Automatic nut cutting equipment

An automatic cutting and nut technology, applied in the field of agricultural machinery, can solve the problems of low work efficiency, easily damaged nuts, and low degree of automation, and achieve the effect of saving manpower and material resources and ensuring normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

[0031] Specifically, the present invention is realized like this:

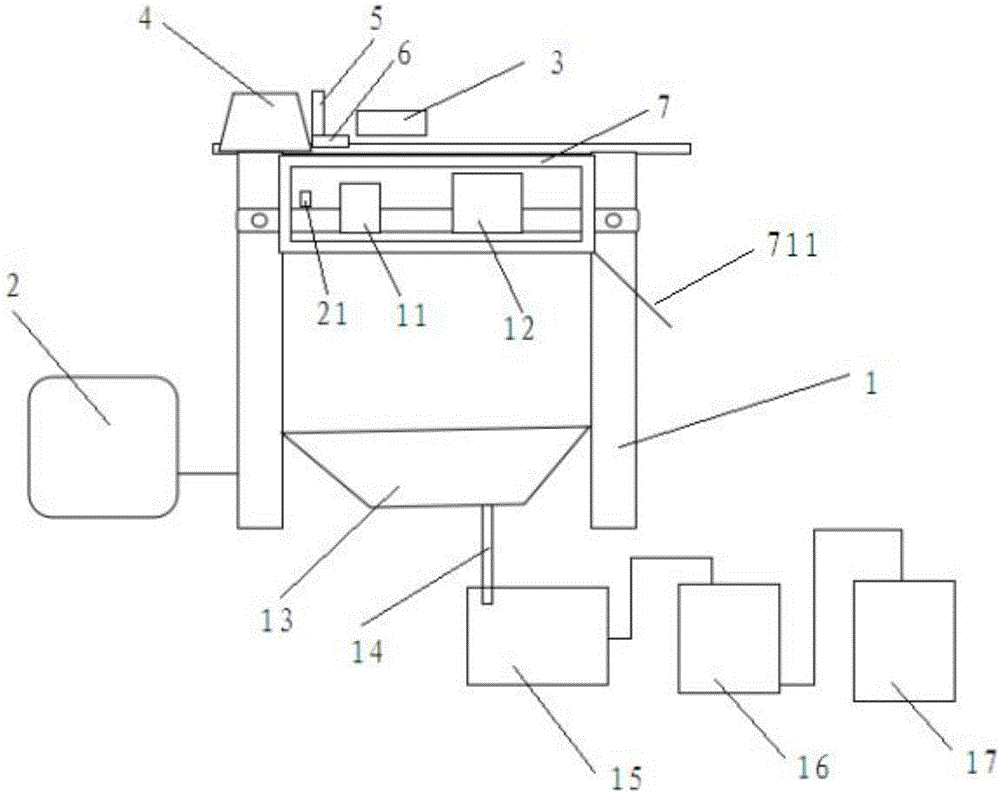

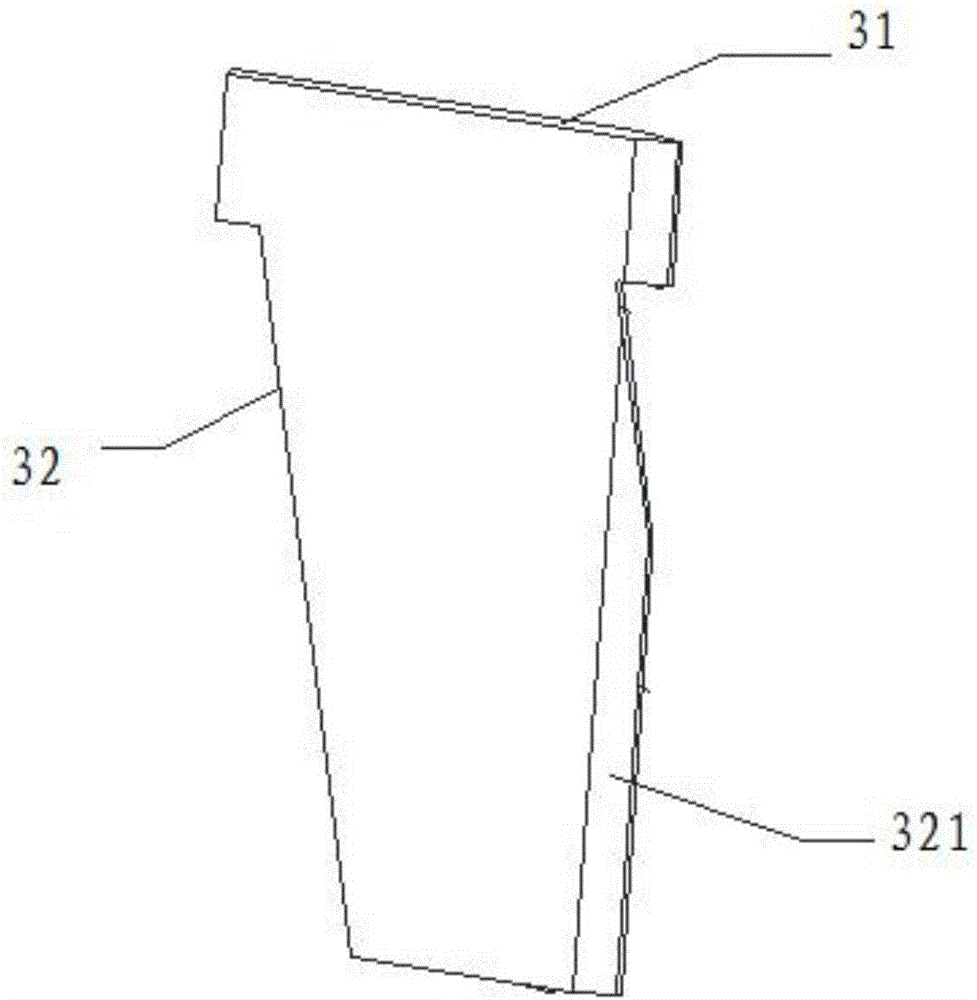

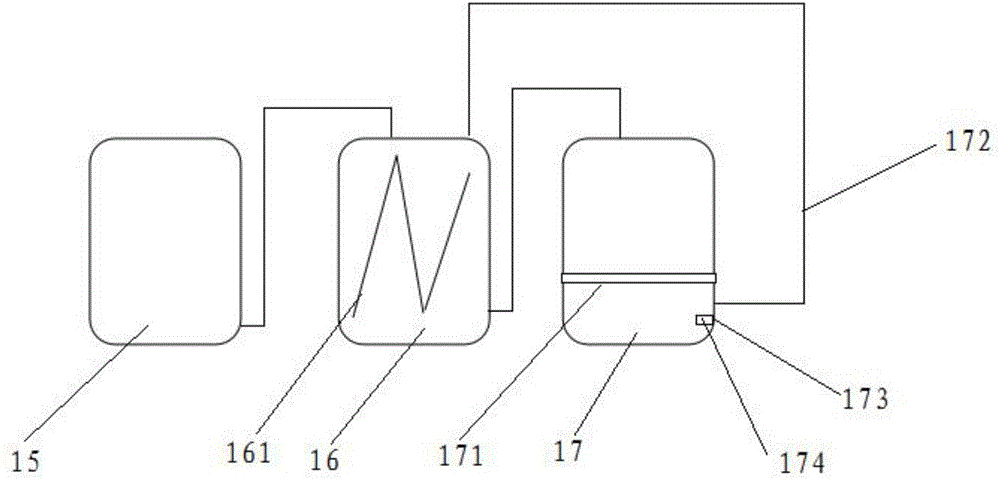

[0032] The invention provides a kind of nut automatic cutting equipment, such as Figure 1 to Figure 4 As shown, it includes a frame 1, a controller 2, a cutting head 3 arranged on the top of the frame 1, and a feed bin 4 arranged at the feeding end of the frame 1. The feed bin 4 is provided with a material shifting mechanism 5, which One end of the 5 is provided with a baffle 6, and the baffle 6 is provided with a groove matching the shape of the nut. The feeding mechanism 5 transfers the nuts to the conveyor belt 7 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com