Patents

Literature

112results about How to "Improve pull performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing cold-rolled steel strips

ActiveCN102416404AImprove pull performanceGood welding performanceMetal rolling arrangementsSlagLight treatment

The invention discloses a method for producing cold-rolled steel strips. The method comprises the following steps of: performing krypton (KR) desulfurization treatment, converter dephosphorization-less slag decarburization and relative humidity (RH) light treatment on molten iron, and performing continuous casting to obtain a high-purity plate blank; heating the plate blank, performing rough rolling and precision rolling to obtain a hot-rolled plate, cooling the hot-rolled plate and coiling the hot-rolled plate into a hot-rolled coil; and performing cold rolling, annealing and flattening on the hot-rolled coil, and coiling the hot-rolled coil into a finished product. By the method for producing the cold-rolled steel strips, the cold-rolled steel strips which have high drawing property and good welding performance and can be used for flux-cored wires can be produced, the production requirement of the flux-cored wires is met, splash in the welding process is reduced, seams with good welding quality are obtained, and the automation level of welding is improved.

Owner:SHOUGANG CORPORATION

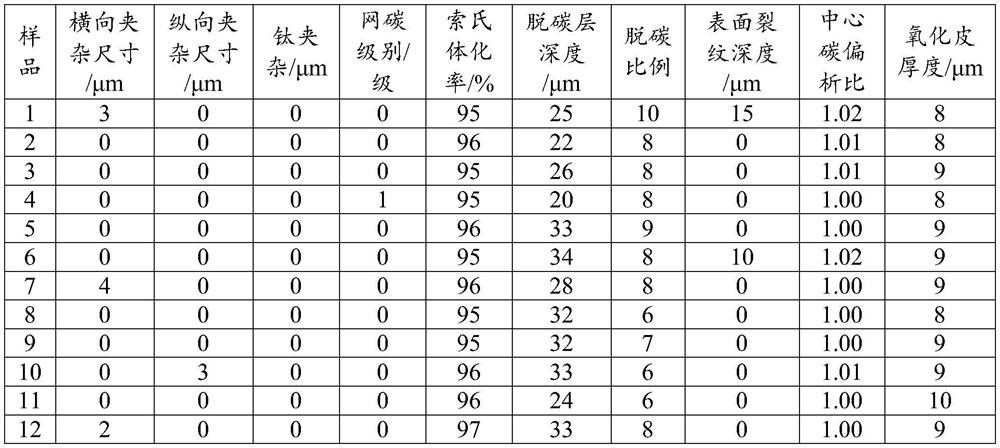

Smelting process for control of spring steel inclusions

ActiveCN105907919AEasy to controlReduce sources of refractory and refractory inclusionsProcess efficiency improvementElectric furnaceSmelting processIntermediate stage

The invention discloses a smelting process for control of spring steel inclusions, wherein the smelting process includes the steps: 1) electric furnace primary smelting; 2) argon blowing; 3) LF refining; 4) VD furnace refining; and 5) continuous casting. In the electric furnace primary smelting steel-tapping process, an Si / Mn Al-free deoxidation process is adopted for pre-deoxidation, and at the same time, active lime, a compound agent and refining slag are adopted; in the earlier stage of the LF refining, an Si / Mn Al-free deoxidation process and active lime are adopted, and the furnace slag basicity is controlled at 1.5-2.5; in the middle stage of the LF refining, refined slag is added, followed by, the Si / Mn Al-free deoxidation process continues to be adopted, deoxidation and desulfuration continues to be carried out, and the furnace slag basicity is guaranteed to be controlled at 0.7-1.4; argon bottom blowing is carried out in the whole process of the LF refining. The Al-free deoxidation process and the low-basicity furnace slag desulfuration process are adopted and are combined with a specific deoxidizing agent, the inclusions in spring steel can be well controlled, and thus the anti-fatigue property of the spring steel is improved.

Owner:HANGZHOU IRON & STEEL GRP

Smelting process for controlling spring steel inclusions

ActiveCN109097518ARelieve pressureFully integratedManufacturing convertersProcess efficiency improvementAlkalinitySmelting process

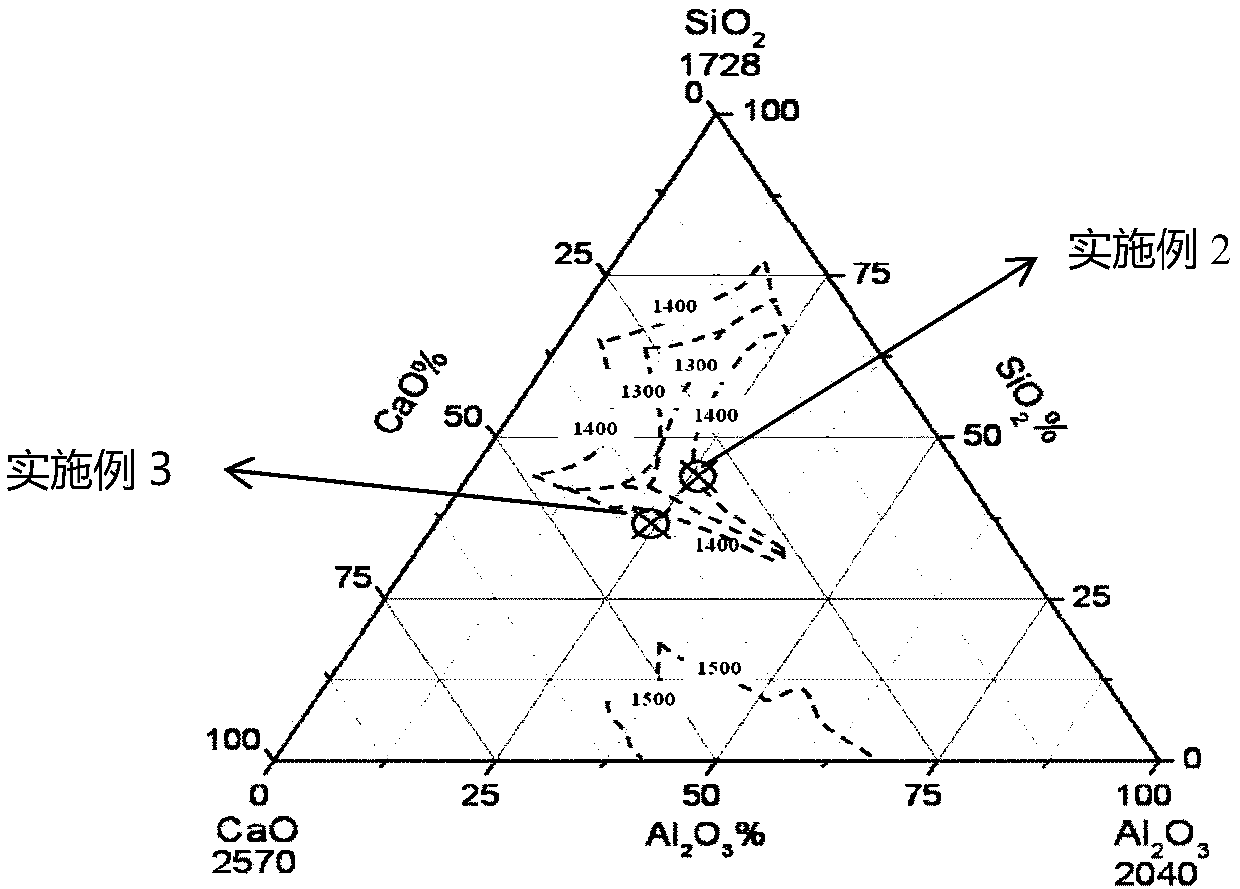

The invention discloses a smelting process for controlling spring steel inclusions. The smelting process comprises the following steps of (1) KR molten iron desulfurization pretreatment, (2) BOF top-bottom double combined flowing converter smelting, (3) LF furnace refining, (4) RH furnace refining and (5) continuous casting process, wherein the mass fraction of S is controlled to be below 0.005% after molten iron is processed by the step (1); the step (3) is carried out by high-purity silicon carbide for diffusion deoxidation, and the refining slag alkalinity is controlled to be 0.6-0.9; a lowalkalinity slag process is adopted in the step (4), and the final slag alkalinity is 0.5-0.7; and it is ensured that a molten steel contact part is free of aluminum in the step (5), a double electromagnetic stirring process is adopted in a secondary cooling zone and a casting blank solidification end zone, and a central carbon segregation index is controlled to be below 1.15. The smelting processadopts molten iron pretreatment, converter catching carbon, refining low alkali slag, continuous casting protective pouring and special refractory materials. Through the control over the oxygen potential of molten steel, the inclusion form and the central carbon segregation, the spring drawing performance is improved, and the spring fatigue limit is increased.

Owner:NANJING IRON & STEEL CO LTD

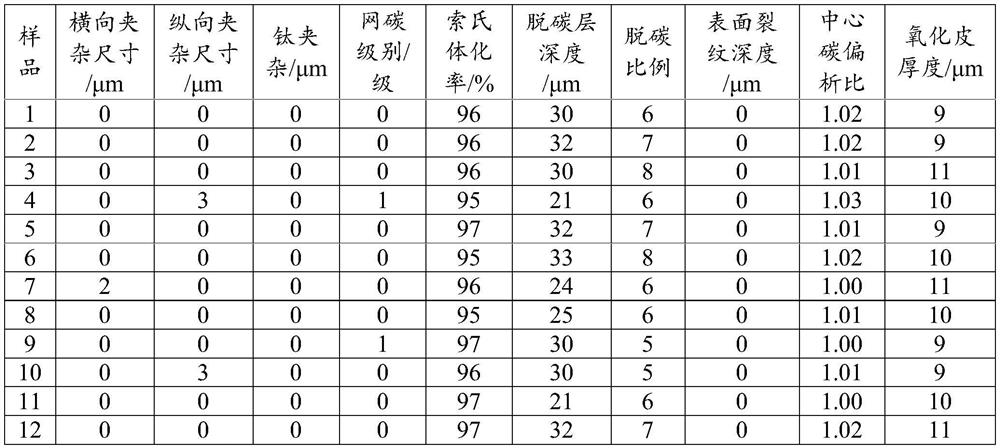

High-carbon steel wire rod low in network cementite precipitation and used for fine wire drawing and production method of high-carbon steel wire rod

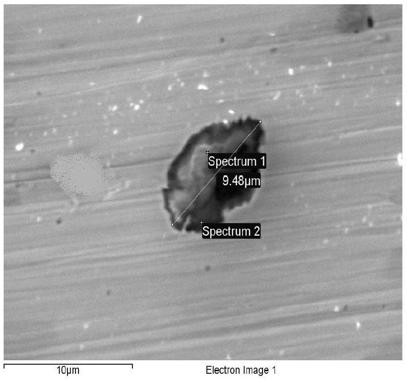

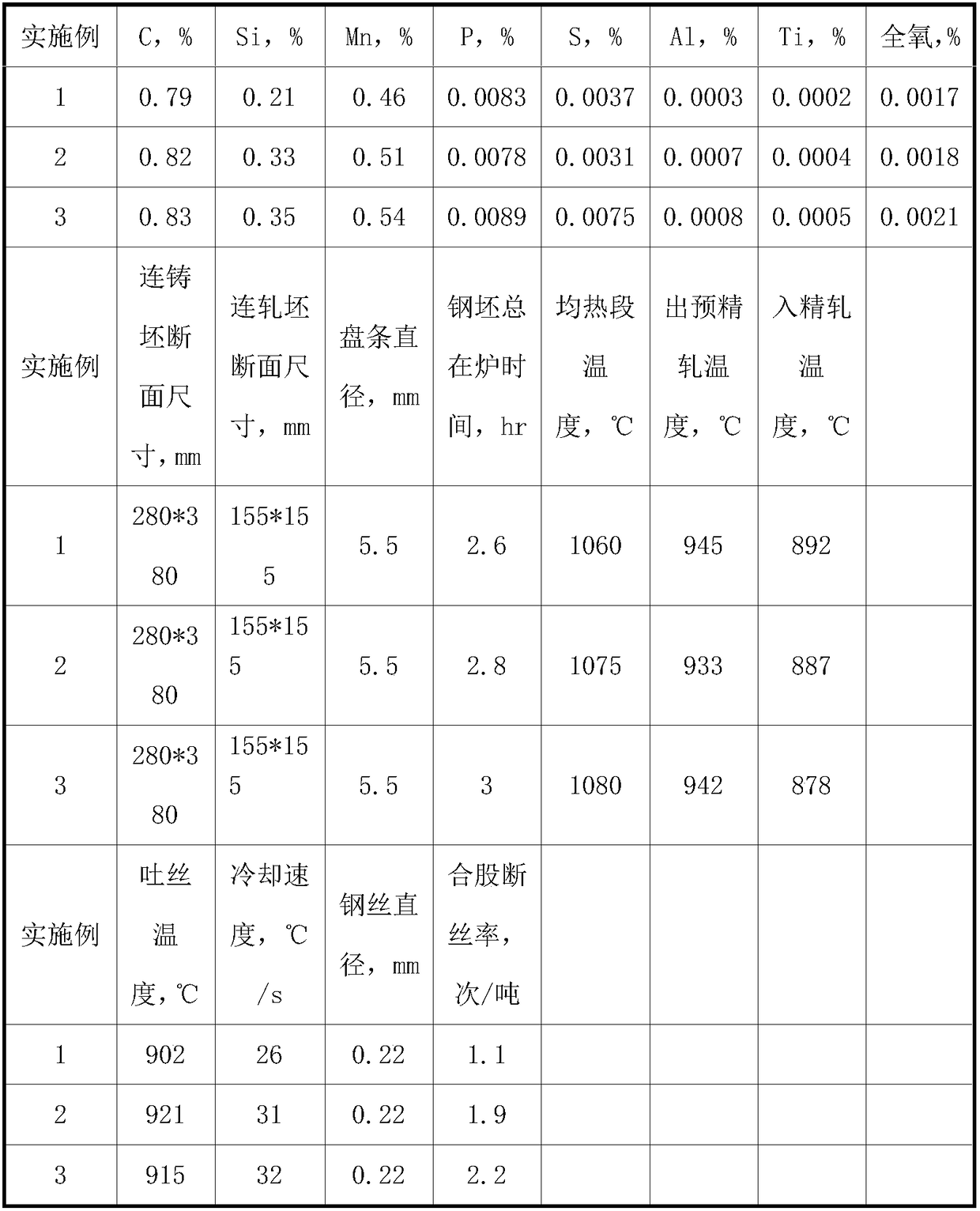

The invention discloses a high-carbon steel wire rod low in network cementite precipitation and used for fine wire drawing and a production method of the high-carbon steel wire rod. The high-carbon steel wire rod comprises 0.79%-0.84% of C, 0.20%-0.40% of Si, 0.45%-0.55% of Mn, smaller than or equal to 0.010% of P, 0.0020%-0.010% of S, 0.0005%-0.00010% of Al, 0.0002%-0.0006% of Ti, 0.0015%-0.0025%of total oxygen and the balance Fe and inevitable impurities. The high-carbon steel wire rod is used for producing a fine steel wire with the diameter being 0.22 mm, the breaking rate of a produced steel wire cord thread is not larger than 3 times / ton, and the using requirement of a user is met.

Owner:ANGANG STEEL CO LTD

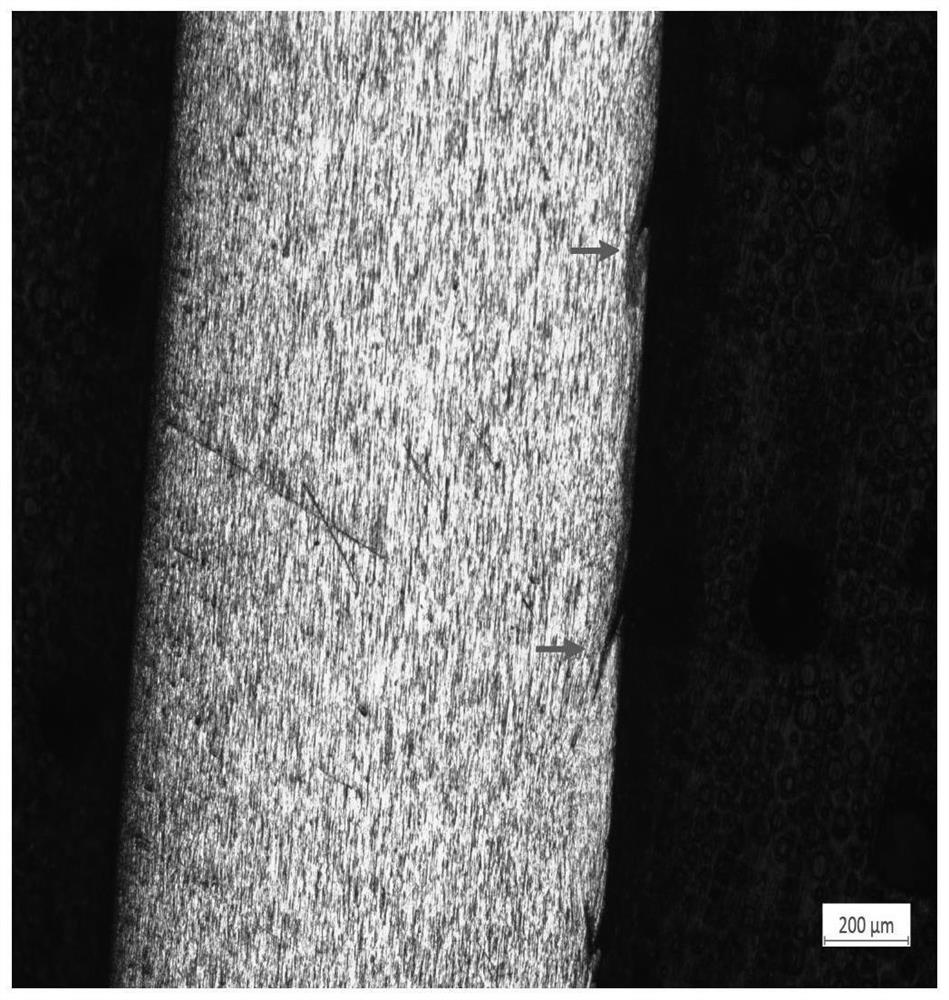

High-speed wire production method capable of controlling same-circle mechanical property fluctuation of high-carbon steel wire rods

InactiveCN104307885AReduce performance fluctuations in the same circleImprove pull performanceTemperature control deviceMetal rolling arrangementsMethods of productionAir cooling

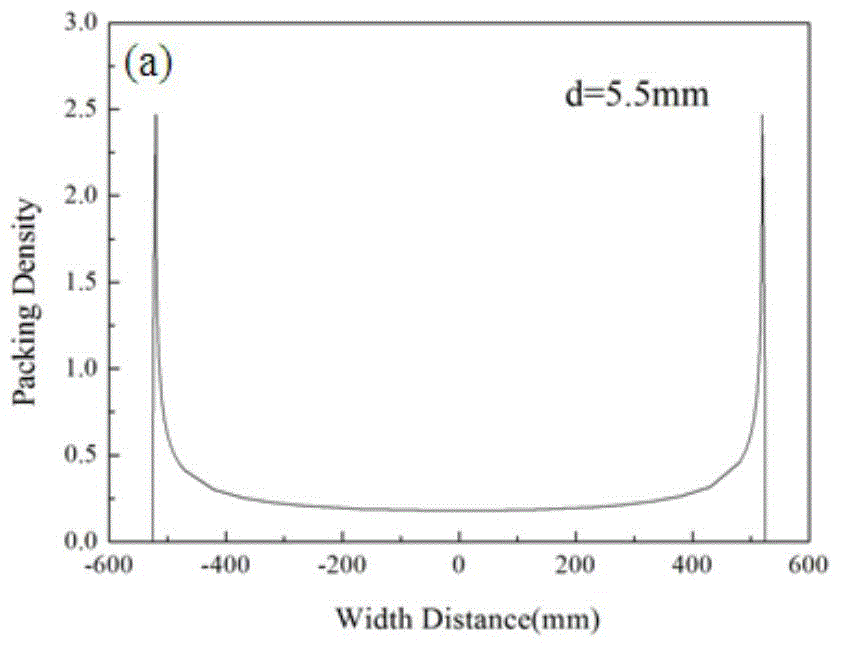

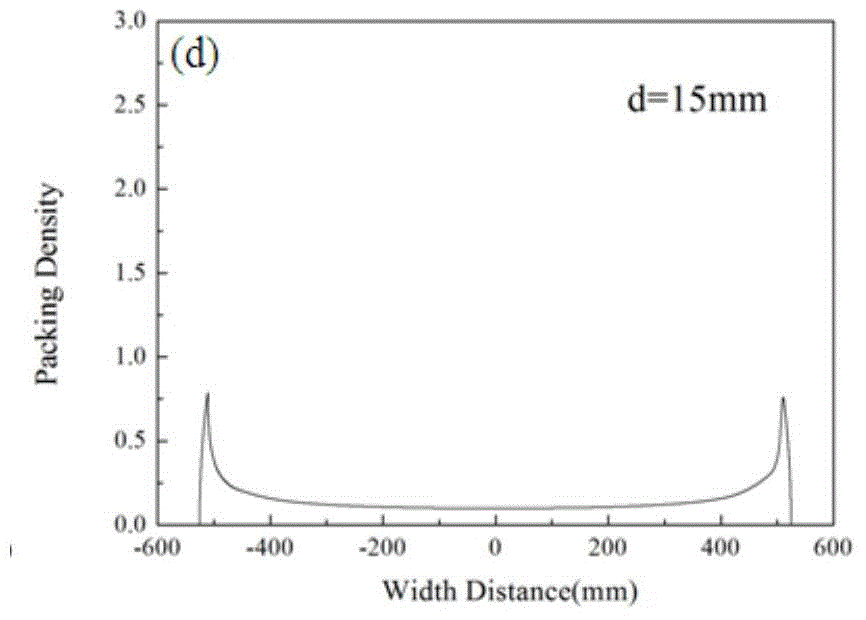

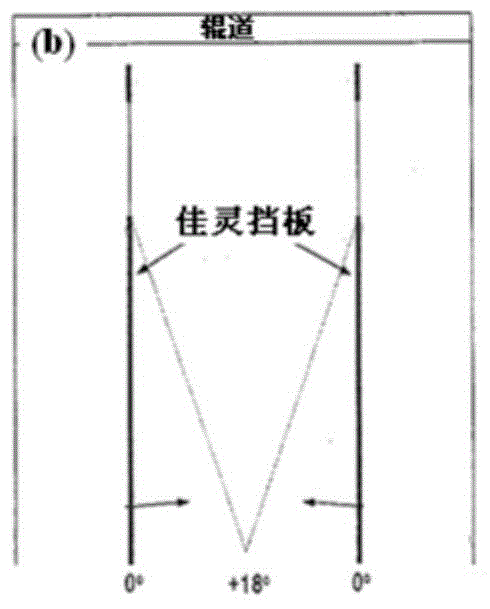

The invention discloses a high-speed wire production method capable of controlling the same-circle mechanical property fluctuation of high-carbon steel wire rods, belonging to the technical field of roll steel. The high-speed wire production method capable of controlling the same-circle mechanical property fluctuation of the high-carbon steel wire rods comprises the following steps: controlling vibration value fluctuation of a wire discharging machine to be 2-3mm per second, controlling the wire discharging circle diameter to be in a range of 9.5-1.1m and ensuring the specific distribution of coils on a Stelmor air-cooling roller channel; controlling the initial rate of the roller channel to be 0.6-0.7m per second and controlling wire rod density of overlapping nodes and non-overlapping points; adjusting angles of Jialing baffles of a fan under the Stelmor air-cooling roller channel according to the specifications of the wire rods; controlling the angles of Jialing baffles of wire rods which are 5.5-8mm long to be 10 degrees, controlling the angles of Jialing baffles of wire rods which are 8-12mm long to be 8 degrees, and controlling the angles of Jialing baffles of wire rods which are 12-16mm to be 5 degrees; controlling phase transformation start temperature to be within 20-30 DEG C. The high-speed wire production method capable of controlling the same-circle mechanical property fluctuation of the high-carbon steel wire rods has the advantages that the same-circle property fluctuation of the wire rods is effectively alleviated, the drawing capability of the wire rods and the stability of the steel wire property are improved, the method is high in practicability and suitable for improving the quality of high-carbon steel wire rods of a high-speed wire factory; the same-circle mechanical property fluctuation of the 82B wire rods of the high-speed wire production factory is controlled to be within 40Mpa.

Owner:SHOUGANG CORPORATION

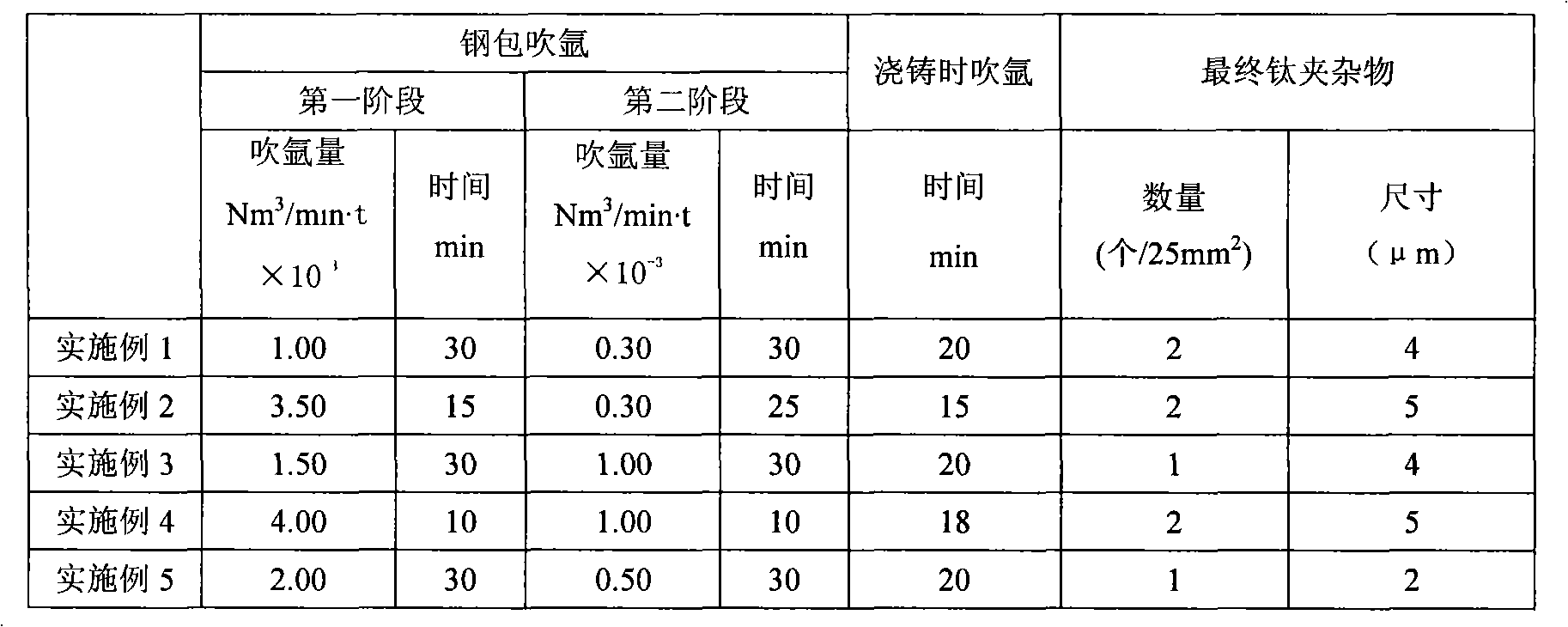

Method for reducing titanium inclusion of molten steel

The invention discloses a method for reducing titanium inclusion of molten steel, which is characterized in that: a ladle wait bit is subject to the bottom blowing argon after cord wire steel is refined and the blowing argon is performed during the steel casting of the ladle; a ladle is subject to the blowing argon by two states during the wait bit, the flow of argon is controlled within 0.3*10 to 4*10Nm / min. t; the blowing argon is performed during the steel casting of the ladle, the maximum flow of the argon is 1.5*10Nm / mim. t, and the flow change of the blowing argon is decreased according to the casting weight of the ladle through the formula Y being equal to (1.5*10 to 3*10.X)Nmmin. t. Because the ladle is subject to the bottom blowing argon by using the wait bit and the blowing argon is performed during the steel casting of the ladle, the invention further removes titanium and other inclusions of the molten steel, improves the purity of the molten steel, balances the ingredients and the temperature in steel, and reduces the granularity of the titanium inclusion and other friable oxide inclusions in the cord wire steel, thereby meeting the requirements of the production process of the cord wire steel and improving the drawing property and the fatigue resistance of the cord wire steel.

Owner:ANGANG STEEL CO LTD

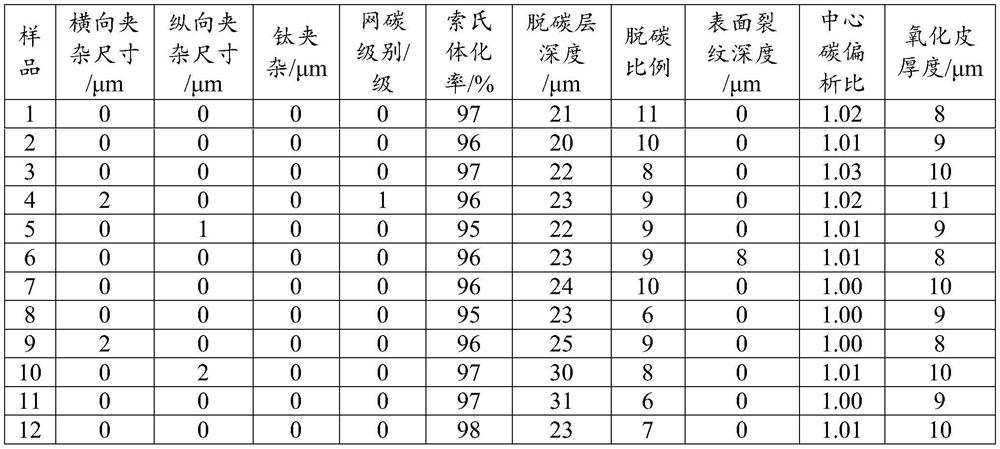

ER70S-6 hot-rolled wire rod and preparation method thereof

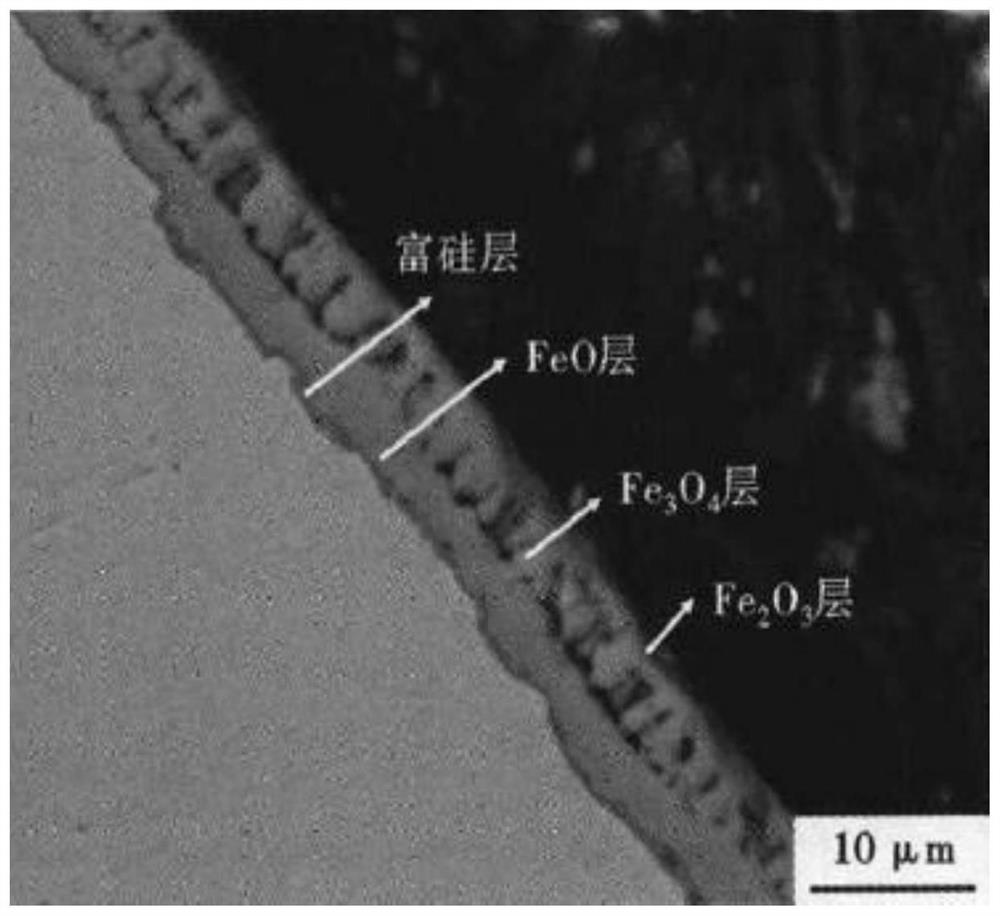

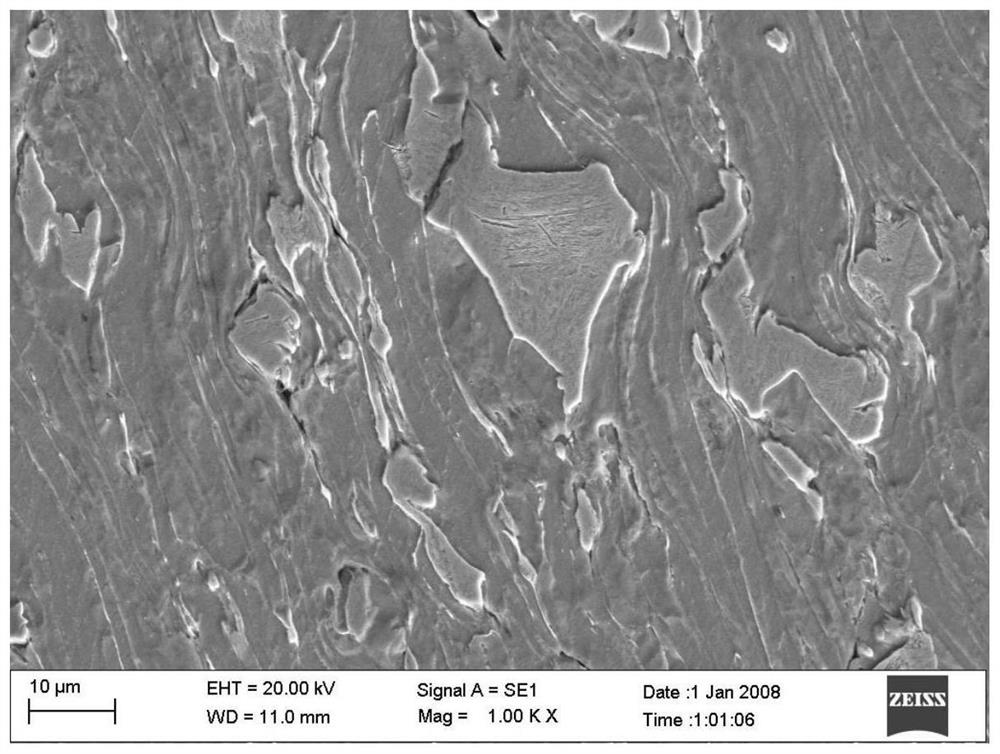

The invention discloses an ER70S-6 hot-rolled wire rod and a preparation method thereof, and belongs to the technical field of ER70S-6 hot-rolled wire rod preparation. The invention aims to solve the technical problem that a conventional ER70S-6 hot-rolled wire rod breaks during drawing. The process route comprises the steps of converter smelting, LF refining, six-machine six-flow arc-shaped square billet continuous casting machine continuous casting, heat storage type heating furnace heating, high-pressure water phosphorus removal, wire rod rolling, bundling, weighing, plate hanging and warehousing. By adjusting the chemical components, the tensile strength of the steel wire rod is effectively reduced, the drawing performance of the steel wire rod is improved, the nitrogen content of the steel wire rod is smaller than or equal to 0.0040%, the coincidence rate reaches 90% or above, and oblique stubble breakage does not occur when the steel wire rod is used for drawing. The structure and thickness of the scale on the surface of the wire rod are improved by adjusting the controlled cooling process, the structure of the wire rod is controlled, abnormal structures are prevented from being generated, and the problem of drawing fracture caused by the abnormal structures is solved.

Owner:建龙北满特殊钢有限责任公司

Rough rolling method capable of improving core tissue of high-carbon steel wire

ActiveCN103846286AImprove pull performanceAlleviate the problem of poor compactnessTemperature control deviceMetal rolling arrangementsCarbon steelParameter control

The invention provides a rough rolling method capable of improving a core tissue of a high-carbon steel wire and belongs to the technical field of high-wire rolled steel. The technical parameters controlled in the process are as follows: high-wire rolling is carried out on a 150mm*150mm or 160mm*160mm continuously-cast small square blank, and the temperature difference between the core and surface of a continuously-cast blank discharged from a heating furnace is controlled at 20-40 DEG C; the rolling speed of a first rack for rough rolling is controlled at 0.15-0.17m / min; the working diameter of a roll is controlled at 550-580mm, and the equivalent strain is controlled at 0.33-0.35; the rolling speed of a second rack for rough rolling is controlled at 0.2-0.22m / s, the working diameter of a roll is controlled at 530-550mm, and the equivalent strain is controlled at 0.28-0.39; the rolling speed of a third rack for rough rolling is controlled at 0.28-0.3m / s, the diameter of a roll is controlled at 600-620mm, the equivalent strain is controlled at 0.55-0.75, and the extension coefficient is controlled at 1.5-1.6. The rough rolling method is suitable for developing high-carbon steel wire varieties by use of rolling in one heat and continuously-cast small square blanks in a steel mill. The rough rolling method has the advantage of improving the comprehensive mechanical property and quality of the high-carbon steel wire.

Owner:SHOUGANG CORPORATION

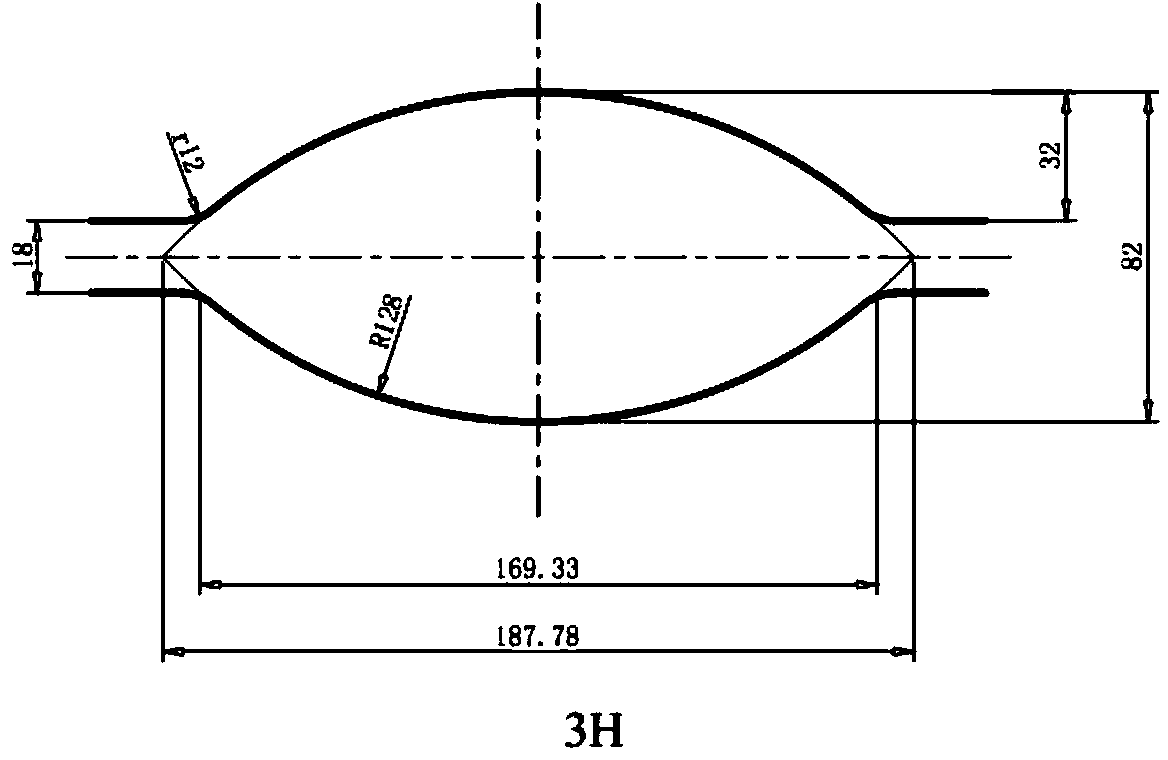

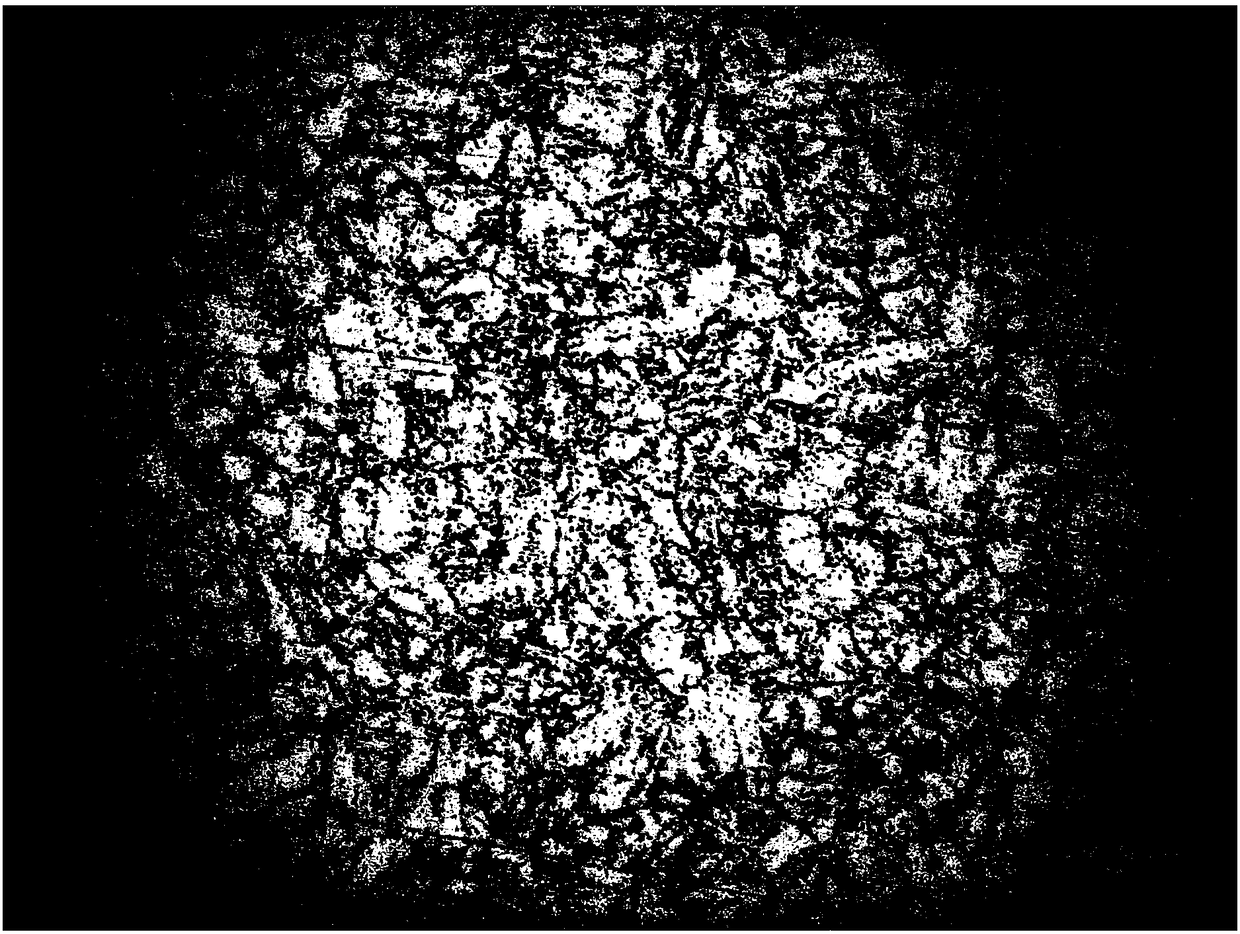

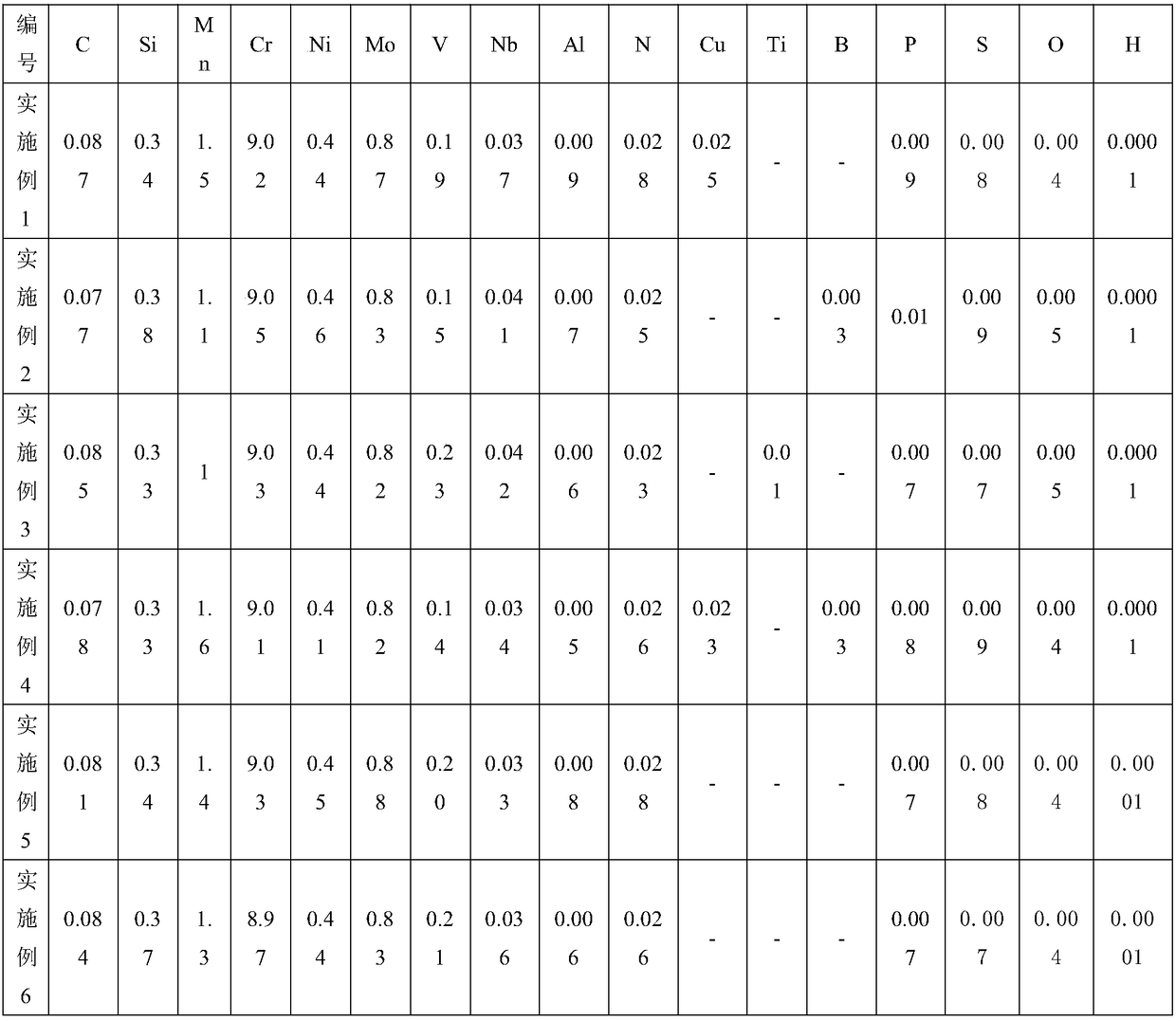

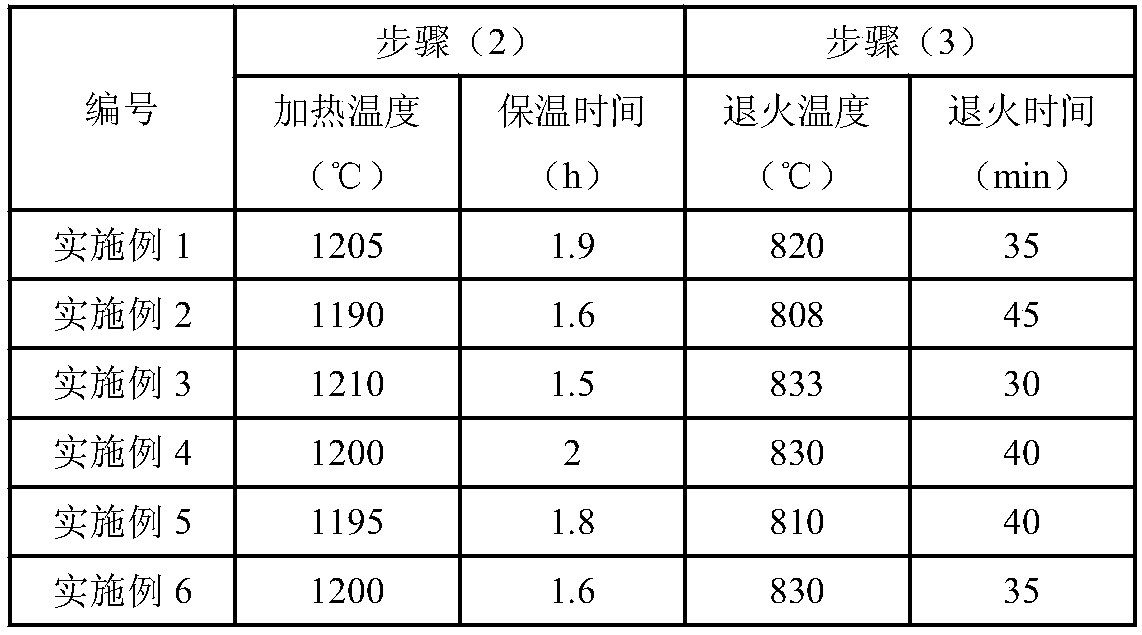

Gas protection welding wire and manufacturing method thereof

InactiveCN109465565ALow weld crack susceptibilityGrain refinementWelding/cutting media/materialsSoldering mediaWire rodImpurity

The invention discloses a gas protection welding wire which comprises, by mass, 0.06-0.15% of C, 0.15-0.50% of Si, 0.5-2.0% of Mn, 8.5-10% of Cr, 0.4-0.8% of Ni, 0.8-1.2% of Mo, 0.10-0.30% of V, 0.02-0.08% of Nb, greater than 0 and smaller than or equal to 0.05% of Al, 0.02-0.07% of N, and the balance being iron and other inevitable impurities. In addition, the invention further discloses a manufacturing method of the gas protection welding wire, comprising the steps: (1), smelting and casting; (2), making a square billet; (3) rolling to obtain a wire rod; (4) wire rod annealing, wherein the annealing temperature is 805-835 DEG C; and (5) rolling or drawing to obtain the gas shielded welding wire. The tensile strength of deposited metal obtained by welding by the gas shielded welding wireis greater than or equal to 600 MPa, and the elongation is greater than or equal to 17 percent.

Owner:BAOSHAN IRON & STEEL CO LTD

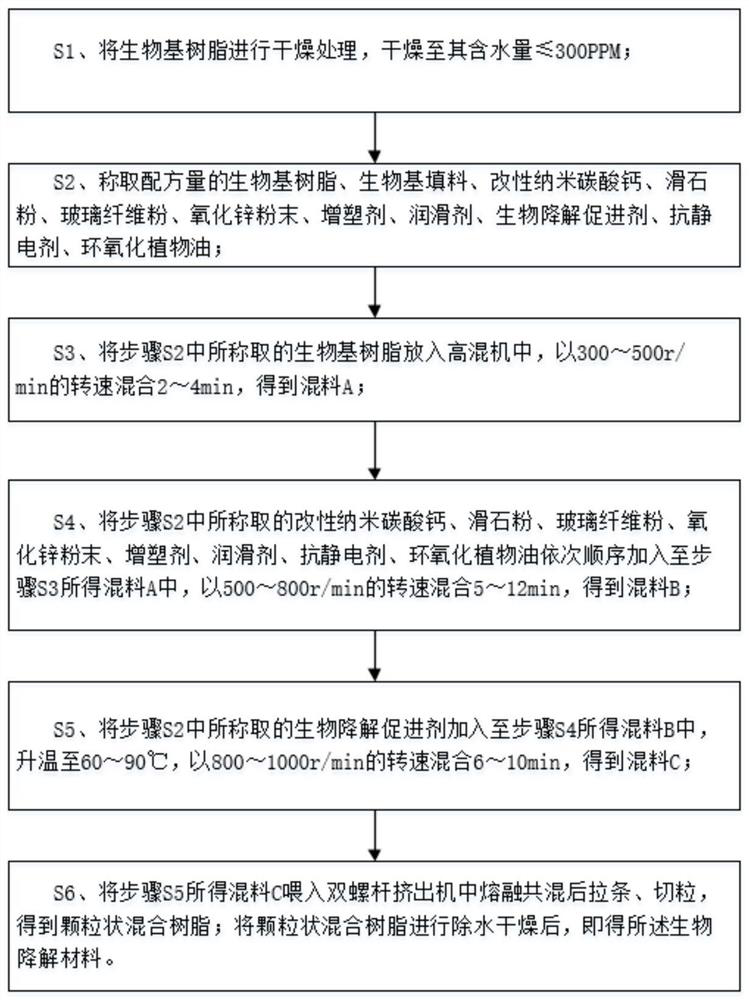

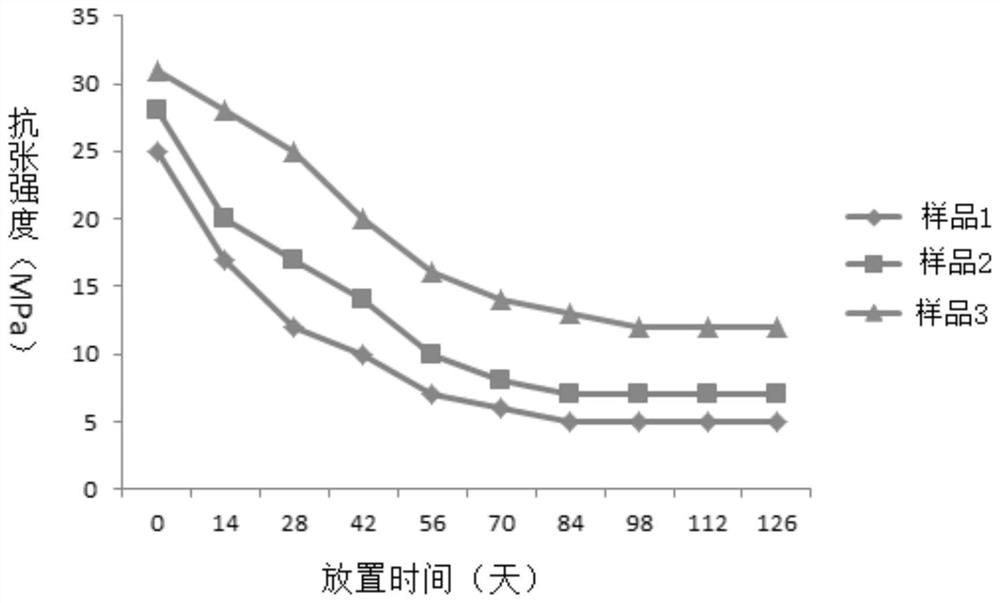

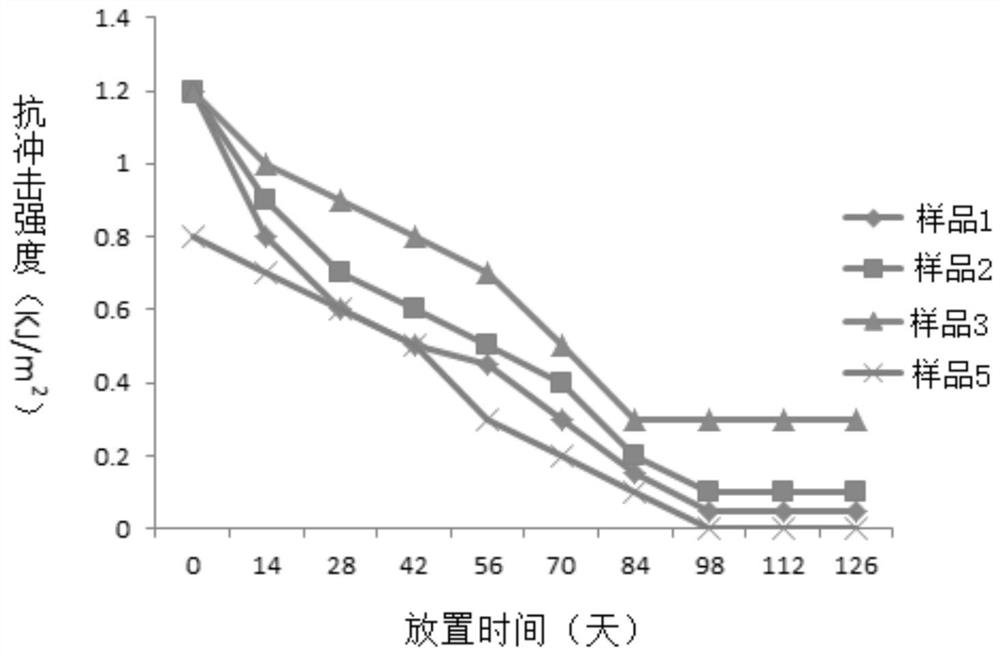

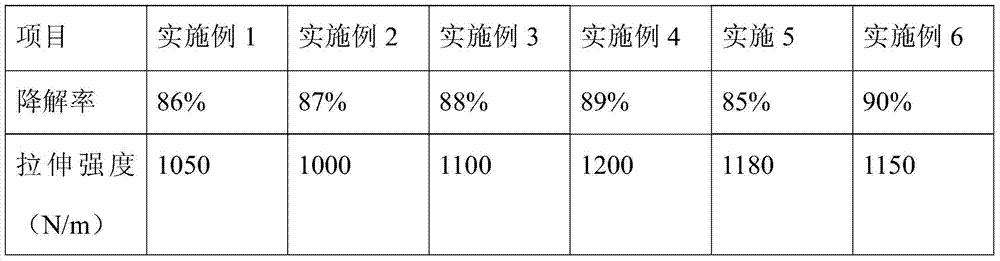

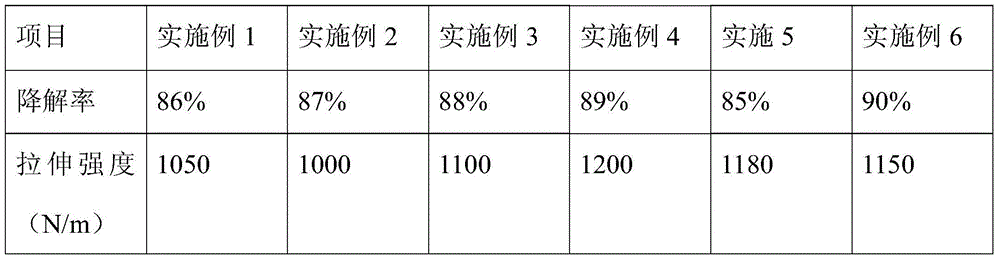

Biodegradable material and preparation method thereof

InactiveCN112029154AGood mechanical propertiesRealize the carbon cycleEnvironmental pressurePlasticizer

The invention discloses a biodegradable material and a preparation method thereof. The biodegradable material comprises the following raw materials in parts by weight: 10-79 parts of bio-based resin,5-45 parts of a bio-based filler, 3-20 parts of modified nano calcium carbonate, 5-15 parts of talcum powder, 5-15 parts of glass fiber powder, 6-18 parts of zinc oxide powder, 5-20 parts of a plasticizer, 1-5 parts of a lubricant, 0.5-5 parts of a biodegradation accelerator, 10-50 parts of an antistatic agent and 3-15 parts of epoxidized vegetable oil. The biodegradable material disclosed by theinvention is safe, environment-friendly and non-toxic, has complete biodegradability, relieves environmental pressure caused by large-scale use of fossil plastic, has excellent mechanical properties compared with an existing biodegradable material, and has the advantages that the temperature resistance, the wear resistance, the hydrophobicity, the creep resistance, the rigidity, the tensile property and the impact resistance are remarkably improved, and production cost is significantly reduced.

Owner:锐保新材料科技(上海)有限公司

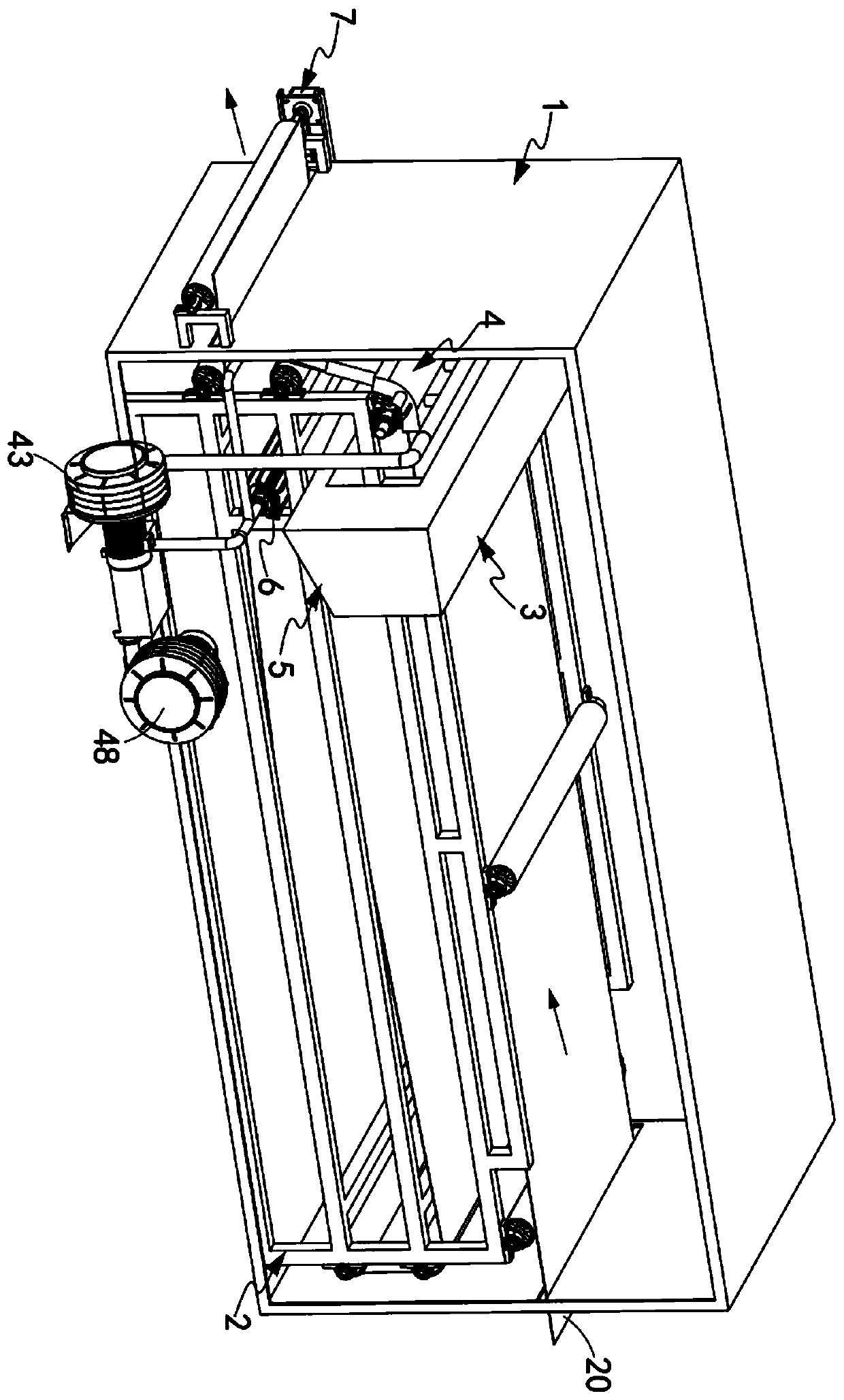

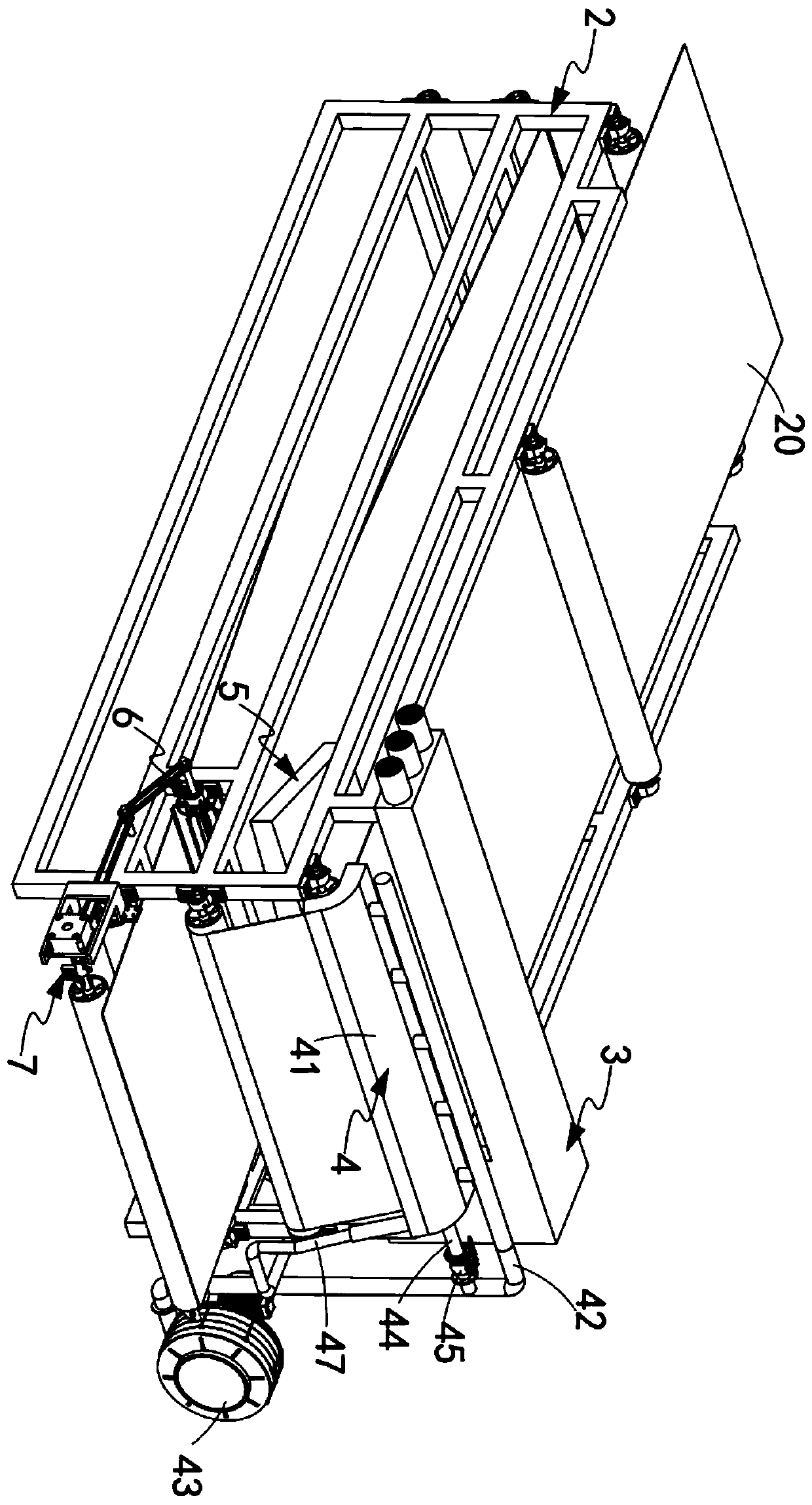

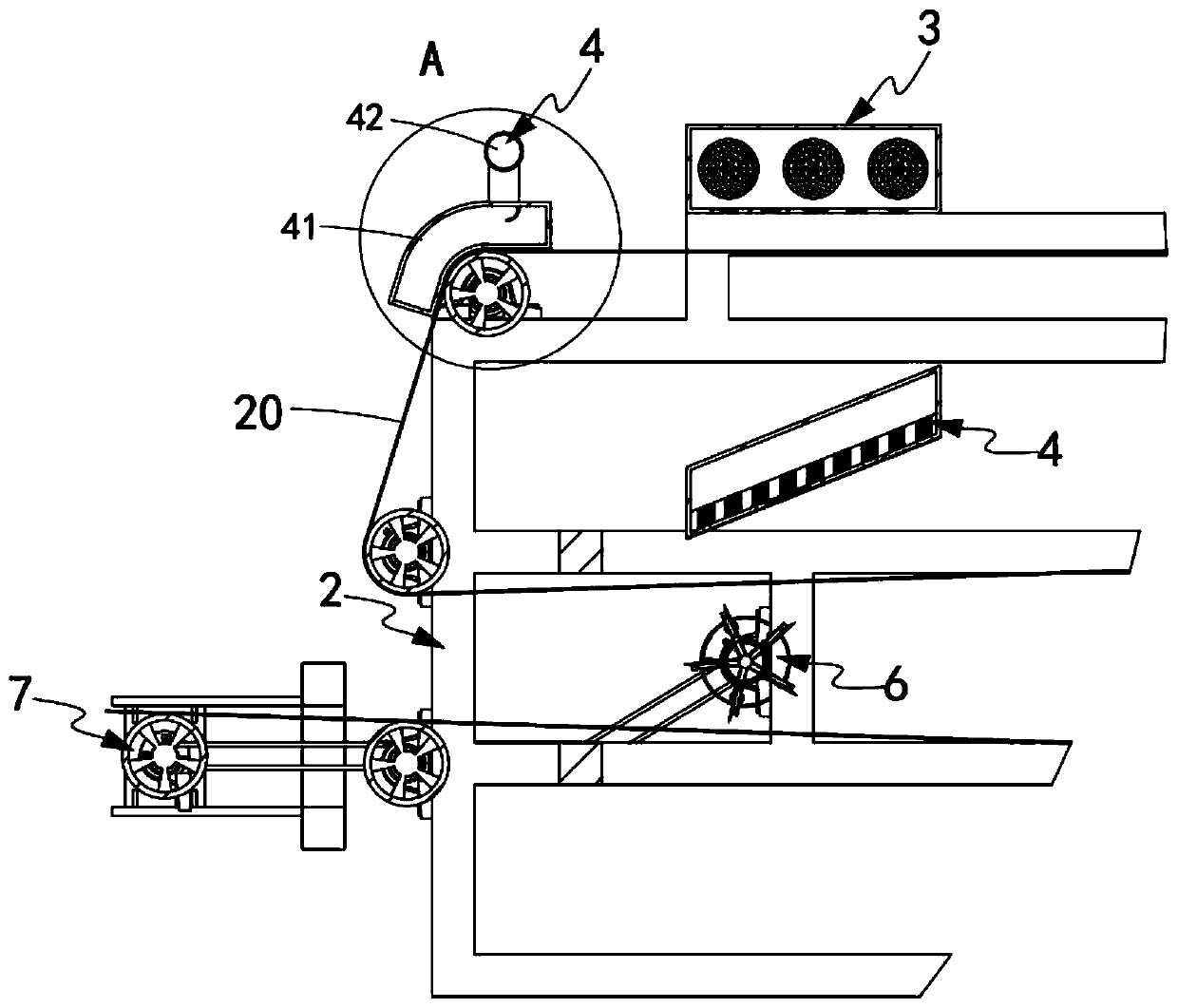

Textile fabric shaping, production and processing device

InactiveCN110067105AGuaranteed flatnessGuaranteed cleanlinessMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention provides a textile fabric shaping, production and processing device. The textile fabric shaping, production and processing device comprises a processing box, wherein a mounting frame ismounted in the processing box; and a fabric is conveyed on the mounting frame, a negative-pressure neatening mechanism, an incineration mechanism, a smoothening mechanism and a dust cleaning mechanismare separately mounted on the mounting frame in the fabric conveying direction, a rolling mechanism is installed outwards during processing, and after being subjected to singeing treatment, home textile fabrics are subjected to rotary scraping cleaning of ash incineration by using the dust cleaning mechanism before rolling; and during cleaning, rotation switching of the dust cleaning mechanism isutilized, a pressing roller is used for carrying out rolling and tensioning adjustment and smoothening treatment on the fabric to be rolled, the fabric is always smooth in a rolling process, and theproblem that the fabric has wrinkles in the rolling process after singeing is solved.

Owner:浙江常鑫纺织品有限公司

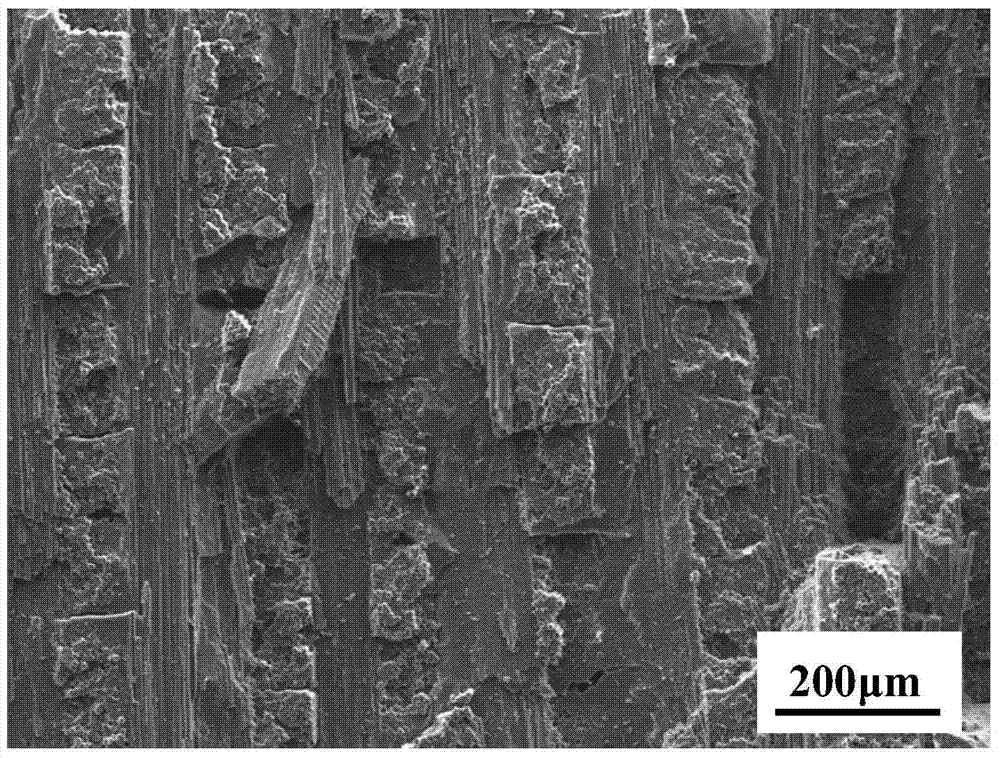

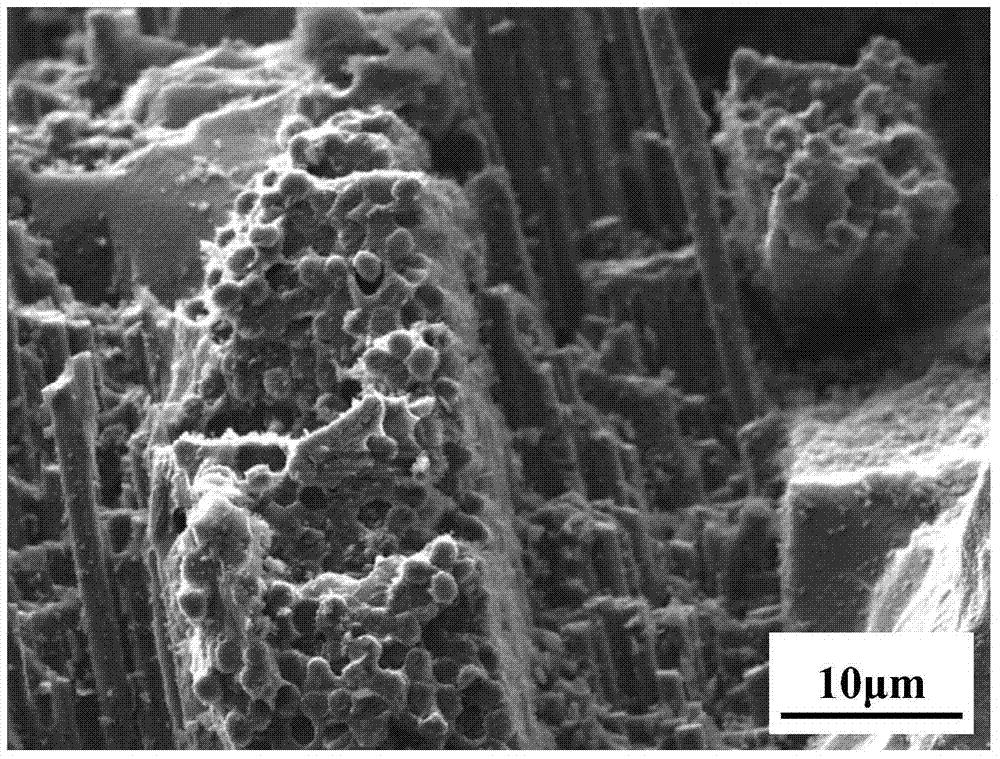

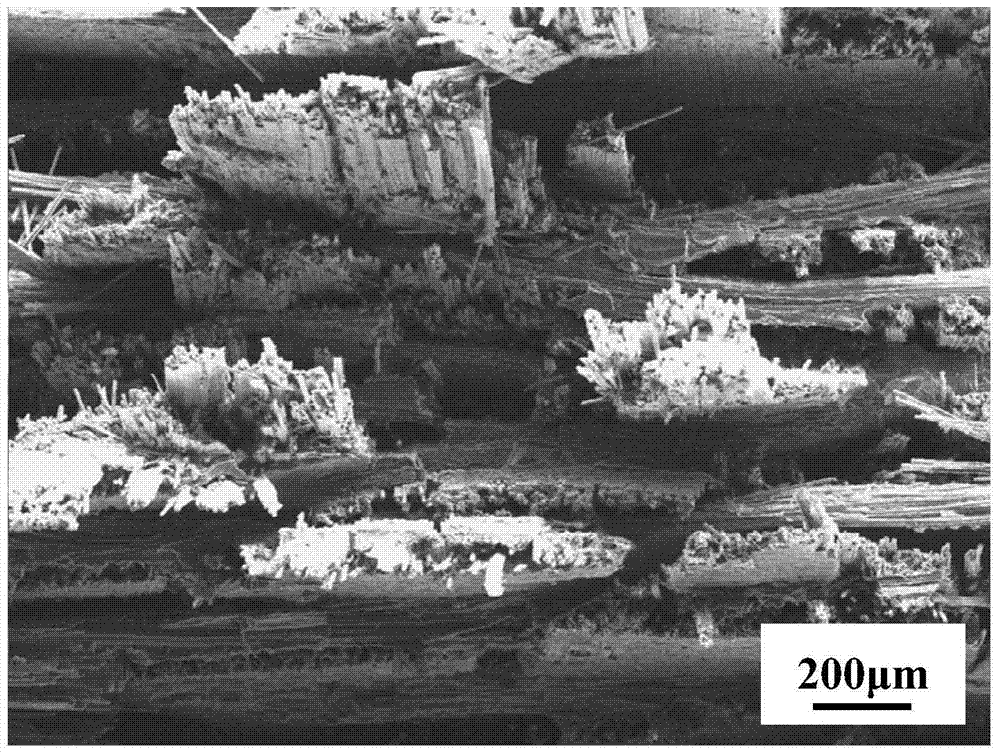

Method for improving binding strength of two-dimensional carbon/carbon composite material

The invention relates to a method for improving the binding strength of a two-dimensional carbon / carbon composite material so as to improve the tensile strength of the material in the horizontal direction, belonging to the technical field of heatproof bearing integrated carbon / carbon composite materials. The two-dimensional carbon / carbon composite material prepared by the method is moderate in binding strength of fibers and matrix interfaces, the fracture appearance is rough, multi-layered and multi-size fibers can be pulled out, the bearing and the force conduction effect of the fibers are brought into good play, the tensile property of the material is greatly improved, and the tensile strength is 137-301MPa, that is, the tensile strength is improved by more than 50% when being compared with the original tensile strength of 92MPa.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

High-strength steel and snap ring manufacturing method

InactiveCN108796166AImprove hardenabilityImprove toughnessProcess efficiency improvementElectric furnaceWire rodHardness

The invention discloses high-strength steel. The high-strength steel comprises, by weight, 0.70-0.85% of C, 0.80-1.15% of Si, 0.60-0.80% of Mn, 0.02-0.08% of Nb, 0-0.010% of S, 0-0.010% of P, 0-15ppmof T.O, 0-0.010% of Alt and the balance Fe and inevitable impurity elements. The high-strength steel is used for manufacturing an elastic snap ring. The invention further discloses a manufacturing method of the snap ring, and the high-strength steel is rolled into a wire rod coil and used for manufacturing the elastic snap ring. The method for manufacturing the snap ring through the high-strengthsteel comprises the steps that 1, a raw material of the high-strength steel is prepared according to the contents of all the elements; 2, the high-strength steel is manufactured through the raw material prepared in the step 1 and is subjected to rod coil rolling to be made into a wire rod; 3, wire rod drawing is conducted; 4, annealing is conducted; 5, cold rolling is conducted; 6, the wire rod isbent to form a circle; 7, the hole shape and the circle shape of the snap ring are made; 8, heat treatment is conducted; and 9, surface treatment is conducted, the snap ring which is good in elasticity and twisty performance is obtained, the hardness of the snap ring is 52-56HRC, and the good fatigue performance is achieved.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Underwater anti-dispersion high-strength acrylate grouting material

The invention relates to a novel composite underwater anti-dispersion high-strength acrylate grouting material which comprises a material A, a material B and a material C. The material A is composed of a calcium magnesium acrylate solution, deionized water, a surfactant, a calcium magnesium ion chelating agent, a cross-linking agent and an accelerant. The material B is prepared from an initiator and deionized water; the material C is prepared from superfine cement, a flocculating agent, steel slag microspheres, an active excitant and low-temperature expandable microspheres. According to the underwater anti-dispersion high-strength acrylate grouting material, the calcium-magnesium ion chelating agent is used as a retarder, so that the grouting material is green, environment-friendly, non-toxic and harmless; superfine cement is matched with a flocculating agent, so that the compressive strength and the water dispersion resistance are greatly improved, and meanwhile, heat is provided forexpansion of the low-temperature expandable microspheres; the low-temperature expandable microspheres are adopted, so that the slurry has excellent elasticity and tensile property while maintaining high compressive strength after hardening, and the elongation rate can reach 205%; and the steel slag microspheres are adopted, so that the viscosity of the slurry is sharply reduced to 8Pa. S, and thegrouting performance is excellent.

Owner:常州绿玛特建筑科技有限公司 +2

Manufacturing method of spaced chain stitch type heavy elastic bonding liner

ActiveCN102599662AIncrease elasticityStrong and goodFilm/foil adhesivesFibre typesPolyesterPolyresin

The invention discloses a manufacturing method of spaced chain stitch type heavy elastic bonding liner. The method comprises (1) preparing a whole-width fabric base formed of plural pieces of fabric bases by sewing on a double thread chain stitch sewing machine, wherein warp yarns of the fabric base adopt polyester filaments of 75-100D and spandex filaments, and weft yarns adopt polyester filaments of 300-350D; (2) refining; (3) subjecting to water-proof finishing in a finishing machine; and (4) adhering resin to the surface of the fabric base, infrared-heating the fabric base with dot-like resin adhered at 250-270 DEG C to dry and fix the resin onto the surface of the fabric base, and subjecting the infrared-heated fabric base to tentering setting in a tentering machine. The product obtained by the inventive method has good stiffness and resilience, can fully satisfy use requirements of general waist liners, has good ductility to improve the stretching effects of the product under force, and improves waist liner quality.

Owner:NITTOBO CHINA CO LTD

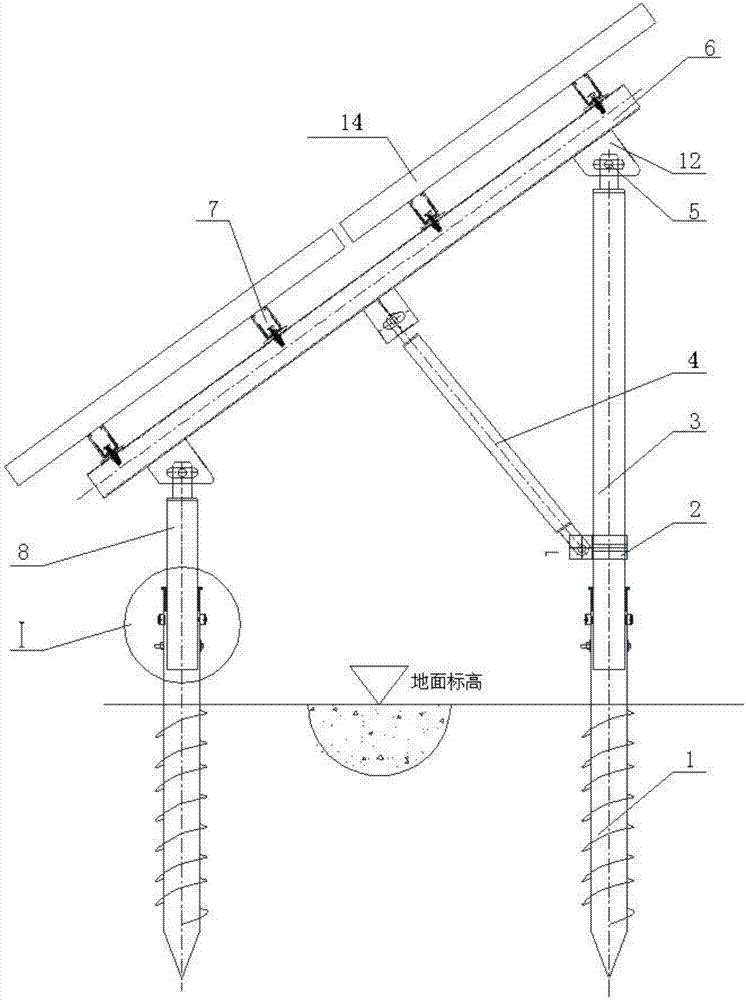

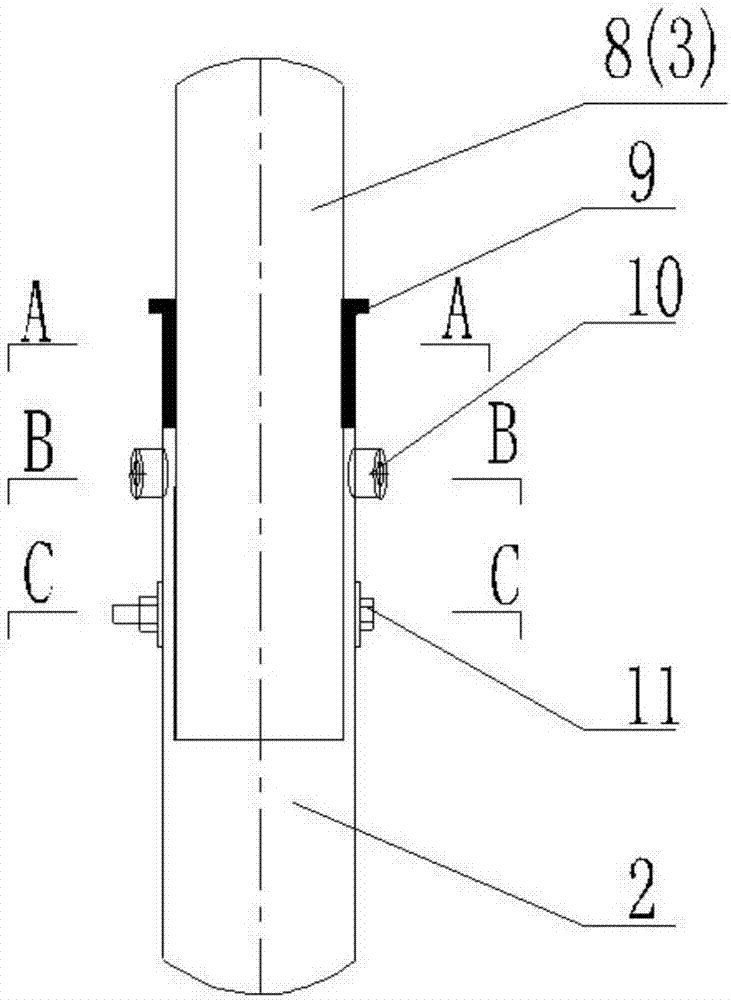

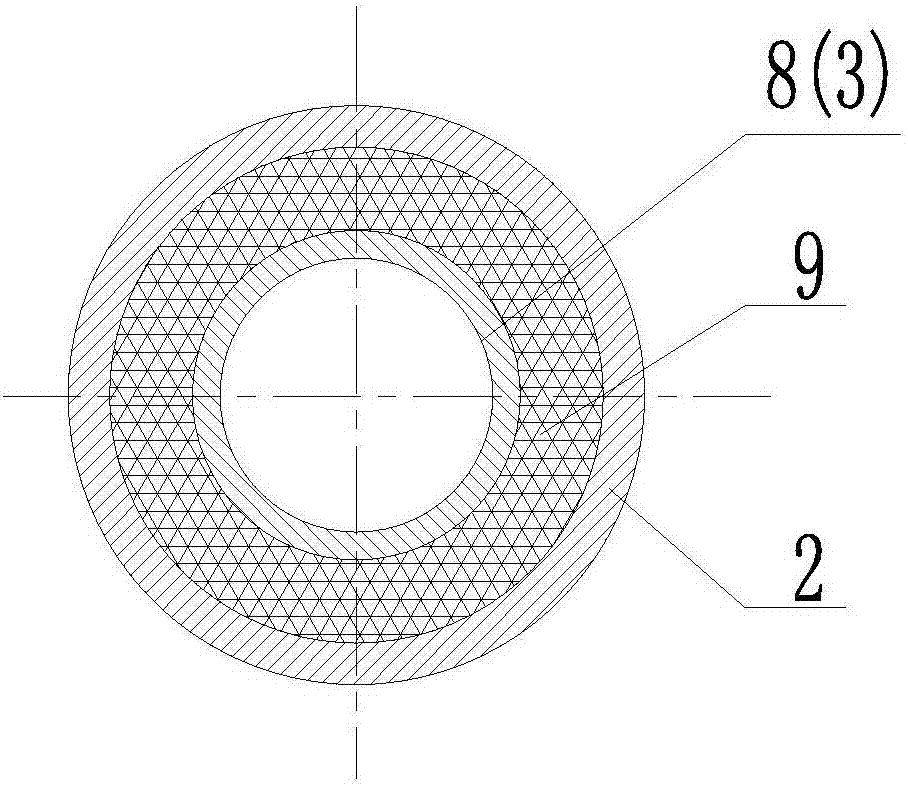

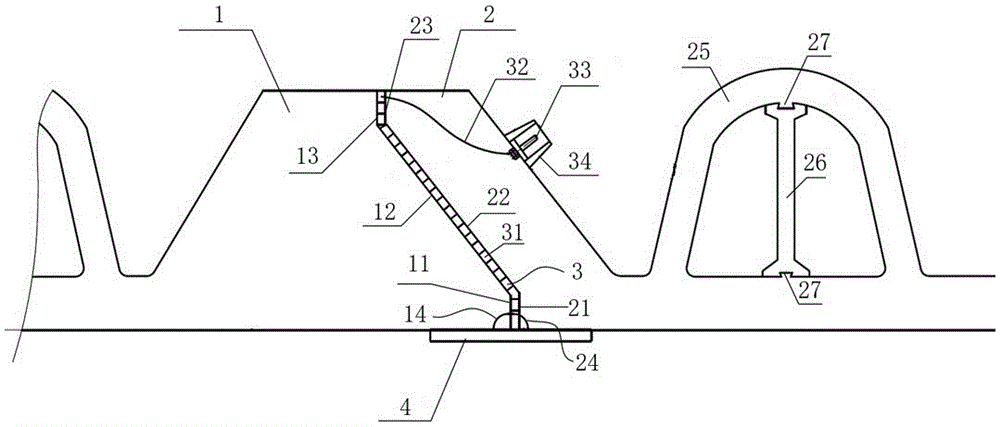

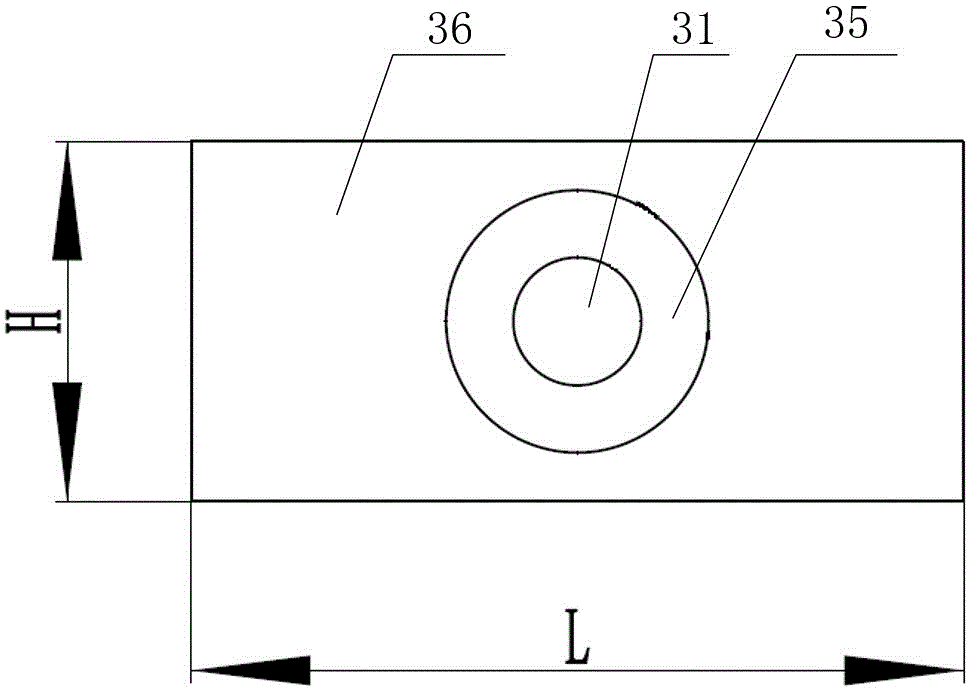

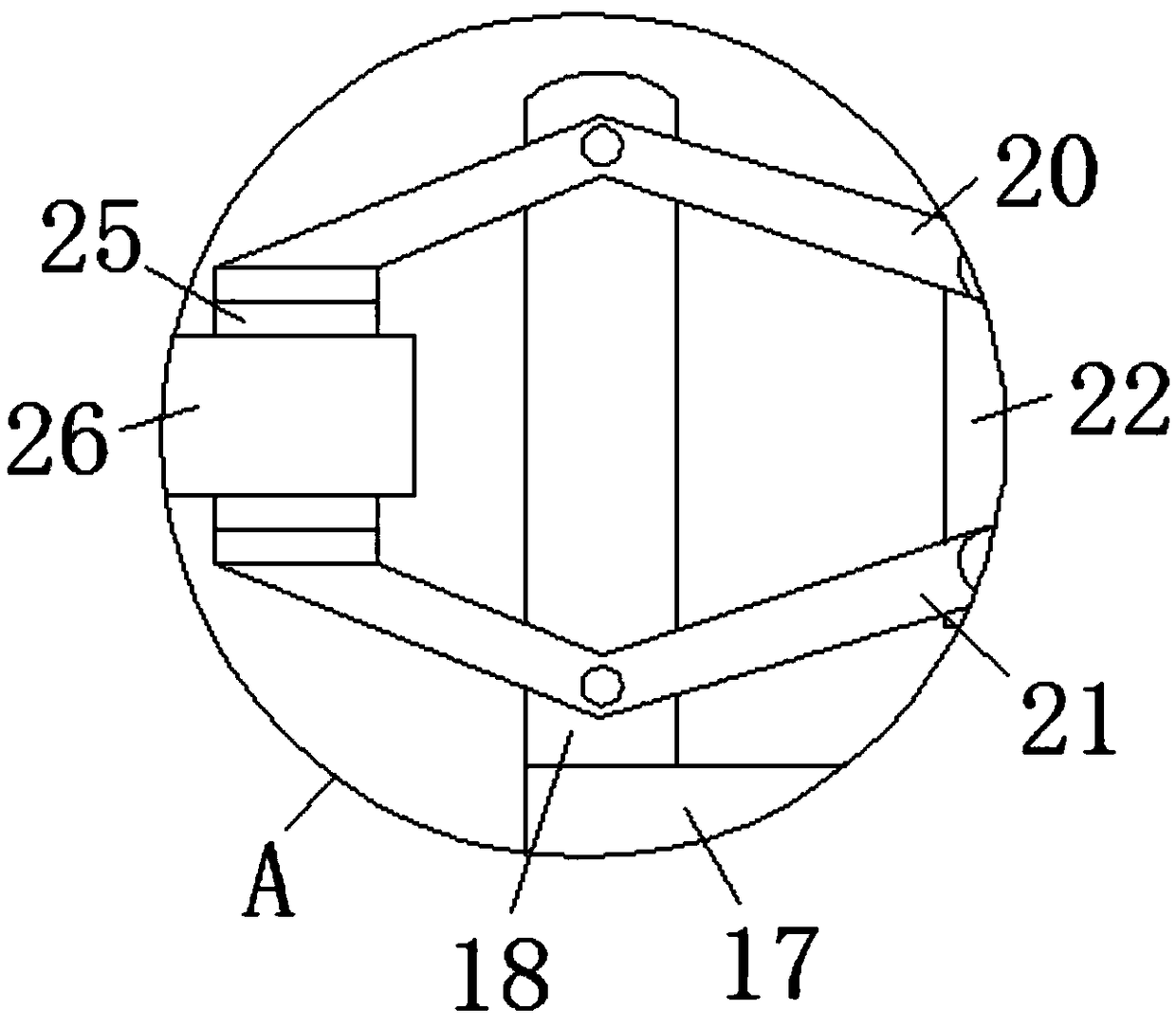

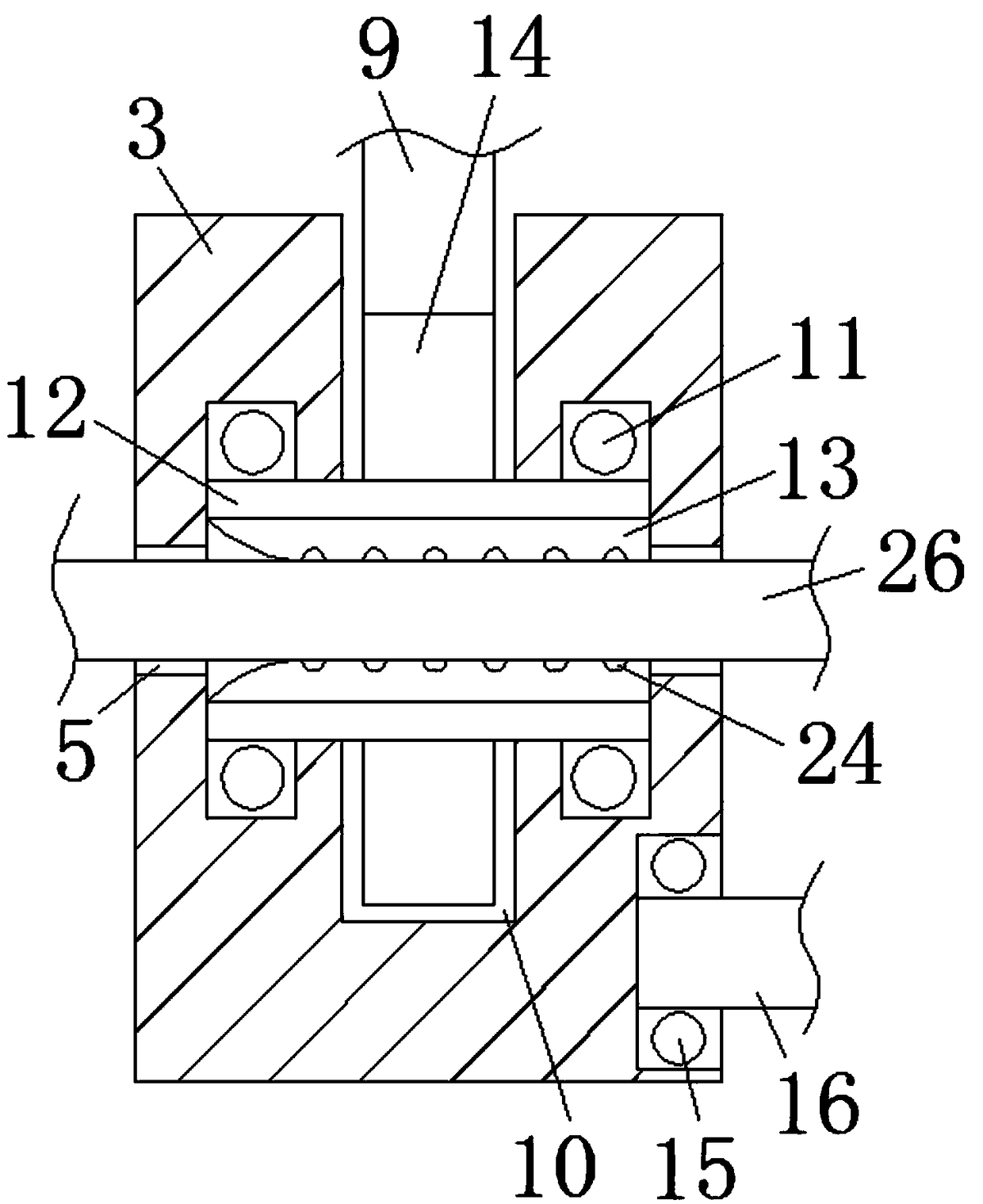

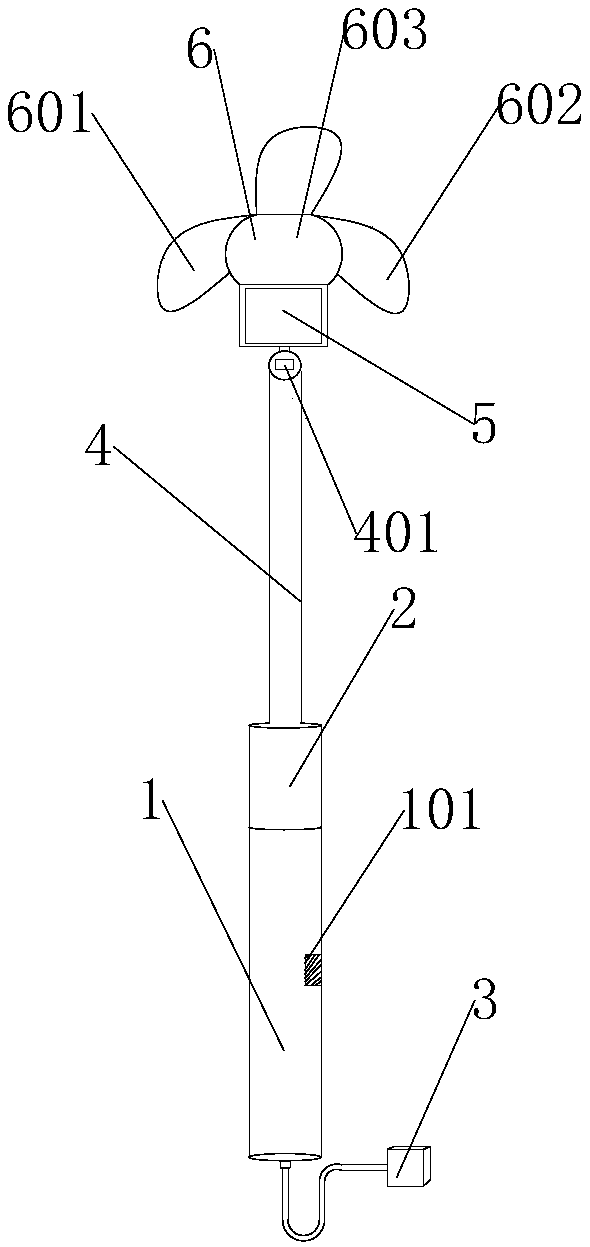

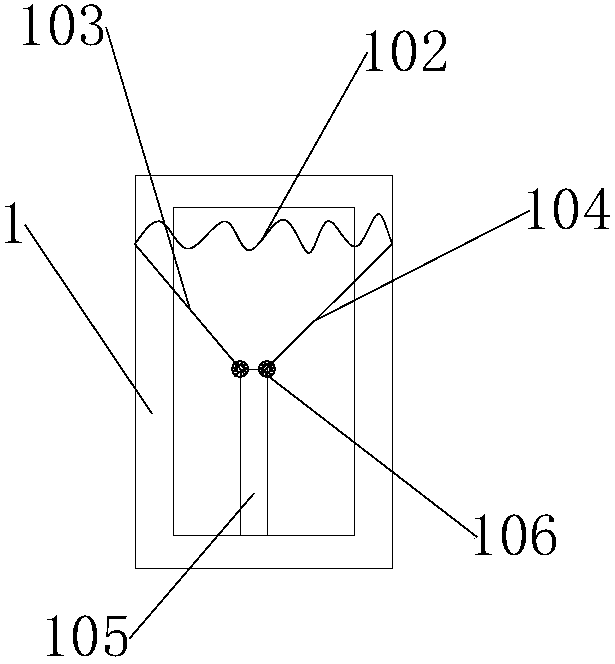

Spiral ground pile adjustable photovoltaic support

PendingCN107342730AEasy installation and constructionShort cyclePhotovoltaic supportsPhotovoltaic energy generationPurlinGeneration rate

The invention discloses a spiral ground pile adjustable photovoltaic support. The spiral ground pile adjustable photovoltaic support comprises multiple supports, wherein each support comprises spiral ground piles, a cross beam, a front vertical column and a back vertical column, wherein the front vertical column and the back vertical column are movably connected with the different spiral ground piles, two ends of the cross beam are hinged with the front vertical column and the back vertical column, and an upper side of the cross beam is provided with multiple purlins. The spiral ground pile adjustable photovoltaic support is advantaged in that the structure is simple, the spiral ground pile adjustable photovoltaic support has economic and economical property and is convenient to mount, not only can the spiral ground pile adjustable photovoltaic support be not influenced by regions (latitude), but also relatively high power generation rate can be guaranteed, and total power generation is improved.

Owner:SINOHYDRO ENG BUREAU 4 +1

Plating aluminium welding wire for carbon dioxide arc welding and preparation method thereof

InactiveCN101633084AImprove rust resistanceReduce splashWelding/cutting media/materialsSoldering mediaTitaniumTitanium alloy

The invention discloses a plating aluminium welding wire for a carbon dioxide arc welding and a preparation method thereof; a magnesium titanium alloy layer is plated on the surface of the welding wire by a hot-dipping method. As the surface plating layer of the prepared welding wire contains metal elements such as aluminium, magnesium, titanium and the like, the welding wire can reduce splash and increases the welding quality in the premise of ensuring the electrical conductivity; in the preparation method, the hot-dipping method is adopted for cladding material and can avoid the pollution brought by about the traditional coppering technique.

Owner:TIANJIN UNIV

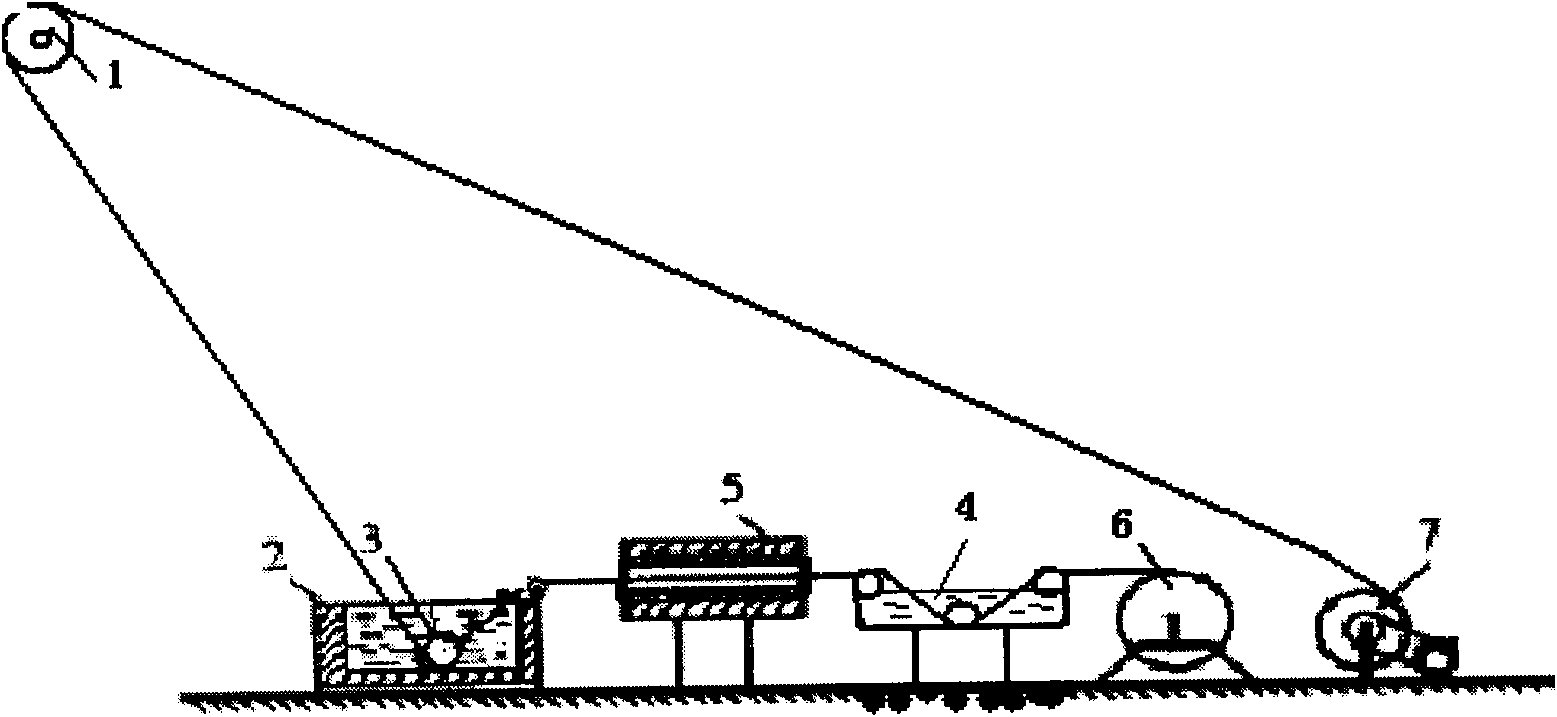

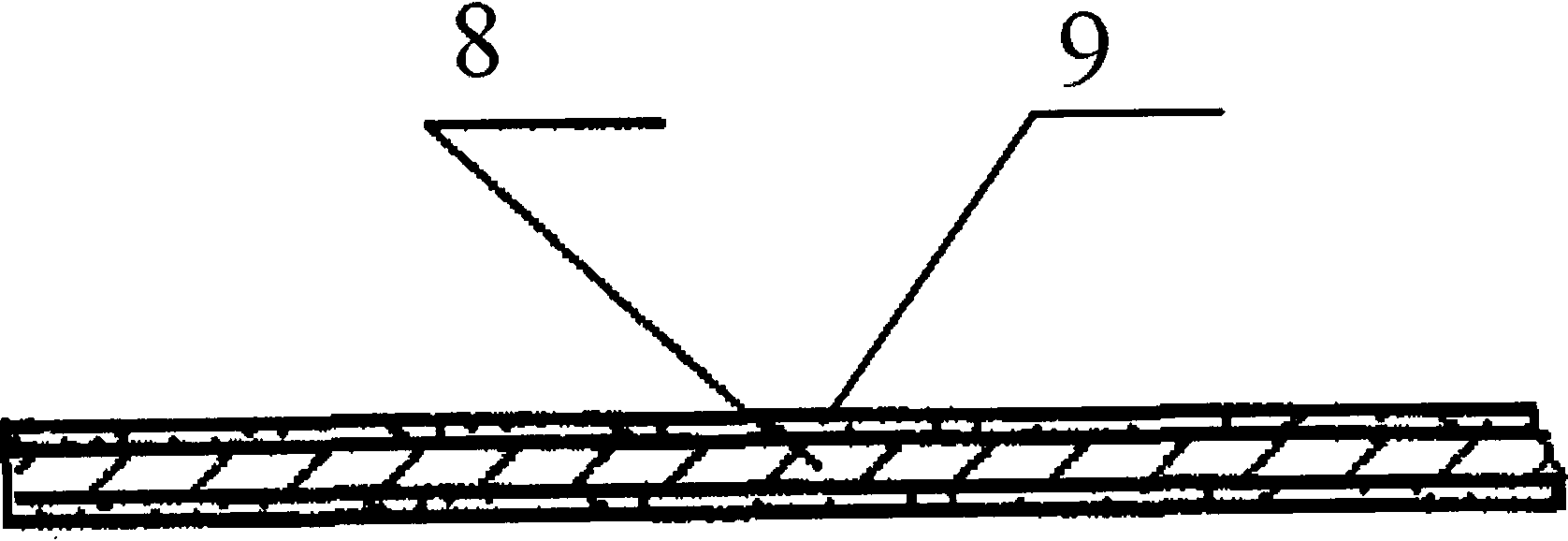

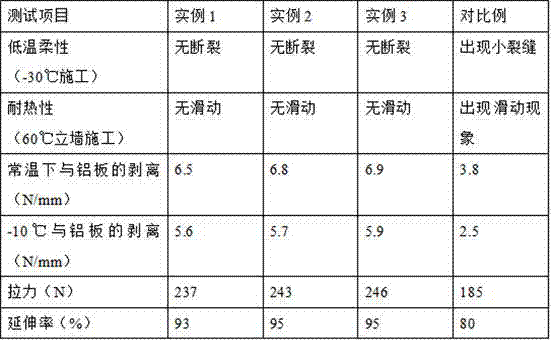

Preparation method of low temperature-resistant modified asphalt waterproof coil

The invention relates to the technical field of preparation of building waterproof materials, in particular to a preparation method of a low temperature-resistant modified asphalt waterproof coil. Thepreparation method comprises the following steps of doping self-prepared SBS (styrene-butadiene-styrene) rubber powder and base oil into asphalt, and emulsifying, so as to obtain rubber powder modified asphalt; melting and mixing the rubber powder modified asphalt, polypropylene master batch and fly ash, so as to obtain modified asphalt coating material; melting and extruding shell powder, silicagel powder and polyvinyl chloride, and cooling, so as to obtain isolation resin particles; paving the isolation resin particles on an oxidized film-coating polyester felt, and calendering, so as to obtain the waterproof coil. The preparation method has the advantages that the SBS forms a special lattice structure in the asphalt, so that the low-temperature sticking property of the waterproof coilis improved; when the modified asphalt coating material is catalyzed and oxidized, the viscosity of the asphalt coating material is improved by the carbonyl compound; after the polypropylene is addedinto the melted asphalt, the viscoelastic property of the asphalt is greatly changed under the adsorbing and swelling functions, so that the waterproof coil can maintain better viscoelastic propertyat low temperature, the tension property is also improved and the application prospect is broad.

Owner:常州可赛成功塑胶材料有限公司

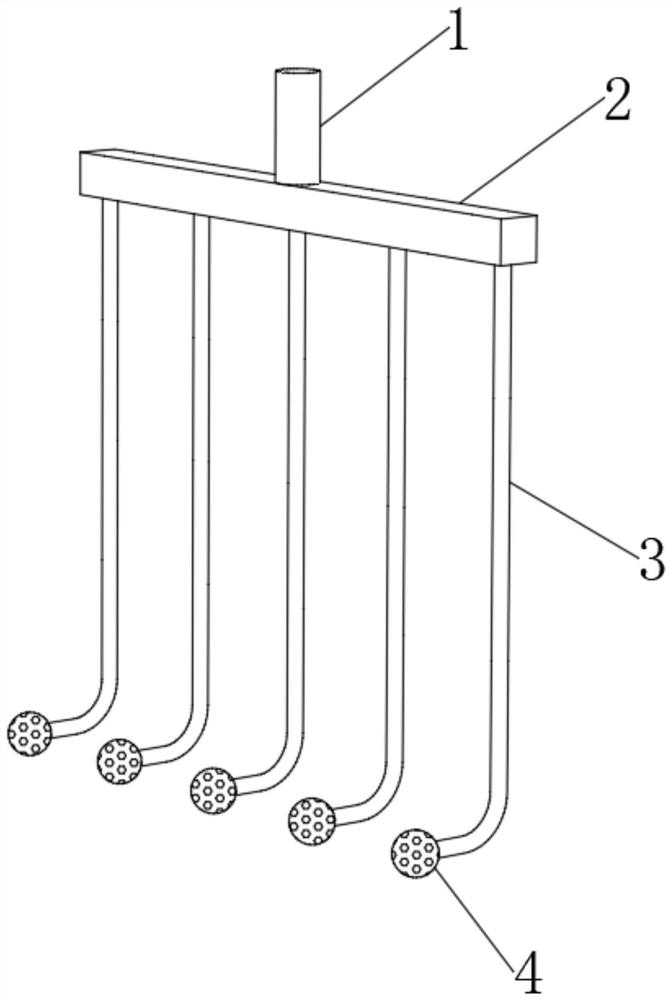

Z-shaped large-caliber plastic pipe connected through inserted electric heat fusion

ActiveCN105135135AImprove pull performanceImprove welding strengthPipe connection arrangementsElectricityButt joint

The invention discloses a Z-shaped large-caliber plastic pipe connected through inserted electric heat fusion. The plastic pipe comprises a pipe body, a socket end, a plug end and an electric heating piece. The socket end is arranged at one end of the pipe body, and the plug end is arranged at the other end of the pipe body. The plug end comprises a first ring face and a second ring face. The diameter of the second ring face is larger than that of the first ring face. A conical transition section is arranged between the first ring face and the second ring face. The socket end comprises a third ring face and a fourth ring face, the diameter of the fourth ring face is larger than that of the third ring face, and a funnel-shaped transition section is arranged between the third ring face and the fourth ring face. The electric heating piece is arranged at the socket end and / or the plug end. The Z-shaped plastic pipe is arranged at the plastic pipe joint. Compared with butt joint heat fusion and parallel inserted electric heat fusion, fusion welding faces are not located on one section and extend to the x direction and the y direction, and the fusion welding strength is greatly improved; and the drawing performance of a pipeline system is improved, and the capability of the pipeline for resisting the surface subsidence is improved.

Owner:张家港戴恩机械有限公司

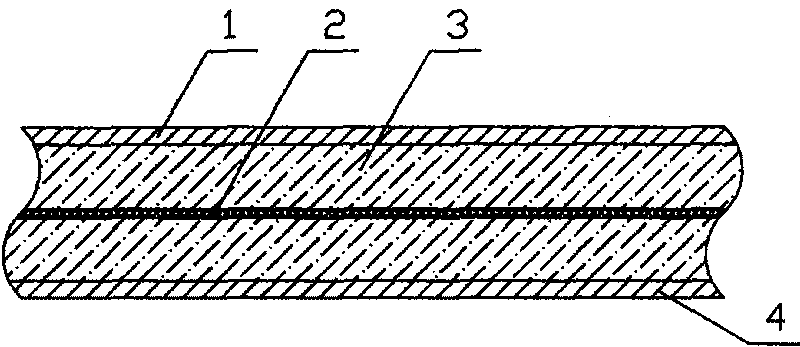

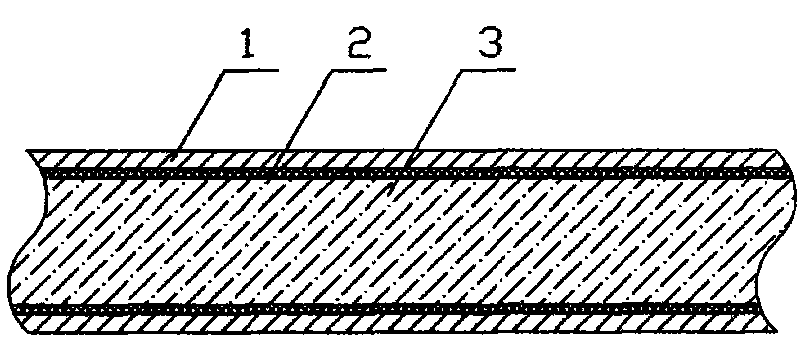

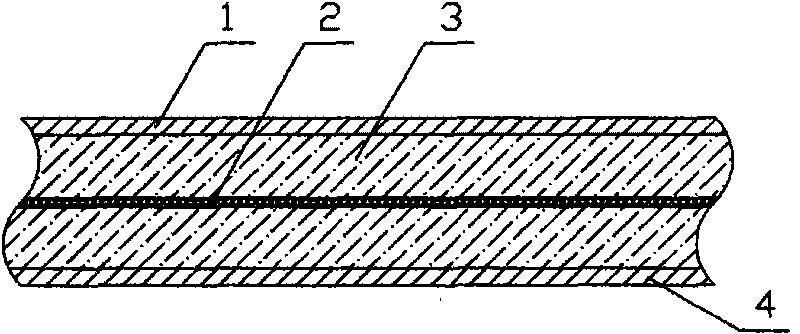

Reinforced composite board and production technology thereof

InactiveCN101693417AImprove pull performanceImprove toughnessMetal layered productsWeather resistanceSheet steel

The invention relates to the technical field of boards, in particular to a reinforced composite board and a production technology thereof. The reinforced composite board comprises a color steel plate layer formed by a steel plate which is subjected to baking varnish treatment, and a fireproof material layer compounded on the color steel plate layer; and is characterized in that at least one reinforced rib layer is arranged between the color steel plate layer and the fireproof material layer or inside the fireproof material layer. The invention has the beneficial effects that the structure is novel and simple, and the original board is internally additionally provided with the reinforced rib layer, thus greatly improving tensile property and toughness and using strength of boards, preventing cracking of core material caused by heat expansion and cold contraction, transportation, installation and the like, improving the repeated using property of a product, achieving the purpose of saving energy, and having the advantages of green and environmental protection property, non-ignitable property and fire resistance, high efficiency and heat insulation, ventilation and mould resistance, water resistance, good weather resistance, strong revolving capability and the like; in addition, the production technology is simple, the cost is low, and the properties are good, thus being widely applied to the fields of temporary buildings, road sound-proof walls, refrigeration, freezing storehouses and the like.

Owner:SHANGHAI JITUO STEEL STRUCTURE

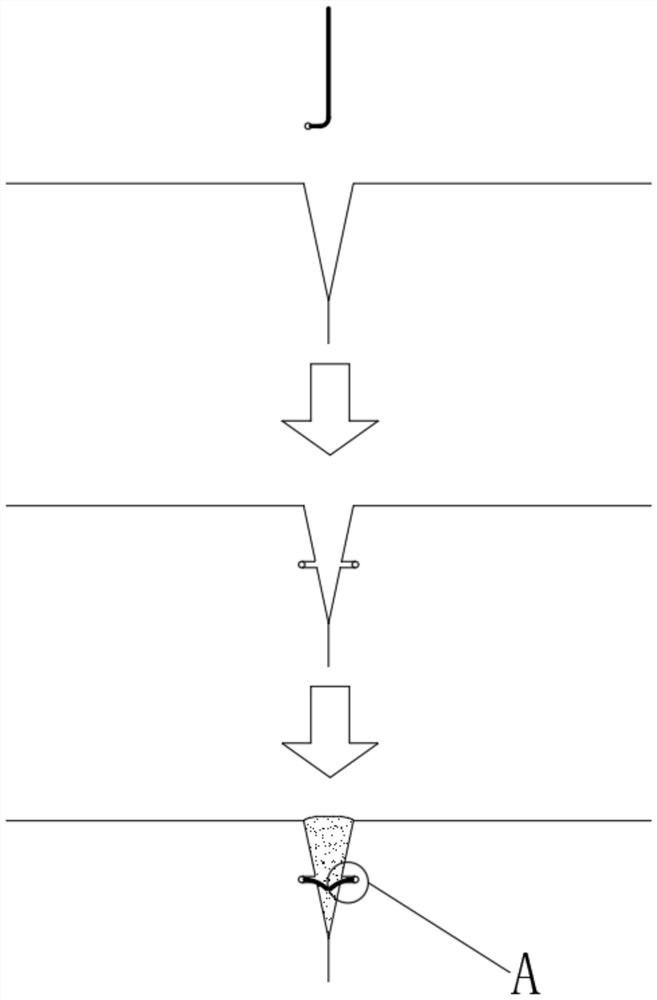

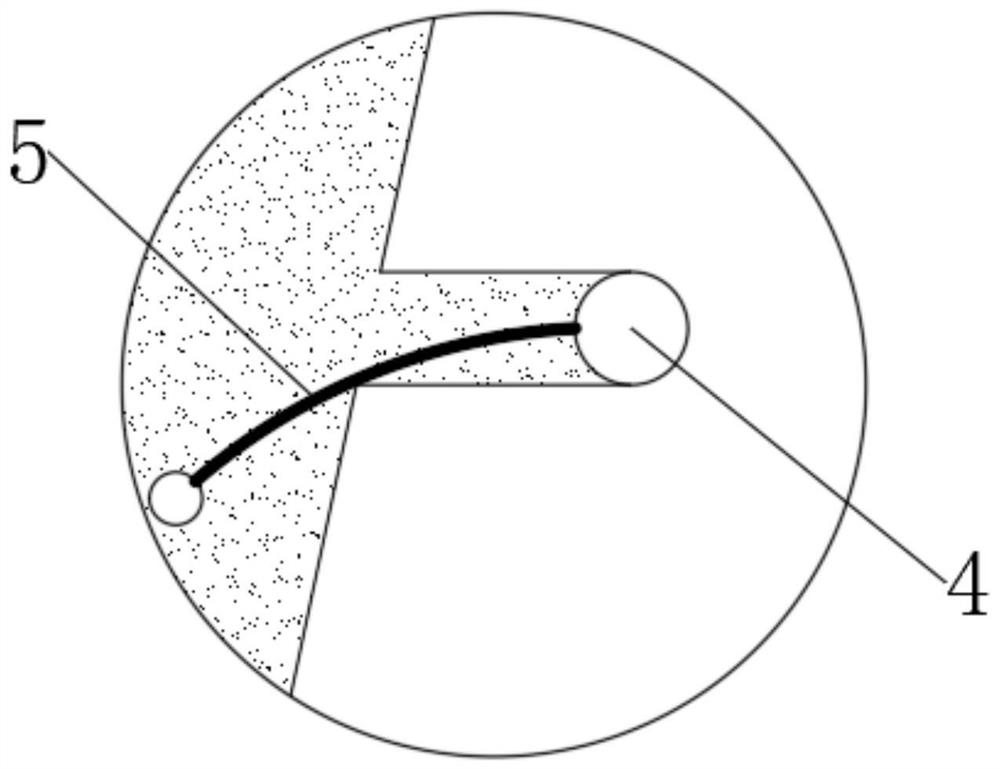

Asphalt pavement crack embedded repairing method

PendingCN112342859AImprove repair strengthAvoid secondary crackingIn situ pavingsRoads maintainenceStructural engineeringAsphalt pavement

The invention discloses an asphalt pavement crack embedded repairing method, and belongs to the technical field of asphalt pavement construction. The method comprises the following steps of: after expanding a crack, uniformly digging a plurality of fusion embedding holes in two side walls in the crack through molten asphalt by using a hole embedding tool, and reserving pre-embedded magnetic ballsin the fusion embedding holes; then preparing a joint sealing material on site, mixing a proper number of chemical force soft rods to be injected into the cracks after being mixed to be uniform, forcing the chemical force soft rods to partially enter the fusion embedding holes to be combined with the pre-embedded magnetic attraction balls through the magnetic attraction effect of the pre-embeddedmagnetic attraction balls on the chemical force soft rods, and foring high-strength combination of the cracks and an original asphalt pavement after the joint sealing material is cured; when the crackis extruded, the downward pressure of the chemical force soft rod is converted into the extrusion of the pavement on the two sides of the crack to the center, so that the pressure can be effectivelycounteracted, secondary cracking at the crack can be prevented, and the crack repairing strength is greatly improved.

Owner:福州市天伟达电子科技有限公司

High-strength weldable aluminum alloy and preparation method thereof

The invention belongs to the field of an aluminum alloy material and discloses high-strength weldable aluminum alloy. The high-strength weldable aluminum alloy comprises the following components: 0.4to 1.2 percent of Mg, 0.7 to 1.4 percent of Si, 0.2 to 0.7 percent of Mn, 0.05 to 0.2 percent of Cu, 0.1 to 0.5 percent of Zn, 0.4 to 0.6 percent of Fe, 0.05 to 0.15 percent of Cr, 0.1 to 0.3 percentof other alloy element and the balance of Al, wherein other alloy element comprises combination of Ni, V, Ti, Zr and rare earth element with the ratio of (1.2-1.4):(0.6-0.8):(2.4-2.6):(0.4-0.6):0.2; and the rare earth element comprises Ce, La and Er, and Ce account for more than 60 percent of the total amount of the rare earth element. Through improvement of the original formula, the aluminum alloy improves strength and mechanical property and can serve as aluminum alloy parts, such as an end plate and a tray, in a power battery of a new energy automobile.

Owner:福建祥鑫股份有限公司

Wire rod for 5000MPa-grade diamond wire and production method thereof

ActiveCN112899566AAvoid formingImprove purityHeat treatment process controlProcess efficiency improvementWire rodManganese

The invention discloses a wire rod for a 5000MPa-grade diamond wire and a production method thereof. The wire rod comprises the following chemical components: 1.01%-1.1% of carbon, 0.15%-0.4% of silicon, 0.3%-0.6% of manganese, 0.01%-0.4% of chromium, 0.0005%-0.002% of boron and / or 0.01%-0.09% of vanadium, and the balance iron and impurities including less than or equal to 0.003% of aluminum, less than or equal to 0.0008% of titanium, less than or equal to 0.005% of sulfur and less than or equal to 0.008% of phosphorus. The production method comprises the steps of vacuum melting, remelting, coping after cogging / forging, high-speed wire rolling and cooling, wherein the casting temperature ranges from 1580 DEG C to 1620 DEG C, and the casting speed ranges from 300 kg / min to 400 kg / min. The center carbon segregation of the wire rod is larger than or equal to 1.00 and smaller than or equal to 1.03, the wire rod can be used for preparing 5000 MPa-grade steel wires of 40-46 microns, and the technical blank of wire rods for ultrahigh-strength diamond wire buses at home and abroad is filled.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

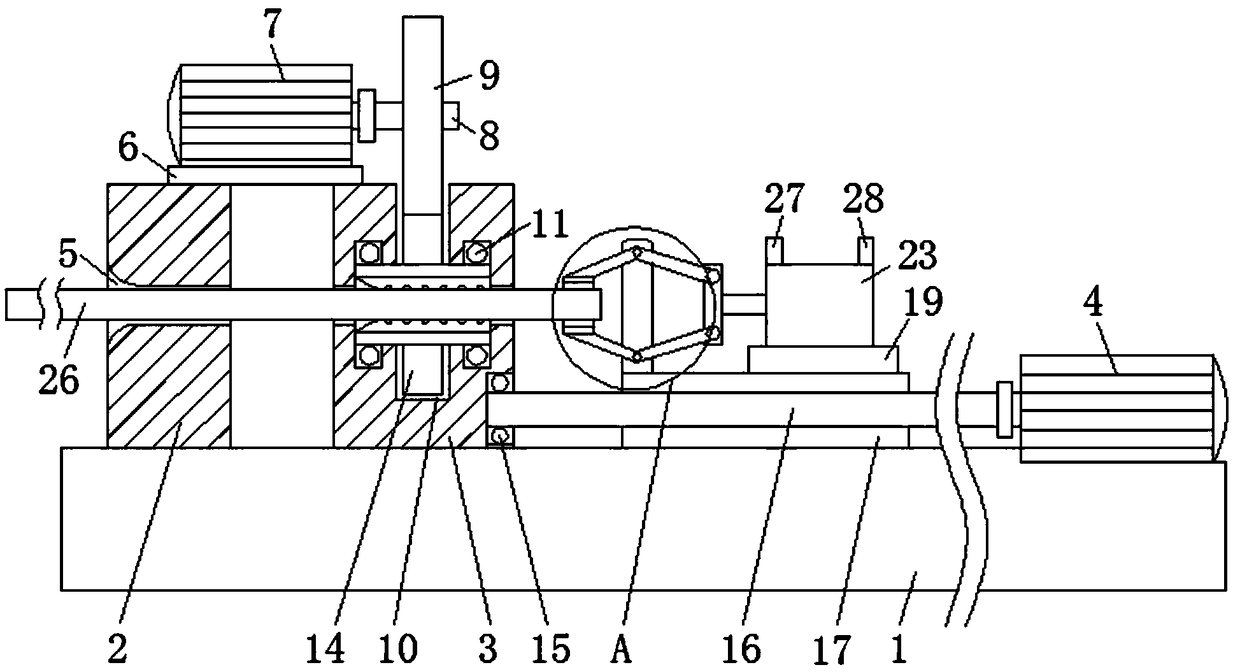

Copper bar combined drawing machine

InactiveCN108097729ATo achieve the effect of rotary polishingReduce material wasteRevolution surface grinding machinesSurface finishCoupling

The invention discloses a copper bar combined drawing machine. The copper bar combined drawing machine comprises an operating table, wherein the upper surface of the operating table is fixedly connected to a first positioning plate, a second positioning plate and a first motor, separately; material guiding holes are formed in the first positioning plate and the second positioning plate; the uppersurfaces of the first positioning plate and the second positioning plate are fixedly connected to a first base; the upper surface of the first base is fixedly connected to a second motor; and the output shaft of the second motor is fixedly connected to a rotary shaft through a coupling. The copper bar combined drawing machine disclosed by the invention achieves an effect of rotatably polishing thesurface of a copper bar body, so that material waste of the copper bar body is reduced; the copper bar body can be drawn; the copper bar combined drawing machine can avoid the problem that copper scales ground by millstones cannot be discharged effectively, and can enhance the drawing effects of an upper manipulator and a lower manipulator on the surface of the copper bar body effectively, so that the problem that materials are easily wasted for surface smoothness treatment of a common drawing machine is solved effectively.

Owner:贵溪静星信息技术服务有限公司

Strawberry picking apparatus

The invention discloses strawberry picking apparatus. The apparatus comprises a rod body and a height adjuster; and the lower part of the rod body is connected with a direct current electrical machine, a power source button is installed above the direct current electrical machine, the upper part of the power source button is connected with the height adjuster, the top of the height adjuster is connected with a telescopic rod, the top end of the telescopic rod is fixedly connected with a fixing member, a fruit receiving box is installed on the fixing member, the top of the fruit receiving box is connected with a shearing device, a rotating disc is fixed in the middle of the shearing device, the right side of the rotating disc is connected with a second shearing component, and a first shearing component is installed at the left side of the second shearing component. According to the invention, the strawberry picking apparatus is provided with two pulleys, the pulleys are arranged in parallel and distributed at symmetrical positions around the center of the rod body, the two pulleys are respectively connected with a first pulling member and a second pulling member, and when a currentreaches the pulleys, the pulleys rotate at a high speed, so that the picking speed is accelerated, and the working efficiency is improved.

Owner:镇江市丹徒区明兰瓜果种植家庭农场

A wire drawing process and application of starch degradable plastic

ActiveCN104441542BImprove pull performanceHigh strengthMelt spinning methodsFilament-forming treatmentPolymer scienceUltimate tensile strength

The invention relates to the technical field of degradable plastics and an application of the degradable plastics, and in particular relates to a drawing process and application of the starch degradable plastics. The process comprises the following steps of 1) respectively weighing 80-99 percent by weight of starch degradable plastics, 0.5-10 percent by weight of ester compatilizers and 0.5-10 percent by weight of aids-acrylic assistants, and uniformly stirring the starch degradable plastics, the ester compatilizers and the aids-acrylic assistants at the temperature of 40-70 DEG C; 2) adding the materials which are stirred uniformly in the step 1 in a single-screw extruding machine, and extruding monofilaments or ribbon-like filaments at the temperature of 120-220 DEG C. Compared with the prior art, the drawing process of the starch degradable plastics has the advantages that the starch degradable plastics can be drawn into filaments, and the filaments are high in flexibility, high in intensity, high in tensile strength and high in mechanical performance; the processing performance of the materials can be obviously improved; the drawn filaments can be widely applied to the fields of silk ribbons, threads, nets, braids, luggage, handbag cloth or curtains and the like and have wide application.

Owner:DONGGUAN FANGZHONG SPORT PROD

Antibacterial high-strength wood-plastic composite board and preparation process thereof

InactiveCN107652580AGood anti-ultraviolet aging performanceImprove chlorine storageGreen environmentPolymer science

The invention relates to a green environment-friendly antibacterial high-strength wood-plastic composite board with a certain heat resistance and thermal deformation resistance, capability of keepingstrong toughness at low temperature, high heat intensity and efficient antibacterial, mould-proof and strong waterproof capacity. Waste chlorinated polyvinyl chloride plastics and waste polyvinyl chloride plastics are used for replacing raw material level chlorinated polyvinyl chloride and polyvinyl chloride, production cost can be reduced, pollution caused by original waste chlorinated polyvinylchloride plastics and waste polyvinyl chloride plastics can be reduced, or cost and time needed by degradation and recovery are greatly reduced, the polyvinyl chloride is modified by mixing and addingthe chlorinated polyvinyl chloride, and the heat resistance and various mechanical properties can be greatly enhanced. Compared with a traditional PVC (polyvinyl chloride) wood-plastic material preparation process, the preparation process has the advantages that uniform plasticizing can be achieved in a short time, and energy is saved.

Owner:浙江天博生物新材料股份有限公司

Temperature-resisting anti-aging modified wood-plastic composite board and preparation process thereof

InactiveCN107603073AImprove acceleration performanceImproved performance against UV agingFlat articlesPlastic materialsAging resistance

The invention relates to temperature-resisting anti-aging modified wood-plastic composite board which is environment-friendly, has high heat resistance and high thermal deformation resistance, can maintain the high toughness at a low temperature, has higher heat strength property and has extremely high ultraviolet aging resistance. The chlorinated polyvinyl chloride is mixed with polyvinyl chloride, and a modification agent is added for modification, so that the mechanical property and temperature resistance of the wood-plastic composite board are improved, and the high temperature resistanceand low temperature resistance are apparently improved; and the preparation process is simple, rapid and efficient; and moreover, the pollution is avoided in the preparation process, the healthy and environment-friendly production requirement can be met, and compared with the traditional preparation process of the PVC wood-plastic material, the preparation process provided by the invention can achieve a purpose of uniform plasticization within a short time and can have an energy-saving effect.

Owner:浙江天博生物新材料股份有限公司

Drawing process and application of starch degradable plastics

ActiveCN104441542AImprove pull performanceHigh strengthMelt spinning methodsFilament-forming treatmentAlant starchBraid

The invention relates to the technical field of degradable plastics and an application of the degradable plastics, and in particular relates to a drawing process and application of the starch degradable plastics. The process comprises the following steps of 1) respectively weighing 80-99 percent by weight of starch degradable plastics, 0.5-10 percent by weight of ester compatilizers and 0.5-10 percent by weight of aids-acrylic assistants, and uniformly stirring the starch degradable plastics, the ester compatilizers and the aids-acrylic assistants at the temperature of 40-70 DEG C; 2) adding the materials which are stirred uniformly in the step 1 in a single-screw extruding machine, and extruding monofilaments or ribbon-like filaments at the temperature of 120-220 DEG C. Compared with the prior art, the drawing process of the starch degradable plastics has the advantages that the starch degradable plastics can be drawn into filaments, and the filaments are high in flexibility, high in intensity, high in tensile strength and high in mechanical performance; the processing performance of the materials can be obviously improved; the drawn filaments can be widely applied to the fields of silk ribbons, threads, nets, braids, luggage, handbag cloth or curtains and the like and have wide application.

Owner:DONGGUAN FANGZHONG SPORT PROD

A graphene-containing static-electricity-conducting polystyrene foaming material and a preparing method thereof

A graphene-containing static-electricity-conducting polystyrene foaming material and a preparing method thereof are disclosed. The weight of graphene in the material is 0.4-1 wt% of the total weight of a styrene monomer and graphene before polymerization. Prepared graphene / polystyrene beads are subjected to foaming, plate pressing and molding to obtain a foam plate. The surface resistance of the foam plate is 10<6>-10<8> [omega], the antistatic requirement is met, the flame retardance grade of the foam plate can be the B1 grade, the heat conductivity decreases from original 0.039-0.042 W / (m.K) to 0.030-0.034 W / (m.K), and the drawing performance increases from original 90 KPa to 220-260 KPa.

Owner:无锡兴达泡塑新材料股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com