Tension control mechanism of annular coil winding machine

A tension control mechanism, technology of annular coil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

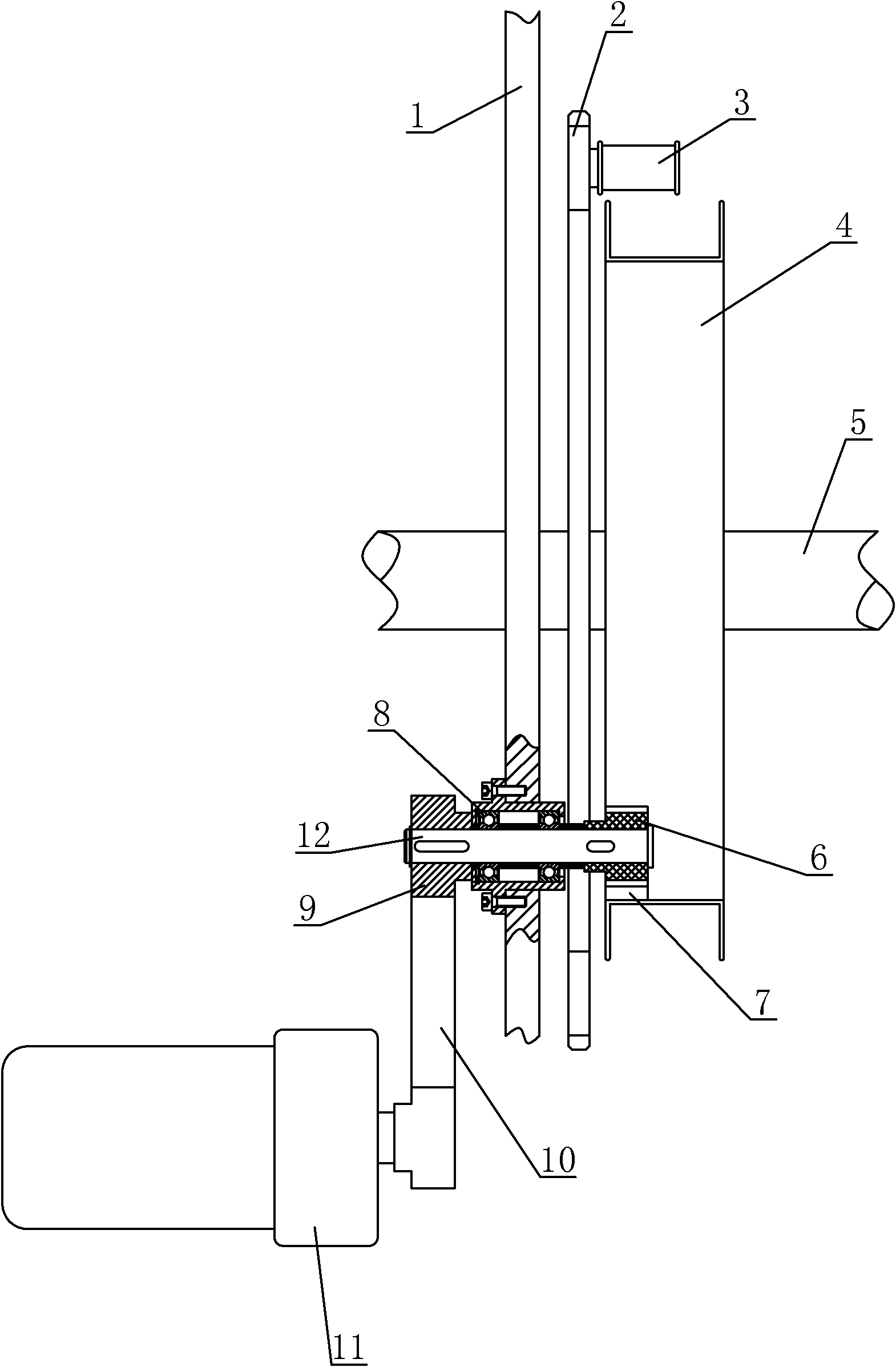

[0018] Such as figure 1 The tension control mechanism of a toroidal coil winding machine shown includes a machine head wall plate 1, an iron core 5 vertically installed on the machine head wall plate 1, a shuttle 2 arranged on the right side of the machine head wall plate 1, a fixed installation The extractor 3 on the right side of the upper part of the shuttle 2 and the wire storage ring 4 arranged on the right side of the shuttle 2, the iron core 5 is vertically installed on the wire storage ring 4, and the inside of the wire storage ring 4 is provided with an inner ring gear 7. The inner ring gear 7 is located at the lower part of the wire storage ring 4, and the lower part of the wire storage ring 4 is provided with a transmission shaft 12 passing through the machine head wallboard 1, the shuttle 2 and the wire storage ring 4, and the right end of the transmission shaft 12 is The gear 6 meshing with the ring gear 7 is installed, the left end of the transmission shaft 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com