface circuit. The interface circuit includes a first and second terminal, each terminal capable of being operably connected to the opto-coupler. A first current-source is operably connected to the first terminal and a second current-source is operably connected to the second terminal. A reference voltage is operably connected to the first current-source and the second current-source wherein the first and second current-source cooperate to provide a total input current in accordance with the operating characteristics of the industrial automation circuit.

Owner:SCHNEIDER AUTOMATION INC

Systems and methods for conducting communications among components of multidomain industrial automation system

ActiveUS20110258359A1Facilitate communicationEasy to set upProgramme controlWireless commuication servicesCommunications systemEngineering

An improved industrial automation system and communication system for implementation therein, and related methods of operation, are described herein. In at least some embodiments, the improved communication system allows communication in the form of messages between modules in different control or enterprise domains. Further, in at least some embodiments, such communications are achieved by providing a communication system including a manufacturing service bus having two internal service busses with a bridge between the internal busses. Also, in at least some embodiments, a methodology of synchronous messaging is employed.

Owner:ROCKWELL AUTOMATION TECH

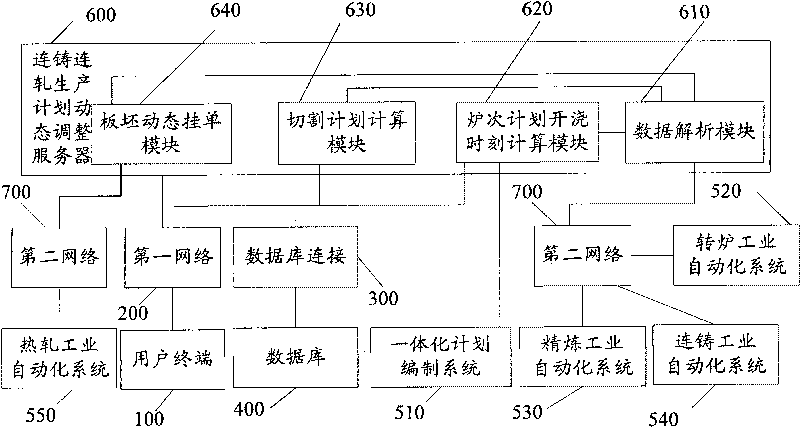

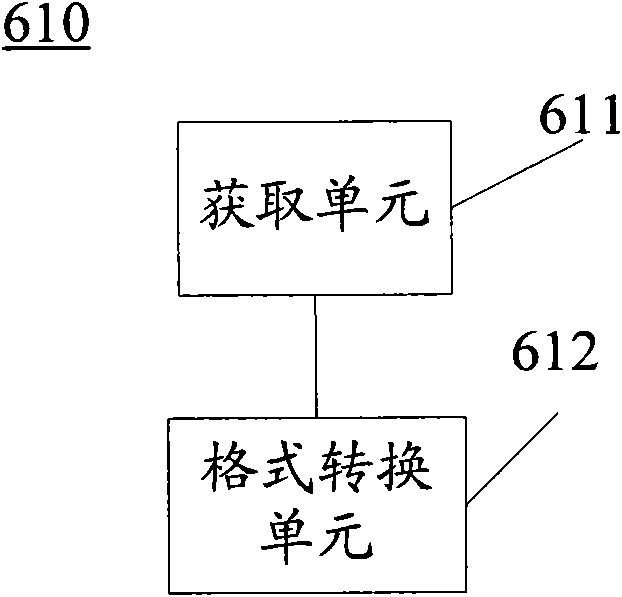

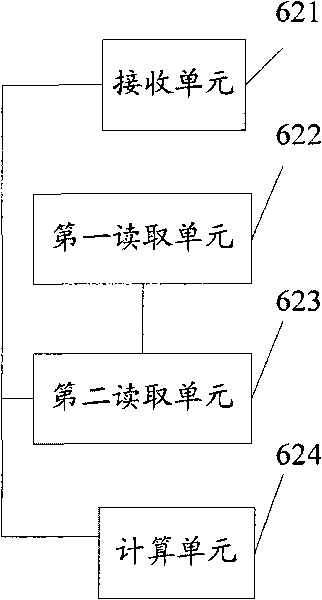

Dynamic adjustment system for metallurgical continuous casting and continuous rolling production plan

InactiveCN101727103AMeet the production process requirementsMaximize steel production capacityTotal factory controlProgramme total factory controlSteelmakingContinuous rolling

The invention discloses a dynamic adjustment system for a metallurgical continuous casting and continuous rolling production plan. The system comprises a dynamic adjustment server for the continuous casting and continuous rolling production plan, database connection and a database, a network, a converter industrial automation system, a refining industrial automation system, a continuous casting industrial automation system, a hot-rolling industrial automation system, and an integral planning system. The dynamic adjustment server for the continuous casting and rolling production plan can acquire the moment data of the converter industrial automation system, the refining industrial automation system and the continuous casting industrial automation system, calculate the cast-on moment of a heat plan in real time and dynamically generate a casting machine cutting plan according to the moment data and a rolling plan stored in the database by the integral planning system, and produce an order according to actual distributed slabs so as to guide the production. Therefore, the dynamic adjustment system for the metallurgical continuous casting and continuous rolling production plan can adapt to the order-oriented production mode, accord with the requirement on production technology, and realize maximized productivity of the steelmaking production and the optimized rolling process.

Owner:武钢集团有限公司

Recognition-based industrial automation control with confidence-based decision support

The present disclosure generally relates to a method for performing industrial automation control in an industrial automation system. As such, the method may include detecting, via a sensor system, positions and / or motions of a human. The method may then include determining a possible automation command corresponding to the detected positions and / or motions. After determining the possible automation command, the method may implement a control and / or notification action based upon the detected positions and / or motions.

Owner:ROCKWELL AUTOMATION TECH

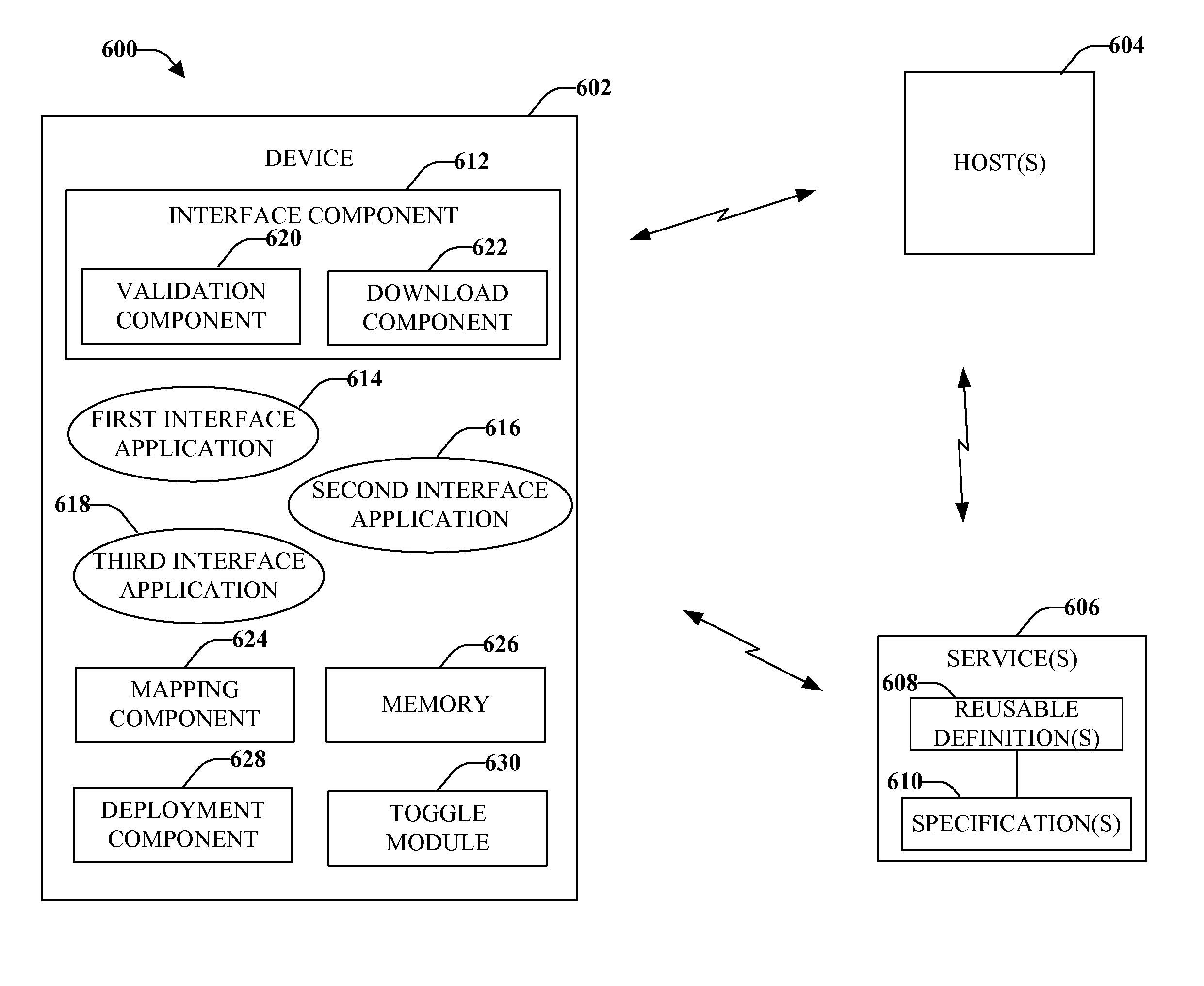

Multiple interface support

ActiveUS20110022827A1Well formedProgramme controlDigital computer detailsHuman–computer interactionIndustrial automation systems

Aspects describe multiple interface support that provides dynamic switching between new and old interface revisions. A first interface application is selected from a set of alternative interface applications for an industrial automation system. Support for each interface application included in the set of alternative interface applications is provided. A second interface application is downloaded and associated with the first interface application. The second interface application is enabled during runtime. If needed, the second interface application can be selectively disabled and an operation resumed with the first interface application.

Owner:ROCKWELL AUTOMATION TECH

Centrally managed proxy-based security for legacy automation systems

ActiveUS7950044B2Improve securityEffective controlProgramme controlDigital data processing detailsCentralized managementDatabase

A system that facilitates enhanced security with respect to an industrial automation environment comprises a legacy device that is existent within an industrial automation system and a central access authority that provides access rules to a proxy. The proxy receives an access request directed to the legacy device and determines whether the access request is permitted based at least in part upon characteristics of the access request and the access rules provided by the central access authority.

Owner:ROCKWELL AUTOMATION TECH

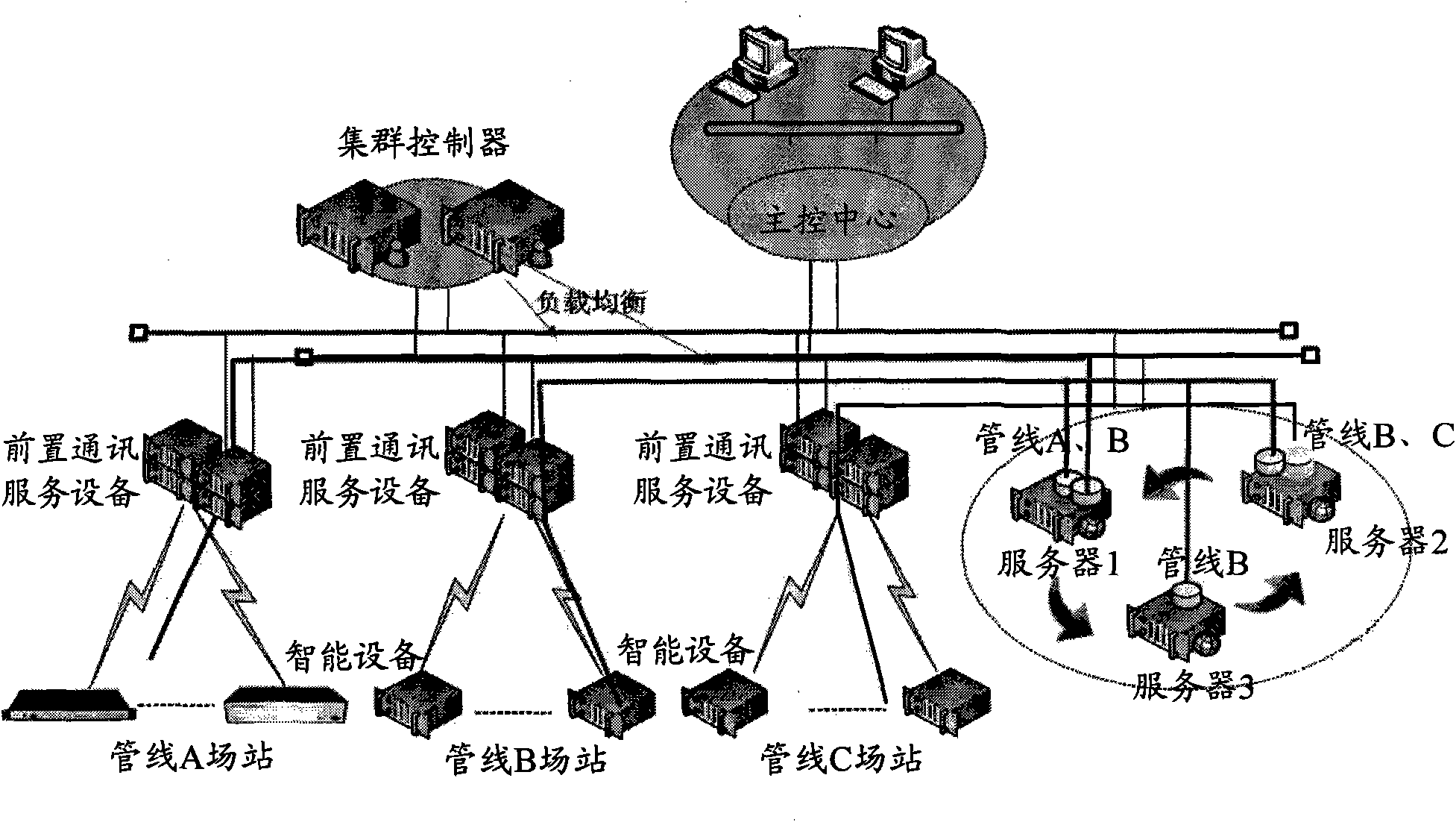

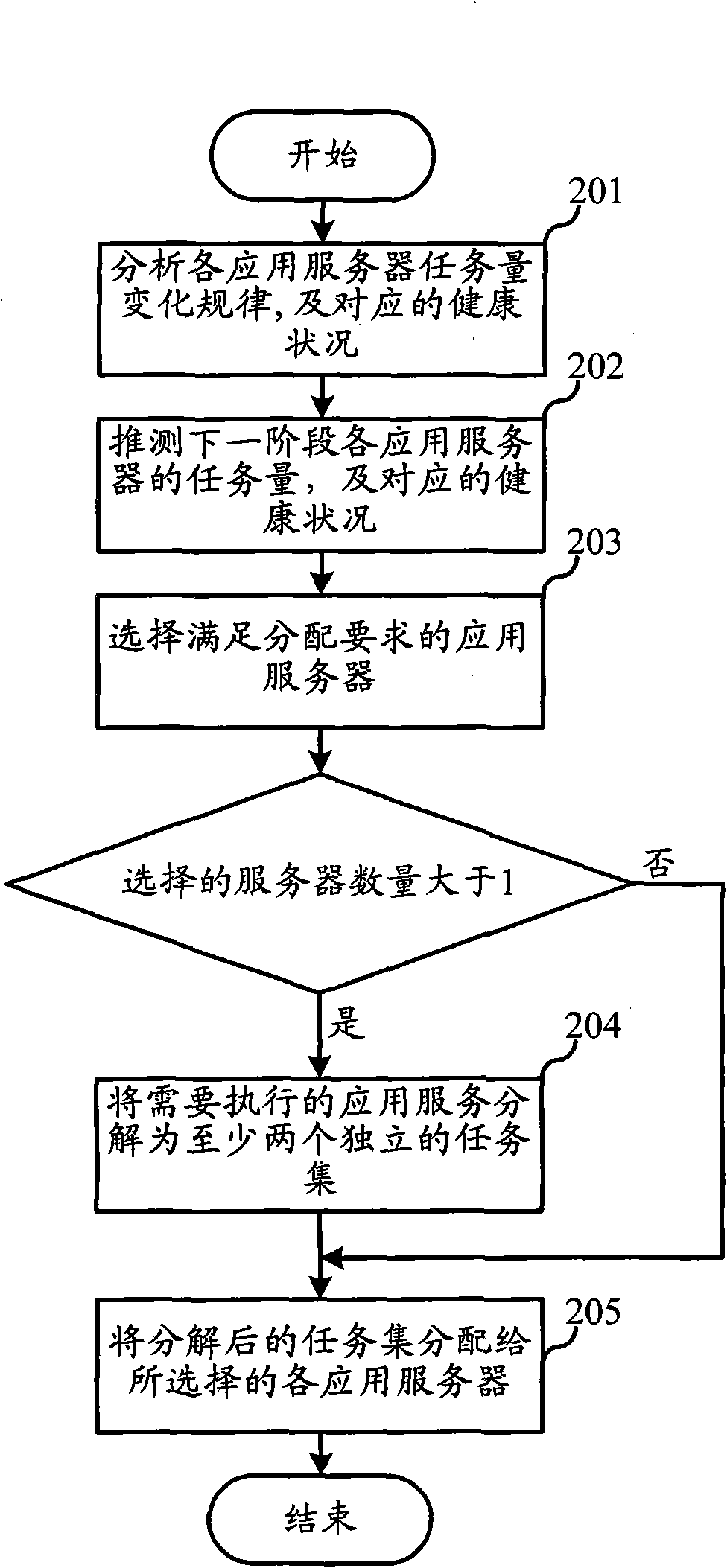

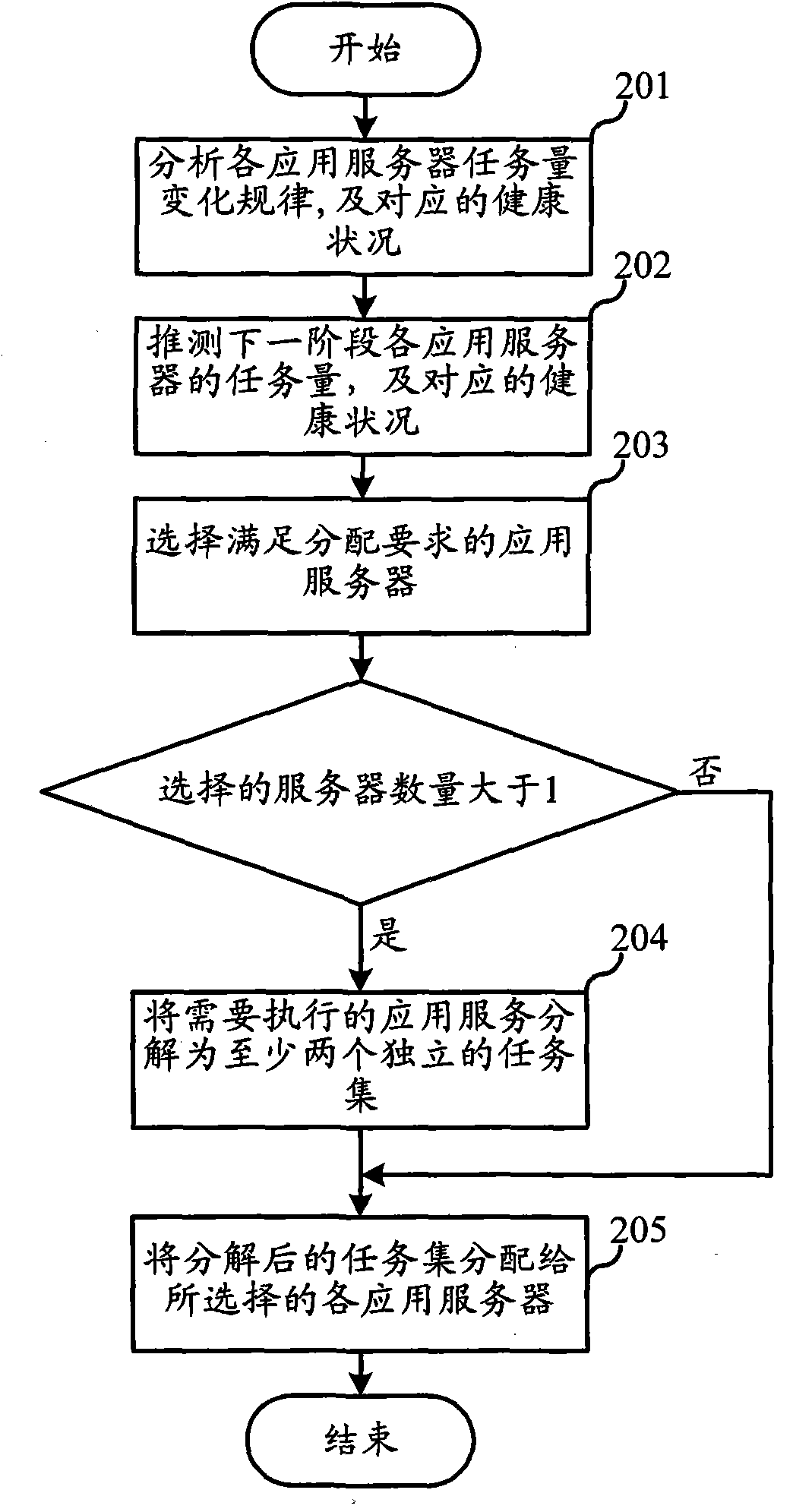

Industrial automatic multi-point cluster system and task management method thereof

ActiveCN102117225ALoad balancing distributionImprove resource utilizationResource allocationTotal factory controlResource utilizationCluster systems

The invention discloses an industrial automatic multi-point cluster system and a task management method thereof. The task distribution condition is determined by combining the distribution of tasks in the multi-point cluster system and the load change tendency of a server according to the next stage task quantity of the server and the change of the health condition. In the industrial automatic system, because the basic services provided by the server are fixed, the task quantity change laws and the corresponding health conditions of the server can be reckoned through front N times of assessment conditions of the task quantity and the health condition, the probable task quantity and the corresponding health condition of the server at the next stage can be known according to the laws, reasonable task distribution is given, resource vacancy formed by overlarge load or reduction of the next stage task of the server due to superposition of the task distributed by a cluster controller and the increased task of the server is avoided, the load of each server can be equally distributed is furthest ensured, and the integral resource utilization rate and the stability of the system are improved.

Owner:ASAT CHINA TECH

Enhanced simulation models for automation

ActiveUS7809534B2Function increaseHigh simulationSimulator controlComputation using non-denominational number representationSimulationIndustrial control system

A simulation tool for an industrial automation system is provided. The tool includes a simulation component that simulates one or more components of an industrial control system. At least one directed model provides one or more suggested parameters or profiles to the simulation component, where the suggested parameters or profiles are derived from data relating to an industry or controls application.

Owner:ROCKWELL AUTOMATION TECH

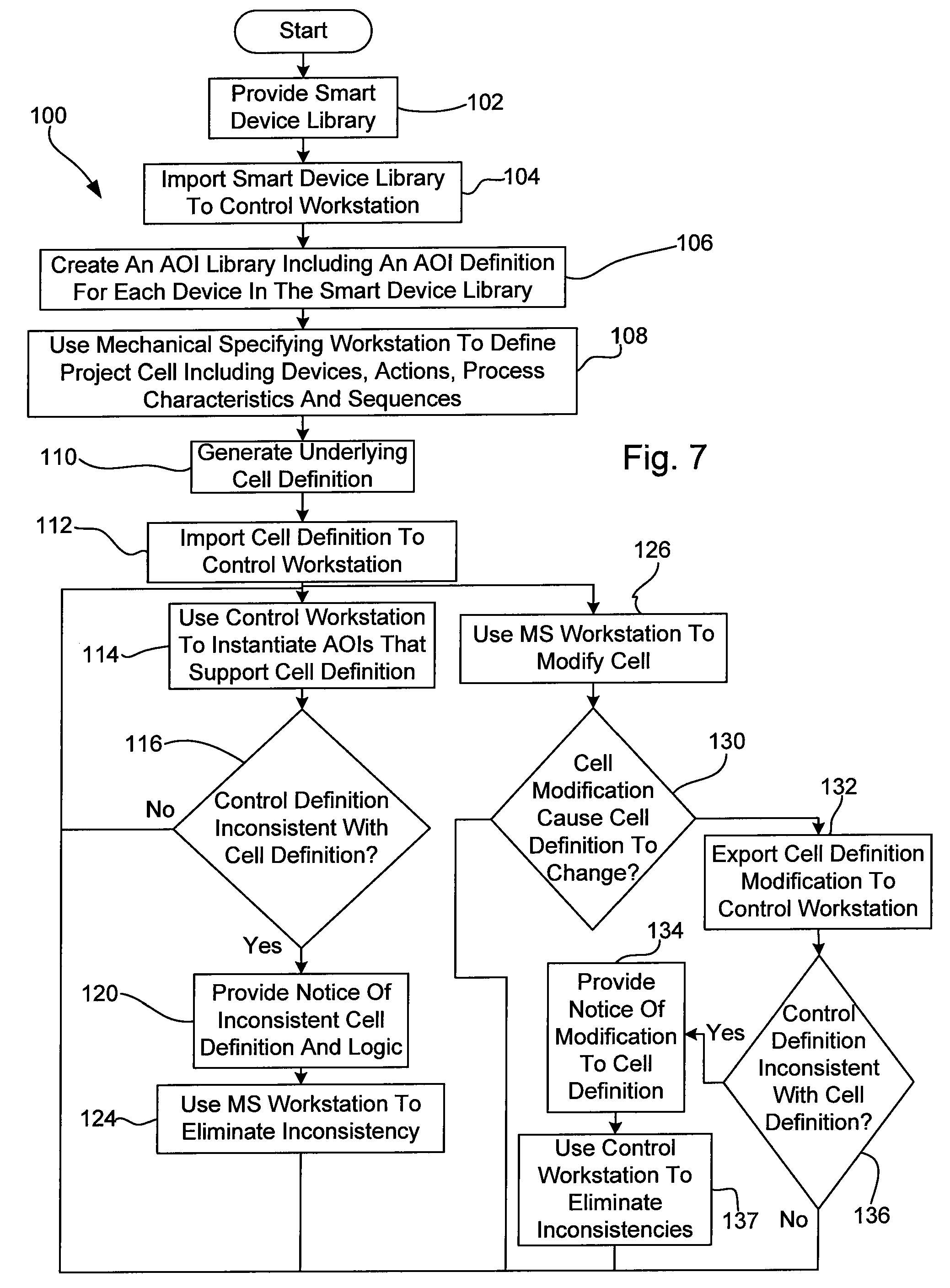

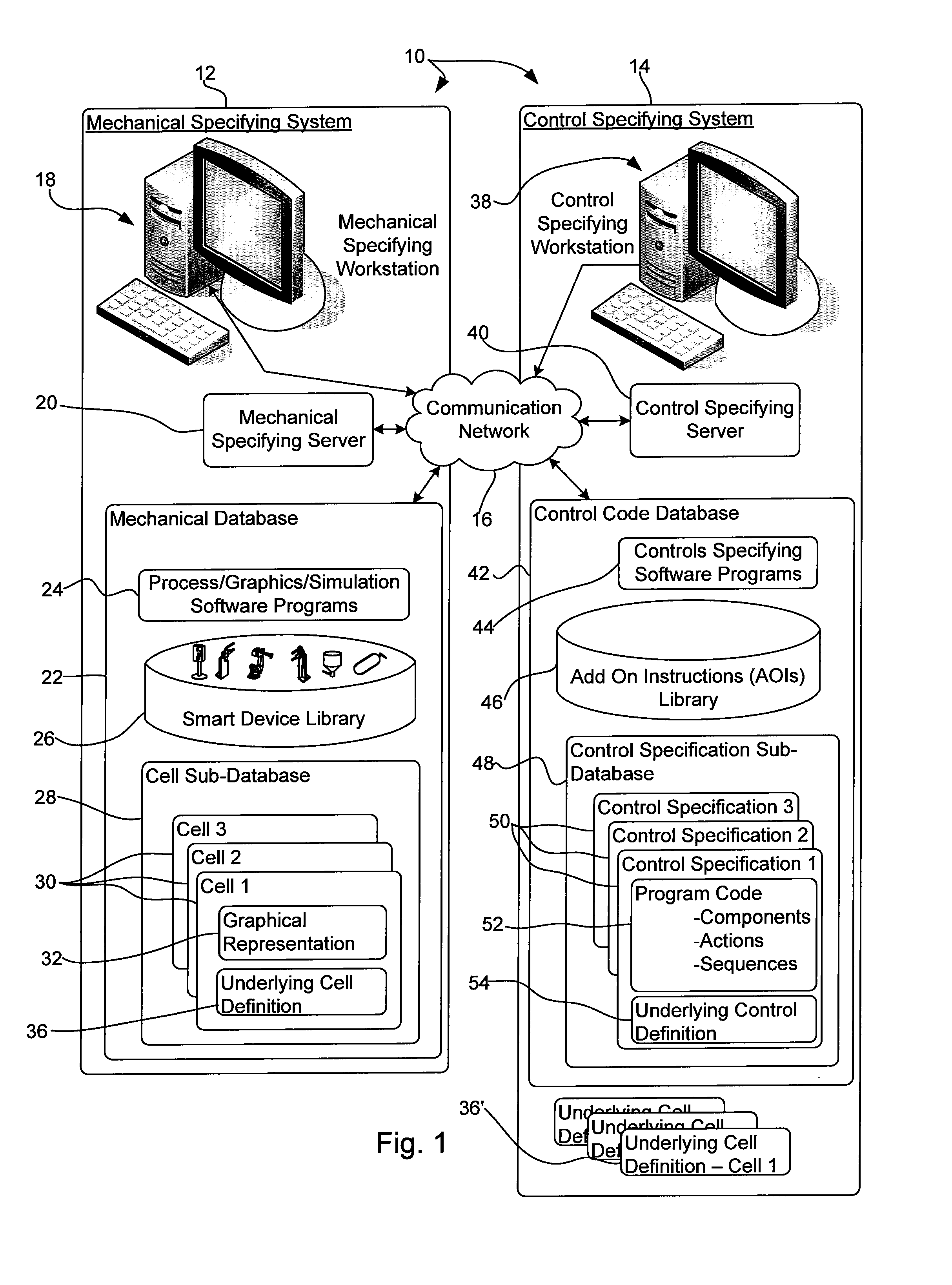

Product Lifecycle Management Method and Apparatus

InactiveUS20090192857A1Easy to processInconsistency can be eliminatedProgramme controlComputer controlInformation typePERQ

A method for synchronizing activities during design of an industrial automated system wherein the automated system includes a plurality of different features and the design of the automated system requires at least first and second different information types, the method comprising the steps of using a first software program to specify a first type system definition including a set of first information type instances corresponding to the automated system, after the first type system definition has been specified, using a second software program to specify a second type system definition including a set of second information type instances corresponding to the automated system, after the second type system definition has been specified, comparing the first and second system definitions to identify system features supported by only one of the first and second type system definitions and where only one of the first and second type system definitions supports a system feature, the second software program providing notice to the first software program indicating that the first and second type system definitions are imperfectly correlated.

Owner:ROCKWELL AUTOMATION TECH

Engineering method and system for industrial automation systems

InactiveUS7657404B2Unified processingEasy to carryProgramme controlComputer controlNetwork connectionDisplay device

The invention relates to an engineering method and system for industrial automation systems, in particular for MES systems, based on at least one computational unit with an input auxiliary device, an output auxiliary device, in addition to at least one display device. According to said method, the modelled objects comprise installation structures or installation parts and are linked to meta information. The modelled objects are structured in the engineering method as hierarchical trees and can be interconnected by lateral networking or by means of a cursor. The objects are executed in run-time by evaluating the meta information in a target system, whereby the functions of an installation that has been modelled in the engineering method are determined from the structure of the tree and the networked connections.

Owner:SIEMENS AG

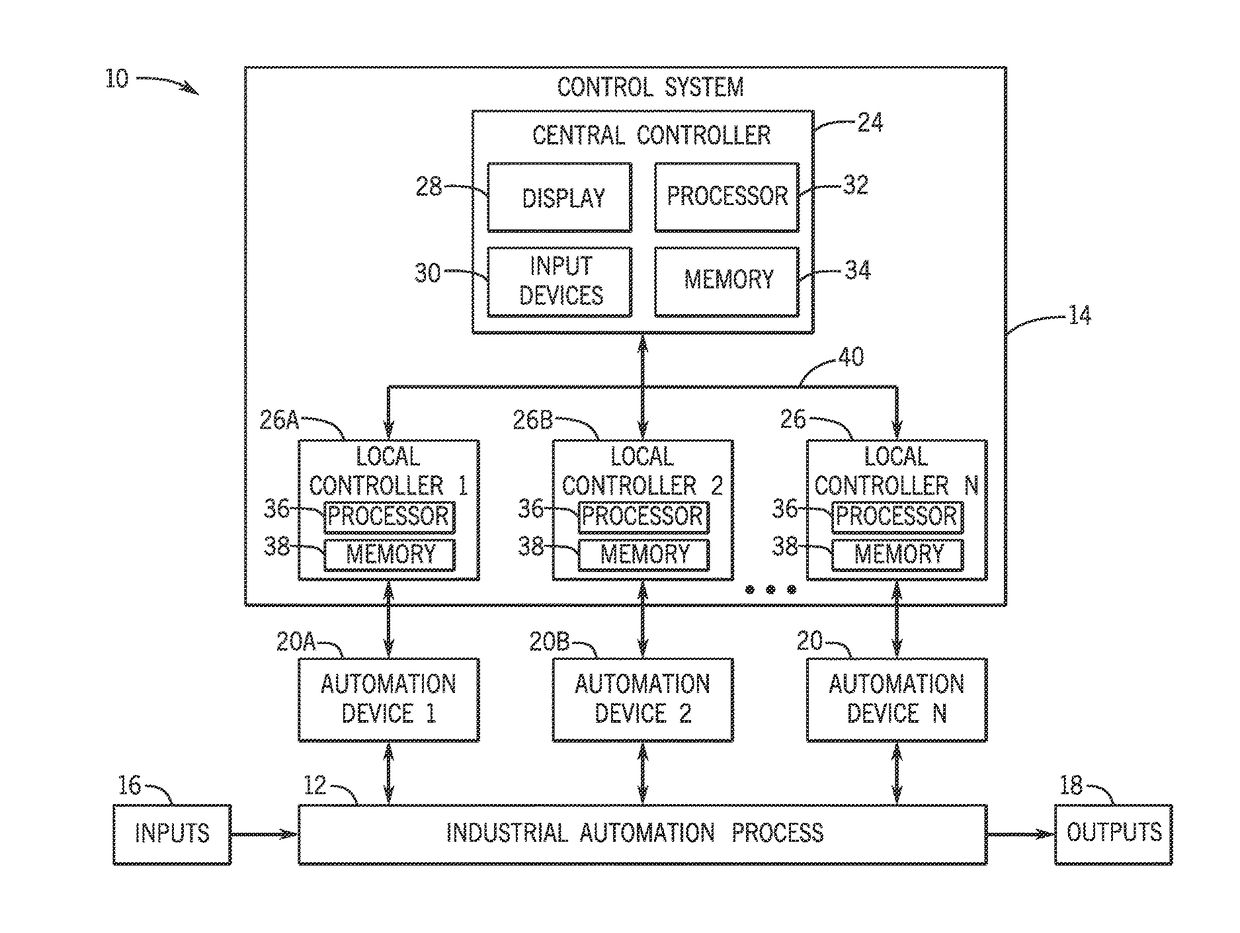

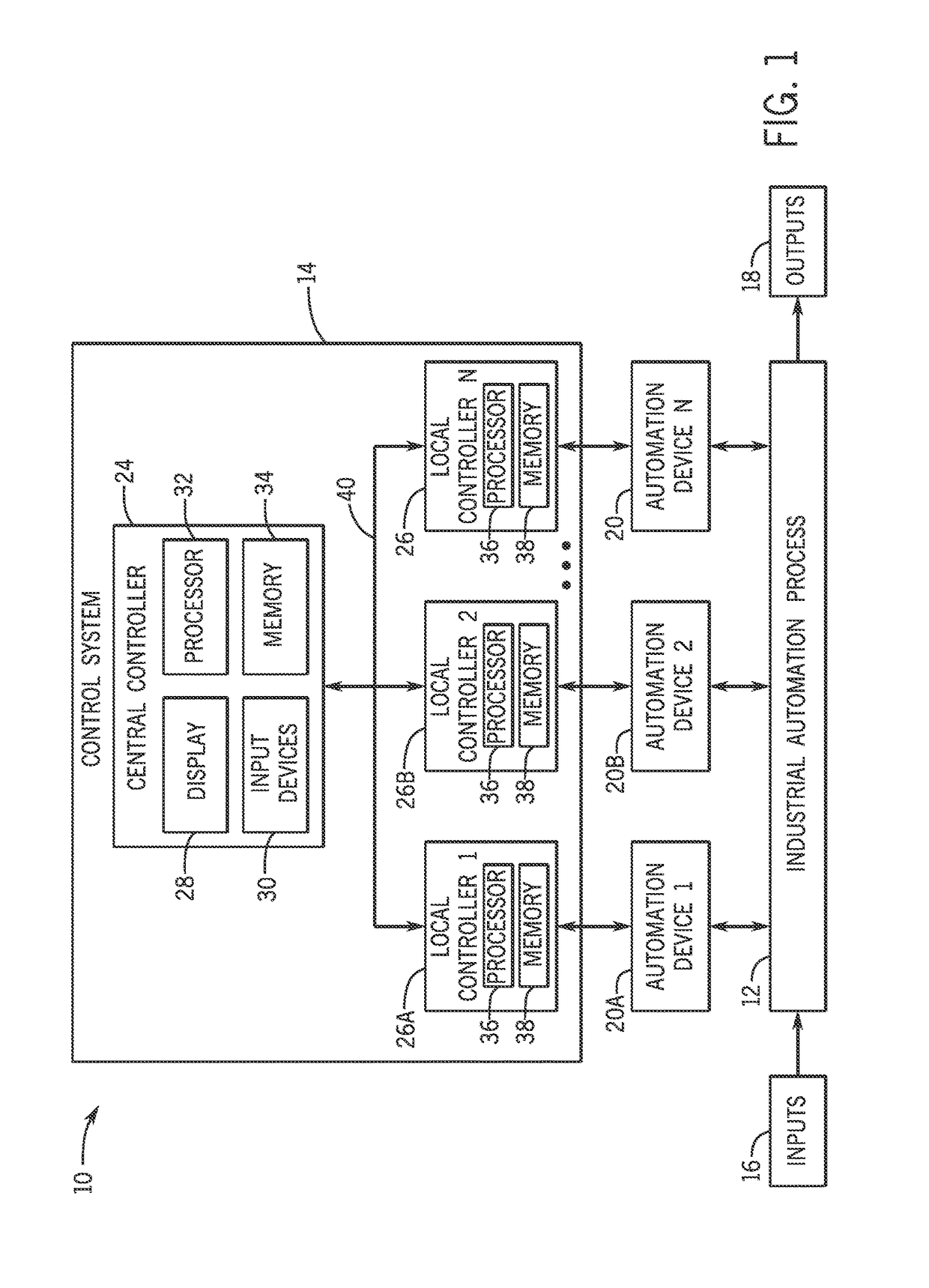

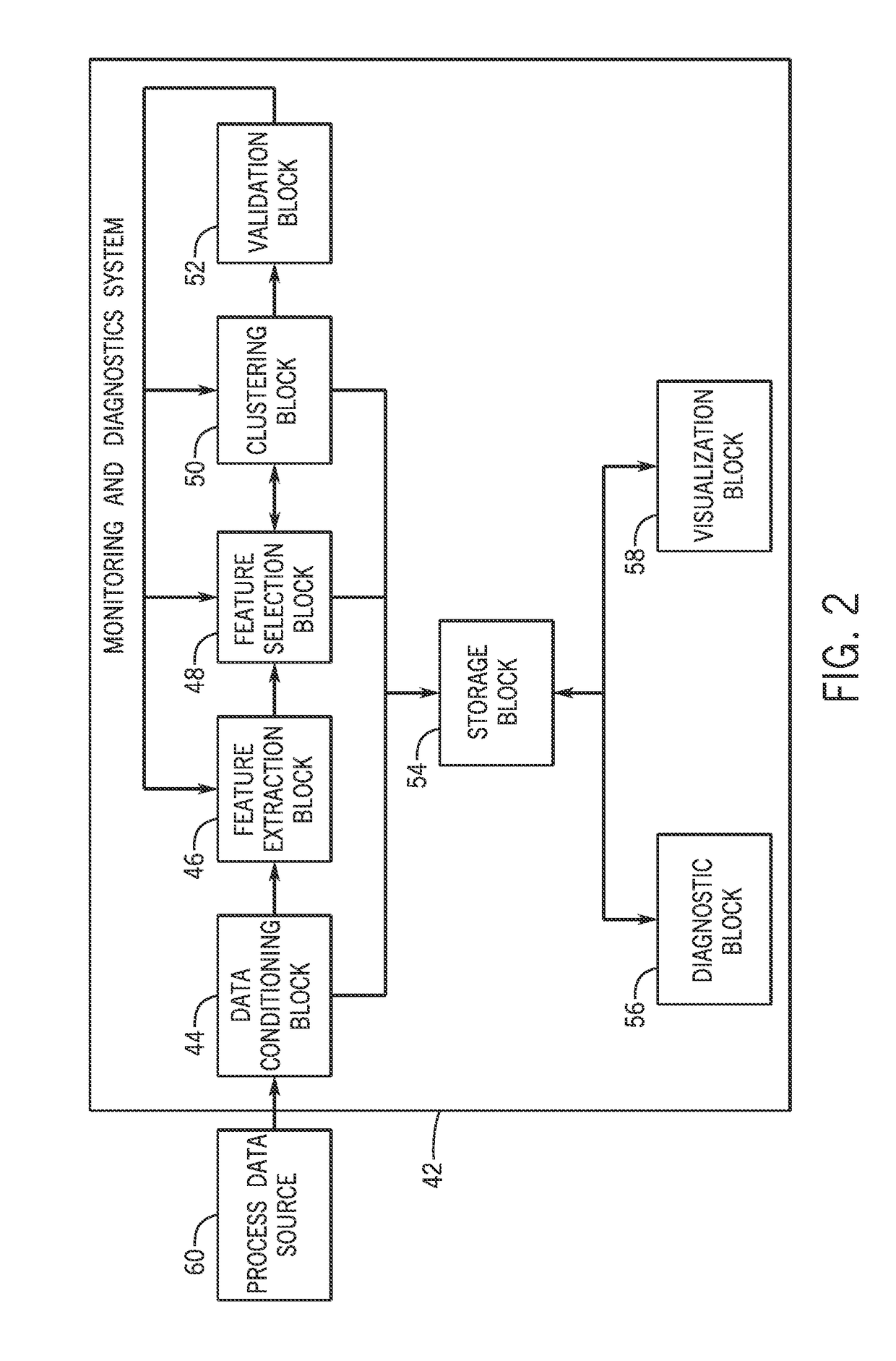

Predictive monitoring and diagnostics systems and methods

ActiveUS20170139382A1Testing/monitoring control systemsAdaptive controlFeature extractionControl system

System and method for improving operation of an industrial automation system, which includes a control system that controls operation of an industrial automation process. The control system includes a feature extraction block that determines extracted features by transforming process data determined during operation of an industrial automation process based at least in part on feature extraction parameters; a feature selection block that determines selected features by selecting a subset of the extracted features based at least in part on feature selection parameters, in which the selected features are expected to be representative of the operation of the industrial automation process; and a clustering block that determines a first expected operational state of the industrial automation system by mapping the selected features into a feature space based at least in part on feature selection parameters.

Owner:ROCKWELL AUTOMATION TECH

Recognition-based industrial automation control with person and object discrimination

The present disclosure generally relates to a method for performing industrial automation control in an industrial automation system may include detecting, via a sensor system, positions and / or motions of one or more humans and / or one or more objects in an industrial automation system and distinguishing, via a programmed computer system, between one or more humans and one or more objects based upon the detected positions and / or motions. The method may then include implementing a control and / or notification action based upon the distinction.

Owner:ROCKWELL AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com