Production assembly line and production technology of optical unit sheath

A production line and optical unit technology, applied in the direction of optical components, light guides, optics, etc., can solve the problem of not meeting the requirements of optical unit water resistance, unable to meet the requirements of sheath thickness and outer diameter, and uneven sheath thickness and outer diameter and other problems, to achieve good radial waterproof performance, stable and easy-to-control extrusion process, and ensure the effect of longitudinal water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

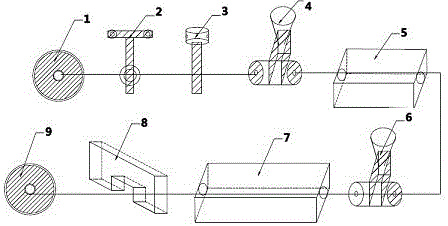

[0026] Such as figure 1 As shown, the production line of a light unit sheath disclosed by the present invention includes a line-off device 1 arranged in sequence, a tension controller 2, a hot-melt adhesive applicator 3, a No. 1 extruder 4, and a preliminary cooling water tank 5. No. 2 extruder 6, complete cooling water tank 7, outer diameter on-line monitor 8 and wire take-up device 9, the stainless steel tube is coiled on the wire pay-off device, the tension is controlled by the tension controller in turn, and the hot melt adhesive is coated The surface coating is carried out by the No. 1 extruder, the first layer of sheath is extruded, the preliminary cooling water tank is used for preliminary cooling, the second extruder is used for the second sheath extrusion, and the complete co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com