Method for reducing titanium inclusion of molten steel

A technology for inclusions and molten steel, applied in the field of iron and steel smelting, can solve the problems of large number of titanium inclusions, large size of titanium inclusions, deterioration of the quality of cord steel products, etc. The effect of pull-out and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments of the present invention.

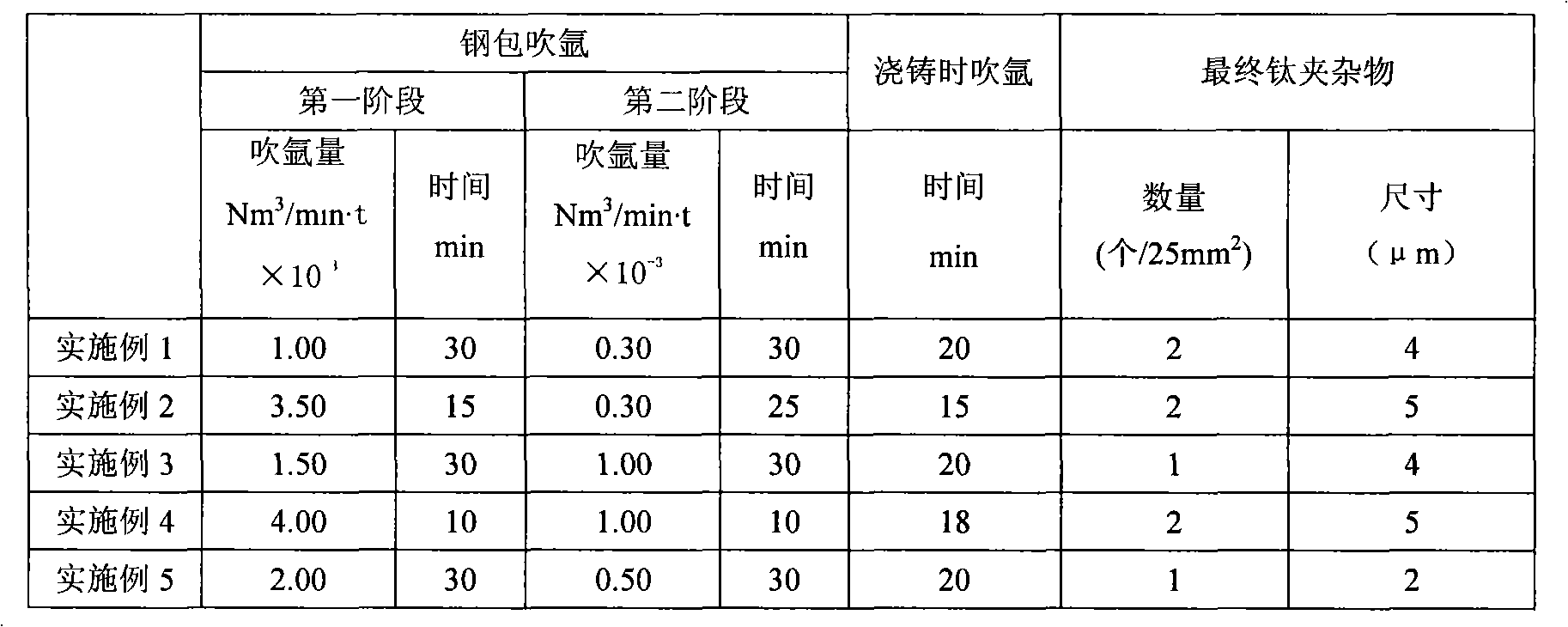

[0013] The feature of the present invention is that, after the production and refining treatment of the cord steel is completed, argon is blown at the bottom of the ladle and argon is blown in the process of pouring steel into the ladle.

[0014] According to the specific actual production requirements, after the refining treatment, the ladle is in the waiting position to blow argon to the bottom of the ladle, and the argon flow rate is controlled at 0.3×10 -3 ~4×10 -3 N m 3 In the range of / min·t, the flow control of argon blowing is divided into two stages, and the flow of argon blowing in the first stage is controlled at 10 -3 ~4×10 -3 N m 3 / min·t, the time is 10~30min; the flow rate of argon blowing in the second stage is controlled at 0.3×10 -3 ~10 -3 N m 3 / min·t; the time is 10~30min.

[0015] Argon blowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com