Plating aluminium welding wire for carbon dioxide arc welding and preparation method thereof

A technology of gas shielded welding and carbon dioxide, applied in welding equipment, welding media, manufacturing tools, etc., can solve problems such as welding quality decline, uneven powder, spatter, etc., and achieve deoxidation performance, wire feeding performance, and drawing performance. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

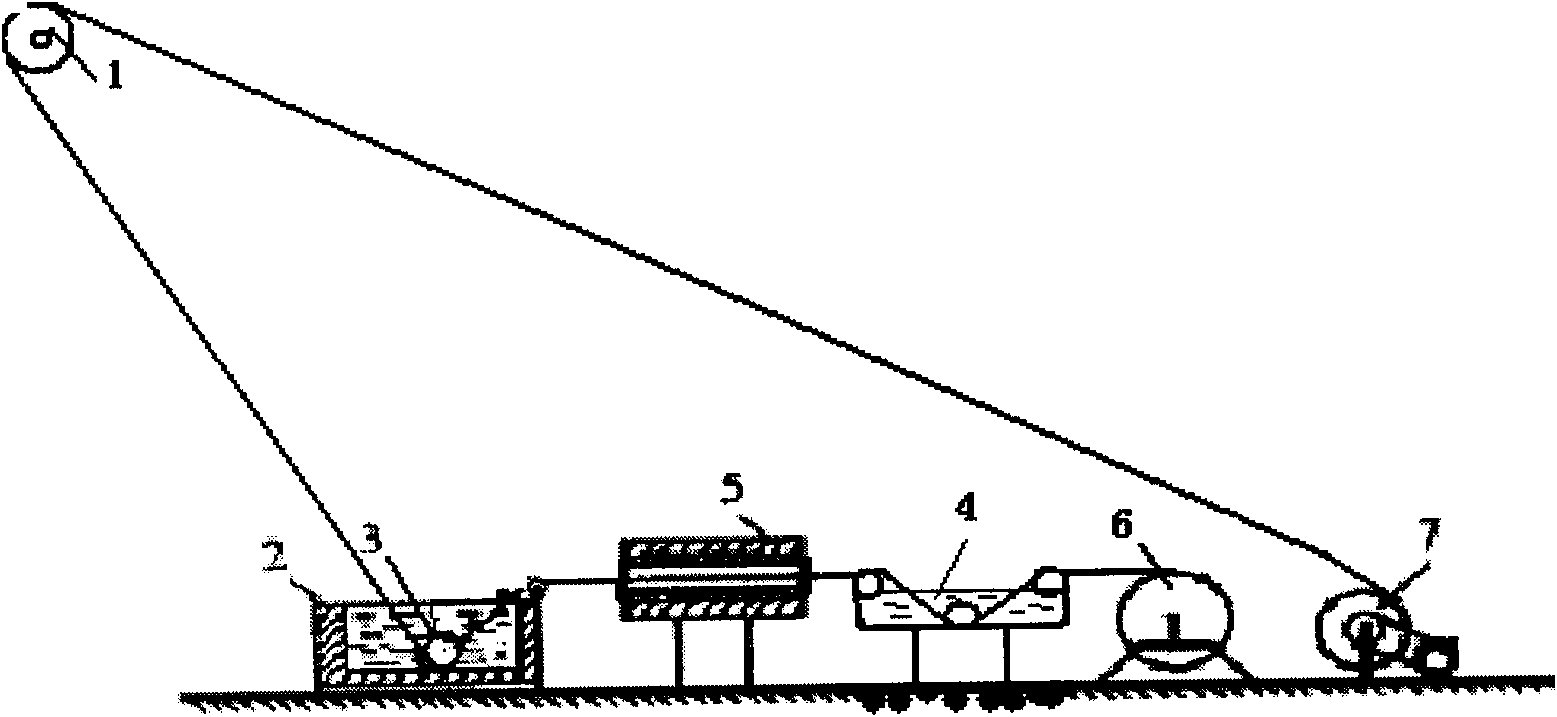

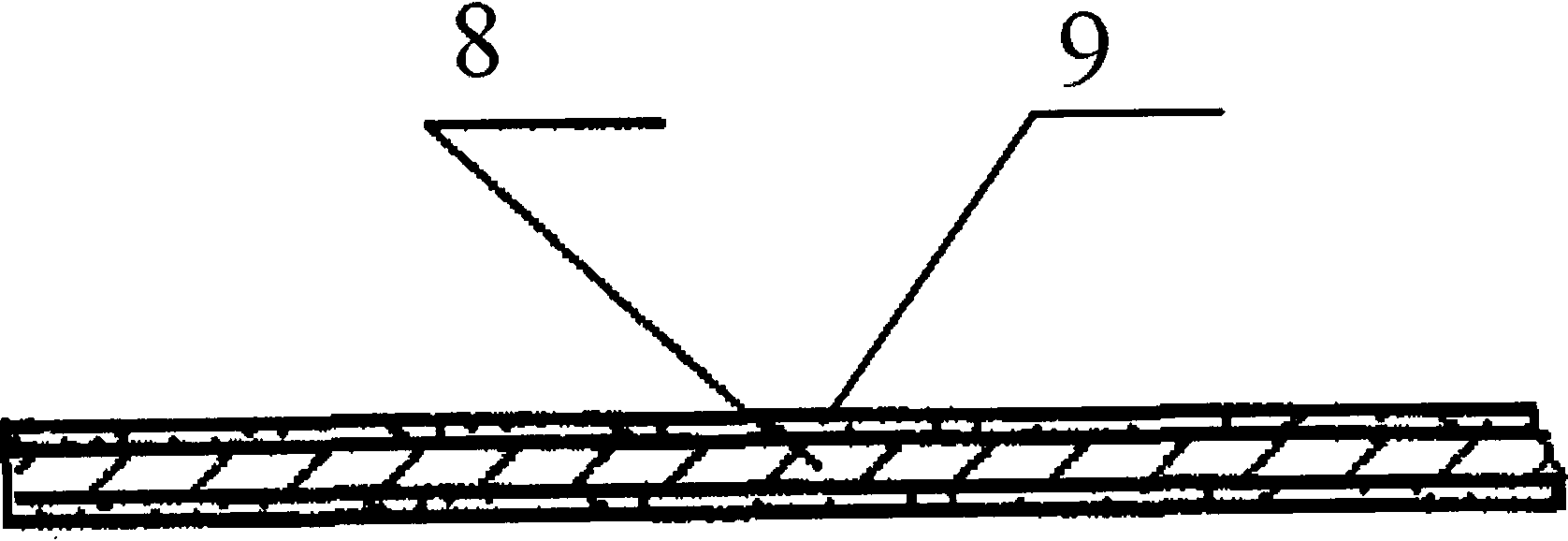

Method used

Image

Examples

Embodiment 1

[0032] (1) Peel off the shell and remove the rust from the wire rod, the raw material of the welding wire, dip it in a borate coating, dry it, and after the first drawing, reduce the diameter of the wire rod to 3.5mm, and take up the wire;

[0033] (2) The wire rod after step (1) is processed to carry out hot alkali washing and degreasing, and successively through the activation tank and the preheating furnace, wherein in the activation tank, there are potassium fluoride aqueous solution of 6% by mass fraction and 4% by mass fraction A flux consisting of sodium chloride aqueous solution, the drying temperature of the preheating furnace is 300 °C;

[0034] (3) Dip the wire rod dried in step (2) into the aluminum-plating solution for hot-dip plating, wherein the aluminum-plating solution is composed of 30g aluminum, 40g magnesium and 30g titanium, the hot-dip temperature is 720°C, and the dip-coating The time is 3s;

[0035] (4) Draw the hot-dipped wire rod for the second time ...

Embodiment 2

[0037] (1) Peel off the shell and remove rust from the wire rod, the raw material of the welding wire, dip it in a borate coating, and dry it. After the first drawing, the diameter of the wire rod is reduced to 2.8mm, and the wire is taken up;

[0038] (2) The wire rod after step (1) is processed to carry out hot alkali washing and degreasing, and successively through the activation tank and the preheating furnace, wherein in the activation tank, there are potassium fluoride aqueous solution of 6% by mass fraction and 4% by mass fraction A flux consisting of sodium chloride aqueous solution, the drying temperature of the preheating furnace is 500°C;

[0039] (3) Dip the wire rod dried in step (2) into the aluminum plating solution for hot-dip plating, wherein the aluminum-plating solution is composed of 60g aluminum, 10g magnesium and 30g titanium, the hot-dip temperature is 650°C, and the immersion plating time is 20s;

[0040] (4) Draw the hot-dipped wire rod for the second...

Embodiment 3

[0042] (1) Peel off the shell and remove rust from the wire rod, the raw material of the welding wire, dip it in a borate coating, dry it, and after the first drawing, reduce the diameter of the wire rod to 3.0mm, and take up the wire;

[0043] (2) The wire rod after the step (1) is processed is carried out hot alkali washing and degreasing, and is processed through activation tank and preheating furnace successively, wherein is provided with potassium fluoride aqueous solution by mass fraction 6% and mass fraction 4 in the activation tank % sodium chloride aqueous solution, the drying temperature of the preheating furnace is 400°C;

[0044] (3) Dip the wire rod dried in step (2) into the aluminum plating solution for hot-dip plating, wherein the aluminum-plating solution is composed of 60g aluminum, 20g magnesium and 20g titanium, the hot-dip temperature is 680°C, and the immersion plating time is 5s;

[0045](4) Draw the hot-dipped wire rod for the second time to a diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com