Patents

Literature

50results about How to "Auto adjust speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

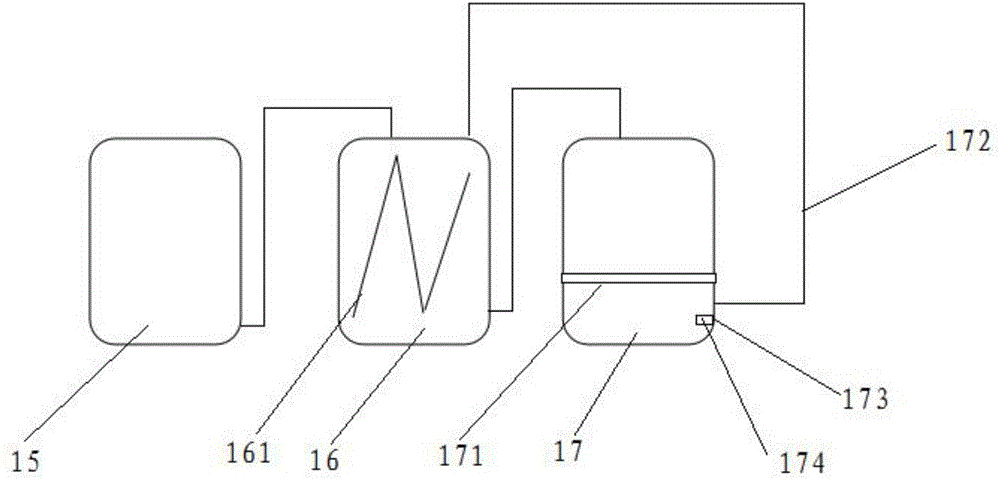

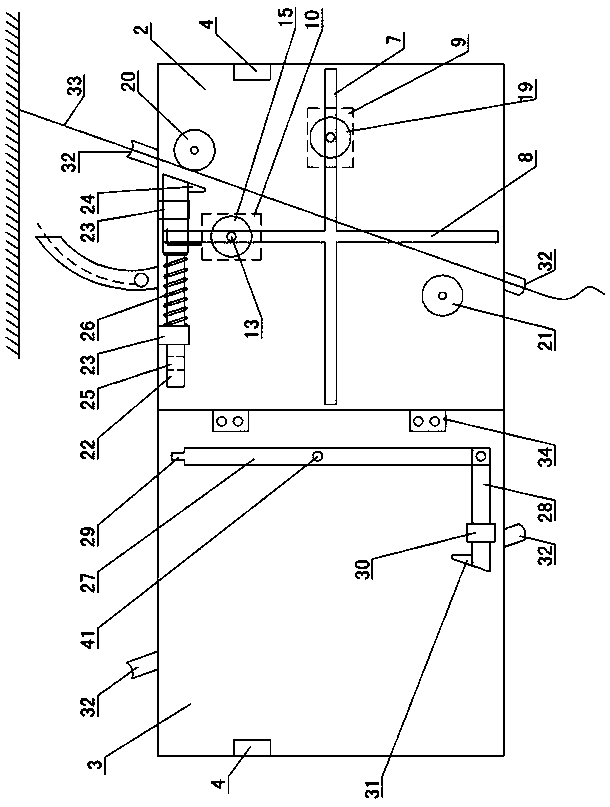

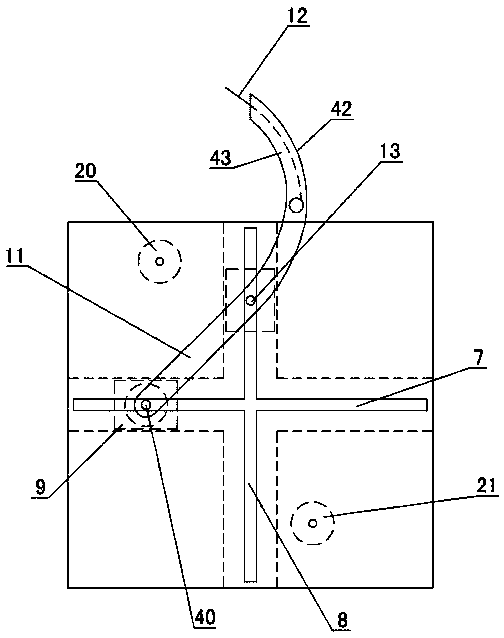

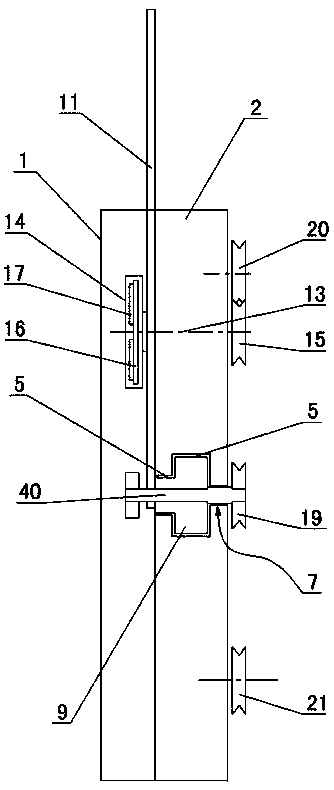

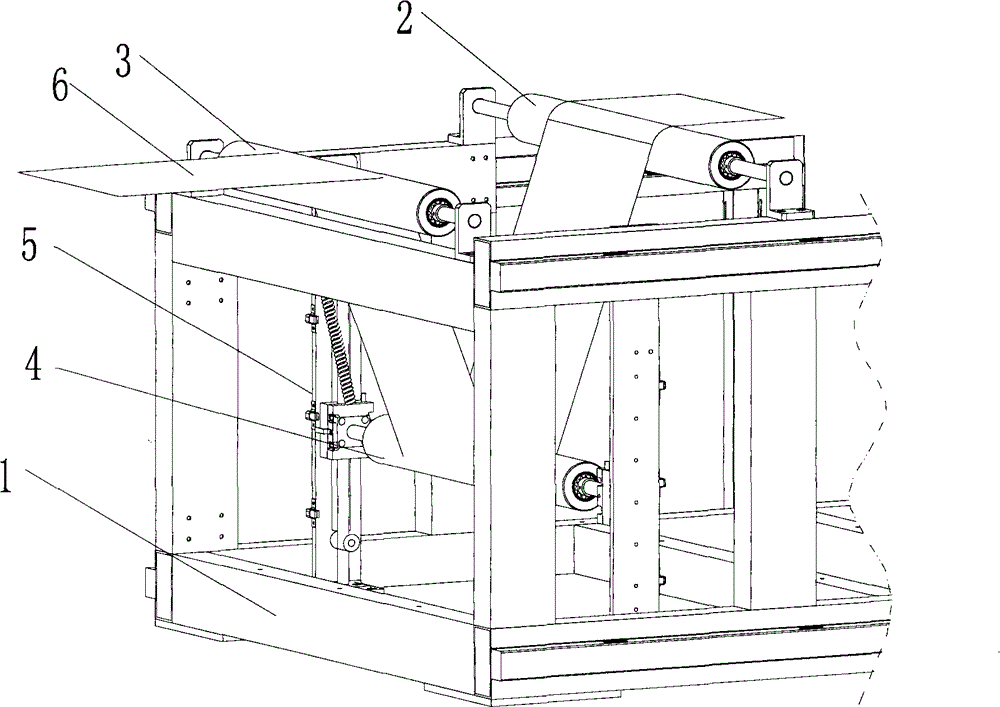

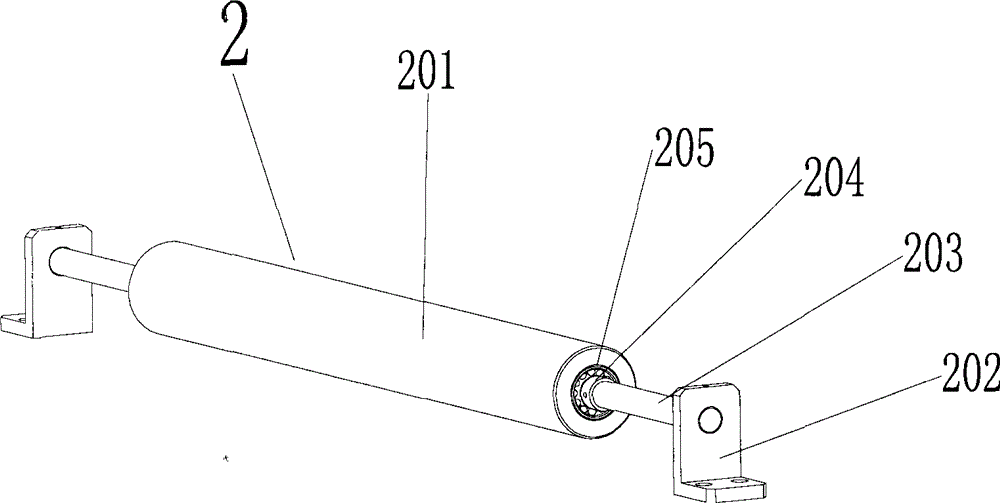

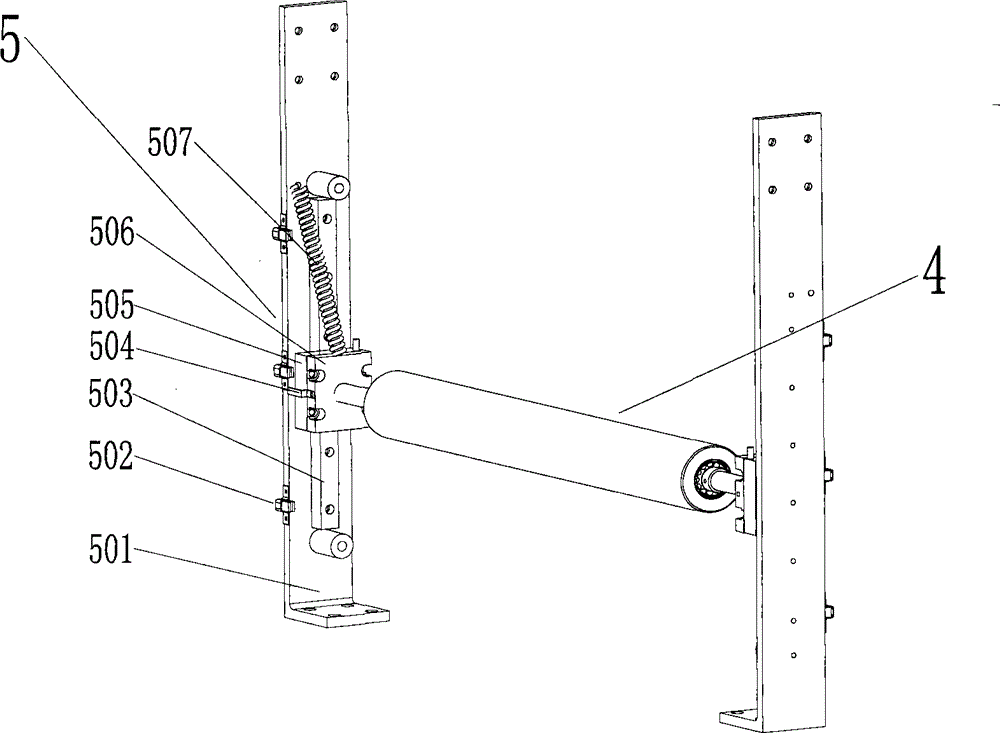

Coiled material conveying tensioning device

ActiveCN102491118AAutomatic tension adjustmentAvoid breakingWebs handlingEngineeringMechanical engineering

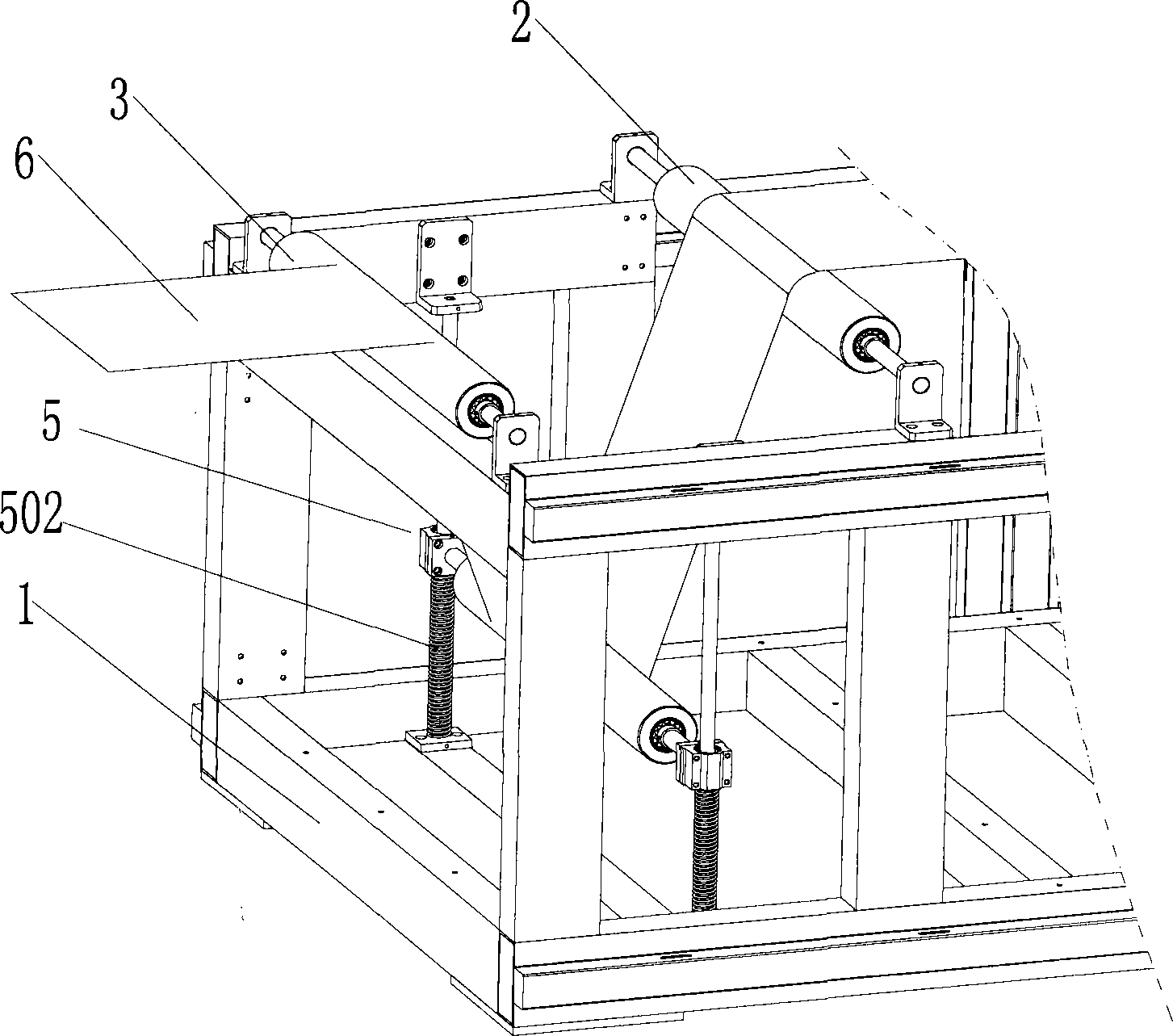

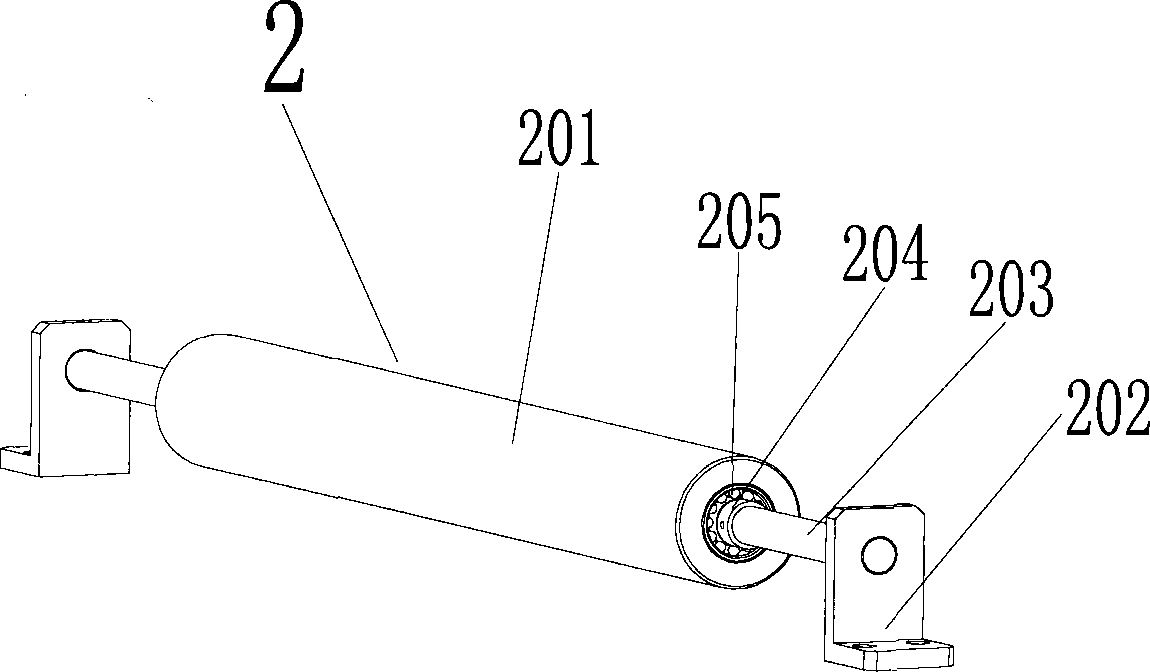

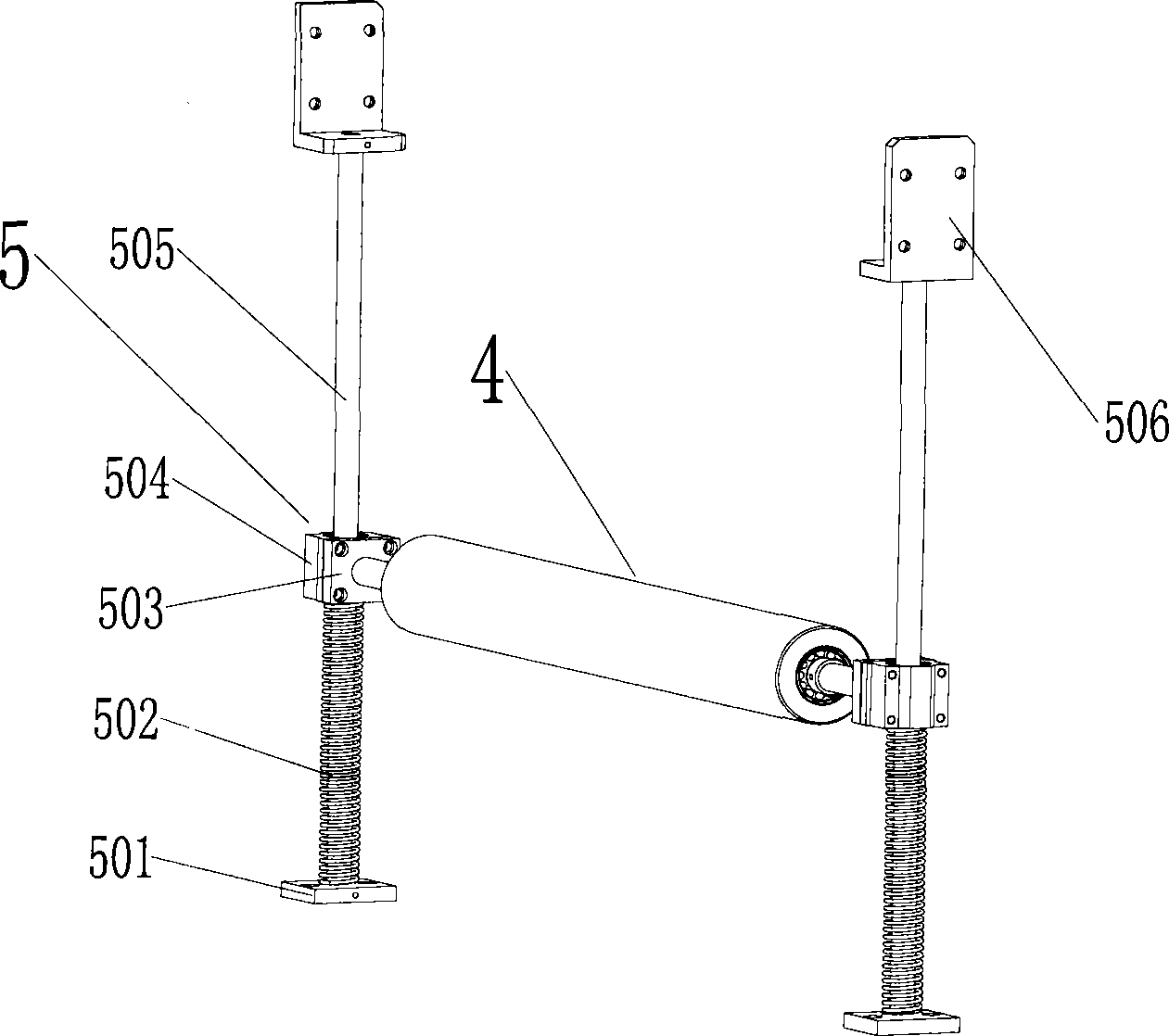

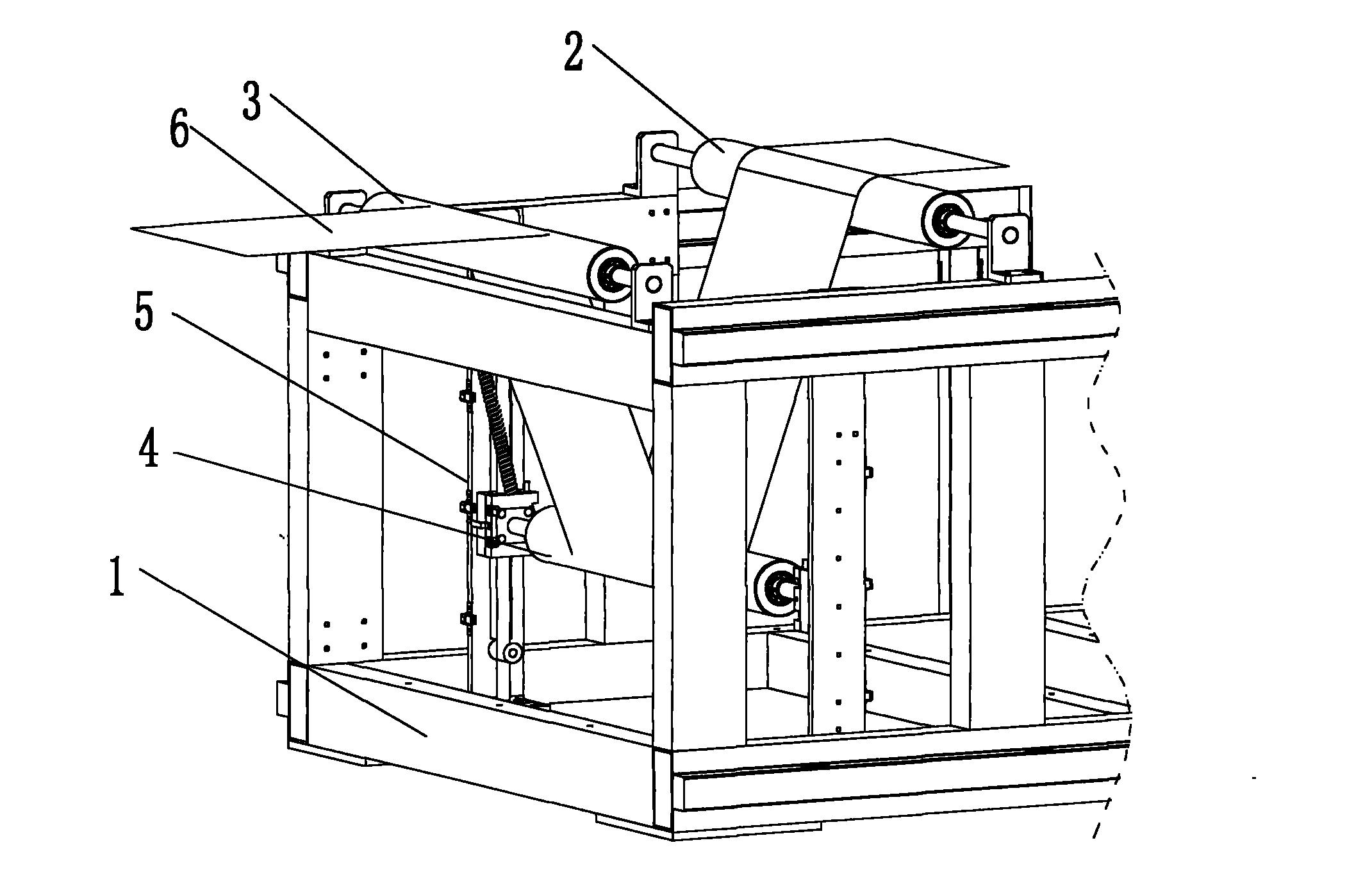

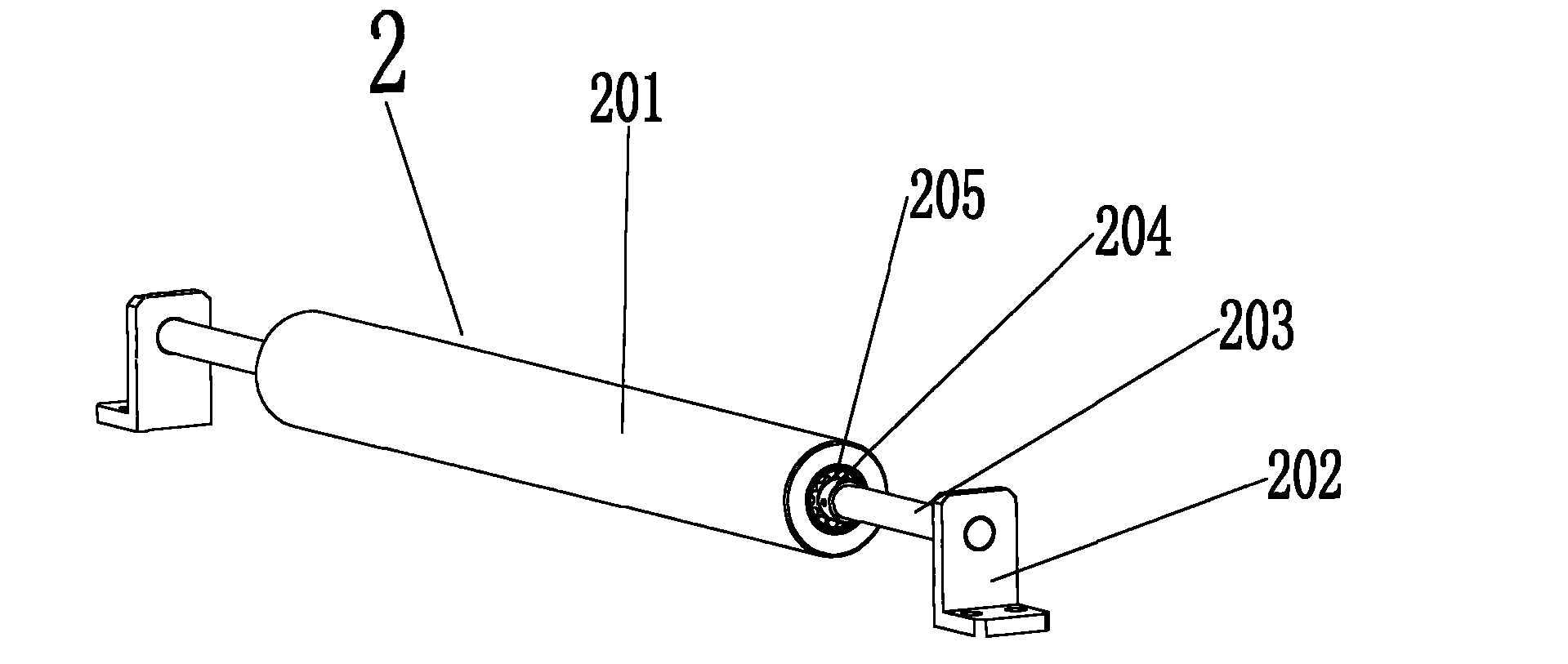

The invention provides a coiled material conveying tensioning device, which comprises a working platform support (1), and a first guide roller assembly (2), a second guide roller assembly (3), a tensioning guide roller assembly (4) and a tensioning guide roller support assembly (5), which are arranged on the working platform support, wherein the tensioning guide roller support assembly (5) is arranged between the first guide roller assembly and the second guide roller assembly, and the tensioning guide roller assembly is supported on the tensioning guide roller support assembly and below the first guide roller assembly and the second guide roller assembly; the tensioning guide roller support assembly can regulate the height of the tensioning guide roller assembly to allow a coiled material to be tensioned after the coiled material passes through a first guide roller, a tensioning guide roller and the second guide roller. The coiled material conveying tensioning device with a simple structure has the advantages of quick response and automatic regulation of the tension of the coiled material at a feeding end.

Owner:CHERY AUTOMOBILE CO LTD

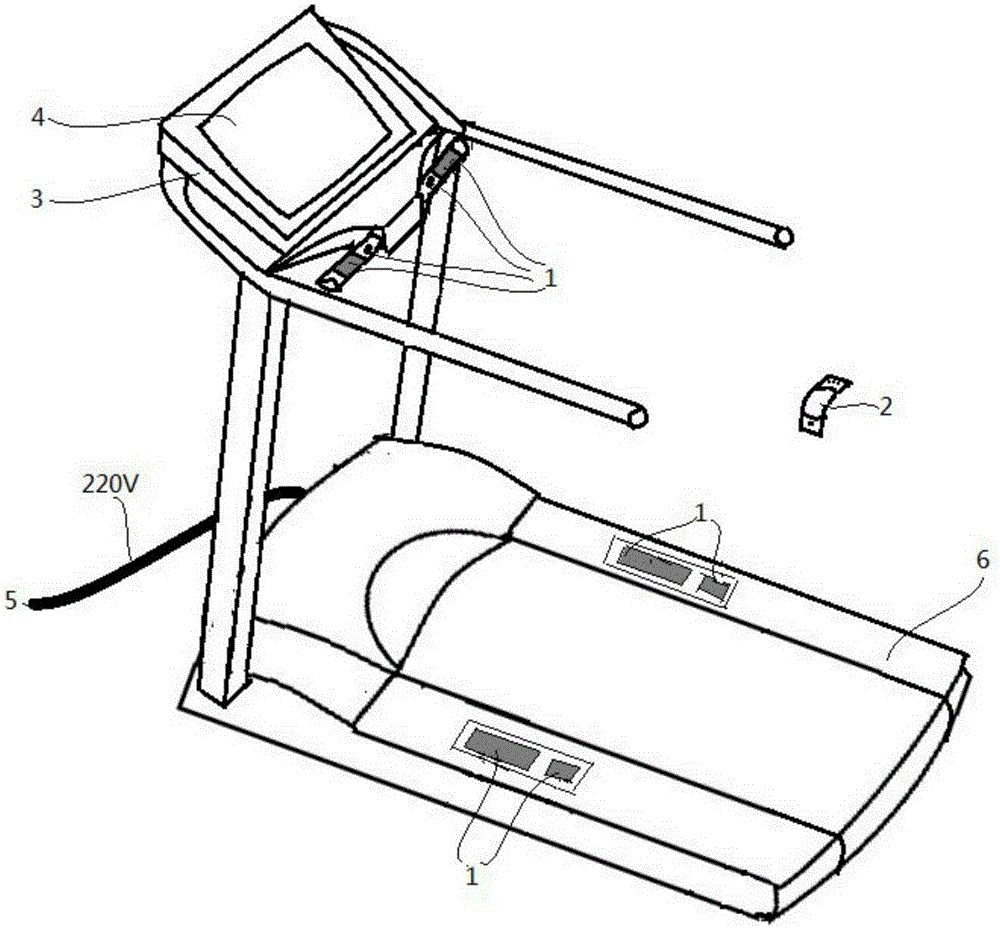

Intelligent fat-reducing treadmill and body building instruction method thereof

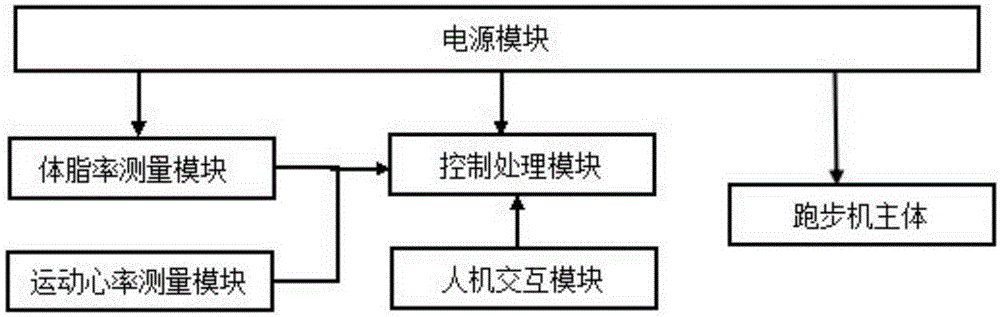

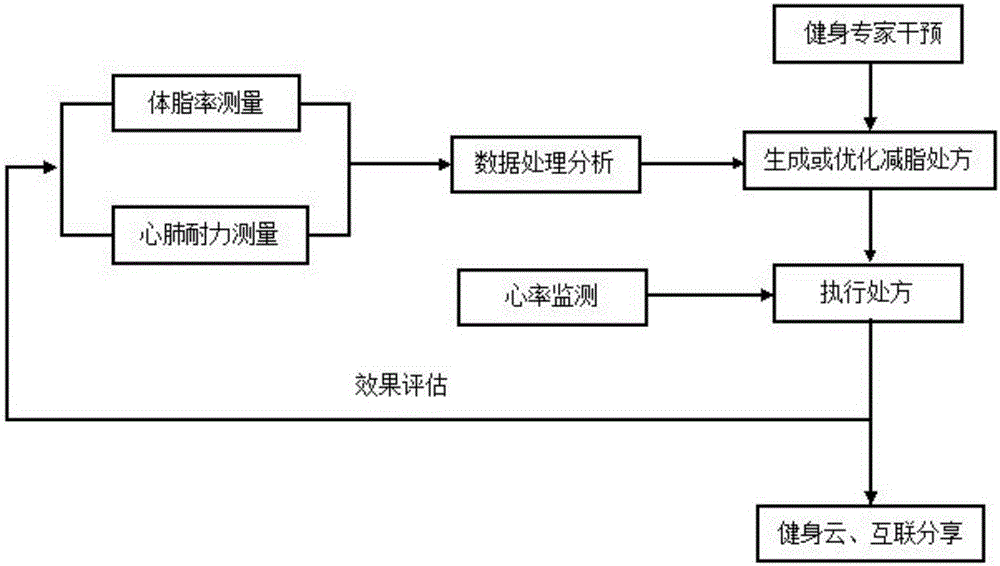

ActiveCN105169620ATest SpecificationConvenient for dynamic adjustmentMeasuring/recording heart/pulse rateMovement coordination devicesComputer moduleHuman system interaction

The invention discloses an intelligent fat-reducing treadmill and a body building instruction method thereof. The intelligent fat-reducing treadmill is characterized by comprising a body fat rate measuring module, an exercising heart rate measuring module, a control and processing module, a man-machine interaction module, a power module and a treadmill body. The intelligent fat-reducing treadmill is capable of providing corresponding fat-reducing exercising schemes for different users, so that more humanized and intelligent body building purposes are achieved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

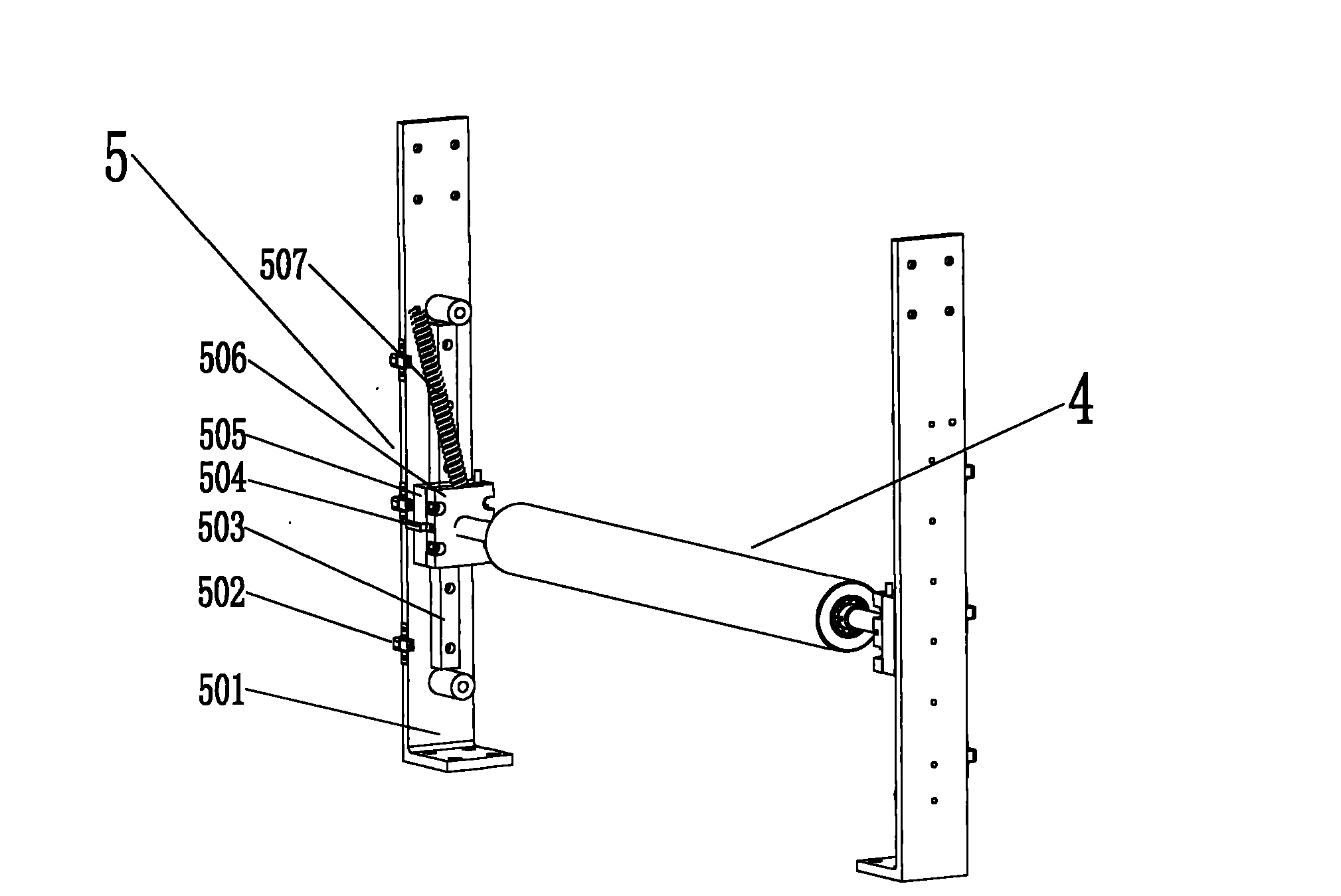

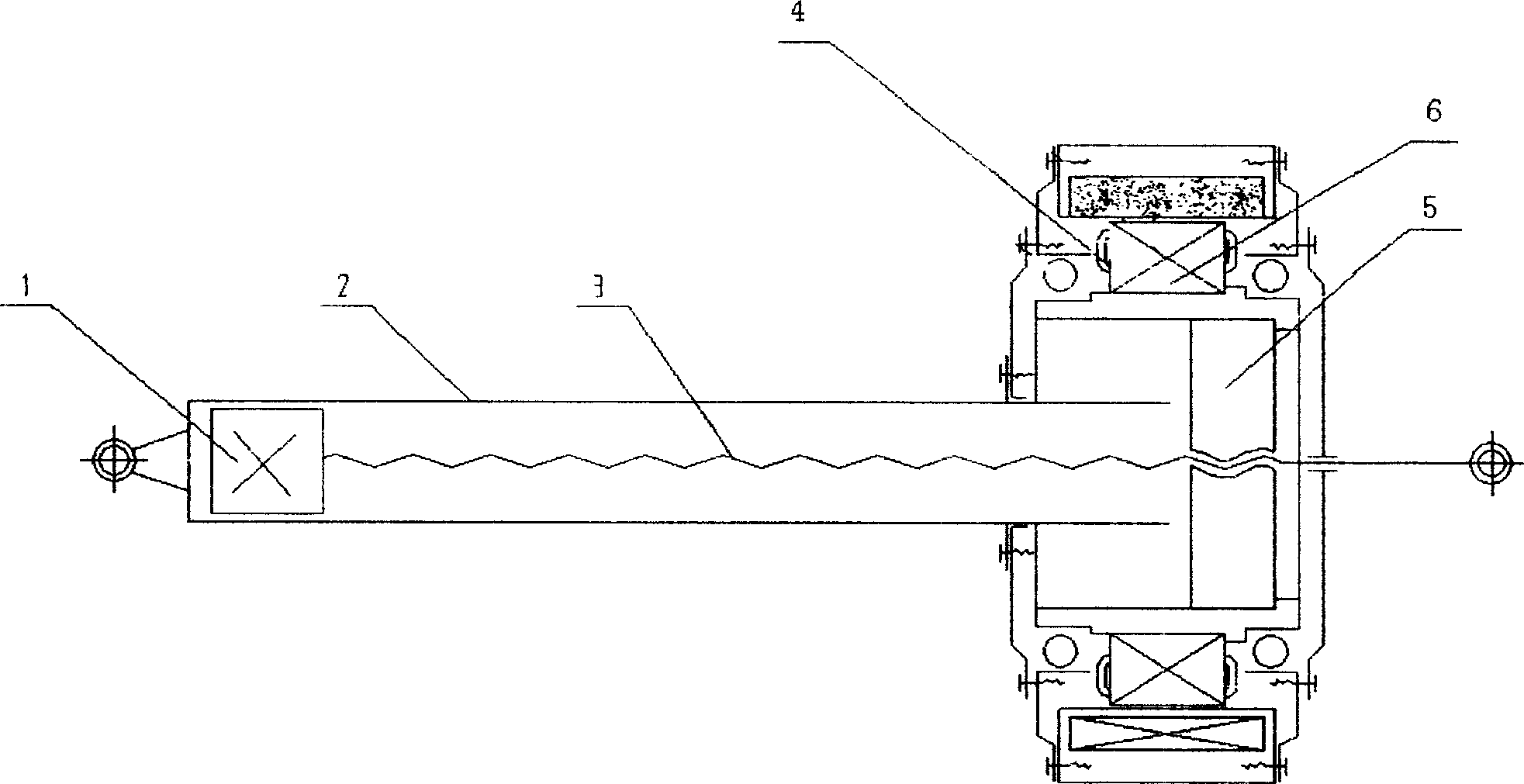

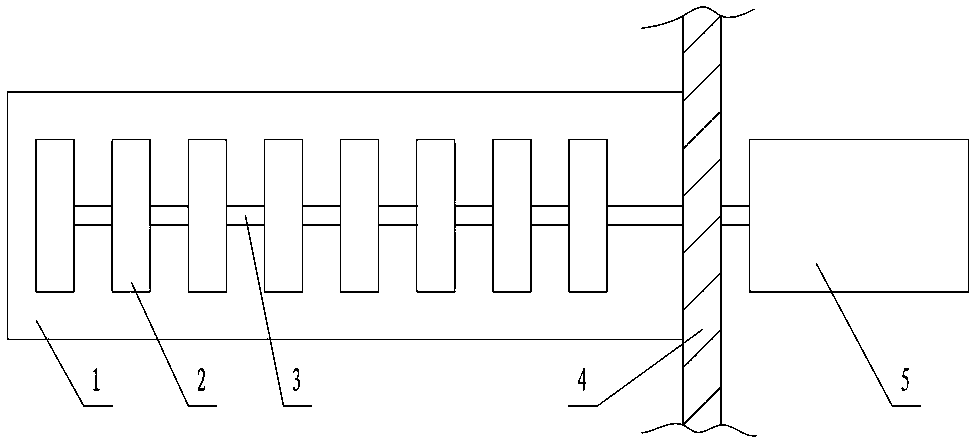

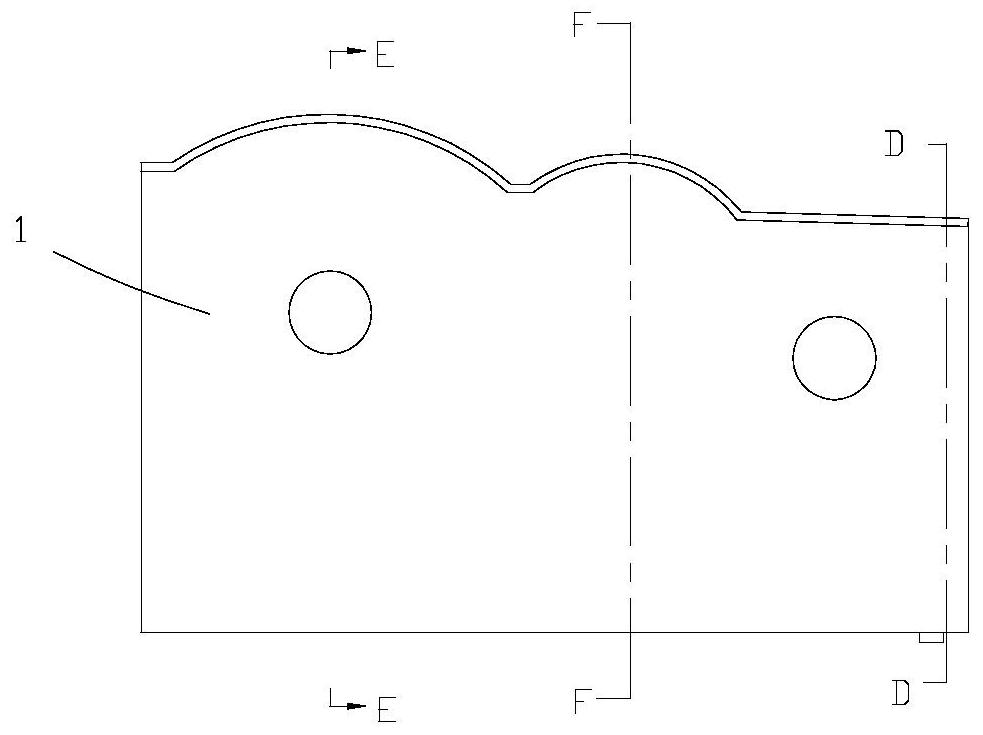

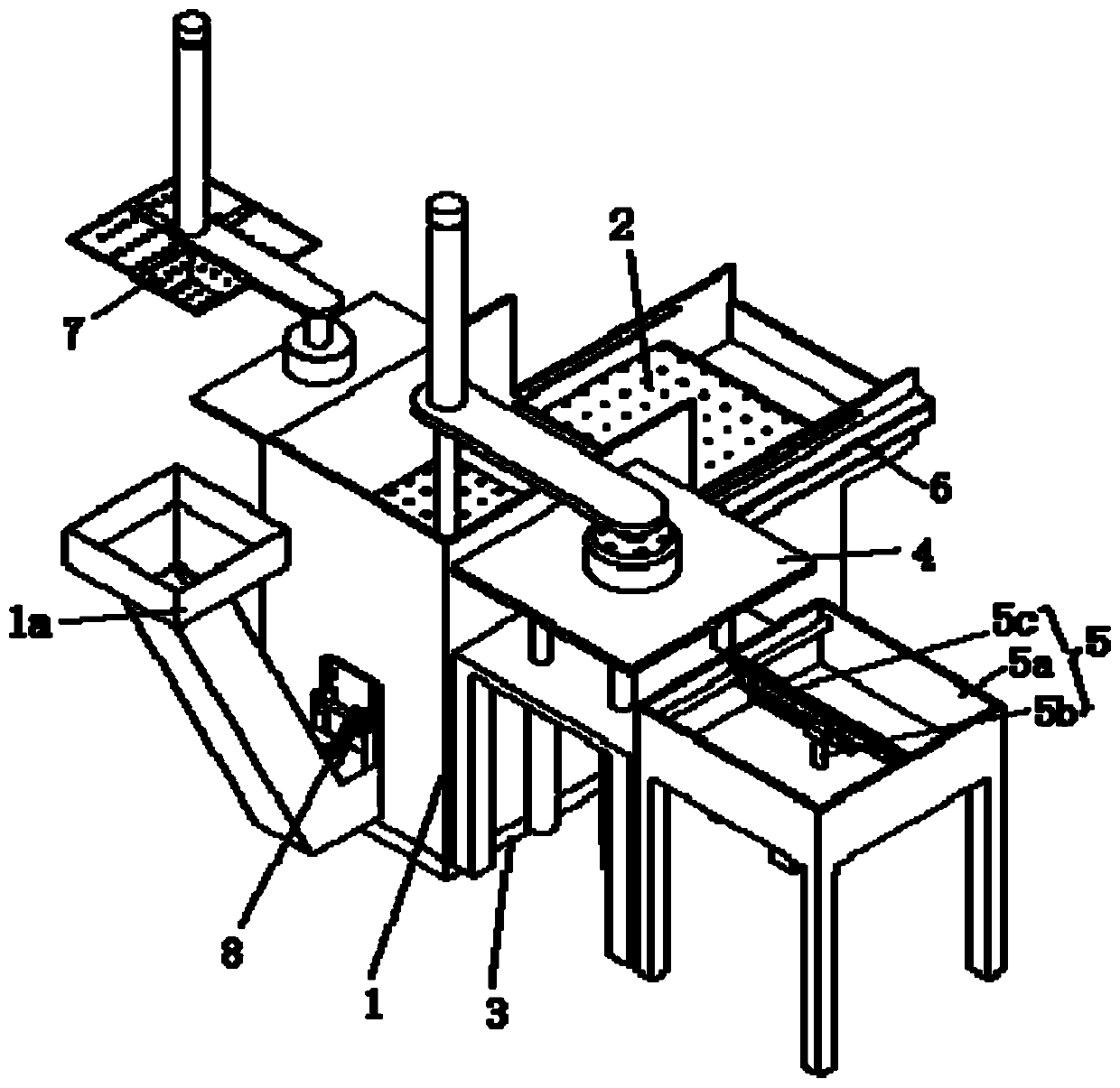

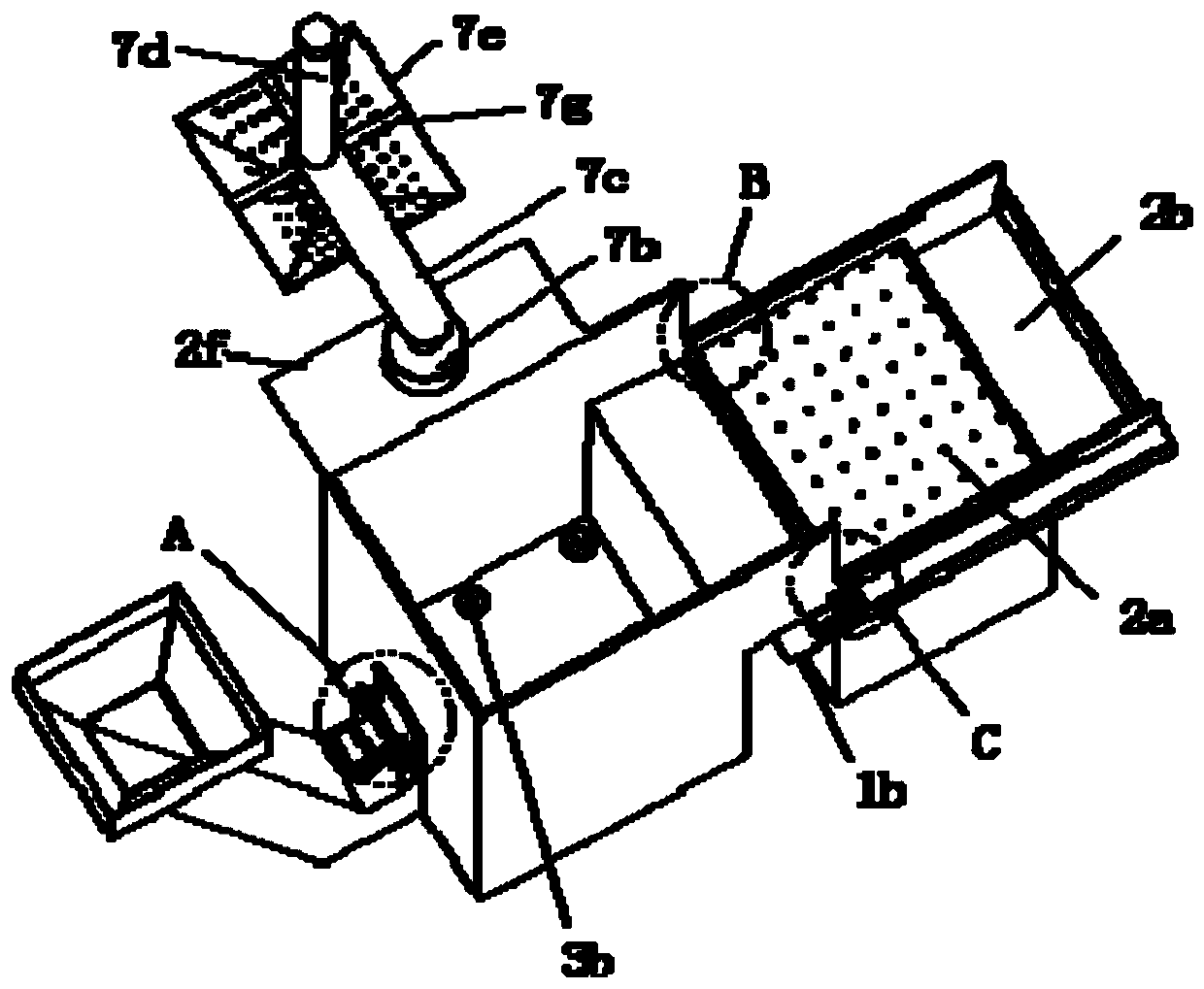

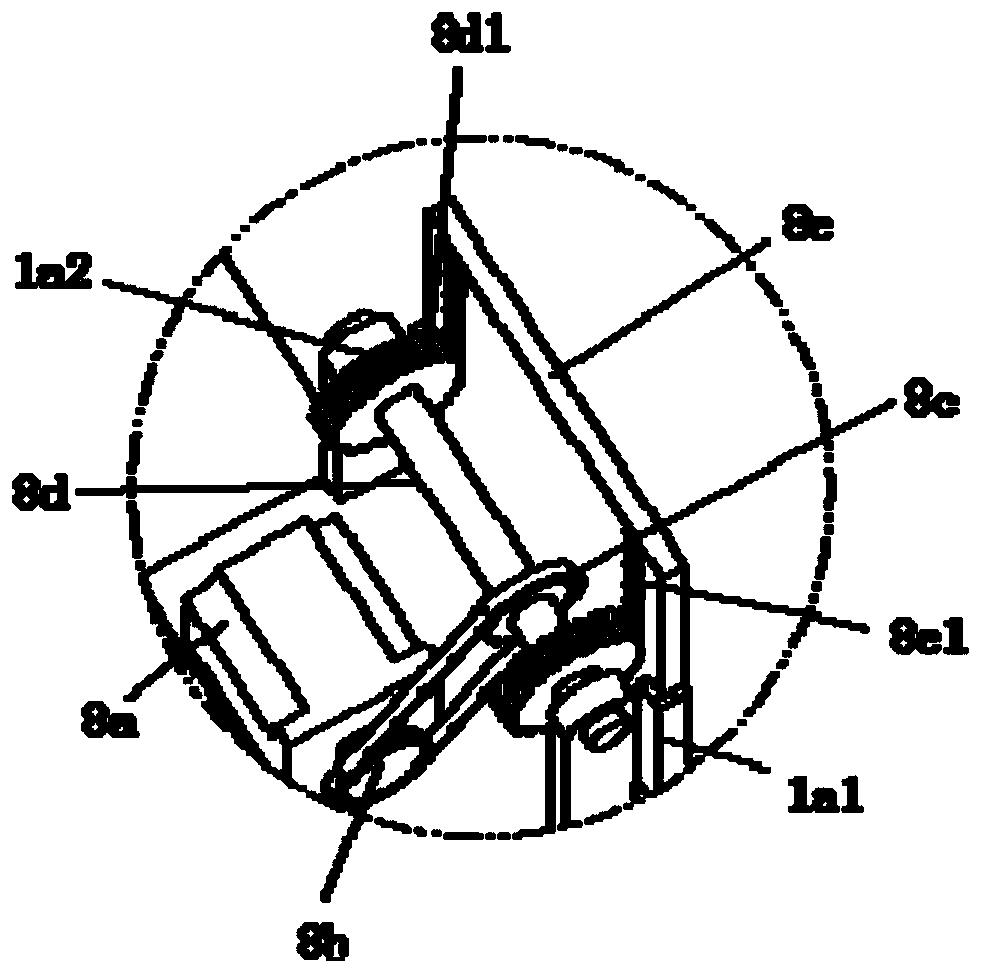

Coiled material conveying and tensioning device

ActiveCN102514968AAutomatic tension adjustmentAvoid breakingWebs handlingEngineeringMechanical engineering

The invention discloses a coiled material conveying and tensioning device, which comprises a workbench support (1), and a first guide roller assembly (2), a second guide roller assembly (3), a tensioning guide roller assembly (4) and a tensioning guide roller support assembly (5) which are arranged on the workbench support, wherein the tensioning guide roller support assembly is arranged between the first guide roller assembly and the second guide roller assembly; the tensioning guide roller assembly is erected on the tensioning guide roller support assembly; the tensioning guide roller assembly is positioned below the first guide roller assembly and the second guide roller assembly; the first guide roller assembly comprises a first guide roller; the second guide roller assembly comprises a second guide roller; the tensioning guide roller assembly comprises a tensioning guide roller; and a coiled material passes through the first guide roller, the tensioning guide roller and the second guide roller in turn to reach a tension state. The coiled material conveying and tensioning device has a simple structure and has the advantages of high response speed and capacity of automatically adjusting the tension of the coiled material at a feed end.

Owner:CHERY AUTOMOBILE CO LTD

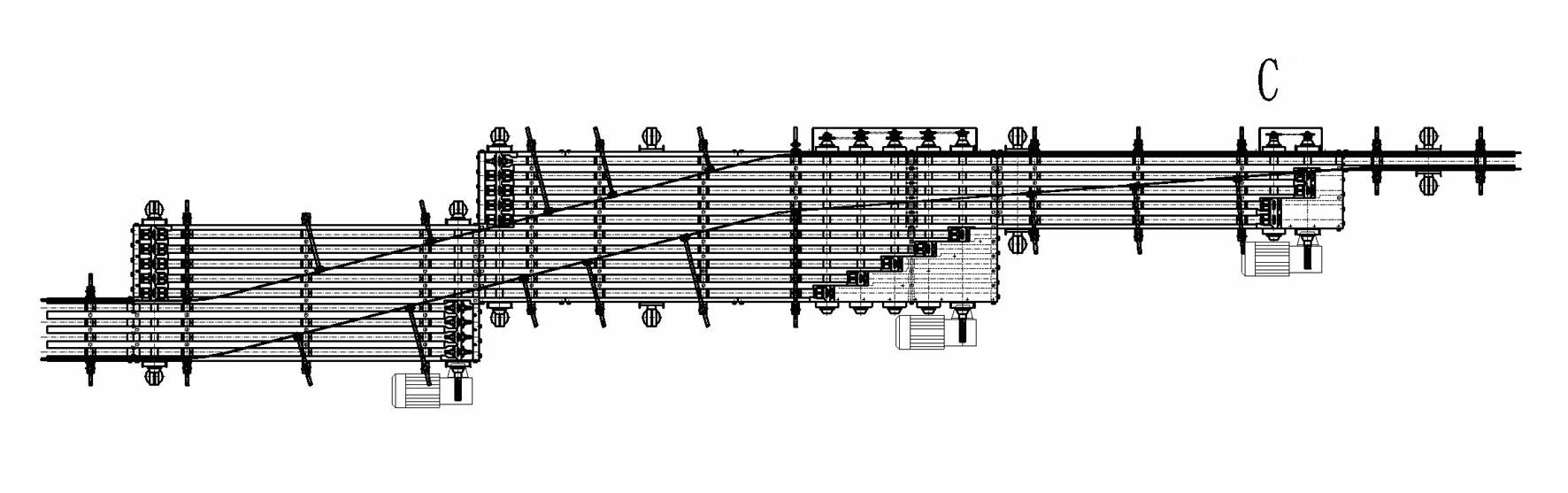

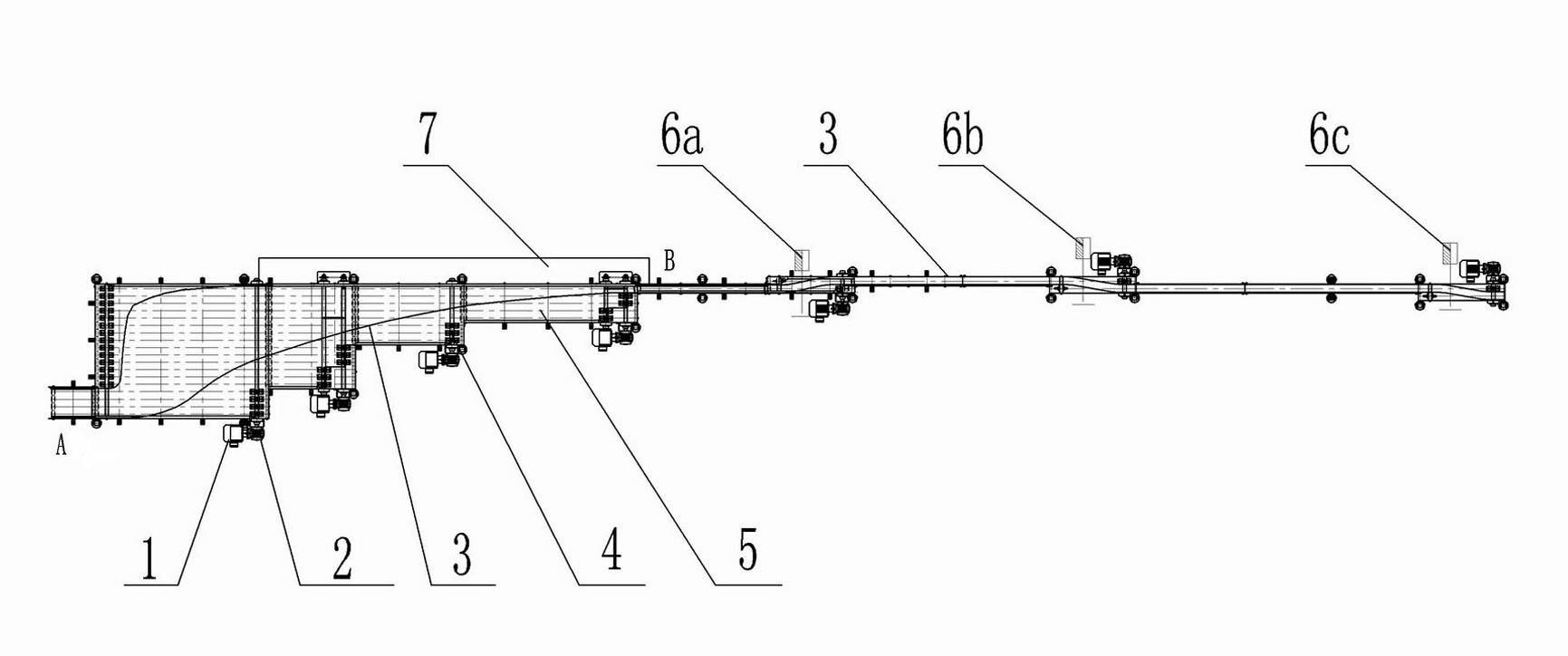

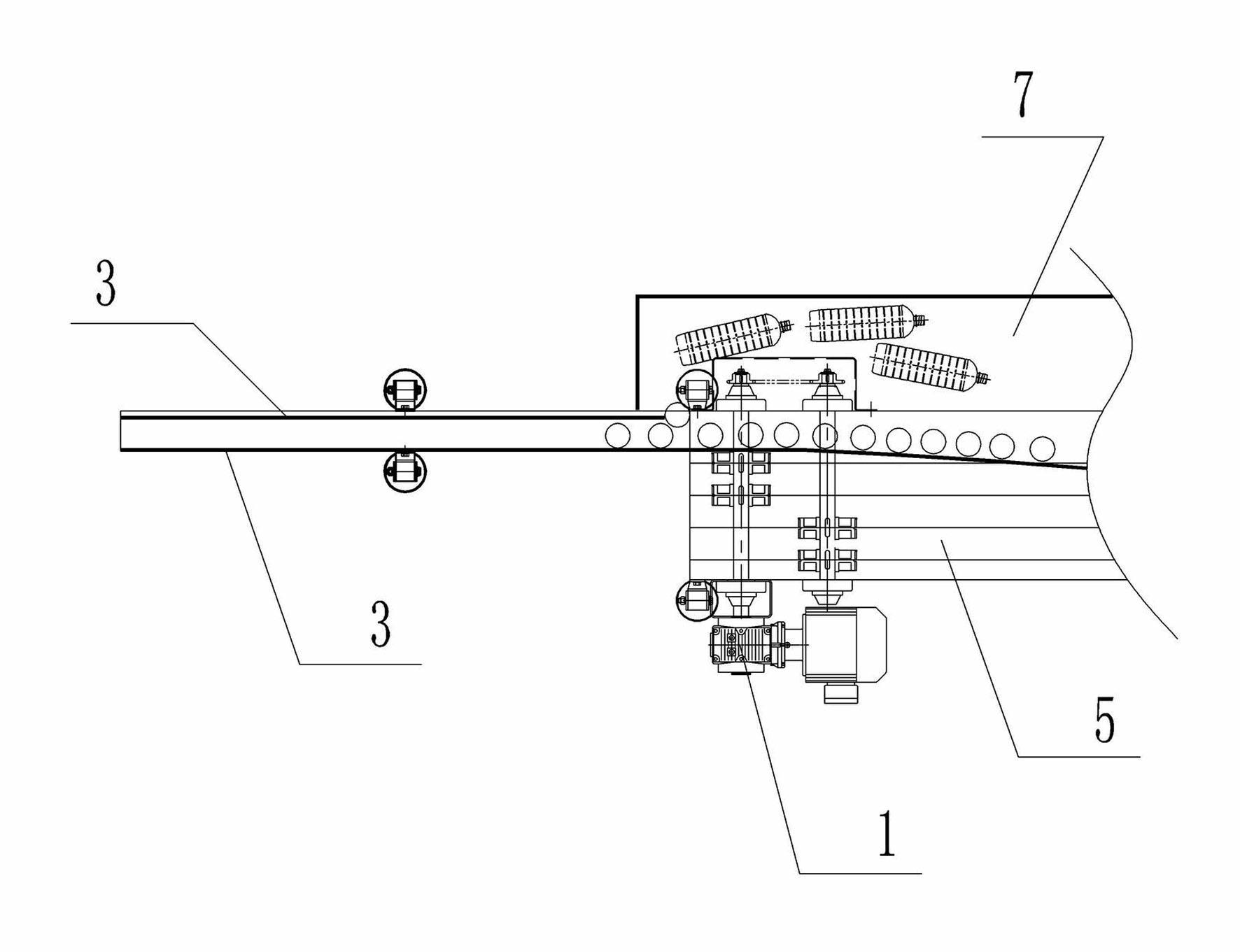

A beverage bottle conveying system

A beverage bottle conveying system, the width of the chain plates from port A to port B is gradually reduced to transport bottles; the motor drives different chain plates to rotate through the reducer and transmission mechanism, providing power for the transmission of beverage bottles and making the chain plates and There is a certain speed difference between the chain plates; the reducer is connected to the motor to reduce the motor speed to the required speed range and adjust the torque; the guardrail is located on the chain plate and guides the bottle from port A to port B; the detection control device is installed In the downstream equipment, it is used to detect the state of the bottle on the chain plate and control the operation of the motor; the signal control system is used in conjunction with the photoelectric detection switch to intelligently control the start, stop and speed of the motor. Its advantages are: it can automatically adjust the speed of the non-pressure conveying device according to the requirements of the production line or downstream equipment; it is suitable for a variety of high-speed beverage production lines, and is suitable for a variety of bottle-type conveying systems, including traditional round bottles and Special square bottles, etc.; suitable for the conveying system of bottles of various materials, including PET bottles, glass bottles, etc.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

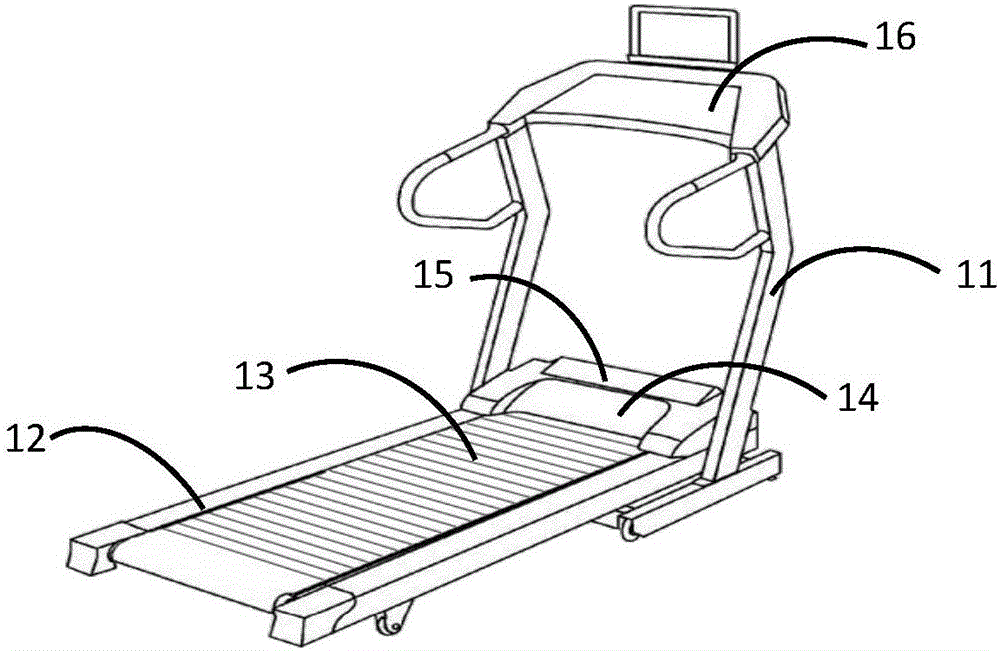

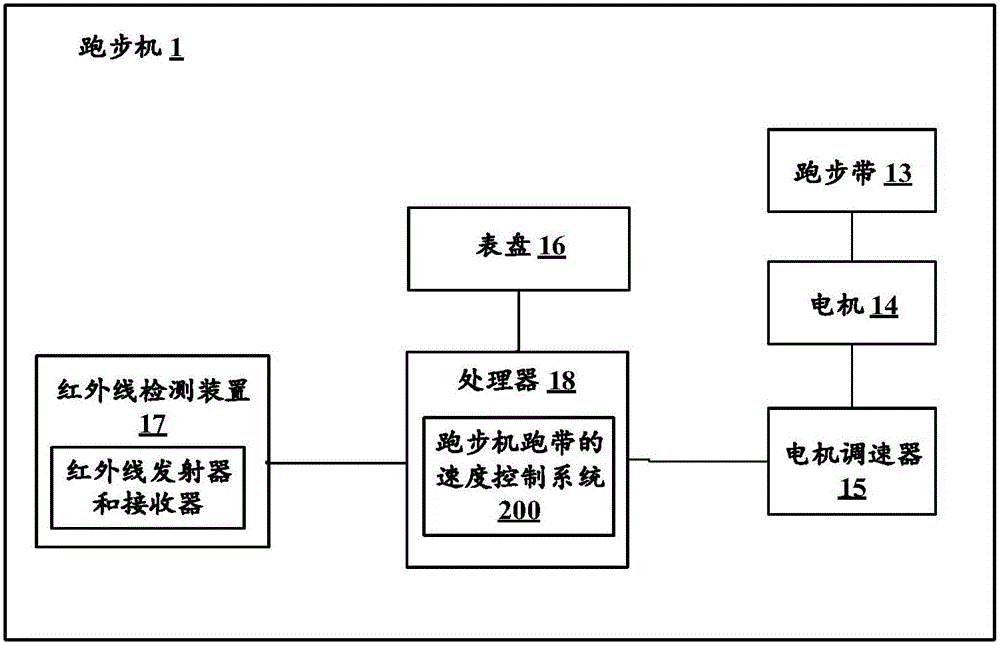

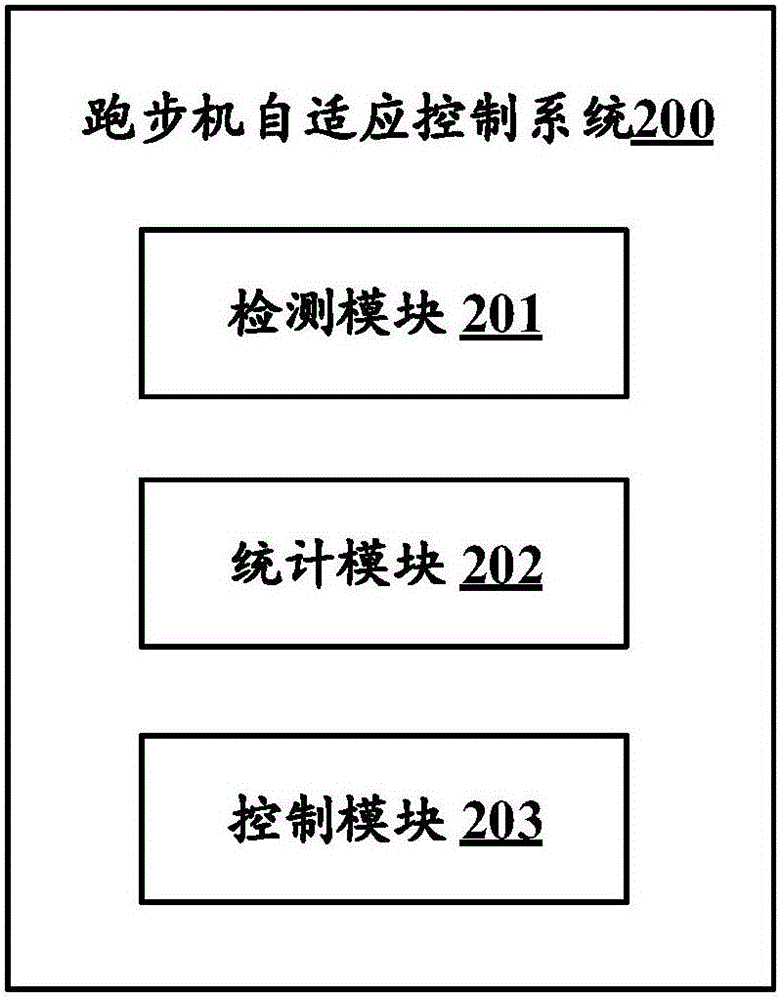

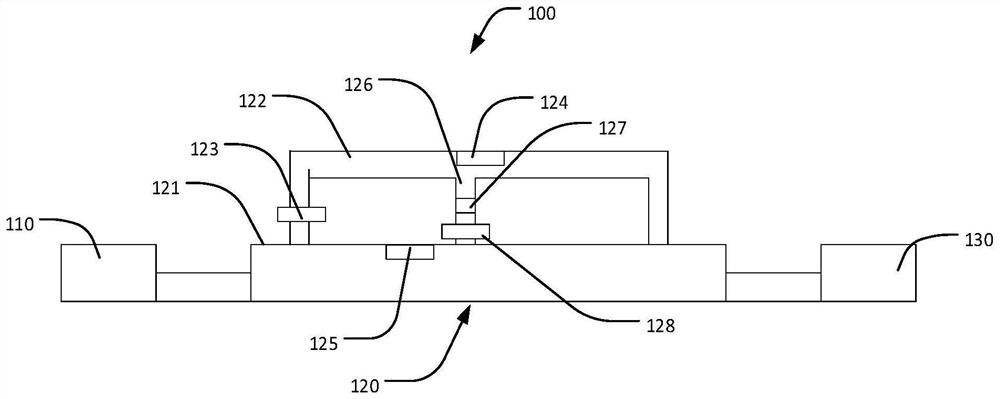

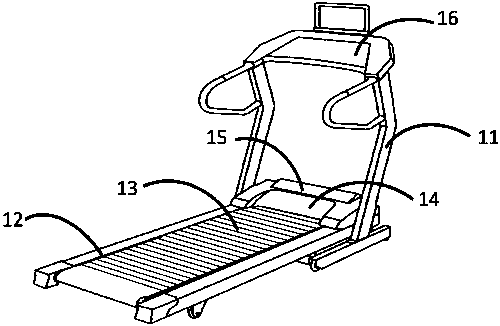

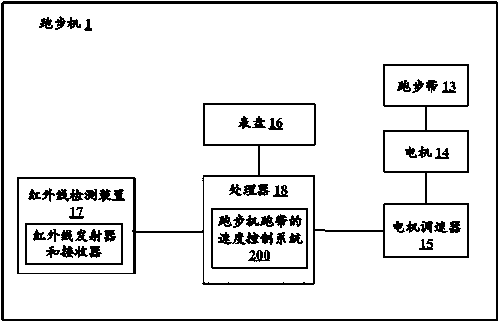

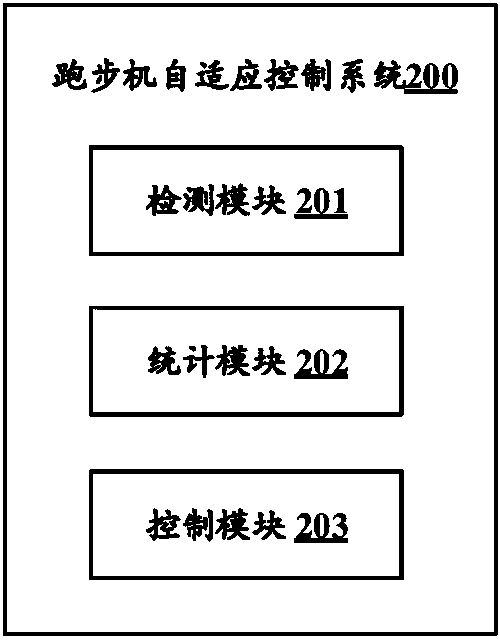

Treadmill, and speed control method and system of running belt of treadmill

InactiveCN105920784AAutomatic speed adjustmentImprove experienceMovement coordination devicesCardiovascular exercising devicesSpeed control systemControl system

The invention relates to a speed control method of a running belt of a treadmill. The method comprises the following steps of detecting the foot pedaling positions of a user on the running belt of the treadmill; determining a foot pedaling region of the user on the running belt of the treadmill according to the foot pedaling positions detected in the preset time; and regulating the speed of the running belt of the treadmill according to the foot pedaling region of the user on the running belt of the treadmill. By using the method provided by the invention, the function of automatic adaptation of the treadmill to the speed of a sportsman is realized; the user experience of the treadmill is improved; and the user can decide the running speed according to the self feeling. The invention also relates to a speed control system of the running belt of the treadmill, and the treadmill using the speed control system of the running belt of the treadmill.

Owner:SHENZHEN YISHI TECH CO LTD

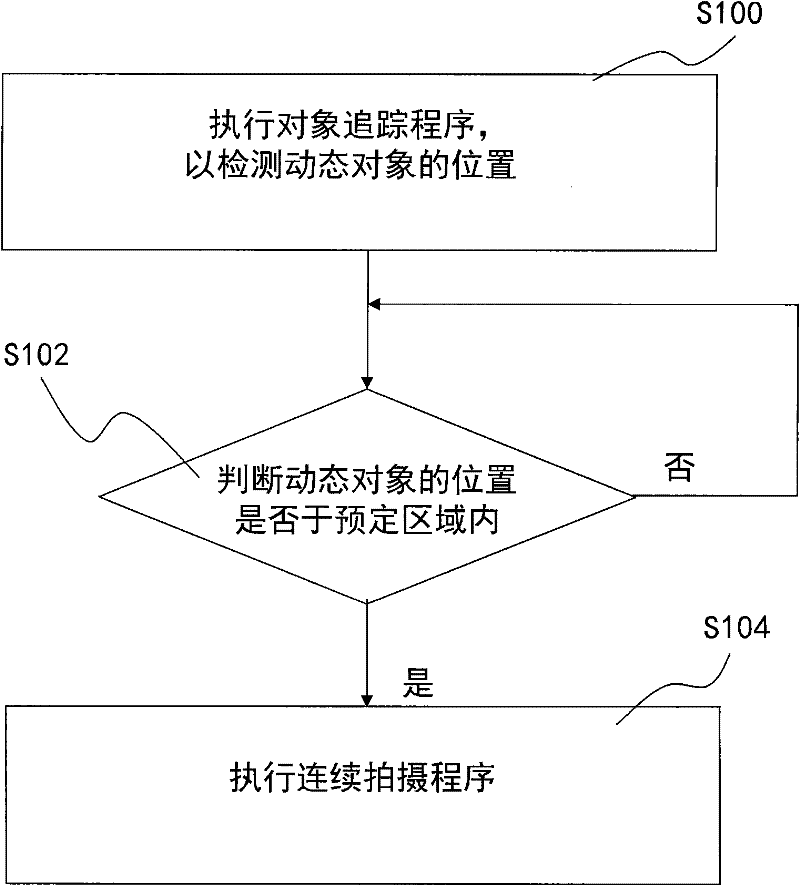

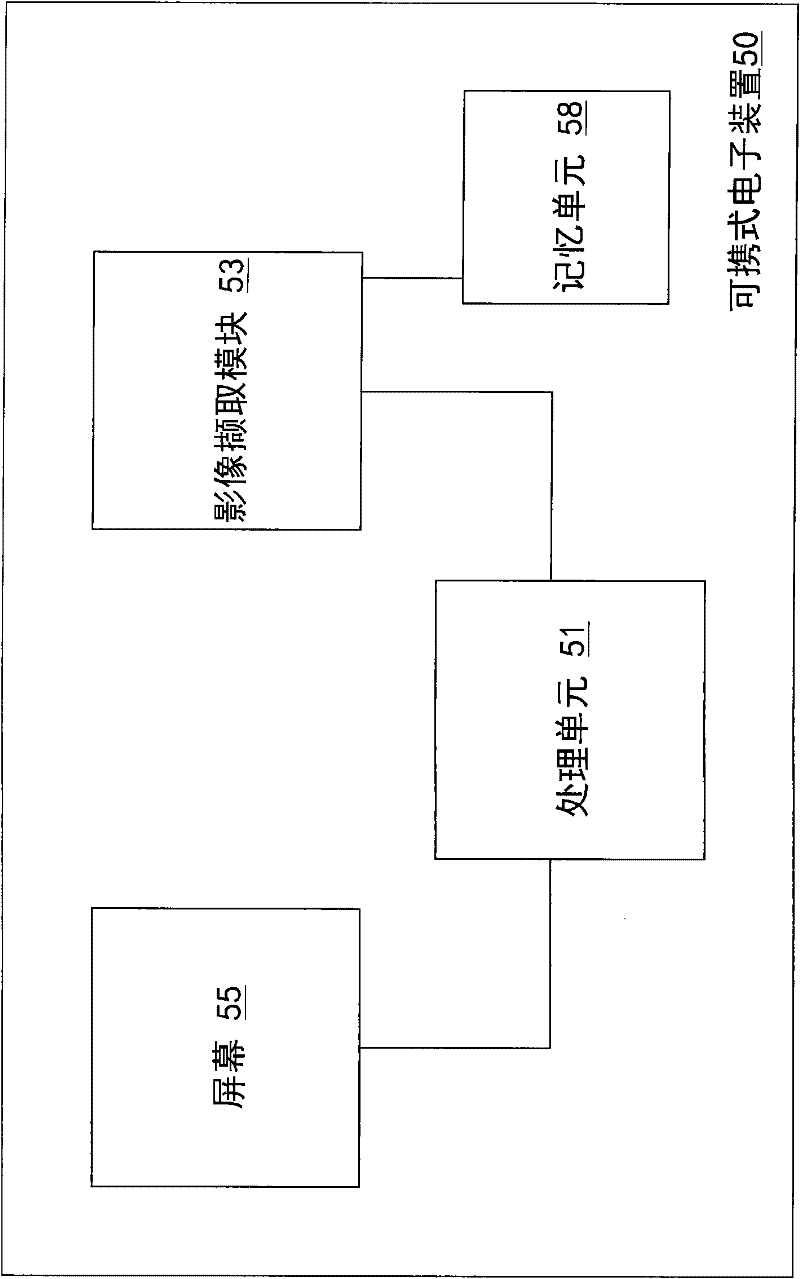

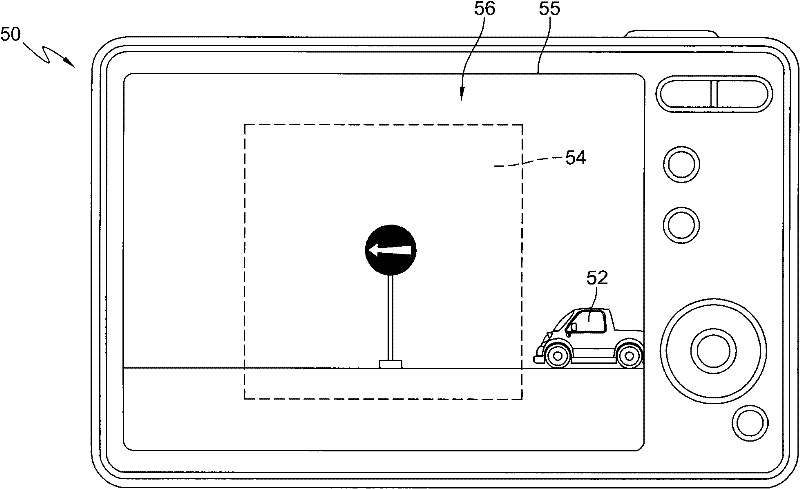

Continuous shooting method for a dynamic object and portable electronic device using the same

InactiveCN102447828ANo memory space wastedAuto adjust speedTelevision system detailsColor television detailsComputer graphics (images)Shooting method

The invention discloses a continuous shooting method for a dynamic object and a portable electronic device using the same, the continuous shooting method for a dynamic object is suitable for the portable electronic device; the portable electronic device has a screen displaying the preview picture. The continuous shooting method for a dynamic object comprises: performing tracking procedure of the object, detecting location of the dynamic object in the preview picture; judging whether the location of the dynamic object is in the predetermined area of the preview screen, and the predetermined area is smaller than the preview screen area; performing continuous filming program when the dynamic position of the object is in a predetermined area,. Therefore, the portable electronic device is capable of shooting images with user's expectations of dynamic objects in a specific position in the preview screen through a continuous shooting method for a dynamic object.

Owner:YINGSHUNDA TECH +1

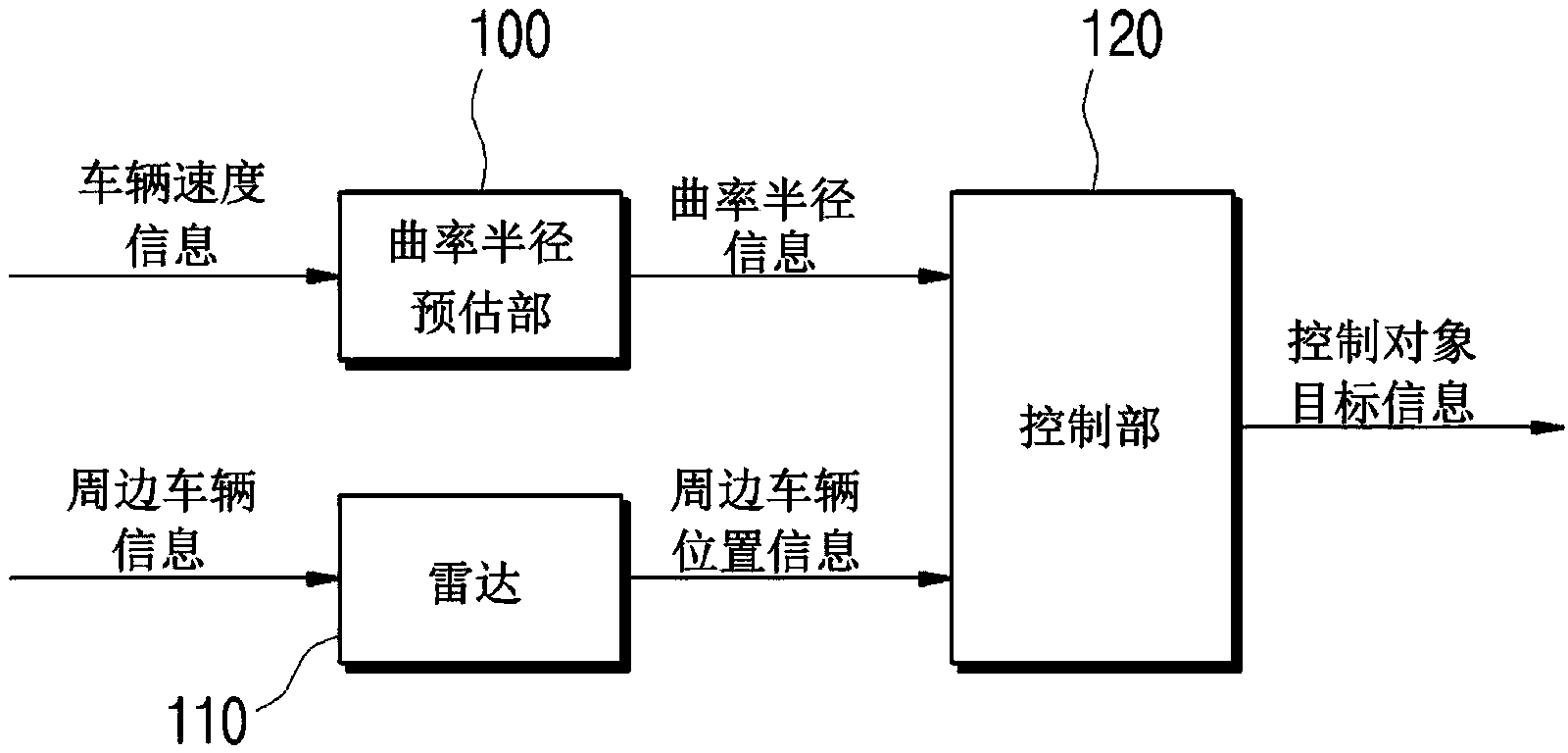

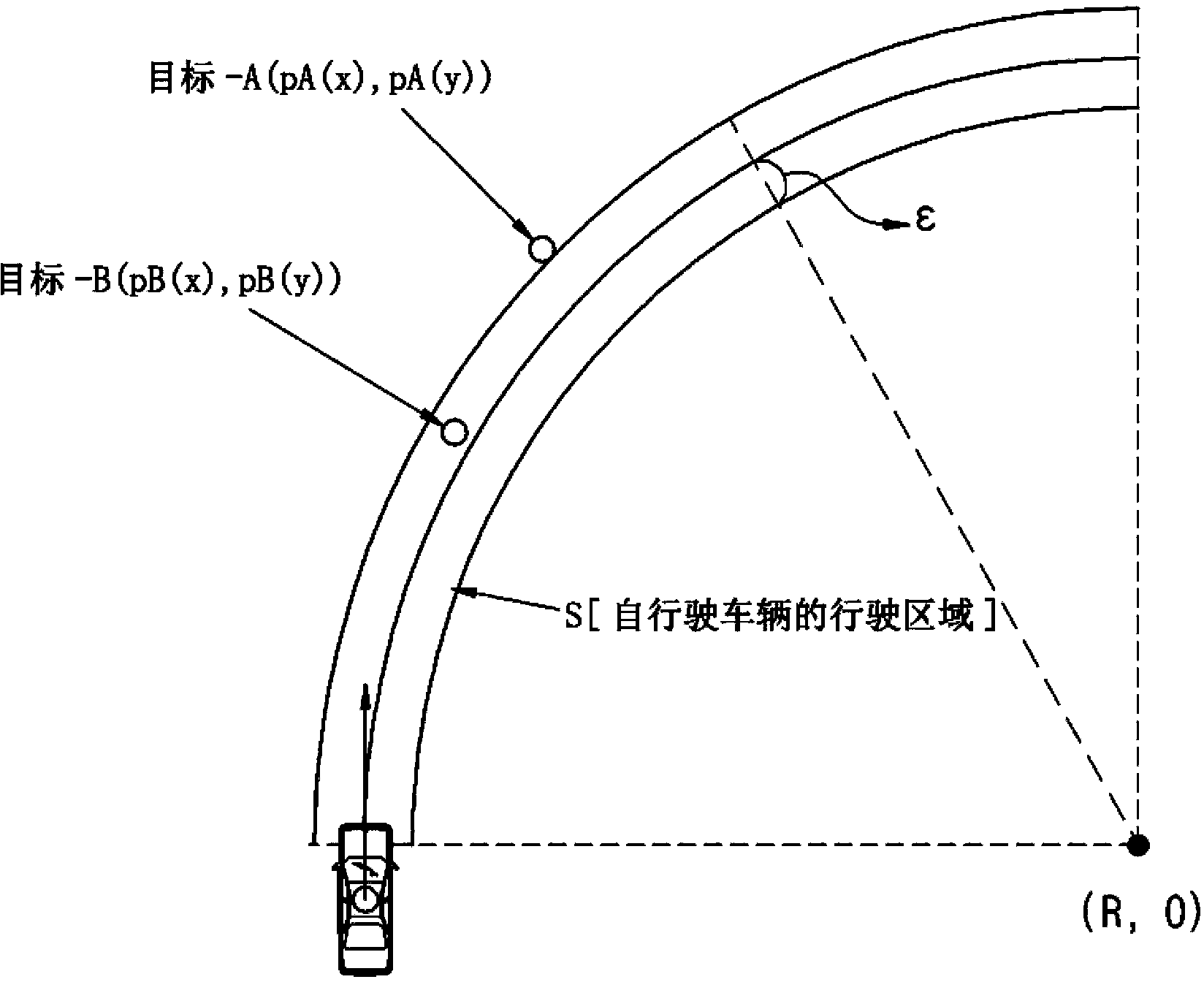

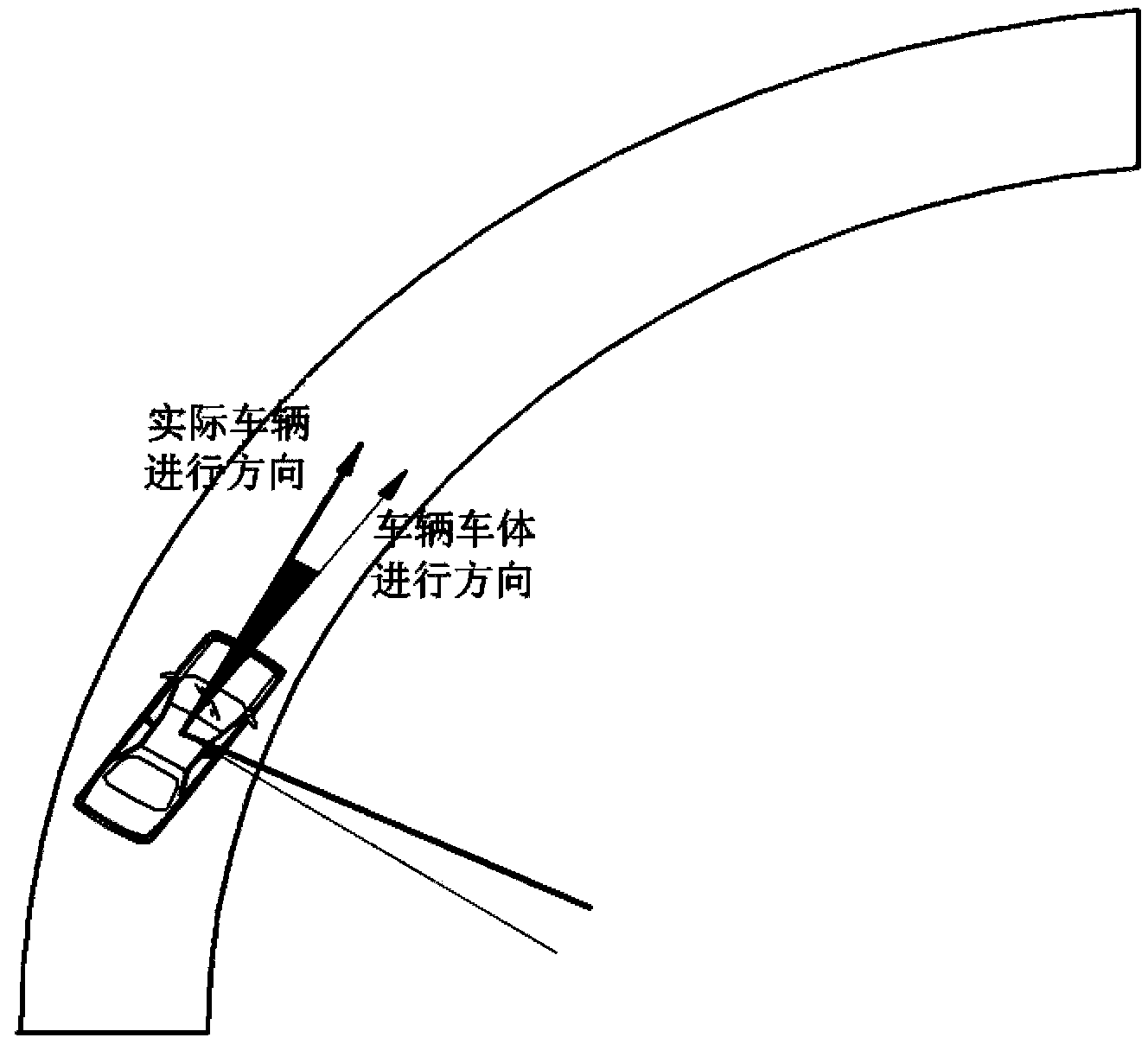

Smart cruise control system and selecting method of controlled target

The invention provides a smart cruise control system. When a vehicle runs on a bend, the system judges a running area of the running vehicle, and determines the position information of the surrounding vehicles, and when the surrounding vehicle is in the running area, the surrounding vehicle is selected to be controlled targets. When the vehicle is running on the bend, because of an angle difference between an actual running direction of the vehicle and a running direction of the vehicle body, and a vehicle body slip side angle exists, the smart cruise control system and a selecting method of the controlled targets can reduce an error of running area judgement by reflecting the slip side angle when the running area is judged, thereby more accurately selecting the controlled targets.

Owner:HYUNDAI MOBIS CO LTD

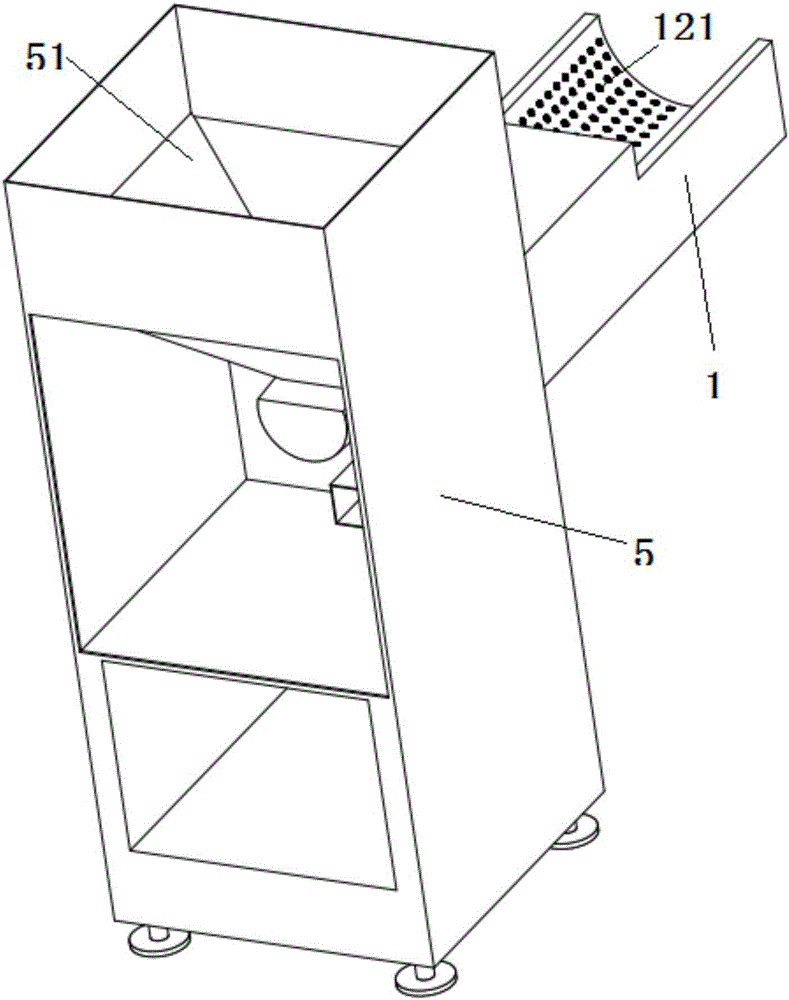

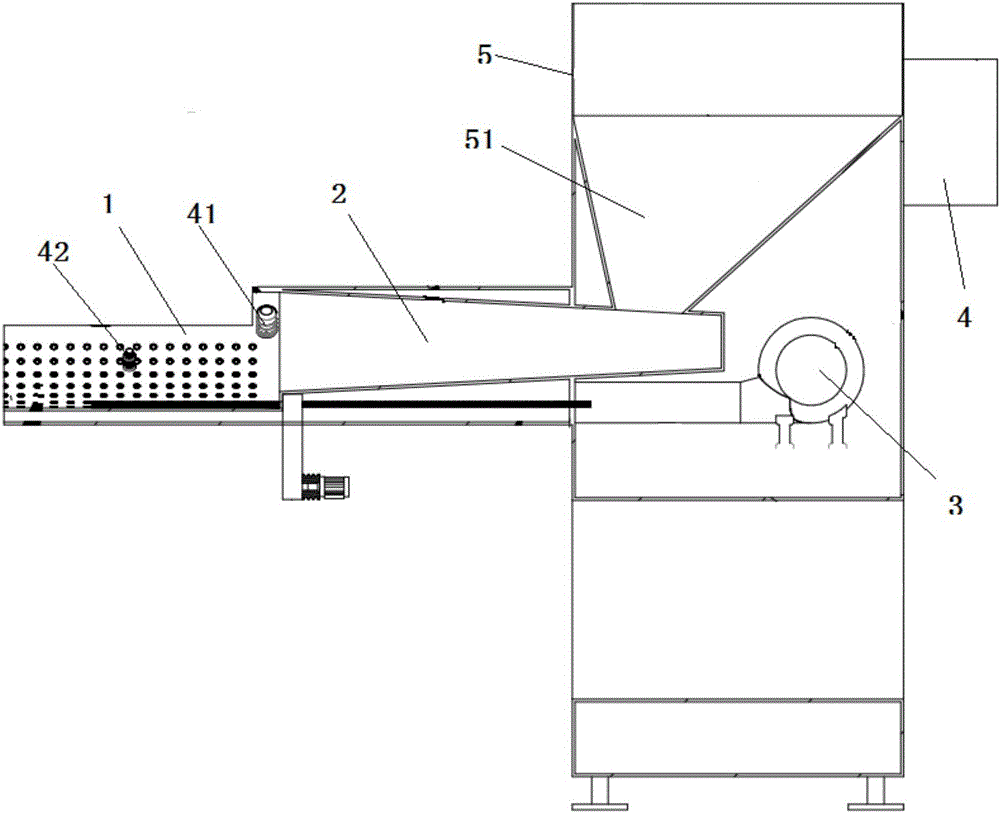

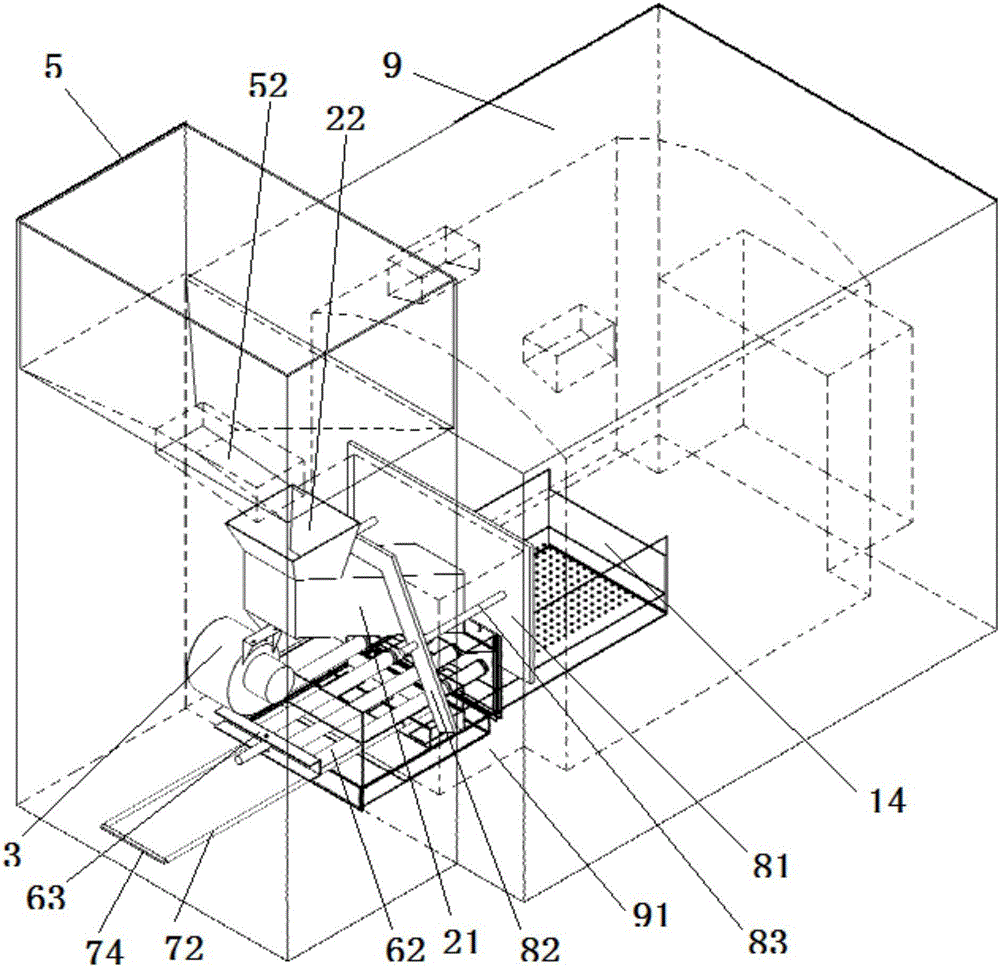

Vibrating feed combustor and control method thereof

ActiveCN106642192ASave man hoursReduce electric powerFuel supply regulationSolid fuel combustionSlagFlue

The invention discloses a vibrating feed combustor, comprising a combustion grate, a feeder, a blower and a controller, wherein the combustion grate comprises a grate enclosure, a first division plate and a second division plate arranged horizontally are arranged in the grate enclosure to divide the space encircled by the grate enclosure into a combustion trough, a combustion trough air flue and a slag receiving chamber, the first division plate is provided with vents, the combustion trough air flue is provided with an air inlet in one side in the horizontal direction, and the blower is communicated with the combustion trough air flue via the air inlet; the feeder is an electric vibrating feeder and comprises a feed pipe, the lower port of the feed pipe is arranged above the combustion trough, a first temperature sensor is arranged in the combustion grate, a second temperature sensor is arranged in a baking room, and the controller is connected with the blower, the electric vibrating feeder, the first temperature sensor and the second temperature sensor and used for controlling the frequency or magnitude of the electric vibrating feeder and the air quantity of the blower according to the temperature in the combustion trough and the difference between the current temperature in the baking room and a preset temperature.

Owner:湖南驱动源电气技术有限公司

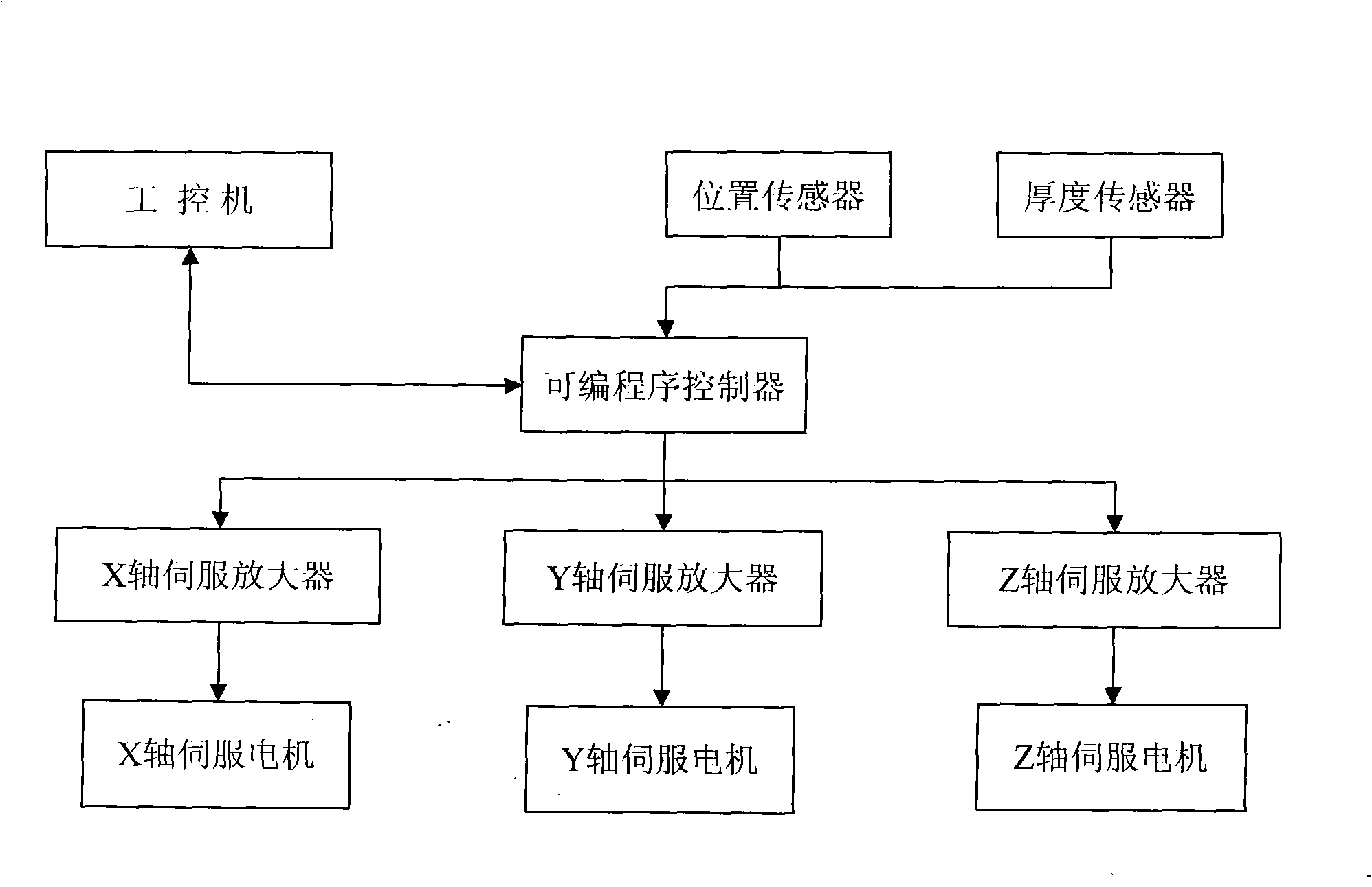

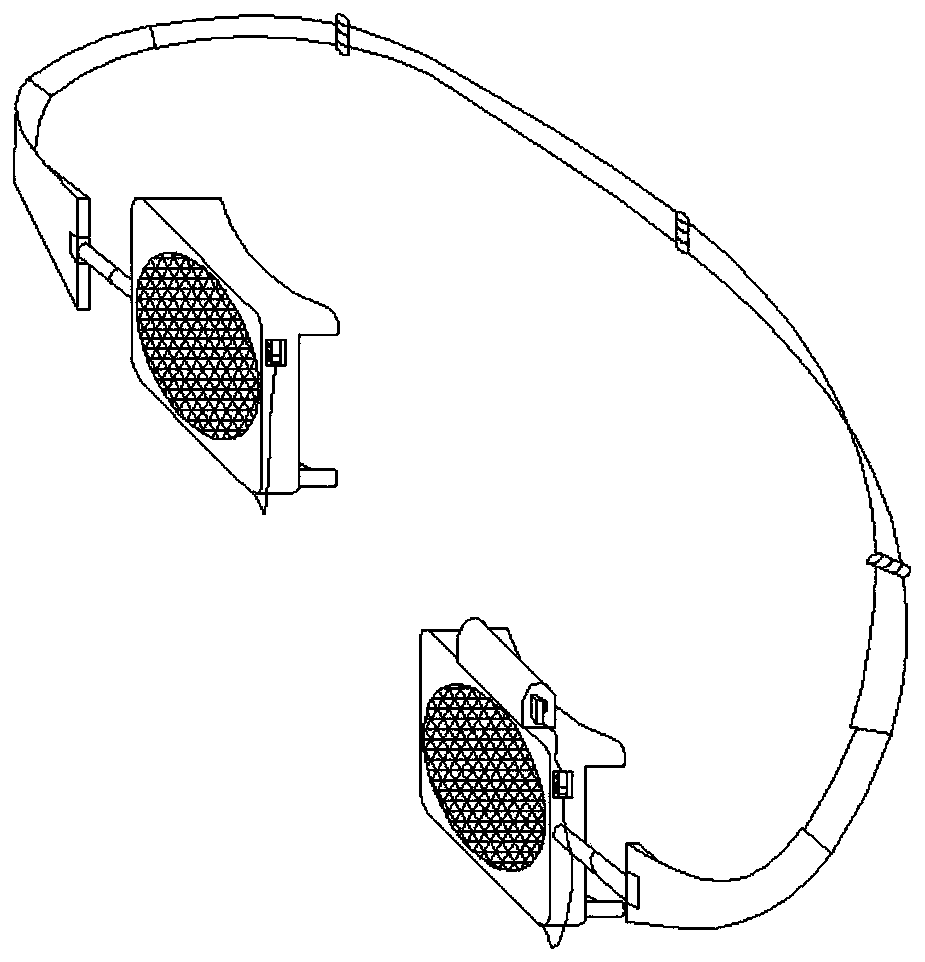

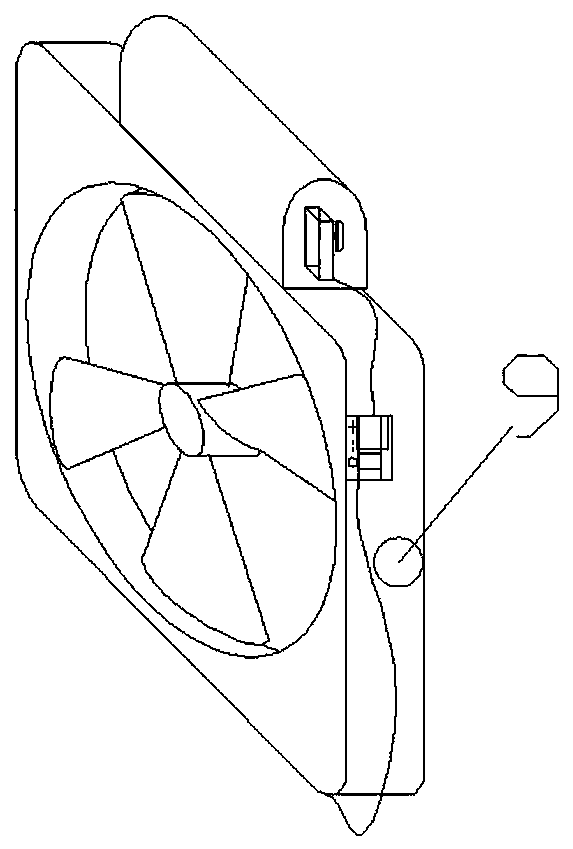

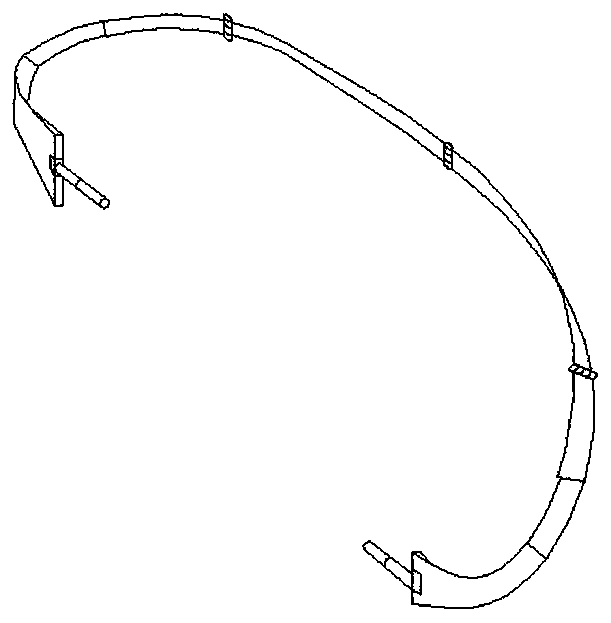

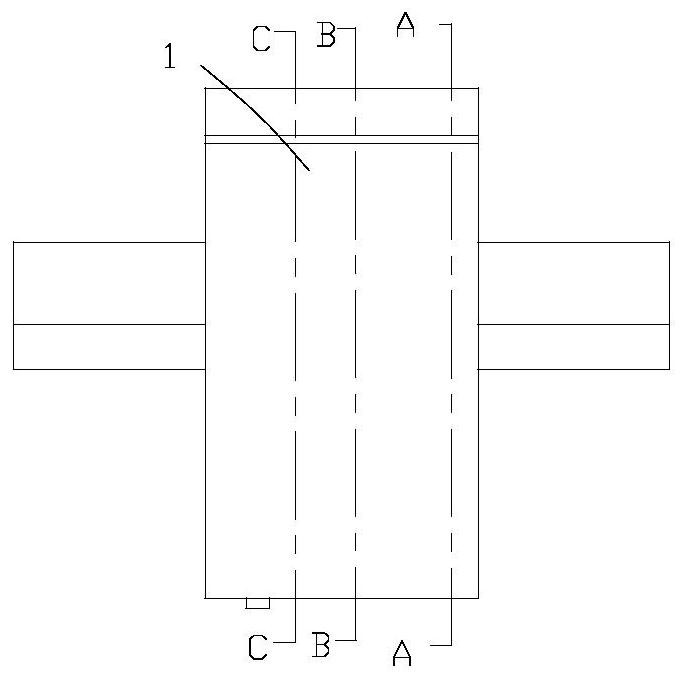

Tyre first stage winding building control system

InactiveCN101407109AReduce labor intensityHigh forming precisionTyresAudio power amplifierProgrammable logic controller

The invention provides a tire first-stage winding control system. The system comprises a servo motor which drives a winding head to do three-axis motion, corresponding servo amplifiers, an industrial computer and a programmable logic controller (PLC) connected with the industrial computer, wherein the servo amplifiers are connected with the PLC. A position and thickness sensor arranged on the winding heat is also connected with the PLC. The industrial computer stores a special winding head control software and a winding design software, and is connected with an input device and a display screen. According to the shape of a cross section of the tire tread and the width and thickness of rubber strips, the industrial computer designs the number of winding layers of all parts of a tire tread, calculates the coordination of turning points of each layer, obtains a control program for the motion of the winding head and sends a command to the PLC to control the winding head to move along design curves. And the industrial computer can automatically adjust the rotation speed of a three dimension motor. The control system has the advantages of high building precision, stable product quality, reduction of labor intensity, increase of production efficiency, suitability for first-phrase building various tires, particularly for first-phrase building of giant tires.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

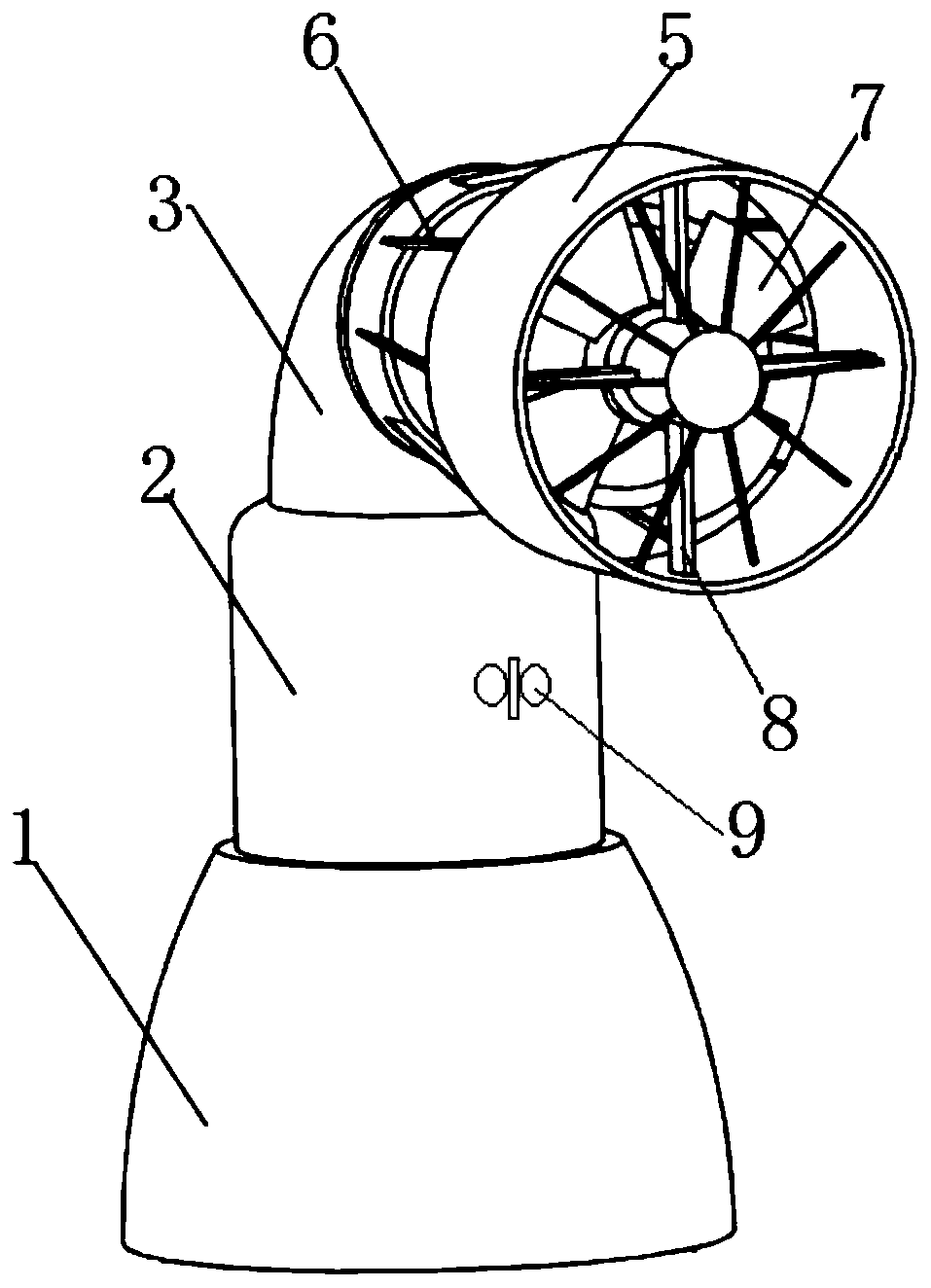

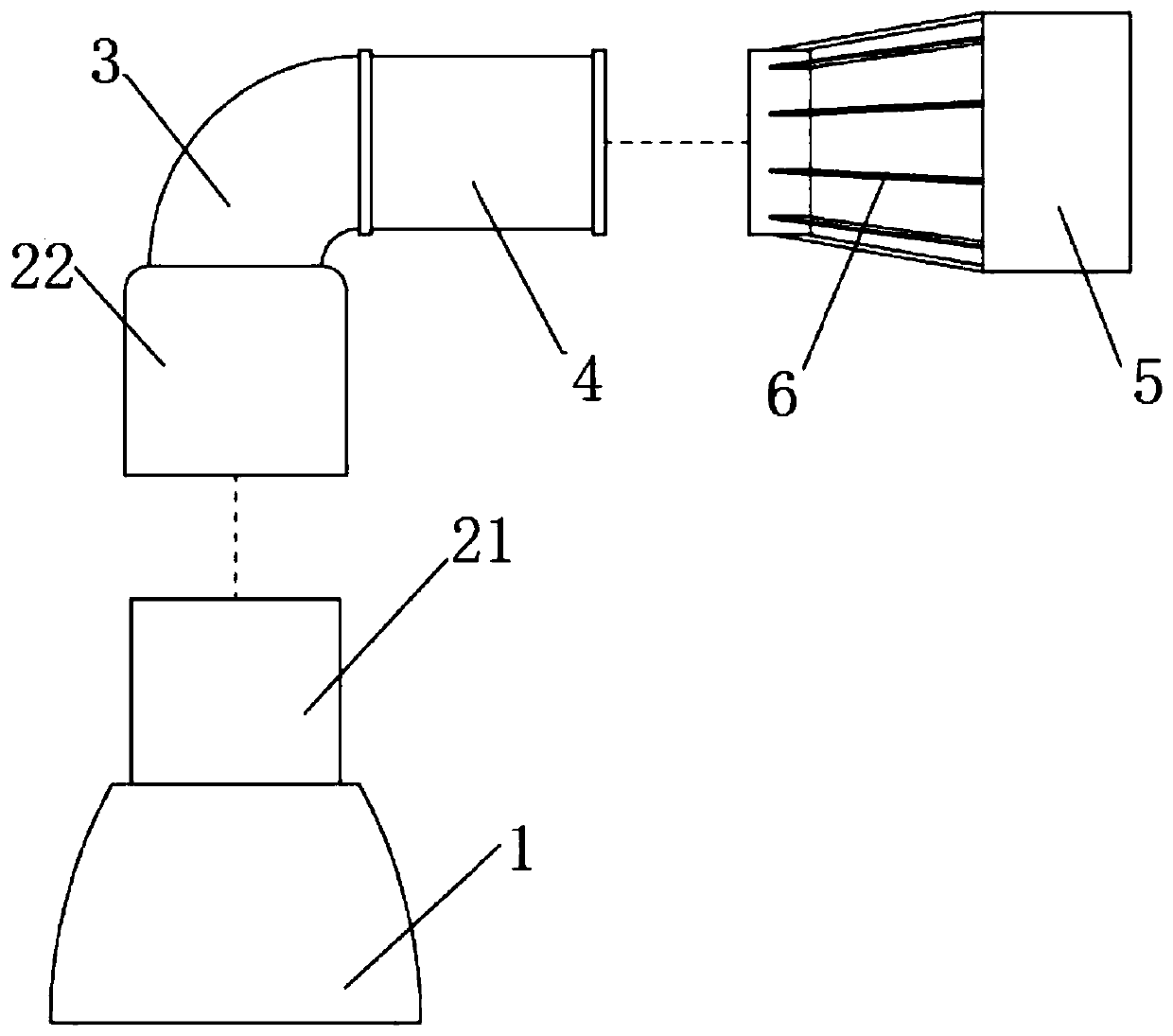

Light air supply device

InactiveCN110107522AAuto adjust speedReduce volumePump componentsLighting elementsElectricityEffect light

The invention discloses a modular air supply device which can be combined for use according to use occasions. The modular air supply device comprises a power supply, an earphone frame, a control switch, a speed regulation component, a fan, a supporting seat and a lighting component. All the components can be separately used and can also be combined for use through the modular design, and differentstructures, functions and use modes can be achieved through combining and deforming; the modular air supply device can be worn on different parts of a human body so that the air can be blown to a part, where heat dissipation and sweating are prone to occurrence, of the human body, so that the problem of a user for heat dissipation or lighting along with the user is solved, the modular air supplydevice can also be placed at environments other than a human body for use, the heat dissipation problem of people in various occasions is solved, auxiliary lighting also can be realized, the effects of being flexible and convenient are achieved, and through the high-efficiency design of a flow guide component, a temperature sensor and an automatic fan electronic speed regulator, the purposes of improving the air supply efficiency of the device, saving electricity and greatly improving the comfort of the human body are achieved.

Owner:王宝全

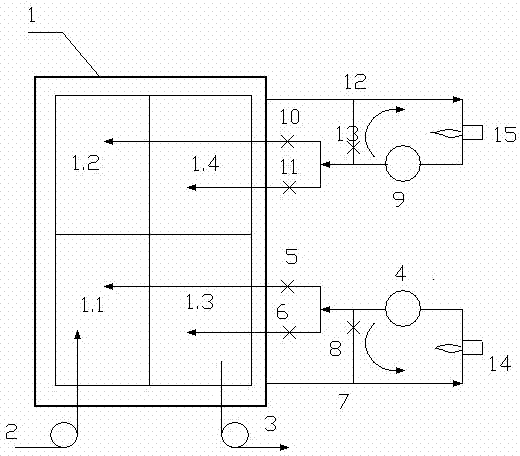

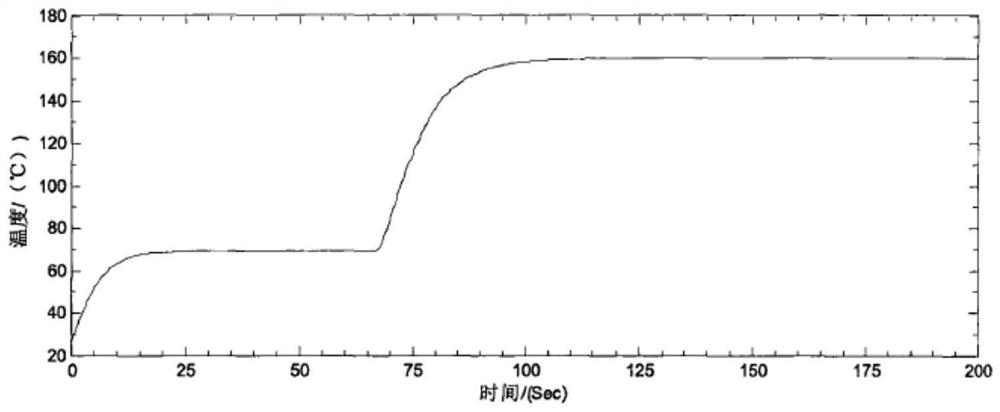

Impregnated tire fabric thermal treatment device and implementing method thereof

ActiveCN103924410AChange timeChange wind speedTextile treatment machine arrangementsHeating timeThermal treatment

The invention relates to an impregnated tire fabric thermal treatment device and an implementing method thereof. The impregnated tire fabric thermal treatment device comprises a main oven, an outer circulating system, a tire fabric lead-in roll and a tire fabric lead-out roll. The main oven is divided into four drying blocks. The outer circulating system is provided with a fan, hot air of the main oven is provided by a heating device, and the outer circulating system is used for adjusting air speed and heating time when the tire fabric speed is changed. By the modified impregnated tire fabric oven, energy source can be saved, air speed and treatment time of the tire fabric can be adjusted by vehicle speed, production of defective tire fabrics is greatly reduced, automation degree is high and labor intensity of workers is reduced.

Owner:JIANGSU HONGSHENG NEW MATERIAL

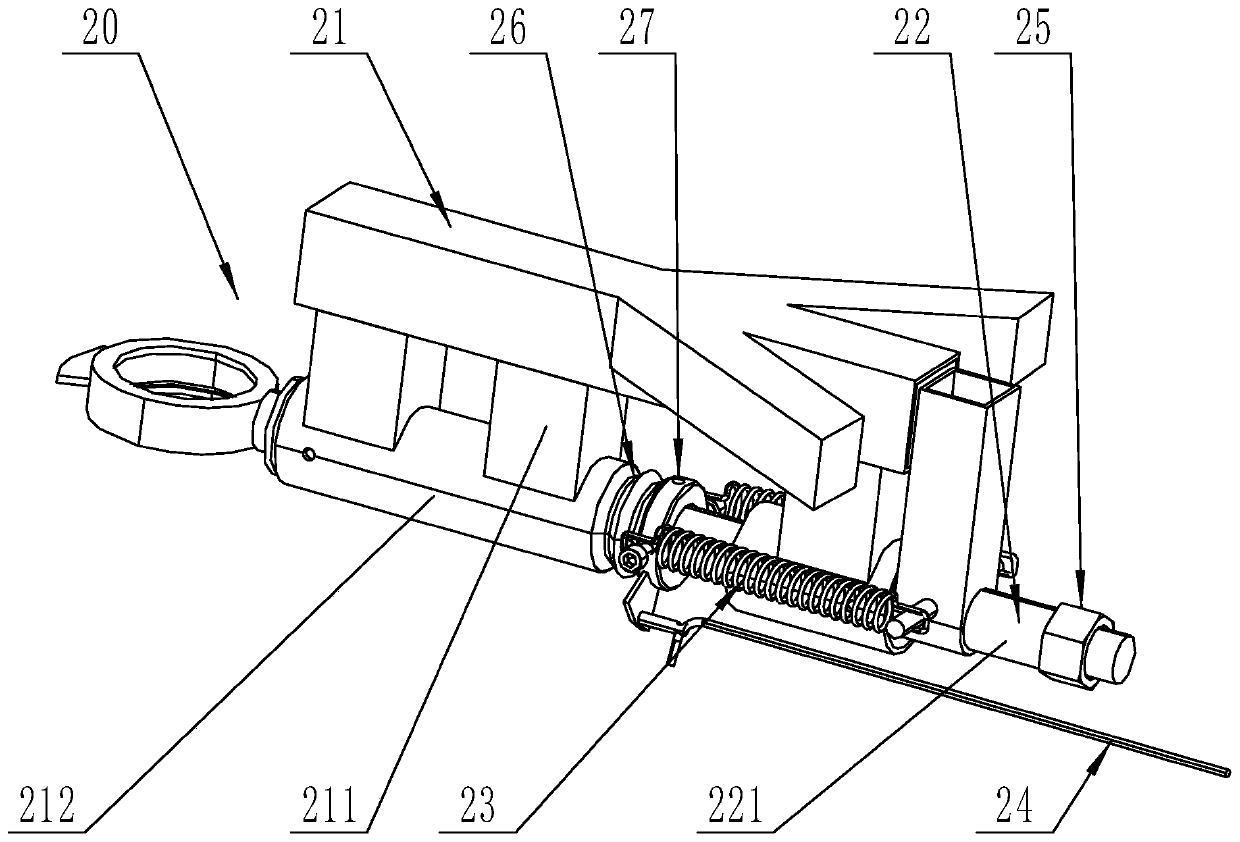

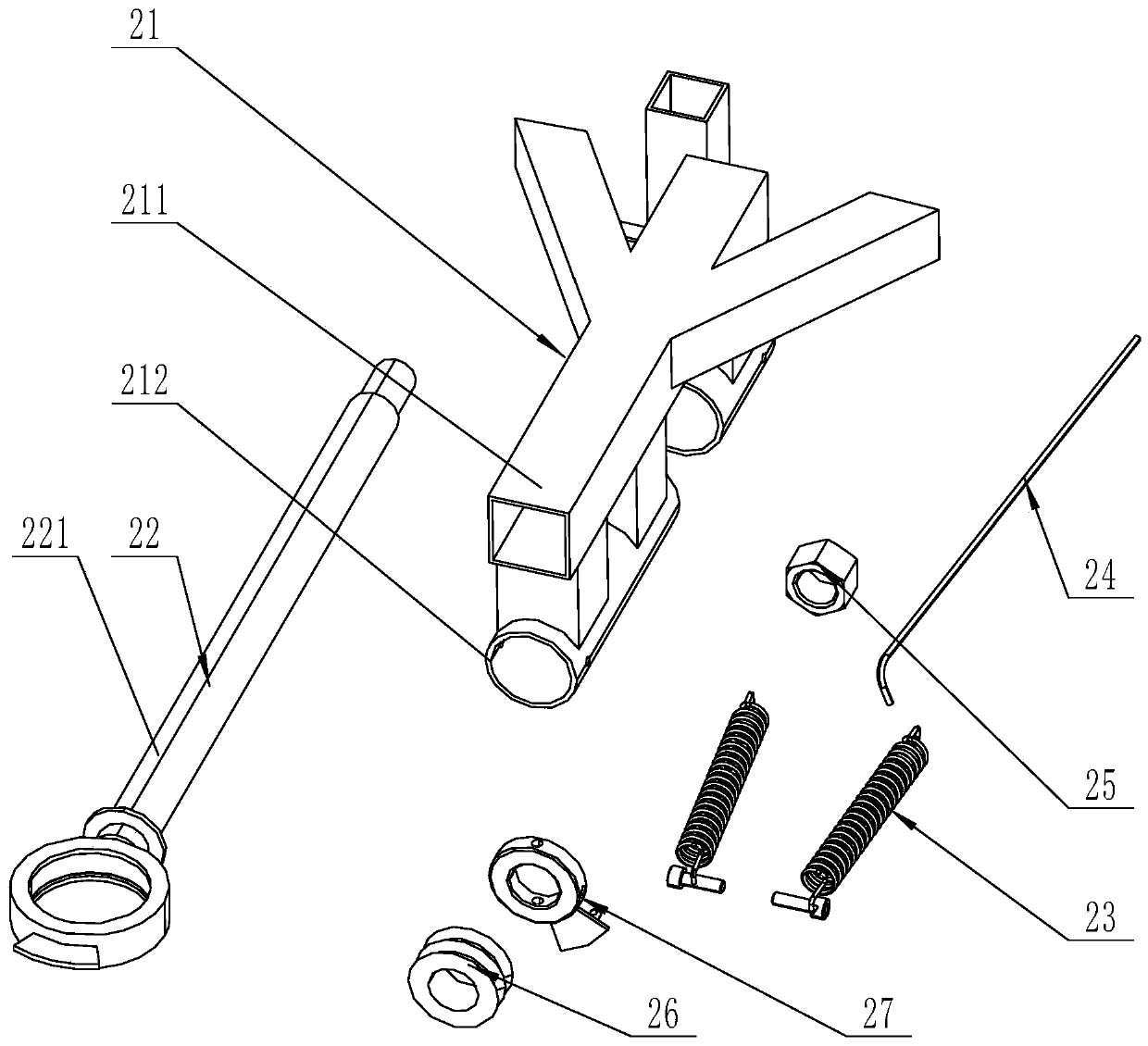

Electric control mechanism for stalled blade damper plate of wind-driven generator

InactiveCN1995746ANo oil leakage problemLow maintenanceWind motor controlMachines/enginesWind drivenEngineering

The invention relates to an electric control mechanism for damping plate of stalled blade in wind turbine, belonging to wind power generation area, characterized in that the guide head of lead screw is located in guide cylinder and connected with the lead screw, the lead screw is connected with nut and the nut is connected with the rotor of permanent magnet motor. There are no pressure and no leakage in the electric control mechanism for wind turbine. The electric control mechanism can not be influenced by climate and the maintenance cost is decreased greatly. The mechanism has big torque. When it does not act, there is no need to electrify to lock the damping plate tightly by big self-locking torque and electric energy exhausted for maintaining locking the damping plate is saved. The control circuit can be sent to actuator mechanism by electric collection ring. Compared with sending the control circuit to the actuator mechanism by hydraulic rotating joint, it is cheaper, simple and stable. The invention can adjust the torque and the speed automatically in random and it is the ideal control mechanism for damping plate of stalled blade in wind turbine.

Owner:包头市汇全稀土实业(集团)有限公司

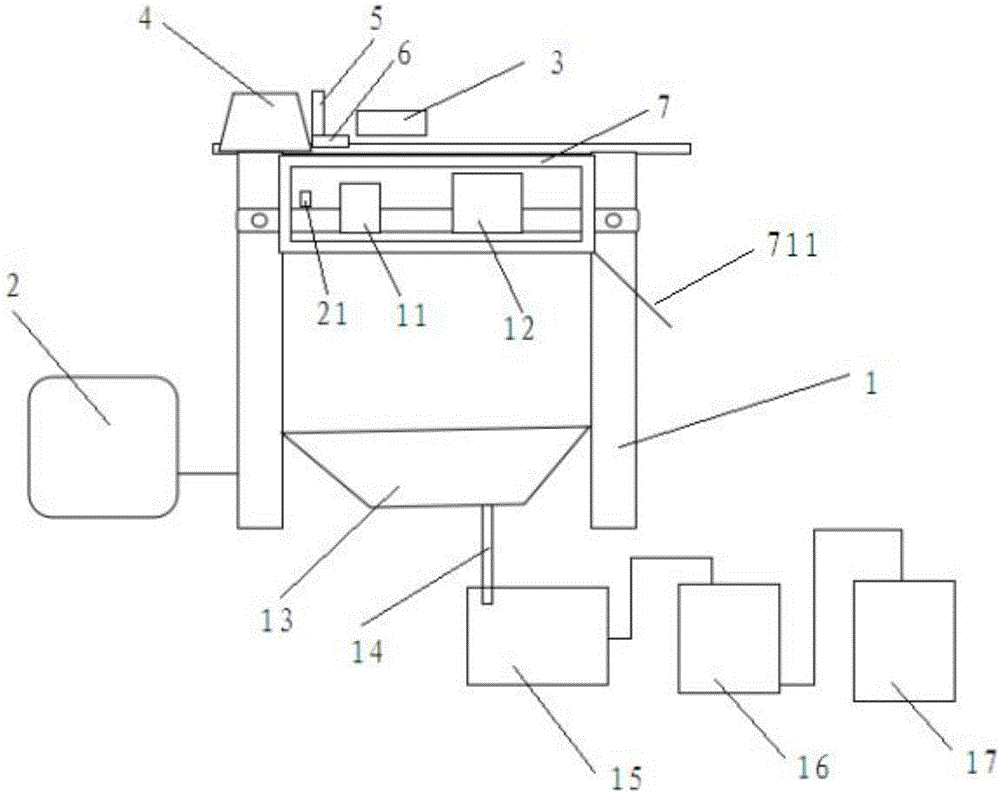

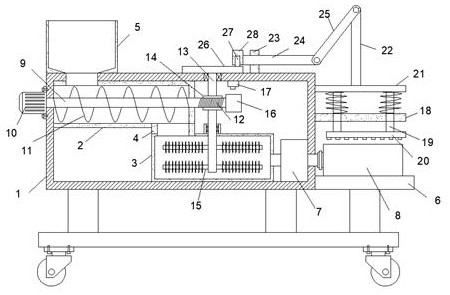

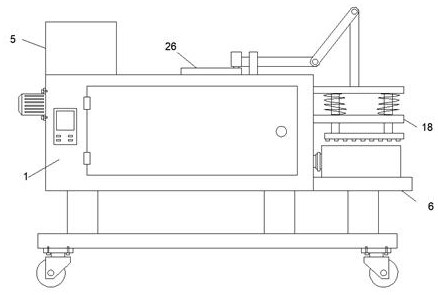

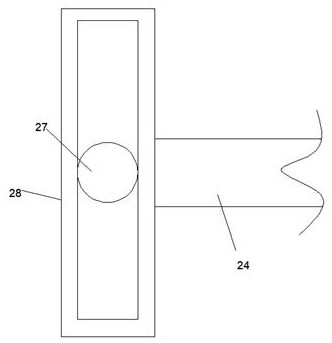

Automatic nut cutting equipment

InactiveCN106737899AAuto adjust speedAutomatically adjust transmission speedFood preservationMetal working apparatusEngineeringMaterial resources

The invention provides automatic nut cutting equipment. The automatic nut cutting equipment comprises a machine frame, a controller, a cutting machine head arranged on the upper portion of the machine frame and a bin arranged at the feeding end of the machine frame. The bin is provided with a shifting mechanism. A baffle is arranged at one end of the shifting mechanism and provided with a groove matched with a nut in shape. A cleaning device, a sterilization device and a drying device are arranged on the upper portion of the machine frame. A sewage collecting device is arranged below the machine frame. The bottom of the sewage collecting device is connected with a sewage pipe. A conveying belt is arranged on the machine frame. A sensor and a discharging speed adjustment device are arranged in the position, near a discharging outlet, of the conveying belt. The automatic nut cutting equipment can automatically cut nuts and automatically adjust the shifting speed and conveying speed of nuts, the normal work of the automatic cutting equipment is guaranteed, and a large amount of labor and material resources are saved.

Owner:INNER MONGOLIA UNIV OF TECH

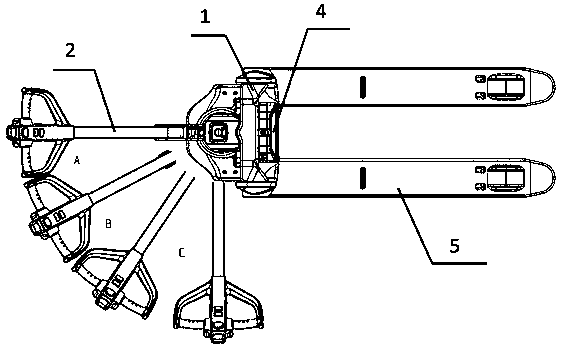

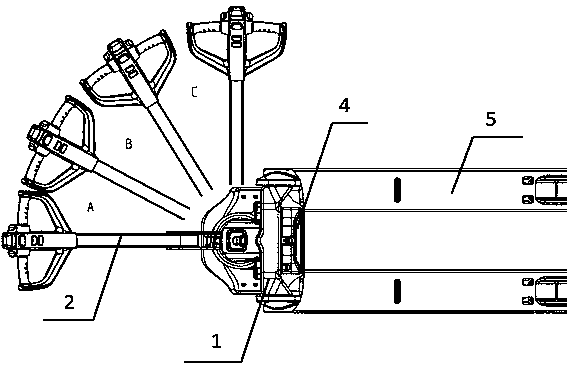

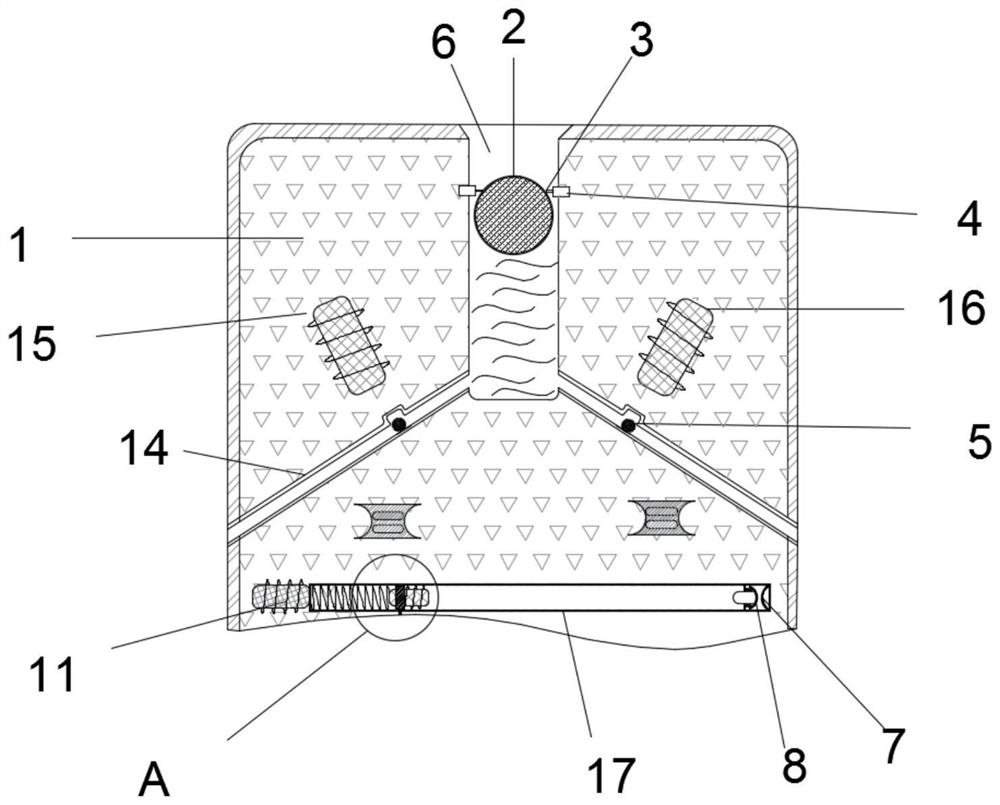

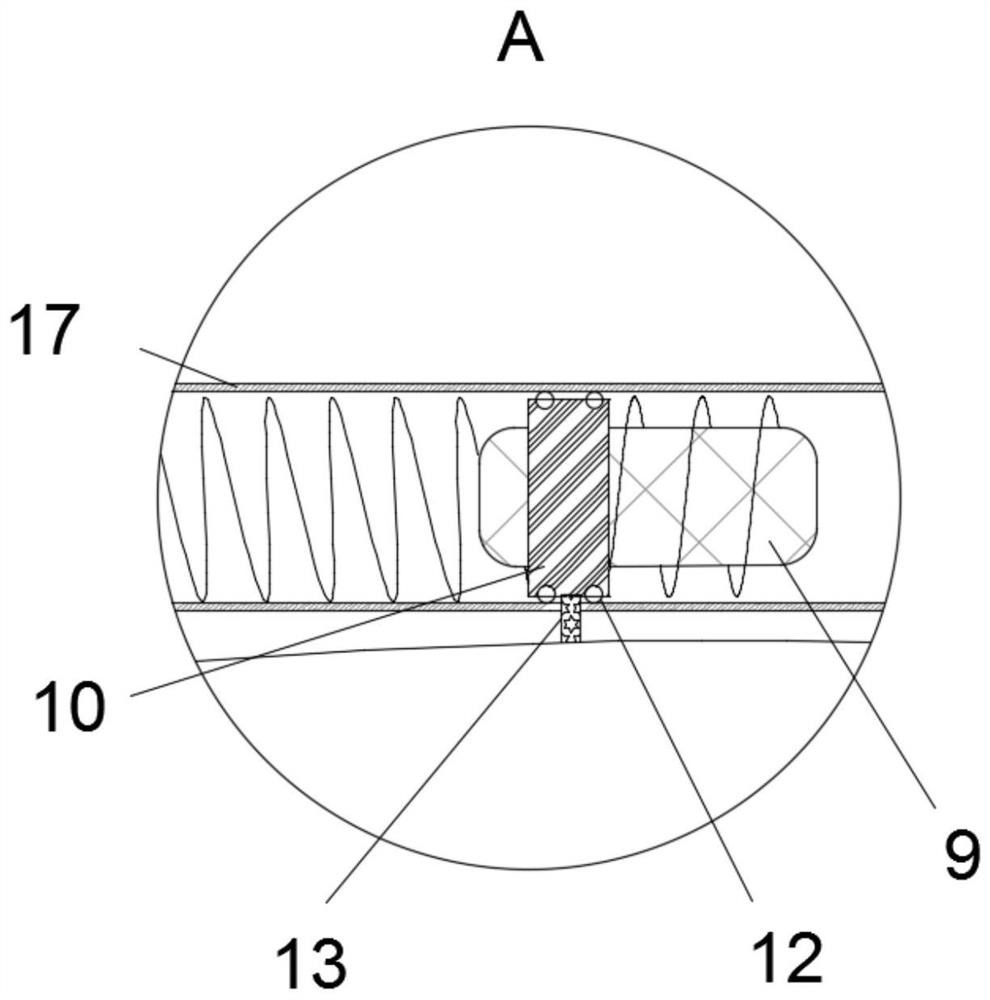

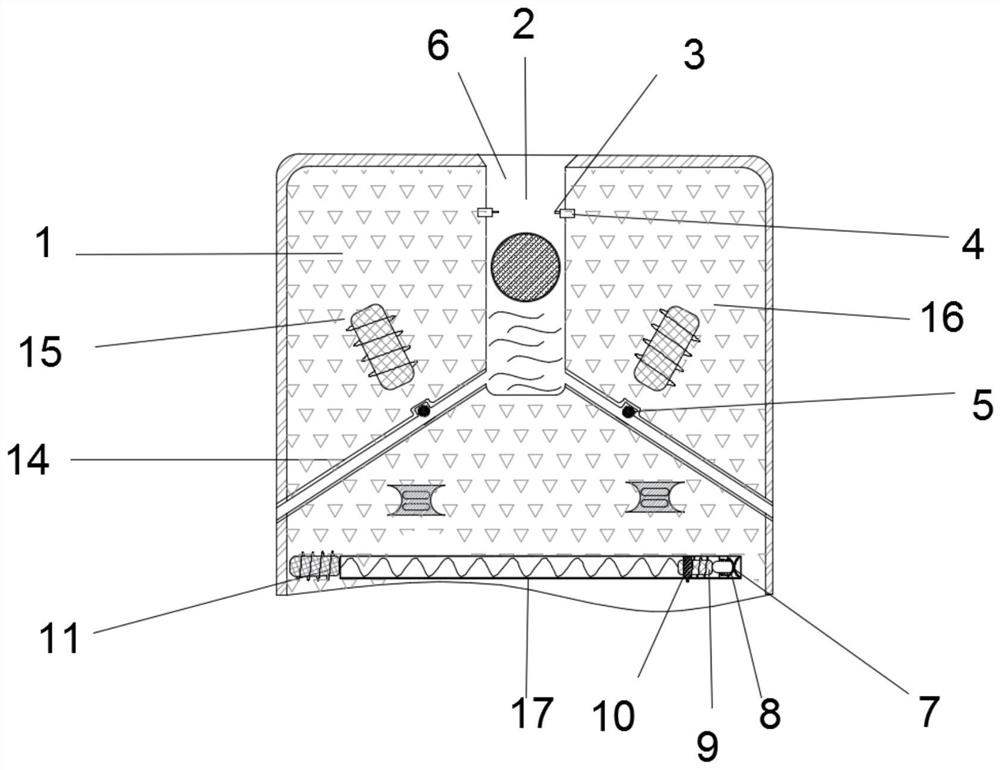

Fire escape device

The invention provides a fire escape device. The fire escape device comprises a rear cover plate, a main plate and a front cover plate. The main plate is provided with a transverse trapezoidal groove,a longitudinal trapezoidal groove, a transverse slot, a longitudinal slot, an upper fixed pulley, a lower fixed pulley and a cross pull rod. A transverse sliding block and the longitudinal sliding block are arranged in the transverse trapezoidal groove and the longitudinal trapezoidal groove correspondingly and are connected through a connecting rod. The upper end of the connecting rod is connected with a safety rope and a safety belt and used for being fixed to a human body. The longitudinal sliding block is connected with the connecting rod through a second fixed rotary shaft and penetratesthrough the longitudinal slot to slide up and down. The two ends of the second fixed rotary shaft are provided with a brake wheel and a longitudinal pulley correspondingly. The transverse sliding block is connected with the lower end of the connecting rod through a first fixed rotary shaft and penetrates through the transverse slot to slide left and right. The two ends of the first fixed rotary shaft are provided with a warning device and a transverse pulley correspondingly. A rope locking brake at the head of the cross pull rod makes contact with the upper fixed pulley. A swing rod and a cross push rod are arranged on the front cover plate. A convex block at the head of the swing rod is matched with a groove at the other end of the cross push rod. An inclined push plate at the tail of the cross push rod makes contact with the longitudinal pulley. The main plate and the front cover plate are both provided with circular arc grooves for arrangement of an escape rope.

Owner:张煌辉

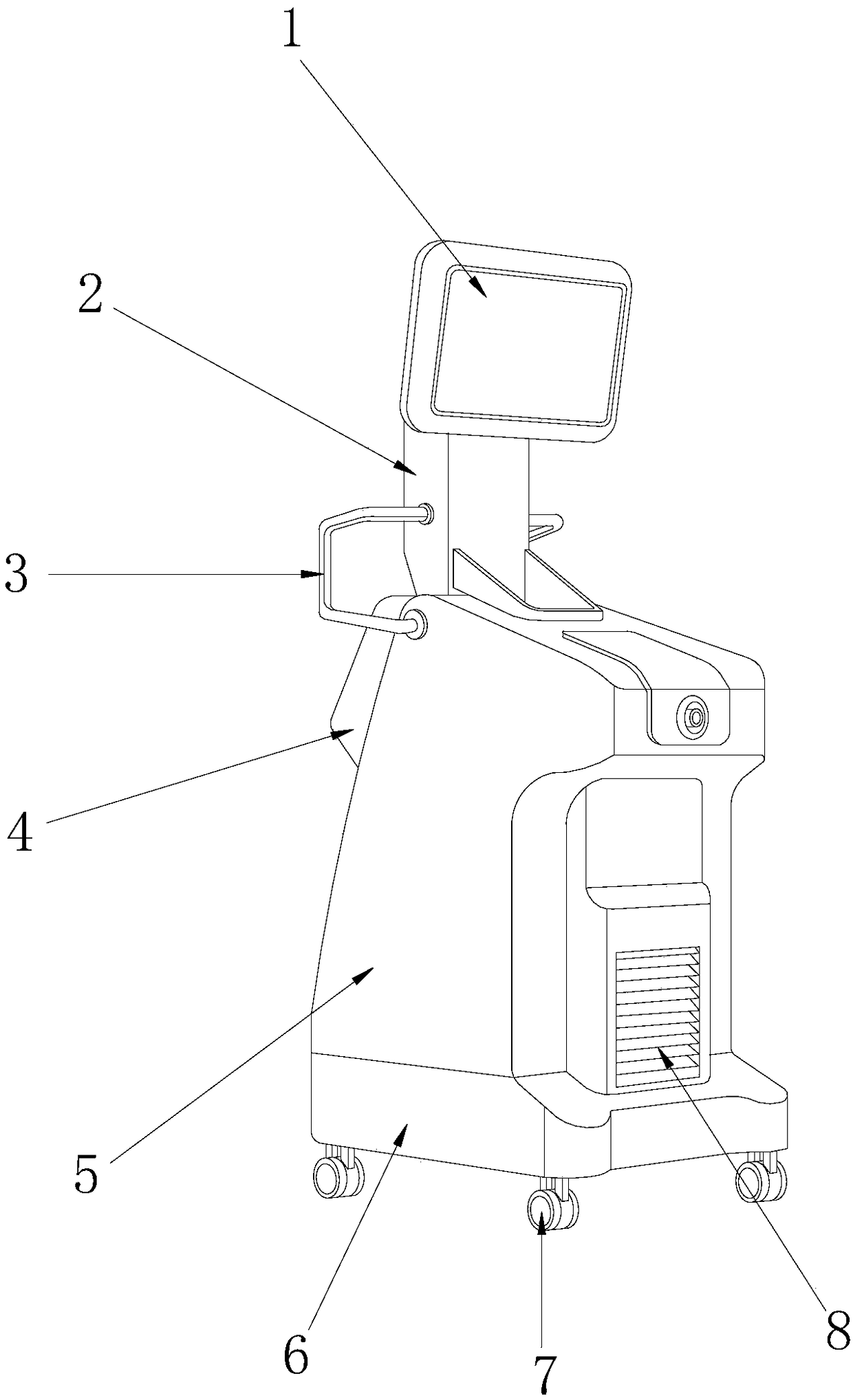

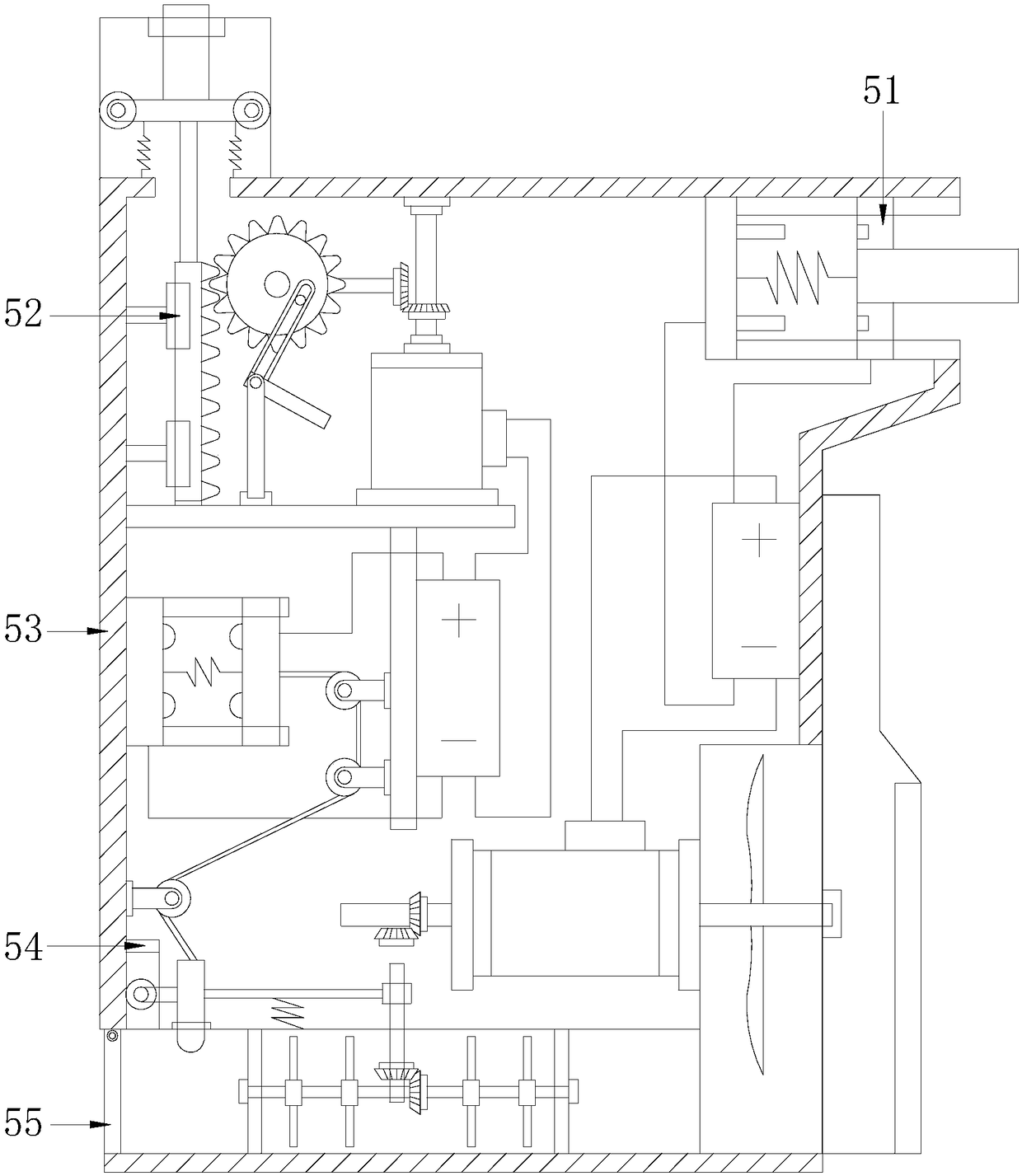

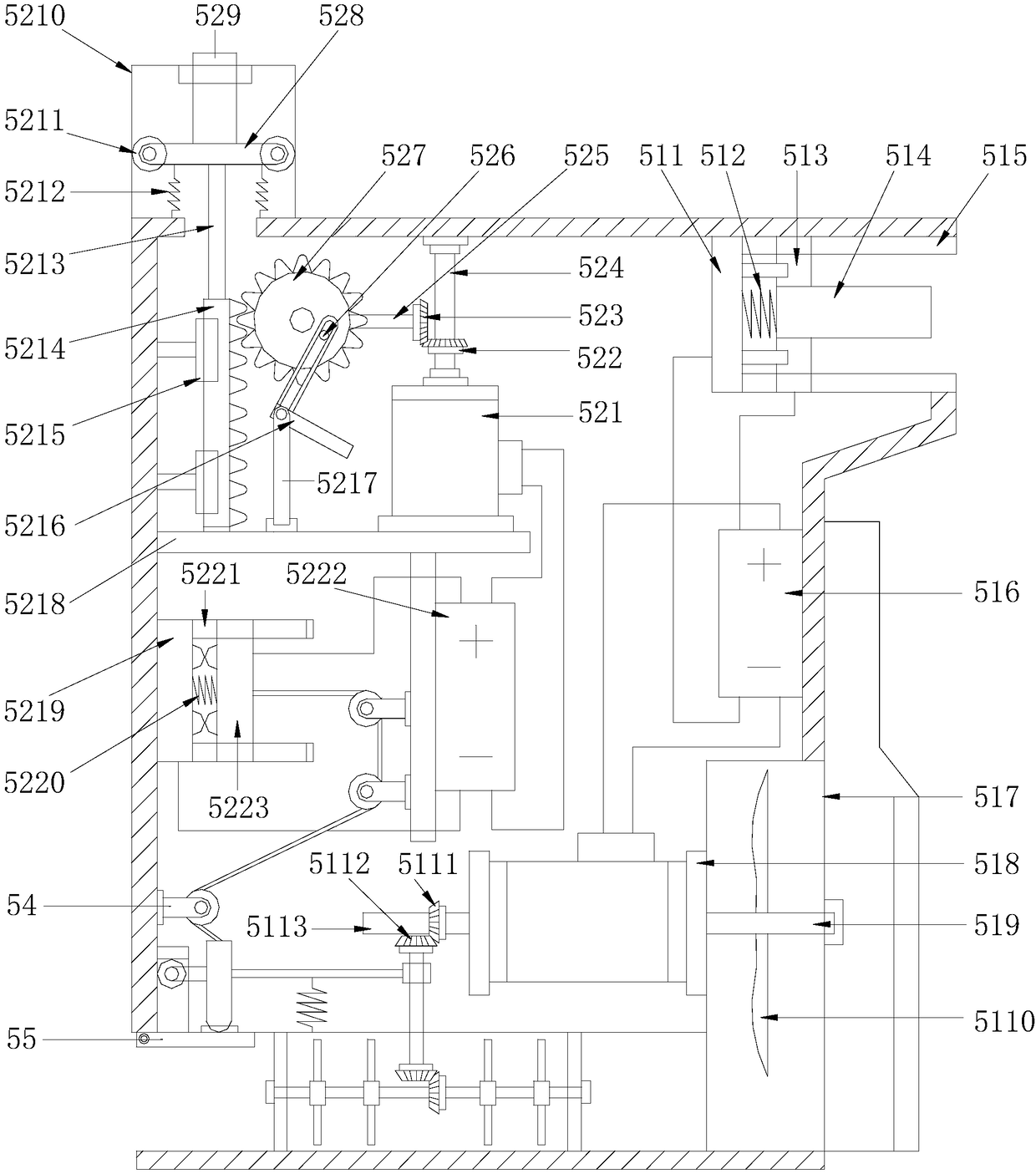

Intelligent obstetrical nursing device

InactiveCN108514408AEasy to seeAutomatically adjust intensityLighting and heating apparatusDiagnostic recording/measuringData displayPush and pull

The invention discloses an intelligent obstetrical nursing device. The structure thereof comprises a data display device, a support column, a push-and-pull handle, a controller, an automatic air delivery device, a base, trundles and an air-out louver. A high-sensitivity probe is worn around a wrist of a pregnant woman. Then, a data interface is inserted into a data reception starting mechanism. The data reception starting mechanism converts a signal of the probe into an electric signal. By automatic calculation of the controller, body temperature and heart rate of the pregnant woman are displayed on the data display device. At this time, an automatic limiting elevating mechanism can automatically elevate the data display device, which facilitates observation by medical staff. Afterwards, intensity of air delivery of a first air wheel is automatically adjusted and rotation frequency of a second air wheel is adjusted. Therefore, speed of air used for purifying a ward is adjusted. As a result, air quality and temperature of the rest ward for the pregnant woman are automatically adjusted.

Owner:李江鸿

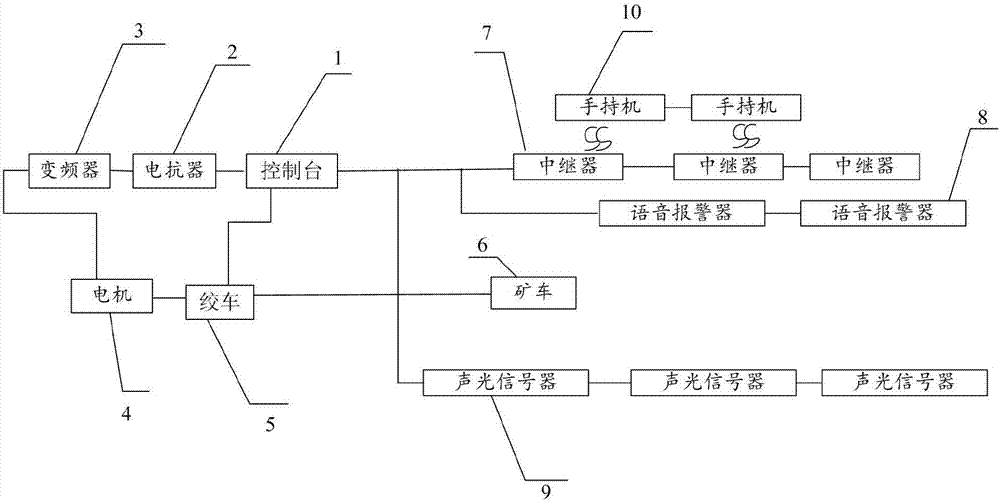

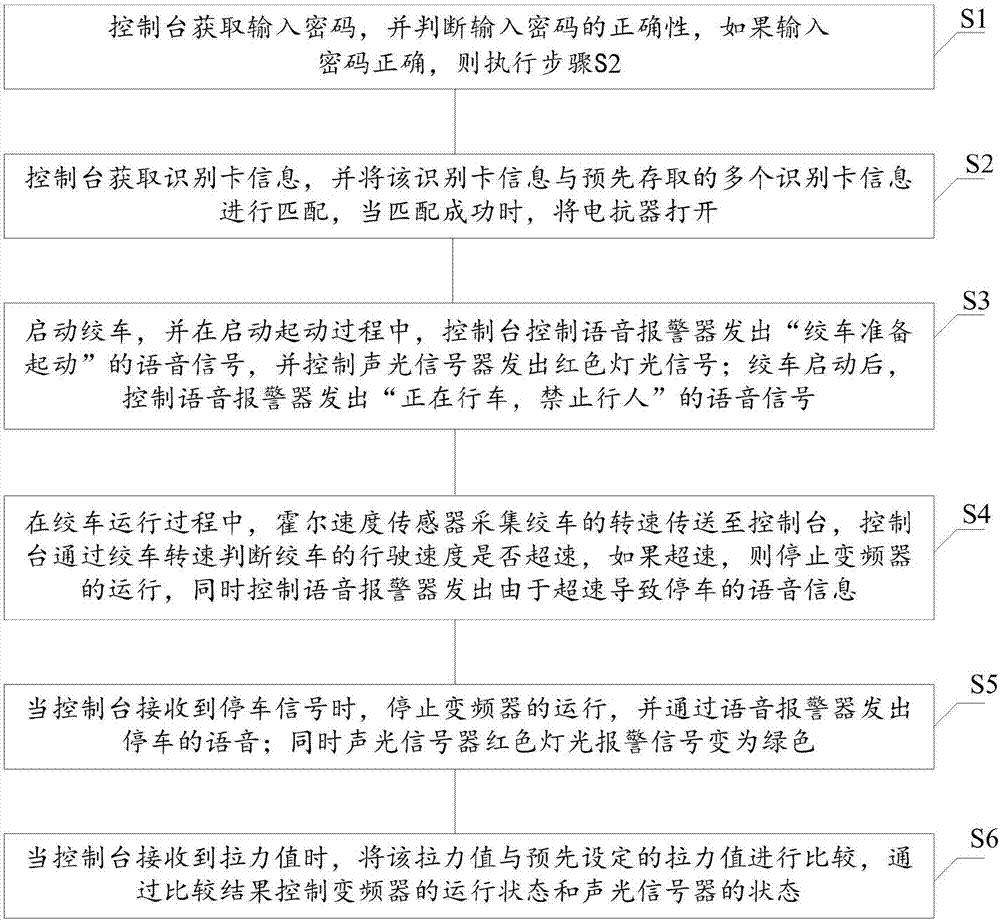

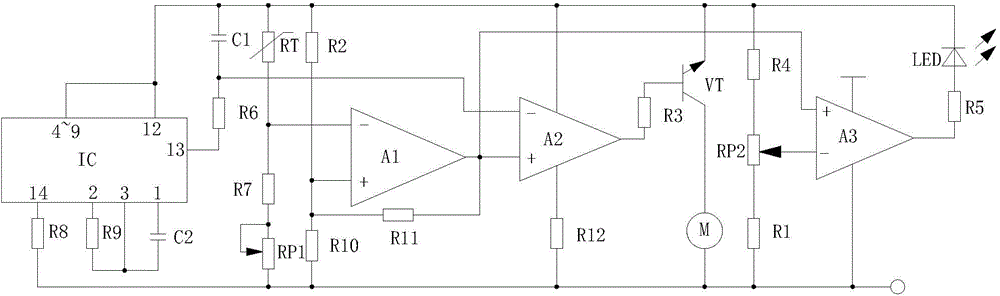

Frequency converter winch system based on PLC and control method thereof

InactiveCN107188064AGuaranteed safe operationAuto adjust speedWinding mechanismsFrequency changerAcousto-optics

The invention discloses a frequency converter winch system based on a PLC and a control method thereof and relates to the technical field of coal mines. The problem of low safety in the prior art is solved. According to the system, a control table controls operation of a motor through a frequency converter; the motor controls operation of a winch; a tensile device is arranged at one end of a mine car and is connected with the winch through a rope; a tensile sensor is arranged in the tensile device; a processor and a zigbee module are arranged on the mine car; a plurality of repeaters, a plurality of voice alarms, a plurality of acousto-optic signal devices and a plurality of handsets are evenly arranged in a mine coal roadway; and the control table is sequentially connected with the multiple repeaters, the multiple voice alarms and the multiple acousto-optic signal devices through leaking cables.

Owner:HARBIN UNIV OF SCI & TECH

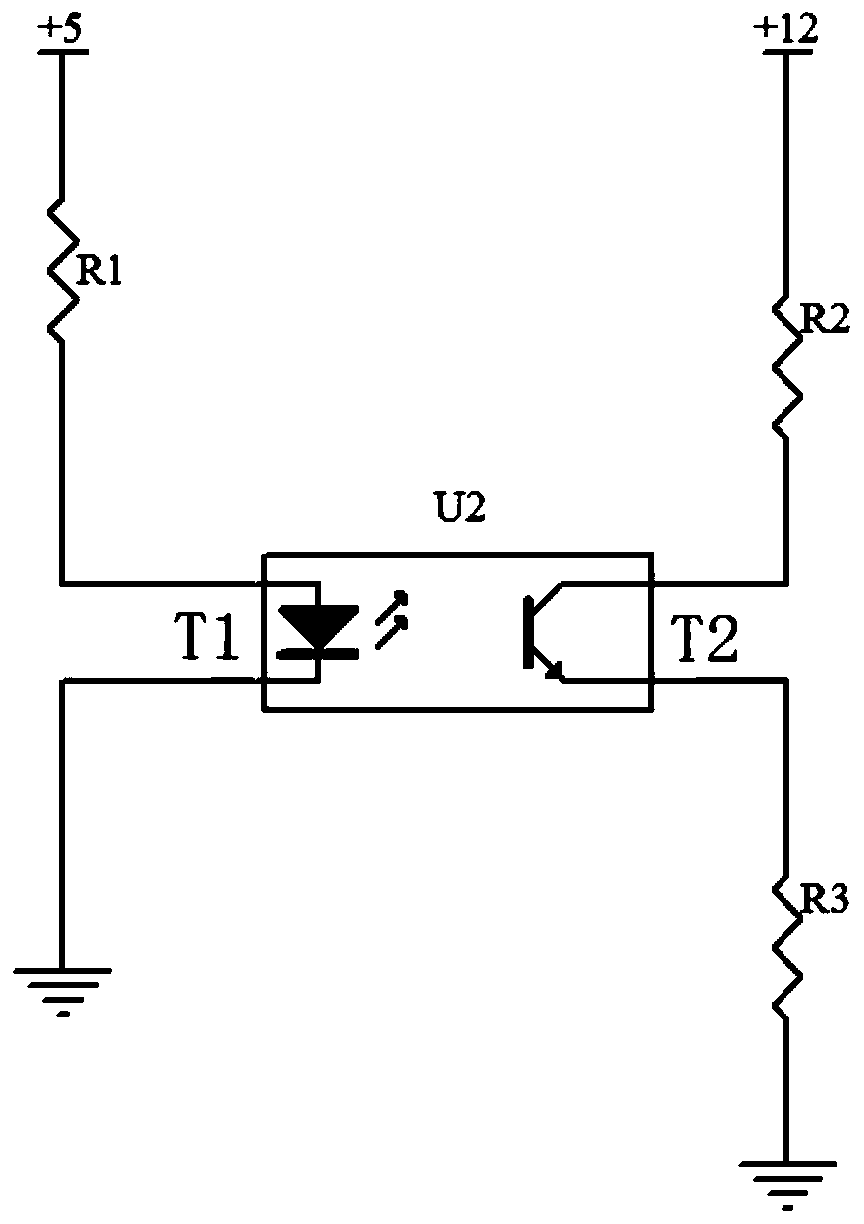

Speed regulating control circuit of pulse-width-modulation computer cooling fan

The invention discloses a speed regulation control circuit of a pulse-width-modulation computer cooling fan. The speed regulation control circuit comprises a first resistor, a second resistor, a third resistor, a fourth resistor, a fifth resistor, a sixth resistor, a seventh resistor, an eighth resistor, a ninth resistor, a tenth resistor, an eleventh resistor, a twelfth resistor, a first capacitor, a second capacitor, a first potentiometer, a second potentiometer, a first comparator, a second comparator, a third comparator, a thermistor, a light-emitting diode, an audion, a multivibrator and the fan. The speed regulating control circuit of the pulse-width-modulation computer cooling fan is a control circuit achieving automatic speed regulating through a pulse-width-modulation cooling fan motor, and the speed of the fan can be automatically regulated according to the temperature inside an instrument; the same-phase input end of the first comparator is connected with the thermistor; and when the potential of the same-phase input end of the first comparator drops due to temperature rising, the output voltage of the first comparator also drops, the duty ratio of the output waveform of the second comparator is improved, and the rotating speed of the fan is increased through the audion.

Owner:CHENGDU KEHONG ELECTRONICS

Industrial vehicle control system for turning state adjusting

The invention relates to the field of automatic mechanical equipment, in particular to an industrial vehicle control system for turning state adjusting. The industrial vehicle control system for turning state adjusting is achieved through the following schemes, specifically, the industrial vehicle control system for turning state adjusting comprises a main vehicle frame and further comprises a handle and driving wheel which are mounted on the main vehicle frame, a gyroscope sensor for sensing the overturning angle of the handle in the horizontal direction is mounted on the handle, the industrial vehicle control system for speed adjusting further comprises a controller, the controller is in communication connection with the gyroscope sensor and comprises a storer, and a data sheet related to the mapping relationship between the overturning angle and the traveling speed of the driving wheel is stored in the storer. According to the industrial vehicle control system for turning state adjusting, the turning state is adjusted through the most convenient handle action, and thus the vehicle is stable in gravity center, convenient and fast in adjusting, and safe in travelling.

Owner:NOBLEELEVATOR INTELLIGENT EQUIP CO LTD

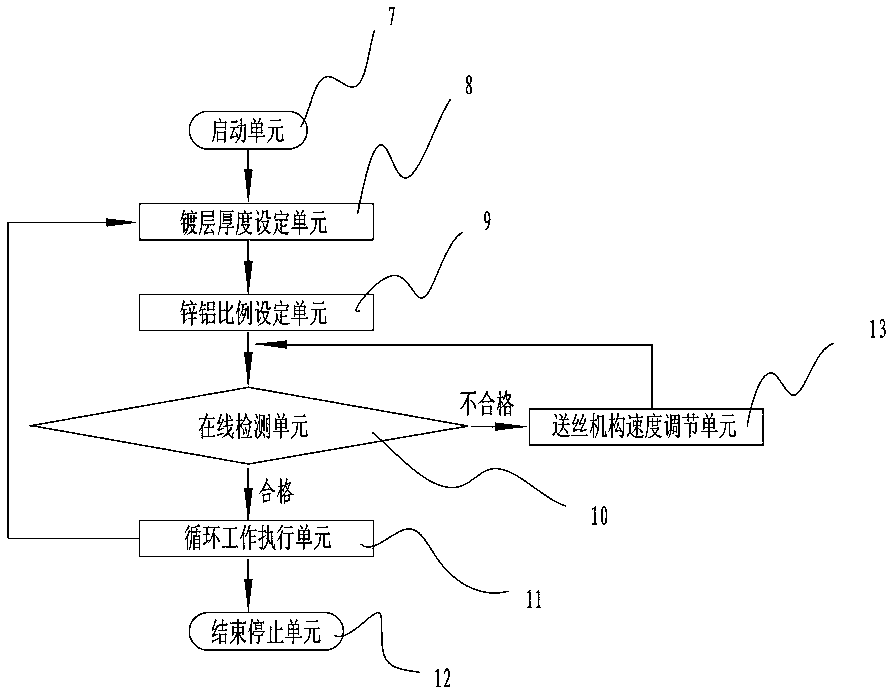

Automatic wire feeding apparatus of evaporation system

InactiveCN105506555AAuto adjust speedAutomatic wire feeding realizationVacuum evaporation coatingSputtering coatingDrive shaftEvaporation

The invention discloses an automatic wire feeding apparatus of an evaporation system. The automatic wire feeding apparatus includes a vacuum support. A vacuum sealing end surface is installed on and connected to one end of the vacuum support and is matched with the end surface of the vacuum support to form vacuum status. A frequency-varying motor is arranged outside the vacuum support and the vacuum sealing end surface. A driving shaft is installed on and connected to the frequency-varying motor, passes through the vacuum sealing end surface and is disposed in the vacuum support. A wire feeding mechanism sleeves the driving shaft and is connected to an automatic wire feeding integrated controller which monitors thin film plating layer thickness and plating film linear velocity on line and can regulate the speed of the wire feeding mechanism. The automatic wire feeding apparatus of the evaporation system can automatically preset the plating layer thickness according to the thin film plating layer and preset Zn / Al ratio. When the plating layer thickness or the Zn / Al ratio is disqualified, the apparatus can regulates the speed of the wire feeding mechanism and then detects the parameters again until the parameters are qualified. Meanwhile, automatic wire feeding in the evaporation system is achieved.

Owner:JIANGMEN ZHAOYE TECH

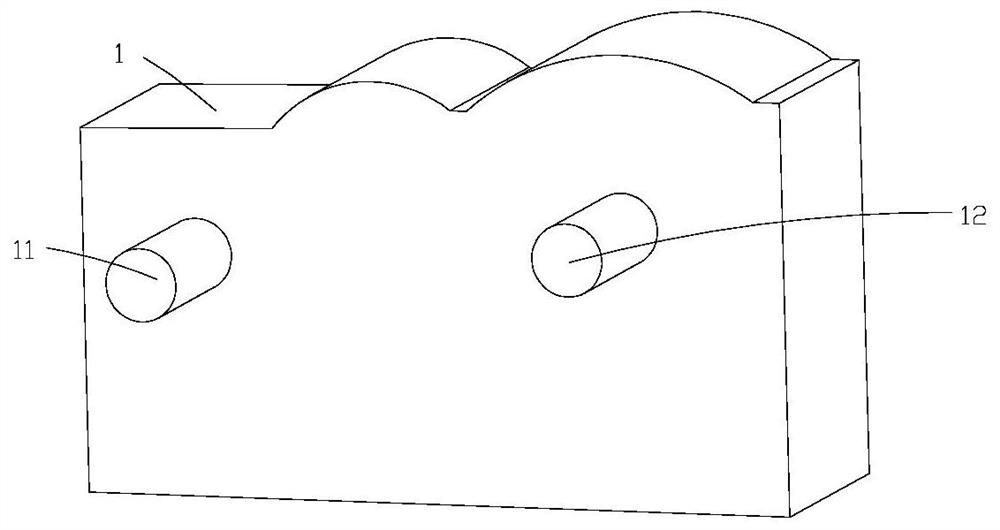

High-universality reduction gearbox special for draught fan

InactiveCN113090743AImprove stabilityRealize automatic reciprocating movementPump componentsGear lubrication/coolingRotational stabilityDrive wheel

The invention discloses a high-universality reduction gearbox special for a draught fan. The high-universality reduction gearbox special for the draught fan comprises a main body, a driving wheel, a speed reduction wheel, an oil storage cavity, a filtering device, a driving wheel and a lubricating device. The filtering device comprises a partition plate, flow guide holes, a filtering block, filtering holes, filtering springs, a static plate, louver boards, convection holes and a cleaning mechanism. According to the high-universality reduction gearbox special for the draught fan, lubricating oil is sprayed to the driving wheel and the speed reduction wheel in a spraying mode through the lubricating device to achieve lubricating and cooling, and the using effect of the lubricating oil is improved; and impurities in the lubricating oil are cleaned away through the cleaning mechanism when the reduction gearbox operates, on one hand, the application effect of the lubricating oil is improved, on the other hand, the rotating stability of the driving wheel and the speed reduction wheel can be improved, the universality of the reduction gearbox is further improved, and the application effect of the reduction gearbox is more stable.

Owner:ZHEJIANG JINGXING GEARED MOTOR

Hot air tentering setting machine and exhaust air rate control method thereof

ActiveCN112680912AIncrease humidityAuto adjust speedHeating/cooling textile fabricsStretchingControl systemFlue gas

The invention provides a hot air tentering setting machine and an exhaust air rate control method thereof. The hot air tentering setting machine comprises a tentering setting cloth feeding device, a drying setting device, a tentering setting cloth discharging device, an oxygen content analyzer, a flue gas content laser detection system, an air return device and a control system which are connected in sequence, The humidity of a front-section drying oven of the setting machine is indirectly detected through the oxygen content analyzer (the humidity of the front section of the drying oven is controlled within a reasonable range), so that the energy consumption value can be effectively reduced. The flue gas content laser on-line detection system is used at the tail part of the rear half section of the drying oven of the setting machine, and the speed of an exhaust fan is automatically adjusted by controlling the flue gas concentration in the drying oven, so that the purposes of energy conservation and environmental protection are achieved.

Owner:HANGZHOU XINYUAN PRINTING & DYEING

Rearview mirror with automatic cleaning function for new energy automobile

InactiveCN114312572AWith automatic cleaning functionGood sightVehicle cleaningOptical viewingDriver/operatorNew energy

The invention relates to the technical field of new energy, and discloses a rearview mirror with an automatic cleaning function for a new energy automobile, the rearview mirror comprises a shell, a thin-wall hollow metal ball is movably arranged on the inner wall of the shell, two limiting rods are fixedly connected in the shell, the limiting rods are fixedly connected with electrode columns, and the electrode columns are fixedly connected with the thin-wall hollow metal ball. And the electrode column is electrically connected with an electromagnet. According to the automatic windshield wiper used on the rearview mirror of the new energy automobile, the windshield wiper is driven to work through linkage between electromagnets, rainwater is hit on the rearview mirror, it is avoided that rainwater is attached to the rearview mirror to form rain flowers, the situation that a driver cannot see the rearview mirror clearly and cannot judge the rear road condition is avoided, and the automobile running safety is improved; meanwhile, rainwater attached to the rearview mirror is treated in time, it is avoided that rainwater forms rain stains on the rearview mirror, the attractiveness and sight line definition are affected after raining, meanwhile, the inconvenience that a driver wipes the rearview mirror is eliminated, and the driving comfort is improved.

Owner:江苏坦途专用汽车制造有限公司

Environment-friendly treatment process for papermaking wastewater

InactiveCN111533297AAvoid cloggingChange interception areaSpecific water treatment objectivesTreatment involving filtrationFiberPapermaking

The invention discloses an environment-friendly treatment process for papermaking wastewater, and relates to the field of sewage treatment processes, and the method comprises the following steps: step1, feeding the papermaking wastewater into a first filter tank; step 2, feeding part of the papermaking wastewater in the first filter tank into a second filter tank; step 3, filtering pulp fibers; step 4, scraping off the pulp fibers on a first filter plate; step 5, automatically cleaning the pulp fibers on a second filter plate; and step 6, automatically fishing the pulp fibers in the first filter tank. The process disclosed by the invention is ingenious in design and smooth in procedure connection, can realize automatic separation, salvage, collection and recycling of the pulp fibers and water, improves the efficiency by more than 10 times compared with manual treatment, can save more than 50% of manpower, has remarkable economic value, and avoids environmental pollution caused by improper wastewater treatment.

Owner:曾文婷

Coiled material conveying and tensioning device

ActiveCN102514968BAutomatic tension adjustmentAvoid breakingWebs handlingEngineeringMechanical engineering

Owner:CHERY AUTOMOBILE CO LTD

Running machine and speed control method and system for running belt thereof

InactiveCN107789792AShorten speedAuto adjust speedMovement coordination devicesCardiovascular exercising devicesControl systemSpeed control system

The invention relates to a speed control method of a running belt of a running machine. The method comprises the steps of detecting the foot stopping position of a user on the running belt of the running machine; according to the foot stopping position detected within the preset time, determining the foot stopping region of the user on the running belt of the running machine; according to the footstopping region of the user on the running belt of the running machine, adjusting the speed of the running belt of the running machine. By means of the method, the running machine achieves the function of automatically adapting to the speed of a sporter, the user experience of the running machine is improved, and the user can determine the running speed according to the feeling of himself. The invention further relates to a speed control system of the running belt of the running machine, and the running machine adopting the speed control system of the running belt of the running machine.

Owner:徐州春华健身器材有限公司

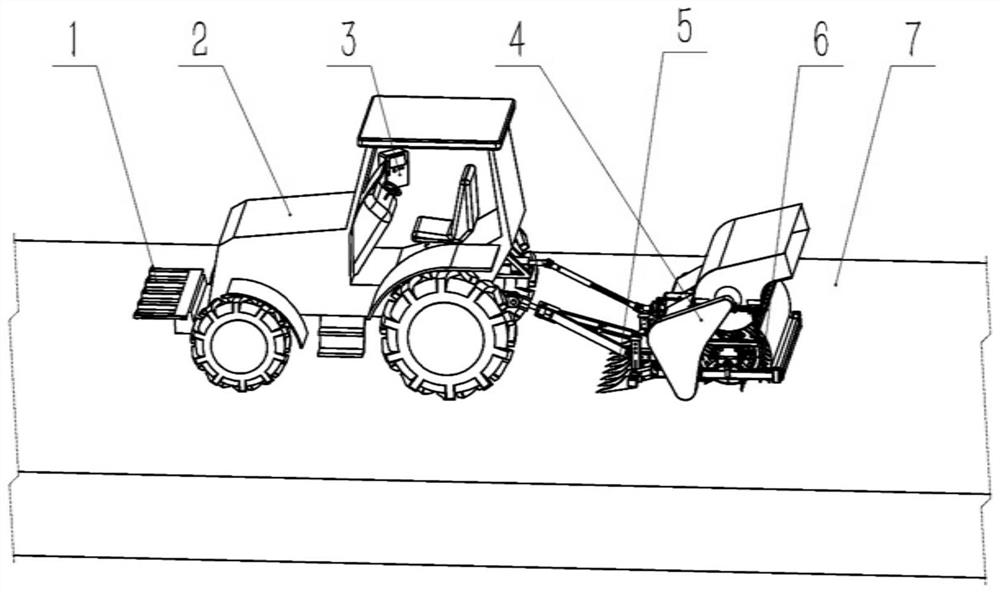

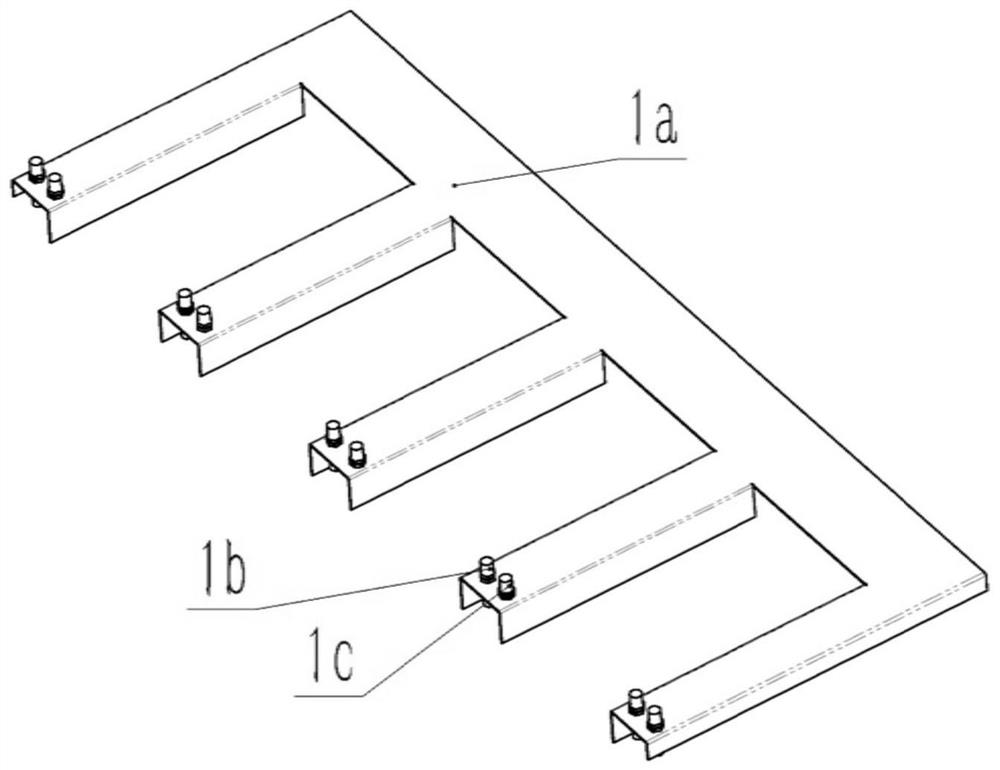

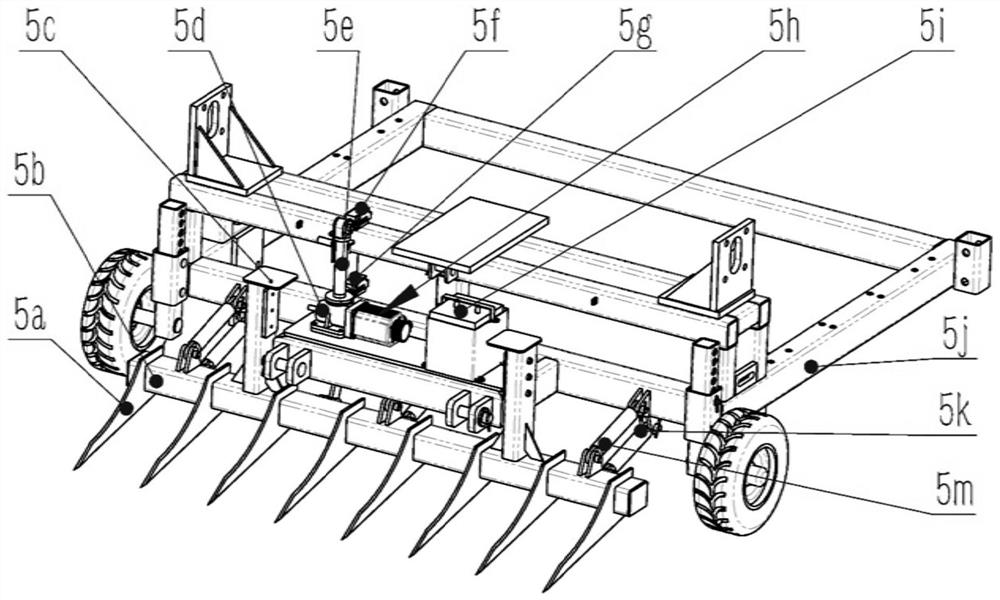

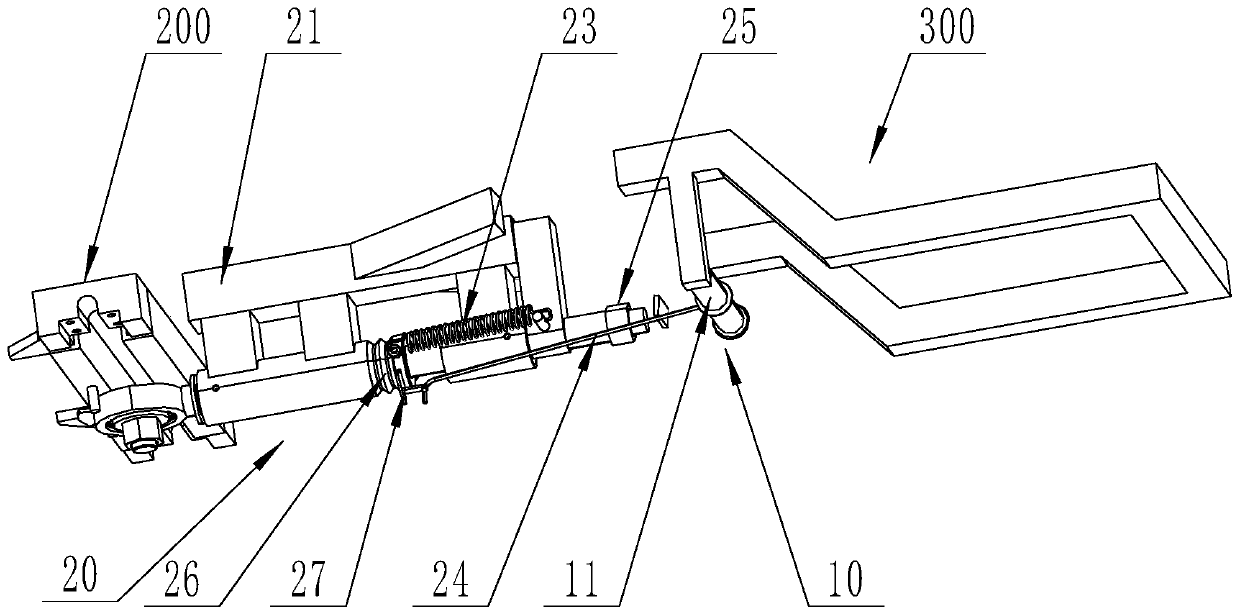

A self-adaptive film shovel and pick-up speed regulating device and a residual film recovery device and system

The invention discloses an adaptive film lifting shovel and picking up speed regulating device, a residual film recovery device and a system, including a terrain detection unit, a film lifting device, a residual film picking detection unit and a controller; a terrain detection unit for detecting The working terrain of the residual film picking machine; the lifting rod of the film lifting device passes through the frame of the residual film machine to connect with the film lifting shovel bracket, and the driving device drives the lifting rod to move up and down, thereby realizing the up and down movement of the film lifting shovel bracket; residual film picking detection The unit includes a bracket, a front residual film pickup sensor, a rear residual film pickup sensor and a speed detection sensor; the front residual film pickup sensor is installed at the front end of the bracket, and the rear residual film pickup sensor is installed at the rear end of the bracket; the rotation speed detection sensor Installed on the rotating shaft of the pick-up drum, it is used to detect the rotation speed of the drum; the controller is connected with the front residual film pickup sensor, the rear residual film pickup sensor, the speed detection sensor, the terrain detection unit and the driving device.

Owner:SHANDONG ACADEMY OF AGRICULTURAL MACHINERY SCIENCES

A booster device for a robot in a scenic spot

ActiveCN109203952BReduce the burden onPowerful and reliableElectric propulsion mountingPropulsion unit arrangementsElectrical connectionElectric drive

Owner:湖北恒星科技有限公司

Humidifier with oriented flow guide function

InactiveCN110986232AIngenious structureSimple structureSpace heating and ventilation safety systemsLighting and heating apparatusPhysicsEngineering

The invention provides a humidifier with an oriented flow guide function. The humidifier comprises a humidifier body; a fog outlet is formed in the humidifier body; a guide pipe is arranged above thefog outlet, and comprises a horizontal part, a bent part and a longitudinal part; the longitudinal part comprises a first connecting pipe and a second connecting pipe; one end of the first connectingpipe is connected with the fog outlet spirally, and the other end of the first connecting pipe is connected with the second connecting pipe in a sleeving manner; the second connecting pipe communicates with the bent part; the bent part communicates with the transverse part; a fan is arranged in the inner wall of the transverse part; and an infrared detection device is arranged on the outer side wall of the second connecting pipe, is connected with the fan electrically, and is used for detecting the distance between a human body and the humidifier, and adjusting output power according to the distance to control the rotational speed of the fan. The rotational speed of the fan can be increased or decreased along with the distance between a user and the humidifier by adopting the infrared detection device, the air discharging and fog spraying speed is adjusted automatically, and the humidifier is ingenious and simple in structure and low in manufacturing cost.

Owner:AUONE ELECTRONICS MFG

Cotton feeding device capable of automatically adjusting cotton feeding speed

InactiveCN112499575ASmooth rotationAutomatic adjustment of cotton feeding speedUpholstery fillingAgricultural engineeringAir pump

The invention discloses a cotton feeding device capable of automatically adjusting cotton feeding speed, which comprises a box body fixed on a moving seat, a feeding cylinder and a cotton loosening box are fixed on the inner side of the box body, a feeding pipe is communicated between the right end of the feeding cylinder and the cotton loosening box, a fixing plate is fixed on the right side of the box body, and a cotton filling air pump is fixed on the inner side of the box body. A cotton filling air pump is communicated between the air inlet end of the cotton filling air pump and the cottonloosening box, the air outlet end of the cotton filling air pump is detachably connected with a cotton containing cloth sleeve located on the fixing plate through a pipeline, a feeding hopper is fixed to the top of the box body, and the lower end of the feeding hopper is communicated with the right end of the feeding barrel. And a transverse rotating rod is rotationally mounted in the feeding cylinder. The whole device can automatically complete cotton feeding, cotton loosening, cotton filling and hammering and pressing work, the whole action is completed at a time, the machining efficiency can be greatly improved, the installation cost can be reduced, and the whole device is simple in structure and low in manufacturing cost.

Owner:舒城娃娃乐儿童用品有限公司

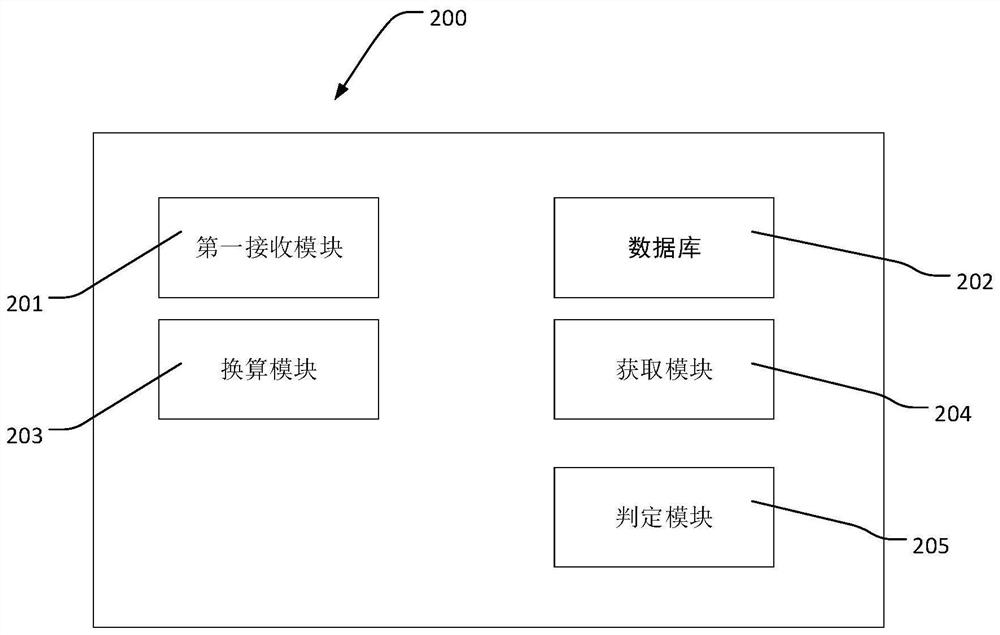

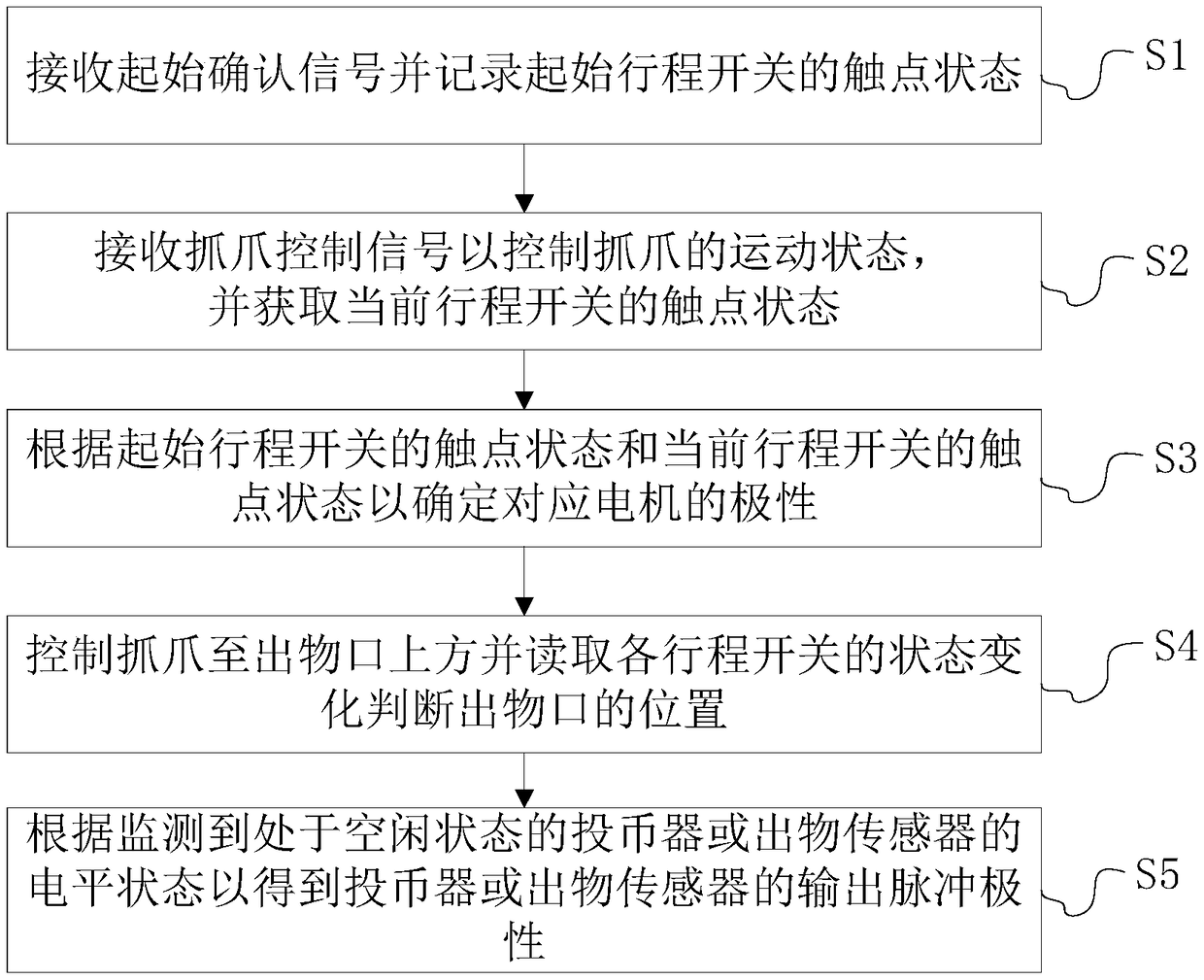

Control matching method and device for fun catcher

ActiveCN108961601AImprove work efficiencyAutomatically judge positive and negative polarityApparatus for meter-controlled dispensingElectric machineryPulse polarity

The invention discloses a control matching method for a fun catcher. The method comprises the following steps of receiving a starting determination signal and recording the contact state of a startingtravel switch; receiving a gripper control signal to control the motion state of a gripper and obtaining the contact state of a current travel switch; according to the contact state of the starting travel switch and the contact state of the current travel switch, determining a polarity of a corresponding motor; controlling the gripper to be located above an object outlet and reading the state changes of each travel switch to judge the position of the object outlet; according to the monitored level state of an object outlet sensor of a coin collector in the idle state, obtaining the output pulse polarity of the object outlet sensor or the coin collector. The invention further provides electronic equipment and a computer readable storage medium. According to the control matching method forthe fun catcher, the working efficiency of assembling workers is greatly improved.

Owner:广州晨日电子技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com