Coiled material conveying and tensioning device

A tensioning device and tensioning technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve problems such as intricate rolls, affecting the progress of the production process, and tensioning effect of the tensioning device, achieving responsiveness Fast speed, avoiding the effect of poor guiding movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

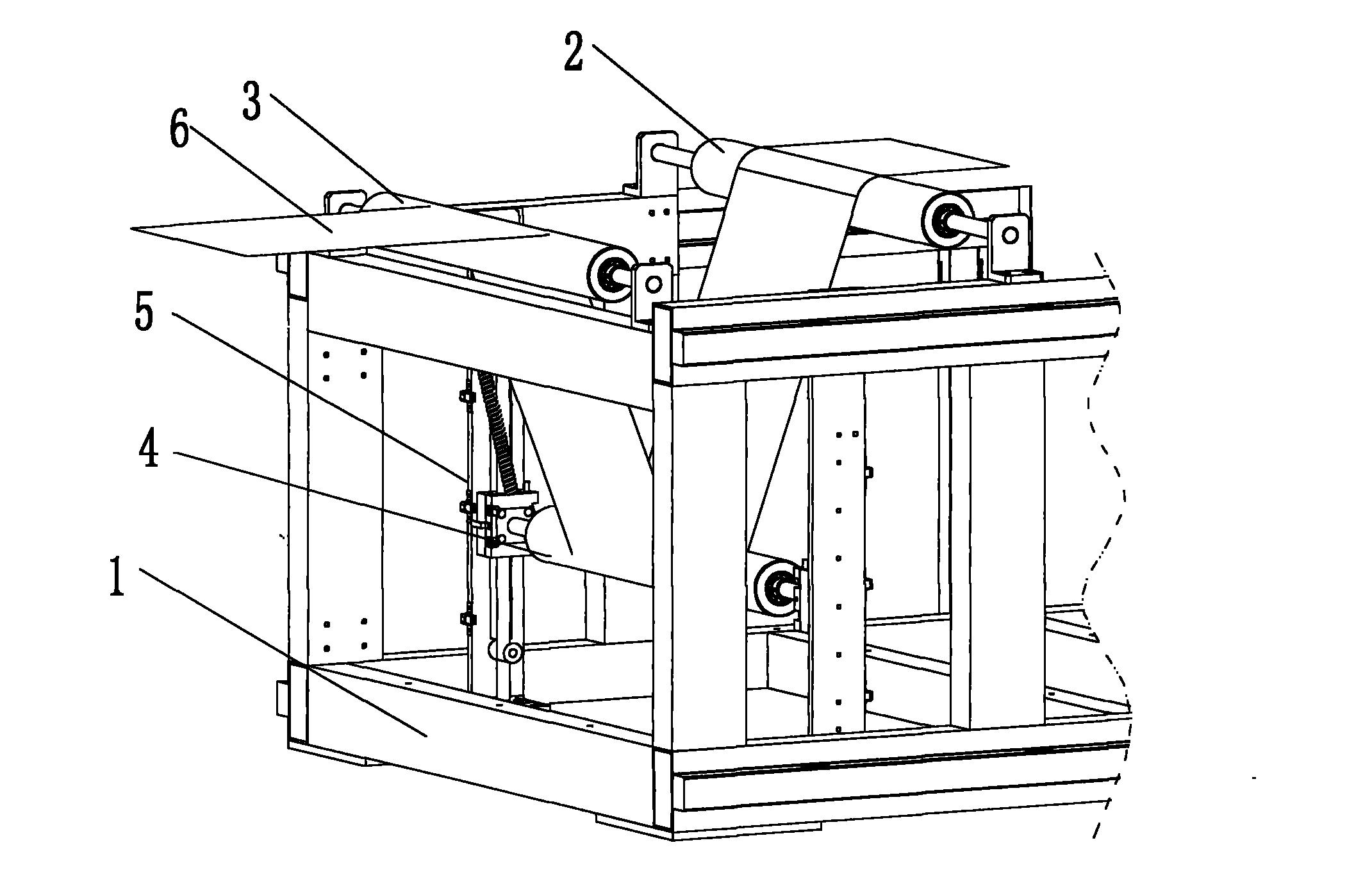

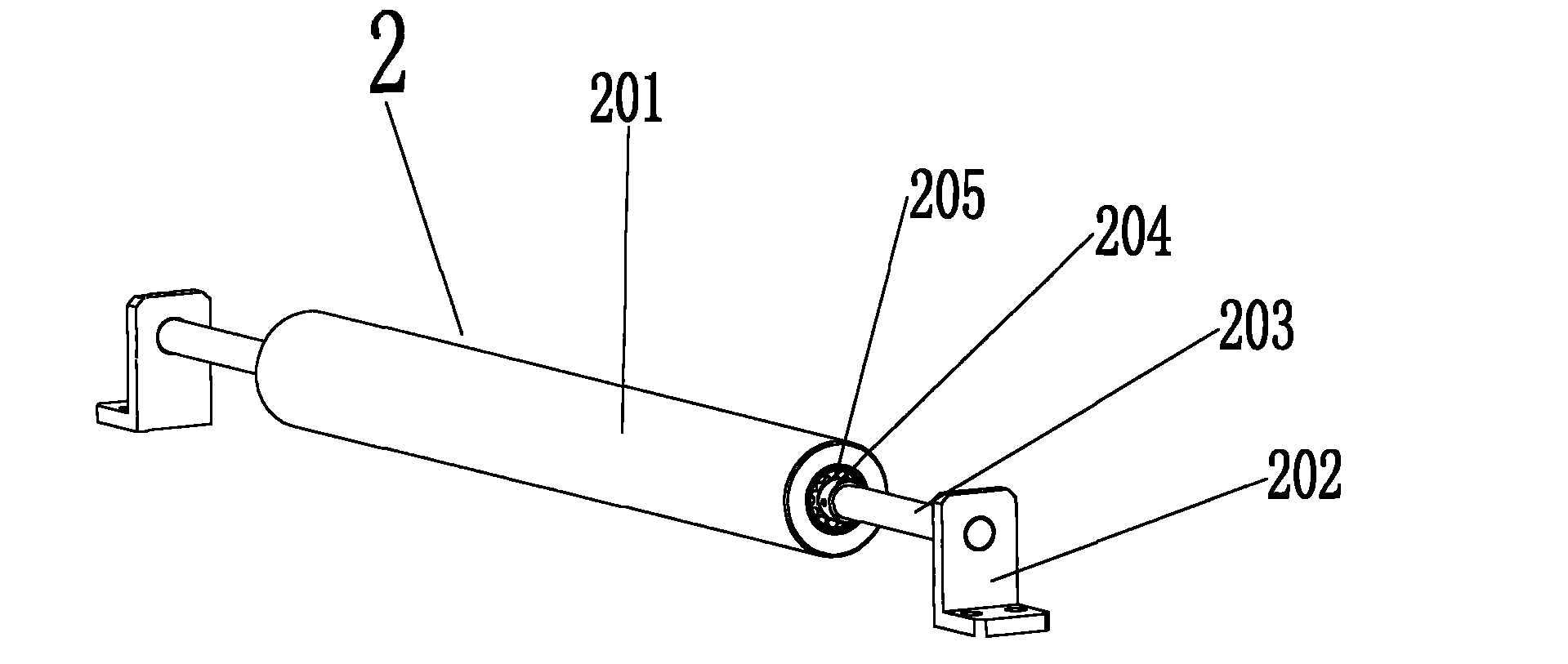

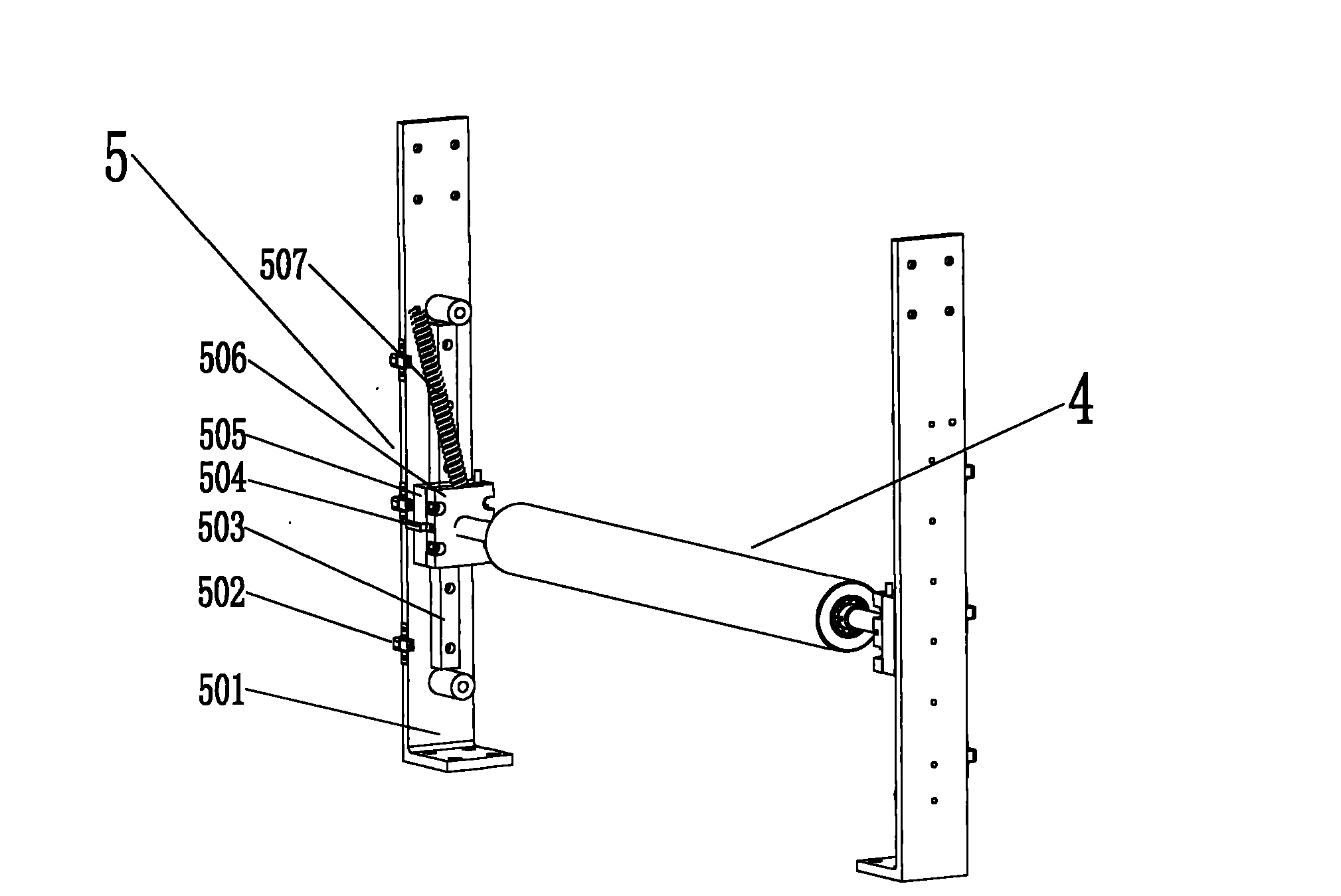

[0034] like figure 1 As shown, in this embodiment, the coil conveying tensioning device includes a workbench support 1 and a first guide roller assembly 2, a second guide roller assembly 3, and a tension guide roller assembly arranged on the workbench support 1. 4 and the tension guide roller bracket assembly 5, the first guide roller assembly 2 and the second guide roller assembly 3 are arranged on the upper part of the workbench bracket, and the tension guide roller bracket assembly 5 is arranged on the first Between the guide roller assembly 1 and the second guide roller assembly 2 , both ends of the tension guide roller assembly 4 are erected on the tension guide roller bracket assembly 5 . The axes of the first guide roller assembly 2 , the second guide roller assembly 3 and the tension guide roller assembly 4 are parallel.

[0035] The first guide roller assembly includes a first guide roller, the second guide roller assembly includes a second guide roller, the tension ...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that there is no limit switch.

[0052] Other structures in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0053] From the above detailed description of the embodiments of the present invention, it can be understood that the present invention solves the problems of complex tension structure and slow adjustment of coil tension in the conventional coil tensioning device. Advantages of adjusting tension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com