Tyre first stage winding building control system

A technology of winding forming and control system, which is applied in the field of tire winding forming control system, which can solve problems such as irregularities and special shapes, and achieve the effects of low cost, increased production efficiency, and reduced labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

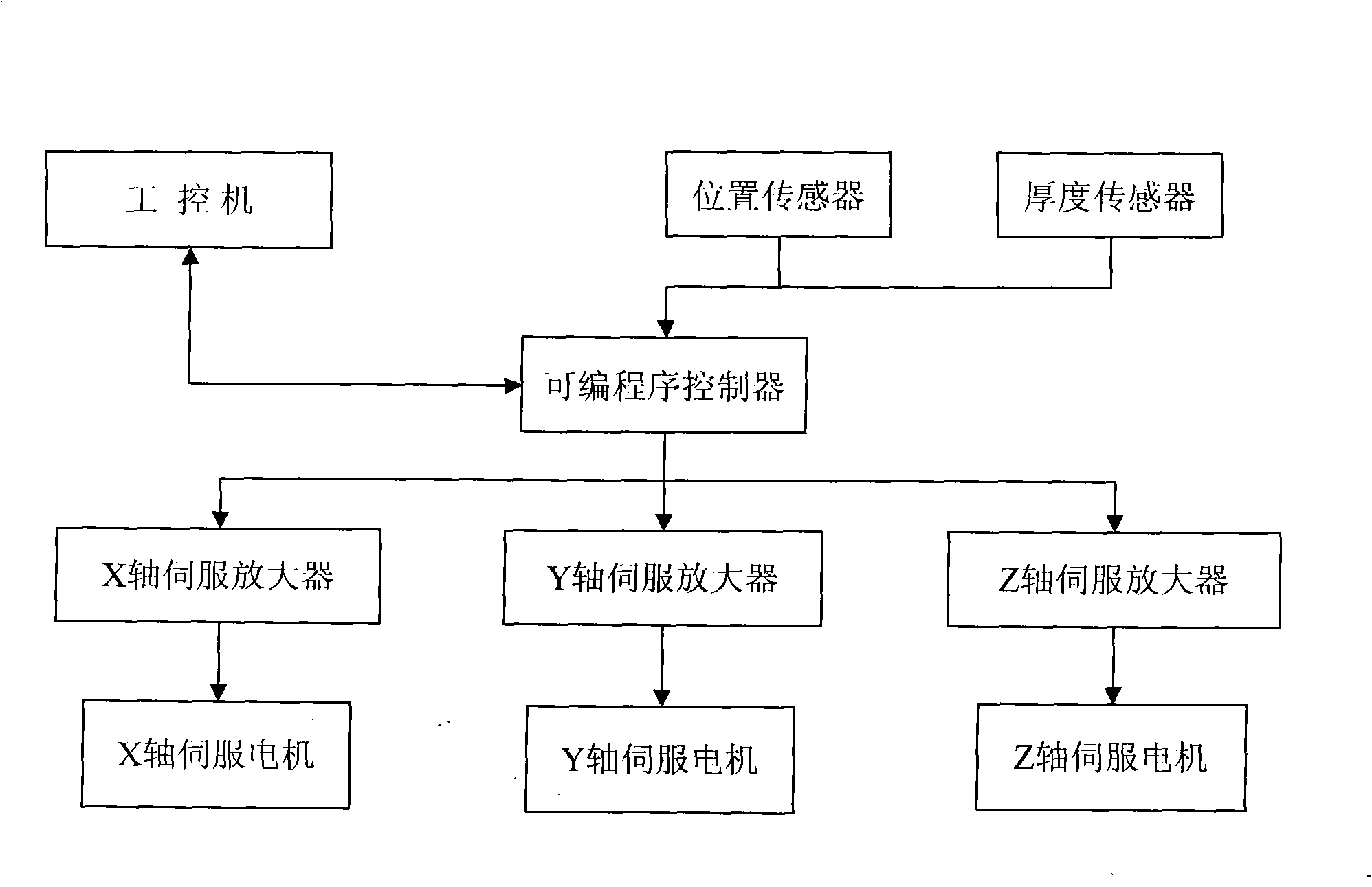

[0009] Example of the control system for one-stage winding of the tire figure 1 As shown, it includes the servo motor and servo amplifier that drive the three-axis movement of the winding head of the winding machine, as well as the industrial computer and the programmable controller connected to it, and the servo motor that drives the X-axis, Y-axis and Z-axis movement of the winding head Connect the X-axis, Y-axis and Z-axis servo amplifiers respectively, and each servo amplifier is connected to the high-speed counting module and digital output module of the programmable controller, and the position sensor and thickness sensor installed on the winding head are also connected with the programmable controller. . The industrial computer is a computer with special winding head control software and winding molding design software. The industrial computer is also connected with input devices keyboard, mouse, plotter and display.

[0010] The above specific embodiments are only spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com