Phosphogypsum-based steel mesh frame composite wallboard and preparation method thereof

A technology of steel wire grid and composite wallboard, which is applied in the field of building materials, can solve problems such as unstable product performance indicators, comprehensive utilization of phosphogypsum, and damage to the ecological environment. Good performance and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

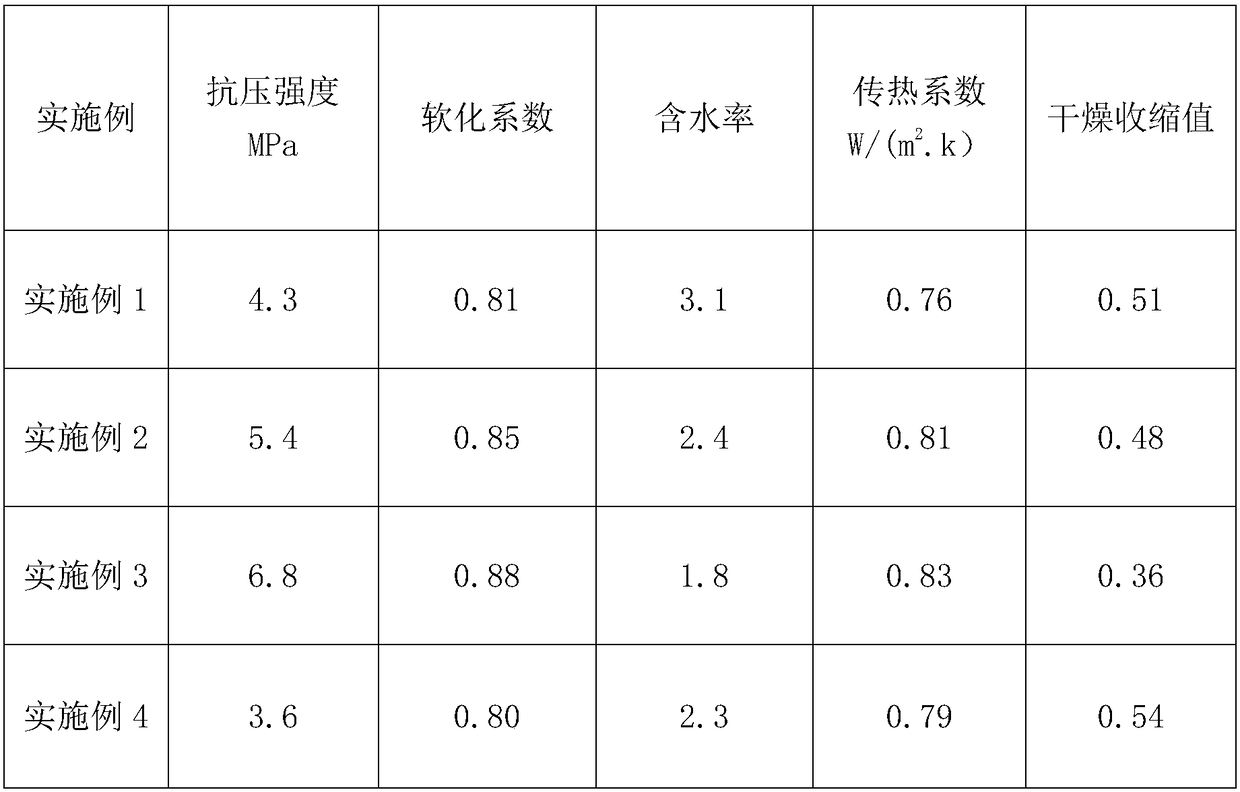

Embodiment 1

[0029] A phosphogypsum-based steel wire grid composite wallboard, comprising the following components by weight on a dry basis: 70 parts of phosphogypsum powder, 15 parts of mineral powder, 2 parts of active mineral powder, 5 parts of cement, 8 parts of quicklime, and a foaming agent 1 part, 0.5 part of admixture, 3 parts of steel wire grid, 0.5 part of glass fiber mesh cloth.

[0030] When preparing, first place the steel wire mesh frame in the mold for use, then weigh phosphogypsum powder, mineral powder, active mineral powder, cement, quicklime and foaming agent and pour them into a mixer to stir and mix to obtain the mixture A. Add water with a material-to-water ratio of 0.45-0.55 into the admixture to obtain an admixture solution, add the admixture solution to mixture A and stir for 1 min with a mixer at a speed of 200 rpm to form a mixed slurry; put the mixed slurry in the mold It is poured and formed at a temperature of 40-48°C, sent to a curing room at 45°C, and left t...

Embodiment 2

[0032] A phosphogypsum-based steel wire grid composite wallboard, comprising the following components by weight on a dry basis: 65 parts of phosphogypsum powder, 15 parts of mineral powder, 5 parts of active mineral powder, 7 parts of cement, 8 parts of quicklime, foaming 1 part of additive, 0.4 part of admixture, 3 parts of steel wire mesh frame, and 0.5 part of glass fiber mesh cloth.

[0033] When preparing, first place the steel wire mesh frame in the mold for use, then weigh phosphogypsum powder, mineral powder, active mineral powder, cement, quicklime and foaming agent and pour them into a mixer to stir and mix to obtain the mixture A. Add water with a material-to-water ratio of 0.45-0.55 into the admixture to obtain an admixture solution, add the admixture solution to mixture A and stir for 1 min with a mixer at a speed of 200 rpm to form a mixed slurry; put the mixed slurry in the mold It is poured and formed at a temperature of 40-48°C, sent to a curing room at 45°C, ...

Embodiment 3

[0035] A phosphogypsum-based steel wire grid composite wallboard, comprising the following components by weight on a dry basis: 60 parts of phosphogypsum powder, 20 parts of mineral powder, 5 parts of active mineral powder, 5 parts of cement, 10 parts of quicklime, foaming 1 part of additive, 0.3 part of admixture, 3 parts of steel wire mesh frame, and 0.5 part of glass fiber mesh cloth.

[0036]When preparing, first place the steel wire mesh frame in the mold for use, then weigh phosphogypsum powder, mineral powder, active mineral powder, cement, quicklime and foaming agent and pour them into a mixer to stir and mix to obtain the mixture A. Add water with a material-to-water ratio of 0.45-0.55 into the admixture to obtain an admixture solution, add the admixture solution to mixture A and stir for 1 min with a mixer at a speed of 200 rpm to form a mixed slurry; put the mixed slurry in the mold It is poured and formed at a temperature of 40-48°C, sent to a curing room at 45°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com