Full-automatic laminating machine

A laminating machine, fully automatic technology, applied in winding strips, thin material processing, transportation and packaging, etc., can solve problems such as time-consuming, laborious, inconvenient and inefficient, and affect the quality of lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

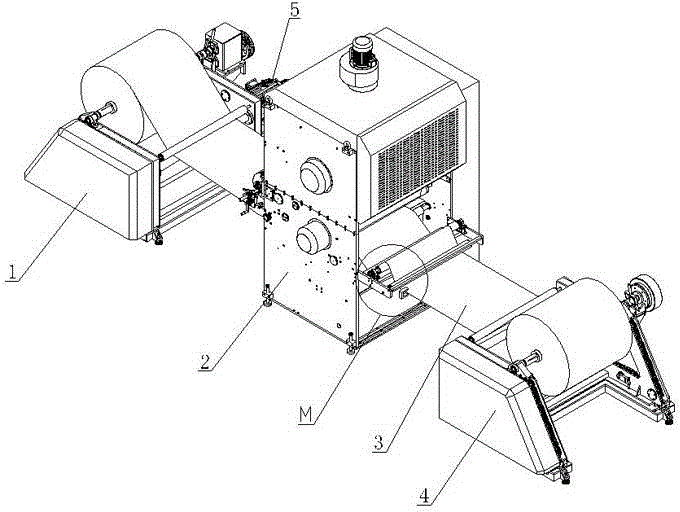

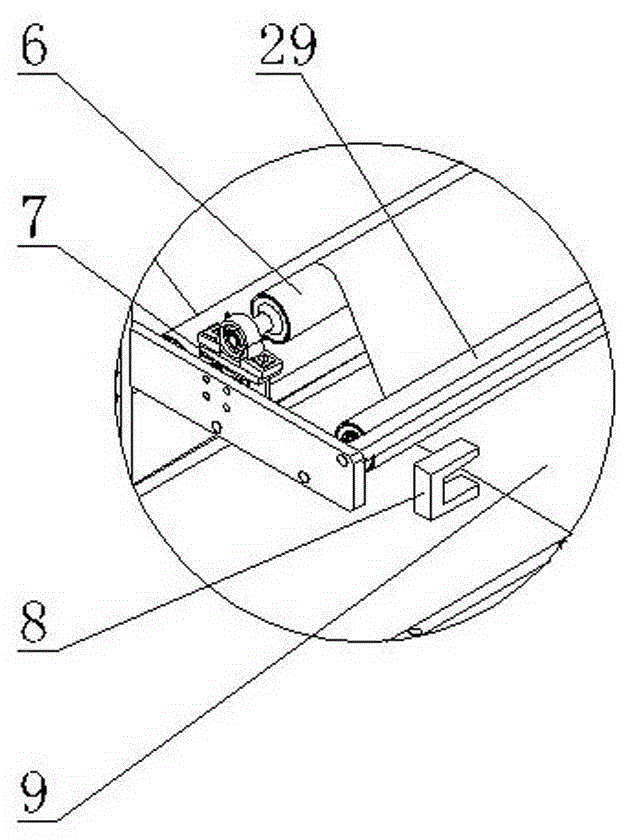

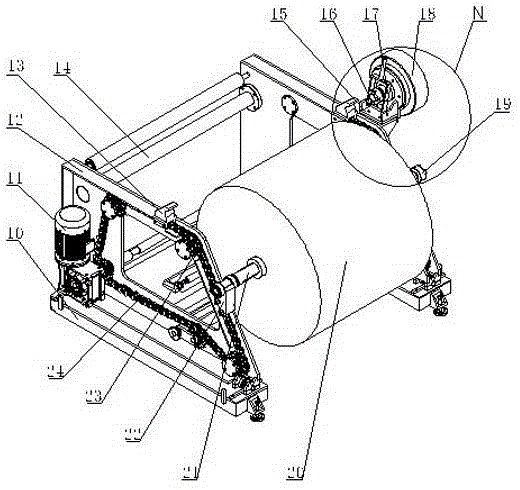

[0014] With reference to the accompanying drawings, this fully automatic laminating machine includes a feeding mechanism 4, a laminating mechanism 2, a receiving mechanism 1 and a programmable controller, and the discharging mechanism 4 has a rack 28, and on the rack 28 A positioning seat is provided, and the roll paper 20 is rotatably arranged on the mounting seat of the material rack 28 through the air expansion shaft 21. The material rack 28 is composed of two side plates 12 connected by connecting rods 14. The frame 28 is slidably arranged on the base 10, and the base 10 is provided with a first drive mechanism connected to the material frame 28 in transmission. Specifically, the first drive mechanism includes a first motor 25, a screw rod 27 and Screw mandrel cover 26, described first motor 25 is located on base 10 and is connected with screw mandrel cover 26 transmission, and described screw mandrel 27 one end is connected with material frame 28, and the other end is scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com