Patents

Literature

163results about How to "Reduce the probability of wire breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wire rod for prestressed concrete steel stick and manufacturing process

InactiveCN101245433AGood comprehensive performance indexReduce the probability of wire breakageRoll mill control devicesMetal rolling arrangementsAlkalinityWire rod

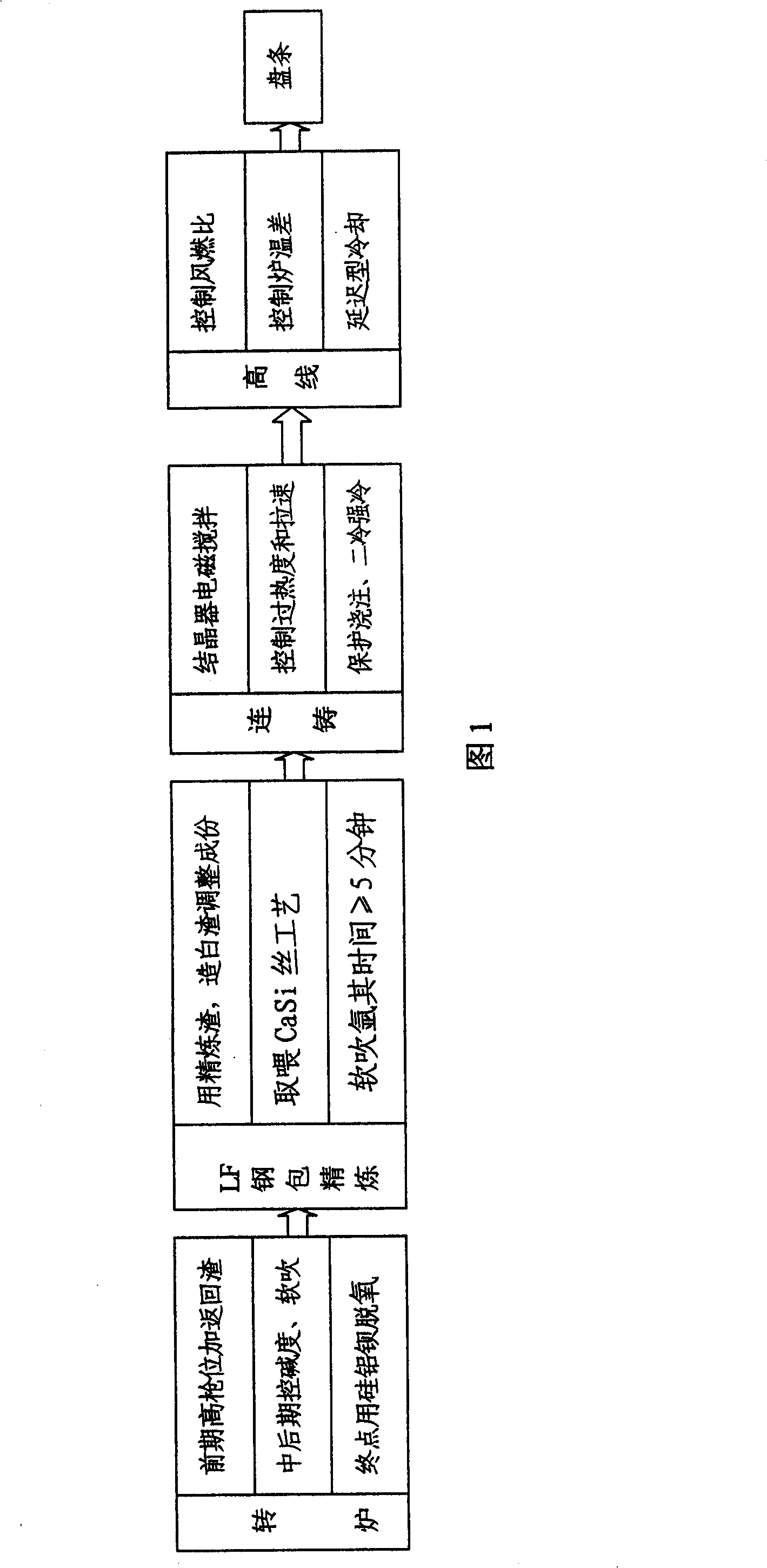

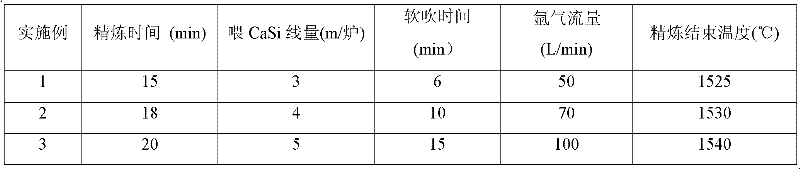

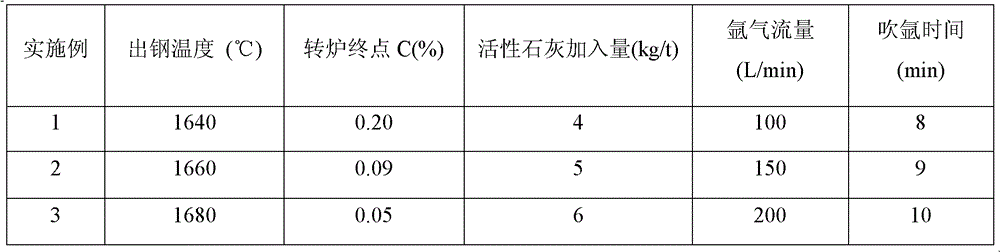

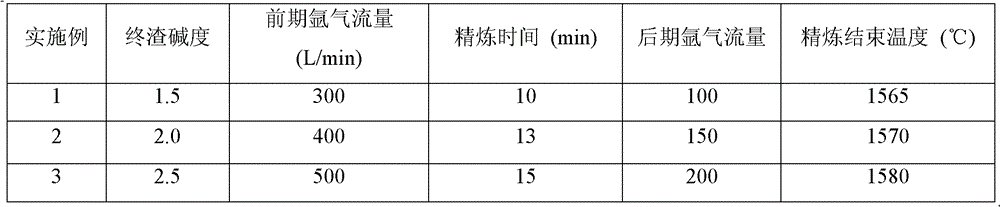

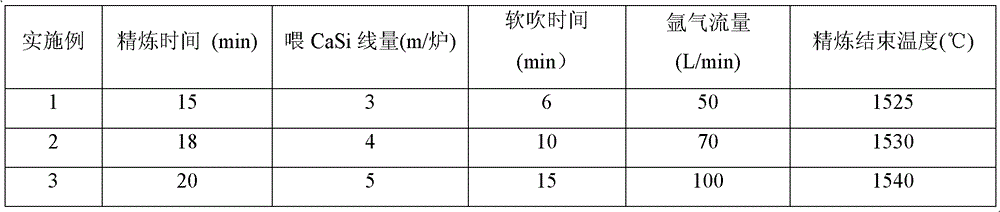

The invention relates to a novel steel wire rod and a manufacturing technique thereof. A prestressed steel bar used as the distributed steel of tubular piles is a new product developed in recent years, and the raw material thereof, namely, the steel wire rod, has no special steel and production technique; the controls for the components and performances, etc. of the steel wire rod are different, which results in larger fluctuation thus bringing the producers and the users more difficulties; therefore, the novel steel wire rod and the manufacturing technique thereof are invented. The components of the novel steel by weight percentage are: 0.28-0.34 percent of C, 0.70-1.10 percent of Si, 1.10-1.50 percent of Mn, less than or equal to 0.025 percent of S, less than or equal to 0.025 percent of P, less than or equal to 0.25 percent of Ni, less than or equal to 0.25 percent of Cr and less than or equal to 0.20 percent of Cu; the adopted technique is converter - ladle furnace (LF) refining - continuous casting - highline mill; in the converter process, high lance height is adjusted, returned slag by the converter is added in the front period, and the alkalinity is controlled in the middle and late period; stirring is done under soft blowing before the end of the process, and then deoxidation by adopting SiAlBa is carried out; in the ladle furnace (LF) refining process, reductive white slag is adopted, the CaSi wires are fed and before finishing the refining, and soft argon blowing is done; in the continuous casting process, the degree of superheat and the casting speed of the molten steel are controlled and casting is preformed under whole course protection; in the rolling process, the delayed cooling technique is adopted. The novel steel wire rod, when in use, the control range of the components is narrow, therefore, the fluctuation of adjacent batches is small; the performance of the novel steel wire rod is stable, and the aberration thereof is small.

Owner:TIANJIN IRON & STEEL GRP

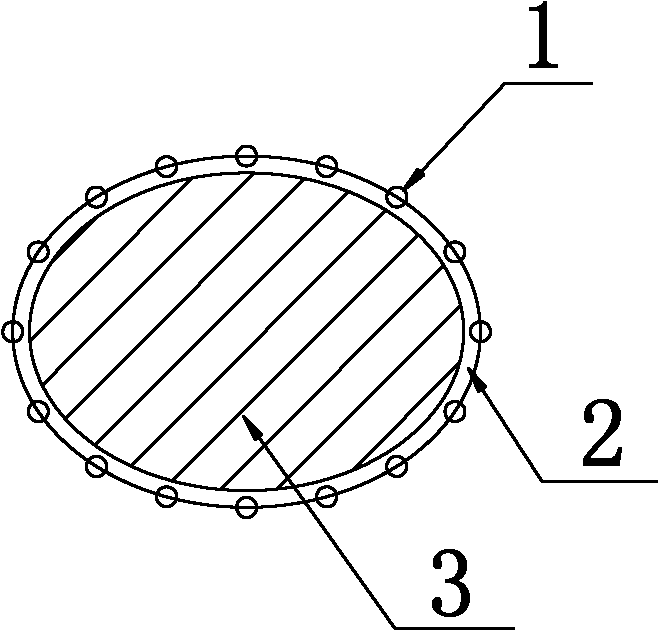

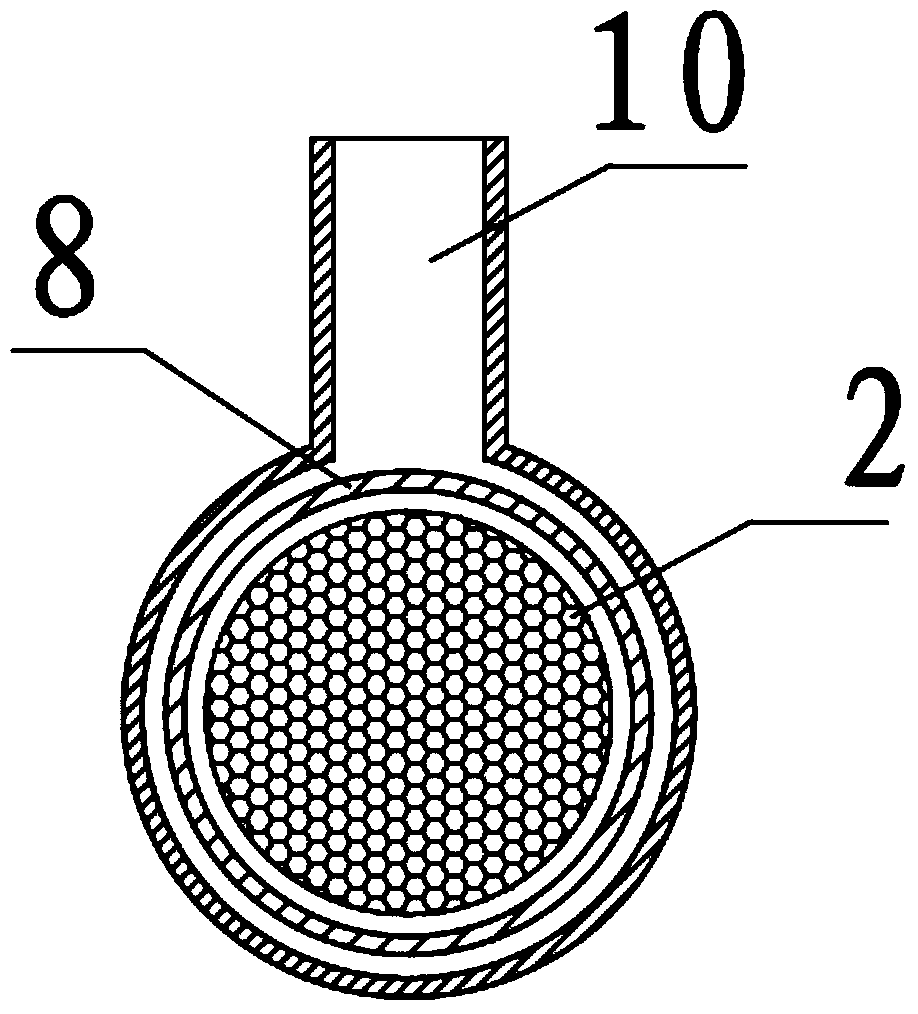

Immersion type hollow fiber membrane component and complete equipment thereof

ActiveCN101497000AReduce the probability of wire breakageReduce rigid fatigue damageSemi-permeable membranesFiberHollow fibre membrane

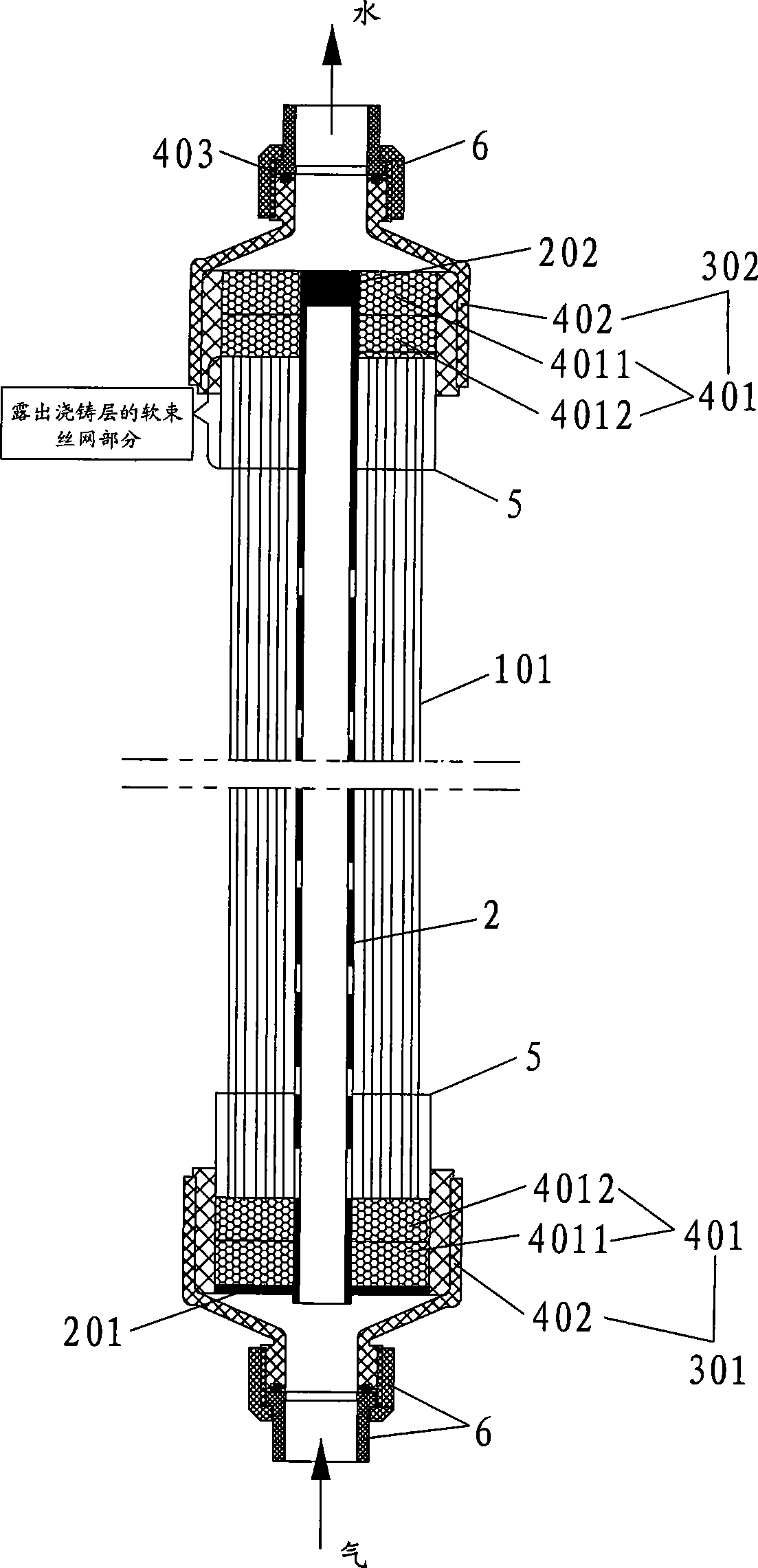

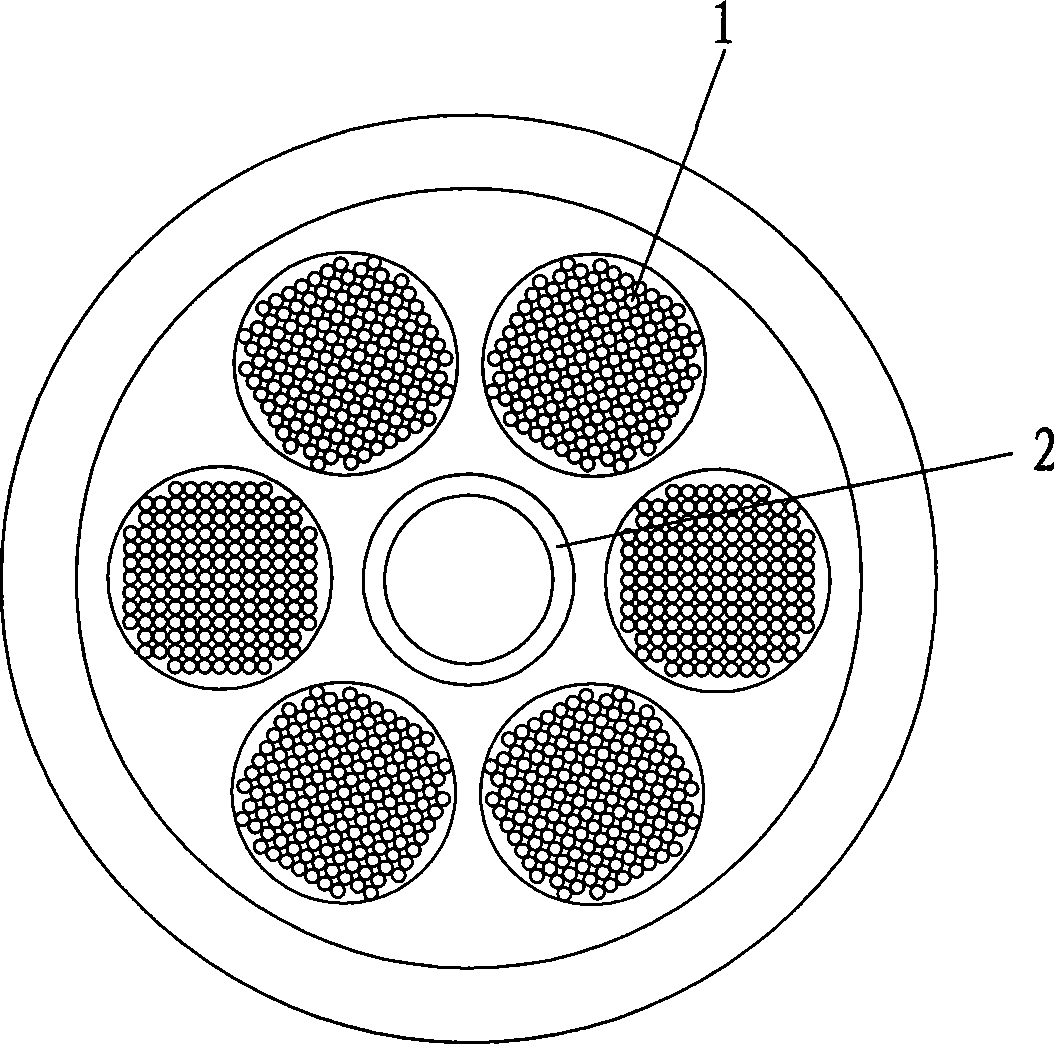

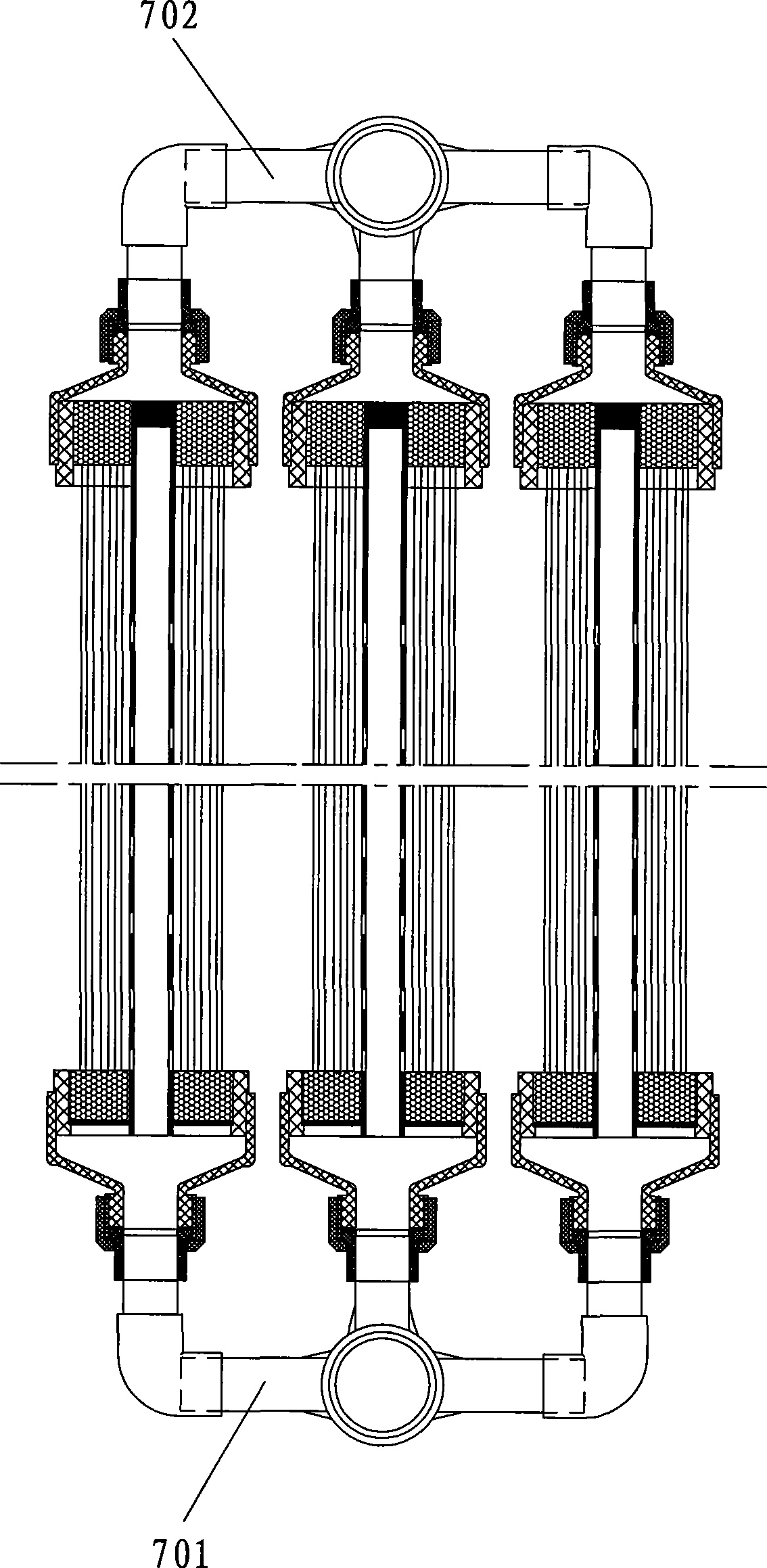

The invention discloses an immersion-type hollow fibrous membrane component and complete equipment thereof and belongs to the technical field of manufacturing a membrane component through water treatment. The immersion-type hollow fibrous membrane component consists of membrane silk bundles, membrane end sockets and a central supporting tube; the membrane silk bundles have at least four bundles and are distributed on the periphery of the central supporting tube; two ends of the membrane silk bundles are provided with one membrane end socket respectively, wherein one membrane end socket is a gas inlet end socket; and the other one is a water producing end socket. A plurality of membrane components can be combined into a small unit and a large unit till membrane stacks on the equipment so as to improve service life of the membrane silk and the membrane component; and the structural design of the membrane component concentrates the advantages that the prior strip curtain-type membrane component is uneasy to pollute and the prior columnar membrane component has large membrane filtering area into a whole and has the advantages of large membrane filtering area, convenient mounting of the membrane component, convenient maintenance and the like.

Owner:XIAMEN LEEBAM MEMBRANE TECH

High carbon steel wire rod for fine steel wire production

The invention provides a high carbon steel wire rod for producing thin steel wire. The wire rod comprises the following chemical components, by weight, 0.6%-0.88% of [C], 0.1%-1.0% of [Si], 0.3%-1.0% of [Mn], less than or equal to 0.015% of [P], less than or equal to 0.010% of [S], less than or equal to 0.020% of [P+S], less than or equal to 0.004% of [N], less than or equal to 0.002% of [O], less than or equal to 0.002% of [Al], less than or equal to 0.002% of [Ti], less than or equal to 0.001% of [Mg], less than or equal to 0.1% of other inevitable impurities, and the balance of iron. With the present invention, the high carbon steel wire rod provided by the present invention has characteristics of reasonable component designing and excellent processing performance; the foreign substances in the wire rod have low melting point, and elongate along a rolling direction during a hot rolling process, and have a length-width ratio more than 3, such that the wire breaking ratio during the steel wire processing is reduced by 16-28%.

Owner:ANGANG STEEL CO LTD

Controlling method for scales on surface of low-carbon cold heading steel hot-rolled wire rods

ActiveCN102601129AShort oxidation timeReduce lossTemperature control deviceTemperature controlWire rod

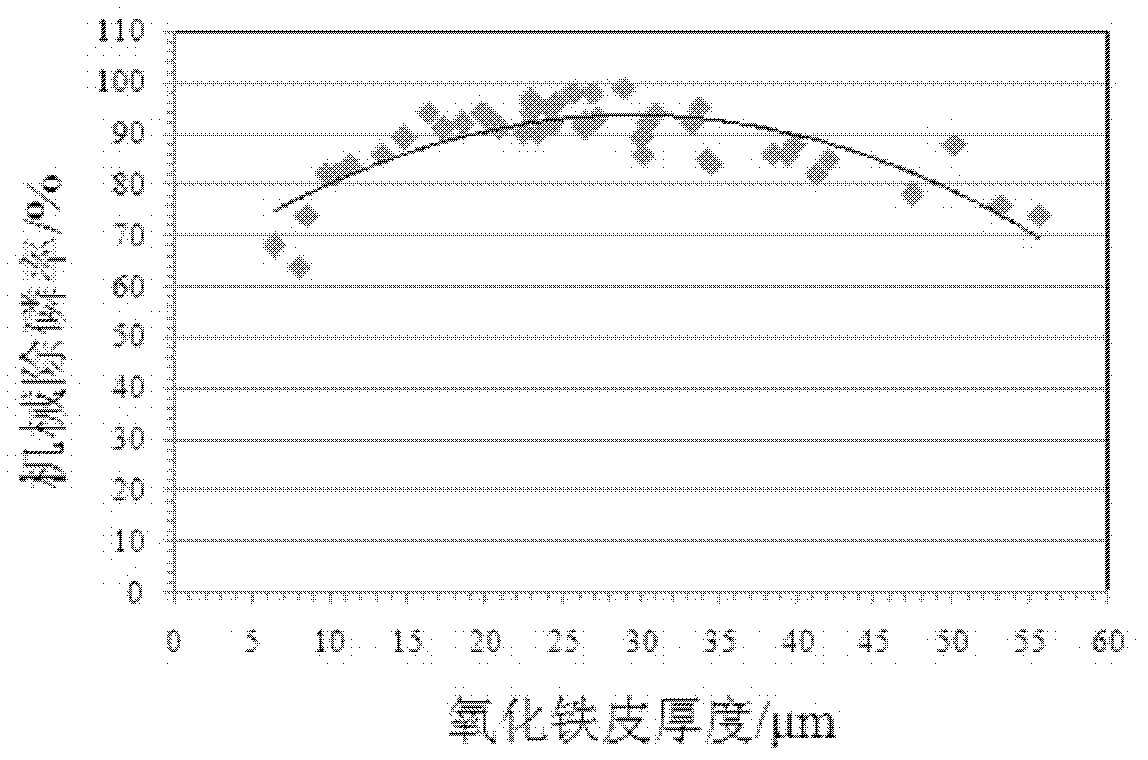

A controlling method for scales on surface of low-carbon cold heading steel hot-rolled wire rods belongs to the field of steel rolling. The method includes steps of precision rolling temperature control, spinning temperature control, and phase-change forepart cooling speed control for an air cooling line. The technical parameters of control includes: controlling the temperature of an entrance of a precision rolling mill in a range of from 900 DEG C to 950 DEG C; controlling the temperature rise in the precision rolling process in a range of from 80 DEG C to 100 DEG C; controlling the spinning temperature in a range of from 880 DEG C to 920 DEG C; adjusting a heat preservation hood of the air cooling line and blower level and controlling the cooling speed of the phase-change forepart of the spun rods in a range of from 2 DEG C per second to 5 DEG C per second; controlling the hood entry temperature in a range of from 760 DEG C to 700 DEG C; and advancing the phase-change area and controlling the time when the wire rods stay in a high-temperature oxidation section in a range of from 60 seconds to 100 seconds. By the method, the thickness of the scales on the surface of the hot-rolled wire rods is controlled evidently in the production of low-carbon cold heading steel SWRCH22A wire rods, mechanical dephosphorization capability is enhanced remarkably while falling during transportation is avoided, and broken rate in spinning and wastage of dies during drawing are reduced.

Owner:SHOUGANG CORPORATION

Wire rod for steel cord and its Al2O3 inclusion control method

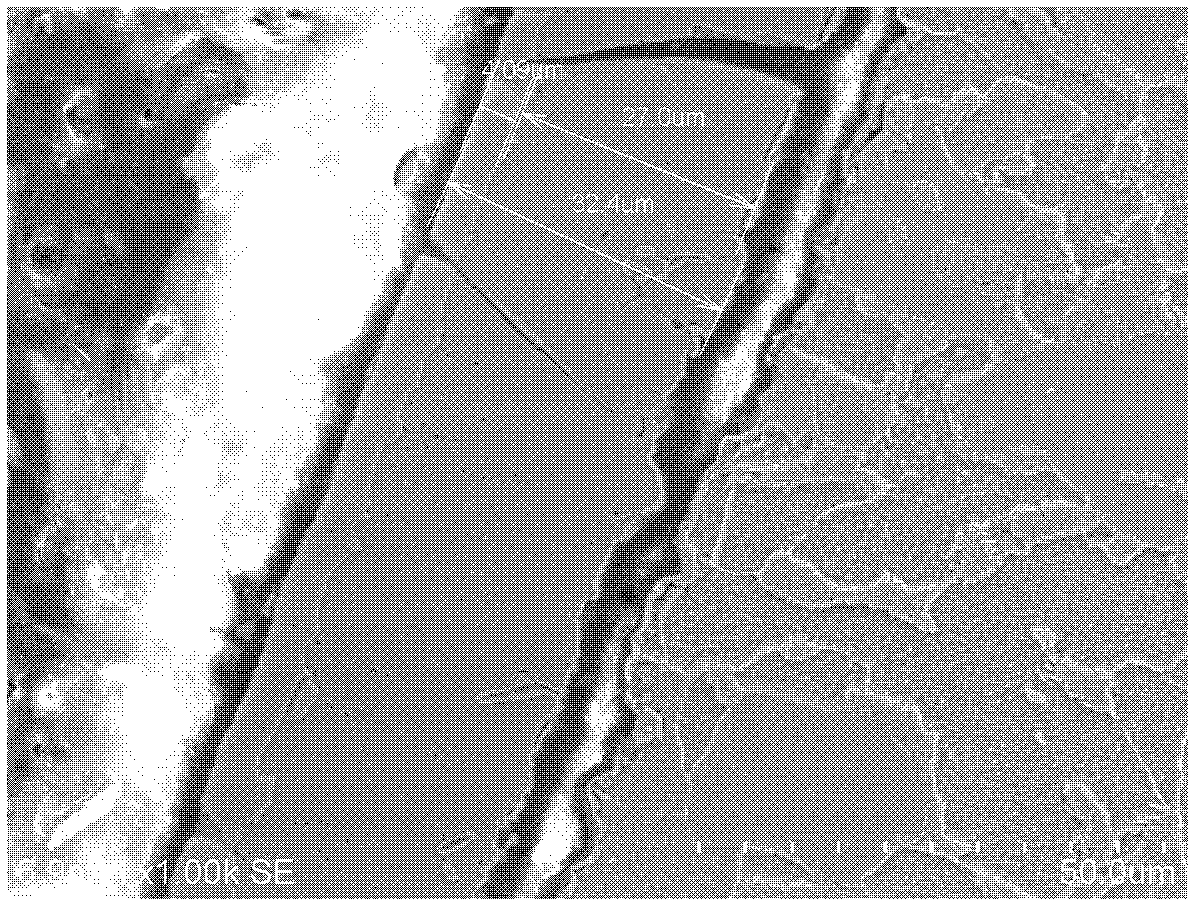

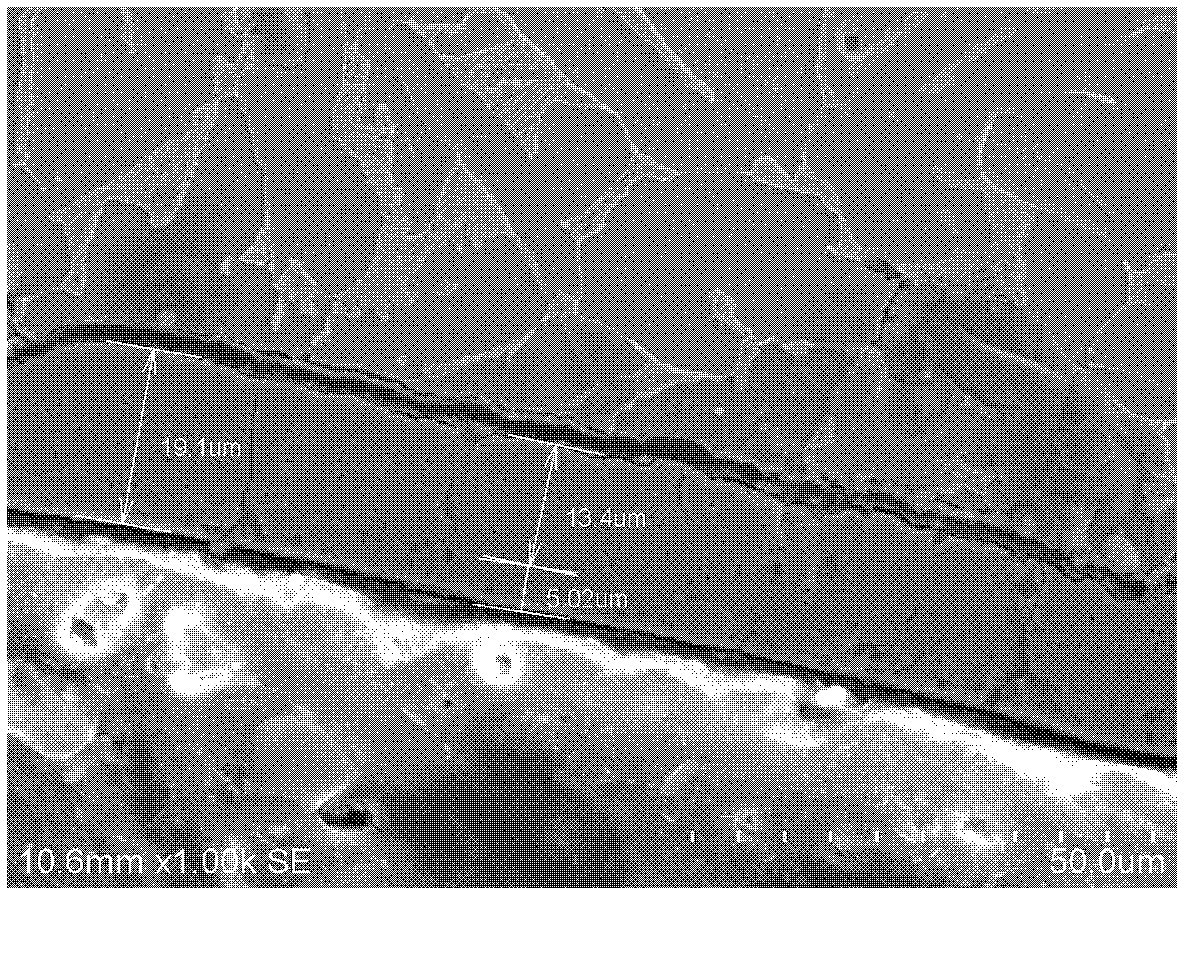

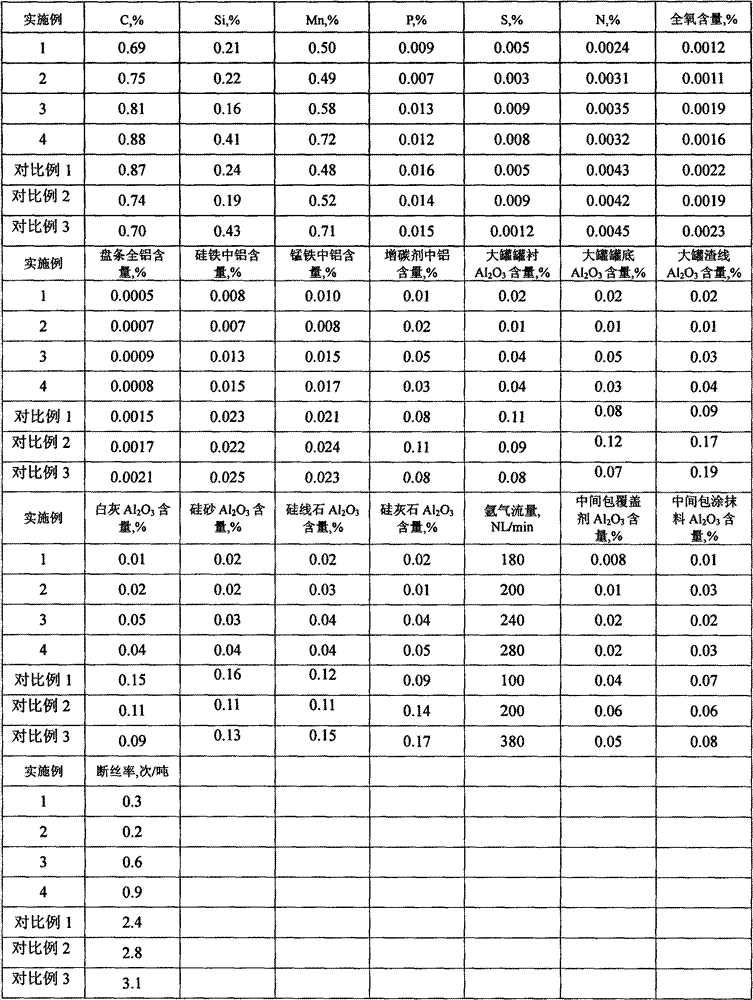

The invention discloses a wire rod for steel cord and its Al2O3 inclusion control method. The wire rod for steel cord comprises 0.68-0.89wt% of C, 0.1-1.0wt% of Si, 0.35-0.80wt% of Mn, 0.015wt% or less of P, 0.010wt% or less of S, 0.004wt% or less of N, 0.002% or less of total oxygen, 0.0010wt% or less of total aluminum, and the balance Fe and inevitable impurities. The Al2O3 inclusion control method comprises the following steps: allowing the content of Si-Fe and Mn-Fe-Al used after converting to be not greater than 0.02% and the content of Al in a carburant to be not greater than 0.05%; allowing the content of Al2O3 in a refractory material at the pot liner, the pot bottom and the slag line of a large pot to be not greater than 0.05% in the refining process and the content of Al2O3 in lime, silica sand, sillimanite and wollastonite slagging materials to be not greater than 0.05%; allowing the large pot used in the molten steel refining to be special; completing the final deoxidation and component micro-adjustment of the wire rod for steel cord within 15min before the ending of an LF furnace refining; carrying out argon stirring treatment of the molten steel, wherein the argon flow is 150-350NL / min; and allowing the content of Al2O3 in a tundish covering agent to be not greater than 0.03% and the content of Al2O3 in a tundish coating to be not greater than 0.04% in the continuous casting process. The Al content in the wire rod for steel cord is not greater than 0.001% in the invention, so the Al2O3 inclusion in the wire rod is eliminated, and the fracture rate of the wire rod in the drawing process is reduced.

Owner:ANGANG STEEL CO LTD

After-roll reinforced cooling process for 82B wire rod steel strand

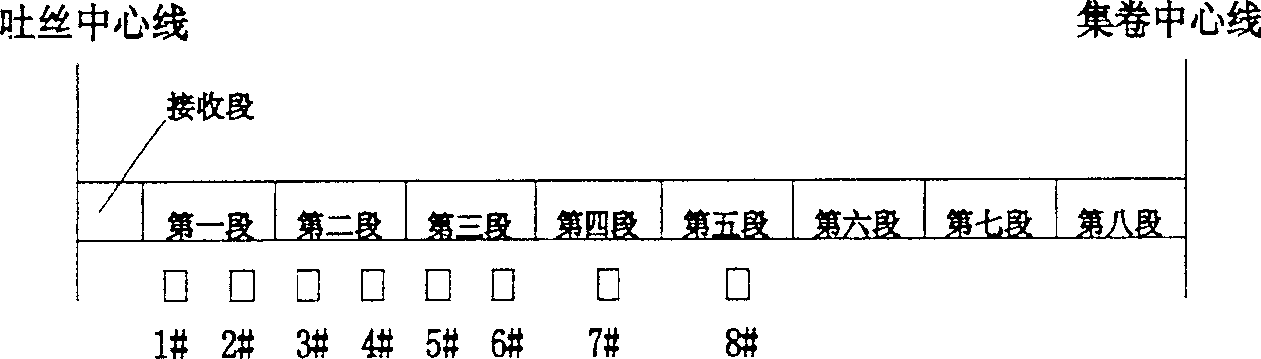

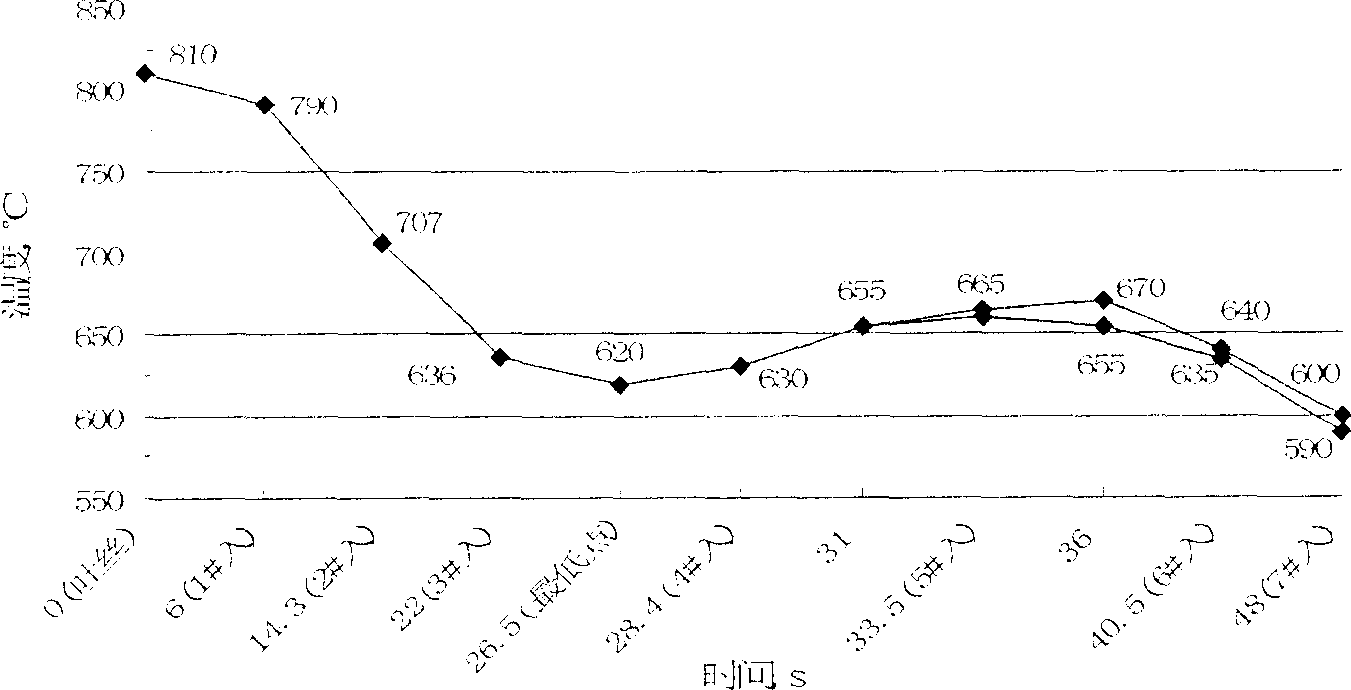

ActiveCN1778486ALower the maximum temperature pointReduce lateral temperature differenceWork treatment devicesMetal rolling arrangementsWire rodAir volume

A forced cooling technology after rolling of the coiled steed rod used for making twisted steel cable features that the roller speed is increased in the temp raising segment of phase changing, the roller speed is lower in the other segments of phase changing, an auxiliary blower is additionally used at the phase changing position, and a small cover plate is used to regulate the transverse distribution of wind for uniform cooling. The resultant coiled steel rod has uniform structure, and high tensional strength (1160-1220 MPa).

Owner:SHOUGANG CORPORATION

Medium carbon steel wire rope and production process thereof

InactiveCN103541249AImprove working environmentReduce consumptionRope making machinesCarbon steelEnergy consumption

The invention relates to a medium carbon steel wire rope and a production process thereof. The medium carbon steel wire rope is characterized in that medium carbon steel (SWRH32A-52A steel or 25#-55# steel) is adopted to sever as a production raw material of the steel wire rope, a phosphating film is coated on the surface of a steel wire of the steel wire rope, and the steel wire rope is made by surface processing, pulling and drawing, normalizing heat treatment, galvanizing, phosphating, pulling and drawing, and stranding and rope combining. The medium carbon steel wire rope and the production process thereof are few in production procedures, low in energy consumption, die consumption and wire breakage rate, and high in labor productivity.

Owner:WUXI UNIVERSAL STEEL ROPE

Stainless steel wire rope and production process thereof

ActiveCN103498112AImprove corrosion resistanceReduce the probability of wire breakageTextile cablesSurface finishingCorrosion

The invention relates to a stainless steel wire and a production process thereof. The stainless steel wire rope is characterized that stainless steel of specific components is used as wire rope production material and the wire rope production material is subjected to surface treatment, drawing, normalizing heat treatment, zincing, drawing, and stranding to obtain a finished wire rope. The stainless steel wire rope and the production process thereof have the advantages that production steps are few, energy consumption, die consumption and wire breakage rate are low, labor productivity is high, and the wire rope is well resistant to corrosion.

Owner:WUXI UNIVERSAL STEEL ROPE

Production method of steel for 82 B steel stranded wires

ActiveCN102211159ARealize cleaner productionProduction organizationManufacturing convertersOxygen contentImpurity

The invention discloses a production method of steel for 82 B steel stranded wires, belonging to the field of metallurgy. In the production method, the steel for the 82 B steel stranded wires is produced by adopting the process flow comprising the following steps of: rotating furnace primary smelting, LF (Low Frequency) refining, RH (Relative Humidity) refining and continuous casting and pouring of a large square billet, wherein the tail end of a solidification end is dynamically and lightly downwards pressed in the procedure of the continuous casting and pouring of the large square billet. According to the production method disclosed by the invention, technologies, i.e. rotating furnace whole-course bottom argon blowing, argon blowing after tapping, RH vacuum degassing, impurity removal,crystallizer electromagnetic stirring, and the like, are adopted in the process flow, and therefore the clean production of the steel for the 82 B steel stranded wires is realized; an antegrade production organization is achieved; obtained components and the quality of casting blanks all meet the requirements for steel grades, and the total oxygen content (T[O]) in the steel is less than 0.0020 percent; and wire breakage does not appear in the wire drawing process of a product, and therefore the wire broken rate of the wire drawing process is reduced.

Owner:PANZHIHUA IRON AND STEEL +2

Method for manufacturing continuous casting low carbon steel containing boron in small square billets

InactiveCN1600885ASolve the blockageReduced content of work hardening elementsManufacturing convertersOxygenBoron

This invention relates to a method for prodn. of square billets of low carbon and high boron content steel by billet caster. The prodn. procedure comprises: removing-sulfure from molten pig iron and slag-removing; converter steel smelting by top-bottom blowing; blocking slag and tapping steel; oxygen-removing and alloying in steel-ladle; modifying slag in steel-ladle; fine-smelting in steel-ladle by blowing argon; feeding-in AL, Ca-Si line, boron line, soft blowing argon, full protection casting in billet caster; after the activity of oxygen reaches the controlled target Ca-Si line is fed to modifying impurities, then boron line is fed (boron absorbing rate being 40-50% being considered), Mn / S ratio being not less than 13. Advantages are: no problem of blocking runner, low hardening elements, so, no serious bubbles formation problem.

Owner:SHOUGANG CORPORATION +1

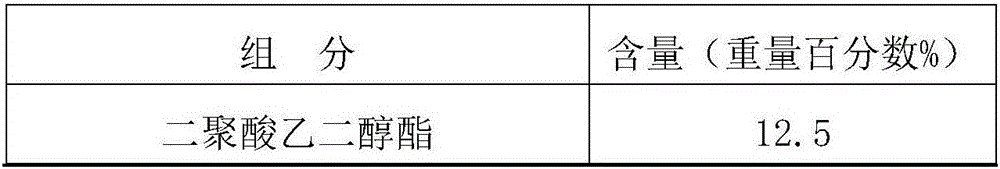

High-intensity brass plating wire drawing lubricant and preparation method thereof

ActiveCN106350190AImprove the lubrication effectReduce lossLubricant compositionWater basedOperability

The invention relates to a high-intensity brass plating wire drawing lubricant and a preparation method of the high-intensity brass plating wire drawing lubricant. The high-intensity brass plating wire drawing lubricant is prepared by heating oiliness agent, phosphorus-containing extreme pressure agent and emulsifying agent to 100-120 DEG C; adding water at 90-100 DEG C under the continuously stirring, and then cooling to 40 DEG C below; adding antiseptic antirust agent, mildew preventive, and antifoaming agent; evenly stirring and obtaining the product. The invention has the beneficial effects that (1) the water-based lubricant provided by the invention is good in lubricating performance, and used for drawing the high-intensity brass plating wire; the drawing speed is high, the mould loss is low, the fracture rate is low, surface of the steel wire is clean and smooth; besides, the drawing residue is few; the lubricant is highly and stably bonded with rubber, and can replace import product, thus the domestication progress of the metal product industry is promoted, the economic benefit and social benefit are significant. (2) The preparation technique of the water-based lubricant is reasonable, operability is strong, and production environment fits for the national environmental protection requirements.

Owner:湖北省化学工业研究设计院 +1

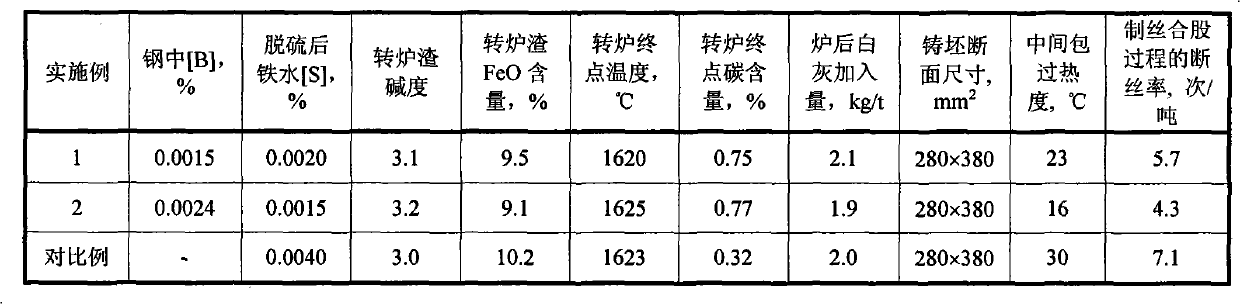

High carbon hard wire rod production method

InactiveCN103334049AReduce carbon segregation indexReduce the probability of wire breakageWire rodLadle furnace

The present invention relates to a high quality 82B high carbon hard wire rod production method, which is characterized in that a large square billet continuous casting billet with a cross section of 280 mm*380 mm is adopted, and a double steel rolling process is performed to produce. The process route comprises: smelting through a converter, ladle refining through a LF furnace, vacuum degassing through a VD furnace, large square billet continuous casting (280 mm*380 mm), track beam breakdown (152 mm*152 mm), and high speed wire rod rolling. The production method has the following advantages that: the large square billet continuous casting billet with the cross section of 280 mm*380 mm is adopted to roll, and process parameter control is combined so as to reduce a carbon segregation index of the casting billet, reduce a wire breaking rate of the wire rod, and improve steel material quality.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

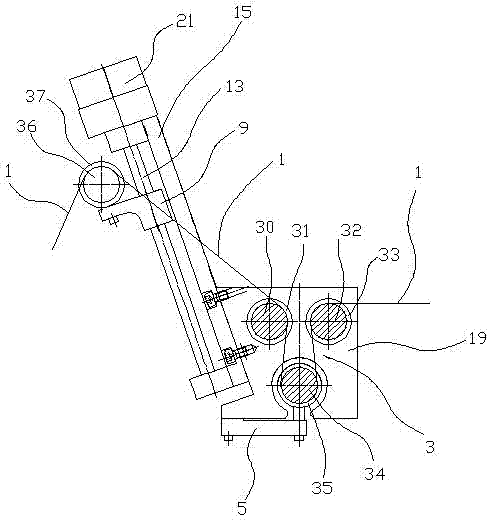

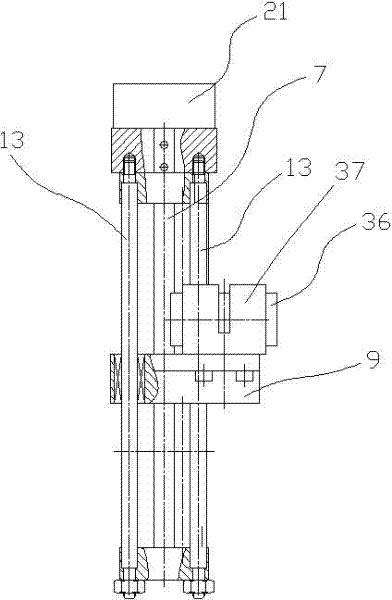

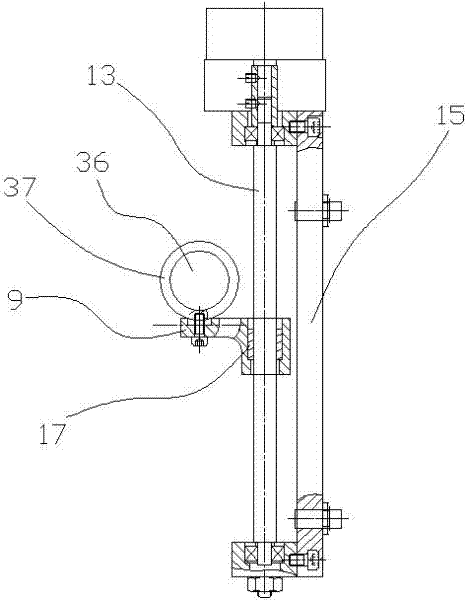

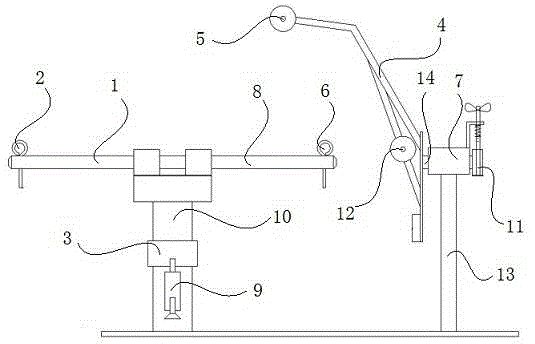

Linear cutting molybdenum wire tensile force automatic control system and tensile force control method

InactiveCN102416510AAutomatic tension adjustmentImprove the finishElectrical-based machining electrodesMicrocontrollerMachine parts

The invention discloses a linear cutting molybdenum wire tensile force automatic control system and tensile force control method. The linear cutting molybdenum wire tensile force automatic control system comprises a plurality of guide wheels, a driving device, a sensor and a control unit, wherein molybdenum wire are wound on the guide wheels; the driving device is used for driving one guide wheel to slide; and the control unit receives a sensor signal and allows the driving device to drive the guide wheels to slide. The tensile force control method comprises the following steps: presetting a standard value on a singlechip; allowing the senor to acquire the value of the ensile force of a molybdenum wire; allowing the singlechip to convert the value of the tensile force into a comparison value; summing the comparison value and a standard value to obtain a driving value; if the driving value is bigger than zero, allowing a step motor to rotate anticlockwise, and if the driving value is smaller than zero, allowing the step motor to rotate clockwise; and repeating the previous step till the driving value is zero. In the invention, the tensile force of the molybdenum wire can be regulated automatically, and the smooth finish of a machined part can be improved greatly.

Owner:NINGBO HUIJIN METAL PRODS

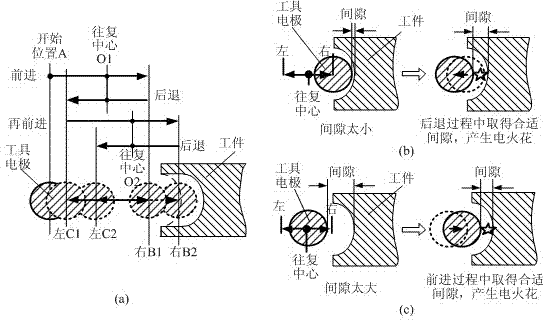

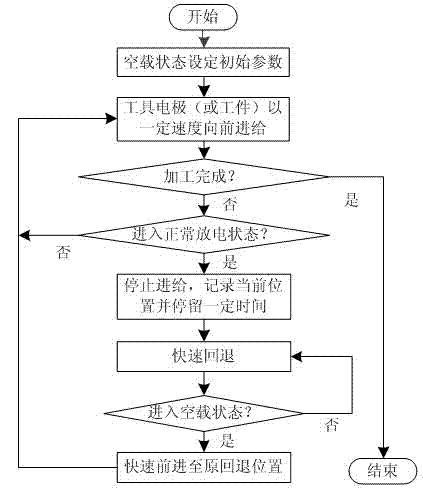

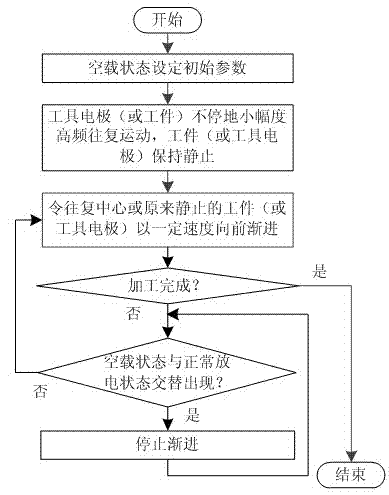

Reciprocating progressive self-adaptive feed control method for electrical spark machine tool

ActiveCN103752962AImplement automatic trackingAchieve holdElectric circuitsAdaptive controlSemiconductor materialsReciprocating motion

The invention discloses a reciprocating progressive self-adaptive feed control method for an electrical spark machine tool. A tool electrode in the electrical spark machine tool is controlled to perform a reciprocating progressive feed motion with a workpiece in an integral manner of reciprocating motion and progressive motion or in a separated manner of reciprocating motion and progressive motion so as to realize high-efficiency and high-quality electrical spark machining of a difficult-to machine material, particularly a semiconductor material, with a metal material. An appropriate discharge gap is automatically formed between the workpiece and the tool electrode, so that normal electrical spark discharge is promoted, continuous machining is ensured, and the method has the beneficial effects of quick chip removal and cooling, preventing the electrode from burning, improving the quality of machining surface, improving the machining efficiency, being wide in application range and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

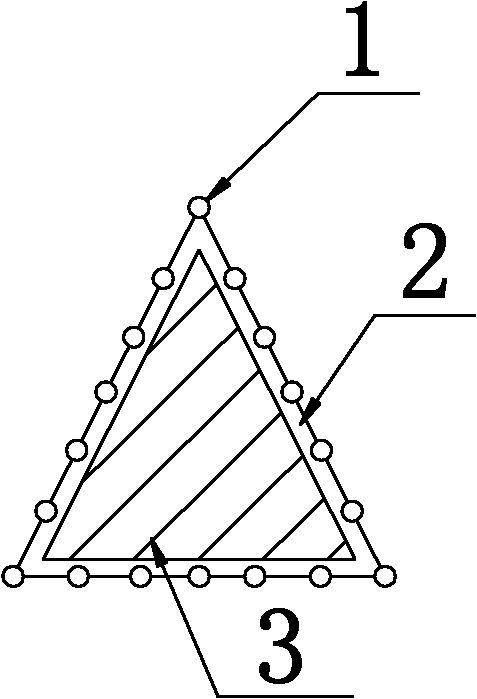

Technology of preparing special-shaped cutting steel wire

InactiveCN102166584AFast cutting speedSimple preparation processExtrusion cleaning devicesMetal rolling arrangementsEllipseElliptic cylinder

The invention relates to a technology of preparing special-shaped cutting steel wire, comprising the following steps: (1) coarse wire drawing, during which step the steel wire rod of Phi5.5-6.5mm is drawn into the steel wire of Phi2.80-3.25mm, (2) middle filament heat treatment, (3) intermediate drawing, during which step the steel wire of Phi2.80-3.25mm is drawn into the steel wire of Phi 0.76-1.15mm, (4) wet drawing, during which step the steel wire of Phi0.76-1.15mm is drawn into the steel wire of Phi0.08-0.3mm, (5) press rolling, during which step the steel wire is rolled into the steel wire having a cross section of polygon or ellipse, (6) electroplate / bonding, during which step SiC or diamond particle abrasive is fixed upon the external surface of the steel wire in an electroplating or glue-bonding manner, and (7) taking up, during which step the finished product is obtained. The preparing technology of the invention is simple, environment-friendly, efficient, and of low cost. The cutting steel wire prepared via this technology takes the shape of elliptic cylinder or polygon body, with hardness and tensile strength substantially improved, effectively decreasing the wire-broken rate, accelerating cutting speed of steel wire, and improving the cutting efficiency.

Owner:合肥得一新材料科技有限公司

Halogen filament and process for manufacturing the same

InactiveCN101083202AImprove grain boundary strengthHigh tensile strengthLamp incadescent bodiesRheniumPotassium

The invention provides a halogen filament and the making method thereof, as compared with traditional anti-drooping filament, W-Re alloy wire has high recrystallization temperature and greater crystal grain length-width ratio and contains K, Al and Si doping agents, and the crystal grain length-width ratio is greater than 15; and the content of Re in the alloy is 0.4-0.8mass%. And the concrete making process comprises: preparing alloy powder with Re content of 0.4-0.8mass%, and preparing W-Re alloy sintered bar by isostatic pressing, presintering and vertical sintering; making the sintered bar into W-Re alloy wire by rotary swaging and drawing and coiling the W-Re alloy wire into filament. And the filament has stable crystal grain structure and can better apply to halogen W lamps.

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

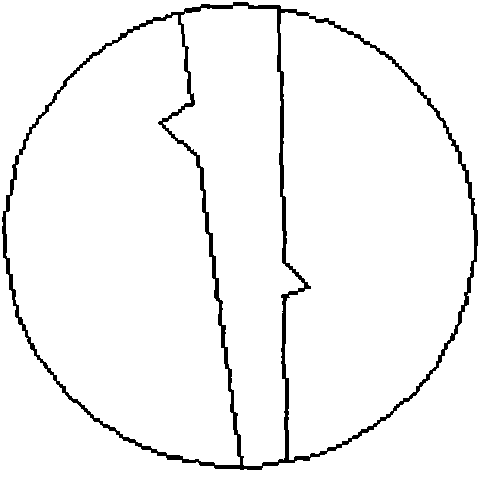

Method for manufacturing viscose-based graphite felt

InactiveCN102031638AHigh tensile strengthImprove toughnessHeating/cooling textile fabricsNon-woven fabricsPorosityGraphite

The invention relates to a process for manufacturing viscose-based graphite felt. The process comprises the following steps of: selecting wood pulp plant viscose-based fibers as a raw material; needling into a felt body by a domestic novel needle machine; and performing preoxidation treatment, special carbonizing treatment and special graphitizing treatment. The viscose-based graphite felt has the characteristics of extremely high tensile strength, high toughness and porosity, low thread break rate, thread yield of between 30 and 33 percent, high purity, stable performance, superior electrical property and the like. The treatment temperature of the viscose-based graphite felt reaches 2,200 DEG C.

Owner:GANSU HAOSHI CARBON FIBER

Production process of stainless steel wire rope

InactiveCN107675534AReasonable formulaEasy to produceCoatingsTextile cablesChemical compositionUltimate tensile strength

The invention discloses a production process of a stainless steel wire rope. The process is characterized in that stainless steel is adopted as a steel wire rope production raw material, and the chemical components of stainless steel include, by mass, 0.012-0.025 % of C, 0.06-0.075% of Si, smaller than 0.03% of P, 0.20-0.30% of W, 15.0-19.0% of Cr, 20.0-23.0% of Ni, 1-1.5% of Mo, 2.50-5.00% of Mn,smaller than 0.03% of S, smaller than 0.1% of Cu, smaller than 0.01% of N, smaller than 0.02% of Ti and the balance Fe and inevitable impurities. The process specifically includes the following stepsof firstly, surface treatment; secondly, drawing; thirdly, normalizing heat treatment and galvanizing; fourthly, drawing; fifthly, stranding to form the rope. The process is reasonable in formula, simple in production process, low in energy consumption, low in fracture rate, high in production efficiency, excellent in comprehensive after-performance, especially large in tensile strength, good incorrosion resistance and worthy of popularization.

Owner:江阴市灵达机械制造有限公司

Ultra-low carbon steel fine wire drawing method

InactiveCN106311781AAvoid secondary rapid work hardeningPrevent wire breakageFurnace typesHeat treatment furnacesWire rodRapid processing

The invention discloses an ultra-low carbon steel fine wire drawing method, which comprises a first stage of drawing process, a recrystallization annealing process, and a second stage of drawing process. According to the first stage of drawing process, the total deformation is calculated to be 75 percent to 85 percent according to a wire rod axial circle area. The method is applicable to the processing field of products such as copper-clad steel wires and electronic leading wires. The cold plastic deformation is hardly carried out during a second-time rapid processing and hardening process, so that the occurrence of the phenomenon that the tensile strength of middle wires is too high can be effectively avoided, the wire breaking rate can be remarkably reduced, the middle wires are prevented from being processed and hardened excessively, and the die loss is reduced; the finished products i.e. fine wires obtained according to the method provided by the invention can meet the requirement of low tensile strength. The ultra-low carbon steel fine wire drawing method provided by the invention has no special requirement on drawing equipment, is applicable to a common connecting tank drawing machine, and has no need to increase equipment and reformation investment; the diameter of each winding drum can be equal or unequal; and the ultra-low carbon steel fine wire drawing method provided by the invention is applicable to ultra-low carbon steel with the carbon content being not more than 0.05 weight percent, and the raw material steel types are wider.

Owner:XINGTAI IRON & STEEL

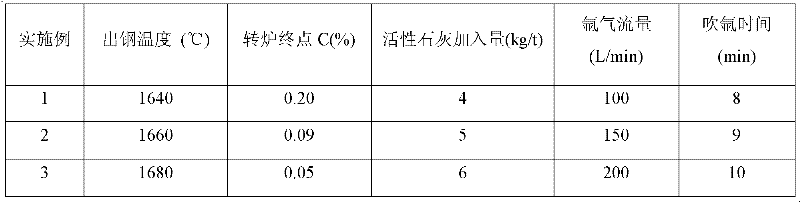

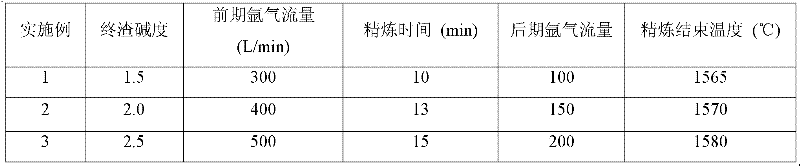

Process for smelting and continuously casting boron-containing high carbon steel for wire production

InactiveCN102019392AEvenly distributedAvoid gatheringManufacturing convertersProcess efficiency improvementHigh carbonBoron containing

The invention provides a process for smelting and continuously casting boron-containing high carbon steel for wire production. The process comprises the following steps of: 1) pretreating molten iron, namely controlling the sulphur content to be below 0.005 percent; 2) smelting by using a converter, namely producing high-basicity dregs at the earlier stage, wherein the basicity of the top dregs is 2.0 to 4.5, the FeO content is 8 to 20 percent, and the final temperature is between 1,600 and 1,680 DEG C; performing high-carbon tapping at the end of the smelting, namely controlling the carbon content to be 0.05 to 0.2 percent of the target carbon content of the steel; deoxidizing by using Si-Mn; and covering the pot by using 1 to 3 kg / t of white ashes after tapping; 3) refining by using a ladle furnace (LF), namely refining at the temperature of between 1,550 and 1,620 DEG C; adjusting molten steel components according to the target boron content of the steel before the end; and 4) performing continuous casting by a low superheat degree continuous casting process, wherein the superheat degree of tundish molten steel is between 10 and 23 DEG C. The process provided by the invention effectively promotes uniform distribution of boron elements in billet steel, prevents steel quality worsening by boron element gathering, and makes full use of the advantages of boron in the steel. The process can reduce the wire breaking rate of boron-containing high carbon steel rolled wires in the wire production gathering process by 18 to 25 percent.

Owner:ANGANG STEEL CO LTD

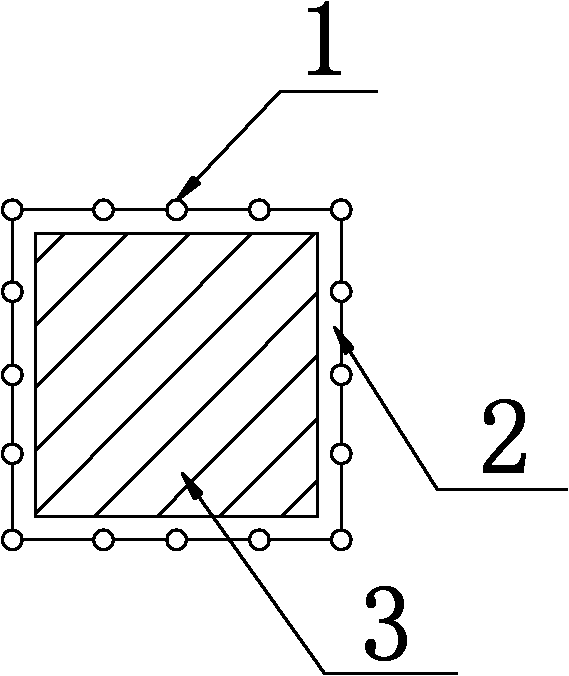

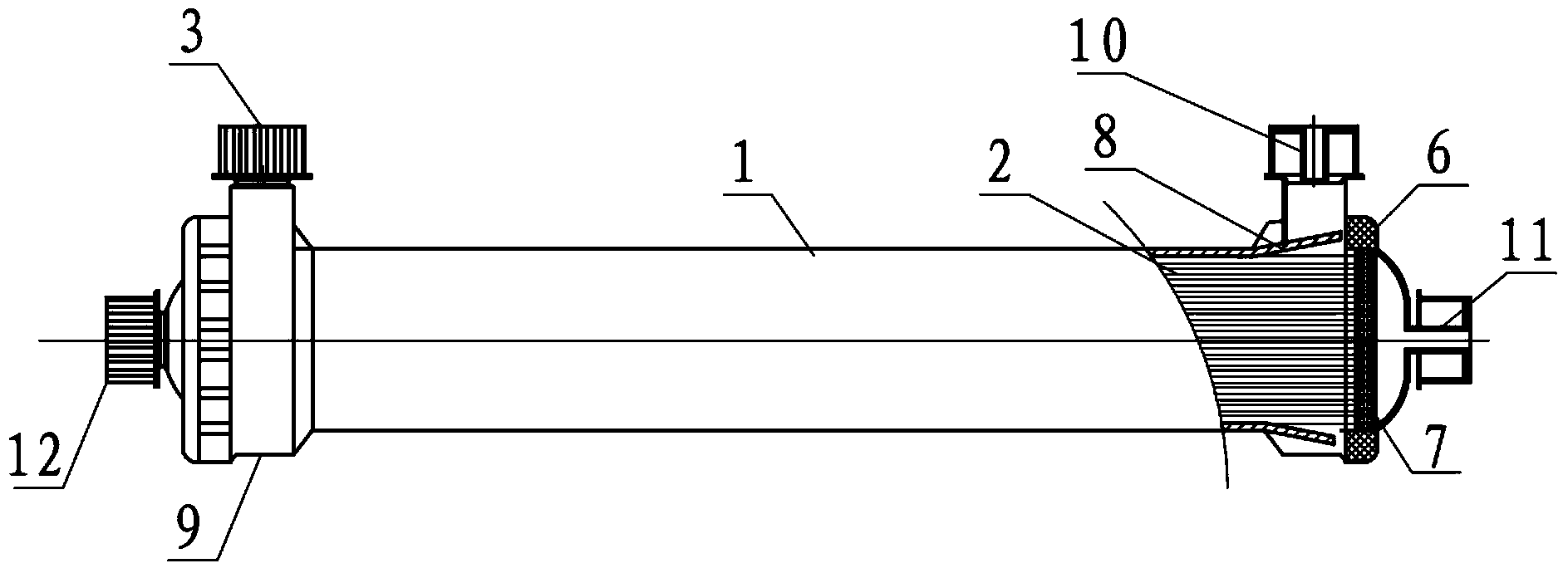

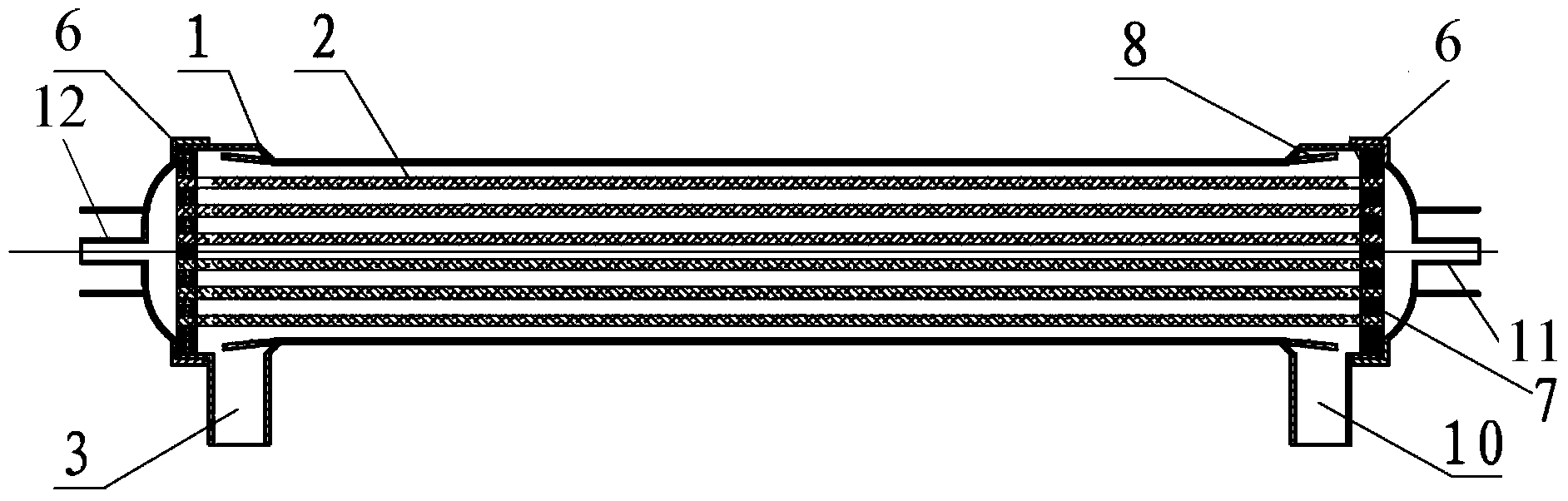

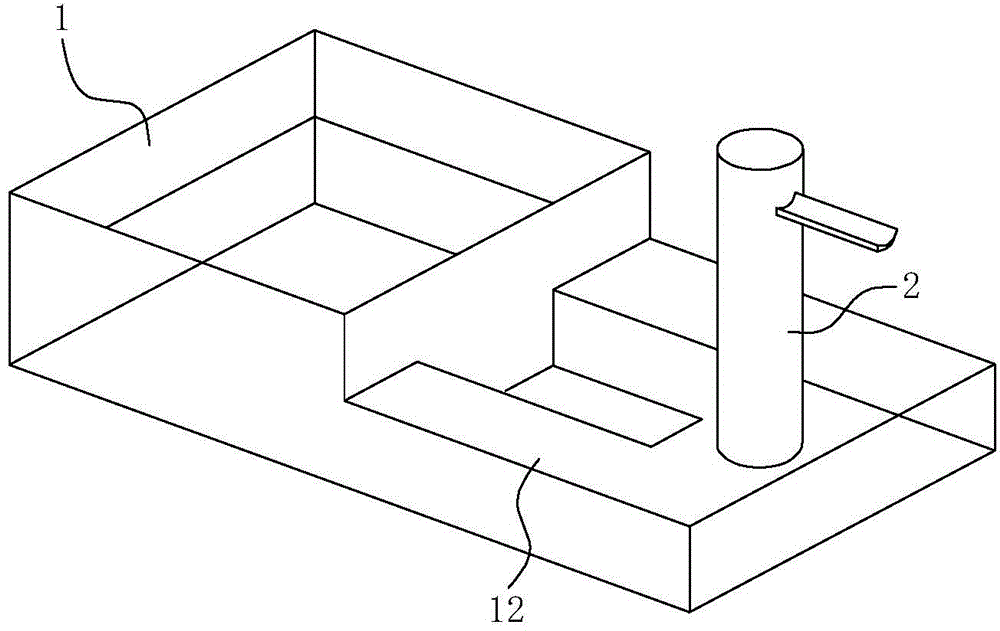

Hemodialyzer and hematodialysis device

ActiveCN103877634ATo achieve the effect of turbulenceReduce the probability of wire breakageSemi-permeable membranesDialysis systemsHollow fibreFiber

Provided are a hemodialyzer and a hematodialysis device. The hemodialyzer comprises an outer shell, a fiber bundle formed by a hollow fiber pipe, an end cover, packaging glue, an annular flow guiding distribution ring, a dialyzate inlet, a dialyzate outlet, a blood inlet and a blood outlet. The annular flow guiding distribution ring is placed at the positions right opposite to the dialyzate inlet and / or the dialyzate outlet, one end of the annular flow guiding distribution ring is connected to the tail end of the outer shell, and the other end of the annular flow guiding distribution ring inclines in the longitudinal direction of the outer shell toward the dialyzate inlet or the dialyzate outlet right opposite to the annular flow guiding distribution ring. The hollow fiber pipe is made of a polyether sulfone hollow fiber film, and the spinning dope of the polyether sulfone hollow fiber film comprises, by weight, 250 parts-650 parts of modified polyether sulfone blends, 20 parts-400 parts of hydrophilia molecular compounds, 1 part-90 parts of nano-modification hydroxide radical titanium dioxide blends and 20 parts-120 parts of alcohols solvents. The hemodialyzer improves the contact area and the removal rate of dialyzate and the surface of the fiber pipe, and the high removal rate and the high ultrafiltration coefficient are achieved.

Owner:广东达爱斯医用科技有限公司

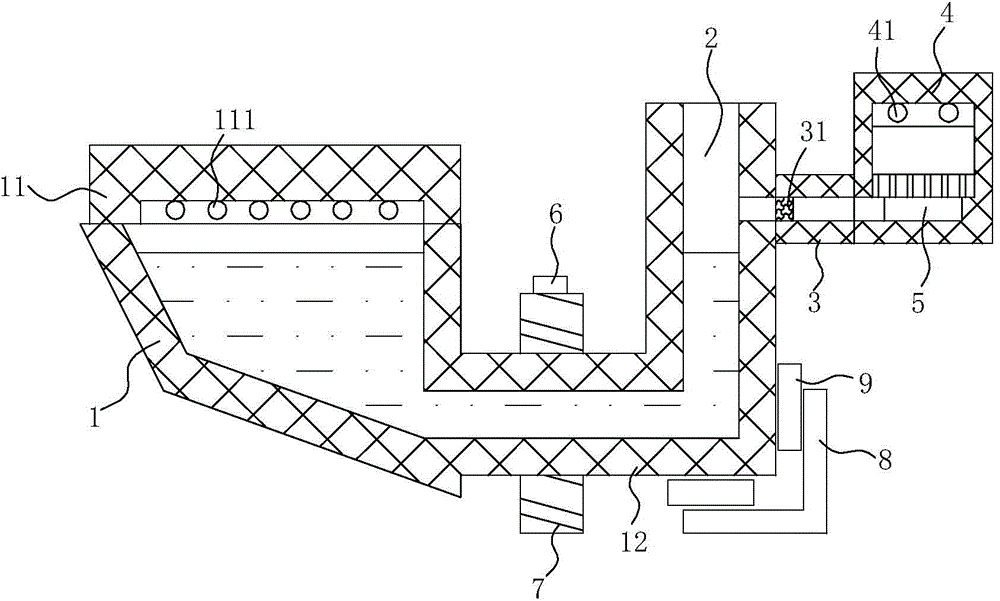

Rolling method for solving continuous cast billet shrinkagehole segregation

ActiveCN1978674AReduce the probability of wire breakageImprove plasticityRoll mill control devicesMetal rolling arrangementsHigh pressureMetallurgy

The invention relates to rolling method used to solve continuous casting small square billet porous shrinkage cavity. It includes the following steps: heating, high pressure water de-scaling, rolling and cold controlling. Its features are that in heating, hot section temperature is increased to 1250+ / -20 degree centigrade and remained for 65+ / -5 minutes; before rolling, the pressure in high pressure water de-scaling is controlled at 70-150MPa; rolling temperature is controlled at 1020-1060 degree centigrade. This method can make the porous shrinkage cavity of the small square billet center seam.

Owner:SHOUGANG CORPORATION

Preparation method of 5356 aluminum alloy ingot

ActiveCN104894443AImprove uniformityEasy to control temperatureIncreasing energy efficiencyMagnetic currentTemperature control

The invention relates to a preparation method of a 5356 aluminum alloy ingot. The method uses an electromagnetic effect for heating and for preserving the temperature of an alloy melt, so that the temperature control is convenient; at the same time of heating, as alternating current supplied in an induction coil can form variable magnetic current, and the variable magnetic current can form induction current in an annular pipe communicated with a crucible, the melt circularly flows by surrounding the annular pipe to achieve a stirring effect, and the component and structure uniformity of the aluminum alloy ingot is effectively improved; under the stirring effect generated by the induction coil, the vacuum purification treatment is supplemented to effectively improve the dispersion speed of hydrogen atoms in the melt, so that the high-speed degassing is facilitated, the degassing effect is enhanced, and the hydrogen content in the 5356 aluminum alloy ingot is reduced; and through detections, the hydrogen content of the 5356 aluminum alloy ingot prepared by the method is lower than 0.15 mL / 100 gAl.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

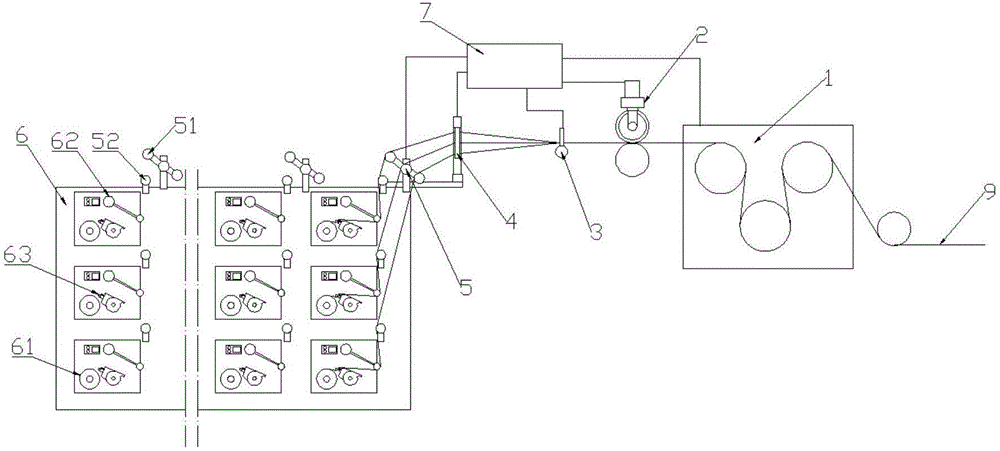

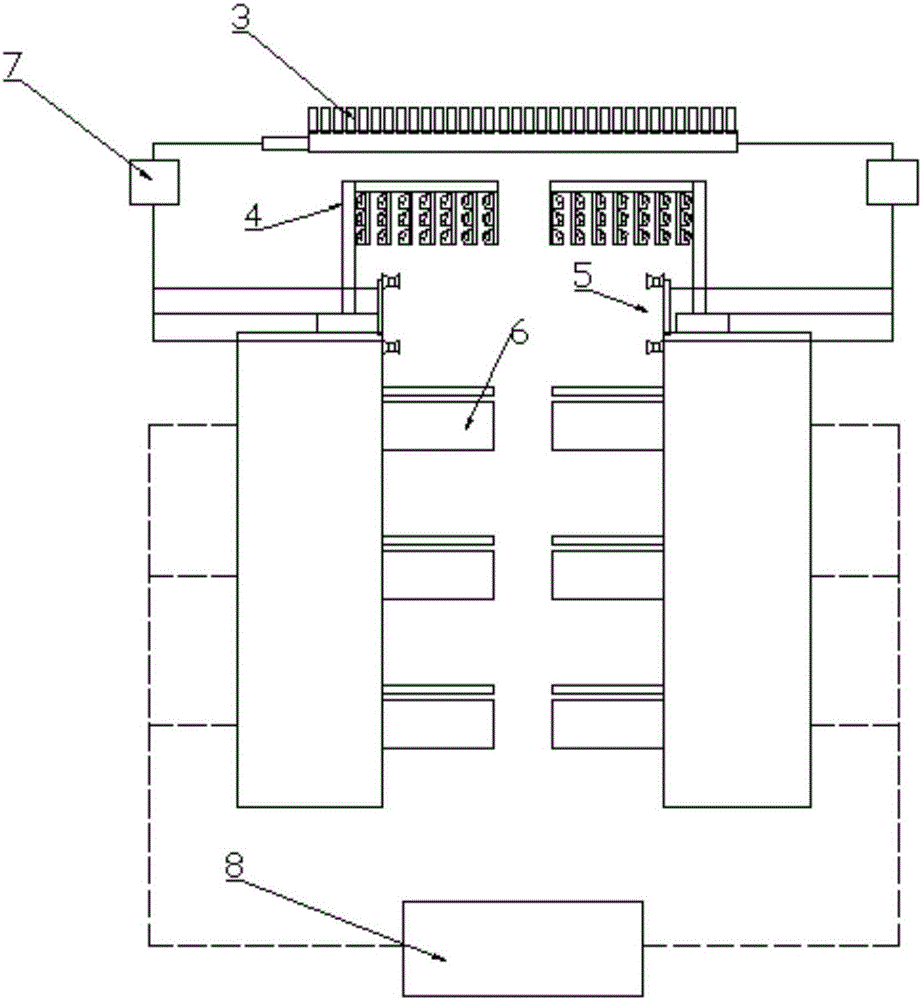

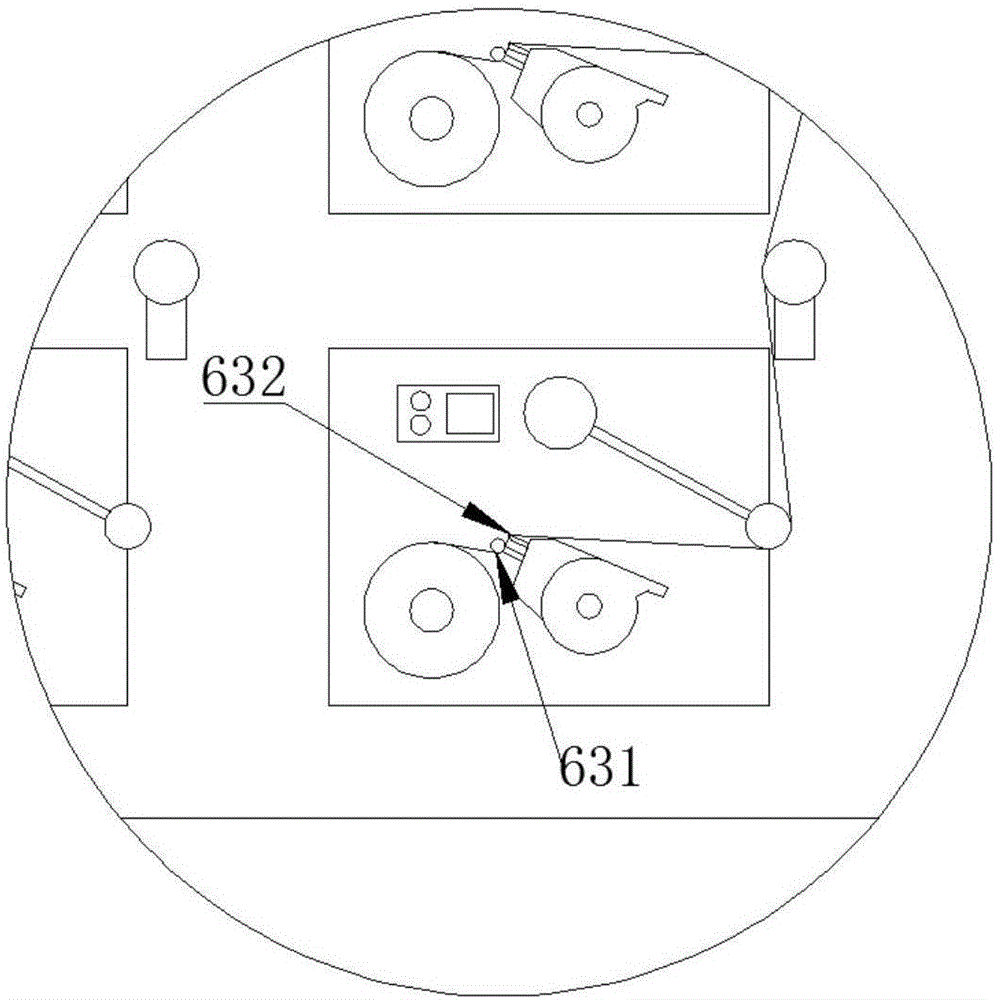

Multi-spinning-station carbon fiber precursor rolling device

ActiveCN106629232AReduce the probability of wire breakageImprove product qualityFilament handlingElectrostatic chargesFiberCarbon fibers

The invention discloses a multi-spinning-station carbon fiber precursor rolling device and belongs to the technical field of carbon fiber processing equipment. The device comprises a static electricity elimination device, a precursor division device, a precursor division guide device, a guide wheel set and winding devices, wherein the precursor division device, the precursor division guide device, the guide wheel set and the plurality of groups of winding devices are connected with the static electricity elimination device; the precursor division device comprises precursor division channels of which the quantity is not less than that of the winding devices; a conduction ceramic hook connected with the static electricity elimination device is arranged on the precursor division guide device; conductive ceramic wheels connected with the static electricity elimination device are arranged on the guide wheel set; the winding devices comprise power mechanisms, precursor winding shafts which are connected with the power mechanisms and used for winding the precursors, a tightness regulating device and a winding guide device. According to the device disclosed by the invention, the drafted carbon fiber precursors sequentially pass through the precursor division device, the precursor division guide device and the guide wheel set and then pulled to the plurality of groups of winding devices, so that multi-station division winding can be realized after one-step drafting, and the working efficiency is greatly improved.

Owner:HARBIN TIANSHUN CHEM TECH DEV CO LTD

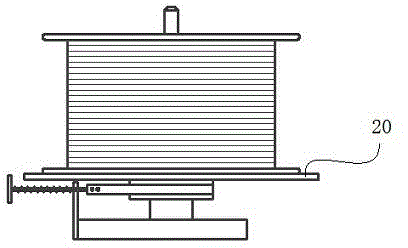

Thermal treatment double-station uninterrupted unwinding device

The invention discloses a thermal treatment double-station uninterrupted unwinding device. The thermal treatment double-station uninterrupted unwinding device comprises a station bracket, coil bobbins and an unwound wire bracket, wherein two unwinding shafts are respectively horizontally arranged at the upper end of the station bracket. Steel wire heads and tails on the two coil bobbins are welded well by a welding machine. When the unwinding of the first reel of wires is about to end, an operator treads on a pedal type positioning pin, the coil bobbins horizontally rotate for 180 degrees, and conversion can be finished. Then, the welding work of the next reel is prepared. The whole process is more convenient and flexible, the continuous conduction of procedures is not affected, consumed labor is less, and the work efficiency is improved. Moreover, unwinding tension is constant, the tension of a tension band does not need to be frequently regulated, the wire breakage rate is reduced, and the stretching of steel wires in the hot galvanizing treatment process is reduced.

Owner:JIANGSU SHENWANG GRP STEEL CABLE CO LTD

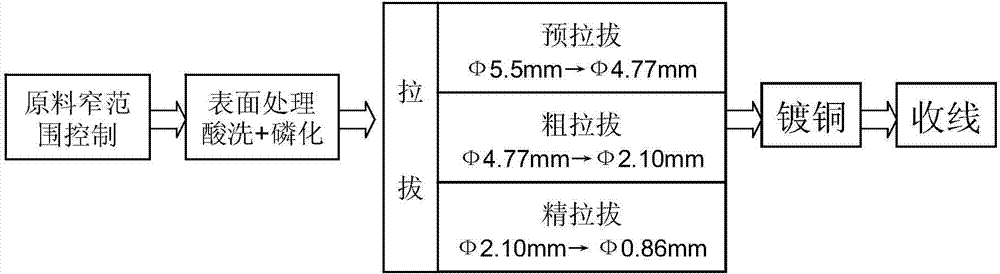

Novel process for producing low carbon gas shielded welding wire

ActiveCN103753056AHelp with attachmentUniform adsorptionLiquid/solution decomposition chemical coatingWelding/cutting media/materialsWire rodCopper plating

Disclosed is a novel process for producing a low carbon gas shielded welding wire. The novel process for producing the low carbon gas shielded welding wire includes following steps of (1) raw material selection, (2) surface treatment processes, (3) drawing process and (4) copper plating process, wherein the step (1) includes that as for steel wire rod composition, C is equal to 0.06-0.010%, Si is equal to 0.80-1.00%, Mn is equal to 1.40-1.60%, P or S is smaller than or equal to 0.020%, and Ca is smaller than or equal to 0.0015%; the step (2) includes an acid pickling process and a phosphating process, as for the acid pickling process, pickling solution proportion includes that prewash hydrochloric acid concentration is 5-10%, hydrochloric acid concentration for substrate washing is 15-20% and FeC12 is smaller than or equal to 300g / l, acid pickling time is 10-25minutes, washing is performed by high pressure water instantly after acid pickling, and as for the phosphating process, phosphating solution proportion includes that Ta total acidity is 50-110pt and Fa free acidity is 5-20pt, phosphating temperature is 70-80DEG C and phosphating time is 1-3 minutes. By means of the novel process for producing the low carbon gas shielded welding wire, a chemical adsorption film is formed on the surface of a steel wire rod, a thin phosphating film is formed on the surface of the steel wire rod by mid-temperature phosphating process and short phosphating time, adsorption of surface lubricating agents is more uniform and compact, the steel wire rod is directly drawn to form a finished product wire in an unannealed state after surface treatment, costs are reduced by 50-80 yuan / ton compared with those of common processes, the wire breaking rate is decreased by 70%, and the producing efficiency is increased by 40%.

Owner:TIANJIN IRON & STEEL GRP

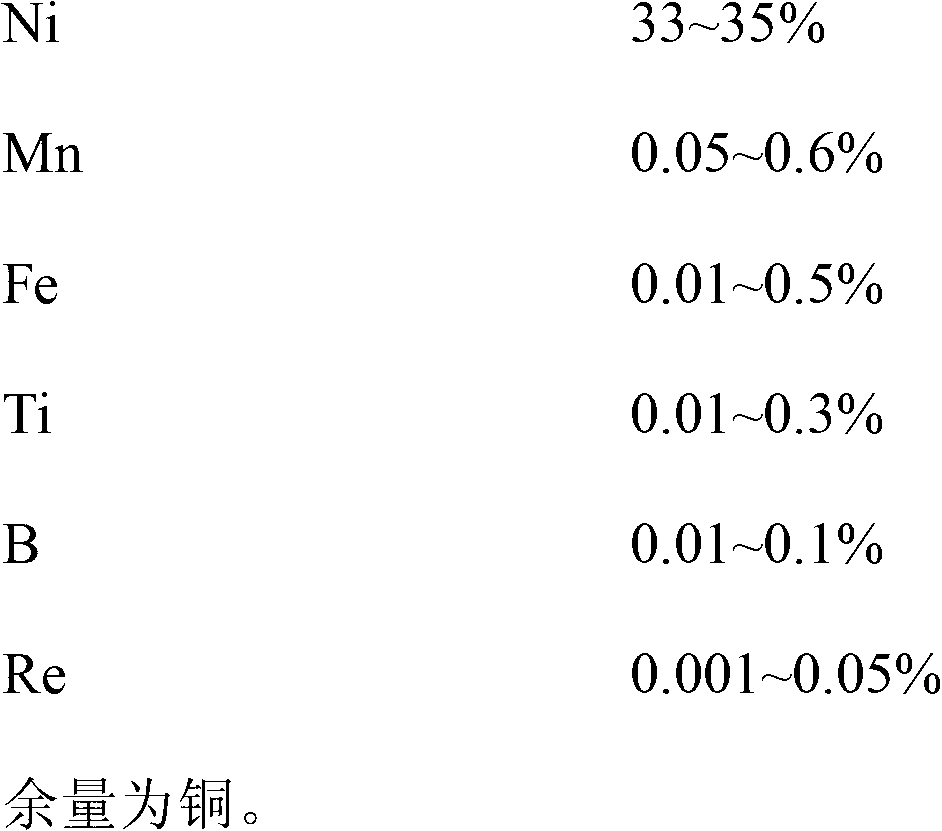

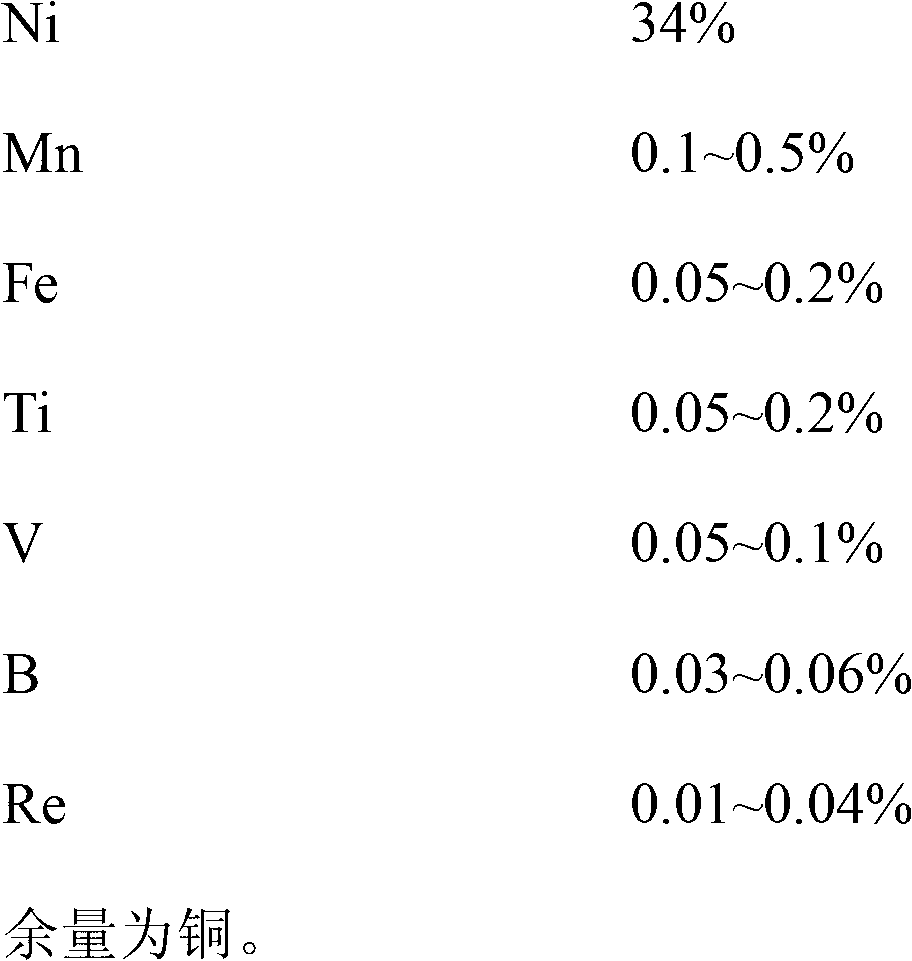

Copper-nickel 34 metal wire and preparation method thereof

InactiveCN102851535ASmall temperature coefficient of resistanceImprove corrosion resistanceMetal/alloy conductorsResistor detailsIngotTemperature coefficient

The invention relates to a relates to the field of copper-nickel alloy, and in particular relates to a copper-nickel 34 metal wire and a preparation method thereof. The copper-nickel 34 wire comprises, by weight, 33-35% of Ni, 0.05-0.6% of Mn, 0.01-0.5% of Fe, 0.01-0.3% of Ti, 0.01-0.1% of B, 0.001-0.05% of Re, and the balance of copper. The preparation method of the copper-nickel 34 metal wire comprises the following steps: conducting mixed melting according to the formula; peeling the obtained ingot and forging; drawing the forged blank; and repeating drawing and annealing for at least 2 times, until the copper-nickel 34 metal wire with desired specifications is obtained. The copper-nickel 34 metal wire prepared by the method of the invention has low resistance temperature coefficient, excellent corrosion resistance, good welding performance and processing performance, high tensile strength and elongation rate, and resistivity about 0.40 ohm.mm<2> / m.

Owner:常丰(无锡)金属制品有限公司

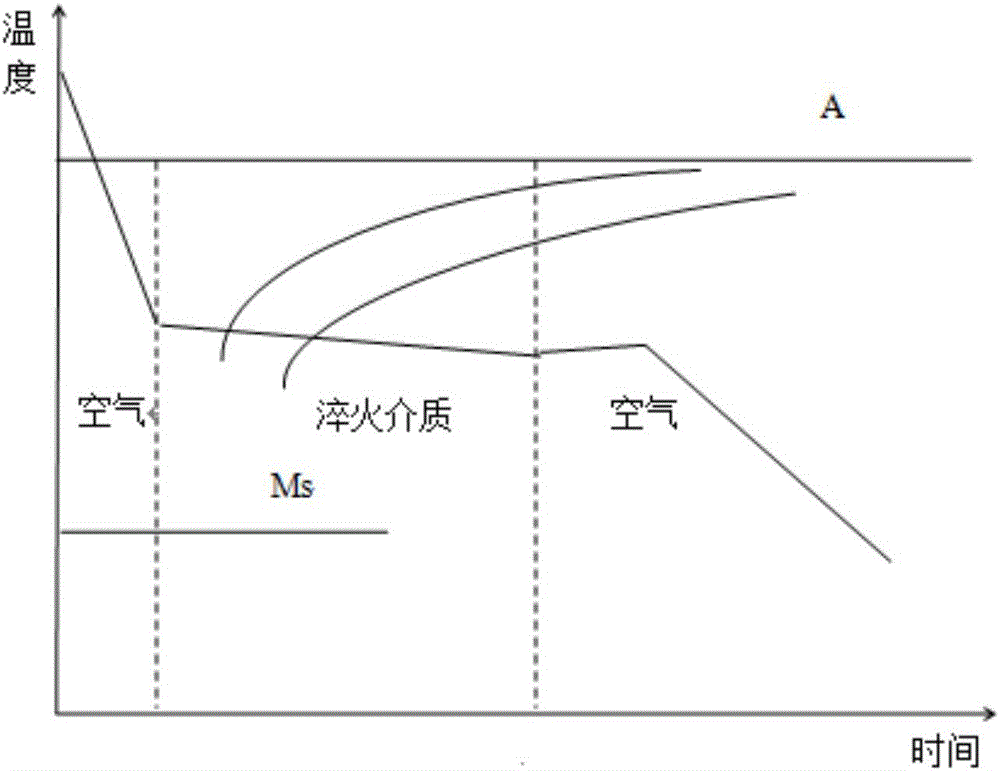

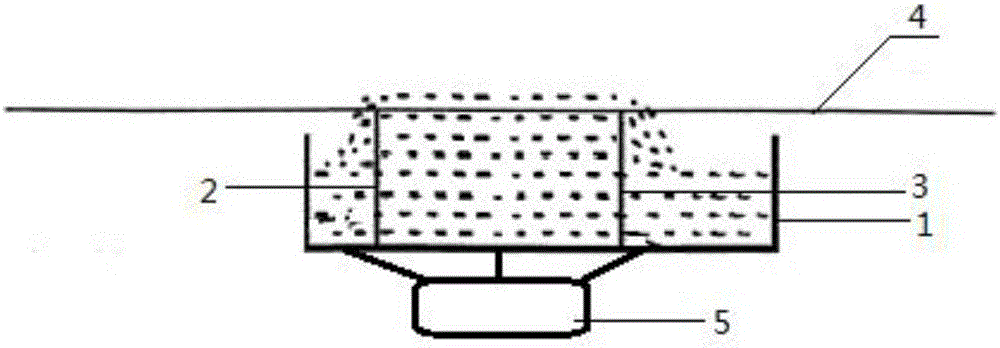

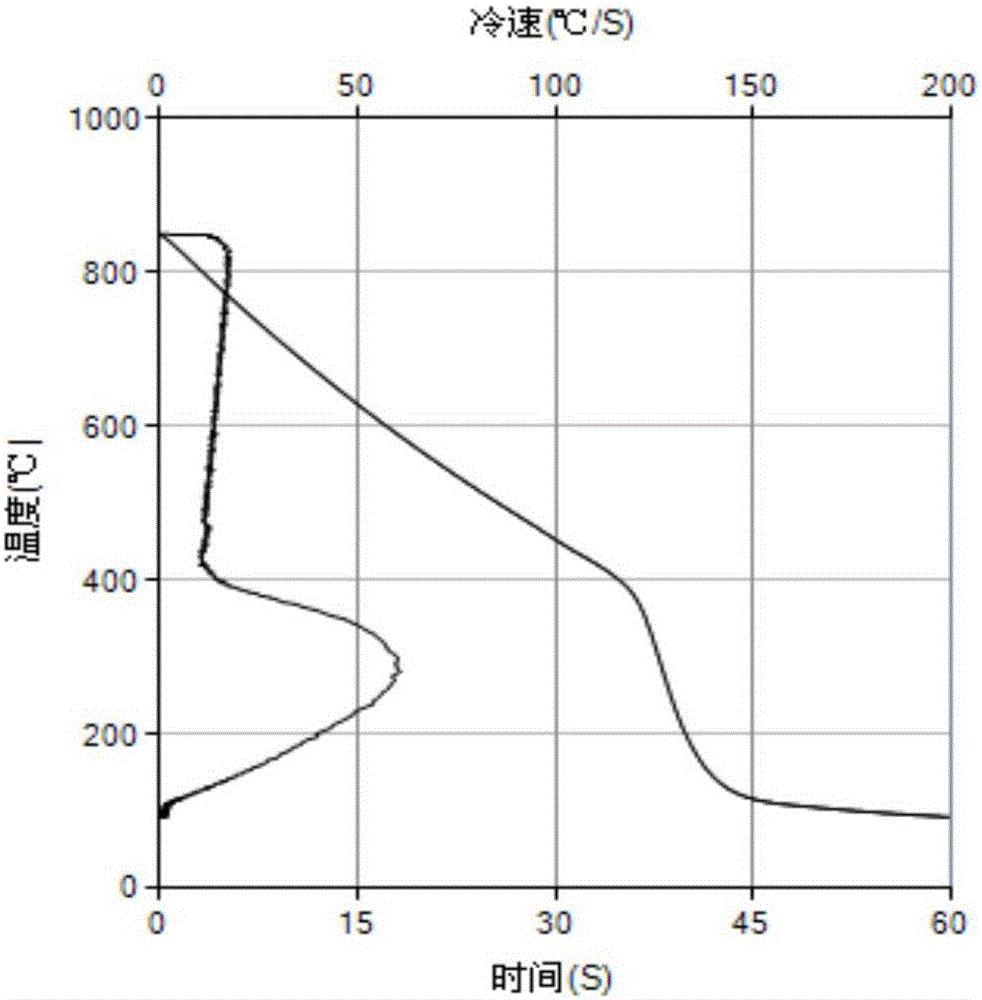

Quenching medium and quenching method for steel cord

ActiveCN105925771AReasonable formulaGood cooling stability and cooling uniformityFurnace typesQuenching agentsSodium polyacrylateQuenching

The invention discloses a quenching medium for a steel cord. The quenching medium comprises the following components in percentage by mass: 2-5% of sodium carboxymethyl cellulose, 15-20% of sodium polyacrylate, 3-5% of additives and water in balancing amount. The invention further discloses a quenching method for the steel cord. The quenching method comprises the following steps: placing the steel cord, which naturally cools in air to 800 DEG C, in the quenching medium provided by the invention; and taking the steel cord out of the quenching medium at 450-550 DEG C by adjusting the size of a quenching region and a core feeding speed. After being taken out of the quenching medium, the steel cord is subjected to sorbite structural transformation in air by virtue of waste heat. The quenching medium provided by the invention is free of pollution, is environment-friendly, can replace high-pollution lead bath to perform sorbite structural transformation heat treatment of the steel cord, and also has favorable stability and cooling uniformity above 500 DEG C; and the quenching technology provided by the invention not only improves the operation environment on a production field, but also effectively reduces the energy consumption and is low in cost.

Owner:NANJING KERUN LUBRICANTS

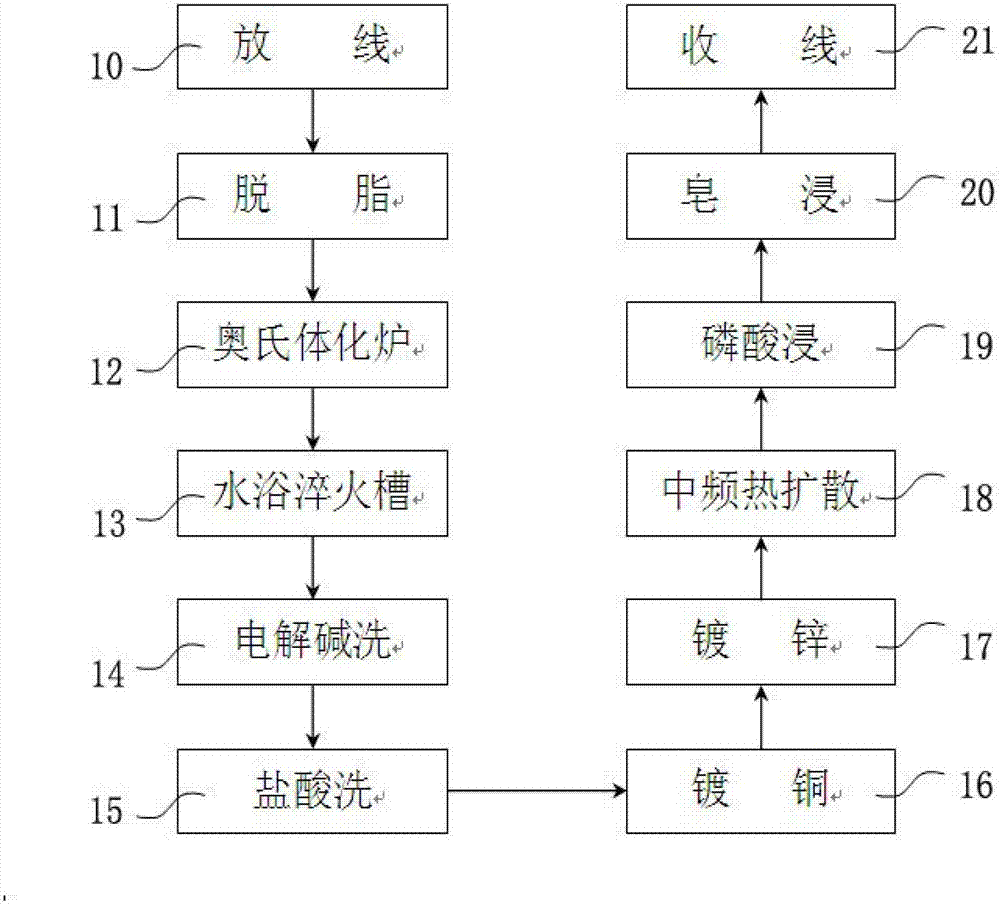

Production method of high pressure rubber tube wire

InactiveCN103205763AThe problem of poor cleaning rod performance is improvedReduce the probability of wire breakageWater bathsPolymer science

The invention relates to a production method of a high pressure rubber tube wire. The production method comprises the following steps of: S10, paying off a pulled rubber tube wire through a paying off device; S11, degreasing; S12, entering into an austenitizing furnace; S13, entering a water bath quenching tank; S14, entering an electrolytic alkaline bath by the steel wire; S15, entering a hydrochloric acid bath by the rubber tube wire; S16, washing at high pressure and entering into an electrocoppering step; S17, entering a galvanizing step by the steel wire; S18, preheating and washing high temperature hot water by the steel wire to enter into middle frequency thermal diffusion; S19, entering into a phosphoric acid bath by thermally diffused rubber tube wire; S20, soaping and drying the steel wire; and S21, entering to a winding device after water washing. With the technical scheme, the problem of poor universality of the steel wire can be improved, and the breakage rate in the pulling process can be effectively reduced.

Owner:JIANGSU SHENGDA TECH

Production method of steel for 82 B steel stranded wires

ActiveCN102211159BRealize cleaner productionProduction organizationManufacturing convertersOxygen contentImpurity

The invention discloses a production method of steel for 82 B steel stranded wires, belonging to the field of metallurgy. In the production method, the steel for the 82 B steel stranded wires is produced by adopting the process flow comprising the following steps of: rotating furnace primary smelting, LF (Low Frequency) refining, RH (Relative Humidity) refining and continuous casting and pouring of a large square billet, wherein the tail end of a solidification end is dynamically and lightly downwards pressed in the procedure of the continuous casting and pouring of the large square billet. According to the production method disclosed by the invention, technologies, i.e. rotating furnace whole-course bottom argon blowing, argon blowing after tapping, RH vacuum degassing, impurity removal,crystallizer electromagnetic stirring, and the like, are adopted in the process flow, and therefore the clean production of the steel for the 82 B steel stranded wires is realized; an antegrade production organization is achieved; obtained components and the quality of casting blanks all meet the requirements for steel grades, and the total oxygen content (T[O]) in the steel is less than 0.0020 percent; and wire breakage does not appear in the wire drawing process of a product, and therefore the wire broken rate of the wire drawing process is reduced.

Owner:PANZHIHUA IRON AND STEEL +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com