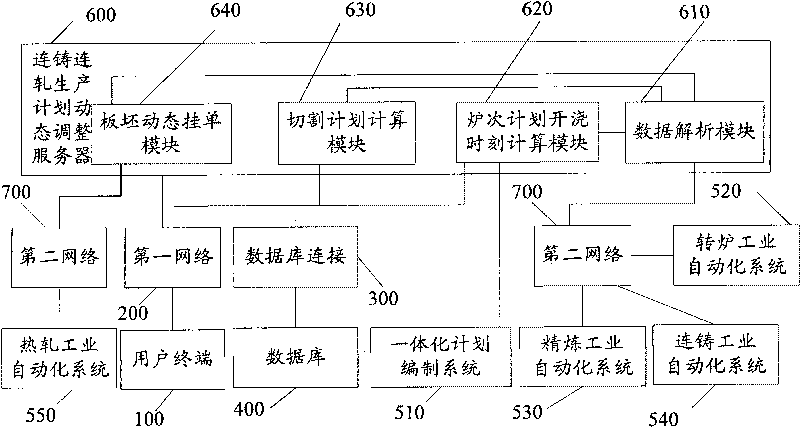

Dynamic adjustment system for metallurgical continuous casting and continuous rolling production plan

A technology of continuous casting and rolling, production planning, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of single production varieties and specifications, and achieve the effect of optimizing the rolling process and maximizing the production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

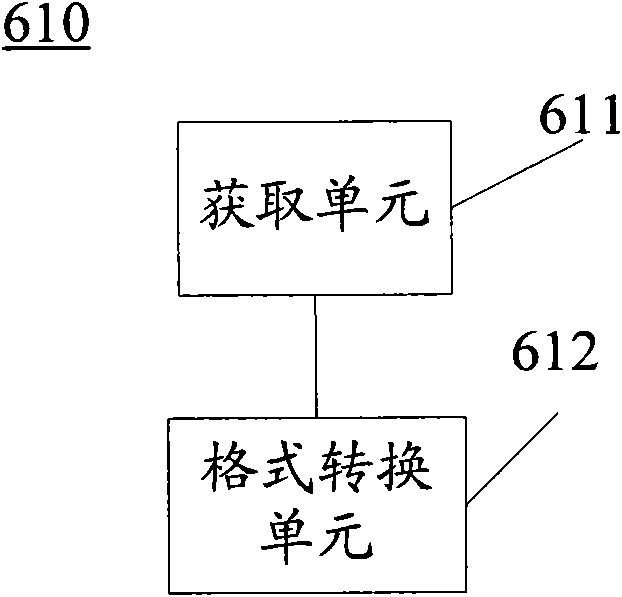

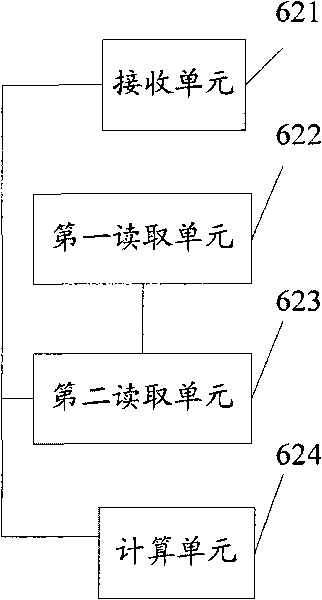

[0023] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the dynamic adjustment system of the metallurgical continuous casting and rolling production plan of the present invention collects the start processing time and end processing time of each steelmaking process in real time according to the pre-compiled production plan, according to the steelmaking refining process process path, and each The residence time of the refining process station is used to calculate the start-up time of the furnace plan in real time; when the ladle arrives at the casting platform, according to the difference between the start-up time of the latest furnace plan between the casting machines, it is used as the early start-up time in the steel rolling plan In the execution process, the cutting plan of the casting machine is dynamically generated, and the cutting plan is sent to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com