Patents

Literature

142results about How to "Automatic tension adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

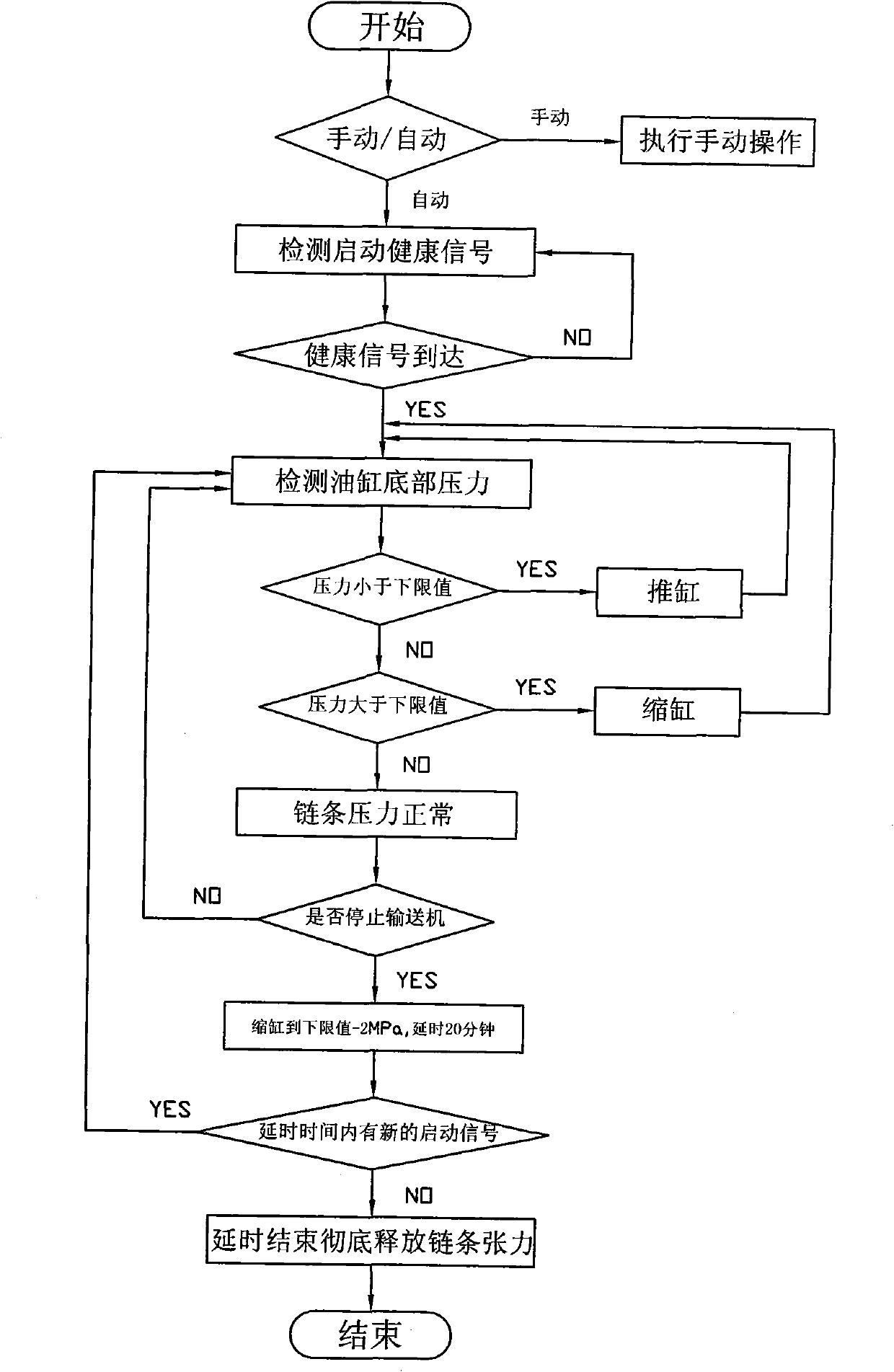

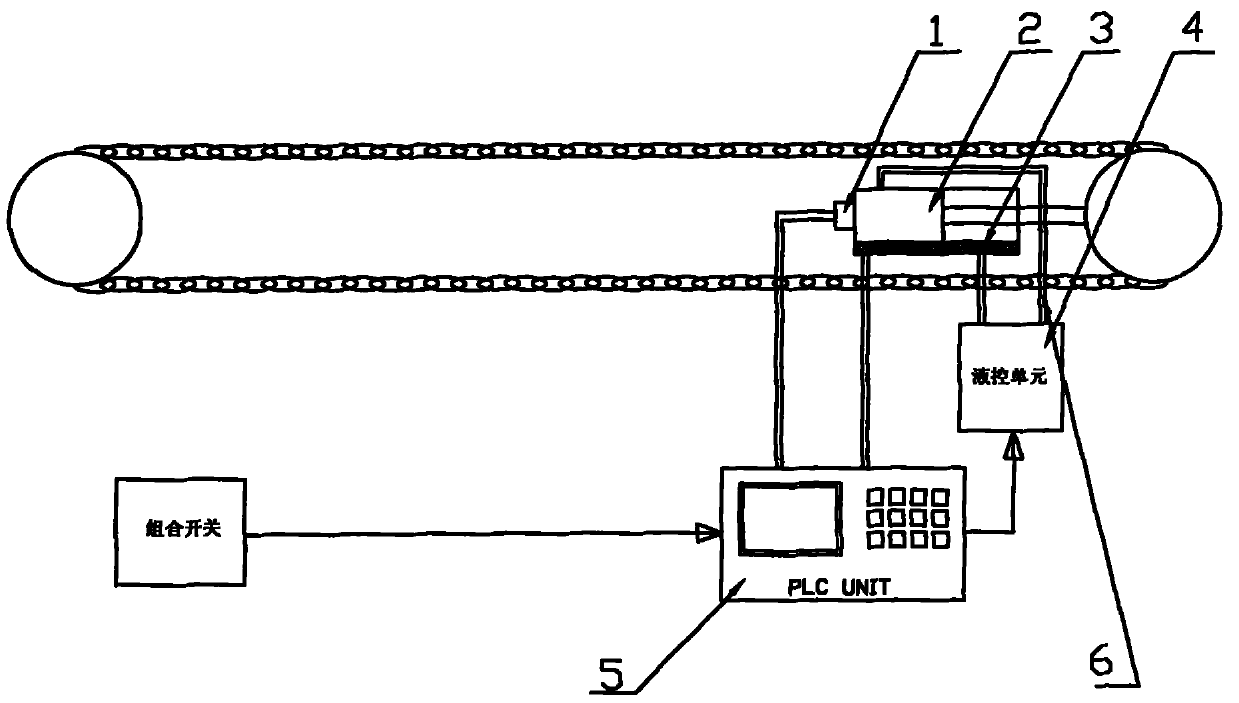

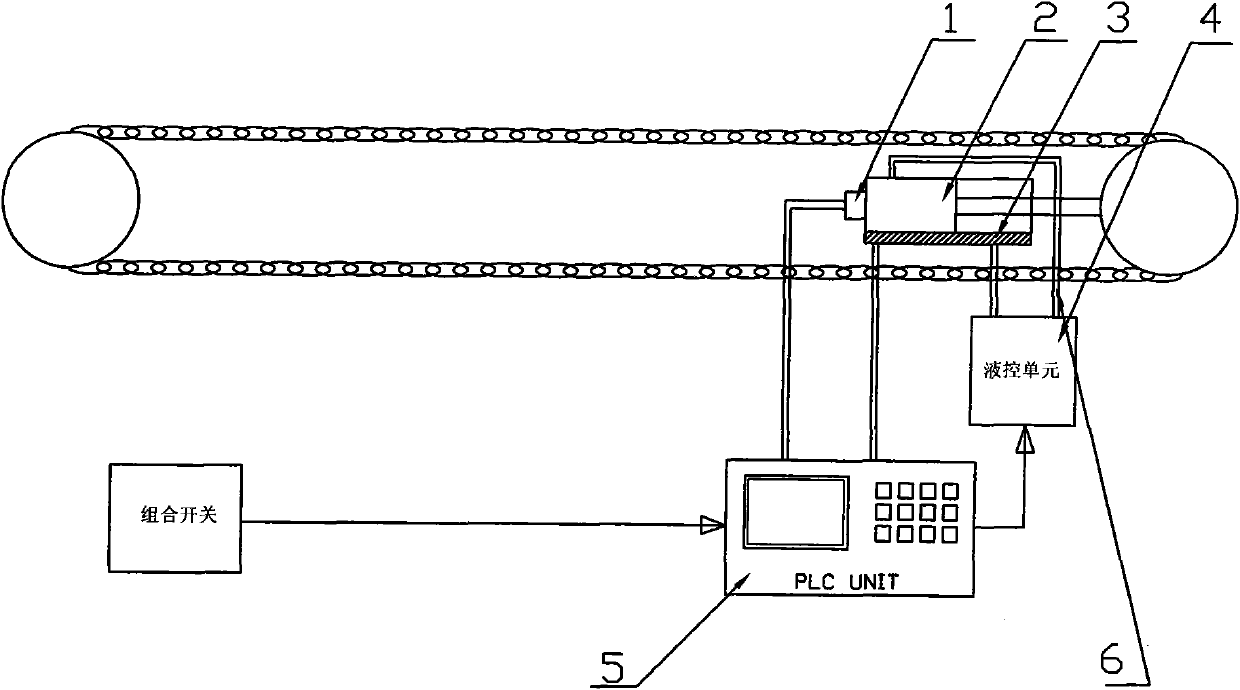

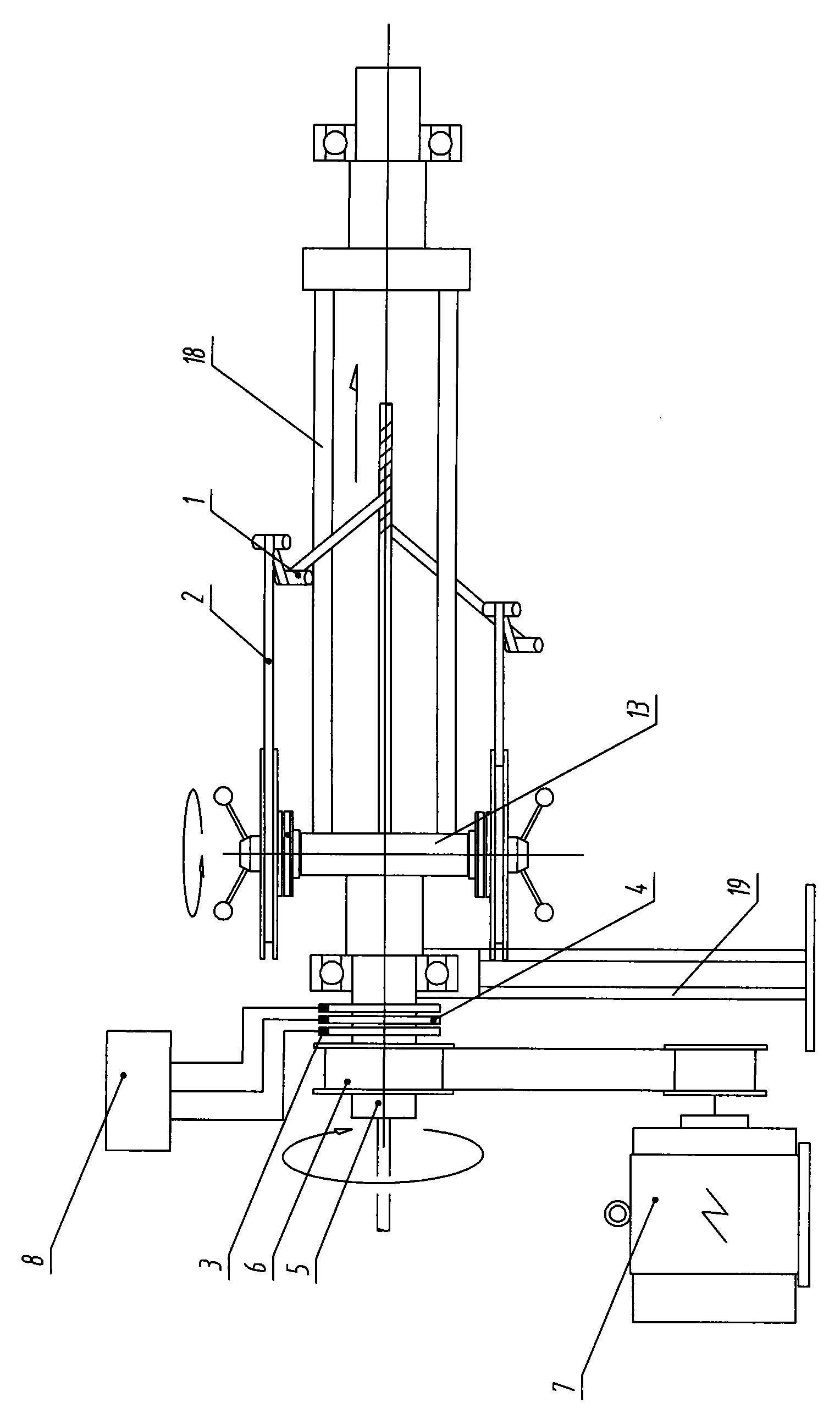

Control device for automatic tension degree of chain

InactiveCN101948045AAutomatic tension adjustmentIdeal tensionConveyorsControl devices for conveyorsHydraulic control unitEngineering

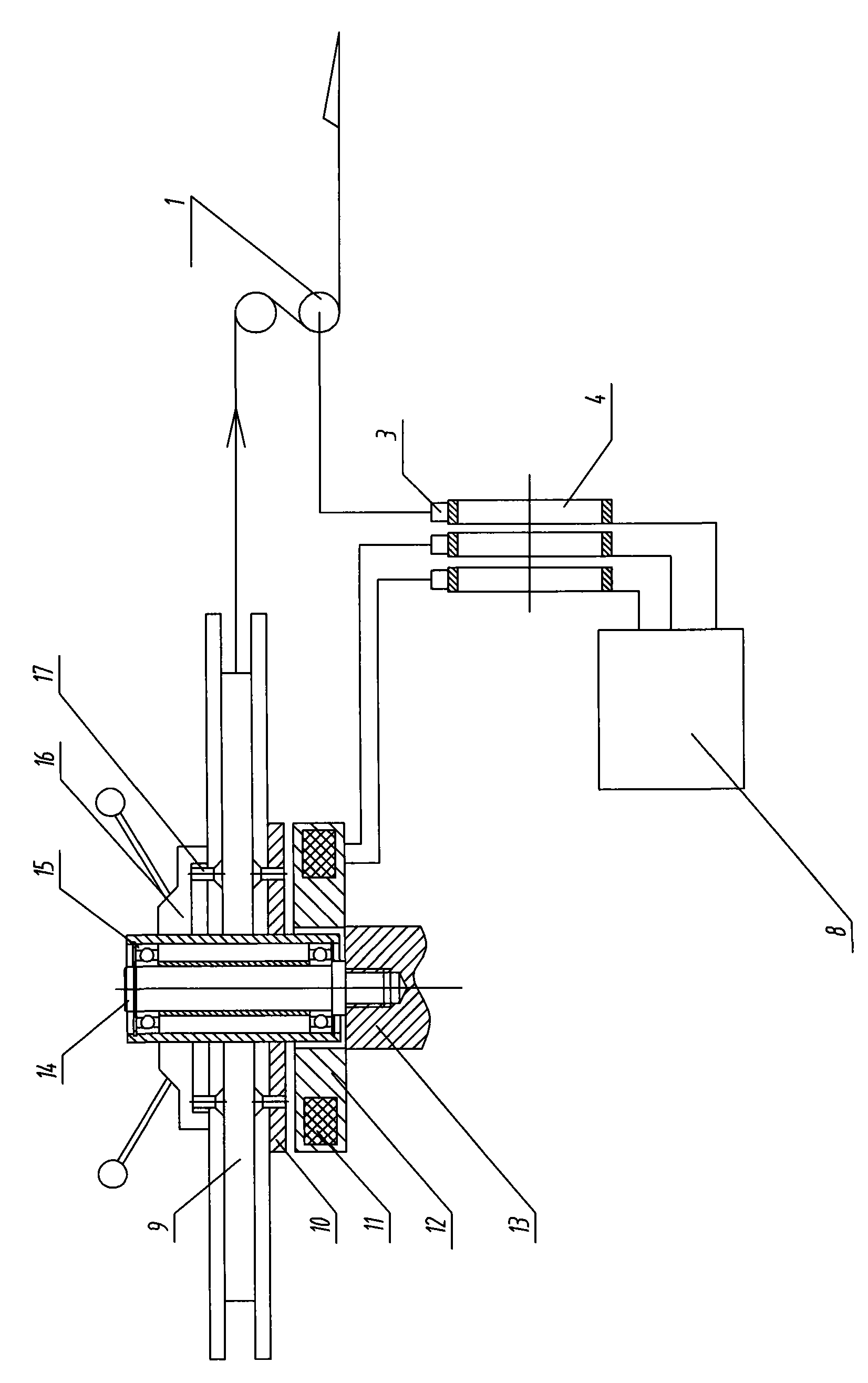

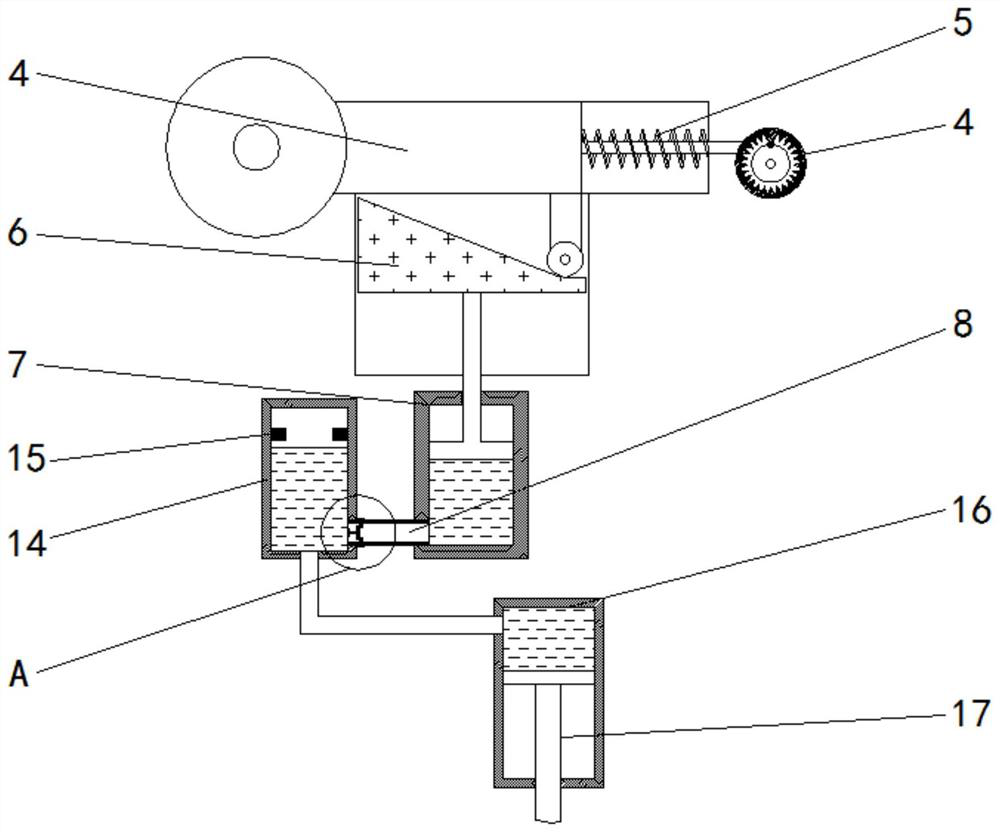

The invention relates to a control device for the automatic tension of a chain, which is suitable for a conveyer on an underground working surface of a coal mine, in particular to a control device for automatic tension degree of a chain, which is characterized by comprising a shift oil cylinder (2), wherein the piston rod of the shift oil cylinder (2) is connected with the shaft of a chain wheel for pushing the chain wheel to make linear translation; the shift oil cylinder (2) is also connected with a hydraulic control unit (4) through a hydraulic pipeline (6); the hydraulic control unit (4) is connected with a controller (5); a pressure sensor (1) and a displacement sensor (3) are also respectively installed beside the shift oil cylinder (2) for detecting the pressure borne by the shift oil cylinder (2) when pushing the chain wheel and the displacement of the shift oil cylinder (2); and the pressure sensor (1) and the displacement sensor (3) are respectively connected with the controller (5). The invention can automatically adjust the tension of the chain and enable the chain to keep in an ideal tension state all the time, thereby increasing the service life.

Owner:NINGXIA TIANDI BENNIU IND GRP

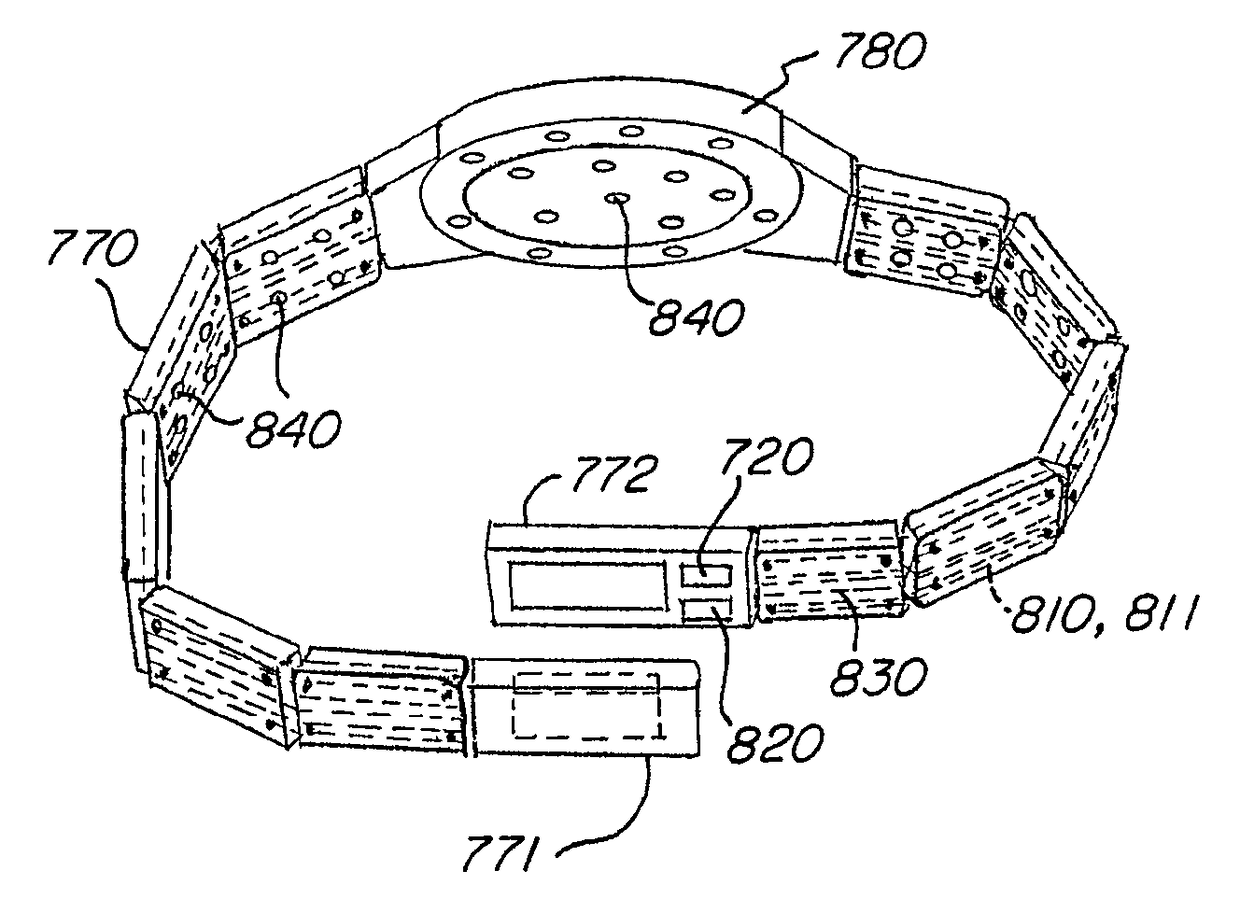

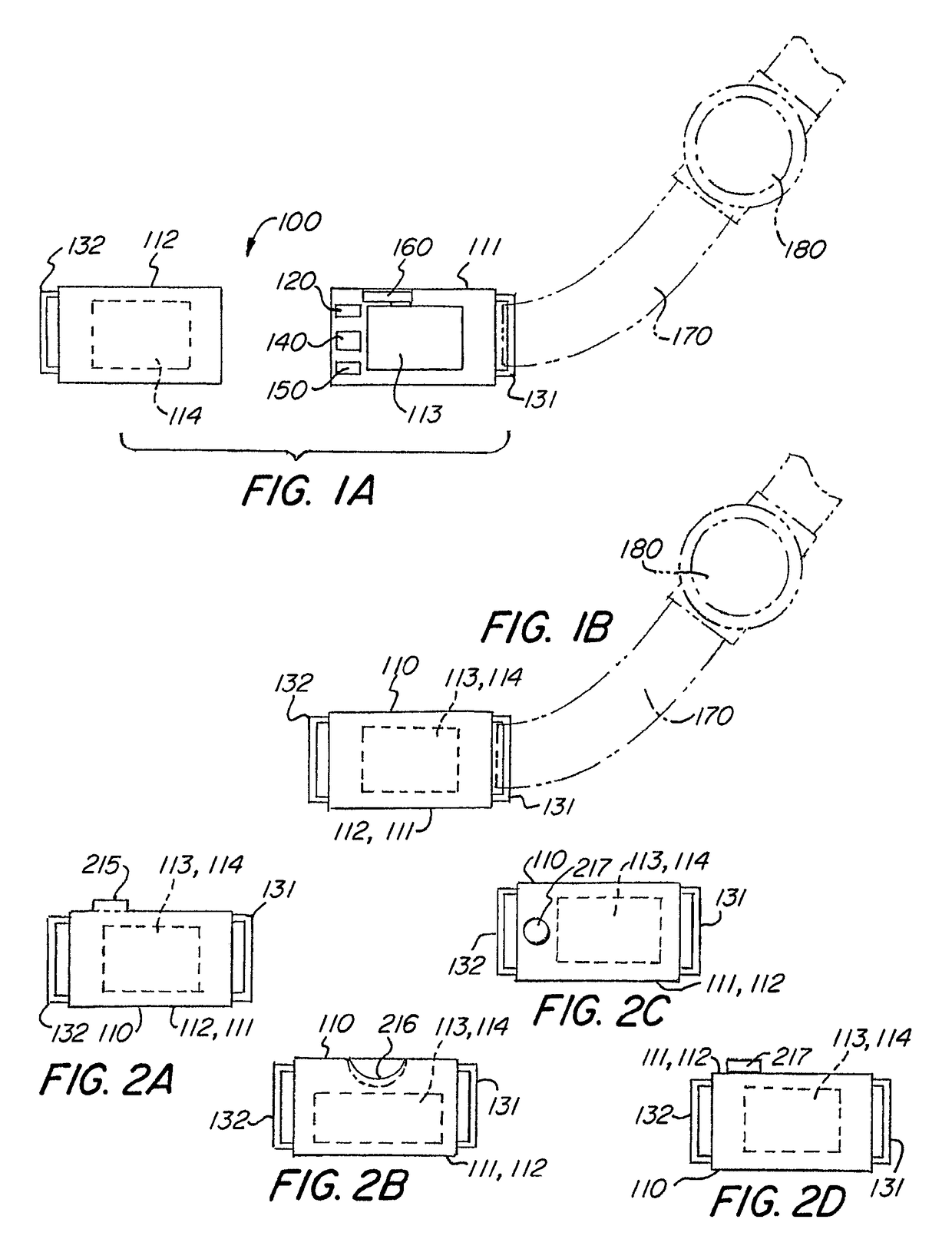

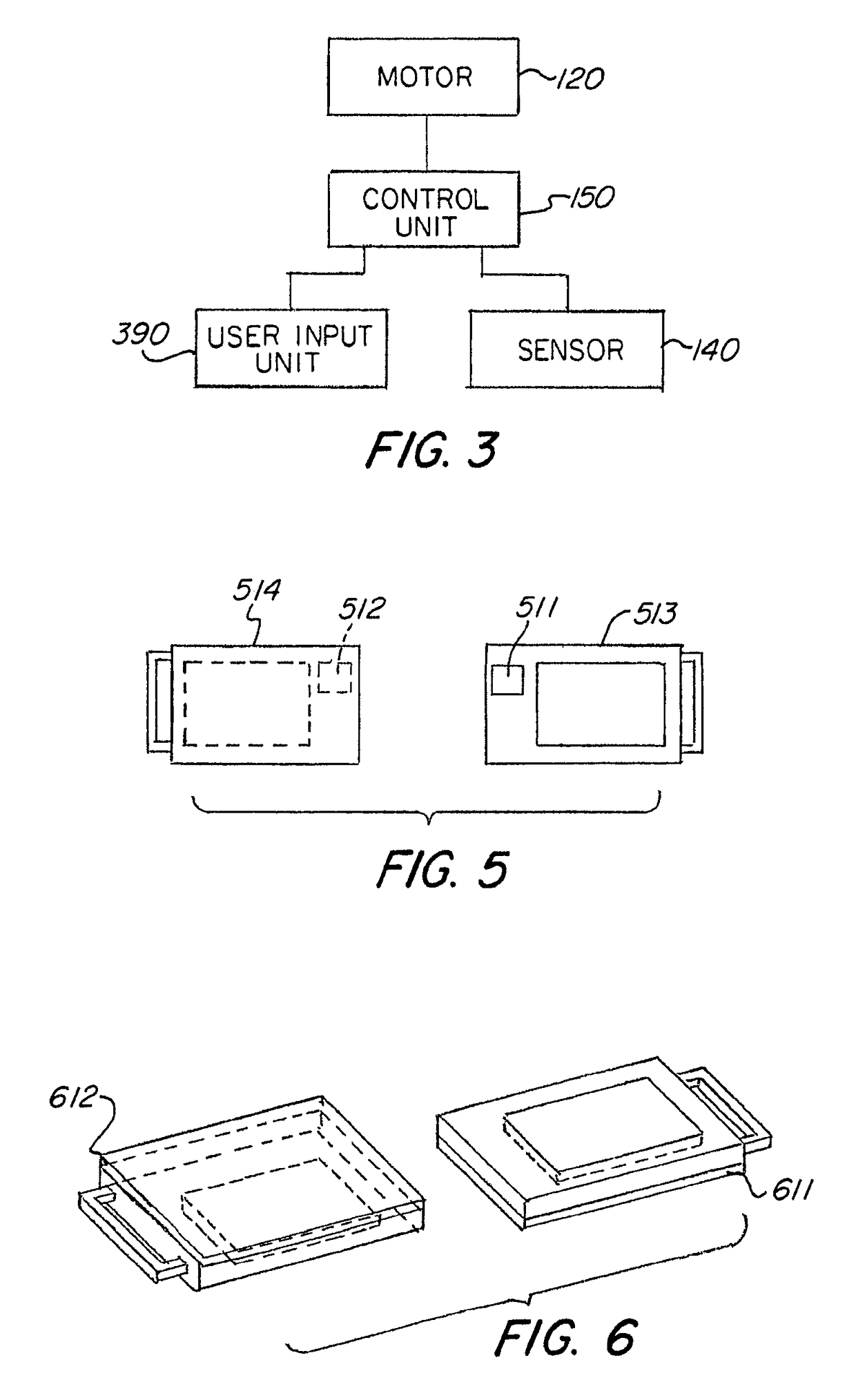

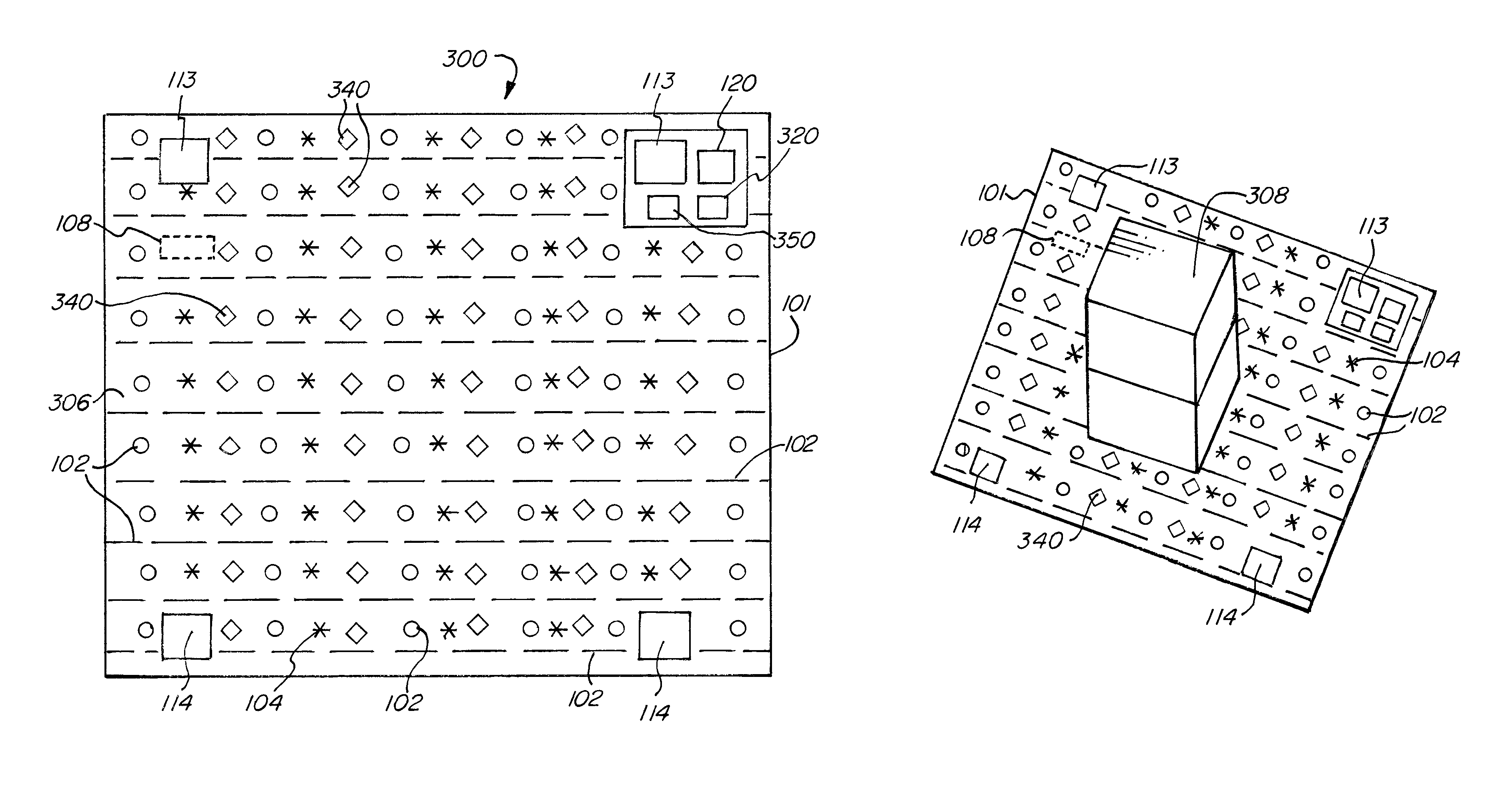

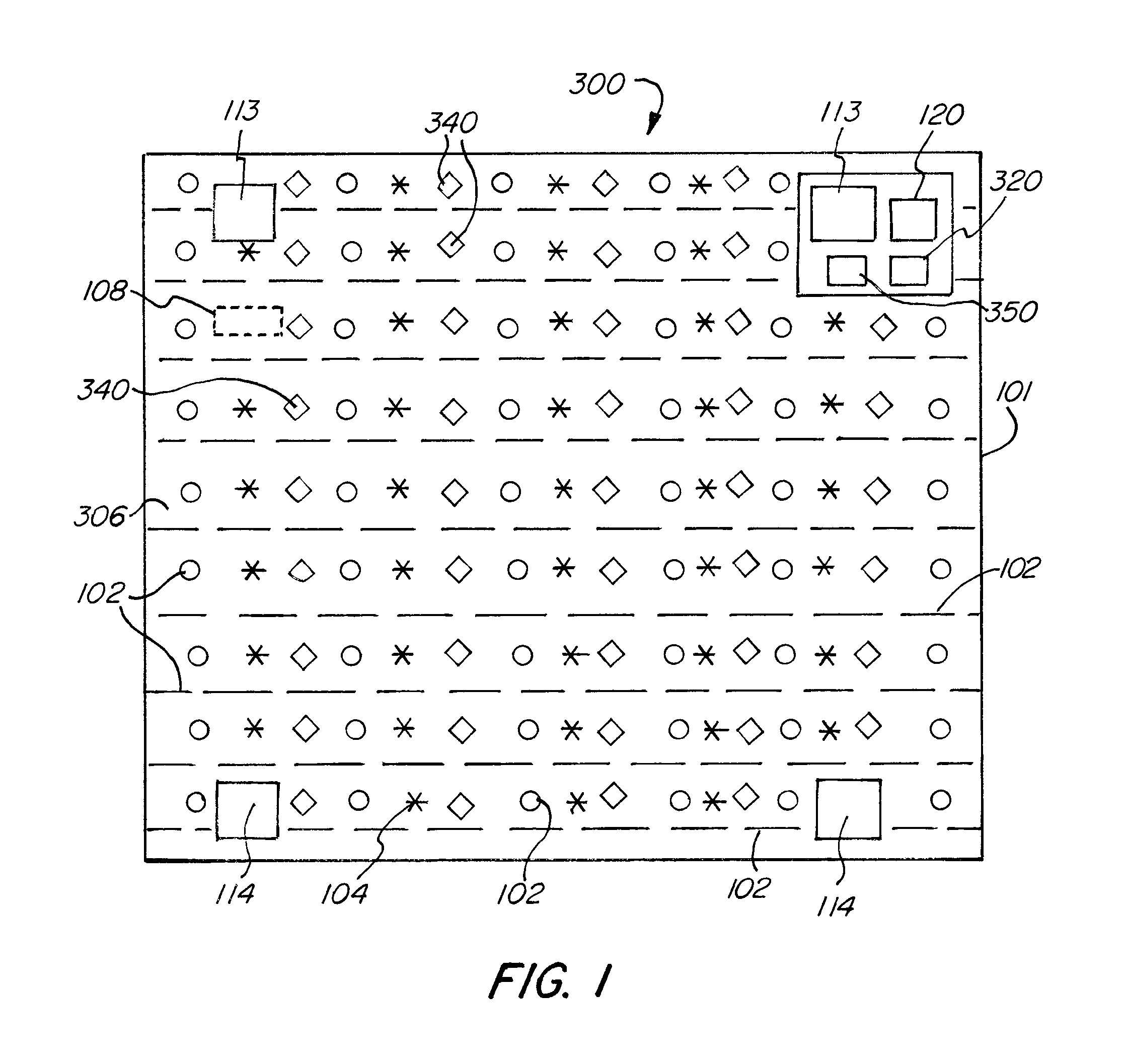

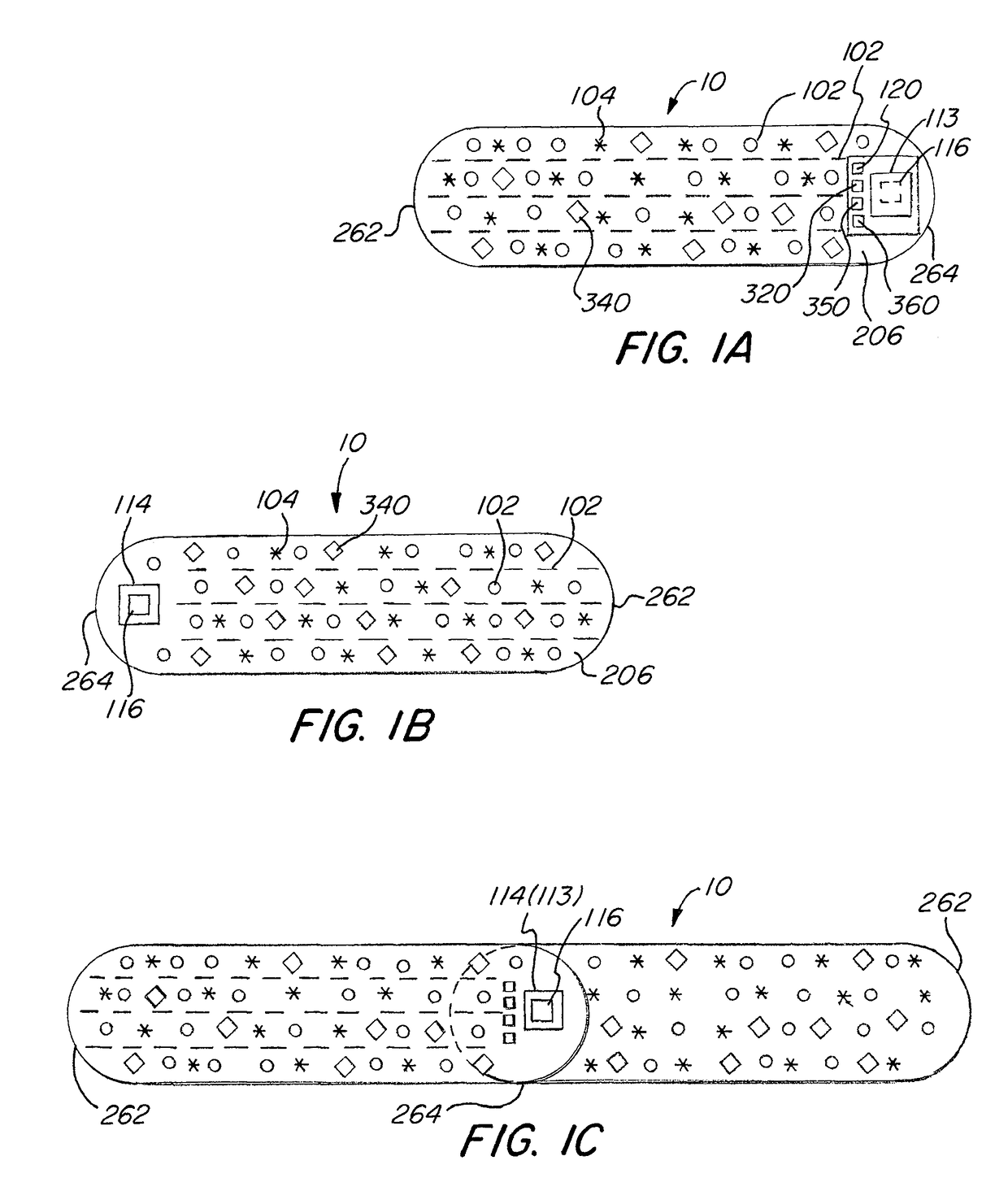

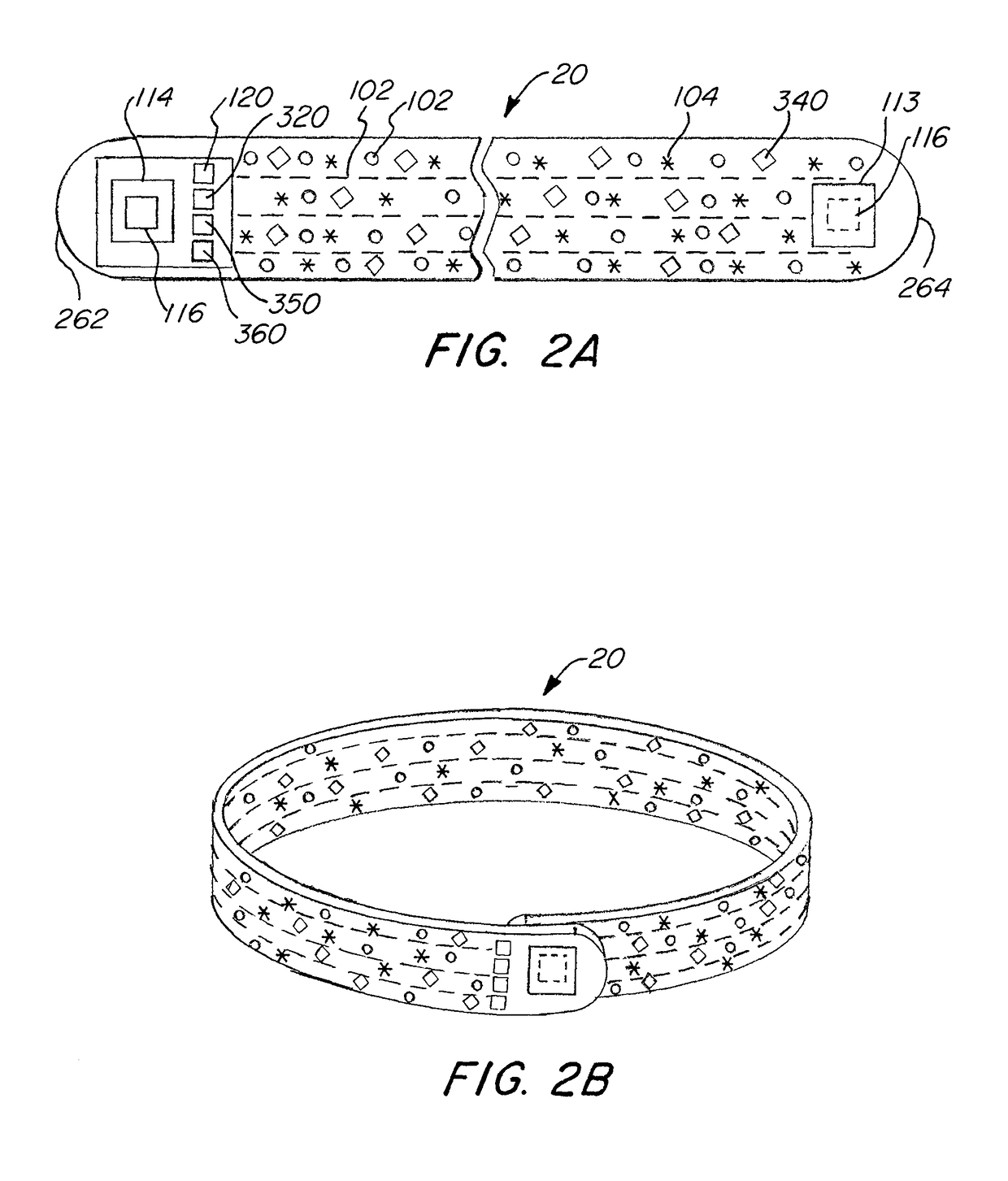

Self-fitting, self-adjusting, automatically adjusting and/or automatically fitting magnetic clasp

ActiveUS9609921B1Simple one handSimple hand free operationShielding materialsMachine supportsEngineeringBiological activation

Provided is an automatically adjustable clasp having two separable magnet pieces which may magnetically adhere to each other to form a closed clasp. The clasp also includes a motor, an anchor mechanism for attaching the clasp to a band, sensors, and a control unit. The sensors acquire and send information related to the clasp or the band to the control unit, which may activate the motor. The activation of the motor changes the position of the anchor mechanism with respect to the rest of the clasp, thereby loosening or tightening of the band attached to the anchor mechanism. Also provided is a wearable band with the automatically adjustable clasp. The wearable band may include a shape memory material such that the band may self-assemble around a body part when a stimulus is applied to the shape memory material. The self-assembly process may enable the automatic clasp of the magnet pieces.

Owner:FEINSTEIN PATENTS

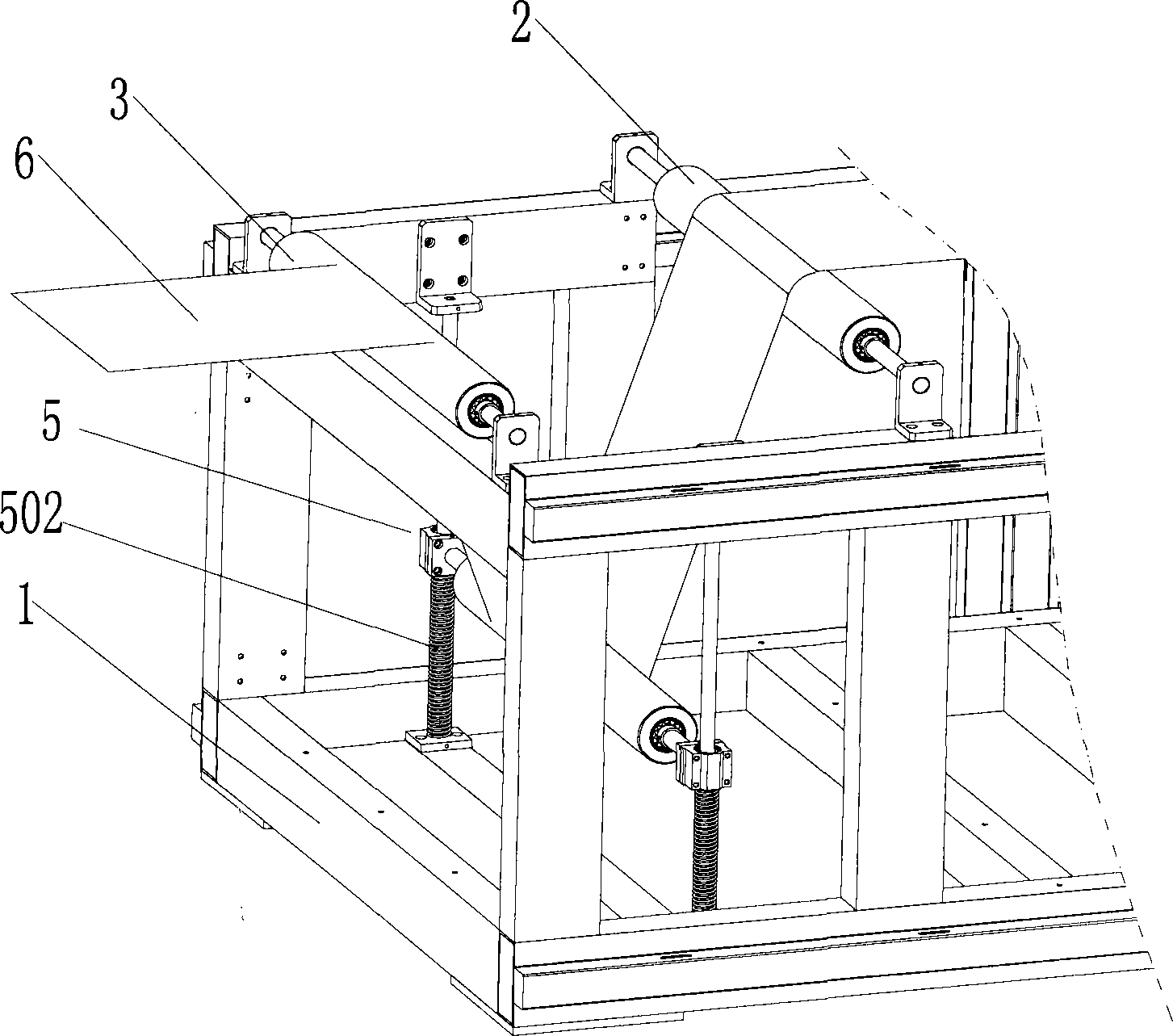

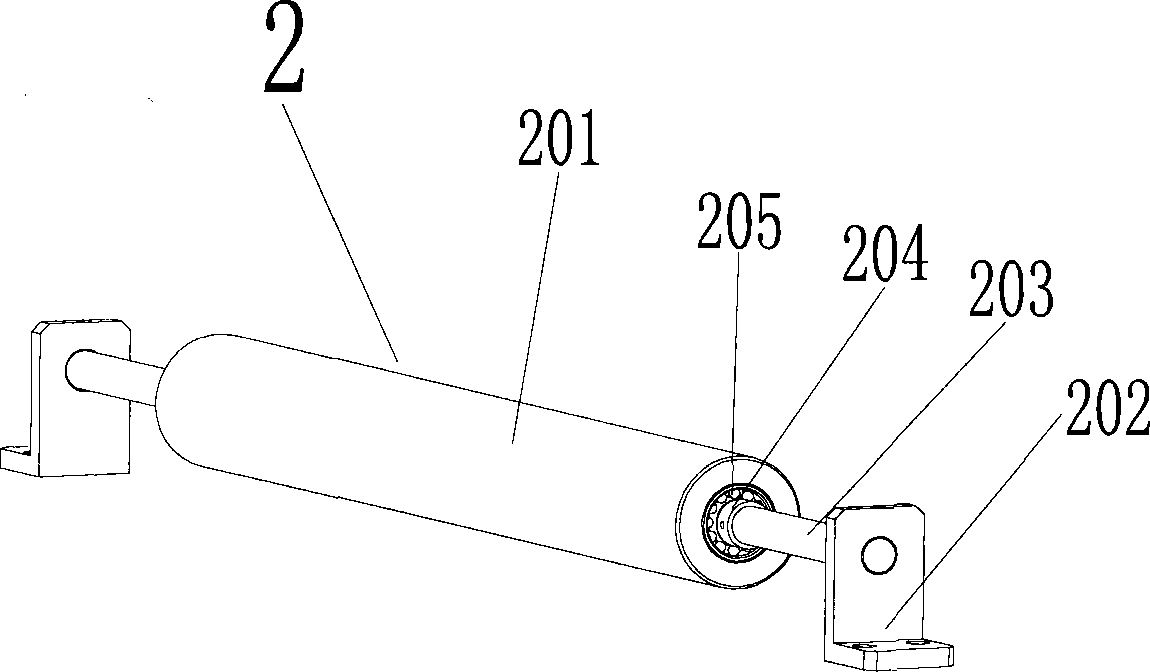

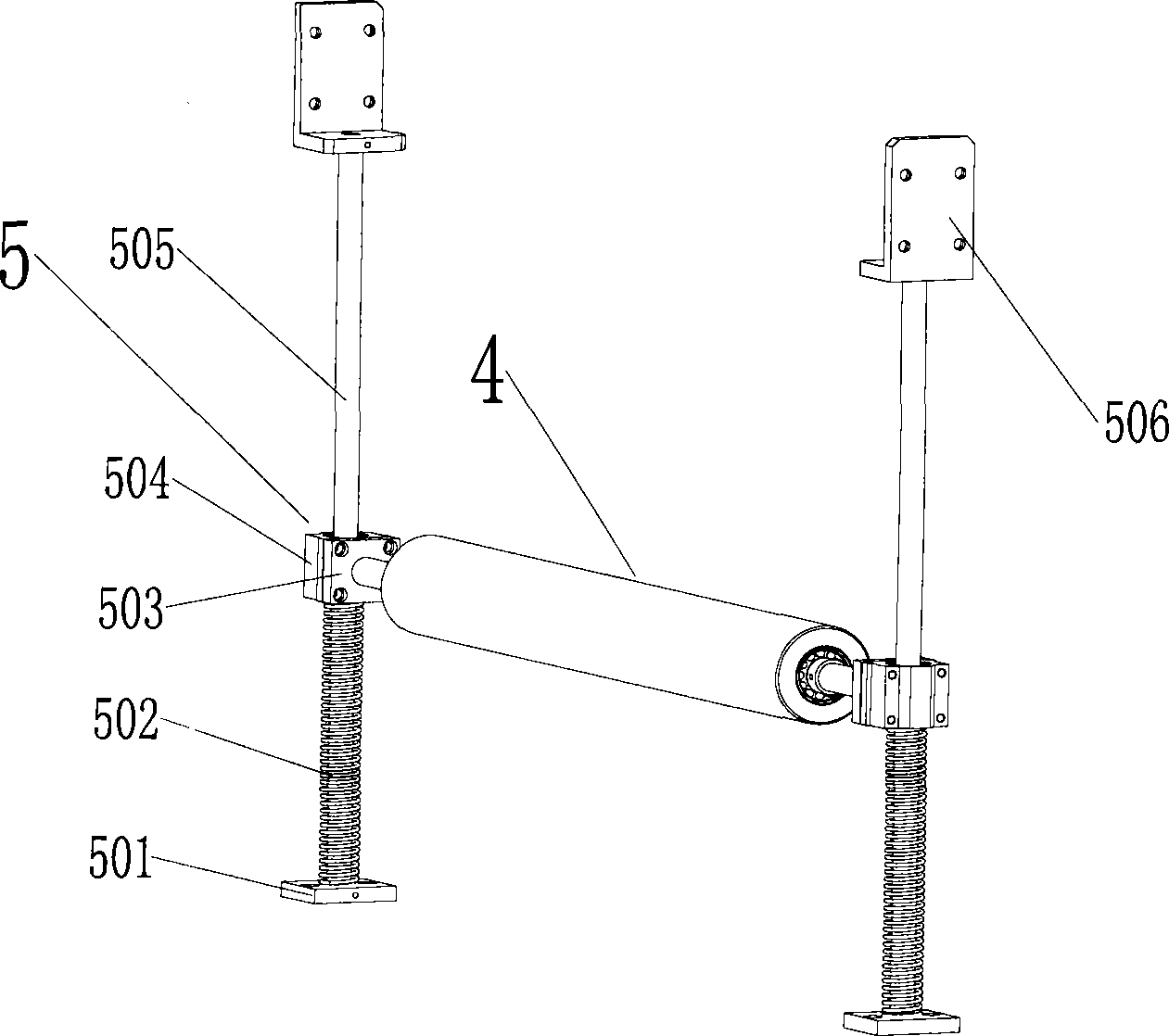

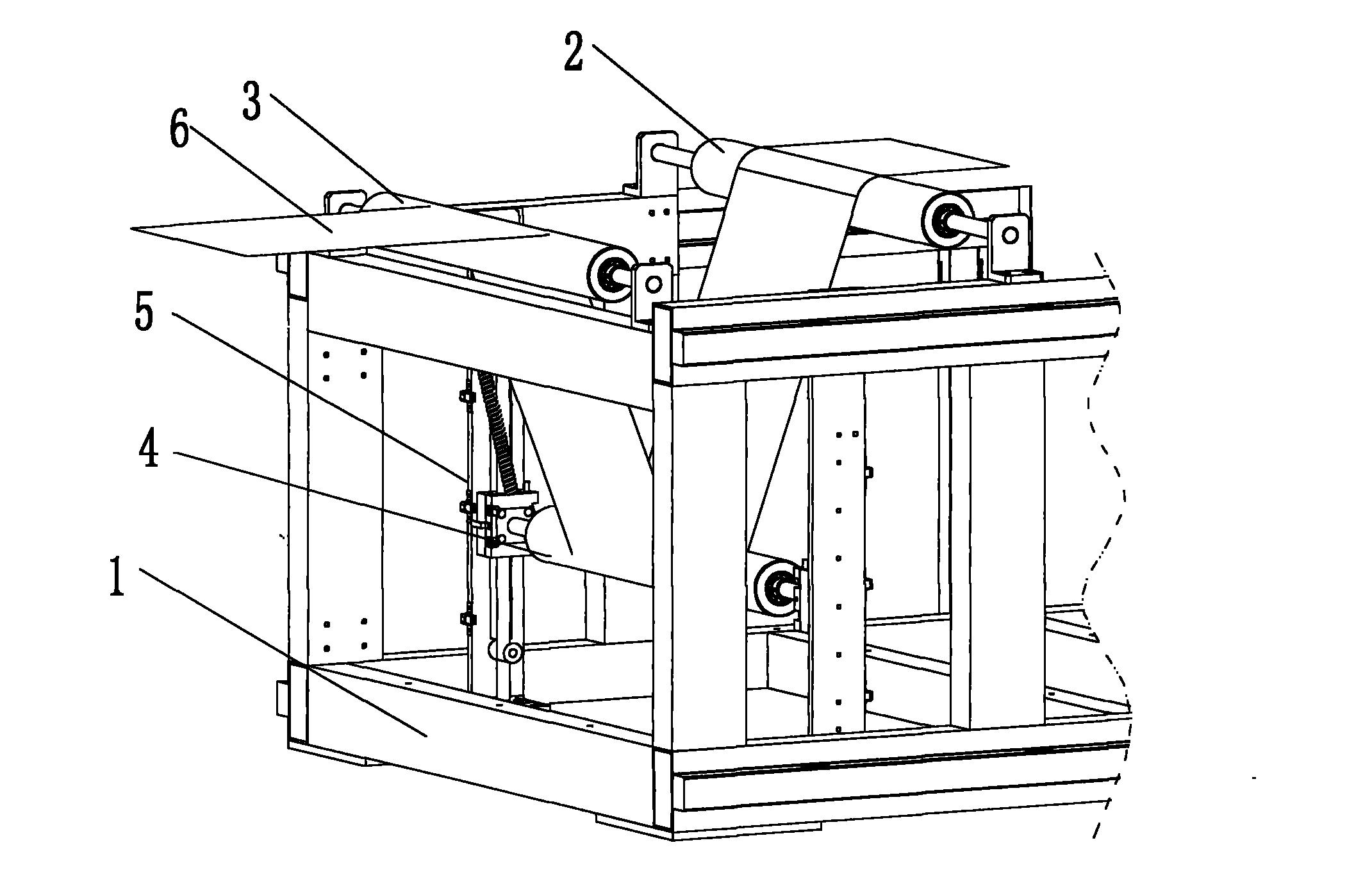

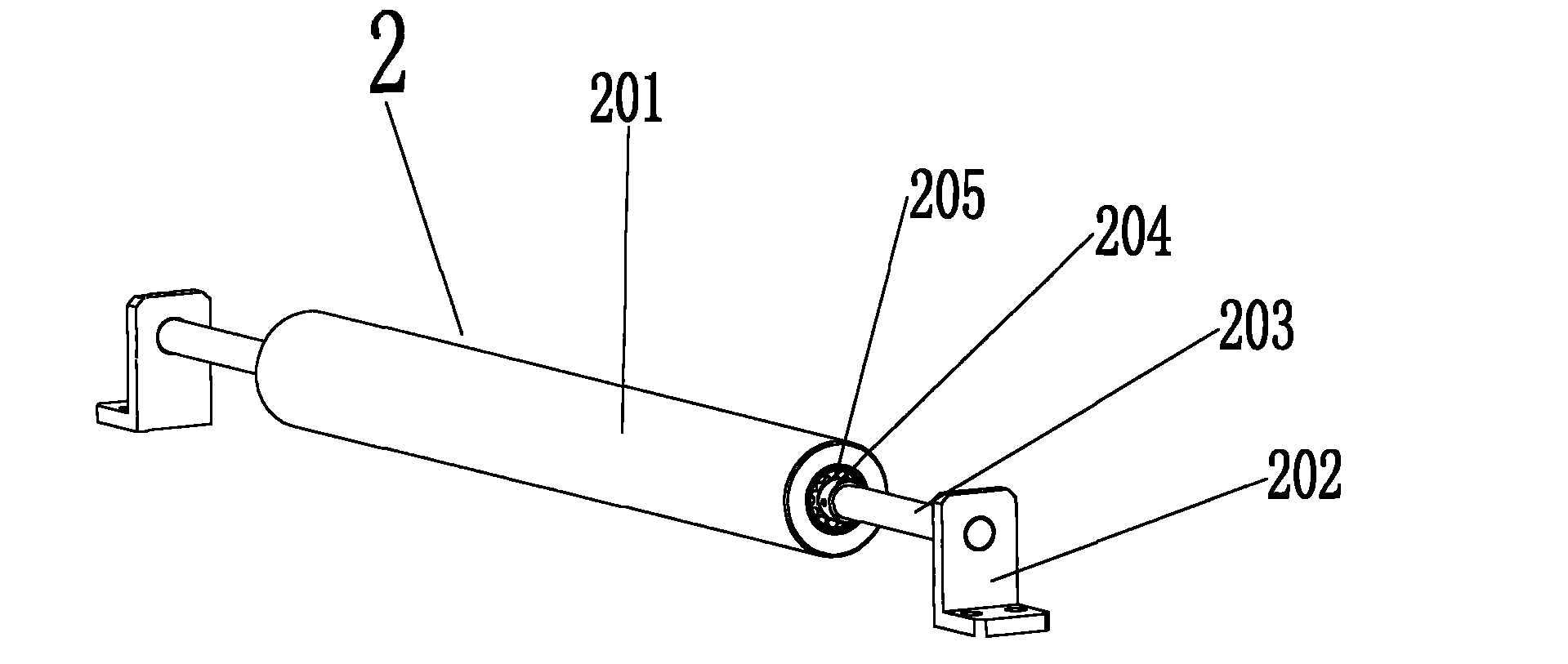

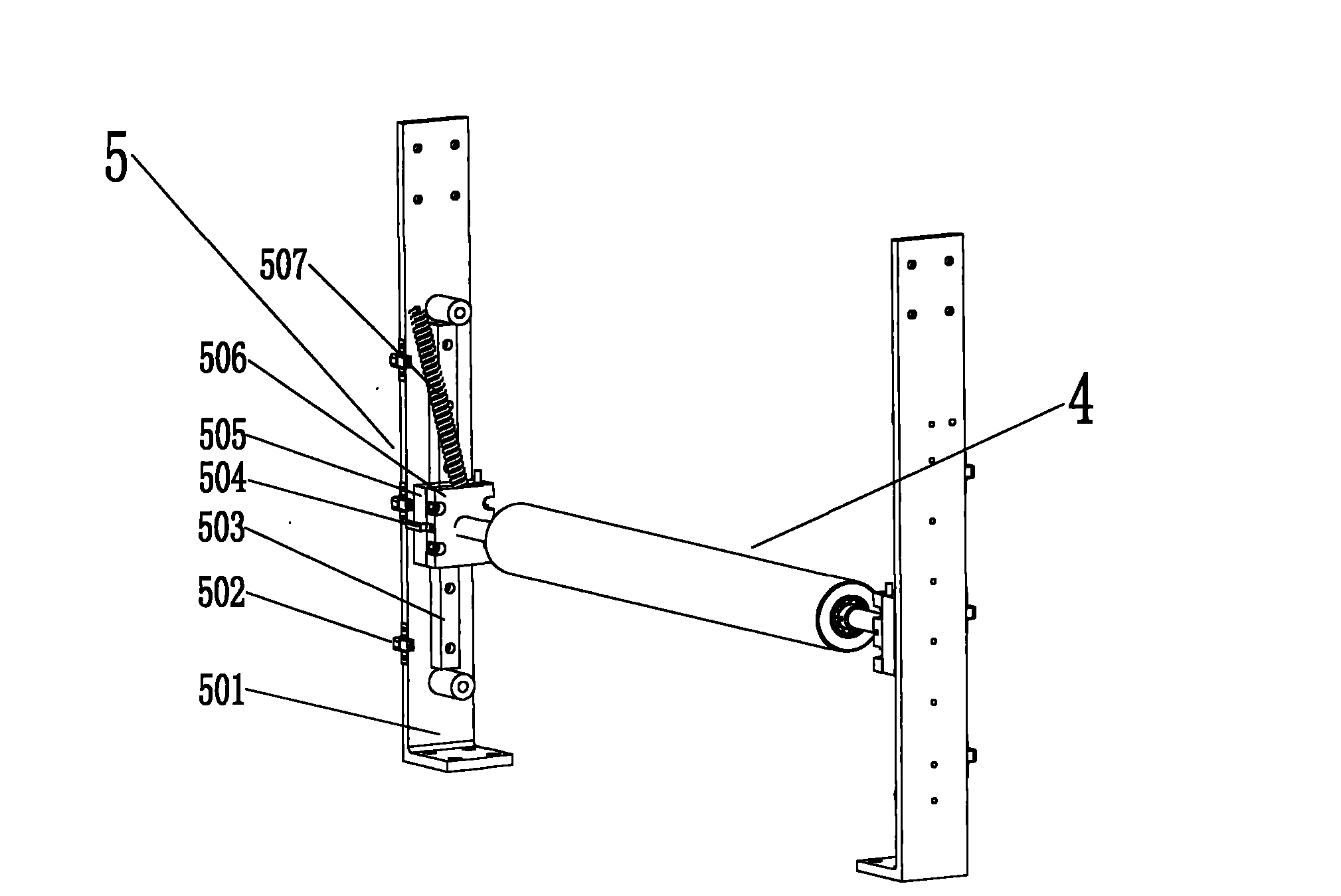

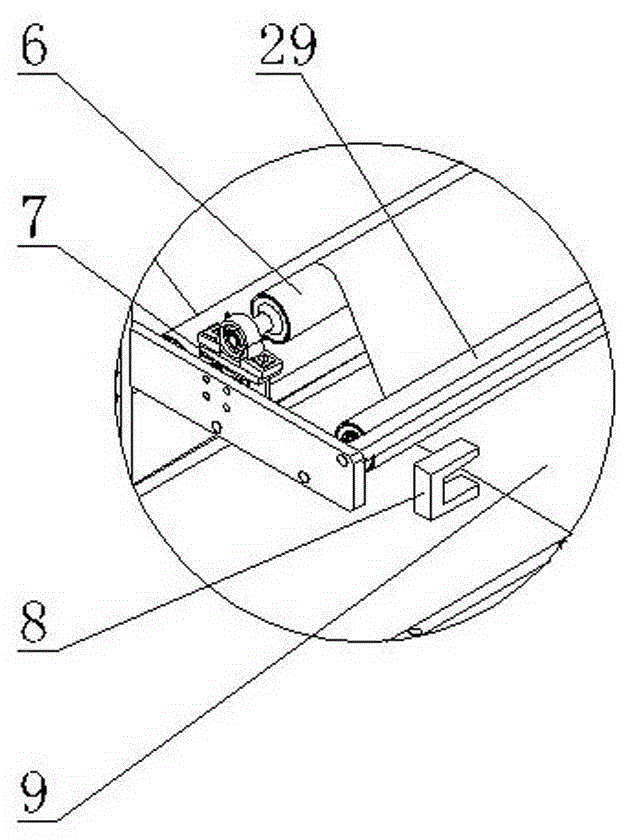

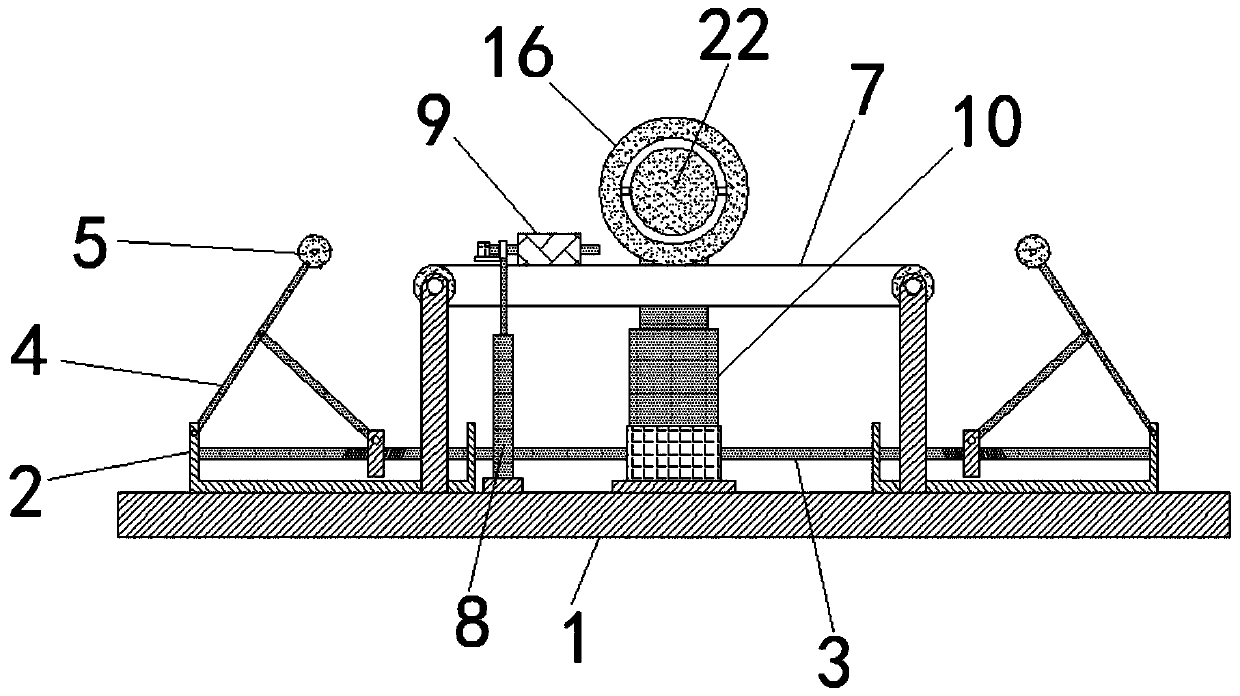

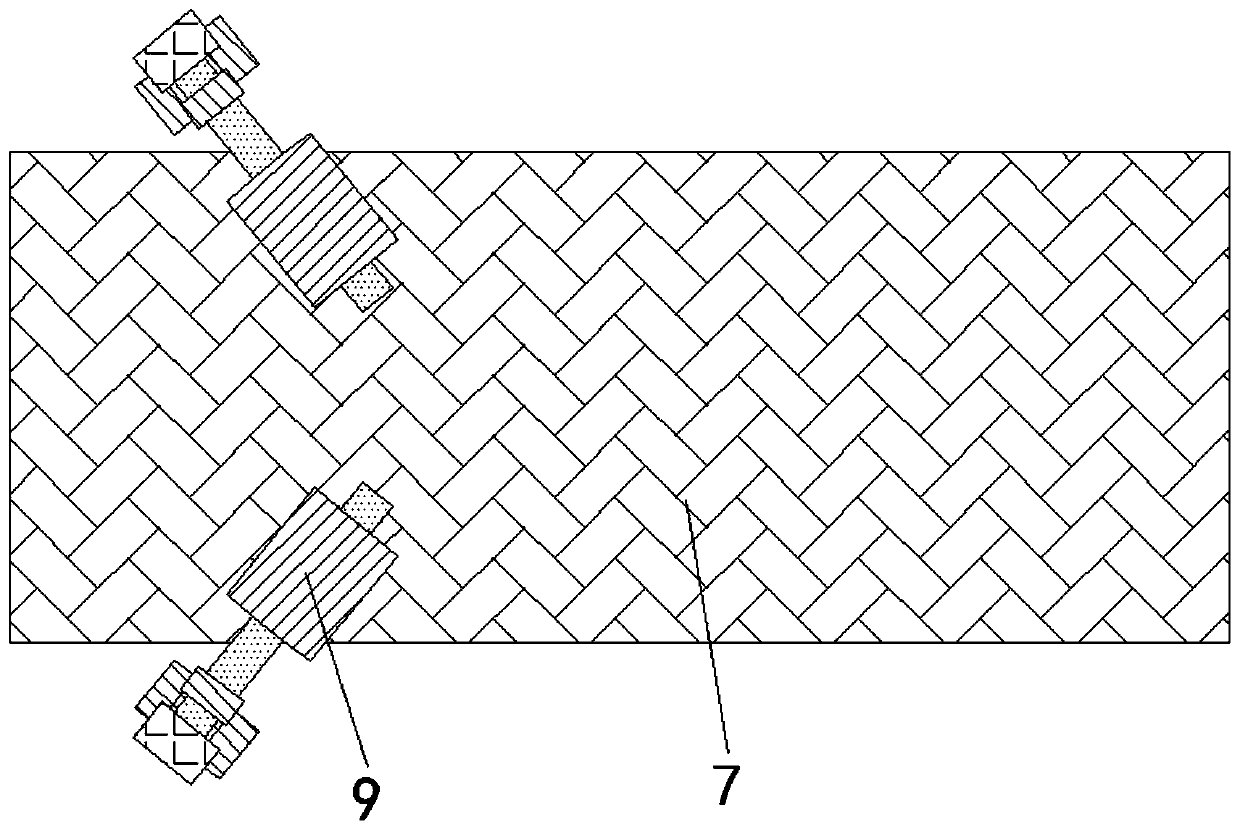

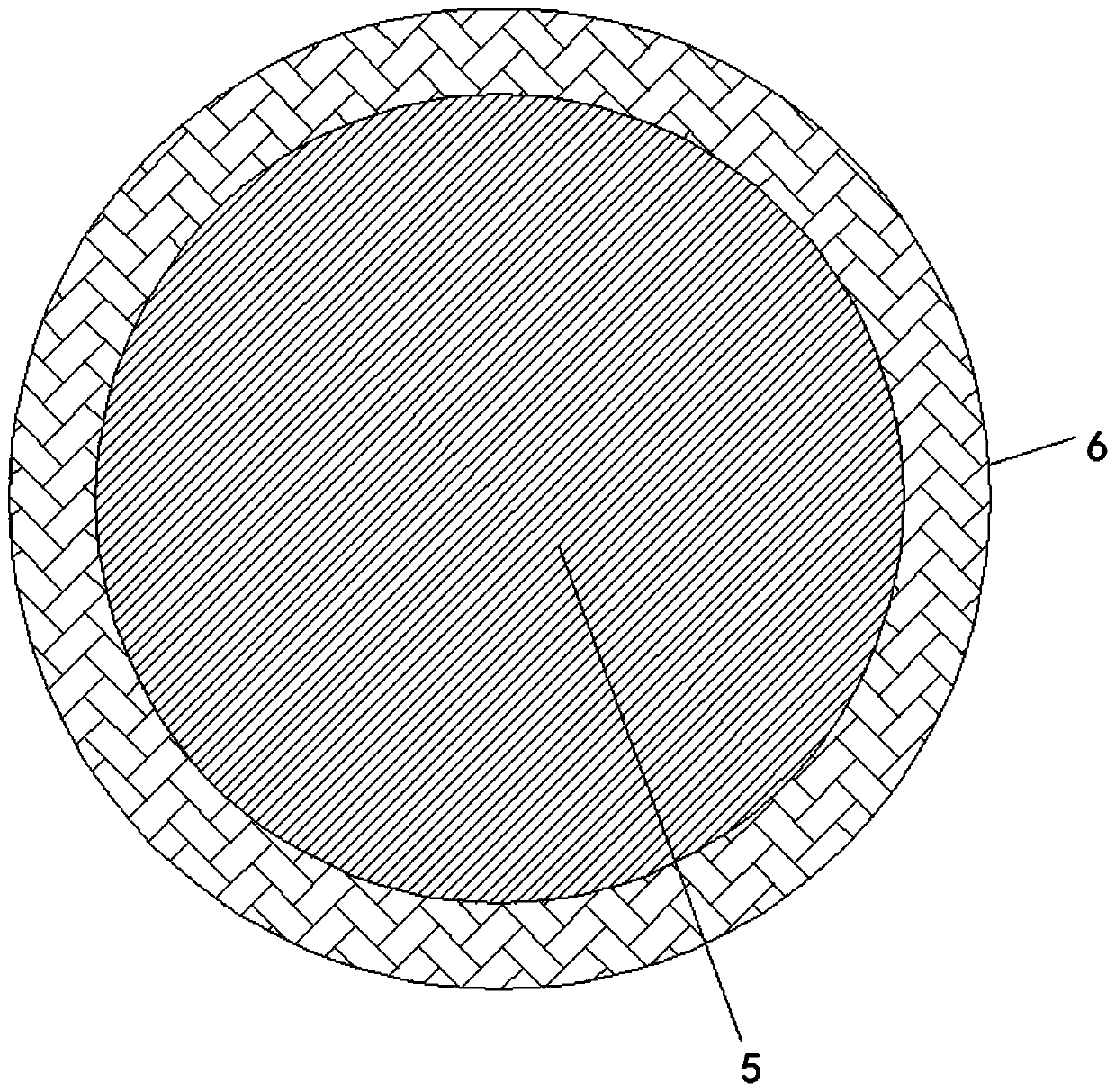

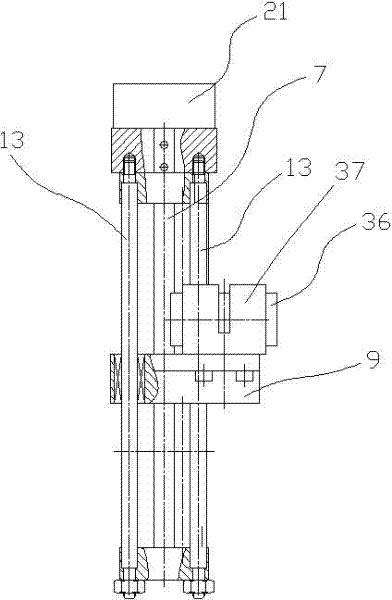

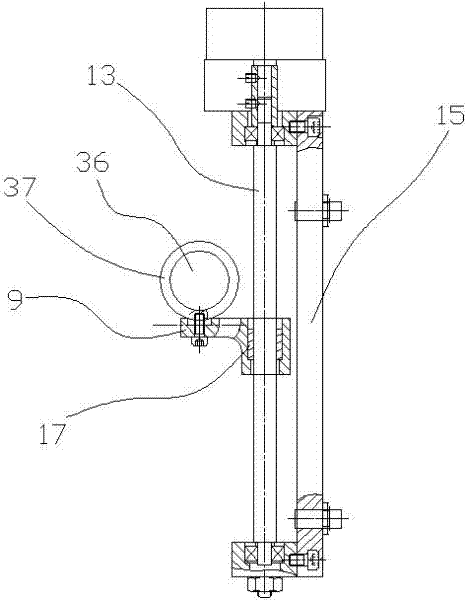

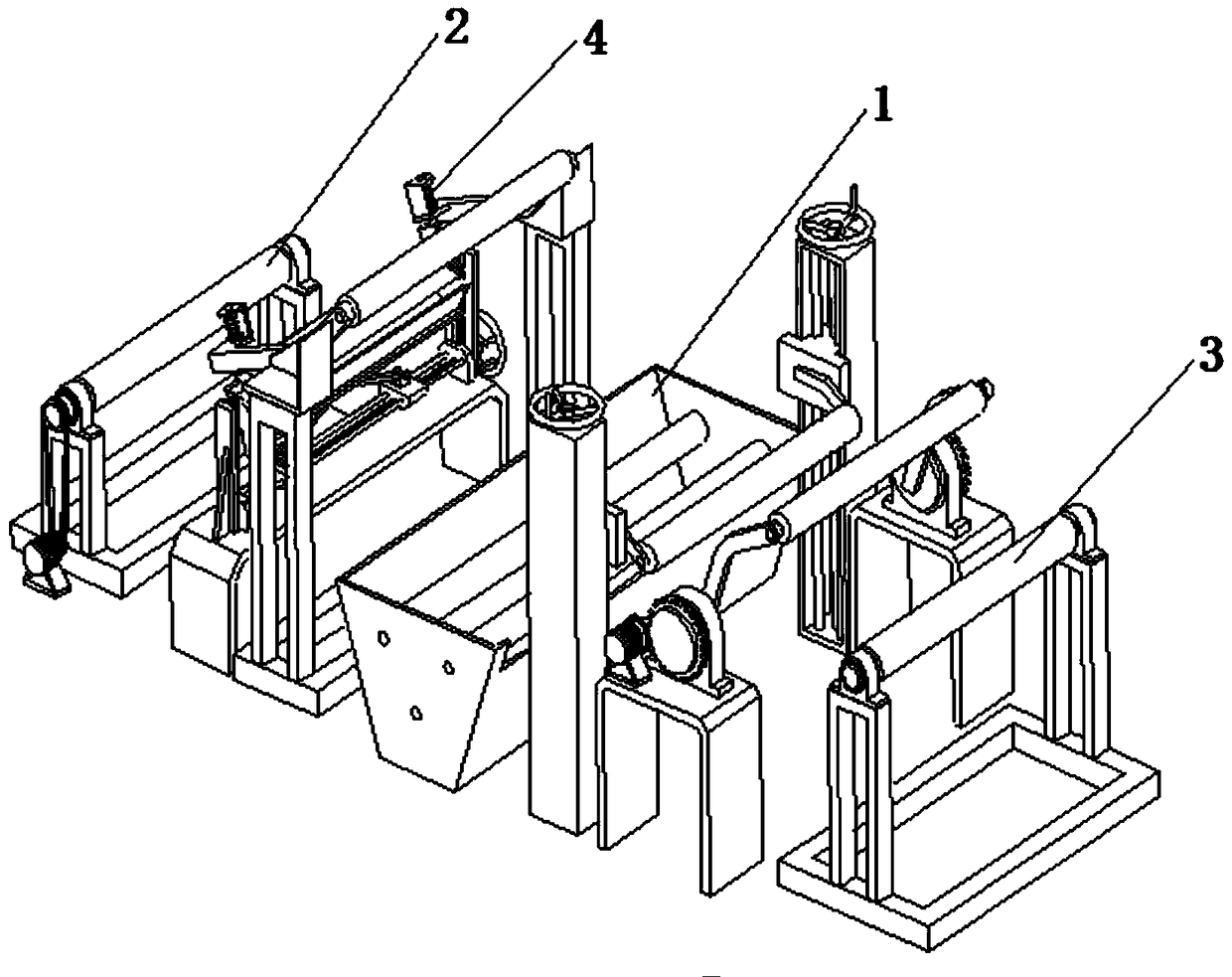

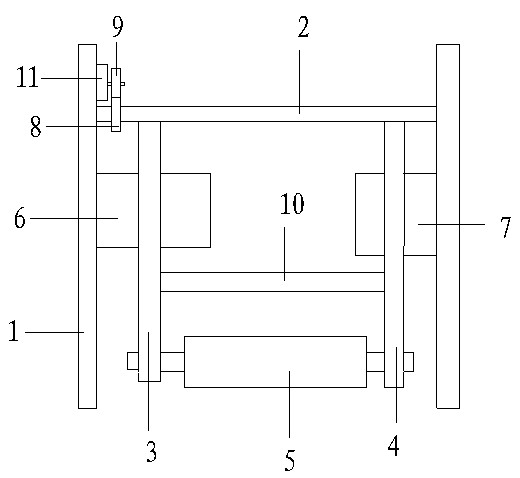

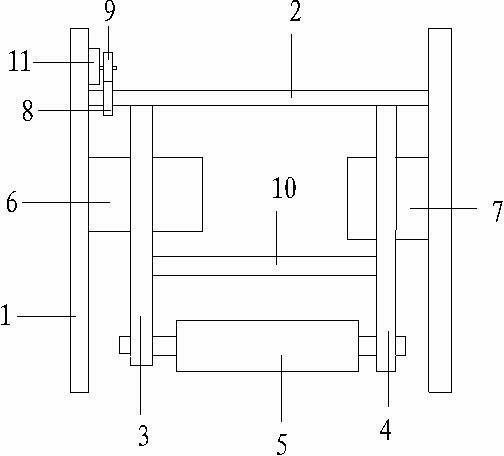

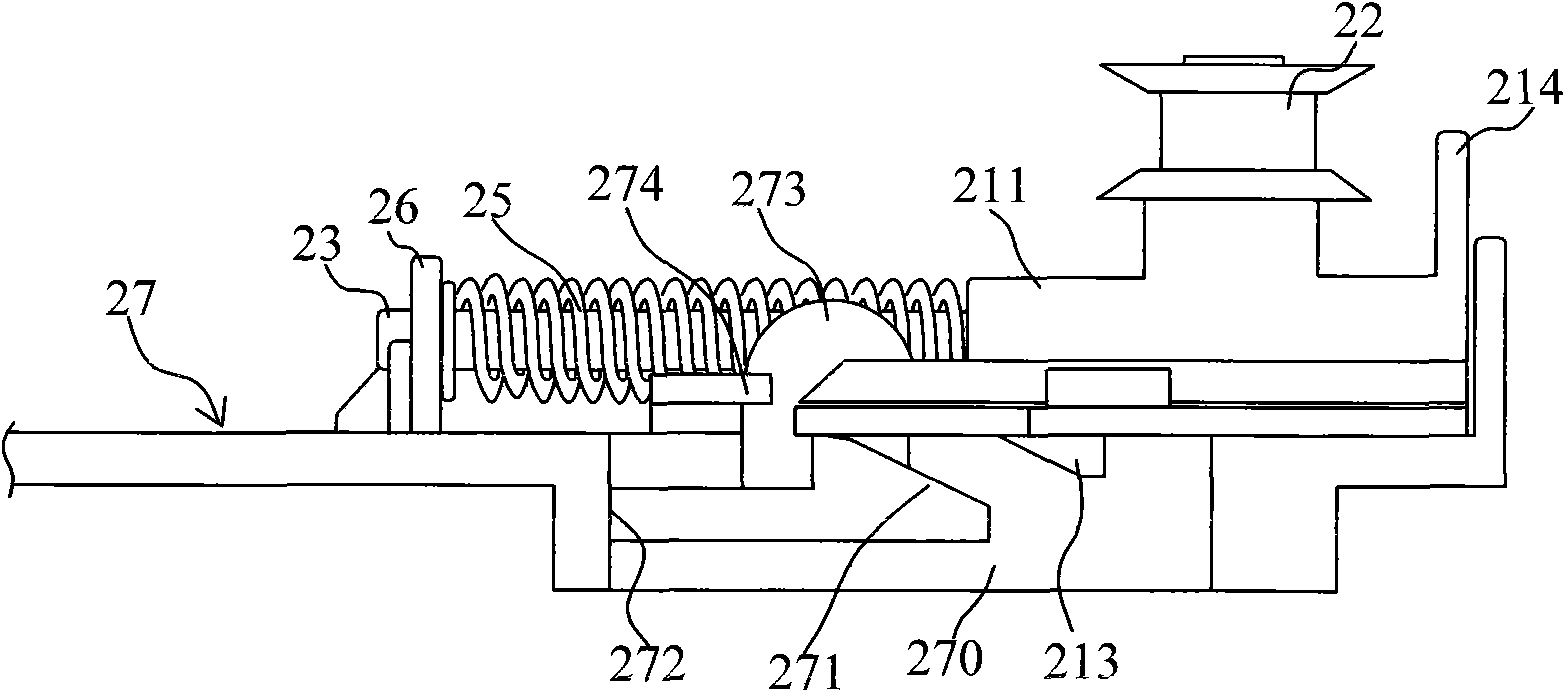

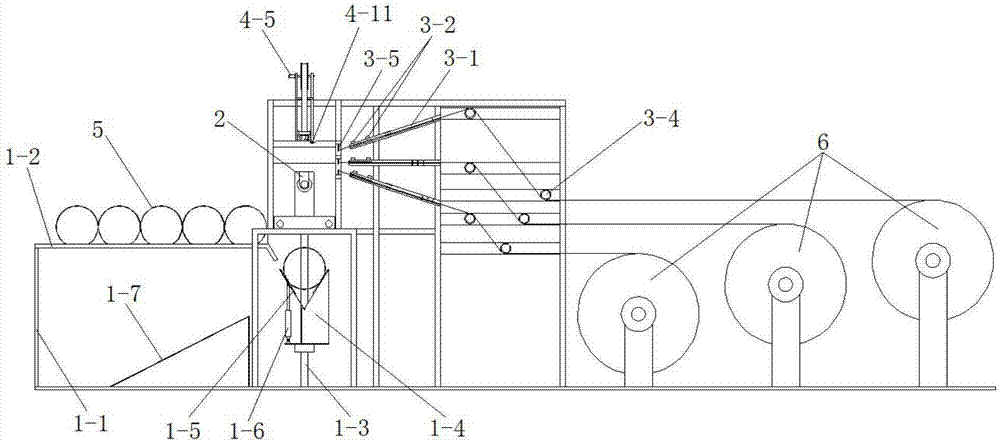

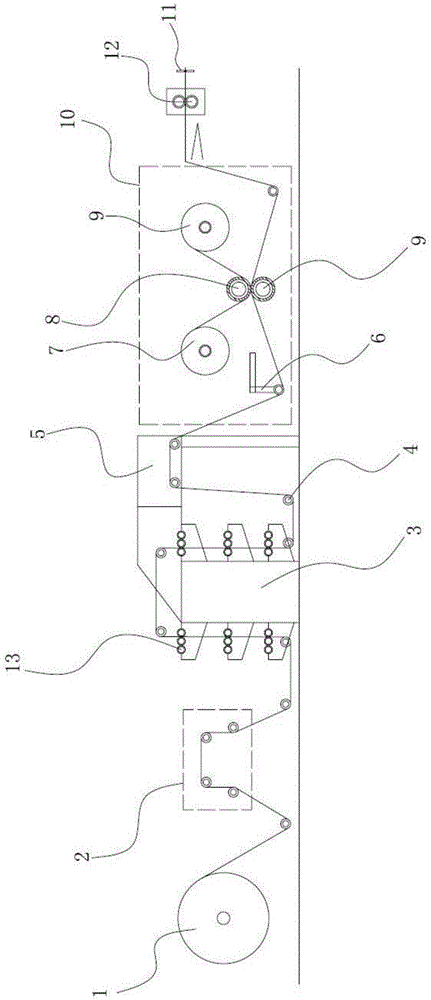

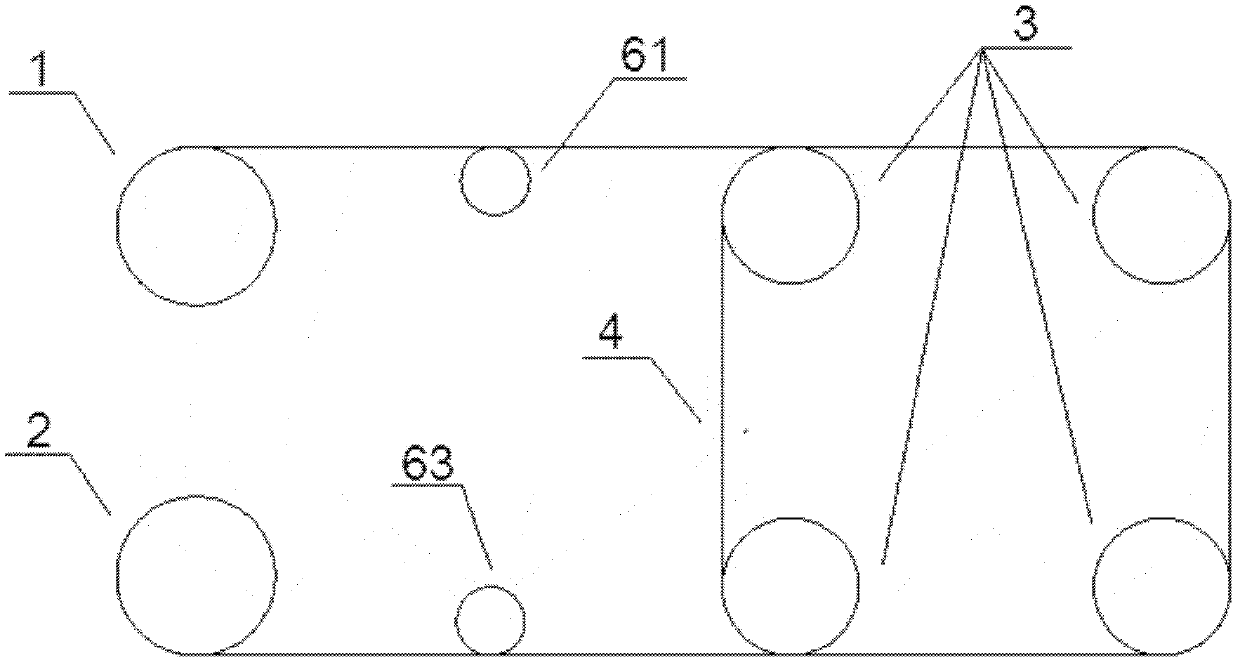

Coiled material conveying tensioning device

ActiveCN102491118AAutomatic tension adjustmentAvoid breakingWebs handlingEngineeringMechanical engineering

The invention provides a coiled material conveying tensioning device, which comprises a working platform support (1), and a first guide roller assembly (2), a second guide roller assembly (3), a tensioning guide roller assembly (4) and a tensioning guide roller support assembly (5), which are arranged on the working platform support, wherein the tensioning guide roller support assembly (5) is arranged between the first guide roller assembly and the second guide roller assembly, and the tensioning guide roller assembly is supported on the tensioning guide roller support assembly and below the first guide roller assembly and the second guide roller assembly; the tensioning guide roller support assembly can regulate the height of the tensioning guide roller assembly to allow a coiled material to be tensioned after the coiled material passes through a first guide roller, a tensioning guide roller and the second guide roller. The coiled material conveying tensioning device with a simple structure has the advantages of quick response and automatic regulation of the tension of the coiled material at a feeding end.

Owner:CHERY AUTOMOBILE CO LTD

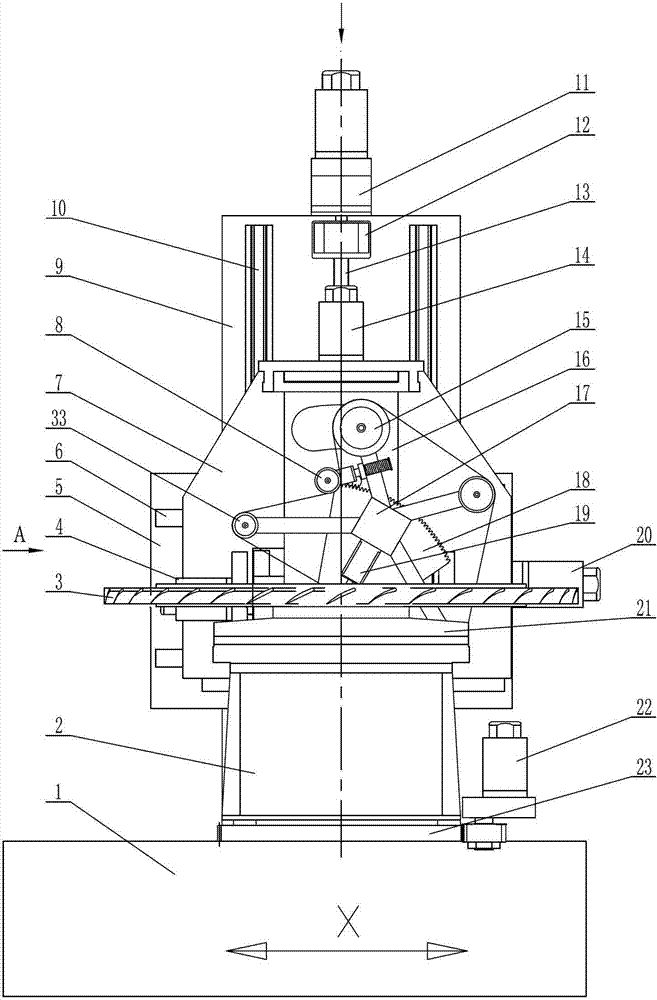

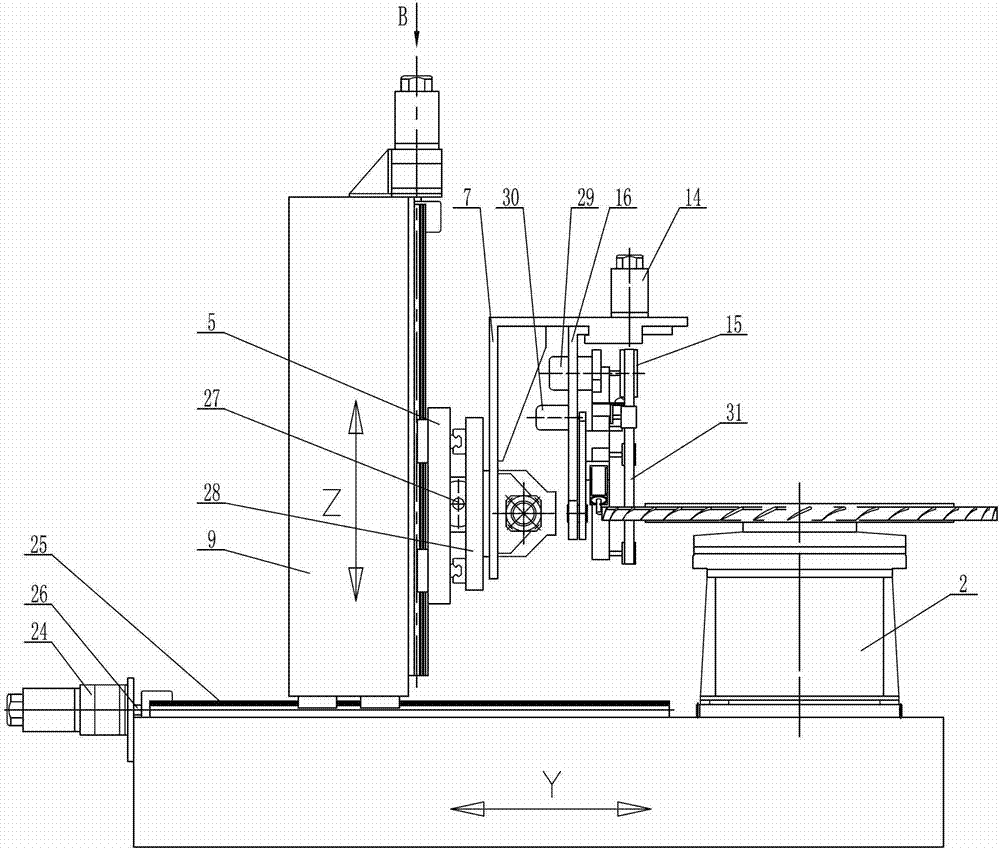

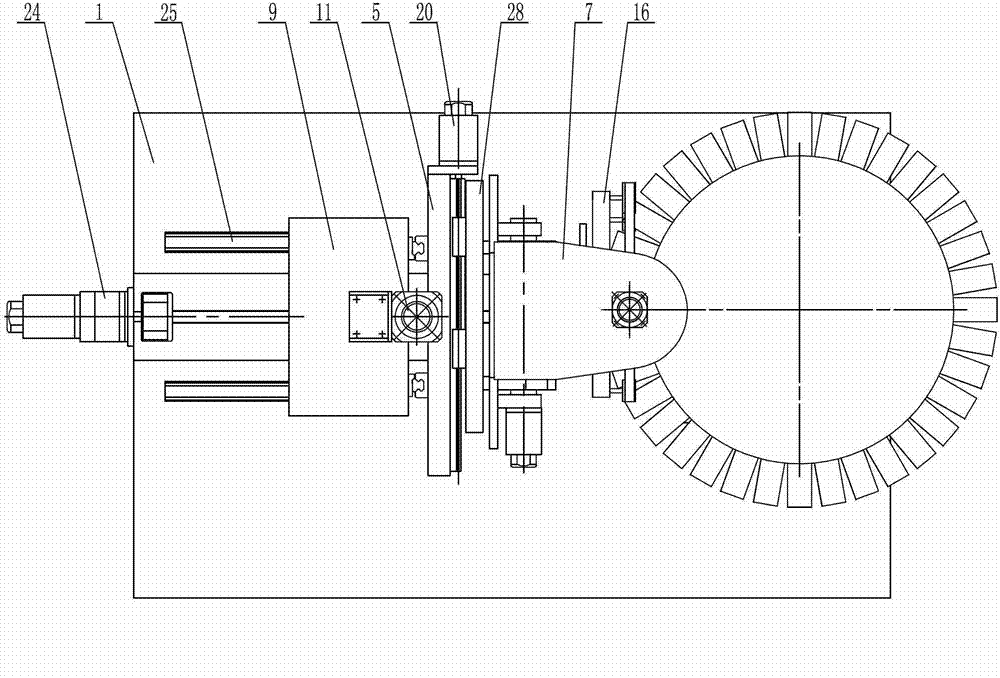

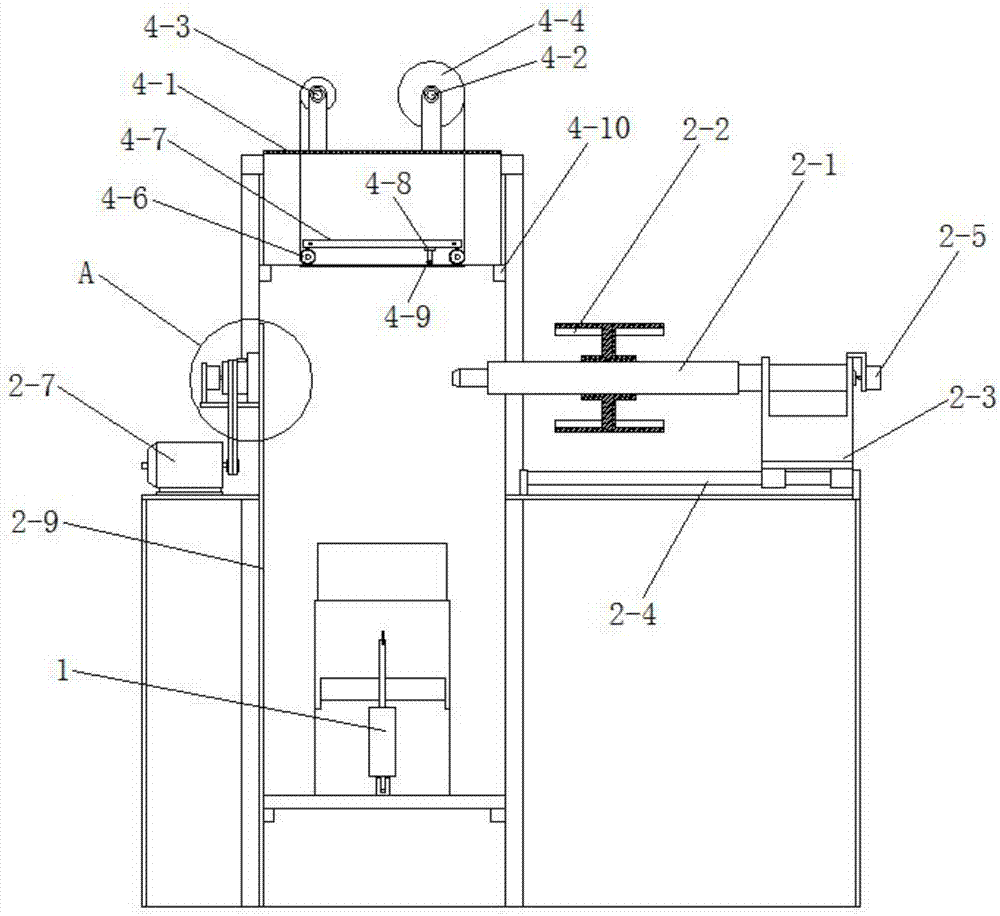

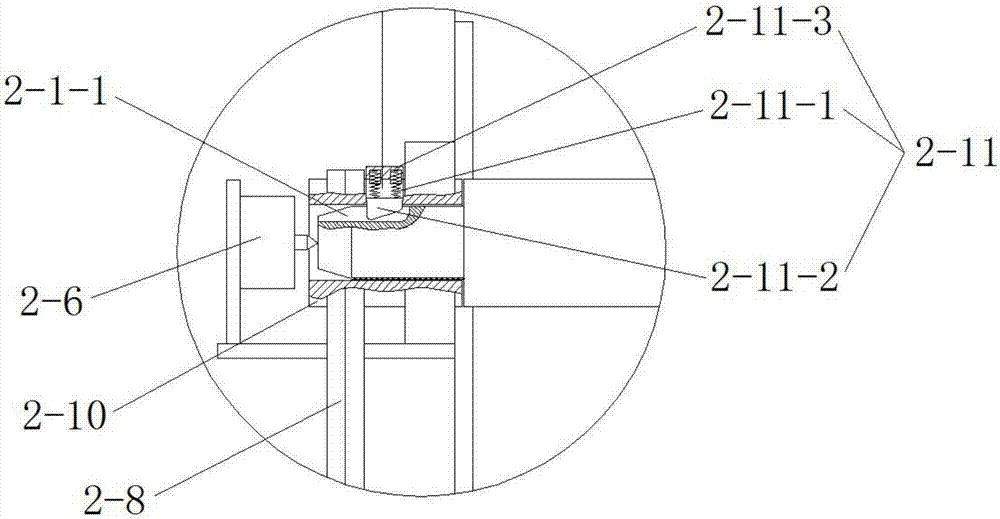

Abrasive belt grinding device applicable to inner and outer cambered surfaces of blades of aerospace blisk

InactiveCN102729124AImprove work efficiencyGuaranteed accuracyBelt grinding machinesSix degrees of freedomBelt grinding

The invention discloses an abrasive belt grinding device applicable to inner and outer cambered surfaces of blades of aerospace blisk. An X axis transverse feed mechanism, a Y axis transverse feed mechanism and a Z axis longitudinal feed mechanism form a grinding head feed mechanism; an A axis deflection motor, an A axis deflection bracket, a B axis motor, a gear train bracket, a C axis motor, a C axis revolving bracket and the like form a position adjusting mechanism of the grinding head. The abrasive belt grinding device provided by the invention guarantees rigidity of a grinding head mechanism and a work piece clamping mechanism through rational distribution of the grinding head feeding, the position adjustment of the grinding head and the position and angle adjustment of the work piece and through combination of space in six degrees of freedom by a short transmission chain; a contact wheel and an abrasive belt can cut into a narrow gap between two blades of the blisk, so as to ensure the contact between the contact wheel and the work piece to be stable when the contact wheel rotates at a high speed; so that the abrasive belt grinding device can improve the work efficiency, and meanwhile, dimensional accuracy of complex cambered surface of the work piece in processing can be guaranteed, the quality of the molded surface is ensured, the rate of qualified products is improved, the labor intensity of workers is reduced and the management and production costs are lowered.

Owner:CHONGQING UNIV +1

Coiled material conveying and tensioning device

ActiveCN102514968AAutomatic tension adjustmentAvoid breakingWebs handlingEngineeringMechanical engineering

The invention discloses a coiled material conveying and tensioning device, which comprises a workbench support (1), and a first guide roller assembly (2), a second guide roller assembly (3), a tensioning guide roller assembly (4) and a tensioning guide roller support assembly (5) which are arranged on the workbench support, wherein the tensioning guide roller support assembly is arranged between the first guide roller assembly and the second guide roller assembly; the tensioning guide roller assembly is erected on the tensioning guide roller support assembly; the tensioning guide roller assembly is positioned below the first guide roller assembly and the second guide roller assembly; the first guide roller assembly comprises a first guide roller; the second guide roller assembly comprises a second guide roller; the tensioning guide roller assembly comprises a tensioning guide roller; and a coiled material passes through the first guide roller, the tensioning guide roller and the second guide roller in turn to reach a tension state. The coiled material conveying and tensioning device has a simple structure and has the advantages of high response speed and capacity of automatically adjusting the tension of the coiled material at a feed end.

Owner:CHERY AUTOMOBILE CO LTD

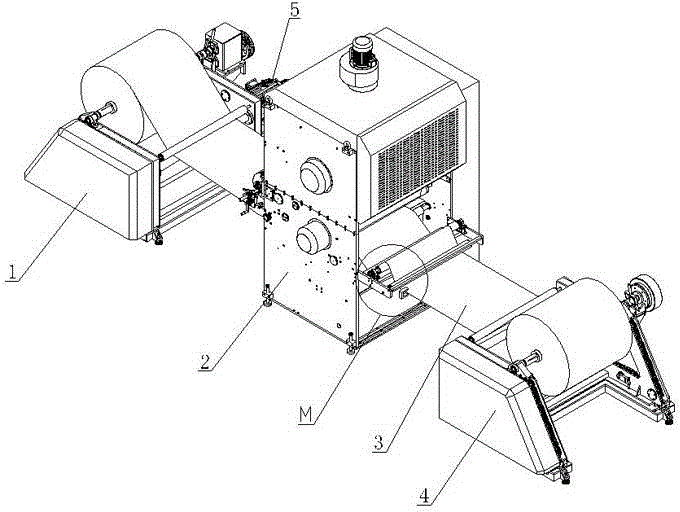

Full-automatic laminating machine

ActiveCN104097972AAutomatic tension adjustmentAchieve installationWebs handlingRolling paperPressure transmission

The invention discloses a full-automatic laminating machine which comprises an emptying mechanism, a laminating mechanism, a material collecting mechanism and a programmable logic controller (PLC), wherein the emptying mechanism is provided with a storage rack which is provided with a locating seat; the storage rack is formed by connecting two side plates by a connecting rod; the storage rack is arranged on a base in a sliding way; the base is provided with a first driving mechanism connected with the storage rack in a transmission way; a pressure sensor and a distance sensor are arranged between the emptying mechanism and the laminating mechanism; the pressure sensor is provided with a pressure transmission roller; paper passes through the distance pressure and comes round the pressure transmission roller from the upper part; a magnetic powder clutch connected with an inflatable shaft is arranged at one side of a mounting seat by a mounting plate; the locating seat comprises a fixed seat and a movable seat; the inflatable shaft is tightly held by the movable seat and the fixed seat which are in a sliding fit way. The full-automatic laminating machine is capable of automatically adjusting the tensity of the paper so as to enable the tension of the paper to be constant, is capable of automatically correcting the deviation of the paper, can be used for loading and unloading roll paper, and is more convenient and faster.

Owner:RUIAN RUISHEN IND

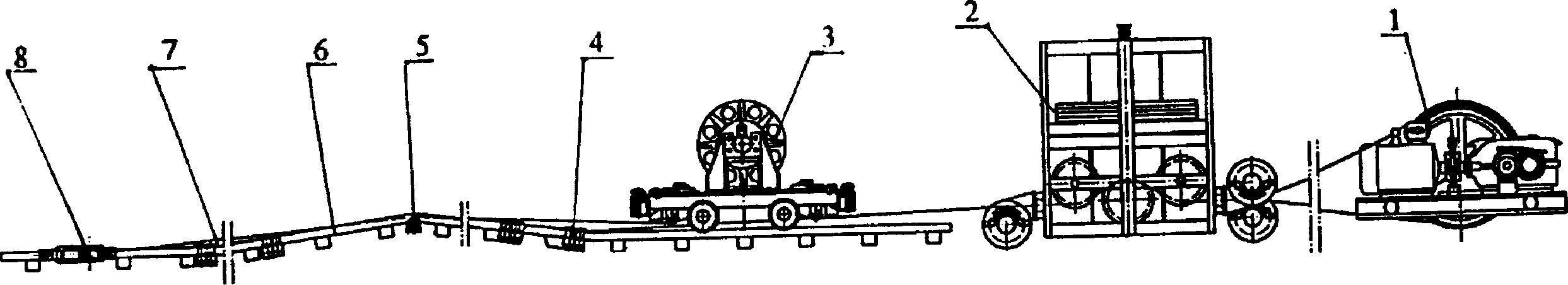

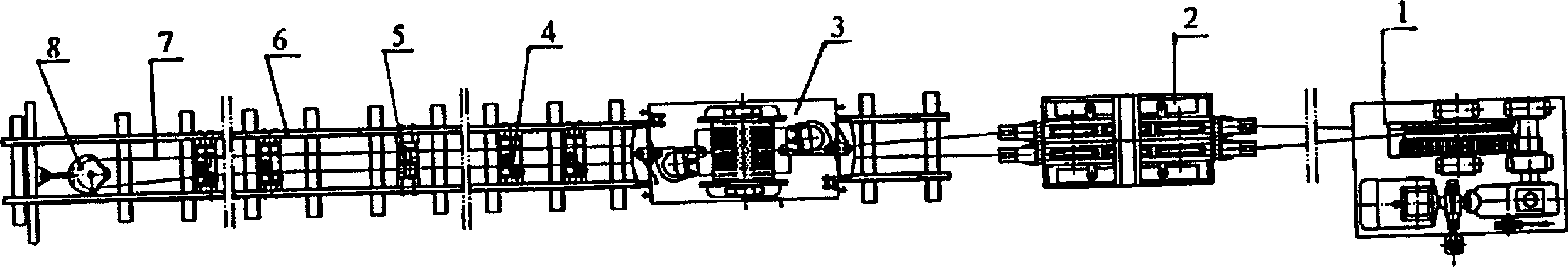

Continuous drafter

InactiveCN1093836CCompact structureAutomatic tension adjustmentDraw-gearWinding mechanismsDesign draftsmanDrafter

The invented continuous tractor is composed of non-polar rope hoister, steel cable tension device, shuttle, rope pressing device, rope supporting wheel, rail, steel cable and tail wheel, the non-polar rope hoister is compact in structure, and the tension of steel cable can be regulated automatically. Measures are adopted with respect to safety and protection of steel cable. It is suitable for usein narrow tunnel lanewidth and is convenient in operating, transfering, installing, maintaining, etc. It is good in technical performance and safety.

Owner:CHANGZHOU DEV & MFR CENT

Levelling and ironing device for textile fabric

InactiveCN111235804AIncrease profitAutomatically adjust fabric tensionTextile treatment machine arrangementsTextile treatment with treating outlet contectStructural engineeringManufacturing engineering

The invention relates to the technical field of textile fabric ironing, and discloses a levelling and ironing device for a textile fabric. The levelling and ironing device comprises a base, wherein symmetrical fixed frames are fixedly arranged at the upper end of the base; a screw is rotationally connected between the fixed frames; the outer side of each fixed frame is movably hinged with a connecting rod which extends to the screw; the top end of each connecting rod is rotationally connected with a compression roller; a conveyor belt is arranged in the middle of the upper end of the base; spring levers are arranged at the upper end of the base and at the front part and the rear part of the conveyor belt; and a levelling roller is arranged at the upper end of each spring lever. According to the levelling and ironing device for the textile fabric, the fabric is levelled and tensioned through cooperation of the compression rollers and the levelling rollers, the release amount of a steamroller is adjusted by using resistance variation of a photo-resistor, and fixed-point release of steam is achieved through pressing movable plates by corresponding metal balls, thereby achieving the effects of automatically adjusting the tension of the fabric, reasonably releasing the steam to iron the fabrics of different thicknesses and improving the utilization rate of the steam.

Owner:杭州源凯诚科技有限公司

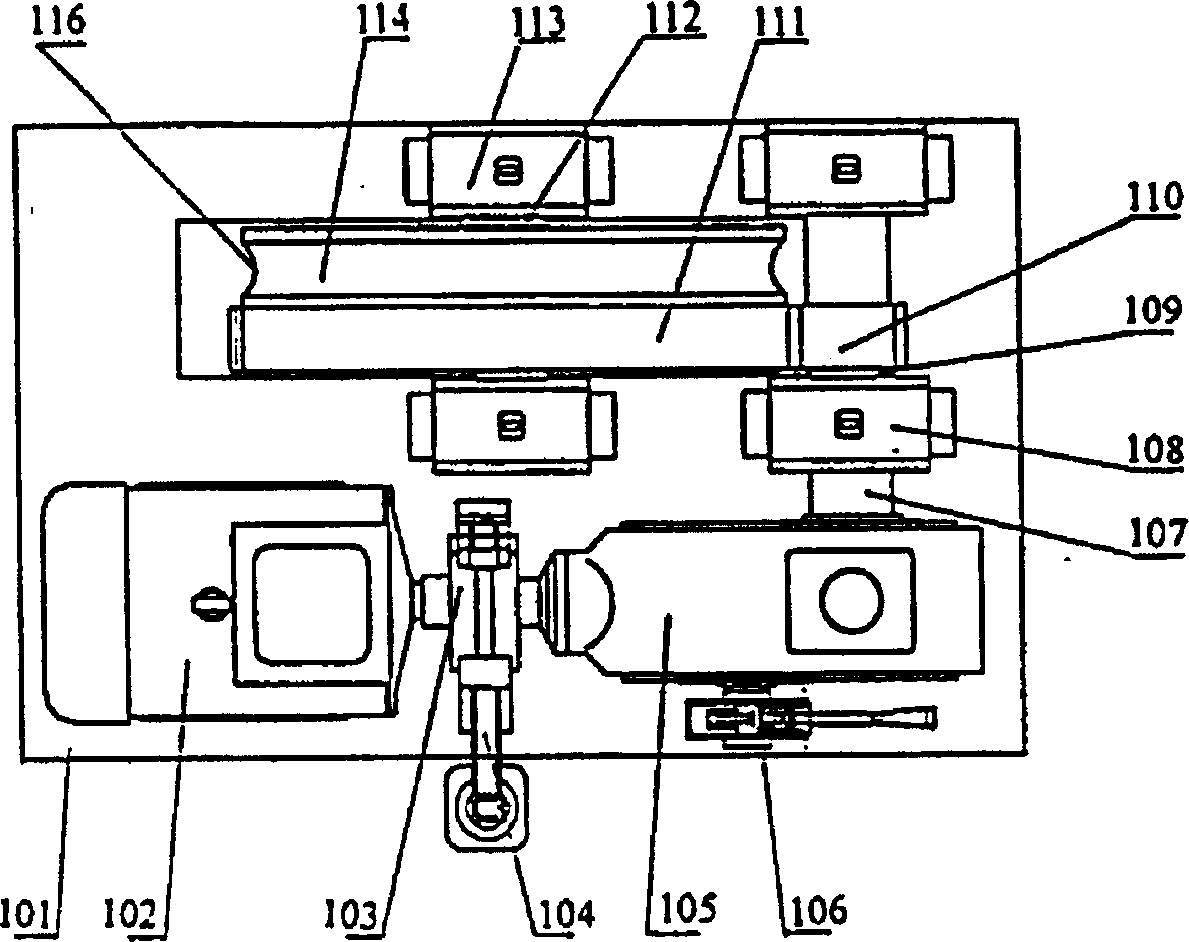

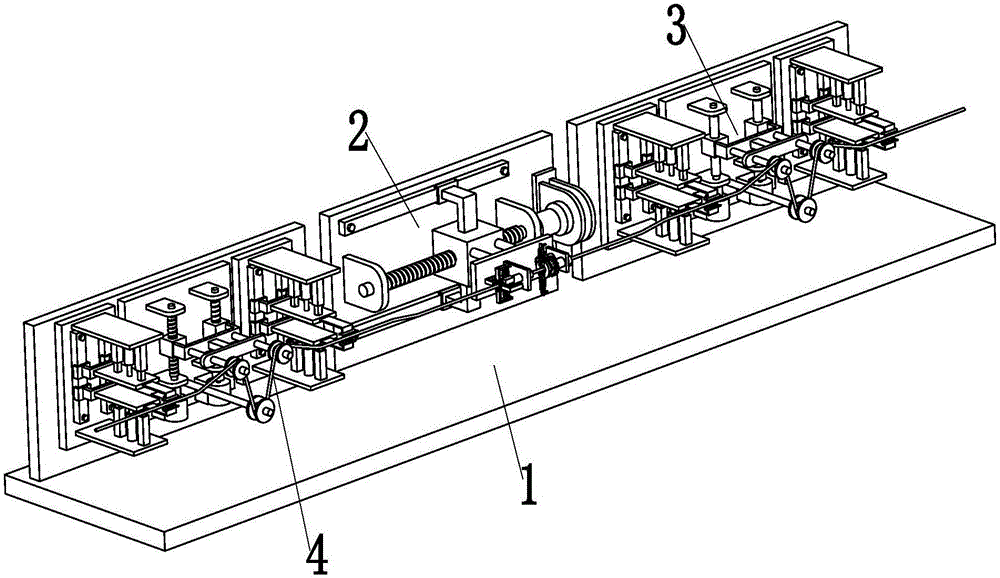

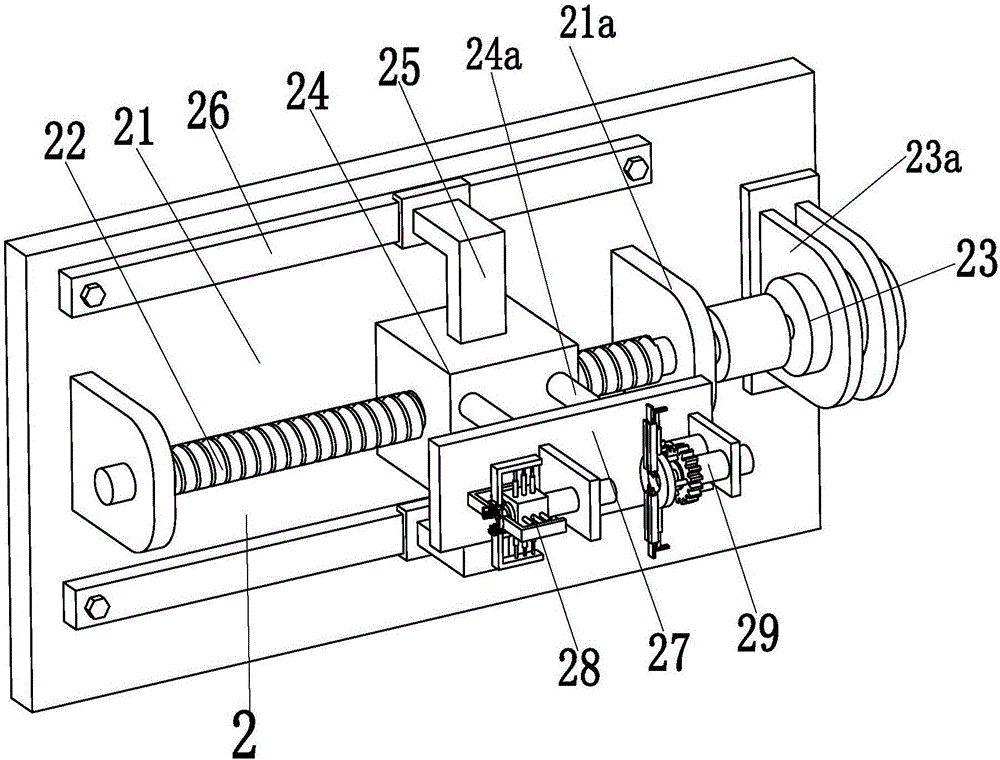

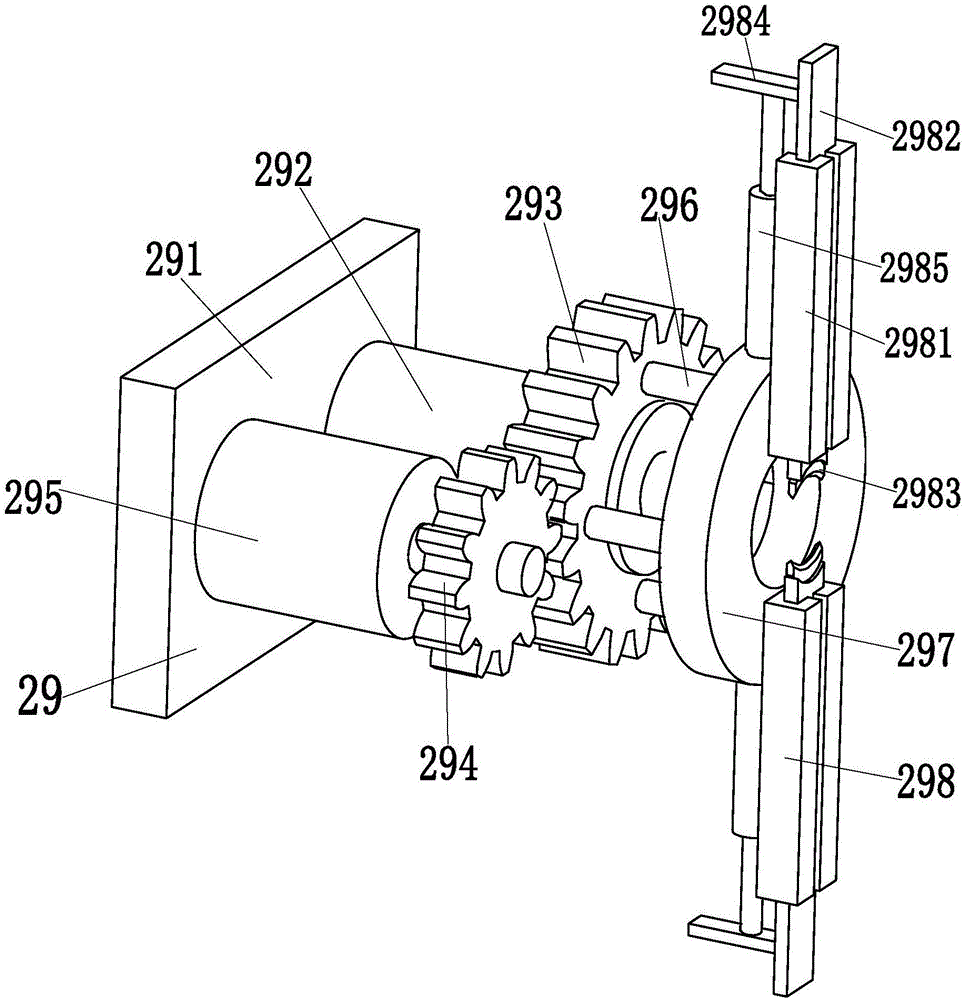

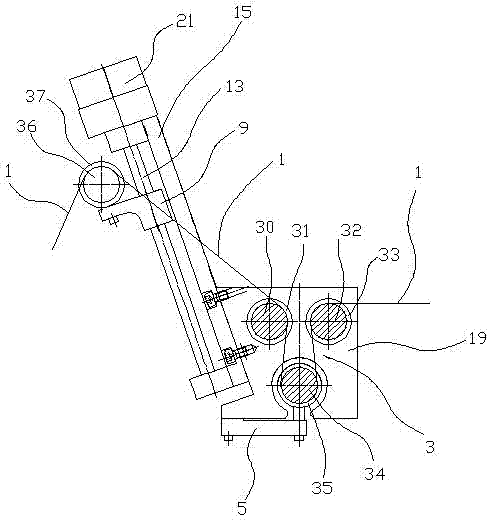

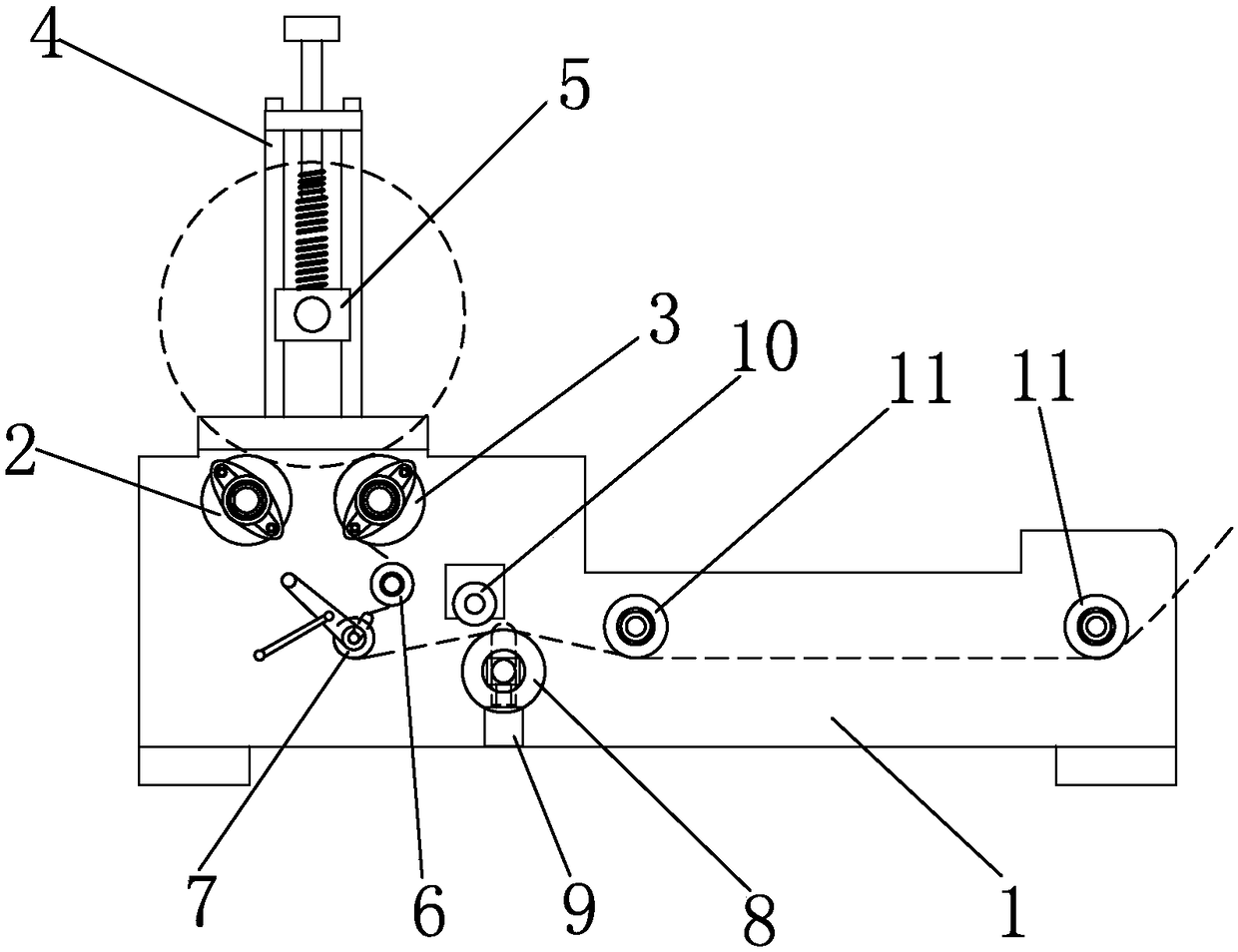

Vehicle wire harness full-automatic processing device

InactiveCN106129779AGood clamping effectFast and even automatic strippingVehicle connectorsLine/current collector detailsAutomatic processingCable harness

The invention relates to a fully automatic processing equipment for vehicle wire harnesses, comprising a base plate and a wire harness body, a ring cutting and stripping device is installed in the middle of the upper end surface of the base plate, and two clamping and tensioning devices are symmetrically installed on both sides of the upper end surface of the base plate; the wire harness body The two ends of the wire harness are passed through two clamping and tensioning devices respectively, and the middle part of the wire harness body is passed through the ring cutting and stripping device. The ring cutting and stripping device can realize the automatic ring cutting and wire stripping function during the processing of the wire harness body. The tensioning device can realize the automatic tensioning and clamping functions during the processing of the wire harness body. The invention can realize the integrated processing functions of automatic tensioning, clamping, ring cutting and wire stripping during the processing of vehicle wire harness, without manual operation, manual ring cutting, manual stripping, manual adjustment of tension force, and manual adjustment The clamping force has the advantages of good automatic ring cutting effect, good wire stripping quality, high wire stripping efficiency, good tension adjustment performance, good tension adjustment effect, poor clamping effect and high work efficiency.

Owner:YJH ELECTRICAL EQUIP

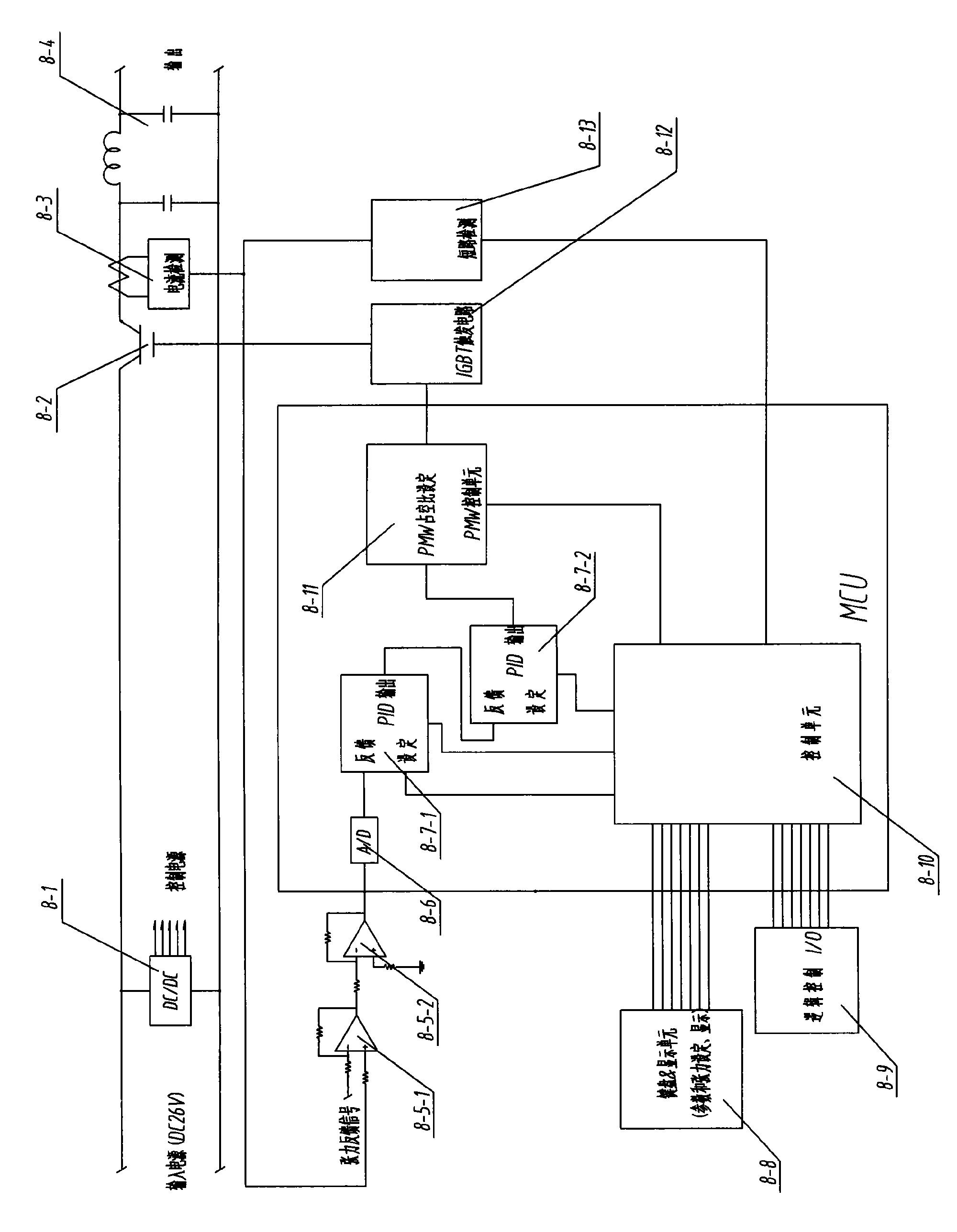

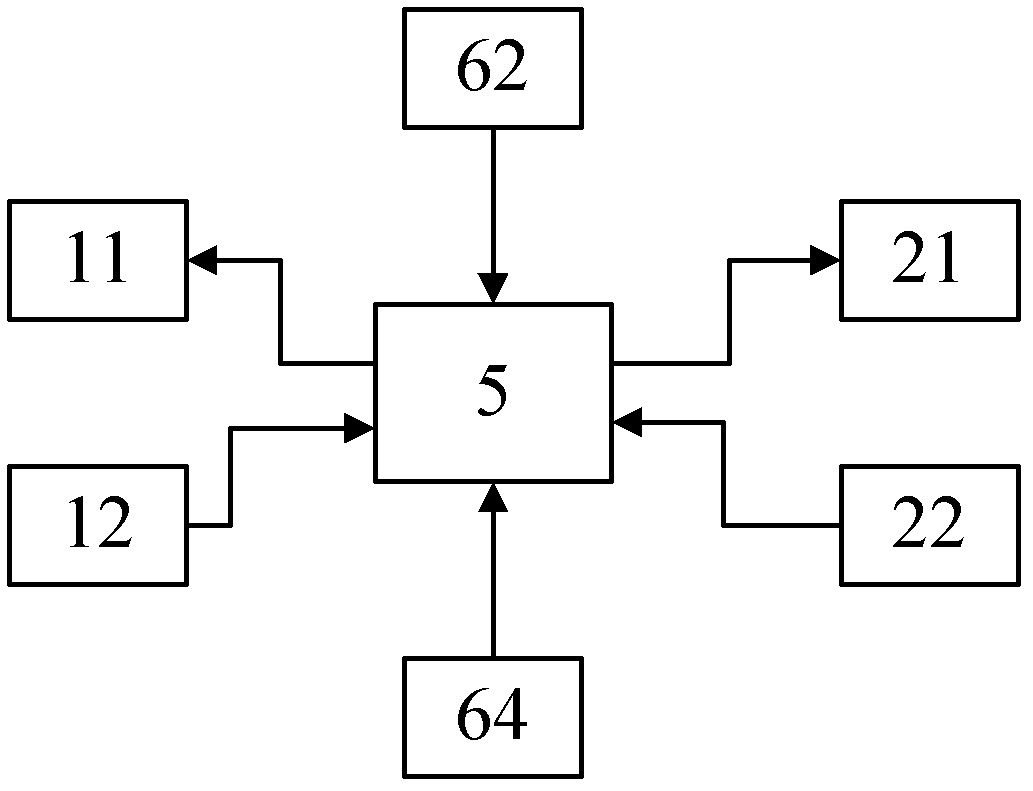

Linear cutting molybdenum wire tensile force automatic control system and tensile force control method

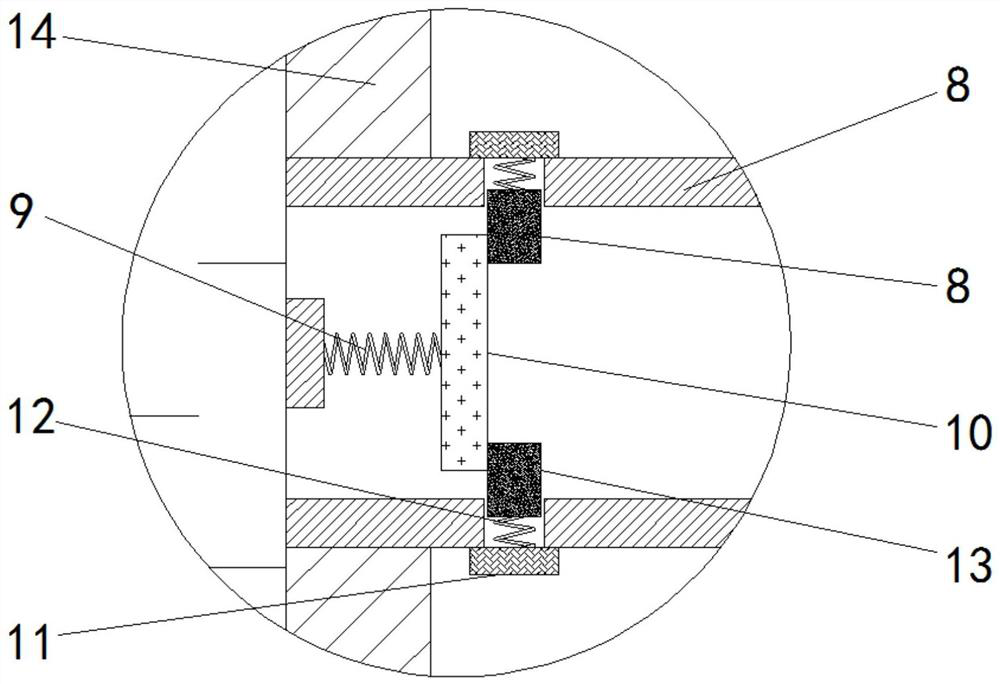

InactiveCN102416510AAutomatic tension adjustmentImprove the finishElectrical-based machining electrodesMicrocontrollerMachine parts

The invention discloses a linear cutting molybdenum wire tensile force automatic control system and tensile force control method. The linear cutting molybdenum wire tensile force automatic control system comprises a plurality of guide wheels, a driving device, a sensor and a control unit, wherein molybdenum wire are wound on the guide wheels; the driving device is used for driving one guide wheel to slide; and the control unit receives a sensor signal and allows the driving device to drive the guide wheels to slide. The tensile force control method comprises the following steps: presetting a standard value on a singlechip; allowing the senor to acquire the value of the ensile force of a molybdenum wire; allowing the singlechip to convert the value of the tensile force into a comparison value; summing the comparison value and a standard value to obtain a driving value; if the driving value is bigger than zero, allowing a step motor to rotate anticlockwise, and if the driving value is smaller than zero, allowing the step motor to rotate clockwise; and repeating the previous step till the driving value is zero. In the invention, the tensile force of the molybdenum wire can be regulated automatically, and the smooth finish of a machined part can be improved greatly.

Owner:NINGBO HUIJIN METAL PRODS

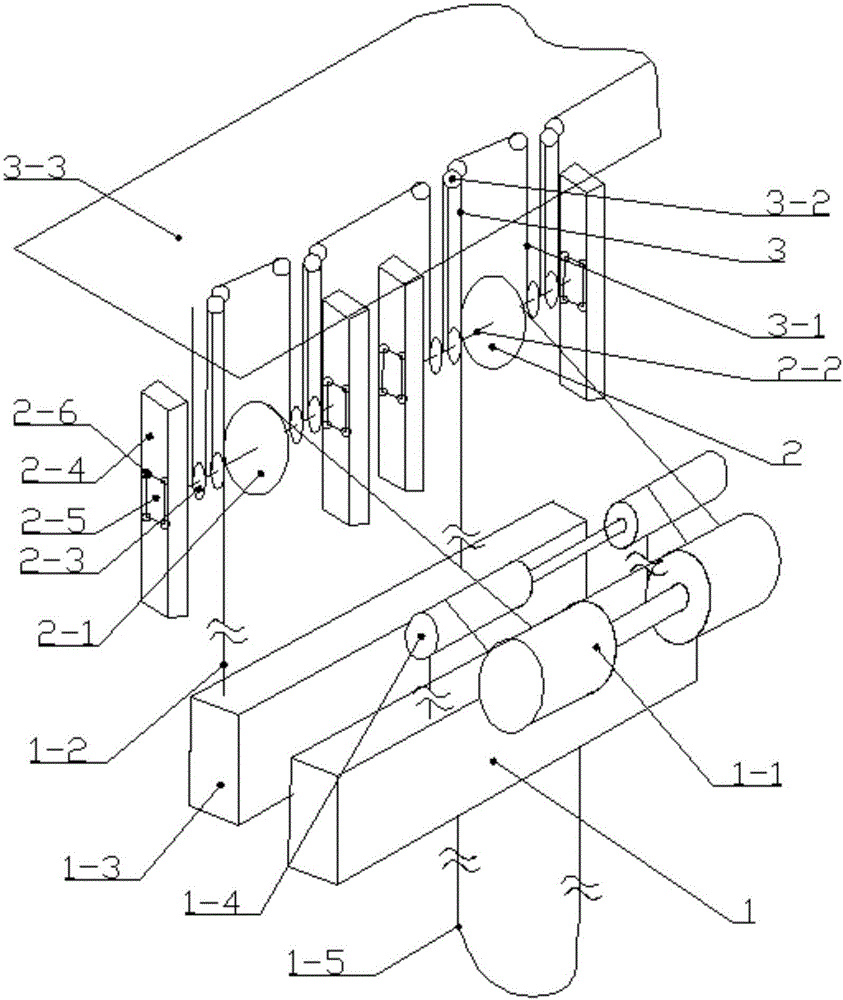

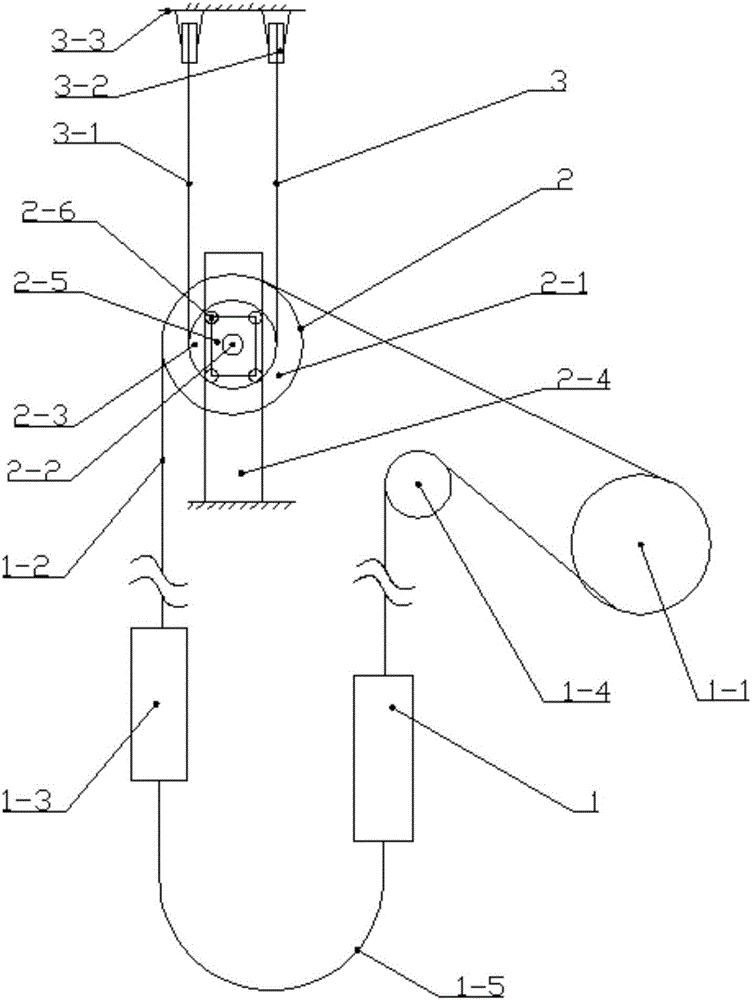

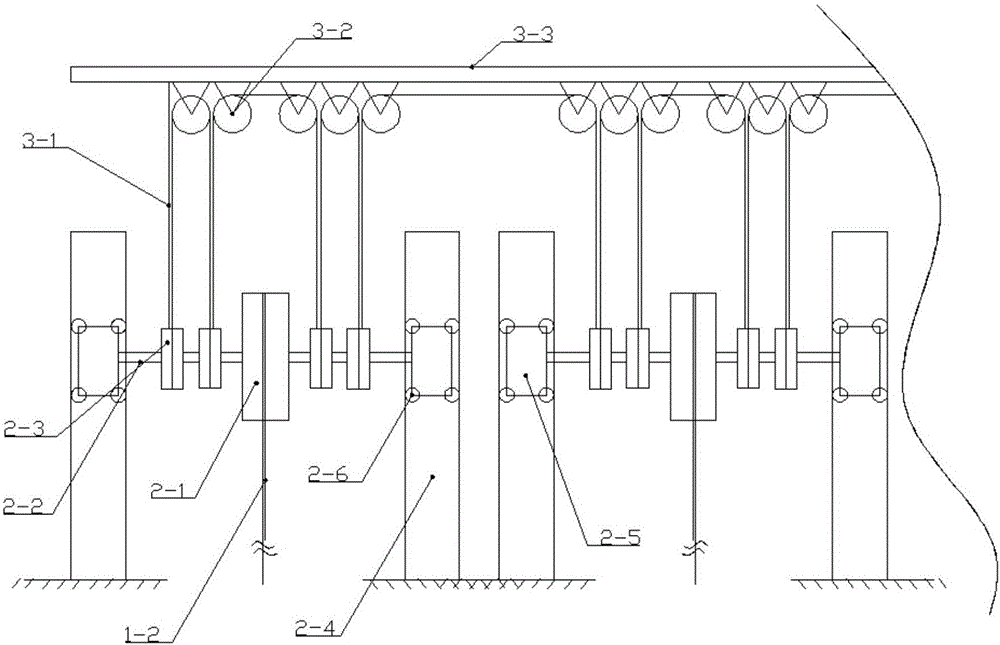

Automatic tension balancing device and method of multi-rope winding hoisting steel wire ropes for deep vertical shaft

The invention discloses an automatic tension balancing device and method of multi-rope winding hoisting steel wire ropes for a deep vertical shaft. The device comprises a driving system composed of roller hoisters, the hoisting steel wire ropes, hoisting containers, diversion sheaves and a tail rope, the driving system is provided with sliding guide head sheaves capable of moving vertically, and the sliding guide head sheaves are connected to tension balance mechanisms composed of balance ropes. In the operation process of a hoisting system, when the tension of the steel wire ropes is not balanced, tension balance can be realized through the tension balance mechanisms connected to the sliding guide head sheaves. The device has the advantages that the structure is simple, machining is easy, the performance is reliable, installation and maintenance are simple and the tension balance of the steel wire ropes can be automatically adjusted.

Owner:CHINA UNIV OF MINING & TECH

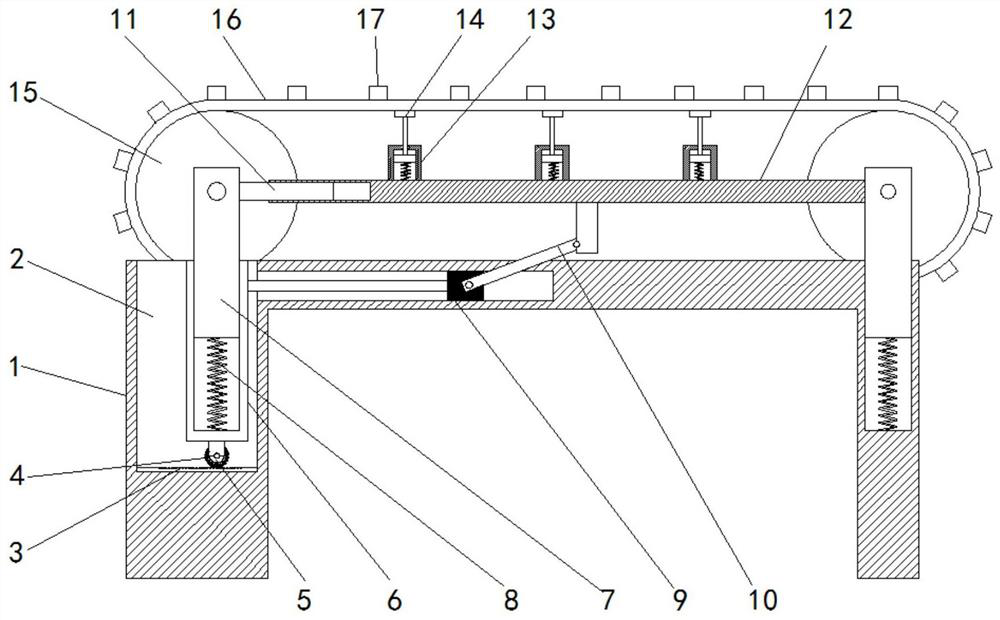

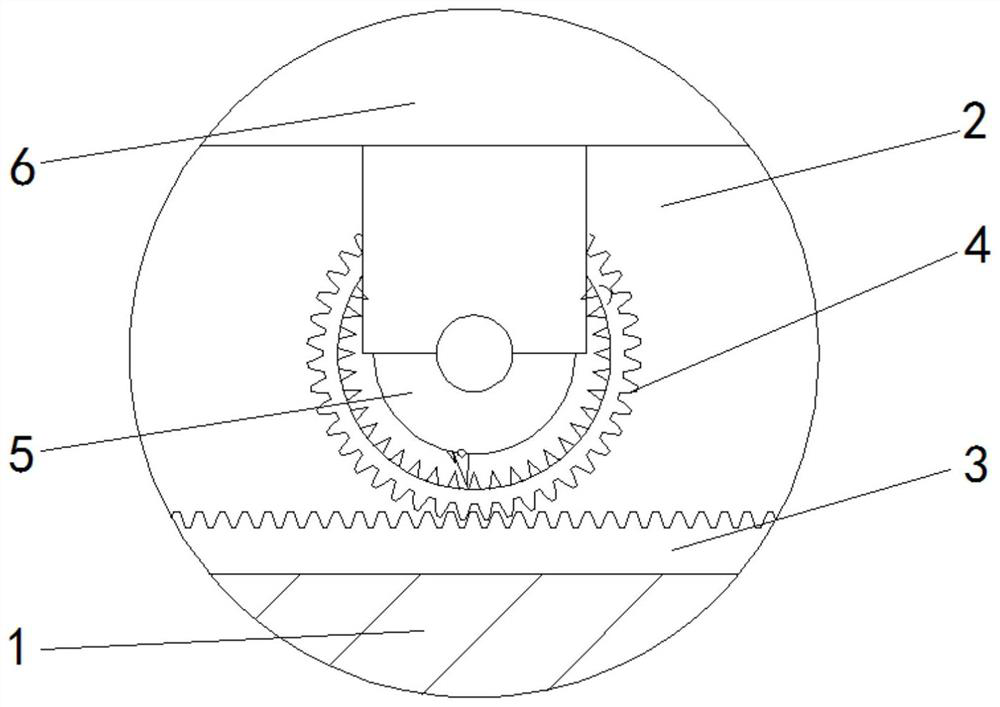

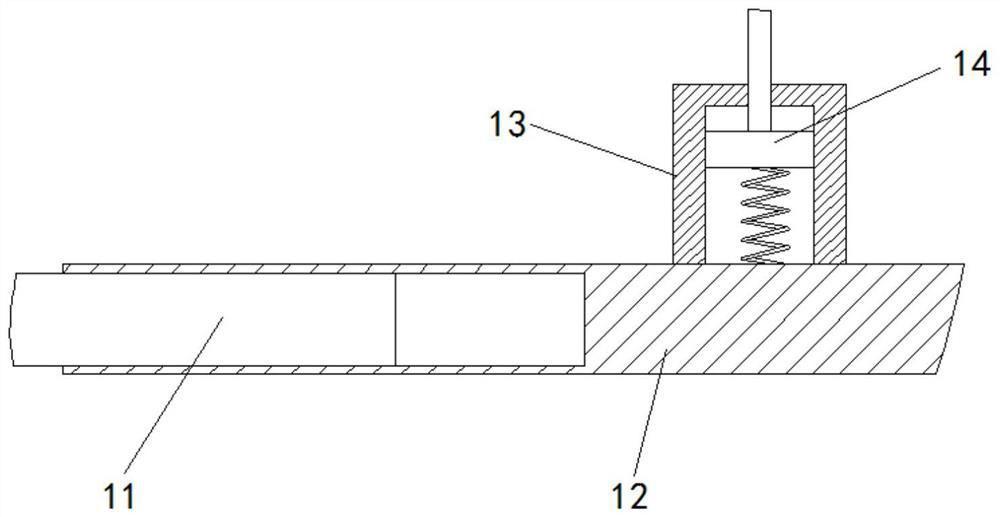

Conveying device capable of automatically adjusting belt tension according to weight of materials

The invention relates to the technical field of conveyors, and discloses a conveying device capable of automatically adjusting the belt tension according to the weight of materials. The conveying device comprises a rack, wherein a driving groove is formed in the top of the rack, a rack is fixedly connected to the inner bottom of the driving groove, a gear is engaged with the top of the rack, a rotating wheel is fixedly connected to the interior of the gear, a movable frame is fixedly connected to the top of the rotating wheel, a support rod is connected to the interior of the movable frame ina sliding mode, a band pulley is fixedly connected to the back surface of the support rod, a conveying belt sleeves the outer side of the band pulley, a catch pawl is connected to the interior of theconveying belt in the sliding mode, and tension springs are fixedly connected to both sides of the bottom of the catch pawl. According to the conveying device capable of automatically adjusting the belt tension according to the weight of the materials, a piston is pressed to move leftwards by the materials, an expansion ball is driven to expand by the piston, and the expansion ball is matched withthe catch pawl, so that the effect that heavy objects can be effectively conveyed and cannot fall off is achieved.

Owner:CBMI CONSTR

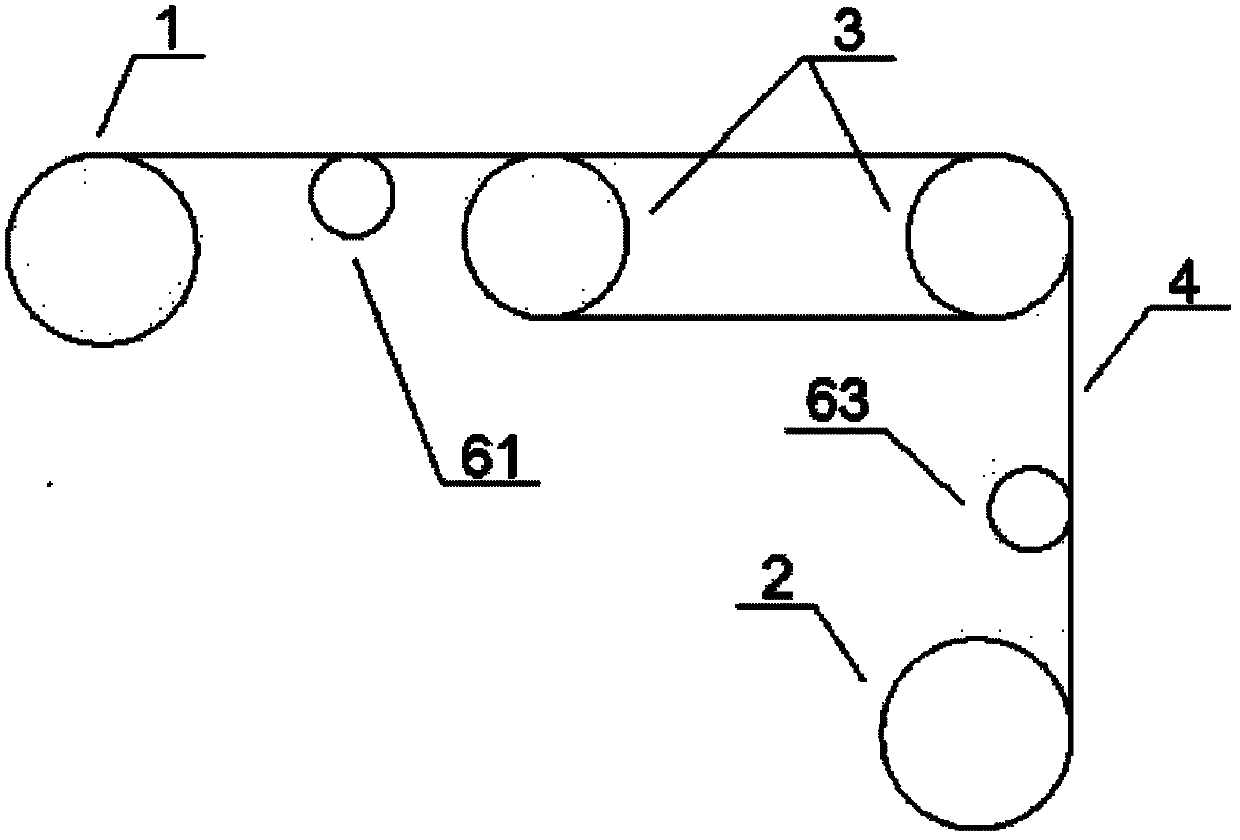

Yarn sizing device for textile

ActiveCN109267267AAutomatic sizingAutomatic dischargeTextile treatment machine arrangementsLiquid/gas/vapor removal by scrapingYarnEngineering

The invention discloses a yarn sizing device for textile, and belongs to the technical field of textile equipment. The device comprises a sizing mechanism, a receiving mechanism, a discharging mechanism and a scraping mechanism, wherein the discharging mechanism comprises a discharging assembly and a yarn limiting assembly, the yarn limiting assembly is arranged at the right end of the dischargingassembly, the scraping mechanism comprises a top-surface scraping assembly and a bottom-surface scraping assembly, the top-surface scraping assembly is arranged above the bottom-surface scraping assembly, the bottom-surface scraping assembly comprises a scraping assembly and a lifting assembly used for driving the scraping assembly to rise and fall, and the scraping assembly is arranged at the top of the lifting assembly. The yarn sizing device for textile has the advantages that scraping can be automatically performed on yarn through the scraping mechanism, thereby ensuring the surface thickness of warp yarn; the tension of the yarn can be automatically adjusted through the yarn limiting assembly, thereby avoiding the phenomena of breakage, abrasion and the like of the yarn during transport.

Owner:江苏富尔达电子科技有限公司

Magnetic damping tension precision adjustment device

ActiveCN101552136AStable jobStable wrapping processCoils manufactureMagnetic dampingMechanical engineering

The invention relates to a magnetic damping tension precision adjustment device which is characterized in that a wrapping tape is arranged between belt-placing plates and fixed by a paper-pressing plate; the wrapping tape passes through a tension sensor after being pulled out; a damping plate is arranged under the belt-placing plate and fixed by a connecting piece; an autorotation body is provided with a rotating bearing and is provided with the damping plate, the belt-placing plate and the paper-pressing plate in sequence; an electromagnetic coil and the autorotation body are directly fixed on a revolution body which is installed on a main shaft; a controller is connected with a sliding ring on the main shaft by a lead; a carbon brush is arranged at the end part of the sliding ring which is arranged on the main shaft; and the main shaft and a director current motor are connected by a synchronous belt wheel. The invention has stable work, and convenient operation, strong safety and reliability, can directly and automatically adjust the tension and the tension angle without stop and can also improve the production efficiency.

Owner:WUXI TOLY ELECTRIC WORKS

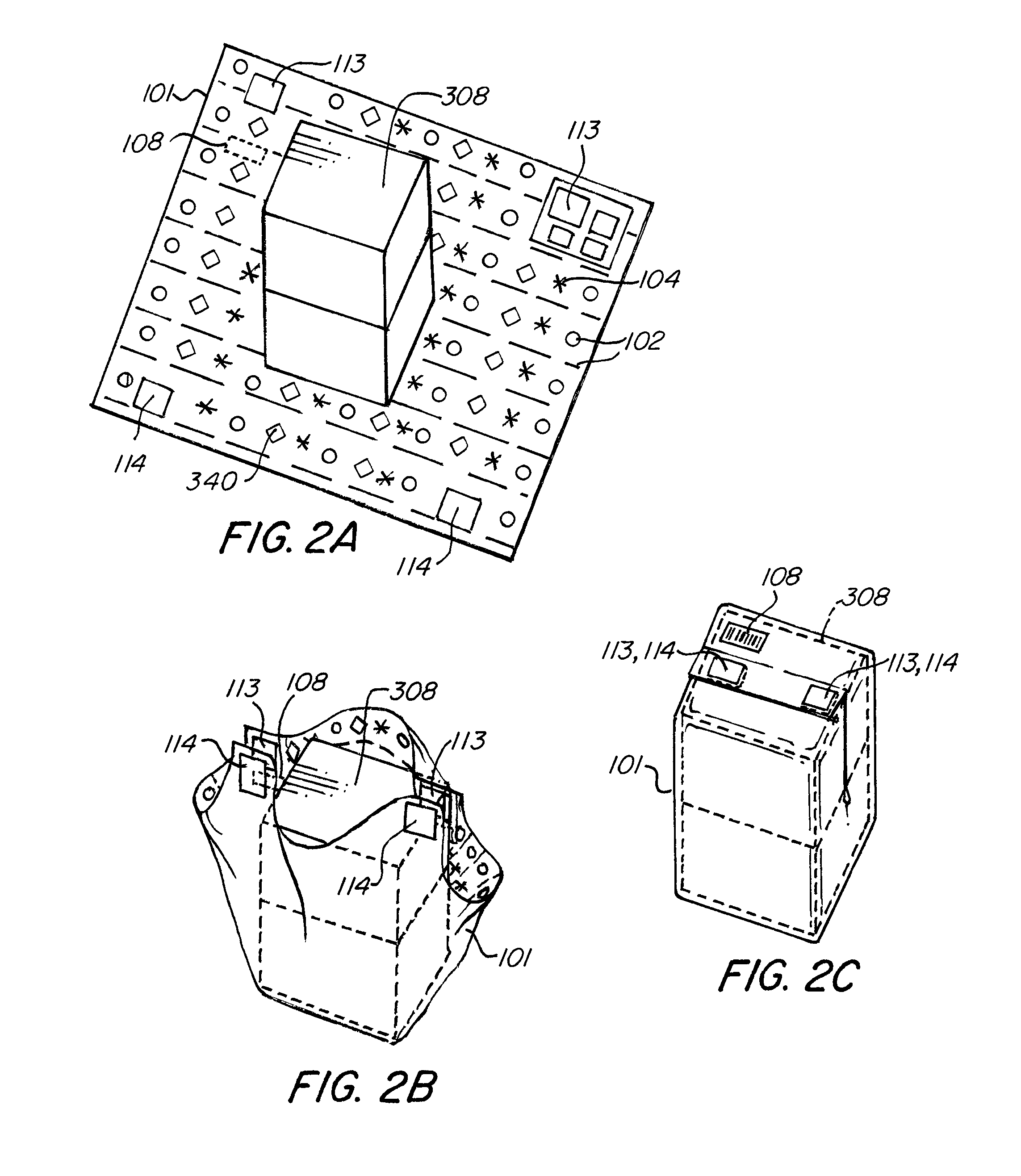

Self-fitting, self-adjusting, automatically adjusting and/or automatically fitting fastener or closing device for packaging

InactiveUS9533786B1Easy to openAutomatic tension adjustmentFlexible coversWrappersEngineeringShrink wrap

Provided is a self-closing and automatically fitting device for packaging (e.g. shrink wrapping, fasteners, enclosures of objects). The device includes a wrapping material and / or closure bands / straps which are made of a shape memory material and a non-shape memory material. The device also includes at least one pair of clasp members attached to the wrapping material and / or closure bands / straps. Upon stimulation by a trigger source, the shape memory material deforms and brings the wrapping material to self-assemble about an object to be packed. The self-assembly of the wrapping material and / or closure bands / straps further brings the two clasp members close to each other and facilitate the clasp thereof to form a self-assembled and closed package. The device may also include a motor, a control unit, and sensors which enable a motor actuated fine tensioning of the self-assembled and closed package.

Owner:FEINSTEIN PATENTS

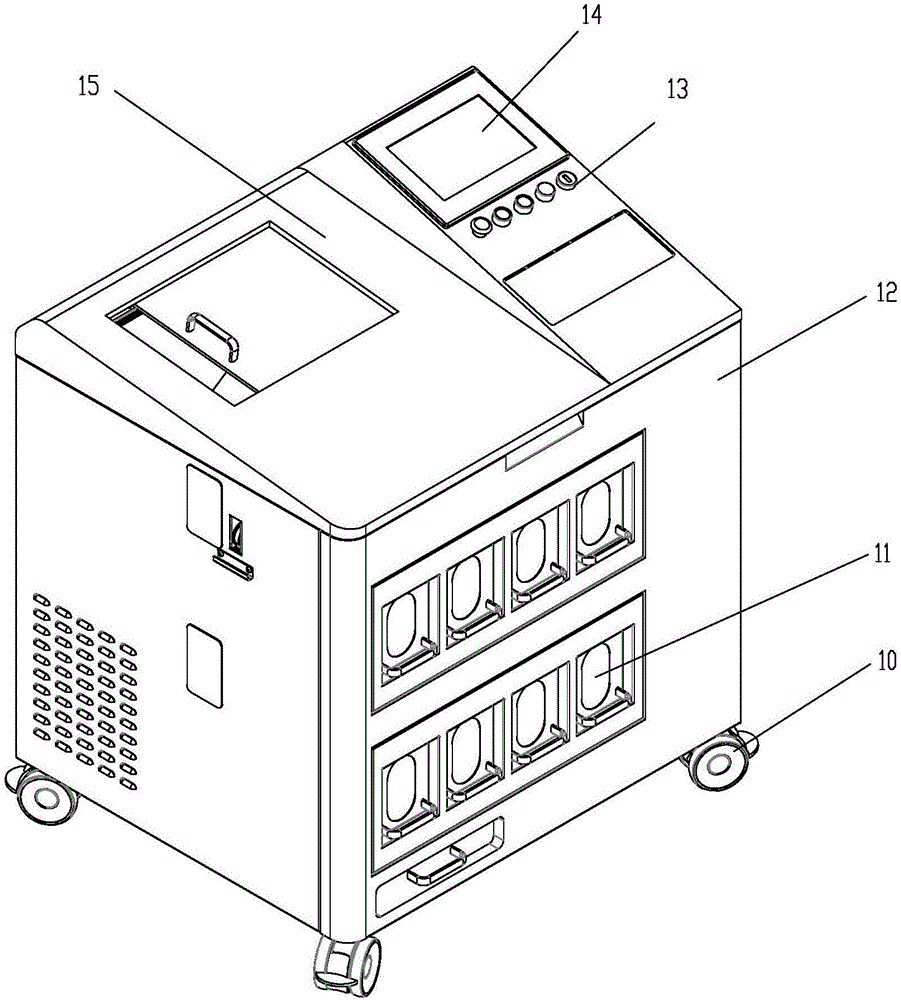

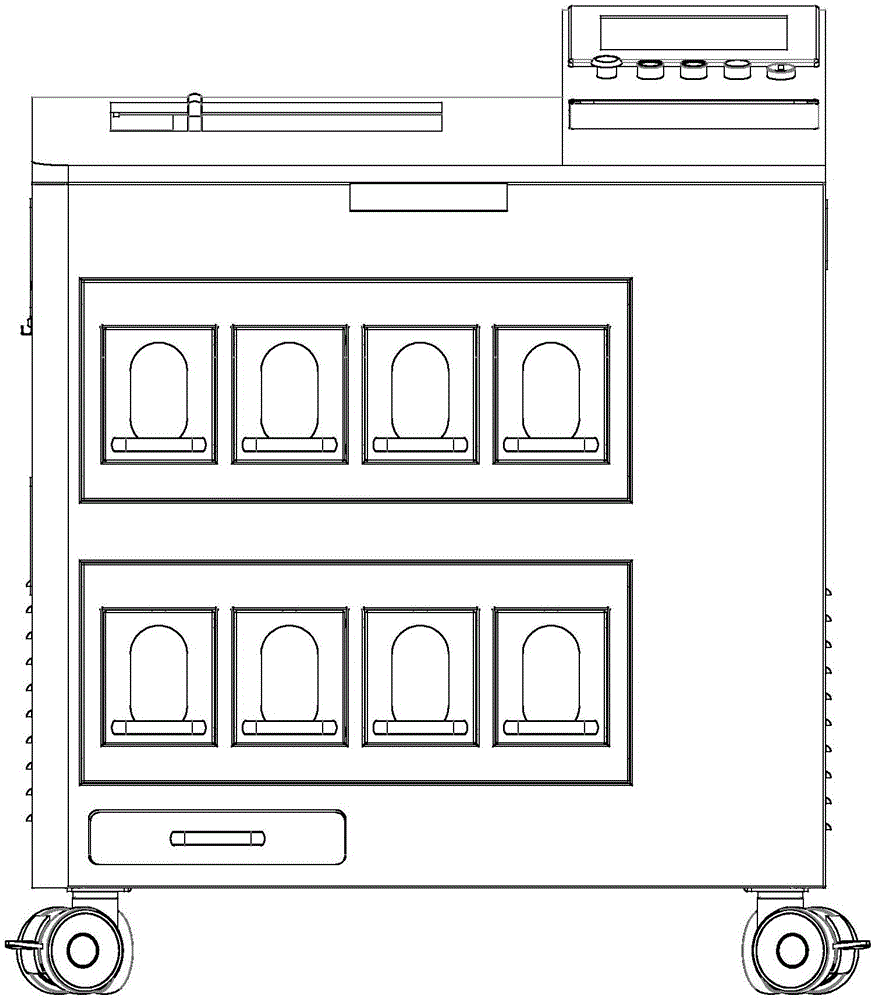

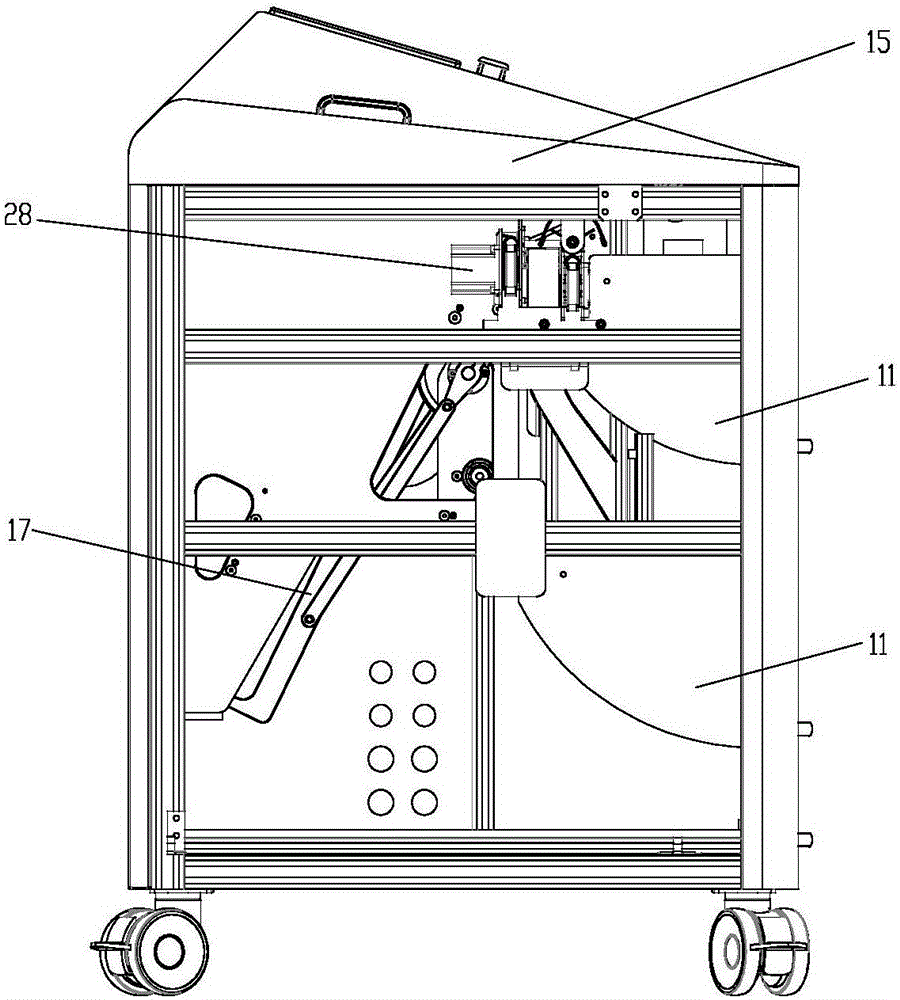

Goods sorting system and sorting method

The invention discloses a goods sorting system and a sorting method. The goods sorting system comprises a feeding device, a transmitting device, a pushing device, a kick-off device and a sorting bin. The sorting bin comprises a plurality of bin bodies; the feeding device, the transmitting device, the pushing device and the kick-off device are sequentially connected; the transmitting device is a U-shaped rotation channel which comprises a feeding line and a blanking line; the feeding device is used for conveying goods onto the feeding line; the pushing device is connected with the feeding line and the blanking line, and is used for pushing goods detected on the feeding line to the blanking line; the kick-off device is used for kicking off each goods on the blanking line into one bin body; the sorting bin is located under the kick-off device; the goods sorting system further comprises a controller; and the feeding device, the pushing device and the kick-off device are controlled by the controller. The goods sorting system is compact in structure and can realize automatic sorting of goods.

Owner:广州奥马自动化设备有限公司

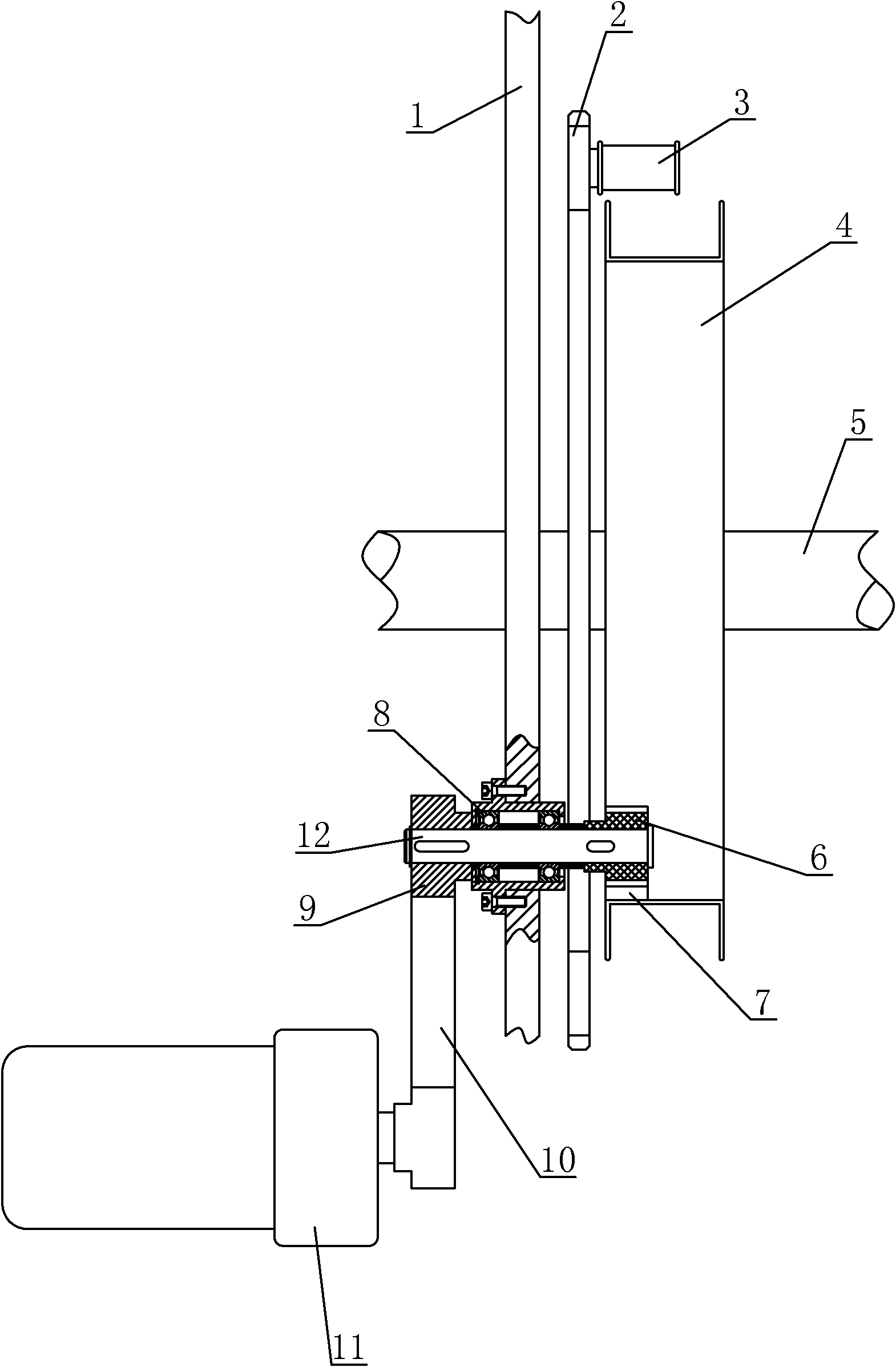

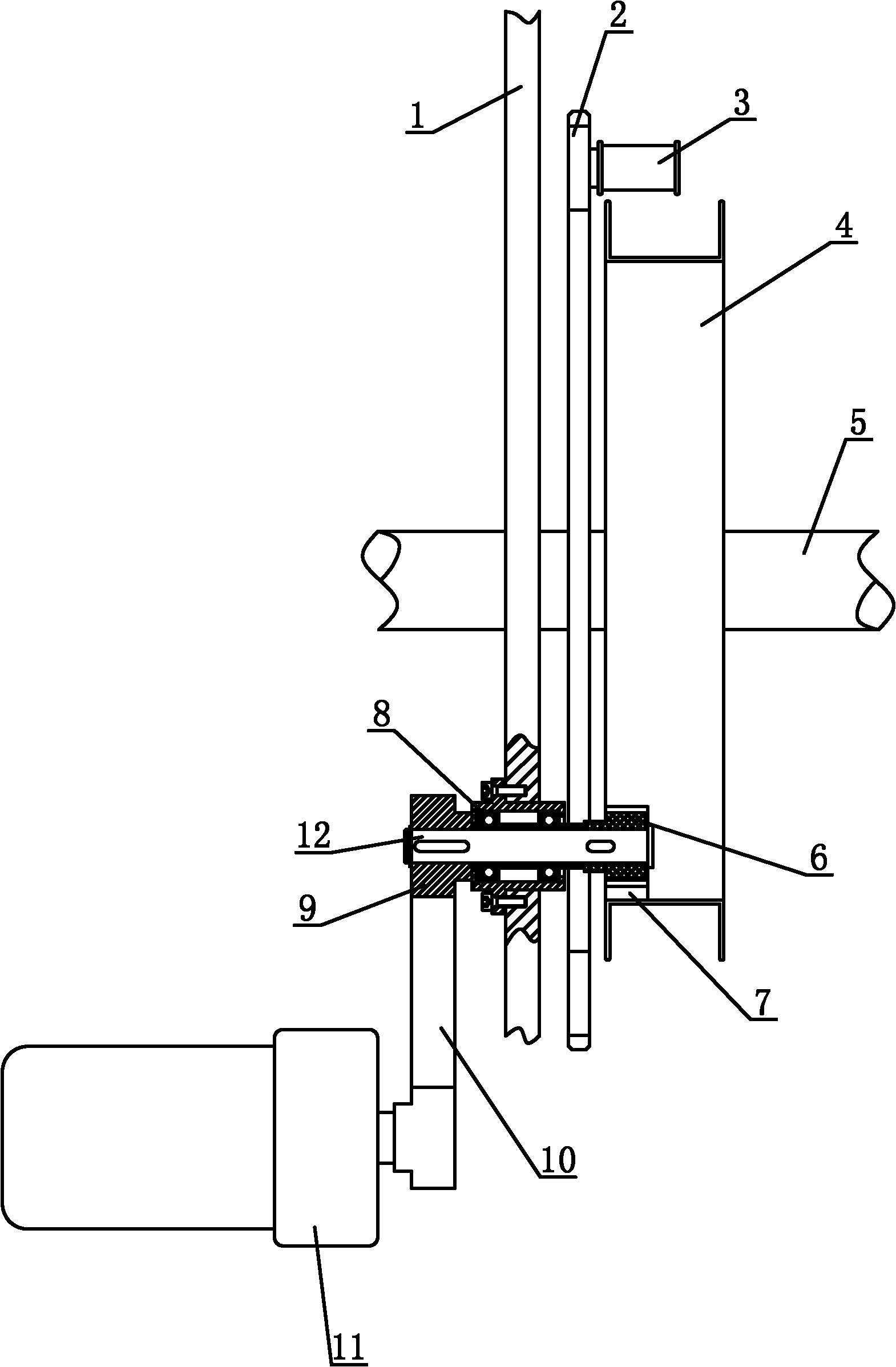

Tension adjusting device on electronic shaft printing machine

The invention discloses a tension adjusting device on an electronic shaft printing machine. The device comprises a rack (1), wherein a rotation shaft (2) is arranged on the rack (1); a first baffle (3) and a second baffle (4) are symmetrically arranged on the rotation shaft (2); one ends of the first baffle (3) and the second baffle (4) are fixedly connected with the rotation shaft (2); and tension rollers (5) are arranged at the other ends of the first baffle (3) and the second baffle (4). Through the tension adjusting device on an electronic shaft printing machine disclosed by the invention, the rolling film tension can be automatically adjusted in the printing process to avoid unqualified product.

Owner:江阴市汇通包装机械有限公司

Tension adjusting device for belt

The invention provides a tension adjusting device for a belt, which comprises a drive wheel, a driven wheel, the belt, a base, a base frame, a spring and an elasticity control mechanism, wherein the drive wheel is driven by a motor to rotate; the belt is sleeved between the drive wheel and the driven wheel; the base frame is used for supporting the driven wheel and is arranged on the base, and can move on the base; the spring is used for adjusting the tension of the belt; and the elasticity control mechanism is used for selectively releasing or accumulating the elasticity of the spring and regulating the distance between the driven wheel and the drive wheel. The base frame and a position wheel of the driven wheel are locked at proper positions through rigid trips on the base frame and elastic chucks that are matched with the rigid trips and are arranged on the base so that the belt is installed, a pressing piece is pressed after the belt is installed, the elastic chucks separate from the rigid trips, and the belt is tightened. When the belt is dismounted, the base frame is pushed, the elastic chucks are buckled with the rigid trips, the distance between the drive wheel and the driven wheel is shortened, therefore, the belt can be conveniently dismounted. The displacement of the belt is the same as the combination of the dismounting and the mounting of the belt.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

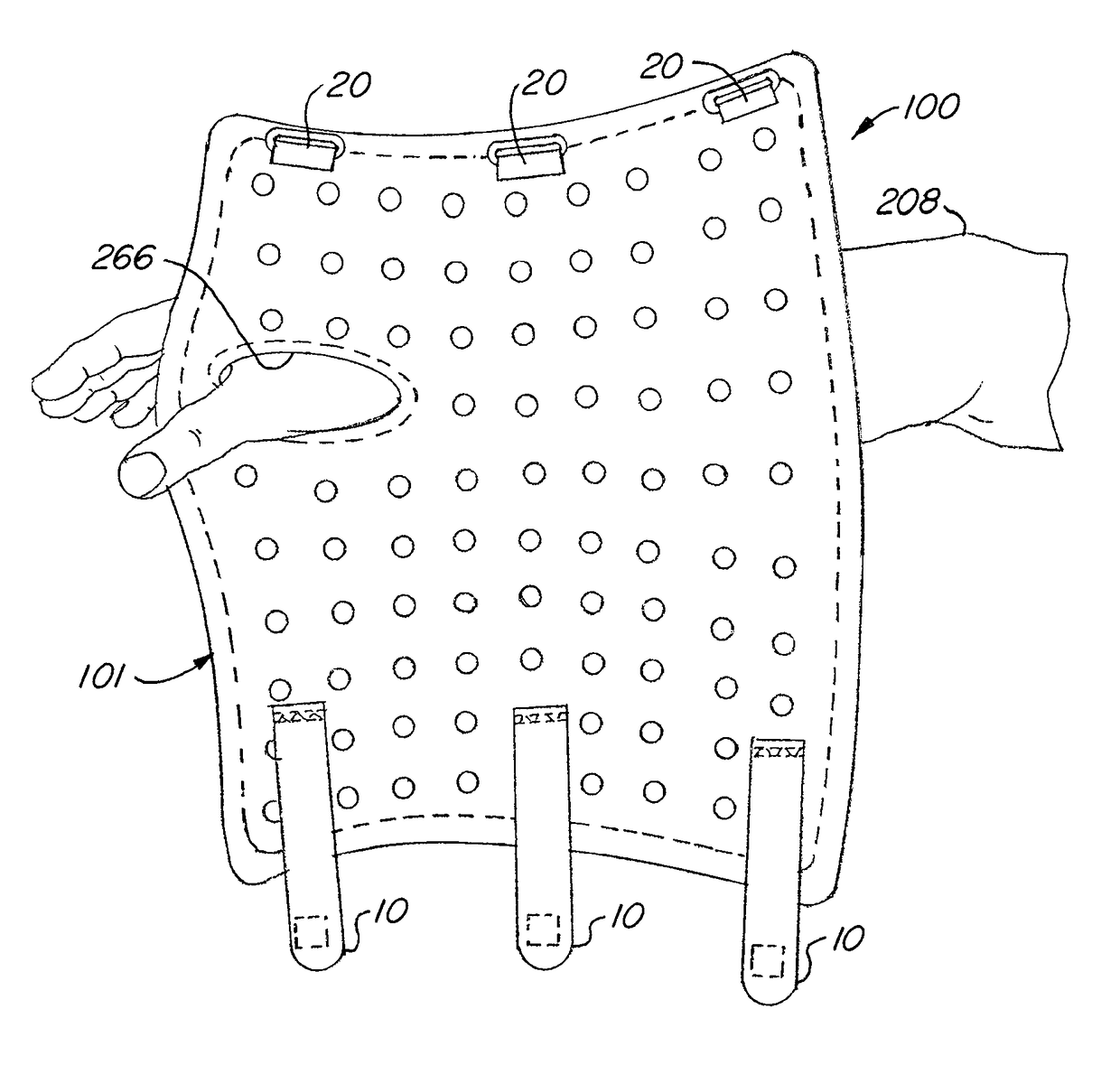

Self-Fitting, Self-Adjusting, Automatically Adjusting and/or Automatically Fitting Orthopedic or other (e.g. non human use) Immobilization Splint or Device

InactiveUS20180008449A1Automatic tension adjustmentRealize automatic adjustmentFractureBucklesHuman useEngineering

Provided is a self-fitting and automatically adjustable clasp band / strap which is usable in medical immobilization (e.g., casts, splints, braces) and multiple other fixation devices. The clasp band / strap may have a shape memory material and clasp members attached to two ends of the clasp band / strap. Upon stimulation by a trigger source, the shape memory material deforms which brings the two end portions closer to each other, causing the two clasp members to attach to each other to form a closure. Additionally, the clasp band / strap may include a motor, a control unit, and sensors to enable a motor actuated fine tensioning. Finally, the clasp band / strap may have an adhesive backing or any other kind of annealing or connective backing, such as a Velcro strap with an adhesive backing, for attaching to a splint or other object.

Owner:FEINSTEIN PATENTS

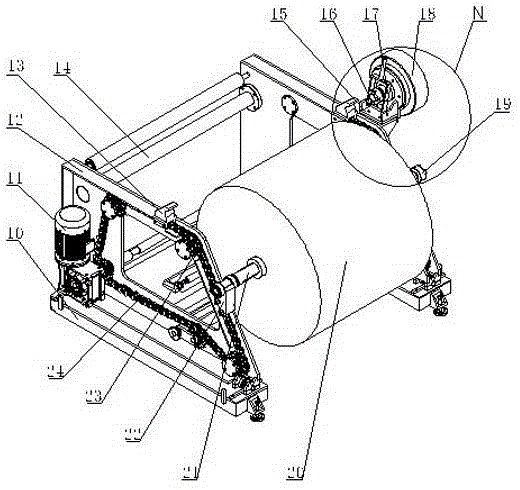

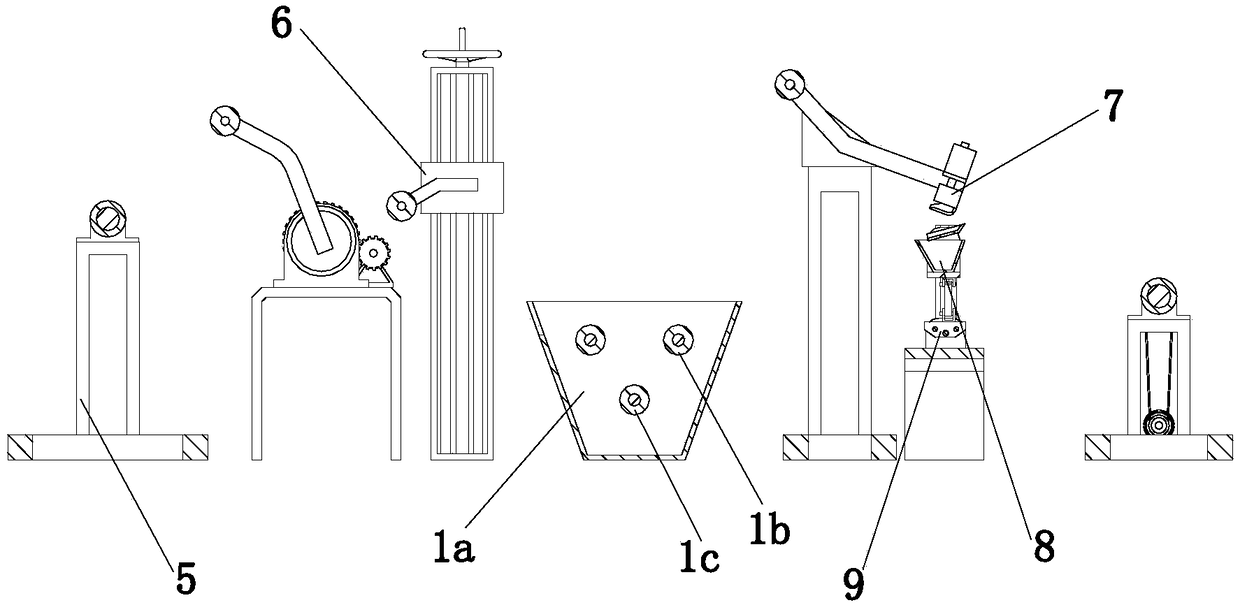

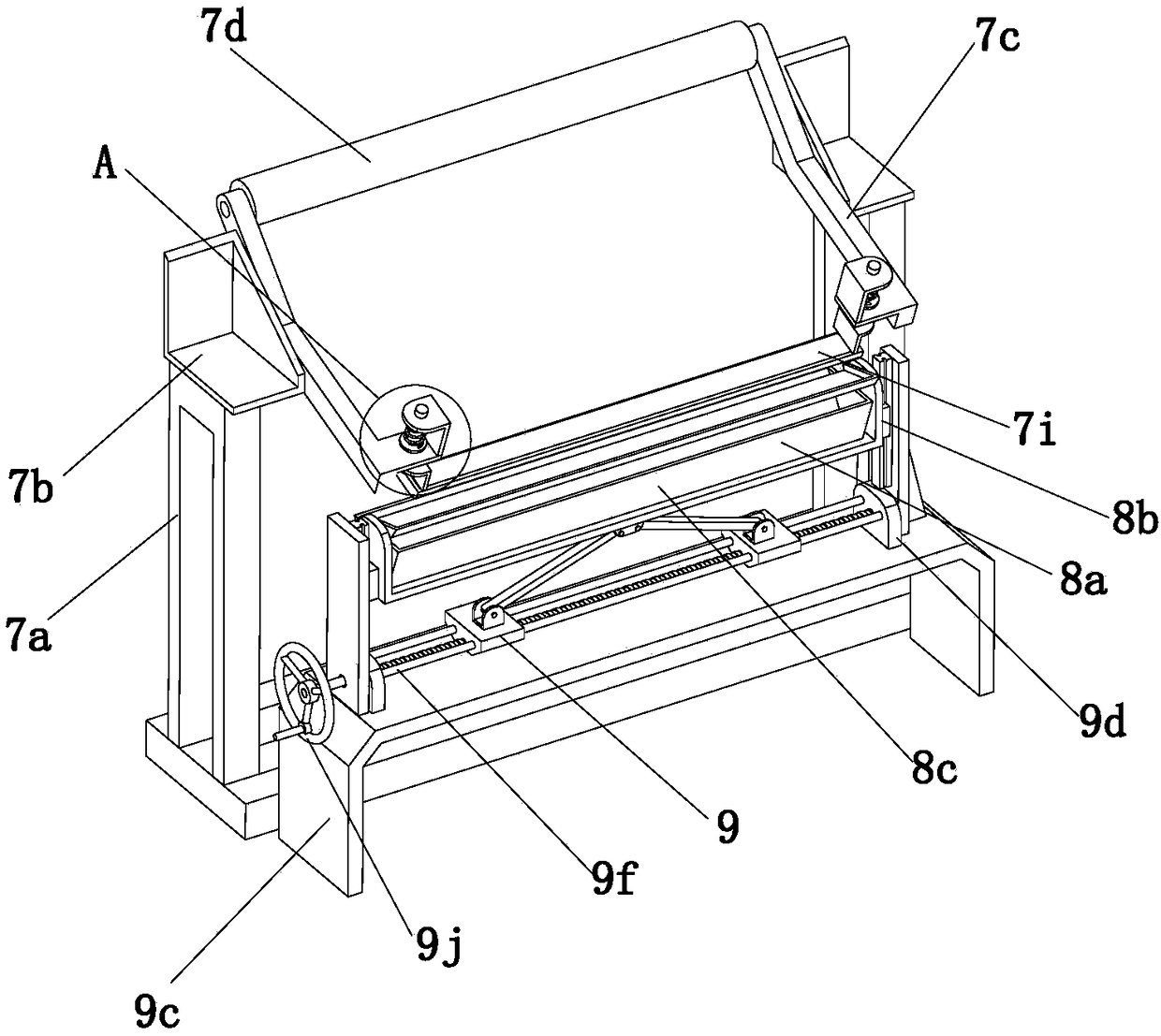

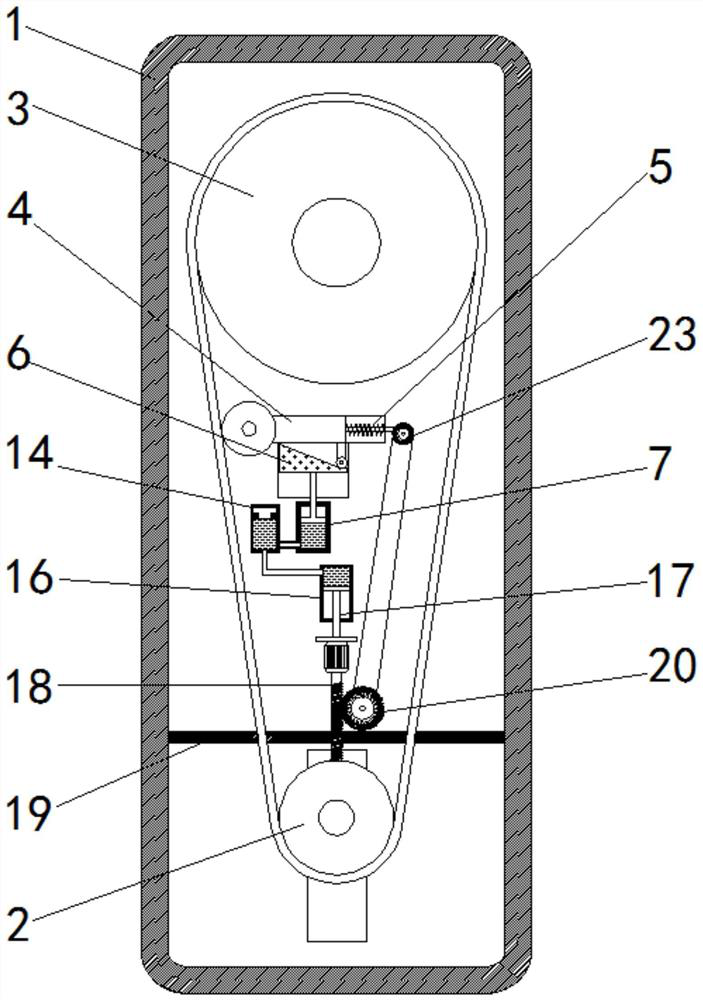

Full-automatic winding machine for multiple filter papers

InactiveCN107298337AFully automatedReduce labor intensityStationary filtering element filtersArticle deliveryWinding machineBobbin

The invention discloses a multi-filter paper full-automatic winding machine, which comprises a filter core skeleton transport positioning mechanism, a skeleton tension winding mechanism, a filter paper transport positioning cutting mechanism, and a tape transport pasting mechanism; the filter core skeleton transport positioning mechanism sends the filter core skeleton to to the skeleton tensioning and winding mechanism; the skeleton tensioning and winding mechanism tightens the filter element skeleton and drives the filter element skeleton to rotate; the filter paper conveying positioning and cutting mechanism is provided with multiple, and each filter paper conveying positioning and cutting mechanism is equipped with A filter paper roll; the filter paper transport positioning and cutting mechanism sends the filter paper on the corresponding filter paper roll to the filter element skeleton expanded by the skeleton expansion and winding mechanism; the tape conveying and pasting mechanism sticks the filter paper to the filter element skeleton through tape superior. The invention realizes the full automation of the winding production of the filter element and filter paper, reduces the labor intensity of the production personnel, improves the production efficiency, and has broad market prospects.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Sewing machine device capable of automatically tensioning belt and facilitating belt replacement

The invention relates to the technical field of clothing production, and discloses a sewing machine device capable of automatically tensioning a belt and facilitating belt replacement. The sewing machine device includes a protective shell, the inside of the protective shell is slidably connected with a driving wheel, and the top of the driving wheel is connected with a driven wheel in a transmission mode, the inside of the protective shell is slidably connected with a top rod, the top of a pulley is connected with a runner in a transmission mode, the inside of the runner is fixedly connected with a reel, and the top of the reel is movably connected with a pawl . According to the sewing machine device capable of automatically tensioning the belt and facilitating belt replacement, the top rod is pushed to move the left by a thrust spring, the top rod drives a slider to slide down, the slider presses water in a hydraulic box into a water pipe, the water pushes a piston to move to the left, the water pipe pours the water into an energized box, the water level in the energized box rises to energize an electrode block, a rotating shaft rotates, the rotating shaft descends under the action of a supporting plate, and the rotating shaft is used in conjunction with the driving wheel to achieve the effect of automatic adjustment of the belt tension degree.

Owner:海宁市旦妮进出口有限公司

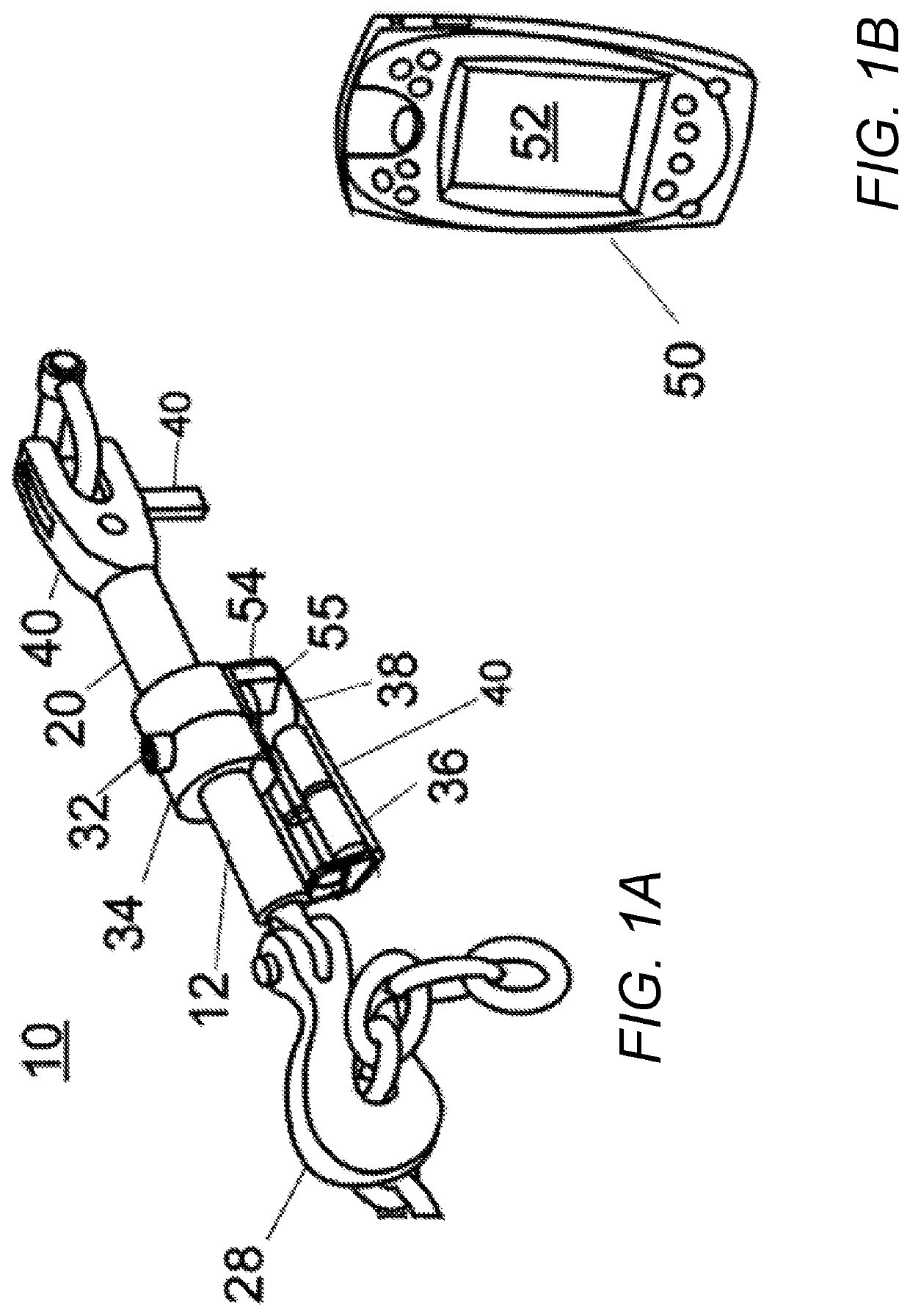

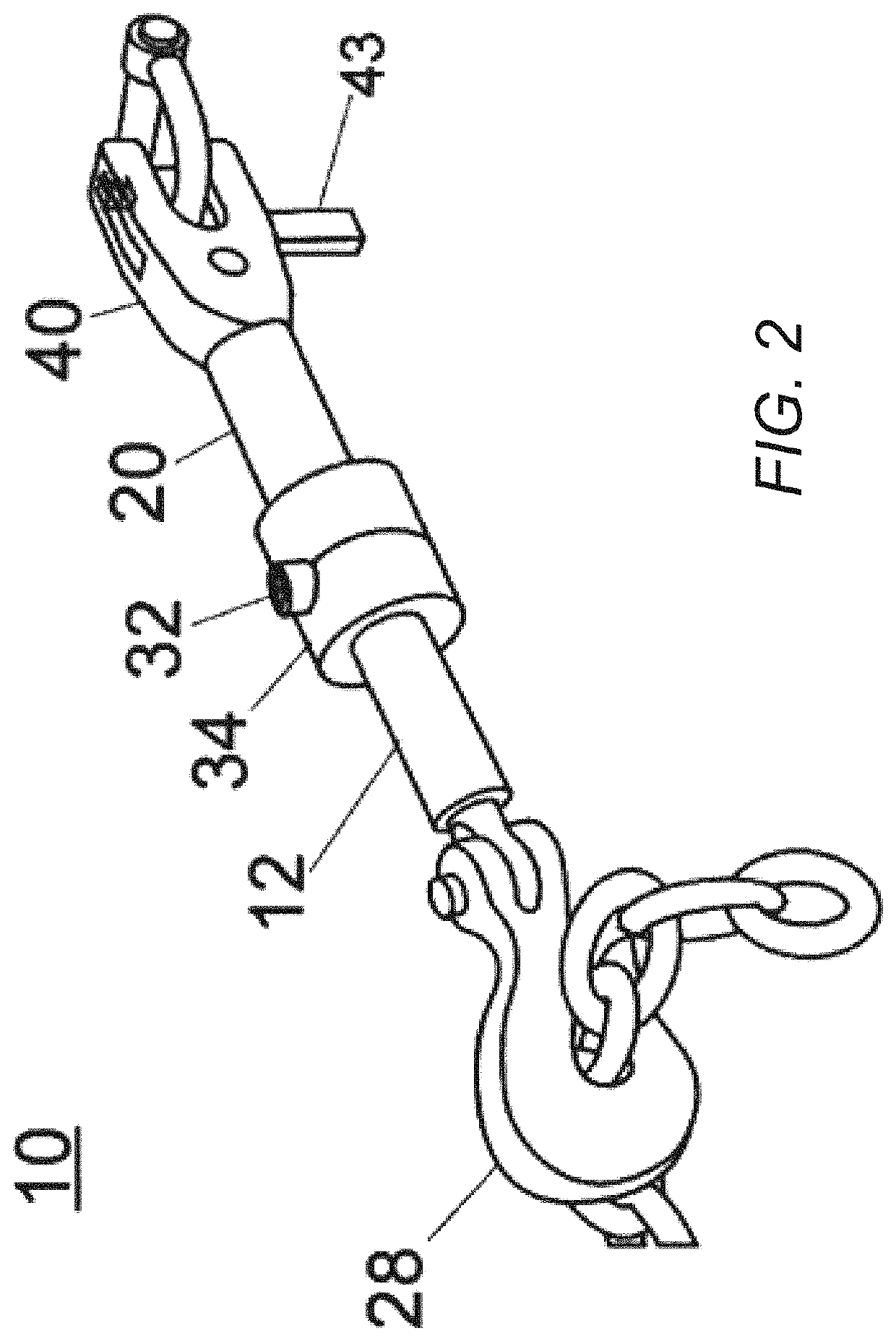

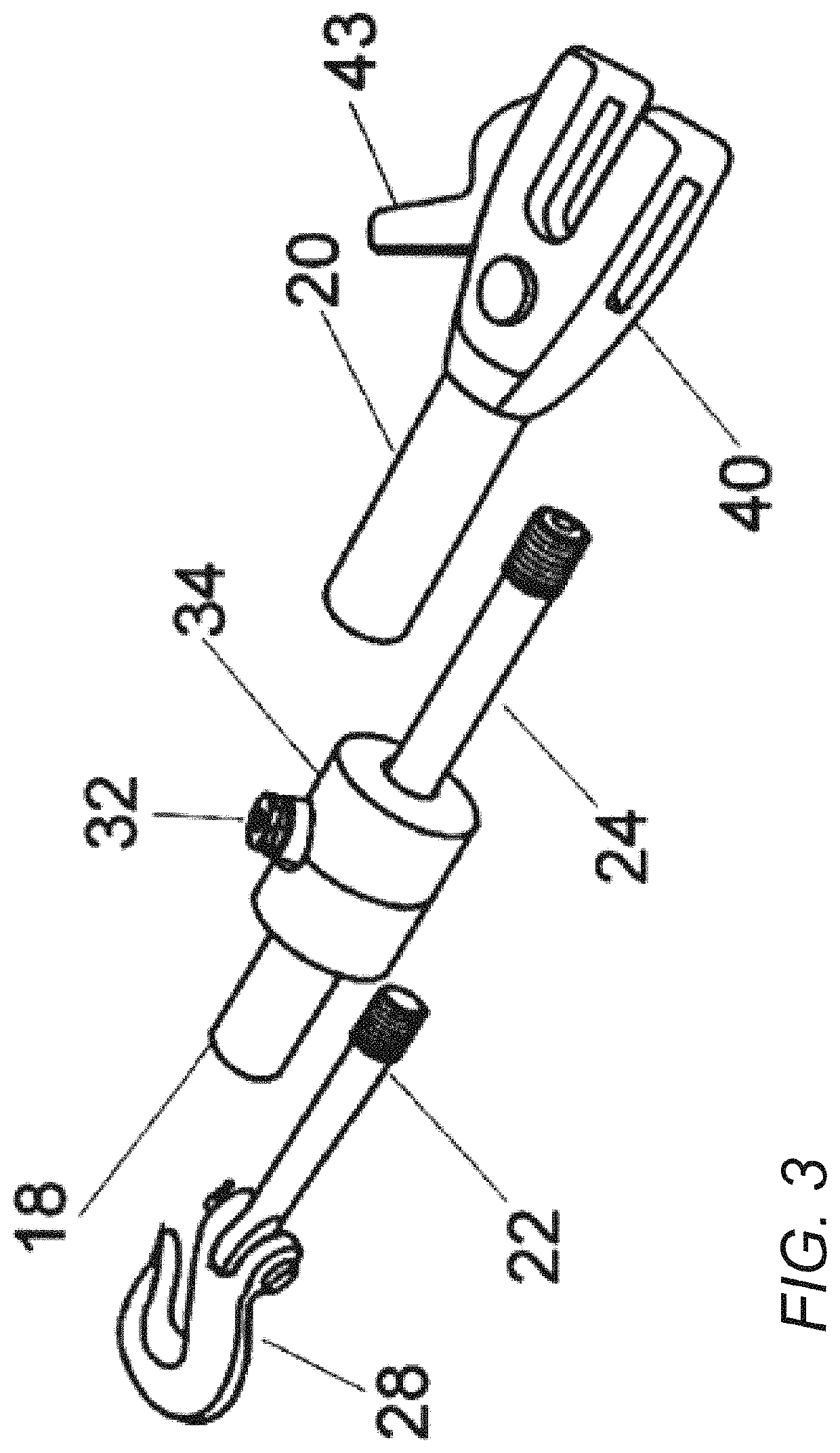

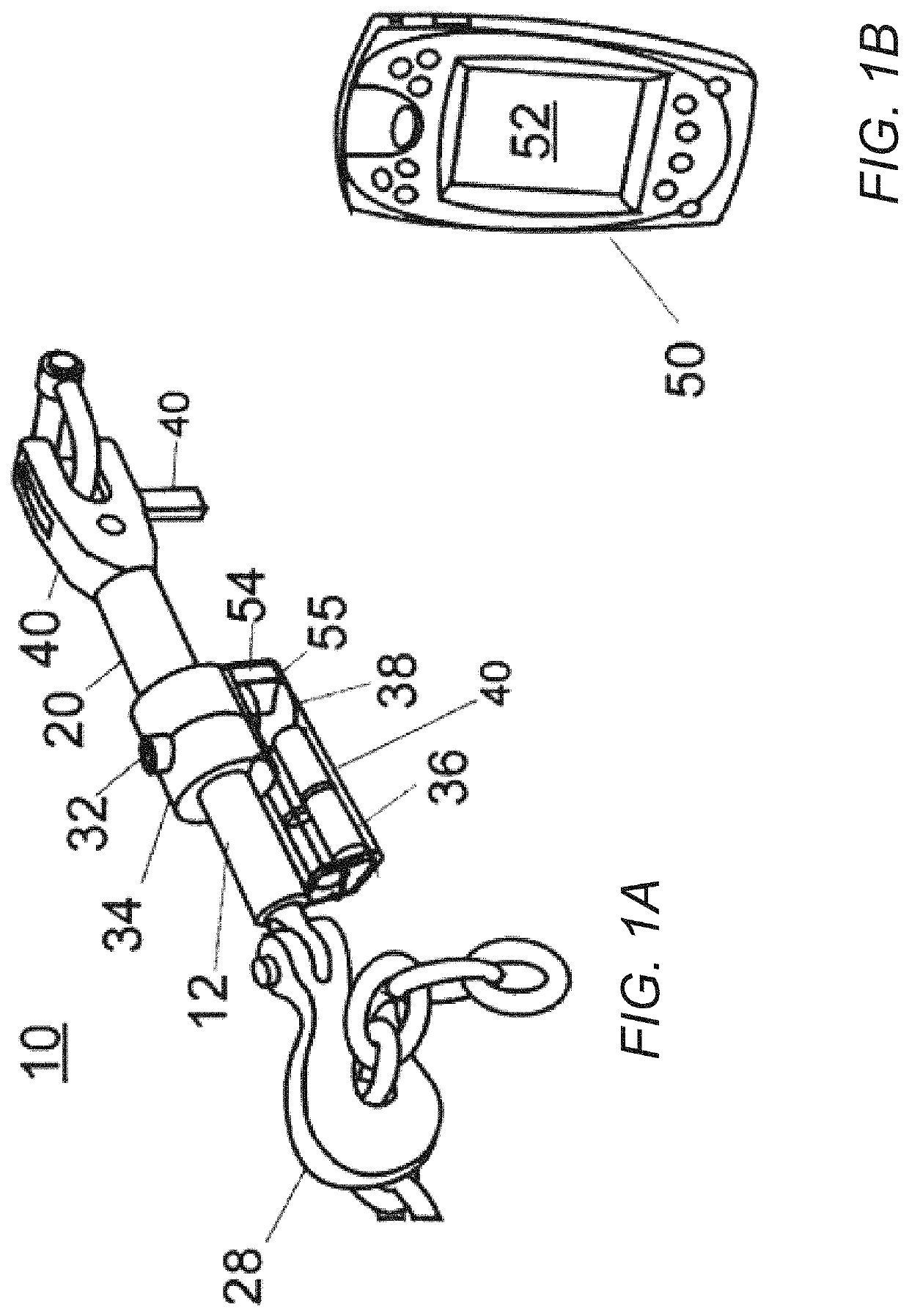

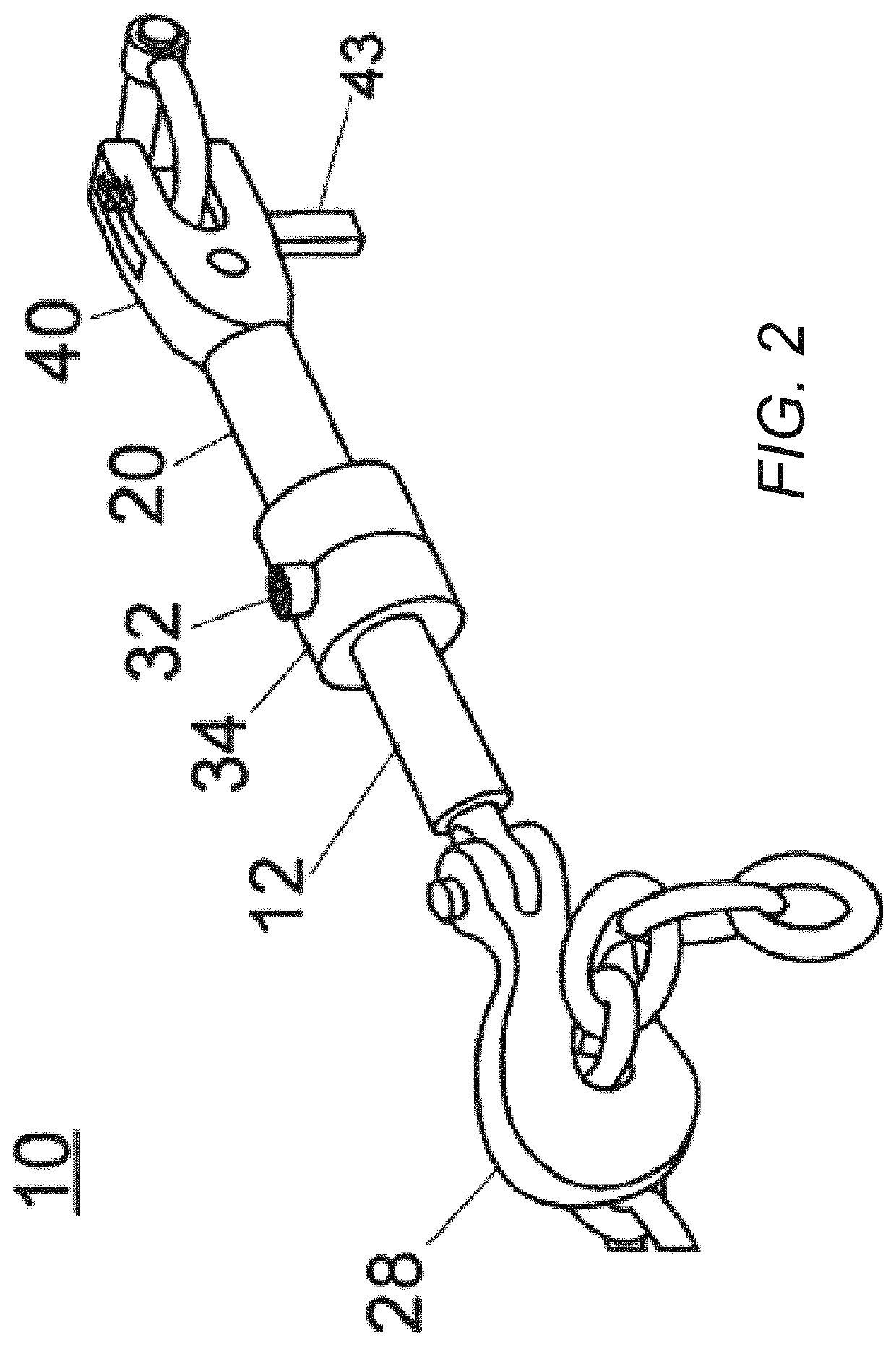

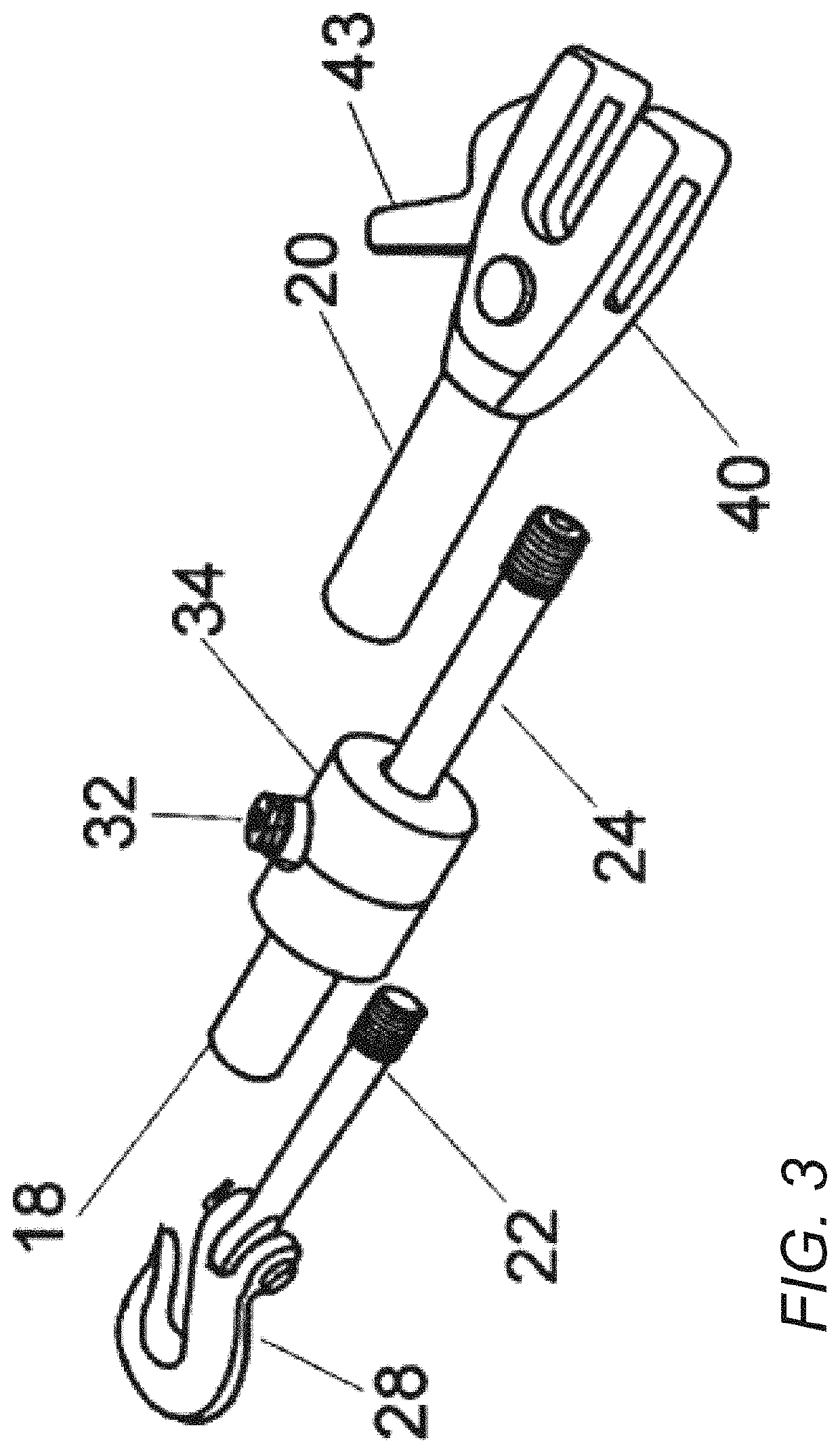

Automated, wireless, cargo restraint tension control and monitoring system

ActiveUS10814773B1Reduce riskAutomatically adjust tensionContainer decorationsLevel indicationsWirelessTension control

A cargo restraint system includes a body, a first connecting end and a second connecting end on opposing sides of the body, wherein the first and second connecting ends are coupled to a securing member which is used to restrain the cargo. One or more load sensors are coupled to the first connecting end and / or the second connecting end. A controller is coupled to the one or more load sensors. The controller is configured to receive tension information from the one or more load sensors. The controller includes a transmitter capable of transmitting the tension information to a remote device. The controller may include a database to store the information.

Owner:RAINONE MICHAEL D +5

Large-roll cloth rolling and unrolling machine

PendingCN109353865AReasonable structureReasonable functionConveyorsWebs handlingEngineeringMechanical engineering

The invention discloses a large-roll cloth rolling and unrolling machine which comprises a rack, a matt surface roller, a mirror surface roller, a fabric drum, a guiding roller, a tightening roller, amovable roller and a traction roller, wherein the matt surface roller and the mirror surface roller are mounted on the rack in parallel side by side; the fabric drum is erected and mounted on the matt surface roller and the mirror surface roller; the fabric drum and the matt surface roller are in parallel; the two sides of the lower part of the fabric drum are in contact with the matt surface roller and the mirror surface roller; fabric is rolled on the fabric drum; from the end of the fabric drum, the fabric sequentially passes through the mirror surface roller, the guiding roller, the tightening roller, the movable roller and the traction roller; and fixing seats are arranged at the two ends of the fabric drum to position and fix the fabric drum. The large-roll cloth rolling and unrolling machine is reasonable in structure, simple to operate, convenient to use and driven through force of friction, can automatically adjust the tension, is high in rolling and unrolling quality and stability, can be adapted to rolling of fabric with different specifications, and is wide in range of application, and high in flexibility and using effect.

Owner:苏州高研纺织科技有限公司

Flexography and gold stamping integrated printing machine

InactiveCN106626747AImproving the quality of printing hot stampingHigh degree of automationRotary pressesEngineeringPrinting press

The invention relates to a flexography and gold stamping integrated printing machine comprising a flexography machine and a material unwinding and winding drum. A deviation rectification mechanism is arranged between the material unwinding and winding drum and the flexography machine. A drying oven is installed at the upper end of one side of the flexography machine. A gold stamping mechanism is arranged on one side of the flexography machine and comprises an alumite unwinding part and a waste alumite winding part, wherein the alumite unwinding part and the waste alumite winding part are arranged side by side. An upper gold stamping roller and a lower gold stamping roller are arranged on the lower side between the alumite unwinding part and the waste alumite winding part. A floating roller with a tension detector is arranged at the position, close to the flexography machine, on the lower side of the alumite unwinding part. A material tractor is arranged on the other side of the gold stamping mechanism. The flexography and the gold stamping process are combined together, the production efficiency is greatly improved, and the printing gold stamping quality of materials is improved.

Owner:宁波长青家居用品有限公司

Silicon wafer cutting equipment with function of automatic tension adjustment

InactiveCN102626956AAutomatic tension adjustmentWorking accessoriesFine working devicesEngineeringConductor Coil

The invention relates to silicon wafer cutting equipment, in particular to silicon wafer cutting equipment with a function of automatic tension adjustment, which belongs to the technical field of cutting machinery. The silicon wafer cutting equipment comprises a wire unwinding roll, a wire winding roll and guide rolls, wherein steel wires are arranged on the wire unwinding roll; the steel wires unwound by the wire unwinding roll are wound on the guide rolls and then wound by the wire winding roll; the wire unwinding roll is connected with a wire unwinding driving mechanism through a wire unwinding transmission mechanism; the wire winding roll is connected with a wire winding driving mechanism through a wire winding transmission mechanism; the silicon wafer cutting equipment with the function of automatic tension adjustment further comprises a microprocessor system; the control end of the wire unwinding driving mechanism and the control end of the wire winding driving mechanism are connected with the microprocessor system respectively; and a tension detecting mechanism is arranged between the wire unwinding roll and the guide rolls. Due to adoption of the technical scheme, the silicon wafer cutting equipment with the function of automatic tension adjustment can automatically adjust the tensions in the wire unwinding and wire winding processes; and the tension adjustment is precise and timely.

Owner:SHANGHAI WUTONG MACHINE MFG

Automated, wireless, cargo restraint tension control and monitoring system

ActiveUS11208027B1Reduce tensionReduce riskForce measurementLoad securingClassical mechanicsMonitoring system

A cargo restraint system a locking ring coupled to an extension tube, wherein the locking ring comprises an annular body and one or more tabs extending from the annular body. The cargo restrain system also includes a locking tube coupled to the main body. The locking tube comprises one or more grooves complementary to the shape and size of the tabs on the locking ring. The grooves of the locking tube inhibit rotational movement of the locking ring.

Owner:SMART SECUREMENT SYST LLC

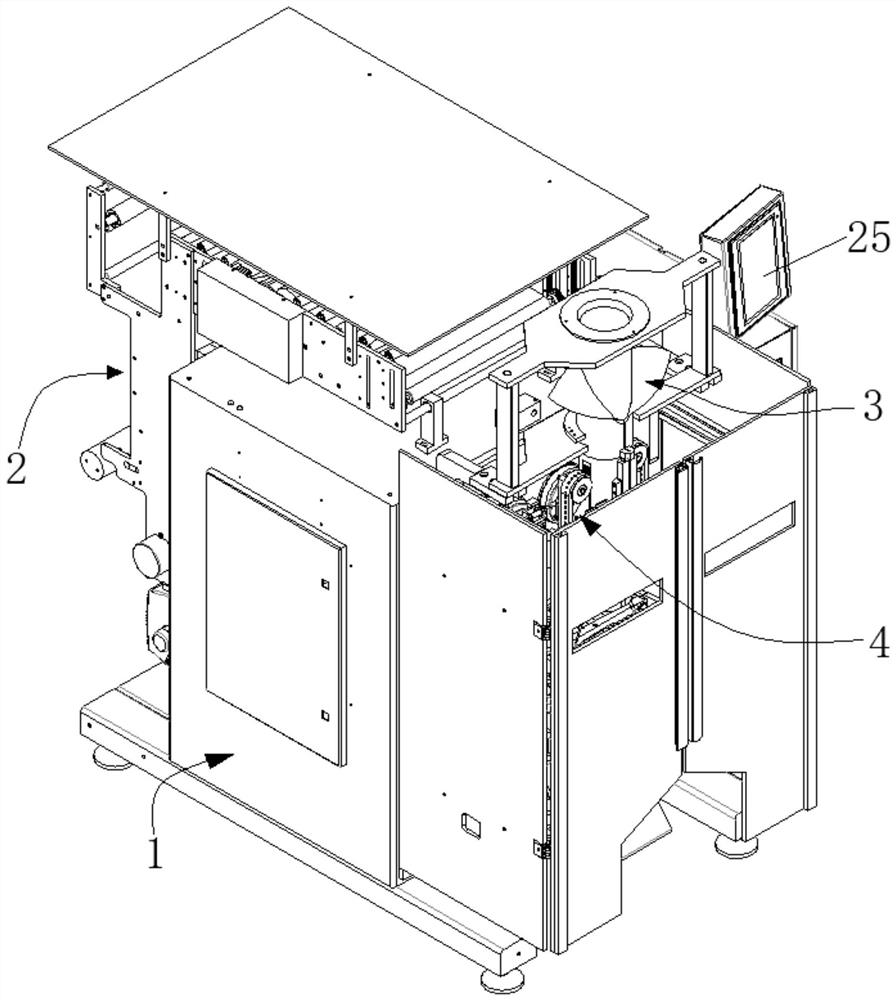

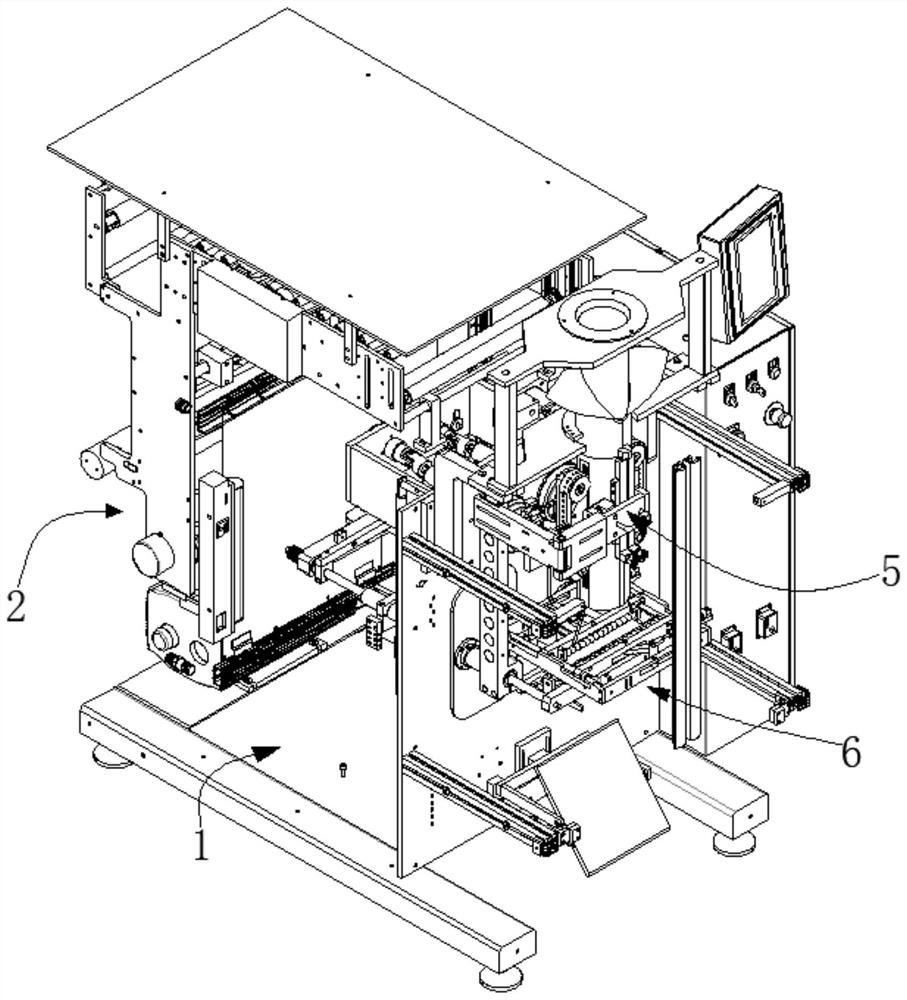

Vertical automatic bag making and packaging machine

ActiveCN113291515AEasy to controlEasy to operateWrapping material feeding apparatusWrapper twisting/gatheringEngineeringSmall footprint

The invention relates to the technical field of bag making and packaging equipment, and discloses a vertical automatic bag making and packaging machine. The vertical automatic bag making and packaging machine comprises a mounting main frame, and a film guiding mechanism, a forming mechanism, a film pulling mechanism, a vertical sealing mechanism and a transverse sealing mechanism which are sequentially mounted on the mounting main frame, wherein the forming mechanism is mainly used for turning and coiling a packaging film, the film pulling mechanism is mainly used for providing power to pull the packaging film to move, the vertical sealing mechanism is mainly used for sealing side seams of the packaging film formed by coiling, and the transverse sealing mechanism is mainly used for transversely sealing a packaging film coiling block vertically sealed by the vertical sealing mechanism at intervals to form a packaging bag. The vertical automatic bag making and packaging machine is high in integration degree and small in occupied area, it is no need to arranged two drives, the cost is saved, the forming time is saved, the production efficiency is greatly improved, the tightness degree of the packaging film is guaranteed, therefore, the quality of the packaging film during forming is improved, the situation that the packaging film is damaged is avoided, and the production quality is high.

Owner:杭州荣祥包装科技有限公司

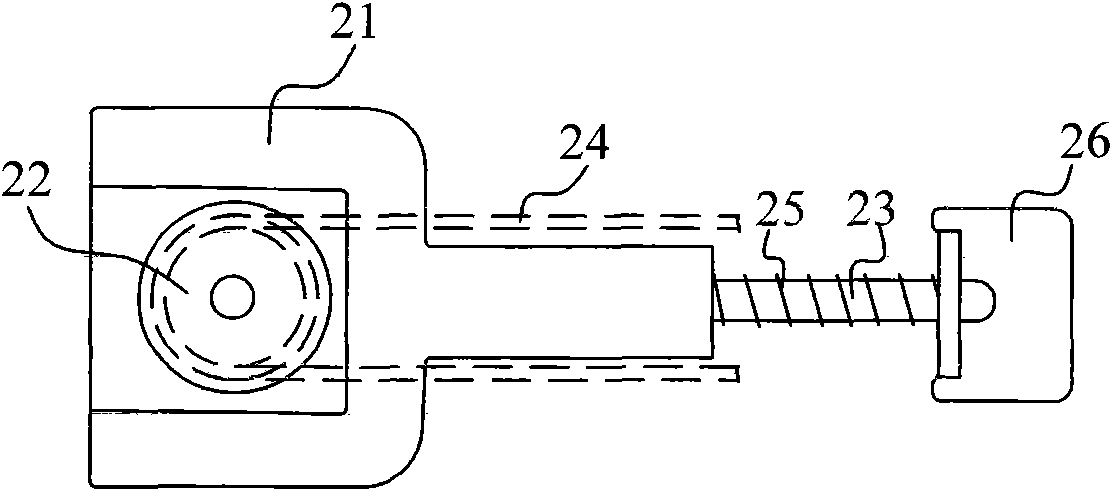

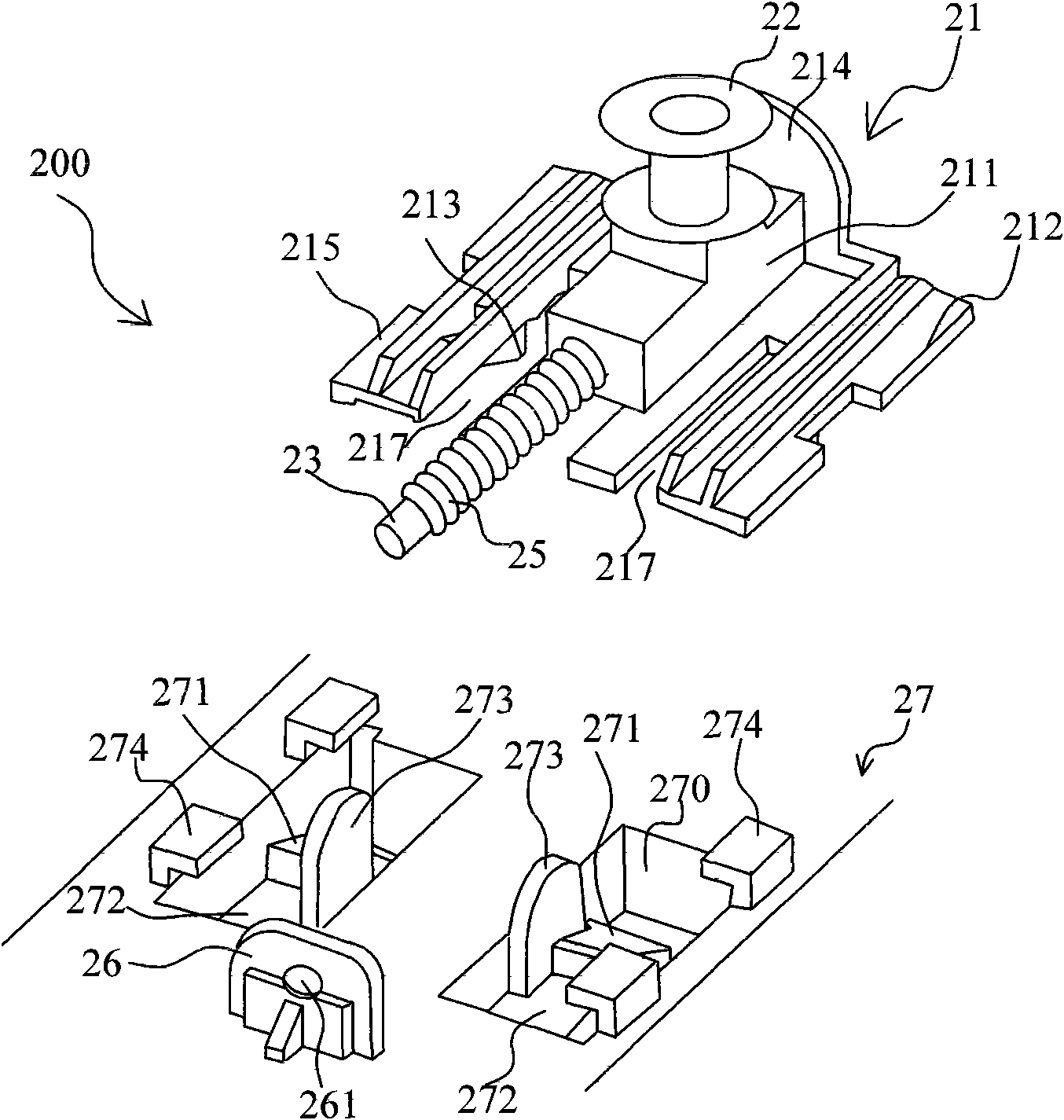

Tension control mechanism of annular coil winding machine

InactiveCN102468050AReasonable designAutomatic tension adjustmentFilament handlingCoils manufactureWinding machineDrive shaft

The invention discloses a tension control mechanism of an annular coil winding machine, which comprises a head wallboard, an iron core which is vertically installed on the head wallboard, a shuttle which is arranged on the right of the head wallboard, a pickup device which is fixedly installed on the right side of the upper part of the shuttle, and a coil storage ring which is arranged on the right of the shuttle, wherein the iron core is vertically installed on the coil storage ring, an inner gear ring is arranged in the coil storage ring and is arranged at the lower part of the coil storage ring, a transmission shaft which penetrates through the head wallboard, the shuttle and the coil storage ring is arranged at the lower part of the coil storage ring, a gear which is engaged with the inner gear ring in a driving way is installed at the right end of the transmission shaft, a belt wheel is installed at the left end of the transmission shaft, a torque motor is arranged on the left side below the belt wheel, and a synchronous belt which is used for driving the belt wheel to drive is arranged between the torque motor and the belt wheel. The tension control mechanism of the annular coil winding machine has the advantages that the structure is simple, the design is reasonable, the problem that enameled wires get loose during winding in the prior art can be effectively solved, and the demand for stable tension during coil winding is met.

Owner:THE NORTHWEST MACHINE

Production assembly line and production technology of optical unit sheath

The invention discloses a production assembly line and production technology of an optical unit sheath. The production assembly line comprises a paying-off device, a tension controller, a hot melt adhesive coating device, a first extruding machine, a preliminary cooling water tank, a second extruding machine, a complete cooing water tank, an online external diameter monitor and a take-up device which are arranged successively; a stainless steel pipe is coiled on the paying-off device; and the tension controller controls a tension force, the hot melt adhesive coating device coats a surface with an adhesive, the first extruding machine carries out first plastic extrusion of the sheath, the preliminary cooling water tank carries out preliminary cooling, the second extruding machine carries out secondary plastic extrusion of the sheath, the complete cooing water tank carries out complete cooling, the online external diameter monitor detects an external diameter value, and the take-up device carries out rolling. According to the invention, the thickness and external diameters of prepared optical units are uniform, the radial water-blocking performance is high, the stainless steel pipe is combined with the sheath tightly, and the vertical water blocking performance is high.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

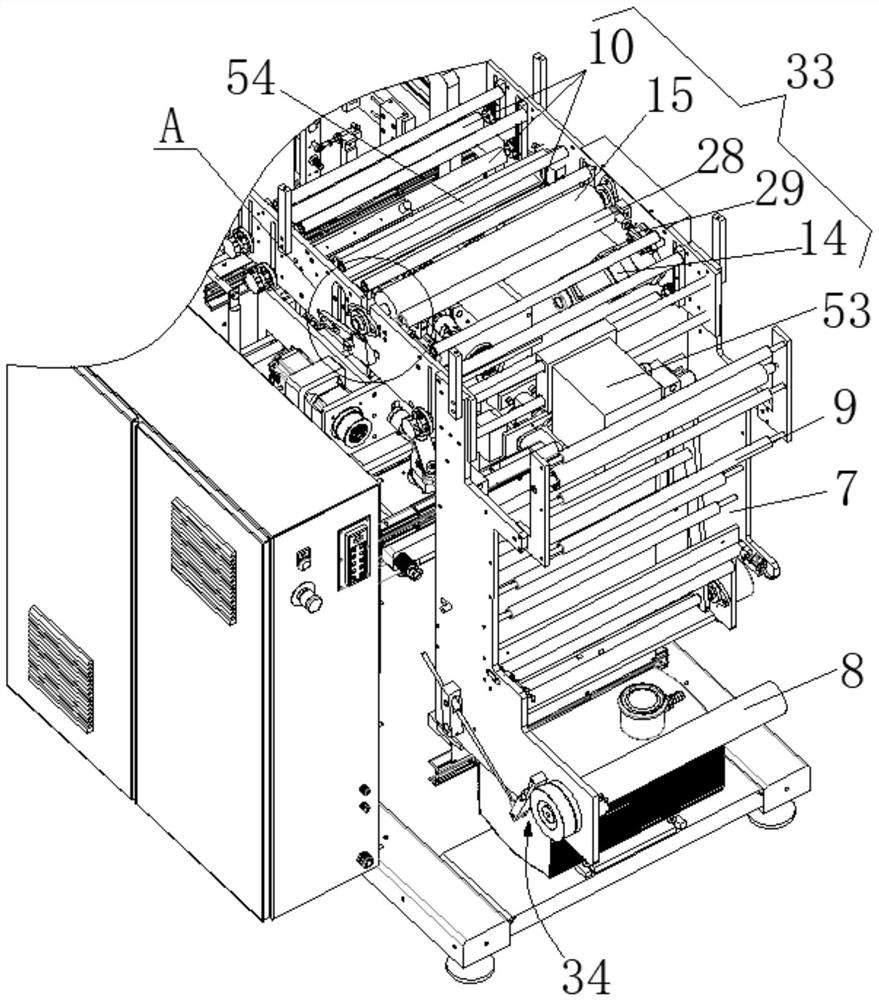

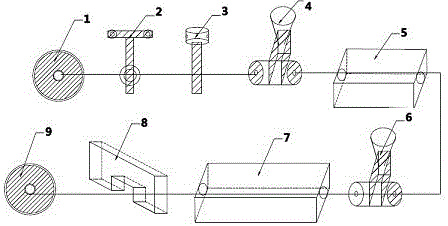

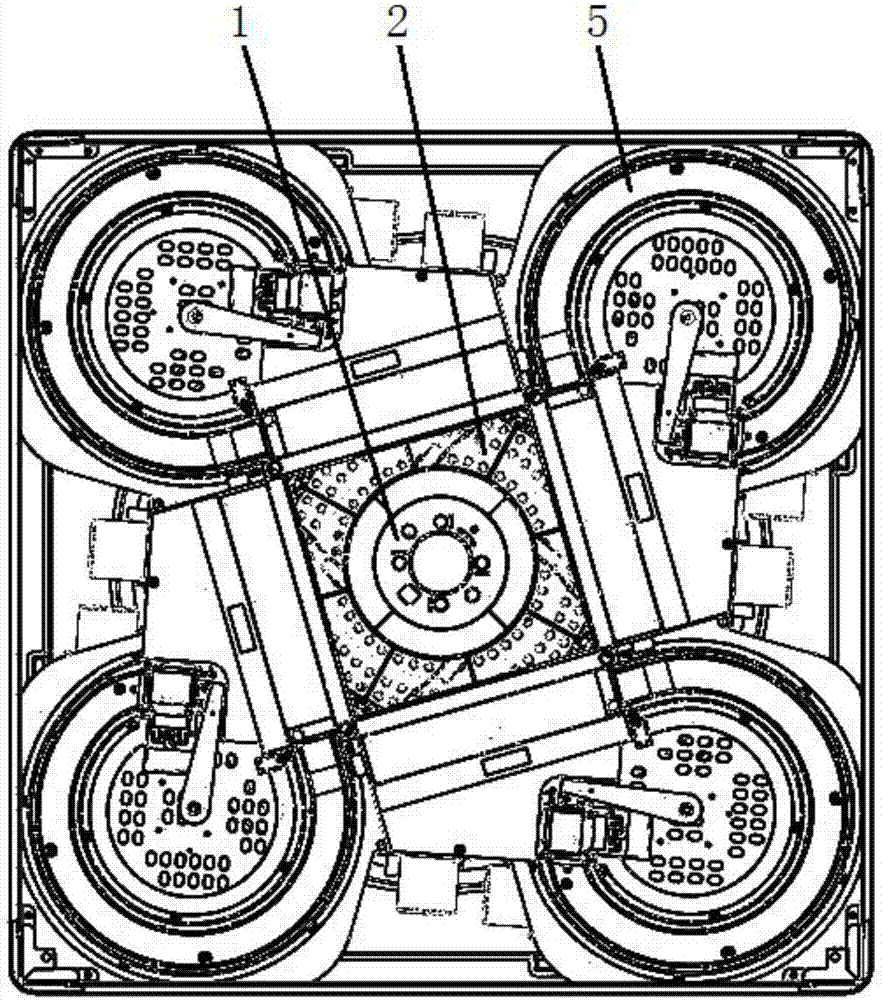

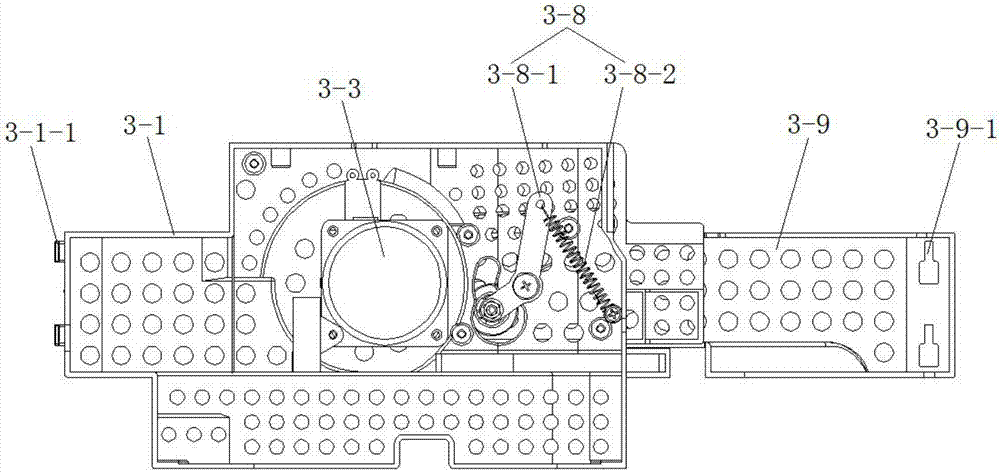

Fully-automatic Mahjong machine

The invention discloses a fully-automatic Mahjong machine. The fully-automatic Mahjong machine comprises an operating disk mechanism, a shuffling mechanism, conveying mechanisms, stacking, lifting and pushing mechanisms and tile feeding mechanisms; the operating disk mechanism is positioned in the center of the Mahjong machine; the shuffling mechanism is positioned at the bottom of the Mahjong machine; the conveying mechanisms, the stacking, lifting and pushing mechanisms and the tile feeding mechanisms are positioned on the four sides of the Mahjong machine; the conveying mechanisms and the stacking, lifting and pushing mechanisms are arranged below the tile feeding mechanism; each tile feeding mechanism comprises a bracket, a tile feeding motor, a tile feeding rocker arm, a tile lifting plate, a tile lifting plate supporting block, a tile lifting motor and a tile lifting rocker arm; a tile feeding rail groove and a tile lifting groove are formed the bracket; the tile feeding rail groove is ring-shaped; and the inlet of the tile lifting groove is communicated with the outlet of the tile feeding rail groove. The conveying mechanisms, the stacking, lifting and pushing mechanisms and the tile feeding mechanisms are small in volume, small in occupied space, small in part quantity and low in cost, and the miniaturization as well as lighting and thinning requirements of the fully-automatic Mahjong machine are met.

Owner:宋拥良

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com