Wire rod for prestressed concrete steel stick and manufacturing process

A concrete steel rod and prestressing technology, which is applied in the manufacture of tools, metal rolling, metal rolling, etc., can solve the problems of wire rod performance fluctuations, large fluctuations, and unstable manufacturing processes, and achieve low wire breakage and high performance. The effect of stability and heat treatment process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

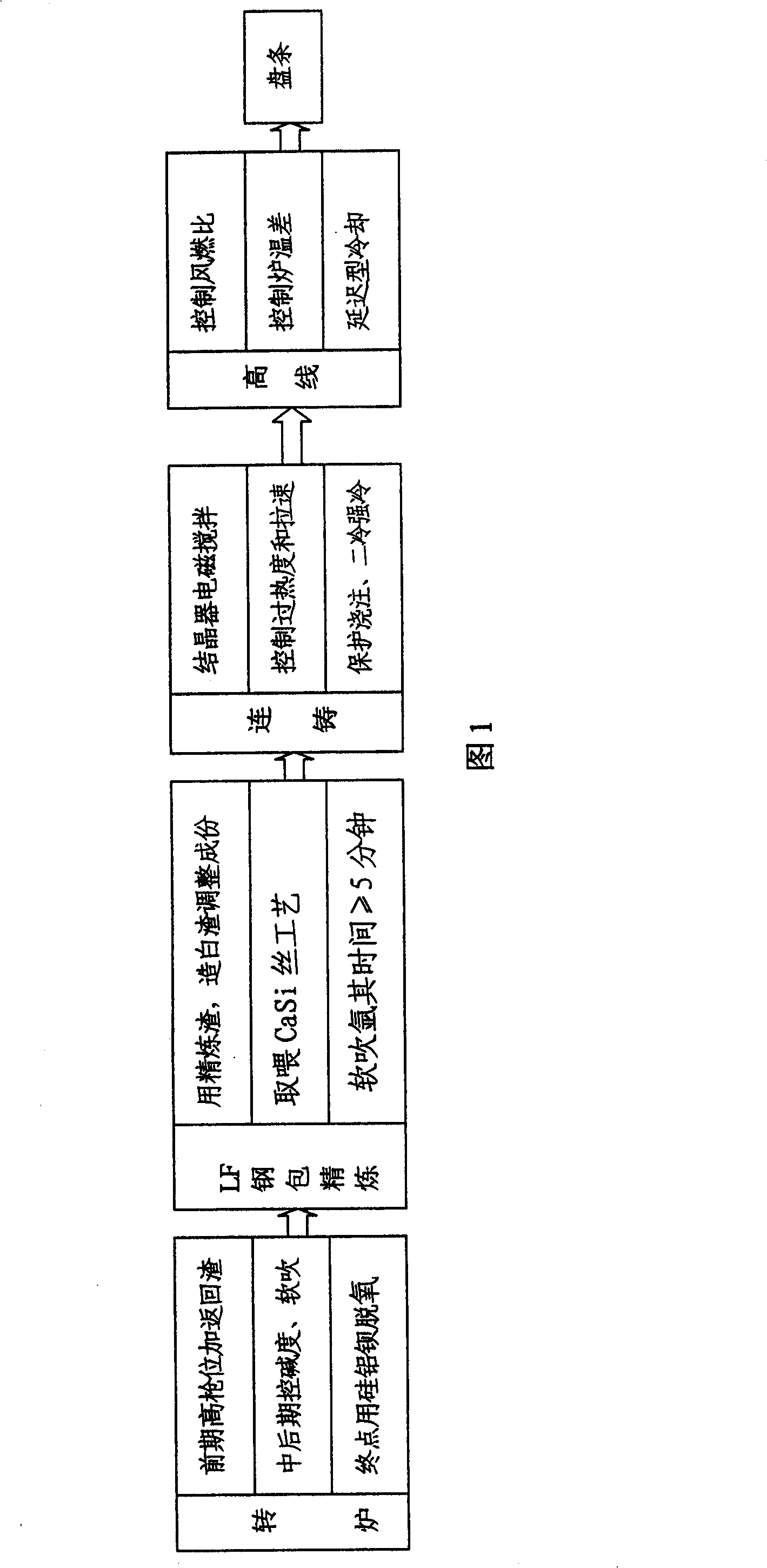

[0011] Describe in detail below in conjunction with accompanying drawing. As shown in the accompanying drawings, the process route of the present invention is the process route of converter → LF ladle refining → continuous casting → high wire rolling.

[0012] Since the wire rod is mainly used to produce high-strength prestressed concrete steel rods to meet the quality requirements of large-diameter pipe piles in special geographical environments, a key control link is proposed for the wire rod, specifically including the chemical composition of the wire rod. Optimize the design and determine the best combination of alloying elements. In terms of production technology, the converter smelting process controls the balance of C and O at the end of the converter to ensure the dephosphorization effect, strengthens deoxidation and alloying, and controls the generation of inclusions; the refining process adopts reducing operations and composition adjustments to ensure deep desulfuriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com